Page 1

CAUTION:

This appliance is not intended for potable water.

TSU-I-O Rev A

Installation & Operation

Manual

Models: TSU 150 - 940

WARNING

Save this manual for future reference.

This manual must only be used by

a qualified heating installer / service

technician. Read all instructions

before installing. Perform steps in

the order given. Failure to comply

could result in severe personal

injury, death, or substantial property

damage.

Page 2

Contents

HAZARD DEFINITIONS .................................................... 2

PLEASE READ BEFORE PROCEEDING ........................ 3

1. GENERAL INFORMATION

Operating Restrictions ........................................................ 4

Tank Shipment................................................................... 4

Components .................................................................... 4-6

Spherical Heat Exchanger................................................. 7

2. PRE-INSTALLATION

Recommended Antifreeze Concentrations ........................ 8

Locating the Tank ............................................................... 8

Recommended Clearances ................................................ 8

3. SOLAR CONNECTIONS

Spherical Pressure Drop Calculations............................... 9

Piping Diagrams ............................................................... 10

4. HYDRONIC PIPING

Basic Hydronic Piping ...................................................... 11

Hydronic Heating Zoned with Circulators ......................... 11

Thermal-Stor Domestic Water Heating ............................ 11

Domestic Hot Water Priority ............................................. 11

High Output Piping ........................................................... 11

Relief Valves .................................................................... 12

Anti-Scald Mixing Valves .................................................. 13

Piping Diagrams........................................................... 14-16

5. STARTUP AND MAINTENANCE

System Startup ................................................................. 17

Maintenance Schedule ................................................ 17-18

Winterizing the System ............................................... 18

To Drain/Flush the System ......................................... 18

NOTES ............................................................................. 19

REVISION NOTES ............................................ Back Cover

Hazard definitions

The following defined terms are used throughout this manual to bring attention to the presence of hazards of various risk levels

or to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or serious

injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but not

related to personal injury or property damage.

2

Page 3

Please read before proceeding

Installation & Operation Manual

WARNING

NOTICE

WARNING

Installer – Read all instructions before

installing. Perform steps in the order given.

Have this storage tank serviced/inspected

by a qualified service technician, at least

annually.

Failure to comply with the above could result

in severe personal injury, death or substantial

property damage.

When calling or writing about the appliance

– Please have the model and serial number

from the tank rating plate.

Consider piping and installation when

determining appliance location.

Any claims for damage or shortage in

shipment must be filed immediately

against the transportation company by the

consignee.

Factory warranty (shipped with appliance)

does not apply to appliances improperly

installed or improperly operated.

If the information in this manual is not

followed exactly, a fire or explosion may

result causing property damage, personal

injury or loss of life.

• Installation and service must be performed by a

qualified installer, service agency, or the gas supplier.

WARNING

Failure to adhere to the guidelines on this

page can result in severe personal injury,

death, or substantial property damage.

When servicing the Thermal-Stor –

• To avoid severe burns, allow the appliance to cool

before performing maintenance.

Appliance operation –

• Do not use this appliance if any part has been under

water. The possible damage to a flooded appliance can

be extensive and present numerous safety hazards. Any

appliance that has been under water must be replaced.

CAUTION

This appliance is not intended for potable

water.

This appliance MUST NOT be installed in

any location where gasoline or flammable

vapors are likely to be present.

WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electric switch; do not

use any phone in your building.

• Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

• If you cannot reach your gas supplier, call

the fire department.

