Lochinvar Power-Fin Series Installation And Service Manual

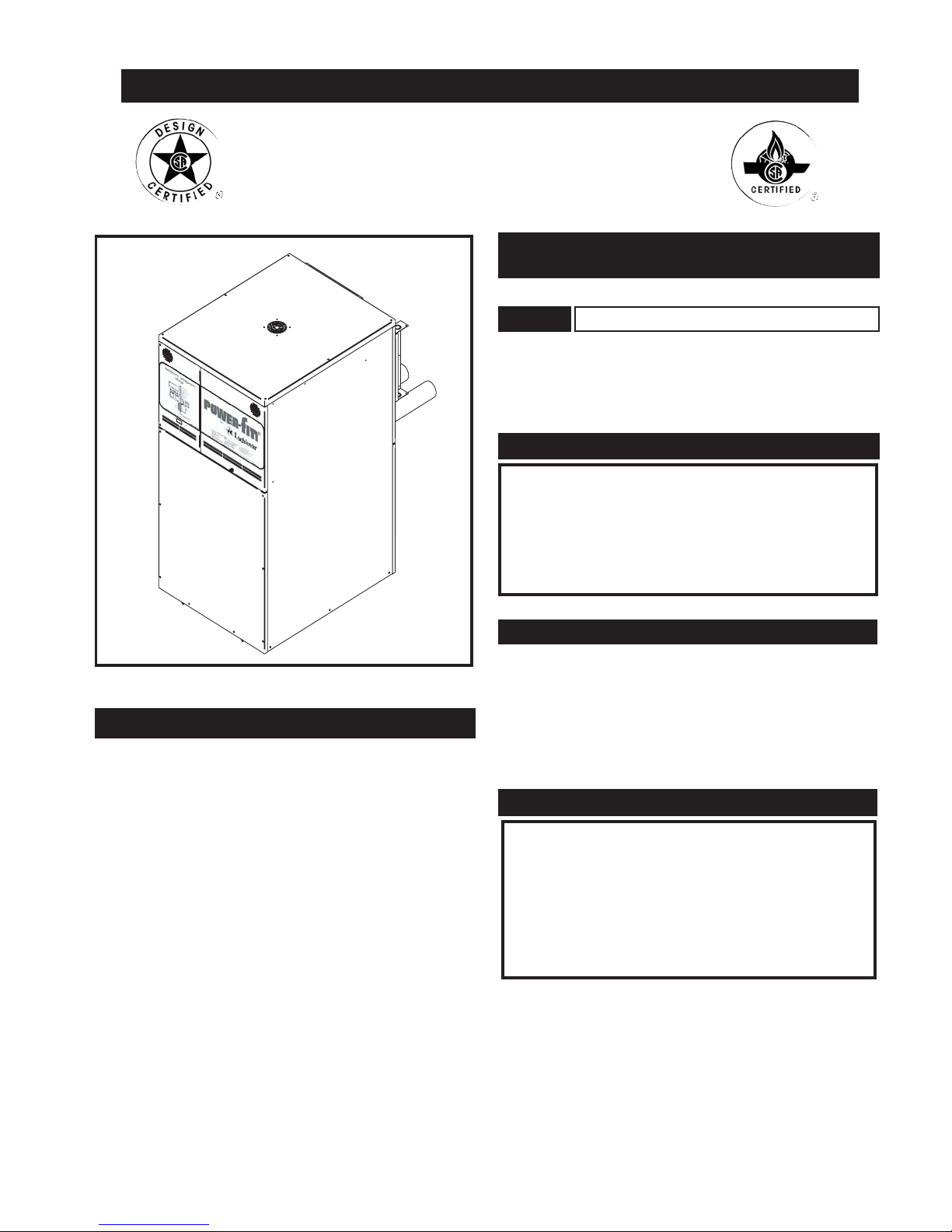

FIG. 1 Front View

Installation and service must be performed by a qualified

service installer, service agency or the gas supplier.

Factory warranty (shipped with unit) does not apply to units

improperly installed or improperly operated.

Experience has shown that improper installation or system

design, rather than faulty equipment, is the cause of most

operating problems.

