Page 1

CAUTION: The heat transfer medium

must be water or other nontoxic fluid having

a toxicity rating or class of 1, as listed in

Clinical Toxicology of Commercial Products,

5th edition.

SIT-I-O Rev H

Installation & Operation

Manual

Models: SIT030 - SIT119

The pressure of the heat transfer medium

must be limited to a maximum of 30 PSIG by

an approved safety or relief valve.

WARNING

This manual must only be used by

a qualified heating installer / service

technician. Read all instructions

before installing. Perform steps in

the order given. Failure to comply

could result in severe personal

injury, death, or substantial property

damage.

Save this manual for future reference.

Page 2

Contents

HAZARD DEFINITIONS .................................................... 2

PLEASE READ BEFORE PROCEEDING ........................ 3

1. GENERAL INFORMATION

Operating Restrictions ........................................................ 4

Single-Wall Heat Exchanger .............................................. 4

2. PRE-INSTALLATION

Locating the Tank ............................................................... 5

Recommended Clearances ................................................ 5

3. BOILER SIDE PIPING

Zone with Circulator to Aquastat ........................................ 6

Zone with Valve to Aquastat .............................................. 6

DHW Prioritization .............................................................. 6

Multiple Tank Connections (Boiler Side) ............................ 6

Table 3A - Pressure Drop Chart ................................... 6

Table 3B - Pressure Drop Values ................................. 6

Piping Diagrams ............................................................ 7-10

4. DOMESTIC SIDE (TANK) PIPING

Basic Domestic Piping ................................................. 11

Multiple Tank Domestic Water Piping .......................... 11

Domestic Water Piping for Distant Fixtures ..................11

Hazard definitions

Anti-scald Valves (Mixing Valves) ............................. 12

Install Drain Valve ...................................................... 12

Temperature and Pressure (T&P) Relief Valve .......... 12

Table 4A - Minimum Relief Valve (AGA Rating) ... 13

5. WIRING

Indirect Water Heater Sensor Setup (Knight Boiler) ........ 15

Install and Connect Tank Sensor ............................... 15

Indirect Water Heater Controlled Using Aquastat and

Zone Circulator ................................................................. 16

6. START-UP AND CHECK-OUT .................................. 17

7. MAINTENANCE

Maintenance Schedule ..................................................... 18

To Fill the Water Heater ............................................. 18

To Drain the Water Heater ......................................... 18

8. PERFORMANCE DATA

IBR Chart.......................................................................... 19

How to Properly Size Your Indirect Water Heater ........... 20

Performance Data Charts ........................................... 21-23

REVISION NOTES ............................................ Back Cover

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels

or to important information concerning the life of the product.

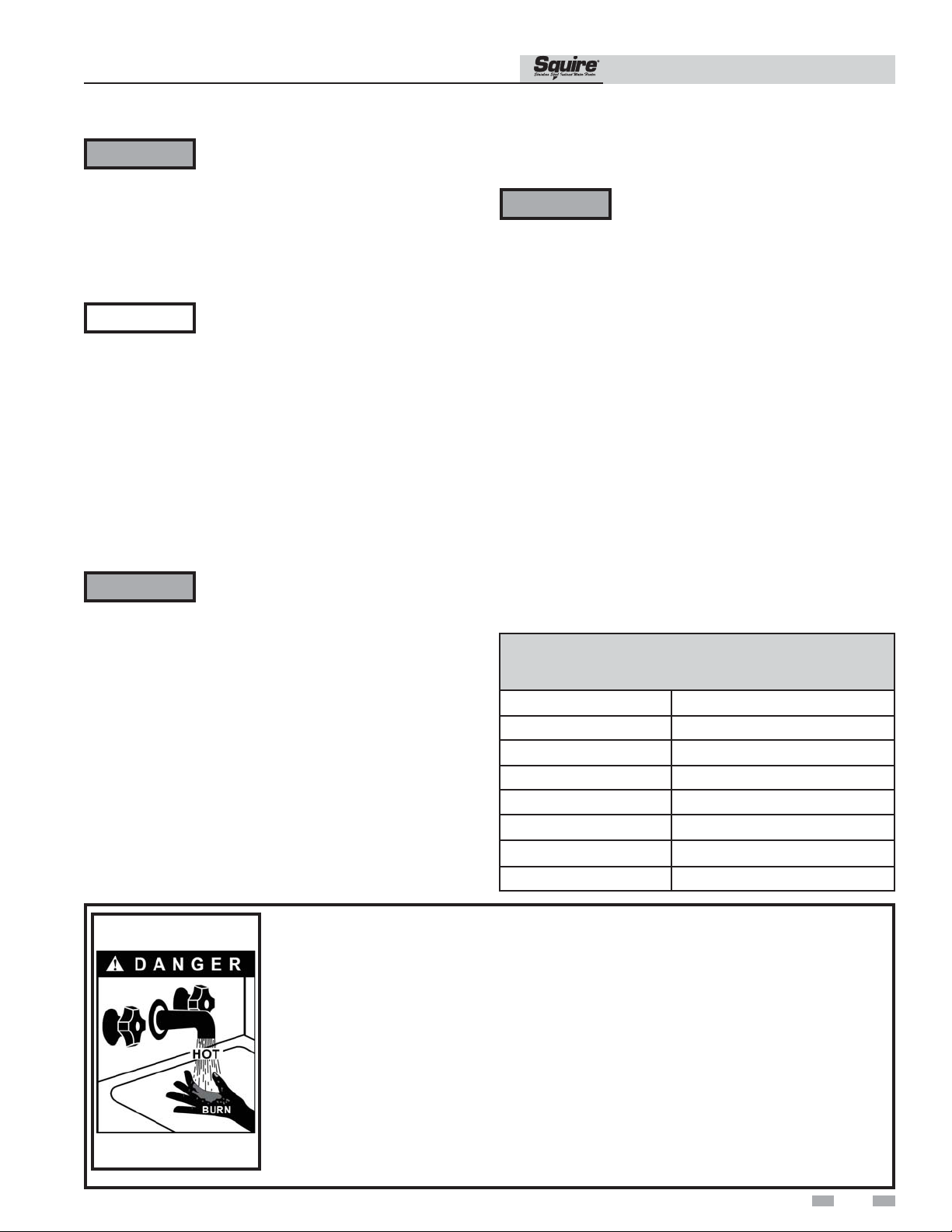

DANGER

WARNING

CAUTION

CAUTION

NOTICE

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

2

Page 3

Please read before proceeding

Installation & Operation Manual

WARNING

NOTICE

WARNING

Installer – Read all instructions before

installing. Perform steps in the order given.

Have this indirect water heater serviced/

inspected by a qualified service technician, at

least annually.

Failure to comply with the above could result

in severe personal injury, death or substantial

property damage.