3

Page 4

Installation & Operation Manual

1 General information

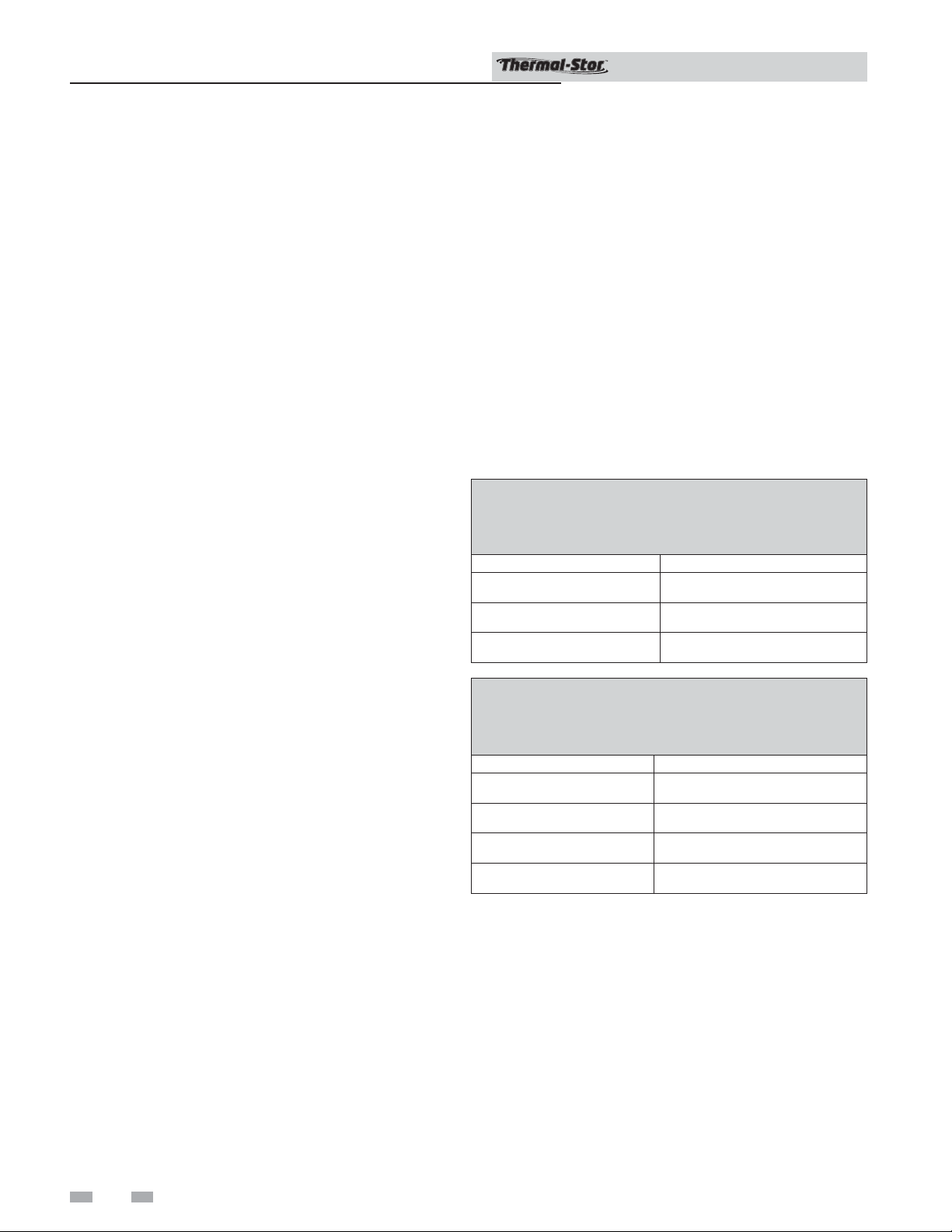

The Lochinvar Thermal-Stor stratified solar tank is designed to use a solar thermal collector system, in conjunction with a

back-up heat source, to provide water for a closed loop hydronic heating system. The appliance consists of a spherical heat

exchanger connected to an unlined storage tank. The Thermal-Stor tank uses solar heated water pumped through the spherical

heat exchanger to heat water in the tank. A backup heat source is used to maintain the desired tank temperature in the event that

adequate solar heat is not available. Tank components and specifications are detailed in FIG.’s 1-1 and 1-2, as well as in Tables

1A - 1D on pages 4 through 6.

The Thermal-Stor buffer tank can provide both thermal storage volume and hydraulic separation between the boiler or heat

pump and the building distribution system. The primary application of a buffer tank is to reduce boiler or heat pump cycling

in systems operating below design load conditions, or in systems having several low Btu heat loads calling for heat at different

times. The solar-assisted buffer tank provides thermal storage volume which can help reduce short-cycling, leading to longer

runtimes, higher efficiency and longer equipment life for the solar thermal system and heat source. If piped correctly, the buffer

tank can also function as a hydraulic separator, effectively separating the flow in the boiler loop from the flow in the distribution

system (FIG.’s 4-2 and 4-3, on pages 14 and 15). This tank has many applications including geothermal, pool and space heating.

Consult the factory if your specific application is not covered in this manual. This tank is not intended for use in gravity water

heating applications.

Operating Restrictions:

• Maximum stored water temperature is 210°F.

• Maximum working pressure for the vessel is 125 psig.

Tank shipment

Tanks taller than 7.5 feet will be shipped horizontally. Four

shipping legs are used to secure the tank to a pallet, and holes

are provided in the top cover for access to lifting lugs. The

shipping legs should be removed when the tank is removed

from the shipping crate.

Use field-supplied insulation to pack the shipping and lug

compartments, then use the factory provided covers to

conceal compartments upon final installation.