1. Excessive water hardness causing a lime/scale build-up in

the copper tube is not the fault of the equipment and is not

covered under the manufacturer's warranty (see Water

Treatment and Water Chemistry).

2. Excessive pitting and erosion on the inside of the copper

tube may be caused by too much water velocity through the

tubes and is not covered by the manufacturer's warranty

(see Boiler Flow Rates and Temperature Rise for flow

requirements).

This manual supplies information for the installation, operation

and servicing of the appliance. It is strongly recommended that

this manual be reviewed completely before proceeding with an

installation.

Upon receiving equipment, check for signs of shipping

damage. Pay particular attention to parts accompanying the

boiler, which may show signs of being hit or otherwise being

mishandled. Verify total number of pieces shown on packing

slip with those actually received. In case there is damage or a

shortage, immediately notify carrier.

DO NOT USE THIS APPLIANCE IF ANY PART

HAS BEEN UNDER WATER. THE POSSIBLE

DAMAGE TO A FLOODED APPLIANCE CAN

BE EXTENSIVE AND PRESENT NUMEROUS

SAFETY HAZARDS. ANY APPLIANCE THAT

HAS BEEN UNDER WATER MUST BE

REPLACED.

DO NOT:

CHECKING EQUIPMENT

IMPROPER INSTALLATION, ADJUSTMENT,

ALTERATION, SERVICE OR MAINTENANCE can

cause injury or property damage. Refer to this manual.

For assistance or additional information, consult a

qualified installer, service agency or the gas supplier.

WARNING

Retain this manual for future reference.

NOTE:

SPECIAL INSTRUCTIONS

TO OWNER

WARRANTY

INSTALLATION AND SERVICE MANUAL

Power-Fin

®

HOT WATER HEATING BOILERS

DOMESTIC WATER HEATERS

500,000, 750,000, 1,000,000 and 1,300,000 Btu/hr MODELS

PB-PF-i&s-03

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Safety Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Installation Requir

ements

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Clearances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Combustion/Ventilation Air Requirements . . . . . . . . . . . . . .4

Combustion Air Supplied to the Equipment Room . . . . . . .6

V

enting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

General Venting Information . . . . . . . . . . . . . . . . .7

Common Venting Systems . . . . . . . . . . . . . . . . . . .9

Conventional Vertical Category I Negative Draft . . . . . . . .10

A Vertical Category II Negative Draft Venting System . . .10

Sidewall Venting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Direct Vent and DirectAire Vent Systems . . . . . . . . . . . . . .13

DirectAire Vent Systems . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Vertical DirectAire w/Sidewall Combustion Air . . . . . . . .15

Vertical DirectAire Venting w/

Rooftop Combustion Air . . . . .16

Horizontal DirectAire w/Vertical Combustion Air . . . . . . .17

Horizontal DirectAire w/Sidewall Combustion Air . . . . . .17

Vertical Direct Vent Systems . . . . . . . . . . . . . . . . . . . . . . . .18

Horizontal Direct Vent . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

Gas Supply

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gas Pressure Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gas Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .20

Gas Train and Controls . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Gas Piping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Gas Manifold Pressure Adjustment . . . . . . . . . . . . . . . . . .22

Checking Gas Supply Pressure . . . . . . . . . . . . . . . . . . . . . .22

Checking Manifold Gas Pressure . . . . . . . . . . . . . . . . . . . .23

Water Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Minimum Water Temperatures . . . . . . . . . . . . . . . . . . . . . .24

Low Water Cutoff Devices . . . . . . . . . . . . . . . . . . . . . . . . .24

Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Electrical Connections

. . . . . . . . . . . . . . . . . . . . . . . . . . .25

Access to Components and Controls . . . . . . . . . . . . . . . . .25

Setting Temperature Control - F9 . . . . . . . . . . . . . . . . . . . .26

Diagnostic Information Center - F9 . . . . . . . . . . . . . . . . . .28

Data Points Visible from Diagnostic Center . . . . . . . . . . . . . . .28

LED Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Default Display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Sensor Faults Shown in Digital Display . . . . . . . . . . . . . . .29