When calling or writing about the appliance

– Please have the indirect water heater model

and serial number from the indirect water

heater rating plate.

Consider piping and installation when

determining appliance location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with appliance)

does not apply to appliances improperly

installed or improperly operated.

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

This appliance MUST NOT be installed in

any location where gasoline or flammable

vapors are likely to be present.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

• Installation and service must be performed by a qualified

installer, service agency, or the gas supplier.

WARNING

Failure to adhere to the guidelines on this

page can result in severe personal injury,

death, or substantial property damage.

When servicing the indirect water heater –

• To avoid severe burns, allow the appliance to cool

before performing maintenance.

Indirect water heater operation –

• Should overheating occur or gas supply fail to shut off,

do not turn off or disconnect electrical supply to

circulator. Instead, shut off the gas supply at a location

external to the appliance.

• Do not use this appliance if any part has been under

water. The possible damage to a flooded appliance can

be extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

The following chart details the relationship of water temperature

and time with regard to scald injury and may be used as a

guide in determining the safest water temperature for your

applications.

APPROXIMATE TIME / TEMPERATURE

RELATIONSHIPS IN SCALDS

120°F More than 5 minutes

125°F 1 1/2 to 2 minutes

130°F About 30 seconds

135°F About 10 seconds

140°F Less than 5 seconds

145°F Less than 3 seconds

150°F About 1 1/2 seconds

155°F About 1 second

Hot Water Can Scald!

• Water heated to temperatures for clothes washing, dish washing, and other sanitizing needs can

scald and cause permanent injury.

• Children, elderly, and infirm or physically handicapped persons are more likely to be

permanently injured by hot water. Never leave them unattended in a bathtub or shower.

Never allow small children to use a hot water tap or draw their own bath.

• If anyone using hot water in the building fits the above description, or if state laws or local

codes require certain water temperatures at hot water taps, you must take special

precautions:

• Use lowest possible temperature setting.

• Install some type of tempering device, such as an automatic mixing

valve, at hot water tap or water heater. Automatic mixing valve must be selected and

installed according to valve manufacturer’s recommendations and instructions.

• Water passing out of drain valves may be extremely hot. To avoid injury:

• Make sure all connections are tight.

• Direct water flow away from any person.

Protection Must Be Taken Against Excessive Temperature and Pressure!

--Installation of a Temperature & Pressure (T&P) relief valve is required.

3

Page 4

1 General information

Installation & Operation Manual

The Lochinvar SIT series indirect water heater (FIG. 1-1) is

designed to generate domestic hot water in conjunction with

a hot water boiler using forced boiler water circulation. This

indirect water heater consists of a 316L Stainless Steel tank in

which a smooth 304L stainless steel coil is located (Table 1A).

Boiler water is pumped through the coil and heats the water

in the tank. This tank is not intended for use in pool heating

applications or for heating any fluid other than water. It is

also not intended for use in gravity hot water heating systems.

Operating restrictions:

• Maximum domestic hot water temperature is 194°F.

• Maximum boiler water temperature is 210°F.

• Maximum working pressure for the vessel tank is

150 psig.

Table 1A

Component Materials

Component Material

Tank 316L Steel Stainless Steel

Coil 304L Stainless Steel

Insulation Polyurethane

Single-wall heat exchanger

Uniform plumbing code

Single-wall heat exchangers are permitted if they satisfy all of

the following requirements --

1. The heat transfer medium is potable water or contains only

substances which are recognized as safe by the U.S. Food

and Drug Administration.

2. The pressure of the heat transfer medium is maintained less

than the normal minimum operating pressure of the

potable water system.

3. The equipment is permanently labeled to indicate that

only additives recognized as safe by the FDA shall be used

in the heat transfer medium.

Other heat exchanger designs may be permitted where approved

by the Administrative Authority.

Jacket Polypropylene / ABS

Figure 1-1 Lochinvar SIT Series Indirect Water Heater

PAR T NO.

“F”

22.5°

45°

1” FPT (SEE NOTE 1)

“E”

“D”

SIT030

SIT040

SIT050

SIT065

SIT080

SIT119

NOTES:

1. 1-1/2” FPT ON MODELS SIT065 - 119 .

2. 1-1/2” MPT ON MODELS SIT065 - 119 .

2

1

3/4” FPT

3

1” MPT

AQUASTAT/SENSOR WELL

“A”

(in.)

3 1/16

3 1/16

3 5/8

3 5/16

3 5/16

3 5/16

“B”

(in.)

8 3/16

8 3/16

9 1/8

9 1/8

9 1/8

9 3/8

“C”

(in.)

21 3/4

25 1/4

24 7/16

27 15/16

27 15/16

31 11/16

“D”

(in.)

32 1/4

48 1/2

39 3/4

52 1/4

61 3/4

60 1/4

1. RELIEF VALVE CONNECTION

2. HOT WATER OUTLET

3. BOILER WATER IN

4. BOILER WATER OUT

5. DRAIN/COLD WATER INLET

“E”

(in.)

39 1/2

55 9/16

47 1/4

59 7/8

69 3/8

68 3/16

WEIGHT

“F”

FULL OF WATER

(in.)

(lbs.)

20

20

24

24

24

28

393

515

614

820

921

1268

4

“C”

“B”

“A”

1” MPT

1” MPT (SEE NOTE 2)

5

SIT030 - SIT119

4

Page 5

2 Pre-installation

Installation & Operation Manual

1. The installation must conform to the instructions

in this manual and all applicable local, state,

provincial, and national codes, laws, regulations, and

ordinances. Installations in Canada must conform to

B149.2 Installation Code.

2. Be certain the domestic water supply to the tank has

physical and chemical characteristics that fall within

the limits shown in Table 2A. Where questions exist

as to the composition of the water on the job, a

qualified water treatment expert should be consulted.

CAUTION

3. Read and understand all installation requirements in

this manual.

Water with characteristics outside the

limits shown in Table 2A may severely

shorten the life of the tank due to

corrosion. Damage to tanks in such

cases is not covered under warranty.

Table 2A

Water Chemistry Requirements

Water used in the tank must have characteristics falling

within the following limits:

Characteristic Min. Max.

Ph 6.0 8.0

Locating the tank

1. Choose a location for your water heater centralized to the

piping system. You must also locate the SIT water heater

where it will not be exposed to freezing temperatures.

Additionally, you will need to place the water heater so that

the controls, drain, and inlet/outlets are easily accessible.

This appliance must not be installed outdoors, as it is

certified as an indoor appliance, and must also be kept

vertical on a level surface.

2. Keep distance between boiler and water heater to a

minimum to:

a. reduce piping heat loss

b. provide minimal friction loss

3. Figure 1-1 on page 4 shows the weights of all the tanks filled

with water. Make sure that the location chosen for the tank

is capable of supporting it.