Table 1A

Thermal-Stor

Tank Component Materials

Component Material

Tank Steel SA414-G

Insulation Polyurethane Foam

Jacket Pre-paint Sheet Metal

Table 1B

Spherical Heat Exchanger

Component Materials

Component Material

Housing Steel S 235 JR

Heat Exchanger Coil Copper

Insulation Polyurethane Foam

Jacket Polypropylene

4

Page 5

1 General information (continued)

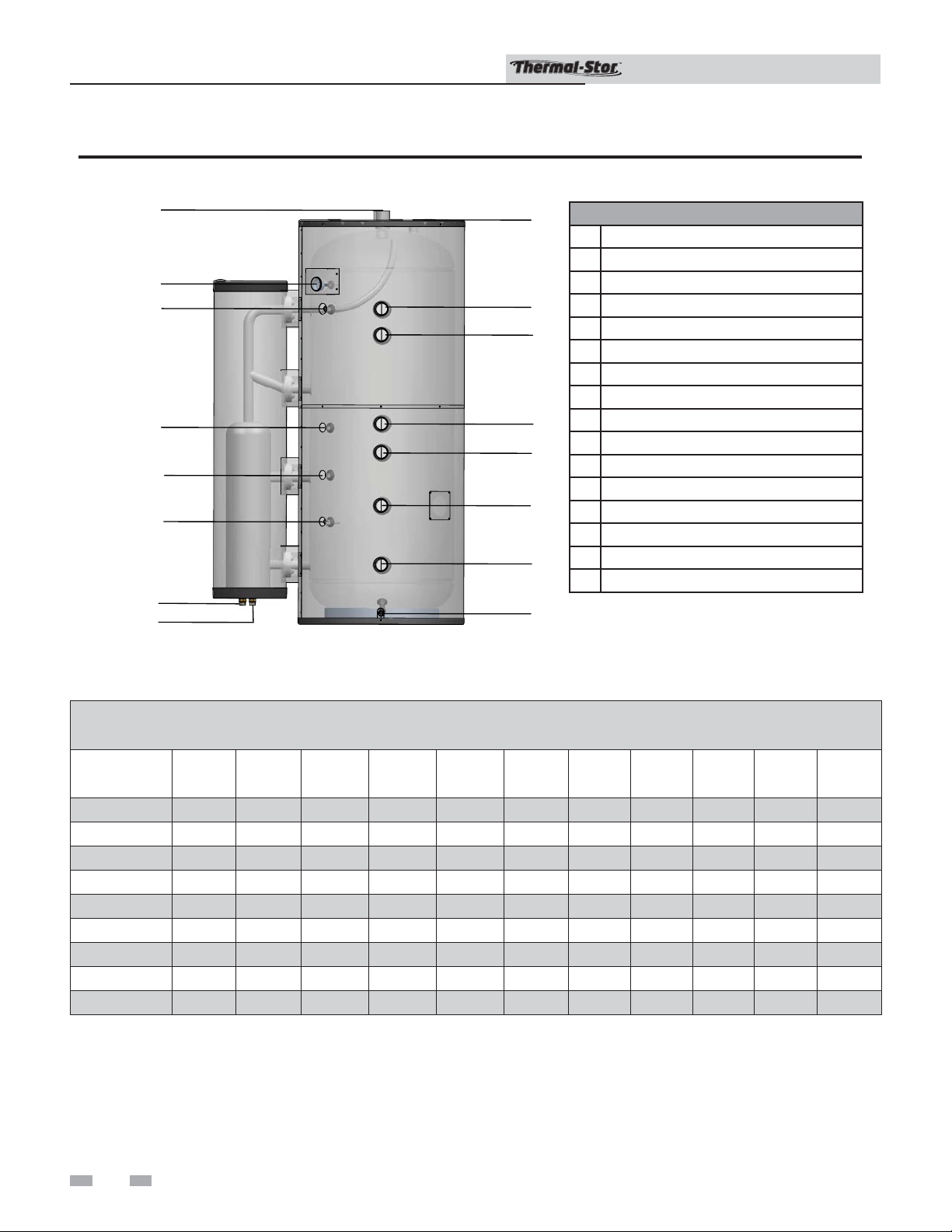

Figure 1-1 Thermal-Stor solar stratified tank components

TEMPERATURE

GAUGE

Installation & Operation Manual

AUXILIARY

HEAT OUTLET

BACKUP

HEAT SOURCE

SENSOR

SPHERICAL

HEAT EXCHANGER

SOLAR

SENSOR

IMG00104

BACKUP

HEAT SOURCE

INLET

BACKUP

HEAT SOURCE

RETURN

AUXILIARY

HEAT INLET

Table 1C

Thermal-Stor Tank Specifications

Boiler

Supply/

Return

(NPT)

Model

Tank

Diameter

(in.)

Jacket

Diameter

(in.)

Hydronic

Tappings

(NPT)

TSU150 24 28 2" 2" 140 1775

TSU200 28 32 2" 2" 190 2300

TSU257 30 34 2" 2" 240 2875

TSU350 36 40 2" 2" 340 3775

TSU423 36 40 2" 2" 420 4650

TSU504 42 46 2" 2" 495 5475

TSU650 48 52 2" 2" 645 7050

TSU752 48 52 2" 2" 745 8100

TSU940 48 52 2" 2" 920 10000

Tank

Water

Volume

(gal.)

Full

Weight

(lbs)

5

Page 6

1 General information

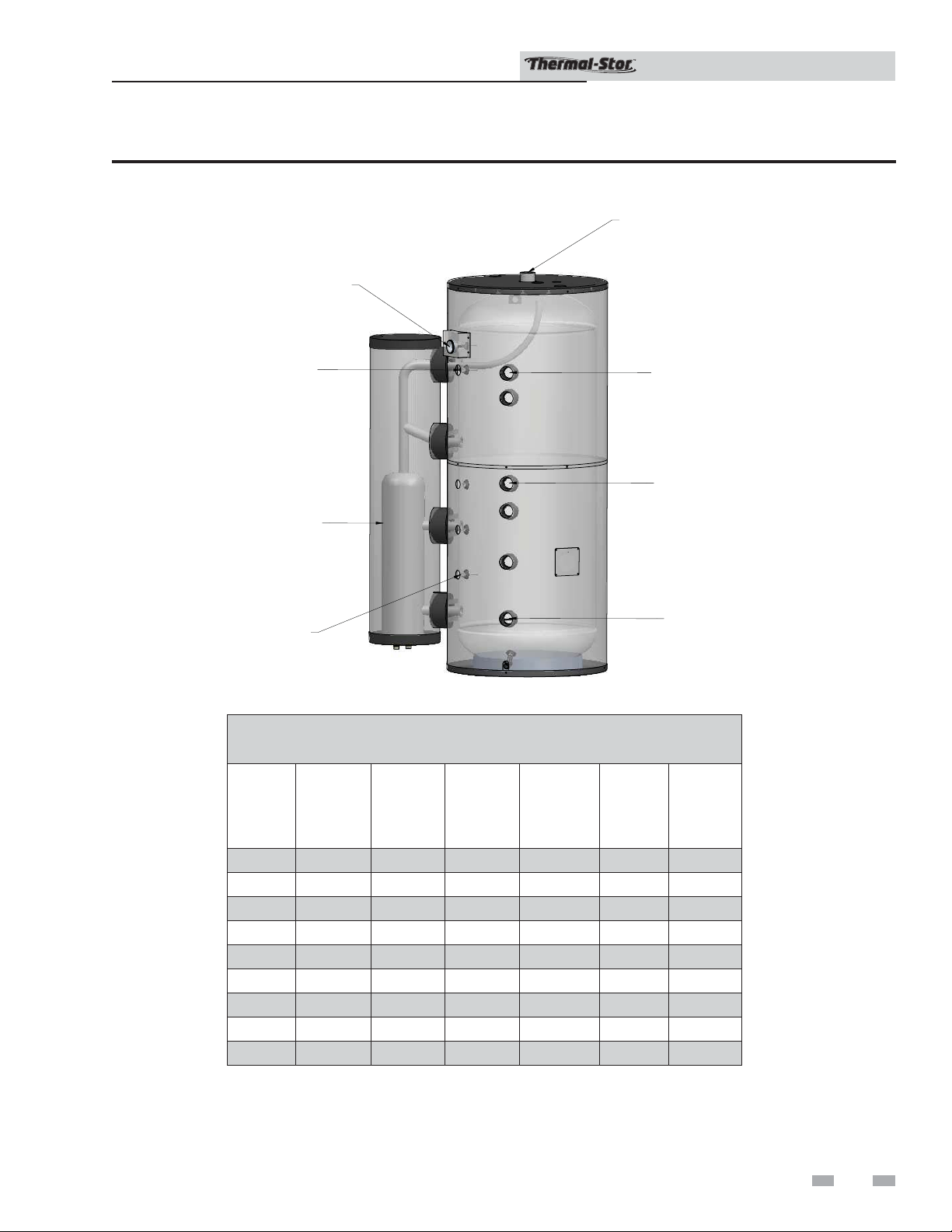

Figure 1-2 Thermal-Stor tappings

I

I

J

J

K

K

L

L

M

M

N

N

P

O

O

IMG00096

Installation & Operation Manual

H

G

F

E

D

C

B

A

Thermal-Stor Elements

A

Drain Valve

B

Auxiliary Heat Return

C

Low Temp Water Return

D

High Temp Water Return

E

Backup Heat Source Return

F

Space Heat Supply

G

Backup Heat Source Supply

H

Relief Valve / Air Vent

I

Auxiliary Heat Outlet

J

Heat Source Thermometer

K

Backup Heat Source Sensor

L

Sensor (Optional)