Electronic Temperature Control - Modulating Burner . . . .30

Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Changeable Data Points . . . . . . . . . . . . . . . . . . . . . . . . . . .30

Status LED’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Operational LED’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Fault Status LED’s . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Power-Up Default Display . . . . . . . . . . . . . . . . . . . . . . . . .31

Temperature Adjustment Procedure . . . . . . . . . . . . . . . . . .32

Outdoor Air Reset Function . . . . . . . . . . . . . . . . .32

User Lockout Procedure . . . . . . . . . . . . . . . . . . . .33

Limited Access Mode . . . . . . . . . . . . . . . . . . . . . .33

Limited Access Features . . . . . . . . . . . . . . . . . . . .33

Limited Access Feature Setting Procedure . . . . . .33

Error Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . .34

High Water Temperature Limit Control . . . . . . . .34

Condensate Trap Installation . . . . . . . . . . . . . . . . . . . . . . . .35

Hot Surface Ignition System . . . . . . . . . . . . . . . . . . . . . . . .36

Lighting Instructions

. . . . . . . . . . . . . . . . . . . . . . . . . . . .37

To Turn Off Gas to Appliance . . . . . . . . . . . . . . .38

Ignition System Checkout . . . . . . . . . . . . . . . . . . .38

Sequence of Operation . . . . . . . . . . . . . . . . . . . . .38

Maintenance

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Burner Removal and Cleaning . . . . . . . . . . . . . . .40

Combustible Materials . . . . . . . . . . . . . . . . . . . . .42

Freeze Protection . . . . . . . . . . . . . . . . . . . . . . . . .42

Water Treatment . . . . . . . . . . . . . . . . . . . . . . . . . .42

Heating Boiler

Installations . . . . . . . . . . . . . . . . . . . . . . .43

Water Connections Heating Boilers Only . . . . . . . . . . . . . .43

Boiler Circulator Requirements . . . . . . . . . . . . . . . . . . . . .43

Primary / Secondary Boiler Piping.. . . . . . . . . . . . . . . . . . .43

Minimum Boiler Water Temperatures . . . . . . . . . . . . . . . . .44

Low Temperature Bypass Requirements . . . . . . . . . . . . . .44

Radiant Floor and Snowmelt Heating Systems . . . . . . . . .45

Temperature / Pressure Gauge . . . . . . . . . . . . . . . . . . . . . .46

Installation with a Chilled Water System . . . . . . . . . . . . . .47

Remote Enable Connections . . . . . . . . . . . . . . . . . . . . . . . .47

Domestic

Water Heaters . . . . . . . . . . . . . . . . . . . . . . . . . .48

Water Velocity Control . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

Water Chemistry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Multiple Storage Tank / Water Heater Installations . . . . . .50

If the information in this manual is not followed

exactly, a fire or explosion may result causing

property damage, personal injury or loss of life.

This appliance MUST NOT be installed in any

location where gasoline or flammable vapors are

likely to be present.

WHAT TO DO IF YOU SMELL GAS

•Do not try to light any appliance.

•Do not touch any electric switch; do not use

any phone in your building.

•Immediately call your gas supplier from a

neighbors phone. Follow the gas supplier's

instructions.

•If you cannot reach your gas supplier, call

the fire department.

Installation and service must be

performed by a qualified installer,

service agency or the gas supplier.

WARNING

2

CONTENTS

Pump Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Thermostat Settings . . . . . . . . . . . . . . . . . . . . . . . . . . . .51

Minimum Water Temperatures

(Domestic Hot Water Use) . . .51

Optional Relief Valve . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Thermal Expansion . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Cathodic Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . .53

Ladder Diagram - F9 Units . . . . . . . . . . . . . . . . . . . . . . . .54

Ladder Diagram - M9 Units . . . . . . . . . . . . . . . . . . . . . . .55

Wiring Diagram - M9 Units . . . . . . . . . . . . . . . . . . . . . . .56

Wiring Diagram - F9 Units . . . . . . . . . . . . . . . . . . . . . . . .58

The information contained in this manual is intended for

use by qualified professional installers, service technicians

or gas suppliers. Consult your local expert for proper

installation or service procedures.