CAUTION

This appliance must be placed where leakage

from the relief valve, leakage from the

related piping, or leakage from the tank or

connections, will not result in damage to the

surrounding areas, or to the lower floors of

the building. A water heater should always

be located in an area with a floor drain or

installed in a drain pan suitable for water

heaters. Lochinvar shall not be held liable for

any such water damage.

Chloride (PPM) -- 80

4. The tank may be located some distance from the boiler

provided the pump is designed to provide the flow

called for in Table 3B - Pressure Drop Values, through

the coil. Also, the further the tank is from the boiler, the

longer the response of the boiler will be to a call from the

tank zone. Insulate piping between the boiler and the tank.

WARNING

Failure to properly support the tank could

result in property damage or personal injury.

Recommended clearances

The installation location must provide adequate clearances

for servicing and proper operation of the water heater. A 12

inch vertical clearance is recommended from the top of the

water heater. A zero clearance is allowed for the sides of the

water heater. However, boiler and servicing clearances must be

figured when locating the water heater.

5

Page 6

3 Boiler side piping

Installation & Operation Manual

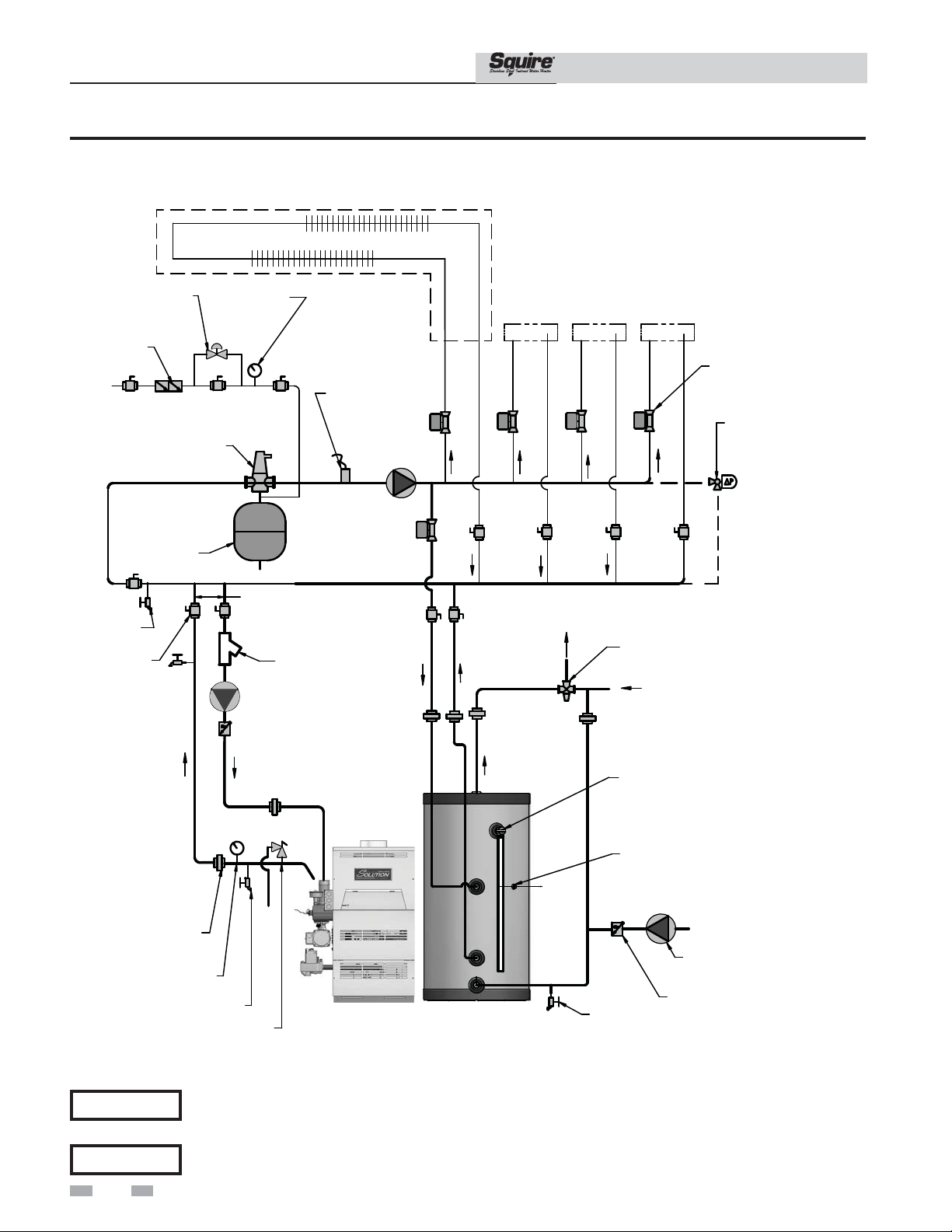

Figures 3-1 thru 3-4 show typical boiler side piping for

several common situations. Regardless of which system is

used it is imperative that the flow rates called for in Table

3B are developed through the coil. This requires properly

sized piping and a properly sized pump.

The system shown in FIG’s 3-1 thru 3-4 are described

below:

Zone with circulator to Aquastat

This system is like the circulator zone system on a straight

heat job except that one of the zones goes to the tank

instead of radiation. As on any circulator zone system

check valves should be installed in each zone to prevent

unwanted circulation through zones which are not calling

for heat. Figure 3-1 on page 7 illustrates typical circulator

zone piping.

Zone with valve to Aquastat

As with the circulator zone system, this system is just like a

standard heating zone system except that one of the zones

is connected to the tank coil as shown in FIG. 3-2. The

system circulator must be large enough to move boiler

water through the coil regardless of the flow rate required

through the heating zones.

DHW prioritization

Multiple tank connections (boiler side)

Multiple tank installations must be done in the “reverse-return”

manner. The reason for this is to create the same pressure drop

(and therefore, the same flow) through the coil of each tank.

The boiler manifold piping must be sized so that each coil has

the flow rate called for in Table 3B.

Because the pressure drop through tank coils varies from size

to size, it is hard to predict the flow rate that will be developed

through each coil when two tanks of different sizes are placed in

the same manifold. For this reason it is best not to mix tanks of

different sizes in the same zone if their recovery is critical.

Table 3A

Pressure Drop Chart

SIT030 -119 FRICTION LOSS

SIT030 -119 FRICTION LOSS

SIT119,

SIT065

&

080,

SIT050

SIT040

SIT030

FOOT HEAD

12.00

12.00

10.00

8.00

6.00

4.00

This piping system is designed to provide direct hot

water priority over the other zones in the heating system.