M

Sensor (Optional)

N

Solar Sensor

O

Spherical Exchanger, Inlet (Red Label)

P

Spherical Exchanger, Outlet (Blue Label)

Model

TSU150

TSU200

TSU257

TSU350

TSU423

TSU504

TSU650

TSU752

TSU940

Table 1D

Tapping Measurements (From Floor)

A

(in.)

2 1/4 10 3/4 21 1/4 28 3/4 33 50 1/4 55 1/4 71 75 3/4 3 1/2 3 1/2

2 1/4 11 1/4 22 3/4 33 38 1/2 55 1/2 60 1/2 76 80 4 1/4 4 1/4

2 1/4 15 1/2 34 1/2 42 1/2 49 62 3/4 67 3/4 87 91 3/4 8 1/2 8 1/2

3 1/4 17 36 3/4 46 1/2 52 3/4 61 1/4 66 1/4 87 1/4 91 1/4 10 10

3 1/4 17 40 1/4 52 58 1/4 75 3/4 80 3/4 100 104 10 10

2 1/2 18 1/2 33 1/2 42 1/4 49 59 3/4 64 3/4 87 91 1/2 11 1/2 11 1/2

2 1/4 20 1/2 36 3/4 44 1/2 51 60 3/4 65 3/4 88 93 13 1/2 13 1/2

2 20 1/2 38 1/4 50 57 1/2 70 75 100 104 3/4 10 1/2 10 1/2

2 1/4 20 1/2 49 63 70 1/2 88 1/2 93 1/2 124 129 13 1/2 13 1/2

B

(in.)

C

(in.)

D

(in.)

E

(in.)

F

(in.)

G

(in.)

H

(in.)

I

(in.)

O

(in.)

P

(in.)

6

Page 7

1 General information (continued)

Installation & Operation Manual

Spherical heat exchanger

The Thermal-Stor uses a copper finned tube spherical heat

exchanger to provide optimum solar stratified charging. The

spherical exchanger helps maintain optimal use of solar energy

for hydronic heating. The multi-functional design improves

efficiency in every system. Insulated with polyurethane foam,

the spherical heat exchanger and tank maintain a space-saving

design with minimal heat loss. Refer to FIG. 1-3 and Tables 1E

and 1F for additional spherical heat exchanger information

and measurements.

Figure 1-3 Spherical heat exchanger w/ tank

B

Table 1E

Tank with Spherical Measurements

Model

TSU150 SHX40000 44 1/2 28

TSU200 SHX40000 48 1/4 32

TSU257 SHX40001 50 1/4 34

TSU350 SHX40001 56 1/4 40

TSU423 SHX40002 56 1/4 40

TSU504 SHX40002 62 1/4 46

TSU650 SHX40003 71 1/4 52

TSU752 SHX40003 71 1/4 52

TSU940 SHX40004 71 1/4 52

Spherical

Model

A

(in.)

(in.)

B

A

IMG00107

Table 1F

Spherical Heat Exchanger Specifications

Tank

Model

SHX40000 8 1/2 14 61 0.75" 28 0.55 7.9 8.45

SHX40001 8 1/2 14 61 0.75" 42 0.65 7.8 8.45

SHX40002 8 1/2 14 61 1" 59 1.1 7.35 8.45

SHX40003 11 3/4 17 61 1.25" 102 2.0 15.8 17.8

SHX40004 11 3/4 17 80 1.25" 102 2.0 15.8 17.8

Diameter

(in)

Jacket

Diameter

(in)

Jacket

Height

(in)

Solar

Inlet

Return

(NPT)

HEX

Surface

Area

(ft2)

HEX

Water

Volume

(gal)

Tank

Water

Volume

(gal)

Total

Water

Volume

(gal)

7

Page 8

2 Pre-installation

Installation & Operation Manual

1. The installation must conform to the instructions in this

manual and all applicable local, state, provincial, and

national codes, laws, regulations, and ordinances.

Installations in Canada must conform to B149.2 Installation

Code.

2. If the heat source water contains antifreeze, a maximum

50/50 mixture of inhibited propylene glycol is recommended.

The heat source water, including additives, must be

non-toxic, having a toxicity rating or class of 1, as listed in

the Clinical Toxicology of Commercial Products.

WARNING

3. Read and understand all installation requirements in

this manual.

Do not use automotive, ethylene glycol or

petroleum-based antifreeze. Do not use

any undiluted antifreeze. This can cause

severe personal injury, death, or substantial

property damage.

Table 2A

Recommended Antifreeze Concentrations

Glycol Freeze

Protection

Propylene Glycol

Only

Percentage

20 18°F

30 8°F

40 -6°F

50 -28°F

Freeze

Protection

Locating the Tank

1. Choose a location for the Thermal-Stor centralized to

the piping system. You must also locate the Thermal-Stor

where it will not be exposed to freezing temperatures.

Additionally, you will need to place the tank so that

the controls, drain, and inlet/outlets are easily accessible.

This tank must not be installed outdoors, as it is

certified as an indoor appliance, and must be kept vertical

on a level surface.

2. Table 1C on page 5 shows the weight of all the tanks filled

with water. Ensure that the location chosen for the tank

is capable of supporting the weight.