A gas appliance that draws combustion air from the equipment

room where it is installed must have a supply of fresh air

circulating around it during burner operation for proper gas

combustion and proper venting.

1. Always keep the area around your appliance free of

combustible materials, gasoline, and other flammable

liquids and vapors.

2. Never cover your appliance, lean anything against it,

store trash or debris near it, stand on it or in any way

block the flow of fresh air to your appliance.

3. UNDER NO CIRCUMSTANCES must flammable

materials such as gasoline or paint thinner be used or

stored in the vicinity of this appliance, vent-air intake

system or any location from which fumes could reach the

appliance or vent-air intake system.

The equipment shall be installed in accordance with those

installation regulations in force in the local area where the

installation is to be made. These shall be carefully followed in

all cases. Authorities having jurisdiction shall be consulted

before installations are made. In the absence of such

requirements, the installation shall conform to the latest edition

of the National Fuel Gas Code, ANSI Z223.1. Where required

by the authority having jurisdiction, the installation must

conform to American Society of Mechanical Engineers Safety

Code for Controls and Safety Devices for Automatically Fired

Boilers, ASME CSD-1. All boilers conform to the latest edition

of the ASME Boiler and Pressure Vessel Code, Section IV.

Where required by the authority having jurisdiction, the

installation must comply with the Canadian Gas Association

Code, CAN/CGA-B149.1 and/or B149.2 and/or local codes.

This appliance meets the safe lighting performance criteria with

the gas manifold and control assembly provided, as specified in

the ANSI standards for gas-fired units, ANSI Z21.13.

1. Locate the appliance so that if water connections should

leak, water damage will not occur. When such locations

cannot be avoided, it is recommended that a suitable drain

pan, adequately drained, be installed under the unit. The

pan must not restrict combustion airflow. Under no

circumstances is the manufacturer to be held responsible for

water damage in connection with this unit, or any of its

components.

2. The appliance must be installed so that the ignition system

components are protected from water (dripping, spraying,

etc.,) during appliance operation and service (circulator

replacement, control replacement, etc.,).

3. Appliances located in a garage or parking structure shall be

installed so that all burners and burner ignition devices have

a minimum clearance of 18" (46cm) above the floor. The

appliance shall be located or protected so that it is not

subject to physical damage by a moving vehicle.

4. The appliance must be installed on a level floor.

Combustible floor locations may be used. Maintain

required clearances from combustible surfaces.

5. The appliance must not be installed on carpet.

6. The appliance must be installed indoors where it is

protected from exposure to wind, rain and weather.

INSTALLATION PROCEDURE

LOCATION OF UNIT

CODES

To minimize the possibility of serious personal

injury, fire or damage to your appliance, never

violate the following safety rules.

WARNING

Should overheating occur or the gas supply fail to

shut off, DO NOT turn off or disconnect the

electrical supply to the pump. Instead, shut off the

gas supply at a location external to the appliance.

WARNING

Consult and follow local Building and Fire Regulations

and other Safety Codes that apply to this installation.

Consult local gas utility company to authorize and

inspect all gas and flue connections.

IMPORTANT:

OWNER WARNING

3

NOTE:

The words “Appliance” and “Unit” are used

interchangeably throughout this manual.

7. This appliance may condense the products of combustion

when operating at water temperatures below 140°F (60°C).

Ensure that the appliance is located near an acceptable

drain where condensate that may form in the venting

system may be properly collected and disposed.