When there is a Domestic Hot Water (DHW) call for

heat, the Knight control will shut off the boiler circulator

and activate the domestic hot water circulator. Once the

2.00

0.00

5 8 12 16 20

GPM

DHW demand is satisfied, the boiler circulator will be

readjusted as demand requires. The circulator must be

large enough to move the boiler water through the coils.

The recommended piping for a DHW priority system is

depicted in FIG. 3-3 on page 9.

Table 3B

Pressure Drop Values

PRESSURE DROP

5

(FT/HD)

12

GPM16GPM

MODEL

WATER

INLET

(NPT)

WATER

OUTLET

(NPT)

COIL

CONNECTION

(NPT)

COIL

LENGTH

(FT)

SQ FT

SURFACE

AREA

GPM8 GPM

SIT030 1 1 1 24 8.0 .36 .91 2.06 3.66 5.71

SIT040 1 1 1 30.8 10.0 .41 1.04 2.34 4.16 6.49

SIT050 1 1 1 36.5 12.0 .46 1.18 2.67 4.74 7.4

SIT065 1.5 1.5 1 41.5 13.5 .61 1.57 3.53 6.27 9.8

SIT080 1.5 1.5 1 41.5 13.5 .61 1.57 3.53 6.27 9.8

20

GPM

SIT119 1.5 1.5 1 67.3 22.0 .73 1.87 4.22 7.5 11.71

6

Page 7

3 Boiler side piping (continued)

Figure 3-1 Piping Diagram Zoned with Circulators

ZONE #1

Installation & Operation Manual

MAKE UP WATER

DRAIN POINT

(TYPICAL)

BALL VALVE

(TYPICAL)

PRESSURE

REDUCING VALVE

BACKFLOW

PREVENTER

AIR SEPARATOR

EXPANSION

TANK

PRESSURE

GAUGE

SYSTEM SUPPLY

SENSOR

(WHEN USED)

NOT TO EXCEED 4 PIPE DIA.

OR A MAXIMUM OF 12" APART

Y-STRAINER

FLOW CHECK

BOILER

CIRCULATOR

VALVE

ZONE #2

HOT

WATER

OUT

ZONE #3

ANTI-SCALD

MIXING VALVE

ZONE #4

COLD

WATER

IN

ZONE CIRCULATORS

(TYPICAL)

NOTICE

NOTICE

RELIEF VALVE

TANK SENSOR/

AQUASTAT

UNION

(TYPICAL)

TEMPERATURE /

PRESSURE

GAUGE

RELIEF VALVE

DRAIN

PRESSURE

SOLUTION

BOILER

SQUIRE

DRAIN

( FIELD SUPPLY )

RECIRCULATION

CHECK VALVE

PUMP

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

Please note that the installer is responsible for ensuring DHW prioritization when piped as a zone.

7

Page 8

3 Boiler side piping

Figure 3-2 Piping Diagram Zoned with Valves

Installation & Operation Manual

ZONE #1

REDUCING VALVE

BACKFLOW

PREVENTER

DRAIN POINT

(TYPICAL)

BALL VALVE

(TYPICAL)

PRESSURE

MAKE UP WATER

AIR SEPARATOR

EXPANSION

TANK

PRESSURE

GAUGE

SYSTEM SUPPLY

SENSOR

(WHEN USED)

NOT TO EXCEED 4 PIPE DIA.

OR A MAXIMUM OF 12" APART

Y-STRAINER

BOILER

CIRCULATOR

CIRCULATOR

ZONE #2

WATER

ZONE #3

HOT

OUT

ZONE #4

ANTI-SCALD

MIXING VALVE

COLD

WATER

IN

ZONE VALVES

(TYPICAL)

DIFFERENTIAL

PRESSURE BYPASS

VALVE (IF USED)SYSTEM

TEMPERATURE /

PRESSURE

NOTICE

NOTICE

8

RELIEF VALVE

TANK SENSOR/

AQUASTAT

UNION

(TYPICAL)

GAUGE

DRAIN

PRESSURE

RELIEF VALVE

SOLUTION

BOILER

SQUIRE

DRAIN

( FIELD SUPPLY )

RECIRCULATION

PUMP

CHECK VALVE

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

Please note that the installer is responsible for ensuring DHW prioritization when piped as a zone.

Page 9

3 Boiler side piping (continued)

Figure 3-3 Knight Boiler Primary / Secondary Piping

PRESSURE

AIR

REDUCING VALVE

PRESSURE

GAUGE

BACKFLOW

PREVENTER

MAKE UP WATER

SYSTEM SUPPLY

SENSOR

SEPARATOR

Installation & Operation Manual

TO

SYSTEM

BALL VALVE

(TYPICAL)

SYSTEM

CIRCULATOR

EXPANSION

TANK

DRAIN POINT

(TYPICAL)

UNION

(TYPICAL)

TEMPERATURE /

PRESSURE

GAUGE

BOILER

CIRCULATOR

DRAIN

PRESSURE

RELIEF VALVE

Y-STRAINER

(RECOMMENDED)

DOMESTIC

HOT WATER

CIRCULATOR

KNIGHT

BOILER

FROM

SYSTEM

ANTI-SCALD

MIXING VALVE

SQUIRE

HOT

WATER

OUT

COLD

WATER

IN

TANK SENSOR/

AQUASTAT

CHECK VALVE

RECIRCULATION

DRAIN

( FIELD SUPPLY )

PUMP

NOTICE

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

9

Page 10

3 Boiler side piping

Figure 3-4 Multiple Tank Connections

PRESSURE

BACKFLOW

PREVENTER

REDUCING VALVE

PRESSURE

GAUGE

Installation & Operation Manual

TO

SYSTEM

BALL VALVE

(TYPICAL)

MAKE UP WATER

SEPARATOR

SYSTEM SUPPLY

SENSOR

SYSTEM

CIRCULATOR

EXPANSION

TANK

AIR

DRAIN POINT

(TYPICAL)

UNION

(TYPICAL)

TEMPERATURE /

PRESSURE

GAUGE

NOT TO EXCEED 4 PIPE DIA.

OR A MAXIMUM OF 12” APART

Y-STRAINER

(RECOMMENDED)

BOILER

CIRCULATOR

DRAIN

PRESSURE

RELIEF VALVE

DOMESTIC

HOT WATER

CIRCULATOR

KNIGHT

BOILER

FROM

SYSTEM

SQUIRE SQUIRE

HOT

WATER

OUT

ANTI-SCALD

MIXING VALVE

RELIEF VALVE

TANK SENSOR/AQUASTAT

COLD

WATER

IN

(TYPICAL)

(TYPICAL)

RECIRCULATION

PUMP

CHECK VALVE

DRAIN

( FIELD SUPPLY )

NOTICE

10

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

Page 11

Installation & Operation Manual

4 Domestic side (tank) piping

Basic domestic piping

Figure 4-2 on page 14 shows typical domestic water piping

for a tank. The function of the components shown are as

follows:

a. Shut-off valves (recommended) - Used to isolate the

tank for servicing.

b. Backflow Preventer (required by some codes) - Used to

prevent water from backing out of the tank and into

the main potable water supply in the event that inlet

water pressure drops.

c. Expansion Tank (required for thermal expansion) This expansion tank absorbs the increased volume

caused by heating water.

