Page 1

SL-DC-I-O Rev A

Solar Differential Control

Installation and Operation

Manual

WARNING:

This manual must only be used by a qualified heating

installer/service technician. Read all instructions,

before installing. Perform steps in the order given.

Failure to comply could result in severe personal

injury, death, or substantial property damage.

Page 2

Contents

HAZARD DEFINITIONS .................................................... 2

1. INTRODUCTION

Application and Safety Instructions ................................... 3

Main Characteristics ........................................................... 4

Technical Characteristics ................................................... 4

Display ............................................................................. 5-6

2. SERVICE

Language ........................................................................... 7

Time and Date .................................................................... 7

Systems 1-8 .................................................................... 8-9

Extra ................................................................................ 10

Thermostat Function ................................................. 10

Cooling Function ....................................................... 10

Diffcontrol Function ................................................... 11

Antistagnation Function ............................................ 11

External sensor ............................................................... 12

Protection Function .................................................... 12-13

Maximum Temperature............................................. 12

Cooling/ Recooling ................................................... 13

Overheat/ Freeze Protection .................................... 13

Sensor Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14-15

Impulse Flow Meter .................................................. 14

GDS1 ........................................................................ 14

GDS2 ........................................................................ 15

Energy Measurement ...................................................... 15

Warm sensor ........................................................... 15

Cold sensor ............................................................. 16

Flow 2 ...................................................................... 16

Pump P1/ Pump P2 ........................................................ 17

Glycol and Glycol Mix...................................................... 18

Factory Setting ................................................................ 18

Reset operation time ....................................................... 18

Time graph temperature .................................................. 19

Time graph operation ...................................................... 19

Calibration Sensors ......................................................... 19

Priority Tank .................................................................... 19

P1 // P2 function in system 5 .......................................... 19

3. SETTINGS MENU

Maximum Temperature tank 1 ........................................ 20

dTMaximum tank 1 .......................................................... 20

dTMinimum tank 1 ........................................................... 20

dTMaximum return .......................................................... 20

dTFs ................................................................................ 20

dTMinimum tank 1 ........................................................... 20

Minimum rev pump .......................................................... 20

Minimum Temperature collector ...................................... 21

Maximum Temperature tank 2 ........................................ 21

dTMaximum tank 2 .......................................................... 21

dTMinimum tank 2 ........................................................... 21

Delay P2 .......................................................................... 21

Extra Functions ........................................................... 22-23

Thermostat Function ................................................. 22

Start 2 Hysteresis ..................................................... 22

Cooling Function ....................................................... 22

Cooling Hysteresis .................................................... 22

Differential Control Function ..................................... 23

Maximum cold tank ................................................... 23

Minimum warm tank ................................................. 23

Antistagnation Function ............................................. 23

Start/ Stop/ Output Option ........................................ 23

4. OPERATION MENU

Automatic and OFF operation ......................................... 24

Manual Testing ................................................................ 24

Operation Hours Menu ............................................... 24-25

Data logger “SD card” ......................................... 25-28

5. TEMPERATURES MENU .......................................... 29

6. SPECIAL FUNCTIONS.............................................. 30

Dimmer ..................................................................... 30

Security ..................................................................... 30

Others ............................................................................... 30

Notes ................................................................................ 31

Revision Notes ................................................. Back Cover

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels or

to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

2

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or moderate

injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

Page 3

1 Introduction

SL-DC lnstallation and Operation Manual

WARNING

WARNING

WARNING

Before starting work the installer should carefully read this Installation & Operation Manual, and

make sure all instructions contained there in are understood and observed.

The Solar controller should be mounted, operated and maintained by trained personnel only.

Personnel in the course of training are only allowed to handle the product under the supervision of

an experienced fitter.

All instructions in this Installation & Operation manual should be observed when working with

the controller. Any other application shall not comply with the regulations. The manufacturer shall

not be liable in case of incompetent use of the control. Any modifications and amendments are not

allowed for safety reasons.

Application Safety Instructions

■ The Solar controller is intended for Solar heating

systems. The temperature of the water in the tank is

controlled by the temperature difference “dt” between

solar collector and tank.

■ The controller is normally used in conjunction with a

pumping station which includes a circulation pump and

a safety valve.

WARNING

Before starting work disconnect

power supply! All installation and

wiring work related to the controller

must be carried out only when

de-energized. The appliance should

be connected and commissioned by

qualified personnel only. Make sure

to adhere to valid safety regulations.

■ The controllers have been designed for use in dry

environments. For example, they are used in residential

rooms, office spaces and industrial facilities.

■ Verify that the installation complies with existing

regulations before operation to ensure proper use of the

installation.

CAUTION

WARNING

The controllers are neither splashnor drip-proof. Therefore, they must

be mounted in a dry place.

Do not interchange the connections

of the sensors and the 120V

connections under any circumstances!

Interchanging these connections

may result in life endangering electrical

hazards or the destruction of the

appliance and the connected sensors

and other appliances.

3

Page 4

1 Introduction

Main Characteristics

SL-DC Installation & Operation Manual

■ Large graphic display with backlight

■ Easy to use interface (4 keys with scroll menu)

■ Several languages available

■ Energy measuring with SD card interface to save the

recordable statistics (Temperatures, Power, Energy, Time

operation) and Parameters

■ Graphic view for temperature, power, energy, operating

time and temperature

■ 8 working systems with several extra functions possible

■ 5 inputs for temperature sensors (PT1000 type)

■ 1 logical input for impulse flow meter input

(for energy measurement)

Technical Characteristics

Table 1A Technical characteristics

Operating Temperature

Electrical Protection

Installation Category

Pollution Degree

Fusible

Power Supply

Maximum Power Consumption

(with all outputs activated)

Outputs:

P1 (Main pump with standard or PWM speed regulation)

P2 (Pump with standard or PWM speed regulation, Booster

pump, valve)

P3 (Extra, Additional heat, cooling . . . )

Inputs:

T1 (Collector 1)

T2 (Tank 1)

T3 (Extra sensor)

T4 (Extra sensor, Tank2, Collector2)

T5 (Collector return)

■ 2 analog inputs for VFS / VPS sensor inputs

(flow, pressure and temperature sensor)

■ 2 pump outputs (standard PWM) with pump exercise

function

■ 1 extra output (to control additional heat, cooling system,

differential control or anti-stagnation function )

■ Automatic, OFF or Manual test mode

■ Sensor auto checks (short circuit and breaks)

■ Collector type choice (tube or panel)

■ Collector protection (freeze or overheat)

■ Permanent memory storage

32°F - 122°F

IP20

II

2

Max T5AH250VAC

120 VAC 60Hz

4.2A (~ 504W)

Triac 1A 120 VAC.