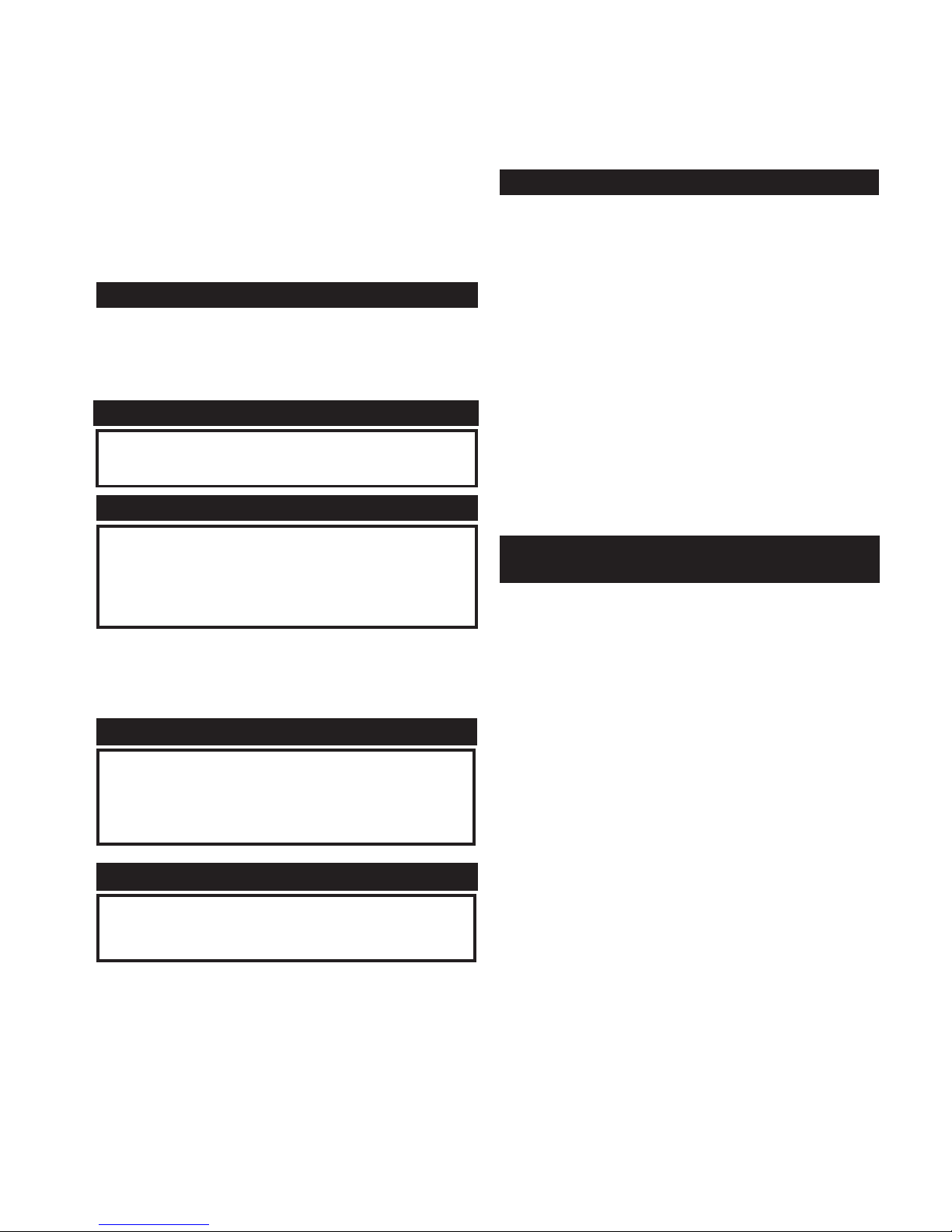

Maintain minimum specified clearances for adequate

operation. All installations must allow sufficient space for

servicing the vent connections, water pipe connections, piping

and other auxiliary equipment, as well as the

appliance. The clearance labels on each appliance note the

same service and combustible clearance requirements as shown

above.

Multiple appliances may be installed in a modular boiler or

water heater installation. Multiple appliances may be installed

side by side with no clearance between adjacent appliances

because this appliance is approved for zero clearance from

combustible surfaces and no service access is required from the

sides.

Provisions for combustion and ventilation air must be in

accordance with Section 5.3, Air for Combustion and

Ventilation, of the latest edition of the National Fuel Gas Code,

ANSI Z223.1, in Canada, the latest edition of CGA Standard

B149 Installation Code for Gas Burning Appliances and

Equipment, or applicable provisions of the local building

codes.

The equipment room MUST be provided with properly sized

openings to assure adequate combustion air and proper

ventilation.