CAUTION

3. The tank may be located some distance from the heat

source provided that the pump is designed to provide

enough flow for both units to perform properly. The

further the distance from the tank to the heat source, the

longer the response time will be to provide sufficient heat

to the tank. Insulate piping between the heat source and

the tank.

WARNING

This tank must be placed where leakage

from the relief valve, leakage from the

related piping, or leakage from the tank

or connections, will not result in damage

to the surrounding areas, or to the lower

floors of the building. A tank should always

be located in an area with a floor drain or

installed in a drain pan suitable for tanks.

Lochinvar shall not be held liable for any

such water damage.

Failure to properly support the tank could

result in property damage or personal

injury.

Recommended Clearances

The installation location must provide adequate clearances

for servicing and proper operation of the appliance.

A 12-inch vertical clearance is recommended from the top of

the appliance. A zero clearance is allowed for the sides of the

appliance. However, boiler and servicing clearances must be

figured when locating the appliance.

8

Page 9

TSU150-200 /

SHX40000

TSU257-350 /

SHX40001

TSU423-504 /

SHX40002

TSU650-940 /

SHX40003

SHX40004

0

5

10

15

20

25

30

0 gpm 2 gpm 4 gpm 6 gpm 8 gpm 10 gpm 12 gpm 14 gpm

Installation & Operation Manual

3 Solar connections

A solar thermal system consists of several components selected to work together to convert solar energy into hot water for

various applications. A controller is used to turn on a pump when the fluid in the solar collectors is warmer than the water in the

Thermal-Stor tank plus the differential. The pump will transport hot fluid from the collector to the heat exchanger and replace it

with cooler fluid returning. The collectors, pump station and heat exchanger should be connected with supply and return piping

that is insulated to minimize heat losses (FIG. 3-1, page 10). The system should be equipped with over-temperature and overpressure devices that prevent unsafe operating conditions. When multiple Thermal-Stor tanks are used, they should be connected

in reverse-return arrangement (FIG. 3-2, page 10). This will help ensure that solar heated water is distributed evenly between the

heat exchangers. Pressure drop and maximum operating values for the Thermal-Stor spherical heat exchanger are listed in Tables

3A - 3C.

Installation and commissioning must be carried out by a licensed contractor. Take appropriate safety measures when carrying

out any installation work on the roof and observe all relevant accident prevention regulations. It is the installer’s responsibility to

comply with the building and installation codes in effect and all regulations that apply to the operation of a solar hot water system.

MODEL

TSU150

TSU200

TSU257

TSU350

TSU423

TSU504

TSU650

TSU752

TSU940

30

Table 3A

Spherical Heat Exchanger

Pressure Drop Values

PRESSURE DROP PSI)

SPHERICAL

MODEL

1

GPM2 GPM4GPM6GPM8GPM10GPM12GPM14GPM

SHX40000 0.20 0.68 2.29 4.66 7.71 11.39 15.67 20.52

SHX40001 0.24 0.81 2.71 5.52 9.13 13.49 18.56 24.31

SHX40002 0.07 0.23 0.78 1.59 2.64 3.90 5.36 7.02

SHX40003 0.03 0.09 0.30 0.61 1.01 1.50 2.06 2.70

SHX40004 0.03 0.09 0.30 0.61 1.01 1.50 2.06 2.70

Table 3C

Spherical Heat Exchanger Pressure Drop Chart

Table 3B

Spherical Maximum Operating

Conditions

Copper Heat

Exchanger

Temperature 230°F 230°F

Pressure 145 psi 125 psi

Tank

25

20

15

10

PRESSURE DROP, PSI

5

0

02468101214

FLOW RATE, GPM

TSU257-350/

SHX40001

TSU150-200/

SHX40000

TSU423-504/

SHX40002

TSU650-940/

SHX40003

SHX40004

9

Page 10

3 Solar connections

Figure 3-1 Solar System Piping

SOLAR

COLLECTOR

SOLAR AIR

RELEASE VENT

(OPTIONAL)

SPHERICAL

HEAT EXCHANGER

TEMPERATURE

GAUGE

Installation & Operation Manual

PRESSURE

RELIEF VALVE

TEMPERATURE GAUGE

(TYPICAL)

SOLAR PUMP STATION /

CONTROLLER

FLUSH VALVE

Figure 3-2 Solar System Piping with Multiple Heat Exchangers

SOLAR AIR

RELEASE VENT

SOLAR

COLLECTOR

(OPTIONAL)

TEMPERATURE

GAUGE

FILL AND

EXPANSION

TANK

SOLAR

SENSOR

SPHERICAL

HEAT EXCHANGER

IMG00095

10

TEMPERATURE

GAUGE

(TYPICAL)

SOLAR

PUMP STATION /

CONTROLLER

NOTICE

SOLAR

PRESSURE

T

P

T

RELIEF VALVE

EXPANSION

TANK

SENSOR

IMG00108

Please note that these illustrations are meant to show system piping concept only, the installer is

responsible for all equipment and detailing required by local codes.

Page 11

4 Hydronic piping

Installation & Operation Manual

Basic hydronic piping

Depending upon the application, there are many different

piping arrangements that can be applied to the Thermal-Stor

buffer tank. A pressure relief valve must be installed on each

boiler and each buffer tank as regulations require. Installation

and commissioning must always be carried out by a licensed

and experienced contractor. It is the responsibility of the

installer to comply with all building and installation codes in

effect.

Hydronic heating zoned with circulators

FIG. 4-2 on page 14 shows typical space heating piping for a

Thermal-Stor tank. The functions of some of the illustrated

components are as follows:

• Shut-off valves (recommended) - Used to isolate the

tank for servicing.

• Backflow Preventer (required by some codes) - Used to

prevent water from backing out into the piping in the

event that inlet water pressure drops.

• Expansion Tank (required for thermal expansion) - Tank

absorbs the increased volume caused by heating water.

Refer to the expansion tank manufacturer’s instructions for

proper sizing and use.

NOTICE

If a valve is used between an expansion tank

and the tank inlet, the installer must ensure

that the valve is open.