Use an expansion tank designed for use on domestic

water systems. Refer to the expansion tank

manufacturer’s literature for the proper size expansion

tank to use.

NOTICE

d. Unions (optional) - Used to disconnect the tank in the

unlikely event that this is necessary.

If an expansion tank is used, do not put

any valves between the expansion tank

and tank inlet.

Domestic water piping for distant fixtures

In some cases the furthest fixture may be quite distant from

the tank. Such an installation would result in an unacceptable

delay before hot water reaches these distant fixtures. Even if all

the fixtures are relatively close to the tank, the building owner

may want hot water at all fixtures as soon as they are opened.

To prevent delays, return circulation piping with a check valve

that allows flow to the inlet of the tank. This should be installed

on each branch circuit at the farthest fixture or device, so that

hot water is supplied upon demand.

Because hot water is always circulating in the hot water branch,

the entire branch should be insulated to prevent excessive heat

loss.

e. Drain (required) - Used to drain the tank for

inspection or servicing.

Multiple tank domestic water piping

The two pipe reverse return piping uses more pipe than the

two pipe direct return piping, but the flow is more balanced

and even in the two pipe reverse return piping layout (see

FIG. 3-4).

Each tank must have its own T&P valve. It is recommended

that each tank be equipped with its own isolation valves,

unions, and drains so that one tank may be removed from

the system. If local codes require a backflow preventer,

check with the appropriate authority to find out whether

one backflow preventer may be used for tanks or each tank

must be equipped with its own backflow preventer. If each

tank must have its own backflow preventer, each tank must

also have its own expansion tank. If a common backflow

preventer is permitted, an expansion tank must be sized to

accommodate the expansion volume of all tanks.

11

Page 12

Installation & Operation Manual

4 Domestic side (tank) piping

Anti-scald valves (mixing valves)

Anti-scald valves used with water heaters are also called

tempering valves or mixing valves. An anti-scald valve

mixes cold water in with the outgoing hot water to assure

that hot water reaching a building fixture is at a temperature

low enough to be safe. ASSE1017 and ASSE1070 certified

valves are recommended.

Usually, the maximum temperature of the outlet water will

stay near the setting of the tank control. In some cases,

however, hot water usage patterns can cause the outlet

water temperature to rise significantly above the control

setting.

The temperature of water going to the fixtures may be

more carefully controlled through the use of a thermostatic

mixing valve. This device blends a controlled amount of

cold water with the hot water leaving the tank so that water

at a more constant temperature exits the mixing valve.

Anti-scald mixing valve piping is illustrated in FIG.’s 3-1

thru 3-4.

WARNING

An anti-scald mixing valve does not

eliminate the risk of scalding.

* Set the tank thermostat as low as

practical.

* Feel water before bathing or

showering.

* If anti-scald or anti-chill protection

is required, use devices specifically

designed for such service. Install

these devices in accordance with

their manufacturer’s instructions.

Temperature & pressure (T&P) relief valve

WARNING

For protection against excessive

temperatures and pressure, install

temperature and pressure protective

equipment required by local codes.

This equipment shall not be less than a

combination temperature and pressure relief

valve certified by a nationally recognized

testing laboratory that maintains periodic

inspection of production of listed equipment

or materials as meeting the requirements for

Relief Valves and Automatic Gas Shutoff

Devices for Hot Water Supply Systems,

ANSI Z21.22 and the Standard CAN1-4.4,

Temperature, Pressure, Temperature and

Pressure Relief Valves and Vacuum Relief

Valves. The combination temperature and

pressure relief valve shall be marked with

a maximum set pressure not to exceed the

maximum working pressure of the water

heater. The combination temperature and

pressure relief valve shall also have an hourly

rated temperature steam BTU discharge

capacity not less than shown in Table 4A.

Install the combination temperature and

pressure relief valve into the opening

provided and marked for this purpose on

the water heater.

Install drain valve

Drain valve and fittings are supplied by others.

Standard Installation

• Install a tee connection at the domestic cold water

inlet (FIG. 4-1).

Figure 4-1 Drain Valve Installed

DRAIN

VALV E

12

Page 13

Installation & Operation Manual

4 Domestic side (tank) piping (continued)

NOTICE

Do not place a valve between the combination T&P relief

valve and the tank.

Determine T&P relief valve size by the following

specifications, unless they conflict with local codes:

- SIT030/040/050 - 3/4" NPT with a minimum CSA

Rating of 105,000 Btu/hr.

- SIT065/080/119 - 3/4" NPT with a minimum CSA

Rating of 200,000 Btu/hr.

NOTICE

Verify that the combination

temperature and pressure relief valve

complies with local codes. If the

combination temperature and pressure

relief valve does not comply with local

codes, replace it with one that does.

Follow the installation instructions in

this section.

The Lochinvar SIT series water heaters

will absorb/store less than 200,000 Btu/

hr when domestic water outlet

temperature is 210°F and boiler water

supply temperature is 240°F. Listed

outputs are based on ASME Section VIII

Interpretation VIII-1-86-136. Check

with local codes for applicability.

Table 4A

Minimum Relief Valve (CSA Rating)

Model Btu/hr

SIT030 105,000

Standard installation

• Install the T&P relief valve in the connection marked

“Relief Valve”.

T&P relief valve discharge piping

T&P relief valve discharge piping MUST be:

- made of material serviceable for a temperature of

250°F or greater.

- directed so that hot water flows away from all persons.

- directed to a suitable place for disposal.

- installed so as to allow complete draining of the T&P

relief valve and discharge line.

- terminated within 6" of the floor.

T&P relief valve discharge piping MUST NOT be:

- excessively long. Using more than two (2) elbows or

15 feet of piping can reduce discharge capacity.

- directly connected to a drain. Refer to local codes.

- subject to freezing.

WARNING

CAUTION

Do not install any valve between the T&P

relief valve and the tank connection or

on the T&P relief valve discharge piping.

Improper placement and piping of T&P

relief valve can cause severe personal injury,

death or substantial property damage.

The T&P relief valve is not intended for

constant duty, such as relief of pressure

due to repeated normal system expansion.

Correct this condition by installing a

properly sized expansion tank in a domestic

water system. Refer to the expansion tank

manufacturer’s installation instructions for

proper sizing.

SIT040 105,000

SIT050 105,000

SIT065 200,000

SIT080 200,000

SIT119 200,000

WARNING

Failure to install and maintain a new, listed

3/4" X 3/4" T&P relief valve will release

the manufacturer from any claim which

might result from excessive temperature

and pressures.