Triac 1A 120 VAC

Relay 2A 120 VAC

PT 1000 type

PT 1000 type

PT 1000 type

PT 1000 type

PT 1000 type

T6 (Flow meter)

GDS1 (Flow meter)

GDS2 (Pressure sensor)

Sensors delivered with the product:

2 Collectors

1 Tank

1 Extra

Software Version

Impulse type (low voltage 5V)

Analog type

(VFS)

Analog type

(VPS)

PT 1000 (1.5M 356°F)

PT 1000 (3M 221°F)

PT 1000 (3M 221°F)

Displayed during the initial start-up

Version xxxxxx

4

Page 5

1 Introduction (continued)

Display

SL-DC Installation & Operation Manual

Figure 1-1 Display, keys

1: Simplified drawing of the installation.

- The logos of pumps turn when they are activated.

- The filled triangles on the valve logo indicate the circulation direction.

2: Solar system is working.

3: SD card storage is active.

4: Temperature of different sensors, Pumps speed indications, Power and Energy quantity stored.

1 2 3

T1

T3

T2

A

T1_ _ _°F

T2_ _ _°F

SD

T3_ _ _°F

T4_ _ _°F

P1_ _ _ %

_ _ _ BTU/h

4

_ _ _ BTU

A. Keypad description:

Figure 1-2 Keypad

Navigation key up or plus key

(+)

Navigation key down or minus key

Navigation key right

Navigation key left

(►)

(◄)

(-)

5

Page 6

1 Introduction

Main Menu Display

Figure 1-3 Main menu

SL-DC Installation & Operation Manual

Information

Services

Settings

Operation

Operation h

Temperatures

Press (►) to enter the navigation menu. (The title of the

active menu is high lighted in black on the top of the display.

When you enter the navigation menu you can choose

another submenu by moving the selection cursor with the

keys (+) or (-), then you can enter this submenu with ( ►).

From all menus you can press (◄) to return to the previous

menu.

-

NOTICE

IMPORTANT

To prevent mistakes after installation,

all critical parameters (system and Extra

function) are not accessible after 4 hours

power on. If you want to modify these

parameters, you must unplug and plug in

the controller. No settings are lost when

unplugging, or after a power failure.

After 4 hours you can still change all

the other parameters to optimize your

system.

Not all submenus, selection, or options

discussed in this manual are available on

all systems. The figures are representative

of what the screen on the control will

look like when the described procedures

are followed.

6

Page 7

SL-DC Installation & Operation Manual

2 Service

Languages

With (+) or (-) select the line “ENGLISH” and press ( ►) to highlight the line. Now that you can change the language with (+)

or (-), there are several choices: English, German, Dutch, Spanish, French, Italian, Portuguese, and Hungarian.

Figure 2-1 Language screen

Service---- --- -

English

Time and date

US version yes

System

Extra off

External sensor no

Protection func.

Figure 2-2 Time and Date

---

Time 6:41

Month 12

With (+) or (- ) select the line TIME and DATE and press

( ►) to enter the submenu Time and Date.

Now you can select the date and time line with (+) or

(- ), then press ( ►) to highlight the value which must

be adjusted.

NOTE: If power supply is lost, the hours will be saved

for 24 hours. After this time the clock will need to be

readjusted.

Time and Date

--- -

20 yaD

1002 raeY

Figure 2-3 U.S. version

Service---- --- -

English

Time and date

US version yes

System

Extra off

External sensor no

Protection func.

YES: °F, 12H am/pm, GPM, BTU and BTUh

NO: °C, 24H, Liter, KW and KWh

On this menu you can choose the displayed units.

7

Page 8

2 Service

SL-DC Installation & Operation Manual

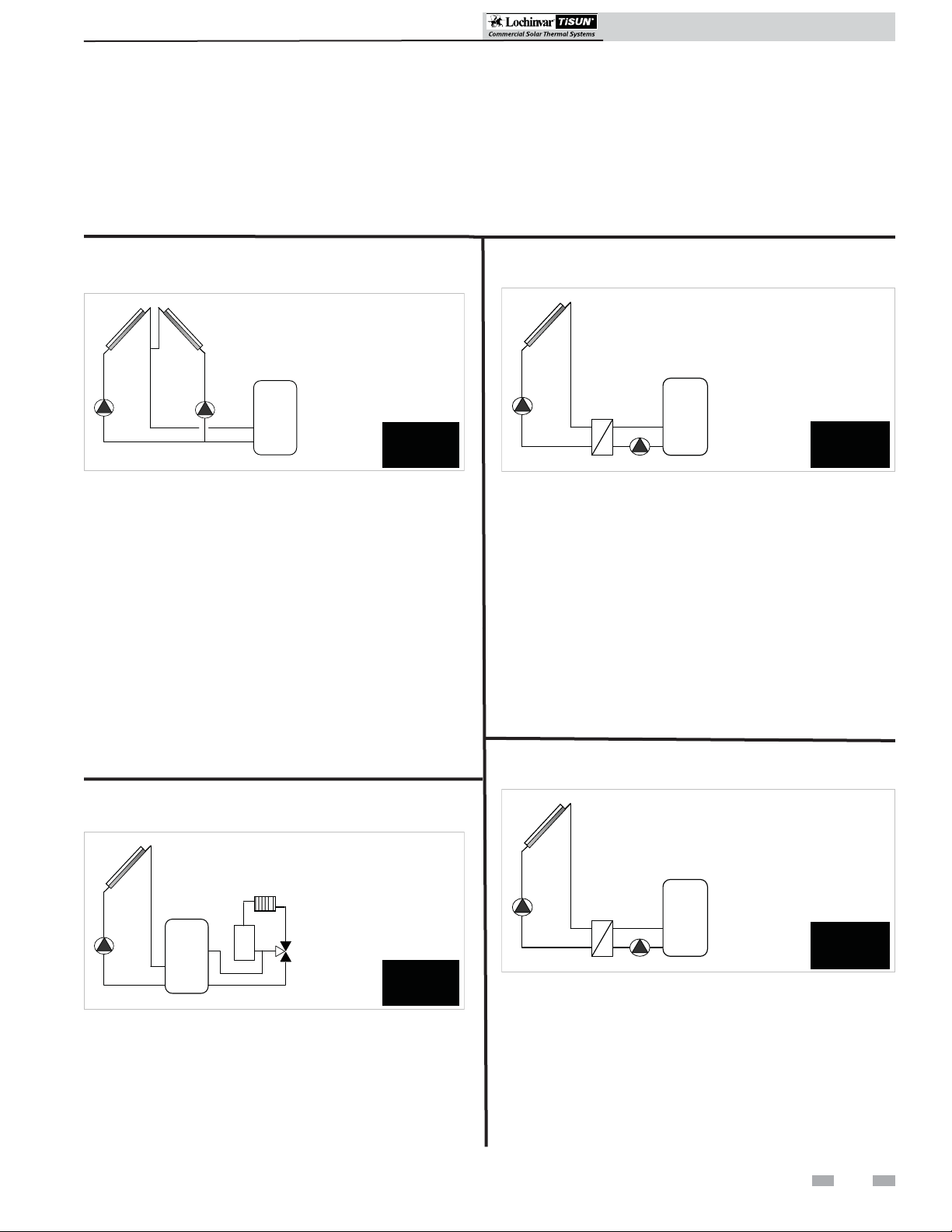

Systems

When the line is selected, press ( ►) to enter the submenu. You

have the choice between 8 systems with the possibility to add

different functions.