• Circulation Pump (recommended) - Used to circulate and

maintain hot water within the piping system.

• Check Valve (required by some codes) - Used to allow

water to flow in only one direction, preventing back-flow.

• Drain (required) - Used to drain the tank for inspection

or servicing.

• Mixing valve (required for domestic water) - Used to mix

hot water with cold water to ensure constant, safe outlet

temperatures.

• Unions (optional) - Used to disconnect the tank in the

unlikely event that this is necessary for service.

Thermal-Stor domestic water heating

When paired with an indirect water heater or a heat exchanger

(FIG. 4-3, page 15) the Thermal-Stor buffer tank can be used

to heat domestic water. The hottest water is taken from the

auxiliary heat supply and piped to the indirect heater where it

is used to heat domestic potable water. The water is returned

to the high temperature return tapping so the hottest water

will be available for domestic heating while preserving tank

stratification. Other hydronic heating applications will be piped

into the low temperature or auxiliary returns.

Domestic hot water priority

Domestic Hot Water (DHW) priority allows a boiler to be

used for both space and domestic water heating by turning

off the boiler output for space heating when there is a call for

domestic hot water. Outdoor reset is required with the use of

DHW priority in order to regulate water temperature and satisfy

heating load. During calls for DHW, the outdoor reset control

will turn off the circulation pump and raise the boiler water

temperature to a minimum of 180°F (FIG. 4-5, page 17).

High output piping

When a large amount of hot water is required for hydronic

heating, there are several different piping alternatives. When

hydraulic separation is desired, multiple boilers coupled with

a buffer tank can provide adequate water for both space and

domestic water heating (FIG. 4-4, page 16).

Multiple Thermal-Stor tanks can also be piped together if there

is a continuous demand for heating water. This is typically

done in the reverse-return arrangement. This method uses

more piping than direct-return systems, but the temperature

and boiler flow are more balanced throughout each tank.

To ensure even charging and discharging of each tank, it is

recommended that only tanks of the same size are placed in the

same manifold. It is recommended that each tank be equipped

with its own isolation valves, unions and drains, so that one

tank may be removed from the system if necessary. It is only

necessary to use one backup heat source sensor for control

(FIG. 4-6, page 17).

NOTICE

Be sure to field-install plugs or caps on any

tank tappings that are not in use.

CAUTION

Piping must be balanced. Failure to balance

piping could result in uneven flow and

improper operation.

11

Page 12

4 Hydronic piping

Installation & Operation Manual

Relief Valves

WARNING

For protection against excessive pressure,

install temperature and pressure protective

equipment required by local codes. A relief

valve must be certified by a nationally

recognized testing laboratory that maintains

periodic inspection of listed equipment or

materials. The equipment and materials

must meet the requirements for Relief Valves

and Automatic Gas Shutoff Devices for Hot

Water Supply Systems, ANSI Z21.22, as well

as the standard CAN1-4.4, Temperature,

Pressure, Temperature and Pressure Relief

Valves and Vacuum Relief Valves. The relief

valve shall be marked with a maximum

set pressure, not to exceed the maximum

working pressure of the appliance. It shall

also have an hourly rated discharge capacity

not less than the Btu output of the heat

source.

Pressure only relief valves (POV)

A pressure relief valve should be installed in the connection

provided on the top of the tank containing hydronic water. It

is imperative that the relief valve be correctly installed because

it also serves as an air vent. Do Not place any valve between

the relief valve and the opening provided. To prevent water

damage, the discharge from the relief valve should be piped to

a suitable floor drain for disposal when relief occurs Do Not

install reducing coupling or other restrictions in the discharge

line. The discharge line should allow complete drainage of the

valve and line. The POV should be sized in accordance with the

maximum working pressure of the tanks, and the Btu output of

the backup heat source.

It is recommended to have a relief valve sized in accordance

with ASME Boiler and Pressure Vessel Code, Section IV

“Heating Boilers”. ASME states in Section VIII, Division 1,

paragraph UG-125 (a), “All pressure vessels within the scope of

this division, irrespective of size or pressure, shall be provided

with pressure relief devices in accordance with the requirements

of UG-125 through UG-137.”

NOTICE

Verify that the relief valve complies with

local codes. If the relief valve does not

comply with local codes, replace it with

one that does. Follow the installation

instructions in this section.

Do not place a valve between the relief valve

and the tank.

12

Figure 4-1 Relief valve

IMG00111

Standard Installation

Relief Valve Discharge Piping

Relief valve discharge piping MUST be:

- Made of material serviceable for a temperature of

250°F or greater

- Directed so that hot water flows away from all

persons

- Directed to a suitable place for disposal

- Installed so as to allow complete draining of the relief

valve and discharge line

- Terminated within 6" of the floor

Relief valve discharge piping MUST NOT be:

- Excessively long. Using more than two (2) elbows or

15 feet of piping can reduce discharge capacity

- Directly connected to a drain (Refer to local codes)

- Subject to freezing

WARNING

CAUTION

WARNING

Do not install any valve between the relief

valve and its connection or on the relief

valve discharge piping. Improper placement

and piping of relief valve can cause severe

personal injury, death or substantial

property damage.

The relief valve is not intended for constant

duty, such as relief of pressure due to

repeated normal system expansion. Correct

this condition by installing a properly sized

expansion tank in a domestic water system.

Refer to the expansion tank manufacturer’s

installation instructions for proper sizing.

Failure to install and maintain a new, listed

and properly sized relief valve will relieve

the manufacturer from any claim which

might result from excessive temperature and

pressure.

Page 13

4 Hydronic piping (continued)

Anti-scald mixing valves

Anti-scald valves used with water heaters are also called

tempering valves or mixing valves. An anti-scald valve mixes

cold water with the outgoing hot water to assure that hot

water reaching a building fixture is at the correct temperature.

A mixing valve is required when the Thermal-Stor is used to

generate domestic hot water.