13

Page 14

4 Domestic side (tank) piping

Figure 4-2 Recommended Domestic Water Piping

SHOCK ARRESTOR

UNION

(TYPICAL)

Installation & Operation Manual

SHUT-OFF VALVE

TO BOILER

FROM BOILER

ANTI-SCALD

MIXING VALVE

SQUIRE

TANK SENSOR/

AQUASTAT

CHECK VALVE

DRAIN

( FIELD SUPPLY)

SHUT-OFF

VALVE

SHUT-OFF

VALVE

EXPANSION

TANK

RECIRCULATION

PUMP

SHUT-OFF

VALVE

BACKFLOW

PREVENTOR

NOTICE

14

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

Page 15

Installation & Operation Manual

5 Wiring

Indirect water heater sensor setup (Knight boiler)

CAUTION

NOTICE

Install tank sensor

The tank sensor is a dual sensor which controls the

temperature of the tank from the boiler(see FIG. 4-1). The

tank sensor has a built-in high temperature limit set at

194°F.

1. Install the sensor inside the tank as depicted

in FIG. 5-1.

2. Connect the wire leads to the DHW Tank Sensor

(AUX) connection point on the Knight boiler

connection board (see FIG. 5-1).

Label all wires prior to disconnection when servicing controls. Wiring errors can cause improper and

dangerous operation.

The sensor supplied contains an Auto Reset High Limit (194°F).

Connect tank sensor

1. Turn OFF the power to the unit. Use wire strippers to strip

one inch of insulation from the ends of each wire that

will be spliced.

2. Splice the two ends of bare wire by twisting them together

with a pair of electrical pliers. Turn the pliers three or

four times to make a sufficient connection.

3. Attach a wire nut at the point where the two wires have been

twisted together. Twist the wire nut until it fits snugly, or

until it cannot be twisted any more.

3. The Knight boiler will automatically read the sensor

and default the tank temperature setting to 125°F.

4. Wrap the wire nut and the two wires with electrical tape to

secure the connection. Cover any exposed wiring with

4. Adjust the tank setpoint program. Reference the

electrical tape.

Knight Installation and Operation Manual for a

detailed explanation of the tank setpoint program.

Figure 5-1 Indirect Water Heater Controlled Using Tank Sensor

TANK BULBWELL

DHW TANK SENSOR / AUTO RESET HIGH LIMIT

(PLACE SENSOR IN

TANK BULBWELL & SNAP

CLIP OVER BULBWELL)

DHW TANK

SENSOR

KNIGHT LOW VOLTAGE

TERMINAL STRIP

INDIRECT TANK

KNIGHT BOILER

15

Page 16

Installation & Operation Manual

5 Wiring

Indirect water heater controlled using Aquastat and zone circulator / valve

1. Install Aquastat to tank. Aquastat control (TST20016) can be ordered from your local Lochinvar distributor.

2. Connect Aquastat to the zone controller for the Indirect Water Heater Zone.

3. Adjust Aquastat to the desired temperature.

Figure 5-2 Wiring for Zone Control

TST20016

TEMPERATURE

ADJUSTMENT

ZONE CONTROL BOX

WIRE

CONNECTIONS

ZONE CIRCULATOR

OR

ZONE VALVE

OR

16

AQUASTAT

CONTROL

INDIRECT TANK

Page 17

6 Start-up and check-out

1. Make sure the system is free of leaks and that air is

purged from the system.

Installation & Operation Manual

CAUTION

2. Many soldering fluxes contain Zinc Chloride which can

cause severe corrosion damage to stainless steel. After

completing all domestic water connections, flush the

indirect water heater thoroughly before leaving the

installation. This is particularly important if the

indirect water heater will be unused for an extended

period of time after installation. Flush the indirect

water heater by drawing at least three times its volume

from the tank.

3. Make sure that all electrical connections are made

correctly and that no exposed high voltage wiring is

present.

4. Make sure that each zone valve or circulator operates

when, and only when, its thermostat calls for heat. Let

each zone operate long enough to purge any remaining

air from the system.

5. Set the indirect water heater to the desired temperature.

Because hot water presents a scald hazard, it is best to set

the thermostat at 120°F or lower and raise it only if

necessary to provide adequate hot water.

Fix any leaks found before proceeding

further. Leakage from the boiler piping

can result in severe damage to the boiler.

6. Re-enable the burner and allow the boiler to operate.

Make sure that the boiler shuts down when the indirect

water heater is satisfied.

17

Page 18

7 Maintenance

Installation & Operation Manual

The Lochinvar SIT series indirect water heater is an extremely

simple device and as such requires very little maintenance.

There are, however, several items which should be checked

out on an annual or as needed basis to ensure a reliable supply

of hot water:

* Make sure that the rest of the boiler and domestic

water piping is free of leaks.

* If there is an oil lubricated circulator in the system,

make sure it is lubricated as called for by the

circulator manufacturer.

* Make sure that the boiler is maintained in accordance

with the boiler manufacturer’s instructions.

* If a water treatment system is required to keep the

water chemistry within the parameters shown in

Table 2A (see Section 2 - Pre-Installation), make sure

that this system is properly maintained.

Maintenance Schedule

Annual service by a qualified service technician

should include the following:

Any procedure required by local codes.

Verify system pressure. Air venting procedure may

require adding water to bring boiler system up to

pressure, typically 12 psig.

Manually operate T&P relief valve at least once a year.

This will release some hot water.

WARNING

Move operating lever to open position for a few

seconds and then move it back, allowing it to snap

closed. After the T&P relief valve is operated, if it

continues to release water, close the cold water inlet to

the water heater immediately. Follow the draining

instructions, and replace the T&P relief valve. If the

T&P relief valve weeps periodically, it may be due to

thermal expansion. Do not plug the T&P relief valve or

discharge piping.

DANGER

Follow instructions on circulator to oil, if required.

Check mixing valve, valves, pipes, and fittings for leaks.

Check function of the field-installed controls and valves.

See component manufacturer’s instructions.

Review homeowner’s maintenance responsibilities and

their frequencies, including any not listed in the

following section.

Before operating a T&P relief valve, make

sure no one is in front of or around the

T&P relief valve discharge piping. Hot

discharge water can cause severe personal

injury or substantial property damage.

Plugging the T&P relief valve or discharge

piping can cause excessive pressure in the

water heater, resulting in severe personal

injury, death, or substantial property

damage.

Homeowner monthly maintenance to include:

Visually check valves, pipes, and fittings for leaks. Call a

qualified service technician to repair leaks.

To Fill the Water Heater

1. Close the water heater drain valve by turning the knob

clockwise.

2. Open the cold water supply shutoff valve.

3. Open several hot water faucets to allow air to escape from

the system.