System 1

This is a basic system, with 1 tank, 1 pump, 1 collector array and

2 sensors. With this system you can add extra functions with 1 or

2 sensors (Booster pump, Thermostat, Cooling, Antistagnation

or Diffcontrol function).

Figure 2-4 System 1

T1

P1

The loading of the tank is authorized by the control if the

temperature difference “dt” between the collector (T1) and the

tank (T2) is greater than the value programmed for “dt”.

System 2

This is a system with 2 tanks, 1 pump, 1 valve, 1 collector array

and 3 sensors. With this system you can add an extra function

with 1 sensor (Thermostat, Cooling, Antistagnation).

T2

T1 _ _ _°F

T2 _ _ _°F

P1 _ _ _ %

System

1

System 3

This is a system with 2 tanks, 2 pumps, 1 collector array and 3

sensors. With this system you can add an extra function with

1 sensor (Thermostat, Cooling, Antistagnation).

Figure 2-6 System 3

T1

T1 _ _ _°F

T2 _ _ _°F

T4 _ _ _°F

P1 _ _ _ %

P2 _ _ _ %

P2P1

T2 T4

System

3

The loading of the tanks is authorized by the control if the

temperature difference “dt” between the collector (T1) and

the tanks (T2, T4) is greater than the value programmed for

“dt”. You can choose different possibilities for the priority

of the tank loading. See chapter “Priority Tank” for more

information.

System 4

This is a system with 1 tank, 1 pump, 1 valve, 2 collector

arrays with 2 different cardinal directions (East/ West) and 3

sensors. With this system you can add an extra function with

1 sensor (Thermostat, Cooling, Antistagnation).

Figure 2-7 System 4

Figure 2-5 System 2

T1

T1 _ _ _°F

T2 _ _ _°F

T4 _ _ _°F

P2

P1 _ _ _ %

P1

T2 T4

System

2

The loading of the tanks is authorized if the temperature

difference “dt” between the collector (T1) and the tanks (T2,

T4) is greater than the value programmed for “dt”. You can

choose different possibilities for the priority of the tank loading.

See chapter “Priority Tank” for more information.

8

T1

T4

T1 _ _ _°F

T2 _ _ _°F

P2

T4 _ _ _°F

P1 _ _ _ %

P1

T2

System

4

The loading of the tanks is authorized by the control if the

temperature difference “dt” between the collectors (T1, T4)

and the tank (T2) is greater than the value programmed

for “dt”. The valve direction of P2 is routed to the warmer

collector.

Page 9

2 Service (continued)

SL-DC Installation & Operation Manual

System 5

This is a system with 1 tank, 2 pumps, 2 collector arrays with

2 different cardinal directions (East/ West) and 3 sensors.

With this system you can add an extra function with 1 sensor

(Thermostat, Cooling, Antistagnation).

Figure 2-8 System 5

T1 T4

T1 _ _ _°F

T2 _ _ _°F

T4 _ _ _°F

P1 _ _ _ %

P1 P2

T2

P2 _ _ _ %

System

5

The loading of the tank (T2) is authorized by the control if the

temperature difference “dt” between the collectors (T1, T4)

and the tank is greater than the value programmed for “dt”.

The tank will be loaded with the warmer collector (T1, T4) if

parameter “P1 II P2 = no” (default setting).

The tank can be loaded from both collector fields at the same

time, if parameter “P1 II P2 = yes”. See chapter “Protection

Function”.

System 6

This is a system with 1 collector array, 1 solar tank, 1 pump,

1 valve and 4 sensors. With this system you can add an extra

function with 1 sensor (Thermostat, Cooling, Antistagnation.)

System 7

This is a system with 1 collector array, 1 solar tank, 2 pumps and

1 external heat exchanger. With this system you can add an extra

function with 1 sensor (Thermostat, Cooling, Antistagnation

and Diffcontrol function).

Figure 2-10 System 7

T1

T1 _ _ _°F

T2 _ _ _°F

P1 _ _ _ %

P2 _ _ _ %

P1

T2

P2

The loading of the tank is authorized by the control if the

temperature difference “dt” between the collector (T1) and the

tank (T2) is greater than the value programmed for “dt”. You

can choose a time delay for the start up of the pump between

the heat exchanger and the tank. Default value is 1 minute to

give the heat exchanger time to heat up. See section “P2 delay”.

System

7

System 8

This is a system with 1 tank, 2 pumps, 1 collector array, 3

sensors and 1 external heat exchanger. With this system you

can add an extra function with 1 sensor (Thermostat, Cooling,

Antistagnation.)

Figure 2-11 System 8

Figure 2-9 System 6

T1

T1 _ _ _°F

T2 _ _ _°F

T3 _ _ _°F

T4 _ _ _°F

P1 _ _ _ %

System

P1

T3

T2

T4

P2

6

The loading of the tank (T2) is authorized by the control if the

temperature difference “dt” between the collectors (T1) and

the tank (T2) is greater than the value programmed for “dt”. If

the “dt” between tank (T3) and the space heating return (T4)

is sufficient, the space heating return will be preheated through

tank 1. This saves energy at the external heating source.

T1

T1 _ _ _°F

T2 _ _ _°F

T4 _ _ _°F

P1 _ _ _ %

P1

T4

P2

P1 starts if the temperature difference “dt” between the collector

(T1) and tank (T2) is sufficient.

The loading of the tank with P2 is authorized by the control if

the temperature difference “dt” between the heat exchanger (T4)

and the tank (T2) is greater than the value programmed for “dt”.

The operation of the P1 & P2 pumps is independent.

T2

P2 _ _ _ %

System

8

9

Page 10

2 Service

SL-DC Installation & Operation Manual

Extras

When the line is selected, press ( ►) to highlight the line.

You have the choice between 4 extra functions . The choices

are not the same with all systems, see the specific system

details for available extras.

Figure 2-12 Extras menu

Service---- --- -

English

Time and date

System

Extra off

External sensor no

Protection func.

Sensor options

Thermostat Function

This function is generally used to control an additional heat

source to load up your primary solar tank in case solar energy

is lacking. (See the Extra Function section.)

Cooling Function

The cooling function is generally used for cooling down

the primary solar tank at time of high solar radiation. With

this function you could dissipate excess energy to another

heat zone. (Swimming pool or other basins for example, as

illustrated in FIG. 2-14 below.) ( See Extra Function section.)

Figure 2-14 Function used to warm basin

T1

Extra Function used to

control the pump to

warm up another basin.