Installation & Operation Manual

NOTICE

The temperature of water going to the fixtures may be more

carefully controlled through the use of a thermostatic mixing

valve. This device blends a controlled amount of cold water

with the hot water leaving the tank so that water at a more

constant temperature exits the mixing valve. Always consult

the mixing valve manufacturer’s instructions and guidelines for

correct piping and usage.

WARNING

WARNING

ASSE1017 and ASSE1070 certified mixing

valves are required.

Hot water can scald! To avoid scalding

potential, mixing valves must be selected and

installed according to valve manufacturer’s

instructions and recommendations. Mixing

valves should be installed by a licensed

contractor.

An anti-scald mixing valve does not

eliminate the risk of scalding.

• Feel water before bathing or showering.

• If anti-scald or anti-chill protection is

required, use devices specifically

designed for such service. Install

these devices in accordance with their

manufacturer’s instructions.

13

Page 14

4 Hydronic piping

Figure 4-2 Piping with Hydronic Heating

Installation & Operation Manual

MAKE UP

W

ATER

PRESSURE

REDUCING

VALVE

PRESSURE

GAUGE

SPACE

HEAT

SUPPLY

TEMPERATURE

HIGH

TEMPERATURE

RETURN

GAUGE

AIR

SEPARATOR

BACKFLOW

PREVENTER

ZONE

CIRCULATORS

(TYPICAL)

EXPANSION

TANK

PRESSURE

RELIEF

VALVE

LOW TEMP.

ZONE

HIGH TEMP.

ZONE #1

Y-STRAINER

(TYPICAL)

BOILER

CIRCULATOR

HIGH TEMP.

ZONE #2

PRESSURE

RELIEF

VALVE

NOTICE

LOW

TEMPERATURE

RETURN

T&P

GAUGE

DRAIN

IMG00123

Please note that these illustrations are meant to show system piping concept only, the installer is responsible for

all equipment and detailing required by local codes.

14

Page 15

4 Hydronic piping (continued)

Figure 4-3 Domestic Indirect Water Heating

Installation & Operation Manual

PRESSURE

GAUGE

MAKE UP

WATER

PRESSURE

REDUCING

VALVE

SUPPLY

TEMPERATURE

HIGH

TEMPERATURE

RETURN

LOW

TEMPERATURE

RETURN

SPACE

HEAT

SEPARATOR

AUXILIARY

GAUGE

AIR

HEAT

SUPPLY

BACKFLOW

PREVENTER

PRESSURE

ZONE

C

IRCULATORS

(TYPICAL)

EXPANSION

TANK

RELIEF

VALVE

LOW TEMP.

ZONE

HIGH TEMP.

ZONE #1

Y-STRAI NER

(TYPICAL)

BOILER

CIRCULATOR

CHECK

VALVE

T&P

GAUGE

HIGH TEMP.

ZONE #2

PRESSURE

RELIEF

VALVE

DRAIN

IMG00125

MIXING

VALVE

SHUTOFF

VALVE

(TYPICAL)

UNION

SHOCK

ARRESTOR

DOMESTIC

HOT WATER

CHECK

VALVE

DOMESTIC

COLD WATER

BRAISED PLATE

HEAT EXCHANGER

WARNING

NOTICE

Boiler must be sized to meet all space heating and domestic hot water loads simultaneously. Failure to properly

size the heat source can cause operational issues.

Please note that these illustrations are meant to show system piping concept only, the installer is responsible for

all equipment and detailing required by local codes.

15

Page 16

4 Hydronic piping

Figure 4-4 Multiple Boiler Piping - Single Temperature

Installation & Operation Manual

PRESSURE

GAUGE

MAKE UP

WATER

PRESSURE

REDUCING

VALVE

AIR

SEPARATOR

EXPANSION

TANK

SPACE HEAT

SUPPLY

AUXILIARY

HEAT SUPPLY

TEMPERATURE

GAUGE

BACKFLOW

PREVENTER

ZONE #1

ZONE

CIRCULATORS

(TYPICAL)

PRESSURE

RELIEF

VALVE

T&P

GAUGE

ZONE #2

DRAIN

ZONE #3

PRESSURE

RELIEF

VALVE

Y STRAINER

(TYPICAL)

BOILER

CIRCULATOR

I

MG00121

UNION

SHOCK

ARRESTOR

DOMESTIC

HOT WATER

MIXING

VALVE

BRAISED PLATE

HEAT EXCHANGER

CHECK

VALVE

DOMESTIC

COLD WATER

WARNING

NOTICE

16

Boiler must be sized to meet all space heating and domestic hot water loads simultaneously. Failure to properly

size the heat source can cause operational issues.

Please note that these illustrations are meant to show system piping concept only, the installer is responsible for

all equipment and detailing required by local codes.

Page 17

4 Hydronic piping (continued)

Figure 4-5 DHW Priority Piping - Multiple Temperature Space Heating

HIGH TEMP.

HIGH TEMP.

ZONE #1

MAKE UP

WATER

FILL

VALVE

ZONE #2

CHECK

VALVE

PRESSURE

GAUGE

PRESSURE

REDUCING

VALVE

AIR

SEPARATOR

SPACE

SUPPLY

TEMPERATURE

HIGH

TEMPERATURE

RETURN

BACKFLOW

PREVENTER

HEAT

GAUGE

ZONE

CIRCULATORS

(TYPICAL)

EXPANSION

PRESSURE

PRESSURE

RELIEF

RELIEF

VALVE

VALVE

TANK

LOW TEMP.