4. When a steady stream of water flows from the faucets, the

water heater is filled. Close the faucets and check for water

leaks at the water heater drain valve, combination

temperature and pressure relief valve and the hot and cold

water connections.

WARNING

To Drain the Water Heater

Should it become necessary to completely drain the water

heater, be sure to follow the steps below:

1. Disconnect the power supply to the heat source. Consult

the plumbing professional or electric company in your area

for service.

2. Close the cold water supply shutoff valve.

3. Open the drain valve on the water heater.

4. Open a hot water faucet to allow air to enter the system.

Drain the water heater if it will be shut off and exposed to

freezing temperatures. Freezing water will expand and damage

the water heater.

• If boiler water contains sufficient antifreeze, then

only the domestic water needs to be drained.

Water from opened drain valves, unions and

other connections may be extremely hot.

To avoid severe personal injury, death, or

substantial property damage:

- Tighten all drain hose connections.

- Direct hot water away from all

persons.

• If boiler water does not contain sufficient

antifreeze, the boiler water and the domestic water

must be drained.

If antifreeze is used in the boiler water, check concentration.

Boiler water (including additives) must be practically non-toxic,

having a toxicity rating or class of 1, as listed in the “Clinical

Toxicology of Commercial Products”. A maximum 50/50

mixture of inhibited propylene glycol is recommended. Follow

the antifreeze manufacturer’s instructions.

WARNING

Do not use automotive, ethylene glycol

or petroleum-based antifreeze. Do not use

any undiluted antifreeze. This can cause

severe personal injury, death, or substantial

property damage.

18

Page 19

Installation & Operation Manual

8 Performance data

Table 8A IBR Chart

Squire Indirect Water Heater

I=B=R Rating

Indirect

Water

Heater

Model

Number

SIT030

SIT040

SIT050

SIT065

SIT080

SIT119

• These ratings were obtained with a heat source output and heat source flow rate as listed in the chart using the parameters of the

Domestic Cold Water Inlet at 58°F, Domestic Temperature Rise of 77°F, and a Boiler Temperature Output of 180°F. Other results

will be obtained under different conditions.

Potable

Water

Volume

Gal.

27.0 1.1 1.5 160 183 99,000 14.0 3.9

40.0 1.6 0.9 181 208 115,000 14.0 4.5

51.6 1.7 0.8 209 255 133,000 14.0 5.3

67.0 1.9 0.7 263 327 154,000 14.0 5.7

81.5 2.1 0.6 266 347 160,000 14.0 5.7

113.4 3.2 0.5 349 459 216,000 14.0 6.5

Heat

Source

Water

Volume

Gal.

Standby

Heat Loss

F/hr

Continuous

Draw Rating

Gal/hr

First Hour

Rating Gal/

hr

Minimum Heat

Output Rate

from

Heat Source

Btu/hr

Minimum

Heat Source

Flow Rate

GPM

Tank Heat

Source

Friction

Loss Feet

W.C.

19

Page 20

Installation & Operation Manual

8 Performance data

How to properly Size Your Indirect Water Heater

Use the First Hour Rating (FHR) to properly size your Indirect Water Heater. The First Hour Rating is the amount of hot

water in gallons the heater can supply per hour (starting with a tank full of hot water), depending on tank capacity, source of

heat, and the size of the burner.

Estimate your peak hour demand as follows:

• Determine what time of day (morning, noon, evening) you use the most hot water in your home. Keep in mind the

number of people living in your home.

• Use the worksheet below to estimate your maximum usage of hot water during this one hour of the day -- this is your

peak hour demand. Note: The worksheet does not estimate total daily hot water usage.

The worksheet example shows a total peak hour demand of 165 gallons; therefore, this household would need a water heater

with a First Hour Rating of no less than 165 gallons.

Fixture Count Guide

To quickly estimate the minimum gallons of hot water required based on a family size number of baths and hot water

appliances the First Hour Rating of the Squire must be equal to or exceed the total first hour requirements.

Peak Hour Demand Worksheet

Description Fill in the Blank Example

40 Gallons for the first 2 people

10 Gallons for each additional person

20 Gallons for each bath after the first

(consecutive bath)

10 Gallons if dishwasher is used

20 Gallons if clothes washer is used

TOTAL

Heavy Usage Buffer

Use if family members take longer than average showers, etc.

First Hour Rating

Proceed to pages 21 – 23 of this manual to locate your Indirect Water Heater and Boiler in the sizing charts. Using the First

Hour Rating calculated in this worksheet, locate your Indirect Water Heater and Boiler along with your First Hour Rating.

This will also determine the flow needed between the Indirect Water Heater and Boiler.

x 1.5 x 1.5

Gals. 40 Gals.

Gals. 20 Gals.

Gals. 20 Gals.

Gals. 10 Gals.

Gals. 20 Gals.

Gals. 110 Gals.

Gals. 165 Gals.

20

Page 21

Installation & Operation Manual

-

8 Performance data (continued)

Table 8B First Hour Rating - 180°F Boiler Loop Water (Knight Boiler)

First Hour Rating - 180°F Boiler Loop Water

(Knight Boiler - Models SIT030 - SIT050)

Model SIT030 SIT040 SIT050

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

WB050 108 83 108 83 122 97 122 97 135 110 135 110

K/WB080 159 119 159 119 173 133 173 133 188 147 188 147

K/WB105 171 128 191 142 217 165 217 165 231 178 231 178

K/WB150 191 142 223 165 252 189 267 200 268 204 292 221

K/WB210 223 165 240 177 267 200 282 211 292 221 307 232

KB285 223 165 240 177 267 196 267 200 282 211 286 213 292 221 307 232 334 251

Boiler Heating Capacity

KB399 267 196 286 213 334 251

KB500 267 196 286 213 334 251

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

77008 89165 105532 114761 129676 92998 112972 123331 129574 132764 94115 114116 125111 134044 146207

First Hour Rating - 180°F Boiler Loop Water

(Knight Boiler - SIT065 - SIT119)

Model SIT065 SIT080 SIT119

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

WB050 153 128 153 128 163 138 163 138 197 172 197 172

K/WB080 207 165 207 165 216 175 216 175 250 209 250 209

K/WB105 250 196 250 196 259 206 259 206 292 239 292 239

K/WB150 319 245 328 252 338 262 338 262 372 296 372 296

K/WB210 356 271 386 293 374 288 409 312 476 371 476 371

KB285 356 271 386 293 388 294 374 288 409 312 424 323 501 388 573 438 596 454

Boiler Heating Capacity

KB399 388 294 424 323 596 454

KB500 388 294 424 323 596 454

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

118488 129139 146864 163768 167924 115860 139106 154002 171229 181544 141419 190161 204795 237649 253504