T3

P1

T2

P3

Suggestions:

- Pump controls for Fuel or Gas burner. . .

- Electrical element inside the solar tank. (Important:

in this case you must connect a relay for switching

the output.) (See FIG. 2-13 below.)

Figure 2-13 Extra function and external burner

T1

Extra Function to control

the pump coupled with

an external burner.

T3

P1

T2

P3

10

Page 11

2 Service (continued)

SL-DC Installation & Operation Manual

Diffcontrol Function

The Diffcontrol function can be used to transfer the heat

energy of one tank to another tank separately from the solar

loading function. With this extra function you can control the

temperature on both tanks and you can choose the different

setting levels to adapt this function to your needs. (See

examples in FIG. 2-15 and 2-16 below and refer to the Extra

Function section for more information.)

Figure 2-15 Function used to warm secondary tank

T1

Extra Function used to control

the pump to warm up another

tank with temperature control

on this tank.

TC = T3

P1

TW = T4

P3

Antistagnation Function

At high solar radiation the solar fluid is protected from

stagnation, where solar fluid would turn into vapor. If the

solar circuit (T1, T4 (when two collector fields)) is heated

over 230°F (default value, changeable), the relay output P3

and the pump P1 are switched ON. You can choose whether

or not to use the antistagnation function.

After the solar circuit is cooled down to 194°F (default,

changeable), the P1 and P3 outputs are switched off.

Figure 2-17 Function used with free heat storage or

underground discharge loop

T1

Antistagnation function build with 1 extra pump “P3”

used to discharge the collector in free heat storage or

under ground discharge loop...

Free heat

P3

P1

storage

T2

Figure 2-16 Function used to warm primary tank if

there is insufficient solar energy

T1

Extra Function used to control

the pump to warm up the

primary tank in case of energy

solar is no sufficient.

P1

TC = T3

P3

T2

TW = T4

Other heating system with tank.

(Fuel, pellets, wood ….)

T2

Underground

loop

Figure 2-18 Function uses P3 to build and P1

manages liquid circulation

T1

Antistagnation function build with 1 extra valve “P3”, the

primary pump “P1” will manage the liquid circulation.

P3

Free heat

P1

T2

storage

Underground

loop

11

Page 12

2 Service

SL-DC Installation & Operation Manual

External Sensor

Figure 2-19 Select External Sensor

Service---- --- -

English

Time and date

US version yes

System

Extra off

External sensor no

Protection func.

Select the line “External sensor” and press ( ►) to highlight

the line. Now select with (+) or (-) for “yes” if your

installation uses evacuated tube collectors. This choice can be

used with the flat collector when the sensor is mounted on the

external part of the collector.

This function can be used if the collector sensor is not

directly mounted inside the collector. This function works

by activating the pump every 30 minutes for 30 seconds to

measure the correct temperature of the collector to avoid

short charge cycles.

Protection Function

Figure 2-20 Select Protection Function

Service---- --- -

English

Time and date

US version yes

System

Extra off

External sensor no

Protection func.

Once the line is selected, press ( ►) to enter the submenu.

Figure 2-21 Enter submenu

Protection func.------------ -

Collector

Max temp 230°F

Cooling no

Overheat prot. yes

Freeze prot no

Maximum temperature

Set the level to start the overheat protection for the collector

array. (It is adjustable 230°F to 300°F with factory setting

value at 230°F.) This value is referenced in the “Cooling” and

“Overheat Protection” functions on page 13.

12

Page 13

2 Service (continued)

SL-DC Installation & Operation Manual

Cooling

When the “cooling” function is set to “Yes,” it is also possible

to activate the “Recooling” function.

Figure 2-22 Select Cooling from submenu

Protection func.------------ -

Collector

Max temp 230°F

Cooling yes

Recooling no

Overheat prot. yes

Freeze prot no

This option is used to protect the collector fluid. It activates

the solar pump P1 or P2 if temperature on the collector

arrays T1 or T4 exceeds the “Max Temp” value even if the

set maximum temperature in the tank is exceeded. The

circulation stops when temperature has dropped 10°F. The

pumps will be stopped if the water temperature in the tank

reaches 200°F.

Recooling

Freeze protection

This option will keep the solar panel temperature T1 or T4

above the freeze setpoint (see below) by activating the pump

P1 or P2.

This option could be used to reduce snow accumulation on

the panel and increases the efficiency during the day or to

avoid solar liquid damages.

CAUTION

Figure 2-23 Select Freeze Protection from submenu

It is preferable not to use this function

in very cold regions in order not to use

too much of the energy stored in the

tank.

Protection func.------------ -

Collector

Max temp 230°F

Cooling yes

Recooling no

Overheat prot. yes

Freeze prot yes

Freeze prot temp 37°F

When the water temperature inside the tank is above the “Max

Temp tank 1” and the collector temperature is 10°F below,

the pump is activated to cool the tank through the collector

array (during the night, or under cloudy conditions). The

pump will be turned off when the water temperature inside

the tank has dropped to the setting level “Max Temp tank

1”or when the difference between the tank and collector array

temperature is below 2°F.

Overheat protection

This function will stop all collector circulations (P1 and P2)

when the collector temperature increases above “Max Temp”

plus 10°F. This function is used to protect the elements of the

installation (pipe, fitting, seals, etc. . . ).

WARNING

For safety reasons, this function

must always be set to “Yes” to avoid

overheating the system.

To activate the freeze and snow protection, press (+) or (-)

to select the “Freeze Prot” line and press ( ►)to activate

“Yes”. Now you have the ability to adjust the Freeze setpoint

(adjustable -4°F to 45°F with a factory value of 37°F).

13

Page 14

2 Service

SL-DC Installation & Operation Manual

Sensor Options

Impulse flow meter

The flow meter is used for energy measuring and monitoring.

If no flow meter is installed (factory setting), you must

manually enter (+) or (-) the flow rate in gallon / minute

(GPM).

Generally you can see this value on the pump marking. It is

adjustable .26 to 26.5 GPM with factory value at 1.0 GPM.

Figure 2-24 Sensor Options sub screen

Sensor options --- -

Imp. Meter no

Flow (gal/min) 1.0

GDS1 NC

GDS2 NC

If the impulse flow meter is installed (on T6 / PF) select

“Yes”, then you must enter with (+) or (-) the flow meter

characteristics in gallon / impulsion. It is adjustable 0.2 to 6.6

Gal / imp with a factory setting of 1.0 Gal / imp.

*When you use an impulse flow meter for energy measuring,

generally you should connect the T5 sensor mounted on the

collector return to have a more accurate calculation. (See the

“Energy Measurement” section for more information.)

GDS1 (Grundfos Direct Sensor)

Your controller has 2 special inputs for analog sensor type VFS

flow sensor or VPS pressure sensor. Generally the flow sensor is

used for energy measuring and supervision, the pressure sensor

is used only to supervise the pressure on the primary circuit.