ZONE

RECIRCULATION

PRESSURE

RELIEF

VALVE

Installation & Operation Manual

RECIRCULATION

LINE

PUMP

SHOCK

ARRESTOR

MIXING

VALVE

CHECK

VALVE

SHUTOFF

VALVE

(TYPICAL)

DOMESTIC

HOT WATER

LOW

TEMPERATURE

RETURN

Figure 4-6 Multiple Tank Piping

PRESSURE

REDUCING

VALVE

PRESSURE

GAUGE

MAKE UP

WATER

SPACE HEAT

SUPPLY

SHUTOFF

VALVE

(TYPICAL)

UNION

TEMPERATURE

GAUGE

AIR

SEPARATOR

Y-STRAINER

(TYPICAL)

BACKFLOW

PREVENTER

PRESSURE

RELIEF

VALVE

ZONE #1

ZONE

CIRCULATORS

(TYPICAL)

T&P

GAUGE

DRAIN

ZONE #2

ZONE #3

CHECK

VALVE

Y-STRAINER

(TYPICAL)

BOILER

CIRCULATOR

IMG00124

PRESSURE

RELIEF

VALVE

DOMESTIC

COLD WATER

WARNING

NOTICE

T&P

GAUGE

DRAIN

Boiler must be sized to meet all space heating and domestic hot water loads simultaneously.

Failure to properly size the heat source can cause operational issues.

Please note that these illustrations are meant to show system piping concept only, the installer

is responsible for all equipment and detailing required by local codes.

IMG00102

17

Page 18

5 Startup and maintenance

Installation & Operation Manual

System startup

1. Make sure the system is free of leaks and that air is

purged from the system.

CAUTION

2. Many soldering fluxes contain Zinc Chloride which

can cause severe corrosion damage to stainless steel. After

completing all domestic water connections, flush the

Thermal-Stor tank thoroughly before leaving the installation.

This is particularly important if the Thermal-Stor will be

unused for an extended period of time after installation.

Flush the storage tank by drawing at least three times its

volume from the tank.

3. Make sure that each zone valve or circulator operates

when, and only when, its thermostat calls for heat. Let each

zone operate long enough to purge any remaining air from

the system.

Refer to the heat source and solar Installation and Operation

Manuals for additional start-up information.

Fix any leaks found before proceeding

further. Leakage from the heat source and

solar piping can result in severe damage to

the system.

Maintenance Schedule

The Lochinvar Thermal-Stor solar tank is an extremely simple

device and as such requires very little maintenance. There are,

however, several items which should be inspected on an annual

or as needed basis to ensure a reliable supply of hot water:

• Ensure that the boiler and solar water piping are free of

leaks.

• If there is an oil lubricated circulator in the system, make

sure it is lubricated as called for by the circulator

manufacturer.

• Make sure that the heat source is maintained in accordance

with the manufacturer’s instructions.

• If antifreeze is required to keep the water chemistry

within the parameters shown in Table 2A (see Section

2 - Pre-Installation), make sure that this system is properly

maintained.

Annual service by a qualified service technician

should include the following:

Any procedure required by local codes.

Verify system pressure. Air venting procedure may require

adding water to bring boiler system up to pressure, typically

12 psig minimum.

Manually operate relief valve at least once a year. This will

release some hot water.

WARNING

Move operating lever to open position for a few seconds

and then move it back, allowing it to snap closed. After the

relief valve is operated, if it continues to release water, close

the cold water inlet to the water heater immediately. Follow

the draining instructions, and replace the relief valve. If

the relief valve weeps periodically, it may be due to thermal

expansion. Do not plug the relief valve or discharge piping.

In this case, ensure that the expansion tank is properly sized

and charged to the appropriate pressure.

DANGER

Verify that expansion tank pressure is equal to system

pressure.

Before operating a relief valve, make sure no

one is in front of or around the relief valve

discharge piping. Hot discharge water can

cause severe personal injury or substantial

property damage.

Plugging the relief valve or discharge piping

can cause excessive pressure in the water

heater, resulting in severe personal injury,

death, or substantial property damage.

18

Page 19

5 Startup and maintenance

Installation & Operation Manual

Follow instructions on circulator to oil, if required.

Check mixing valve, valves, pipes, and fittings for leaks.

Check function of the field-installed controls and valves.

See component manufacturer’s instructions.

Review owner’s maintenance responsibilities and their

frequencies, including any not listed in the following

section.

Owner monthly maintenance to include:

Visually check valves, pipes, and fittings for leaks. Call a

qualified service technician to repair leaks.

Winterizing the system

Drain the tank and spherical heat exchanger if the appliance will

be off and exposed to freezing temperatures. Freezing water will

expand and damage the appliance.

• If the tank, spherical heat exchanger and heat source

water contain sufficient antifreeze, then the tank does

not need to be drained.

If antifreeze is used in the heat source water, check the

concentration. Heat source water (including additives) must be

non-toxic, having a toxicity rating or class of 1, as listed in the

“Clinical Toxicology of Commercial Products”. A maximum

50/50 mixture of inhibited propylene glycol is recommended.

Follow the antifreeze manufacturer’s instructions.

WARNING

Do not use automotive, ethylene glycol or

petroleum-based antifreeze. Do not use

any undiluted antifreeze. This can cause

severe personal injury, death, or substantial

property damage.

To drain/flush the system

1. Turn OFF main electrical power to the tank, solar collectors

and any other heat source connected to the tank.

2. Turn OFF the main manual gas shutoff for any heat source

connected to the tank.

3. Turn OFF electrical power to the circulating pump (if used).

4. Close off the boiler or heat source inlet connection.

5. Ensure that the drain (located on the bottom of the tank)

is routed to a floor drain with adequate capacity to allow

the tank to be flushed.

6. Open the drain valve and allow the incoming cold water

“Boiler Return” to flush the soft sediment out of the bottom

of the storage tank.

CAUTION

7. Observe the color of the water initially discharged from

the tank drain. This water will generally be milky or

slightly discolored by the sediment discharge. Allow the

drain to run until the water runs clear.

8. Close the drain valve on the tank.

9. Open the hot water relief/air valve on the top of the

tank.

10. Turn ON main electrical power for the heat source, solar

collectors, tank and circulating pump.

11. Turn ON gas supply to the heat source(s).

12. Observe heat source and solar piping to ensure that all

components are functioning properly.

Hot water will be released under pressure.

Avoid contact with hot discharge water to

prevent the risk of severe scald injury.

19

Page 20

Revision Notes: Revision A (ECO C08886)

initial release.

11/11 - Printed in U.S.A.

TSU-I-O Rev A

Loading...

Loading...