21

Page 22

Installation & Operation Manual

8 Performance data (continued)

Table 8C First Hour Rating - 180°F Boiler Loop Water (Universal Sizing)

First Hour Rating - 180°F Boiler Loop Water

(Universal Sizing - 45,000 - 295,000 Btu/hr)

Model SIT030 SIT040 SIT050

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

45,000 108 83 108 83 122 97 122 97 135 110 135 110

60,000 136 103 136 103 150 118 150 118 164 131 164 131

75,000 165 123 165 123 179 138 179 138 194 151 194 151

95,000 171 128 191 142 202 150 217 165 217 165 217 165 233 179 233 179 233 179

115,000 171 128 191 142 223 165 240 177 217 165 252 189 252 189 252 189 233 179 268 204 273 207 273 207

140,000 191 142 223 165 240 177 267 196 252 189 267 200 282 211 286 208 268 204 292 221 307 232 322 242

165,000 240 177 267 196 267 200 282 211 286 213 292 221 307 232 334 251

195,000 334 251

Boiler Heating Capacity

225,000

260,000

295,000

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

77008 89165 105532 114761 129676 92998 112972 123331 129574 132764 94115 114116 125111 134044 146207

First Hour Rating - 180°F Boiler Loop Water

(Universal Sizing - 45,000 - 295,000 Btu/hr)

Model SIT065 SIT080 SIT119

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

45,000 153 128 153 128 163 138 163 138 197 172 197 172

60,000 183 149 183 149 193 159 193 159 226 193 226 193

75,000 213 170 213 170 222 180 222 180 255 213 255 213

95,000 252 197 252 197 252 197 261 207 261 207 261 207 294 241 294 241 294 241

115,000 291 226 291 226 291 226 291 226 300 235 300 235 300 235 300 235 333 268 333 268 333 268 333 268

140,000 305 235 319 245 338 259 338 259 338 259 304 238 347 268 347 268 347 268 347 268 384 302 382 302 382 302 382 302 382 302

165,000 305 235 319 245 356 271 386 293 388 294 304 238 349 270 374 288 395 302 395 302 387 306 429 337 429 337 429 337 429 337

195,000 319 245 356 271 386 293 388 294 349 270 374 288 409 312 424 323 483 375 485 376 485 376 485 376

Boiler Heating Capacity

225,000 356 271 386 293 388 294 374 288 409 312 424 323 501 388 548 421 541 416

260,000 388 294 424 323 573 438 596 454

295,000 596 454

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

118488 129139 146864 163768 167924 115860 139106 154002 171229 181544 141419 190161 204795 237649 253504

22

Page 23

Installation & Operation Manual

8 Performance data (continued)

Table 8D First Hour Rating 200°F Boiler Loop Water (Universal Sizing)

First Hour Rating - 200°F Boiler Loop Water

(Universal Sizing - 45,000 - 295,000)

Model SIT030 SIT040 SIT050

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

45,000 105 84 105 84 118 97 118 97 132 109 132 109

60,000 133 104 133 104 145 117 145 117 160 130 160 130

75,000 160 124 160 124 173 137 173 137 188 151 188 151

95,000 197 151 197 151 197 151 209 163 209 163 209 163 226 179 226 179 226 179

115,000 224 171 233 176 233 176 233 176 245 190 245 190 245 190 245 190 263 206 263 206 263 206 263 206

140,000 255 194 277 210 277 210 277 210 271 209 291 224 291 224 291 224 291 224 295 230 311 241 311 241 311 241 311 241

165,000 277 210 308 232 317 240 335 256 335 256 335 256 295 230 329 254 358 276 358 276 358 276

Boiler Heating Capacity

195,000 308 232 352 265 335 256 362 276 375 285 329 254 375 288 399 306 404 309

225,000 375 288 399 306 404 309

260,000 404 309

295,000

325,000

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

107695 126355 140102 153900 184539 129980 151466 164149 178059 186356 131965 159672 172739 187562 189713

First Hour Rating - 200°F Boiler Loop Water

(Universal Sizing - 45,000 - 295,000)

Model SIT065 SIT080 SIT119

Circulator Flow

GPM

Domestic Outlet 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140 115 140

45,000 150 127 150 127 161 138 161 138 194 171 194 171

60,000 179 148 179 148 189 159 189 159 222 192 222 192

75,000 207 169 207 169 218 180 218 180 250 213 250 213

95,000 245 197 245 197 245 197 255 208 255 208 255 208 288 241 288 241 288 241

115,000 283 225 283 225 283 225 283 225 293 236 293 236 293 236 325 268 325 268 325 268

140,000 331 260 331 260 331 260 331 260 331 260 341 270 341 270 341 270 341 270 373 303 373 303 373 303 373 303

165,000 350 274 377 294 377 294 377 294 377 294 374 295 386 304 386 304 386 304 386 304 419 337 419 337 419 337 419 337 419 337

195,000 350 274 391 305 432 337 432 338 432 329 374 295 440 343 440 343 440 343 440 343 479 381 479 381 479 381 479 381 479 381

Boiler Heating Capacity

225,000 391 305 445 345 487 375 487 375 440 343 475 369 498 386 498 386 533 422 533 422 533 422 533 422

260,000 495 381 499 384 475 369 525 406 536 414 601 470 601 470 601 470

295,000 536 414 667 519 667 519

325,000 536 414 688 534 695 540

MAX BTU INPUT

5 8 12 16 20 5 8 12 16 20 5 8 12 16 20

146842 171693 200077 225514 235239 154198 192471 211523 237540 247474 194143 245777 282047 305766 319025

23

Page 24

Revision Notes: Revision A (ECO C05265) initial release.

Revision B (ECO C05399) reflects the addition of the Pressure Drop

Chart and updates made to the Performance Data Charts.

Revision C (ECO C05587) reflects the update of tables 3A and 3B

(Pressure Drop charts) on page 6, table 4A on page 13, the update of

the “Domestic water piping” paragraph on page 11, and the update of

Performance data table 8A on page 19.

Revision D (ECO C05788) reflects new images for section 3 “Boiler Side

Piping” FIG. 3-1 -- 3-4, a new image for section 4 “Domestic Side (Tank)

Piping” FIG. 4-2, and the update of the Pressure Drop chart on page 6.

Revision E (ECO C06035) reflects the update of FIG. 1-1 on page 4 to

revise listed dimensions.

Revision F (ECO C06300) reflects the update of images and additional

CSA cautions on manual cover and “Connect tank sensor” section

added to “Wiring” on page 15.

Revision G (ECO C06670) reflects the update of the IBR chart

information on page 19.

Revision H (ECO C08396) reflects the addition of the First Hour Ratings

of SIT080 at 20GPM for 115°F to Table 8B on page 21.

07/11 - Printed in U.S.A.

SIT-I-O Rev H

Loading...

Loading...