Figure 2-25 VFS/ VPS option

Sensor options

Imp. Meter no

Flow (gal/min)

GDS1 VFS 1-12 l/min

GDS2 NC

You have the choice between flow or pressure sensor with

different scales.

■ “VPS 0 – 4 bar” (0 -60 PSI) Pressure sensor

■ “VPS 0 – 6 bar” (0 - 87 PSI) Pressure sensor

■ “VPS 0 – 10 bar” (0 - 145 PSI) Pressure sensor

■ “VFS 1 – 12 l/min” (.26 - 3 GPM) Flow sensor

■ “VFS 2 – 40 l/min” (.5 - 10.5 GPM) Flow sensor

■ “VFS 5 – 100 l/min” (1.3 - 26.5 GPM) Flow sensor

■ “VFS 10 – 200 l/min” (2.6 - 53 GPM) Flow sensor

You can check the measuring value of the sensor in the submenu

“Manual testing”. (See the “Operation” section.)

1.0

14

Note: The Grundfos Direct sensors also have the ability to

measure the temperature. This is why if you choose the GDS1

input to connect a flow sensor “VFS”, you will have the ability

to use the VFS sensor for energy measurement. (See the

“Energy measurement” section for more information.)

CAUTION

To avoid electrical damage to controller

and sensor, check the installation

manual before electrical connection.

Don’t forget to remove the power supply

before connecting the sensors.

Page 15

2 Service (continued)

SL-DC Installation & Operation Manual

GDS2 (Grundfos Direct Sensor)

Figure 2-26 GDS2 VPS

Sensor options --- -

Imp. Meter no

Flow (gal/min) 1.0

GDS1 NC

GDS2 VPS 0-4 bar

GDS2 input is only reserved to connect a pressure sensor

for supervision of the primary circuit. It is available with

theGRUNDFOS VPS type with different scale.

■ “VPS 0 – 4 bar” (0 - 60 PSI) Pressure sensor

■ “VPS 0 – 6 bar” (0 - 87 PSI) Pressure sensor

■ “VPS 0 – 10 bar” (0 - 145 PSI) Pressure sensor

See the installation manual for more information on electrical

connections.

Warm sensor

On this menu you can choose the sensor used for the “warm”

point temperature measure. To change the sensor, press ( ►)

to highlight the line and select your choice with (+) or (-).

(With default value on “Auto”.)

Figure 2-28 Energy measurement submenu

Energy measurement --- -

Temperatures

Warm sensor Auto

Cold sensor Auto

Flow Auto

– “Auto”

The controller will automatically choose the

corresponding hot sensor according to the system used

(T1 or T4 collector sensors).

Energy Measurement

In this menu you can configure the sensors to be used for

energy calculation.

Energy metering calculation logic:

– To calculate the energy, the controller needs two temperature

measurement points: “Warm” and “Cold,” along with flow

rate.

Figure 2-27 Solar energy metering

Warm point

Function use for solar

energy metering.

P1

– “T3”

The controller will use the PT1000 sensor T3 or T5

according to your choice.

– “GDS1”

The controller will use the temperature sensing element

of the Grundfos vortex sensor “VFS type”.

Cold point Flow meter

15

Page 16

2 Service

SL-DC Installation & Operation Manual

Cold sensor

On this menu you can choose the sensor used for “cold” point

temperature measure. To change the sensor, press ( ►) to

highlight the line and select your choice with (+) or (-). (The

default value is set on “Auto”.)

Figure 2-29 Energy measurement cold sensor

Energy measurement --- -

Temperatures

Warm sensor Auto

Cold sensor Auto

Flow Auto

– “Auto”

The controller will automatically choose the corresponding

tank sensor according to the system used (T2 or T4 tank

sensors).

– “T5”

The controller will use the PT1000 sensor T5.

Flow

On this menu you can choose the sensor used for the “flow”

measure. To change this sensor, press ( ►) to highlight the

line and select your choice with (+) or (-). (The default value

is set on “Auto”. )

Figure 2-30 Energy measurement flow

Energy measurement --- -

Temperatures

Warm sensor Auto

Cold sensor Auto

Flow Auto

– “Auto”

The controller will use the theoretical flow (gal/min)

manually entered in the “Sensor options” section.

– “Impulse meter”

The controller will use impulse meter connected on the

input “T6”.

– “GDS1”

The controller will use the temperature sensing element

of the Grundfos vortex sensor “VFS type”.

– “GDS1”

The controller will use the flow sensing element

of the Grundfos vortex sensor “VFS type”.

16

Page 17

2 Service (continued)

pump

r

pump

SL-DC Installation & Operation Manual

Pump P1

In this menu you can choose the type of the pump used on

the output P1. To change the type of the pump press ( ►) to

highlight the line and select your choice with (+) or (-).

Figure 2-31 Service_P1

Service---- --- -

System

Extra off

External sensor no

Protection func.

Sensor options

Energy measurement

Pump P1 No SC

You will have 3 possibilities:

– “No SC” - No speed control or electric valves. Power

relays are also possible. (>1W electric valves with

additional resistor can be used.)

– “PhAC SC” - For standard pump with speed control. The

speed regulation is done by TRIAC (phase control).

Please check the following before changing:

- Your pump can work with this type of speed regulation.

- The minimum speed rating of the pump.

- The speed selector on your pump must be put on the

maximum position.

You will have 4 possibilities:

– “No SC” - See description under “P1”.

– “Phase SC” - See description under “P1”.

– “PWM SC” - See description under “P1”.

– “Boost xmin” - For Booster pump.

Use this function when a second pump is installed in

series, on the primary circuit to help the first pump to

start the flow in the hydraulic circuit.

Figure 2-33 Service_P2_Boost

Service---- --- -

Extra off

External Sensor no

Protection func.

Sensor options

Energy measurement

Pump P1 No SC

Pump P2 Boost 1min

You can choose the duration for the running time of P2 with

(+) or (-). It is adjustable 1 to 10 minutes.

Figure 2-34 P2 used as a Booster pump

Collector

T1 (°F)

Tan k1

T2 (°F)

Maxtemp

Tank1

dT = T1 –T2

– “PWM SC” - For high efficiency PWM pumps with speed

control. The speed regulation is done by PWM control

(0-10V), available with Grundfos “Solar PM” type.

Pump P2

In this menu you can choose the type of the pump used on

the output P2. To change the type of the pump press ( ►) to

highlight the line and select your choice with (+) or (-).

Figure 2-32 Service_P2

Service---- --- -

Extra off

External Sensor no

Protection func.

Sensor options

Energy measurement

Pump P1 No SC

Pump P2 No SC

P1

Main

P2

Booste

dTMax

dTMax

100%

0%

Boost time

(P2 running time)

dTMin

dTMax

17

Page 18

2 Service

SL-DC Installation & Operation Manual

Glycol

This is a type of solar fluid used in the installation. Pay

attention to this parameter if you use the energy calculation;

it has a direct impact on the energy calculation.