COMBUSTION AND VENTILATION

AIR REQUIREMENTS FOR

APPLIANCES DRAWING AIR

FROM THE EQUIPMENT ROOM

Clearances from combustible construction are

noted on the appliance rating plate.

NOTE:

Right Side - 0"

Rear - 6" (15cm) (Minimum 24" (0.61m) suggested for

service to pump and components)

Left Side - 0"

Front - ALCOVE* (Minimum 24" (0.61m) suggested

for service)

Top - 6" (15cm) (Minimum 24" (0.61m) suggested for

service)

Flue - 2" (51mm)

Hot Water Pipes - 1" (25.4mm)

*An ALCOVE is a closet without a door.

TABLE — A

Clearances from Combustible

Construction:

4

CLEARANCES FROM COMBUSTIBLE CONSTRUCTION

FIG. 2 Clearances from Combustible Construction - Front & Rear View

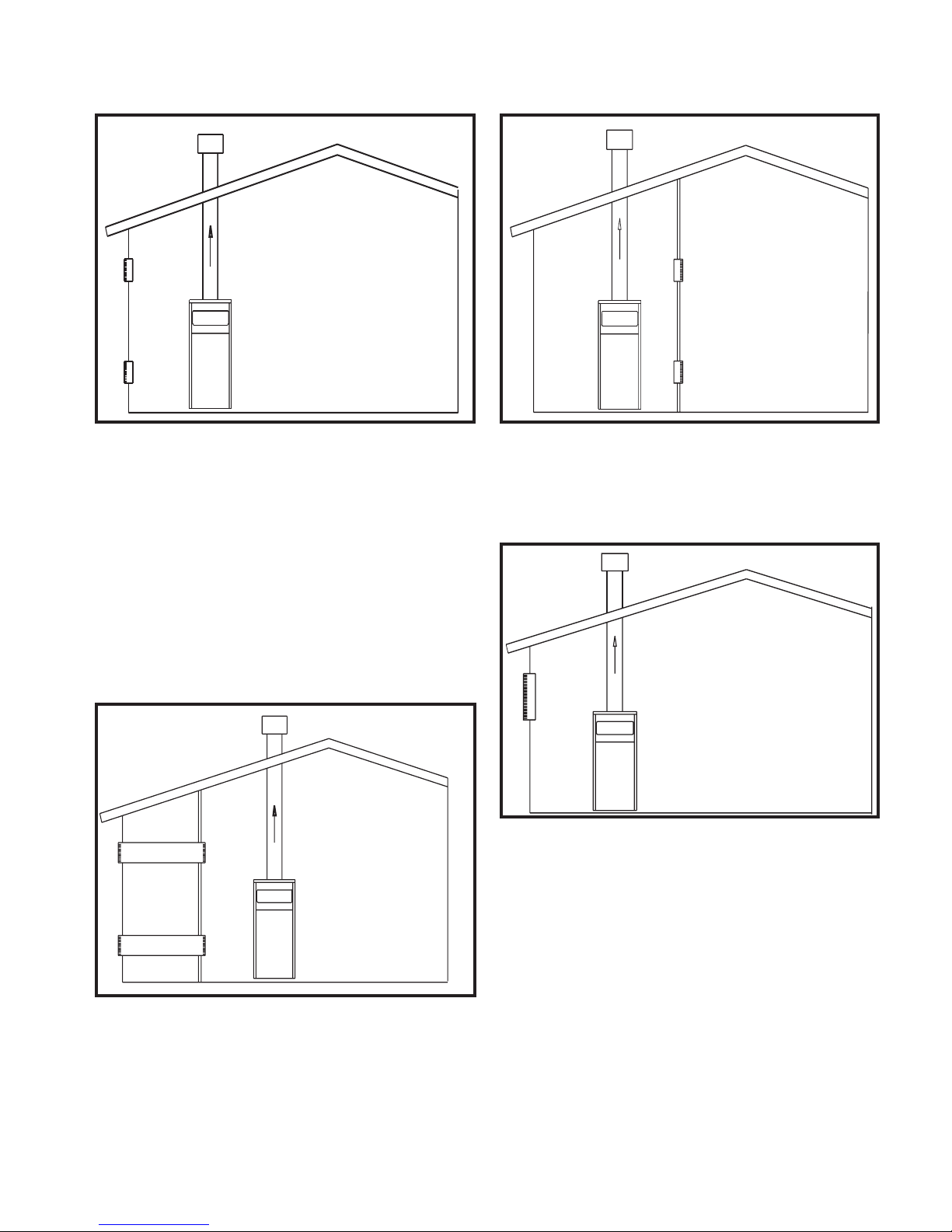

FIG. 3 Combustion Air Direct from Outside

1. If air is taken directly from outside the building with no

duct, provide two permanent openings:

a. Combustion air opening, with a minimum free area of

one square inch per 4000 Btu input (5.5 cm

2

per kW).

This opening must be located within 12" (30 cm) of the

bottom of the enclosure.

b. Ventilation air opening, with a minimum free area of

one square inch per 4000 Btu input (5.5 cm

2

per kW).

This opening must be located within 12 inches (30 cm)

of the top of the enclosure.

FIG. 4 Combustion Air Through Ducts

2. If combustion and ventilation air is taken from the outdoors

using a duct to deliver the air to the equipment room, each

of the two openings should be sized based on a minimum

free area of one square inch per 2000 Btu (11 cm

2

per kW)

of input.

FIG. 5 Combustion Air from Interior Space

3. If air is taken from another interior space, each of the two

openings specified above should have a net free area of one

square inch for each 1000 Btu (22 cm

2

per kW) of input, but

not less than 100 square inches (645 cm2).

FIG. 6 Combustion Air from Outside - Single Opening

4. If a single combustion air opening is provided to bring

combustion air in directly from the outdoors, the opening

must be sized based on a minimum free area of one square

inch per 3000 Btu (7 cm

2

per kW). This opening must be

located within 12 inches (30 cm) of the top of the enclosure.

All dimensions are based on net free area in square inches.

Metal louvers or screens reduce the free area of a combustion

air opening a minimum of approximately 25%. Check with