Figure 2-35 Service menu_Glycol

Service---- --- -

External sensor no

Protection func.

Sensor options

Energy measurement

Pump P1 No SC

Pump P2 No SC

Glycol No

- “no” Water liquid only

- “Dowfrost HD” Water/ Glycol mix

Glycol mix

The quantity of Glycol in the fluid can be adjusted from 0 to

50%.

Figure 2-36 Service menu_Glycol mix

Factory setting

Figure 2-37 Service menu_Factory setting

Service---- --- -

Sensor options

Energy measurement

Pump P1 No SC

Pump P2 No SC

Glycol No

Glycol Mix 0%

Factory setting no

NOTICE

If you want to reload all parameters with factory values, press

( ►) to highlight the line. Then select “yes” with (+) key.

Now, press ( ◄) repeatedly to return to the main menu.

Reset operation time

Figure 2-38 Service menu_Reset OP time

For the purpose of error protection the

chosen system and the time settings will

not be reset.

Service---- --- -

Protection func.

Sensor options

Energy measurement

Pump P1 No SC

Pump P2 No SC

Glycol No

Glycol Mix 0%

Service---- --- -

Energy measurement

Pump P1 No SC

Pump P2 No SC

Glycol No

Glycol Mix 0%

Factory setting no

Reset op time no

If you want to reset all operation hours press ( ►) to

highlight the line. Then select “yes” with the (+) key.

Now, press ( ◄) again to return to the main menu.

CAUTION

This function will reset all stored data

(power, energy, temperature. . . etc.)

18

Page 19

2 Service (continued)

SL-DC Installation & Operation Manual

Time graph temperature

See “Temperatures” section of menu for more information.

Time graph operation

See “Operation h” section of menu for more information.

Calibration sensors

Figure 2-39 Service_Calibration

Service---- --- -

Glycol No

Glycol Mix 0%

Factory setting no

Reset op time no

Time graf temp 1m

Time graf op 1h

Calib sensors

Figure 2-40 Sensor T1

Sensor---- --- -

Sensor T1 0°F

Sensor T2 0°F

Sensor T3 0°F

Sensor T4 0°F

Sensor T5 0°F

In this submenu you can calibrate all temperature sensors

connected to your system.

NOTICE

Priority Tank

This is available only with two tank systems (2 and 3). In

this menu you can choose a primary tank for the priority of

loading.

Check the actual value of the sensors

with a calibrated thermometer before

adjusting. (The calibration range is -6°F

to 5°F with a factory value of 0°F.)

Figure 2-41 Priority Tank

Service---- --- -

Glycol No

Factory setting No

Reset Op time No

Time graph temp 5m

Time graph Op 1h

Calib sensors

Prio tank

You will have 3 possibilities:

– “No Prio” - No priority on the tanks. The two tanks are

loaded independently; the only condition is that the “dt”

value is sufficient to authorize the loading.

– “1” - The primary tank will be the tank managed by the

sensor T2. It will be named with a small number “1” in the

tank on the main screen.

– “2” - The primary tank will be the tank managed by the

sensor T4. It will be named with a small number “2” in the

tank on the main screen.

The primary tank will be loaded in priority and the second

tank will be loaded when:

- The “Min Temp Prio” level is reached. (See the

corresponding part.)

- The primary tank will reach the “Max Temp Tank 1”

value adjusted on “setting” menu.

- The collector temperature is under the primary tank

temperature.

In these cases the tank will be loaded up to the “Max Temp

tank 2”.

No Prio

P1 // P2 function in system 5

Use this function to authorize running 2 pumps P1 and P2

at the same time. (The tank will be loaded through the two

collectors.)

Figure 2-42 P1 // P2

Service---- --- -

Glycol No

Factory setting No

Reset Op time No

Time graph temp 5m

Time graph Op 1h

Calib sensors

P1 // P2

No

To activate the function, press (+) or (-) to select “P1 // P2”

line and press ( ►) to activate “yes” with (+) or (-).

19

Page 20

3 Settings Menu

p

SL-DC Installation & Operation Manual

On this menu you have all the adjustable parameters of your

installation. Several parameters are not available with all

systems.

Maxtemp tank 1

Maximum value of desired water temperature on the tank1

during normal operation. (It is adjustable from 59°F to 203°F

with factory value set at 149°F.)

dTMax tank 1

This is the difference between collector temperature T1 and

tank1 temperature T2 used to start the main pump P1. (It is

adjustable from 7°F to 72°F with factory value set at 12°F.)

dTMin tank 1

This is the difference between collector temperature T1 and

tank1 temperature T2 used to stop the main pump P1. (It is

adjustable from 3 to dTMax tank1 -3°F with factory value set

at 3°F.)

dTMax return

Available only with system 6. This is the difference between

tank1 temperature T2 and external space heating return T4

to start the preheating of this external space heating return

through tank1. (It is adjustable between 7°F to 72°F; the

default value is 12°F.)

Minimum rev pump

This is available only if “Phase Speed Control” is selected on

the pump menu, as shown in FIG. 3-2 below.

Figure 3-2 Min rev pump_screen

Settings ----------------- -- -----

Maxtemp tank1 149°F

dT Max tank1 45°F

dT Min tank1 37°F

Maxtemp tank2 149°F

dT Max tank2 45°F

dT Min tank2 37°F

Min rev pum

With (+) or (-) select the line “Min rev pump” and press

( ►). Now you can choose the minimum speed of the pumps

with (+) or (-). (It is adjustable 30 to 100% with factory value

set at 50%.)

The speed of the pump is variable when the value of dt is

between “dtFs” and “dtMin”.

Note: Be sure to start the pumps correctly. The start-up speed

will always be 100% for two seconds.

Figure 3-3 Speed regulation with standard pump _

Phase speed control

50%

dTMin return 1

Available only with system 6. This is the difference between

tank1 temperature T2 and external space heating return T4 to

stop the preheating of the external circuit. (It is adjustable 3°F

to (dTMax return -3°F) with factory value at 5°F.)

dTFS: Fullspeed

This is the difference between collector temperature T1 and

tank temperature T2 to have the speed (100%) of the pump.

(It is adjustable between minimum “dTMax tank1” and

maximum 90°F. The default value is 50°F.)

Figure 3-1 dTMax_Min graph

Collector

T1 (°F)

Tan k1

T2 (°F)

P1

Maxtemp

Tank1

100%

0%

dT = T1 –T2

dtMax

dt Fs

85%

dtMin

dt Fs

dtMax

100%

Pump startup

Min rev pump

30%

Controlled

dTMax

dTFs dTFs

dTMin

Figure 3-4 Speed regulation with high efficiency solar

pump _PWM variation 0-10V

100%

Pump startup

Controlled

0%

dTMax

dTFs

dTFs

dTMin

OFF

100%

Control

100%

Control

100%

OFF

20

Page 21

3 Settings menu (continued)

SL-DC Installation & Operation Manual

Mintemp collector

This setting level is used to define a minimum temperature of

the collector to authorize the solar loading. (It is adjustable

between 32°F and 210°F. The default value is 32°F.)

Figure 3-5 Mintemp_screen

Settings ----------------- -- -----

Maxtemp tank1 149°F

dT Max tank1 45°F

dT Min tank1 37°F

Min rev pump 50%

dT Fs 86°F

Mintemp coll. 32°F

Maxtemp tank2

This is available only in systems with two tanks (2 and 3). This

is the maximum value of desired water termperature on tank2.

(It is adjustable 59°F to 203°F with a factory value 149°F.)

Delay P2

This is available only in system 7. This is the delay time for the

start up of P2 after the pump P1 start up.

- With (+) or (-) select the line “delay P2” and press ( ►).

- Now you can choose the delay for the P2 start up with (+)

or (-). (It is adjustable 0 to 30 minutes with factory value set

at 1 minute.)

Figure 3-6 P2 delay_screen

Settings ----------------- -- -----

dT Max tank1 68°F

dT Min tank1 41°F

Min rev pump 50%

dT Fs 86°F

MinTemp coll. 32°F

delay P2 1min

dTMax tank2

This is available only in systems with two tanks (2 and 3).

This is the difference between collector temperature T1 and

tank2 temperature T4 to start the main pump P1 with system

2 or pump P2 with system 3. (It is adjustable 7°F to 72°F with

factory value 12°F.)

dTMin tank2

This is available only in systems with two tanks (2 and 3).This

is the difference between collector temperature T1 and tank2

temperature T4 used to stop the main pump P1 with system 2

or pump P2 with system 3. (It is adjustable from 3 to dTMax

tank2 -3°F with factory value set at 3°F.)

Note: With a system with two tanks, you can choose a priority

tank in the “Service” menu, submenu “Priority tank”. You

can also choose the time of the loading cycle for the secondary

tank in the submenus “Prio tank load” and “Prio tank break”.

21

Page 22

3 Settings menu

Extra Functions

SL-DC Installation & Operation Manual

Thermostat function

This is available only if the extra function “Thermostat” is

selected in submenu “Extra”.

Figure 3-7 Thermostat

Water temperature on top of tank1 T3 ( F)

T3 start +

hysteresis

T3 start

Extra P3

0

Start

This is the setpoint to start the additional pump P3 when

the water temperature on top of the tank T3 falls under this

setpoint. (It is adjustable 68°F to 194°F with factory value

104°F.)

Hysteresis

Cooling function

This is available only if the extra function “cooling” is selected

on submenu “Extra”.

Figure 3-8 Cooling cycles

Cooling start

Cooling stop

(start – hysteresis)

Water temperature on top of tank1

P3

T3 (°F)

Start

This is the setpoint to start cooling the tank (by activating P3

output) to another heat storage, for example, when the water

termperature in the top of the tank (T3) is above the setpoint.

(It is adjustable 68°F to 194°F with factory value 104°F.)

Hysteresis

The value of the hysteresis stops the additional pump P3 when

the water temperature on the top of the tank T3 is more than

start temperature plus hysteresis value. (It is adjustable 3°F to

54°F with factory value 18°F.)

The value of the hysteresis to stop the cooling of tank1 when

the water temperature on top of the tank (T3) is under

Cooling start temperature minus hysteresis value. (It is

adjustable 3°F to 50°F with factory value 18°F.)

22

Page 23

3 Settings menu (continued)

SL-DC Installation & Operation Manual

Antistagnation function

This is available only if the extra function “anti-stagnation” is

selected on submenu “Extra”.

Figure 3-10 Antistagnation Cycles

Start level

Stop level

Standard

loading cycle

Antistagnation cycle

if P1 authorised

Collector (T1°F)

P3

Tank (T2°F)

P1

Start level

The setpoint on collector (T1) will start the function. The

pump P1 will be turned on to discharge the warm temperature

of the collector through the output(s) P1 and P3. (It is

adjustable 32°F to 392°F with factory value 230°F.)

Stop level

Differential control function

This is available only if the extra function “diff control” is

selected on submenu “Extra”.

Figure 3-9 Diff_control

MaxCold

Tank

MinWarm

tank

dTMax

dTMin

Extra P3

Warm storage TW

Cold storage

TC

Max cold tank

This is the maximum level on tank1 to stop the exchange

function (T3 = TC). (It is adjustable 59°F to 203°F with

factory value 149°F.)

Min warm tank

This is the minimum level on tank 1 to start the exchange

function (T4 = TW). (It is adjustable 32°F to 203°F with

factory value 59°F.)

The setpoint on collector (T1) will stop the antistagnation

function, the output(s) P1 and P3 will be turned off. (It is

adjustable 32°F to 302°F with factory value 194°F.)

Ouput option

The output(s) will be activated if the antistagnation function

is started (P1 and P3 ,or P3 only).

dTMax

This is the value of the difference between cold and warm

storage to start the exchange function. (It is adjustable 5°F to

72°F with factory value 18°F.)

dTMin

The is the value of the difference between cold and warm

storage to stop the exchange function. (It is adjustable 3°F to

54°F with factory value 3°F.)

23

Page 24

4 Operation Menu

_

r

_

r

SL-DC Installation & Operation Manual

Figure 4-1 Operation menu screen

Operation----------------- -- -----

Automatic (Active)

OFF

Manual testing

Automatic and OFF operation

- To put your system in Automatic operation, press (+) or

(-) to select the “Automatic” line. Then, press ( ►) to

activate this working mode.

- To put your system in OFF mode, repeat the same

sequence of above. A small “OFF” icon will be displayed

on the main screen.

Manual testing operation

Figure 4-2 Select manual testing

Operation----------------- -- -----

%0 1 pmuP

Pump 2 (or valve) 0%

%0 knaT

T1 _ _ °F T2 _ _°F

T3 _ _ °F T4_ _°F

T5 _ _ °F

GT

°F F _ _ gal/min P _ _ Ba

Figure 4-3 Select manual testing

Operation----------------- -- -----

%09 1 pmuP

Pump 2 (or valve) 0%

%0 knaT

T1 _ _ °F T2 _ _°F

T3 _ _ °F T4 _ _°F

T5 _ _ °F

°F F _ _ gal/min P _ _ Ba

GT

Note: When you exit this menu all outputs are turned off.

Press ( ◄) repeatedly to return to the main menu.

Operation hours menu

In this menu you can see the graph for operation hours, dT,

power and energy registered by your controller.

Figure 4-4 Operation hours screen

*

Operation h-------------- -- --- --

Operation _ _ h

F°_ _ Td

Power _ _BTU/h

Energy _ _BTU

gal _ _ olumeV

SD card OFF

Figure 4-5 Op hours chart

In this mode you can check the status of Pump1,

Pump2/Valve and extra outputs. You can also check the

values of all sensor inputs.