louver manufacturers for exact net free area of louvers. Where

two openings are provided, one must be within 12 inches (30

cm) of the ceiling and one must be within 12 inches (30 cm) of

the floor of the mechanical room. Each opening must have net

free area as specified in the chart on page 6. Single openings

shall commence within 12 inches (30 cm) of the ceiling.

5

6

The combustion air supply must be completely free of any

flammable vapors that may ignite or chemical fumes which

may be corrosive to the appliance. Common corrosive

chemical fumes which must be avoided are fluorocarbons and

other halogenated compounds, most commonly present as

refrigerants or solvents, such as Freon, trichlorethylene,

perchlorethylene, chlorine, etc. These chemicals, when burned,

form acids which quickly attack the heat exchanger finned

tubes, headers, flue collectors, and the vent system. The result

is improper combustion and a non-warrantable, premature

appliance failure.

5. A gas fired boiler, water heater, or combination of units may

be installed in an equipment room and have the required

combustion and ventilation air supplied by a mechanical

fan. The total Btu/hr input of all gas appliances in the

equipment room must be considered to properly size a

combustion air fan. Per the latest edition of the National

Fuel Gas Code, a fan used to mechanically supply air to the

equipment room must be sized to provide a minimum of

0.35 ft

3

per minute per 1000 Btu/hr of the total gas input in

the equipment room.

EXHAUST FANS: Any fan or equipment which exhausts air

from the equipment room may deplete the combustion air

supply and/or cause a down draft in the venting system.

Spillage of flue products from the venting system into an

occupied living space can cause a very hazardous condition that

must be immediately corrected. If a fan is used to supply

combustion air to the equipment room, the installer must make

sure that it does not cause drafts that could lead to nuisance

operational problems with the appliance.

The optional Direct Vent and DirectAire venting systems have

specific requirements for a special combustion air duct from the

outside that is directly connected to the appliance. See the

requirements for this combustion air duct in the venting section

for each specialized vent system.