Note: The sensor inputs not used are noted with the maximum

value.

- To activate the output select the desired line with (+) or

(-) and press ( ►) to highlight this line. Now with (+) or

(-) you can test the different ouputs.

Pump activation starts with the minimum value xx% adjusted

on the “Setting” menu (see below “Pump speed”) and you

can increase this value up to 100% by 5% steps with (+) key.

24

-+

Operation 0.0h

The graph symbol seen in FIG. 4-4 and FIG. 5-1

*

indicates that there is a chart of this data recorded over

time. It can be set in the “Service / Time graph Op”

menu on page 19. To view graph press (►).

0d 00h

Page 25

4 Operation menu (continued)

SL-DC Installation & Operation Manual

- With (+) or (-) select the line “Time graf op” and

press ( ►) to highlight the line.

- Now you can change the scale with (+) and (-). It is

adjustable 1 to 48 hours with factory value 1h.

- Pres ( ◄) repeatedly to return to the main menu.

Data logger “SD card”

Your controller also has the ability to store all data and

parameters of the installation on an SD card. This feature is

very useful for viewing and analyzing the efficiency of your

solar installation, and it can also configure your installation in

your computer.

Once the SD card is inserted, you must activate it.

- Select the SD card line with (+) or (-) and press ( ►) to

highlight this line.

- Now with (+) or (-) you can turn ON or turn OFF the

SD card.

SD card ON => the SD card is already

working

SD card OFF => the SD card is out or

deactivated

Note: The storage of data on the SD card will be effective only

when the SD card is inserted and activated. All data previously

registered by the solar controller will not be visible on the

computer. A small SD card logo on the main screen is visible

when the SD card is inserted and activated.

IMPORTANT

To check the settings and logged data, plug the SD card into the

SD card slot on your computer

NOTICE

The software for reading the logged files on the SD card is preinstalled on the SD card from the factory.

If the window in Figure 4-6 (below) does not automatically

open, select the SD card slot driver under the “My Computer”

menu. Make sure that the log files WExxxx.dat and WEPARA.

ini are in this folder. If not, the SD card was not activated to log

data from the controller.

Do not extract the SD card before

deactivation.

Software is not compatible with Apple /

MAC computers.

Figure 4-6 Log files screen

WExxxx.dat

WEPARA.ini

25

Page 26

SL-DC Installation & Operation Manual

4 Operation Menu

- Double-click on “DataViewer” application to run software and select “OK” on start screen, as shown in Figure 4-7.

Figure 4-7 DataViewer screen

You have two tabs to choose from: “Charts” and “Settings” (Figure 4-8).

By selecting the “Charts” tab, you are able to view temperature, pump, flow and energy curves. By selecting or un-selecting

check-boxes, you can activate or deactivate different curves.

Figure 4-8 Charts screen

On the right-hand side of the “Charts” tab you can change the time period shown in the graphs. You can also select different

sensors, pumps, flow-sensors and energy values that you want to see in the graph. This is shown in Figure 4-9 on page 27.

26

Page 27

4 Operation menu (continued)

Figure 4-9 Charts screen_handling

SL-DC Installation & Operation Manual

The “Settings” tab allows you to view all of the available settings of your control unit. It also allows you to change different values

for programming the differential control. Definitions and explanations of values can be found in this manual.

Figure 4-10 Settings screen

27

Page 28

SL-DC Installation & Operation Manual

4 Operation Menu

Make the necessary changes to the control setting by choosing values from the drop down menu. Once the settings are to your

satisfaction, press the “Write” button and the changes will be saved to the SD card.

Figure 4-11 Write to SD card

After closing the software you can safely remove the SD card

from your computer and plug it back into the SD slot of the

differential control unit.

Once the SD card is installed in the differential control, you

will be asked if you want to update the control unit to apply

the new settings. Choose “YES” if you want to do so. Once

“YES” has been selected, the differential control unit has been

updated with the values you selected from Figure 4-11.

Note: For trouble-shooting the log files WExxxx.dat and

WEPARA.ini can be emailed to the Lochinvar / TiSUN service

partner of your choice to help you maintain and optimize your

solar system.

28

Page 29

5 Temperatures Menu

SL-DC Installation & Operation Manual

Figure 5-1 Temperatures menu screen

Temperatures --- --

Collector 1 _ _°F

Collector 2 _ _°F

Tank1 Bottom _ _°F

Tank1 Top _ _°F

In this menu you can see the instantaneous values of all sensors

connected.

– With (+) or (-) you can select a sensor and see its time

graph by pressing ( ►).

– For information about the graph symbol in FIG. 5-1 see

the bottom of page 24.

Figure 5-2 Temperatures time graph

82

50

18

-+

Collector1 _ _°F

0 :00

Figure 5-3 Temperatures time graph screen

Service------------- - ------

Pump P2 No SC

Glycol No

Glycol Mix 0%

Factory setting no

Reset op time no

Time graf temp 5m

Time graf op 1h

- With (+) or (-) select the line “Time graf temp” and press

( ►) to highlight the line.

- Now you can change the scale with (+) or (-). (It is

adjustable 1 to 60 minutes with factory value 5m.)

- Press (◄) repeatedly to return to the main menu.

- Move the time cursor with (+) or (-) to view the complete

scale. When you reach the end of the first window, the

graph will change to show another 100 points.

- You can change the scale of these graphs on the “Service”

menu in the submenu “Time graph temp”.

29

Page 30

6 Special Functions

SL-DC Installation & Operation Manual

Pump exercise function

If pumps were not activated during the previous 48 hours,

they will be activated for 15 seconds to avoid seizing of the

pumps.

Dimmer function

For better energy efficiency, the controller backlight is

switched OFF when no key is pressed for 15 minutes.

Security function

To prevent mistakes after installation, all critical parameters

(system and extra function) are not accessible after 4 hours

power ON. If you want to modify these parameters, you must

unplug the controller, then plug it back in. No settings are lost

when unplugging, or after a power failure.

After 4 hours you can still change all the other parameters to

optimize your system.

Others

Corresponding value for sensor PT1000:

(To be checked with an Ohmmeter, only when the sensor is

disconnected.)

-10°C / -14°F 960 ohms

0°C / 32°F 1000 ohms

10°C / 50°F 1039 ohms

20°C / 68°F 1077 ohms

30°C / 86°F 1116 ohms

40°C / 104°F 1155 ohms

50°C / 122°F 1194 ohms

60°C / 140°F 1232 ohms

70°C / 158°F 1271 ohms

80°C / 176°F 1309 ohms

90°C / 194°F 1347 ohms

100°C / 212°F 1385 ohms

120°C / 248°F 1461 ohms

140°C / 284°F 1535 ohms

30

Page 31

Notes

SL-DC Installation & Operation Manual

31

Page 32

Revision Notes: Revision A (ECO C06520)

initial release.

SL-DC-I-O Rev A

9/10

Loading...

Loading...