Vent Options

This appliance has several vent options available depending on

the firing control of the unit

For units with on/off burner firing, the available venting

options are:

(1) Conventional Vertical Negative Draft Venting using a

Category I double-wall flue with a vertical rooftop termination

and combustion air supplied from the equipment room. These

units operate with on/off burner firing and are identified with an

“F” prefix on the firing controls.

(2) Vertical DirectAire Venting which uses a vertical negative

draft flue with a rooftop termination for flue products and a

combustion air pipe from the sidewall or rooftop.

For units that operate with modulating burner operation,

the available venting options are:

(1) Vertical Negative Draft Venting using a Category II

corrosion resistant flue with a vertical rooftop termination and

combustion air supplied from the equipment room. These units

operate with a modulating burner firing and are identified with

an “M” prefix on the firing controls.

(2) Sidewall Venting which uses which uses the unit’s internal

fan to exhaust the flue products out to a sidewall vent

VENTING

Under no circumstances should the mechanical room

ever be under a negative pressure. Particular care

should be taken where exhaust fans, attic fans, clothes

dryers, compressors, air handling units, etc., may take

away air from the unit.

CAUTION

COMBUSTION AIR SUPPLIED TO

THE EQUIPMENT ROOM BY A FAN

TABLE — B

Minimum Recommended Combustion Air Supply to Equipment Room

Boiler

Input

500,000

750,000

1,000,000

1,300,000

Outside Air*

2 - Openings

125 in

2

(806 cm2)

188 in2(1,213 cm2)

250 in2(1,613 cm2)

325 in2(2,097 cm2)

Outside Air*

1 - Opening

167 in

2

(1,077 cm2)

250 in2(1,613 cm2)

334 in2(2,155 cm2)

434 in2(2,800 cm2)

Inside Air

2 - Openings

(500 in

2

) (3,226 cm2)

(750 in2) (4,839 cm2)

(1000 in

2

) (6,452 cm2)

(1300 in

2

) (8,387 cm2)

COMBUSTION AIR SOURCE

*Outside air openings shall directly communicate with the outdoors. When combustion air is drawn from the outside

through a duct, the net free area of each of the two openings must have twice (2 times) the free area required for Outside

Air/2 Openings. The above requirements are for the boiler only; additional gas fired appliances in the equipment room

will require an increase in the net free area to supply adequate combustion air for all appliances. Combustion air

requirements are based on the latest edition of the National Fuel Gas Code, ANSI Z223.1; in Canada refer to the latest

edition of CGA Standard CAN B149.1 or .2. Check all local code requirements for combustion air.

termination with a sealed Category IV flue and combustion air

supplied from the equipment room.

(3) Vertical DirectAire Venting which uses a vertical negative

draft flue with a rooftop termination for flue products and a

combustion air pipe from the sidewall.

(4) Horizontal DirectAire Venting which uses the unit’s

internal fan to exhaust the flue products out a sidewall vent

termination with a sealed Category IV flue and a combustion

air pipe from the rooftop or from a sidewall other than the one

where the flue terminates.

(5) Direct Venting with a sealed Category IV flue and a

separate combustion air pipe to the outdoors. This system

terminates both the flue and combustion air inlet in the same

pressure zone. Both the flue outlet and combustion air intake

may terminate at either a sidewall (horizontal) or the rooftop

(vertical).

All units are shipped from the factory equipped for a vertical

negative draft venting system. All other optional vent systems

require the installation of specific vent kits and venting

materials. The following is a detailed explanation of the

installation requirements for each type of venting system,

components used, and part numbers of vent kits for each model.

General Venting Information

Vent installations for connection to gas vents or chimneys must

be in accordance with Part 7, “Venting of Equipment”, of the

latest edition of the National Fuel Gas Code, ANSI Z223.1, in

Canada, the latest edition of CAN/CGA Standard B149

Installation Code for Gas Burning Appliances and Equipment

or applicable provisions of the local building codes.

All venting applications where combustion air is drawn from

the equipment room must have adequate combustion and

ventilation air supplied to the equipment room in accordance

with the latest edition of the National Fuel Gas Code, ANSI

Z223.1, in Canada, the latest edition of CGA Standard B149

Installation Code for Gas Burning Appliances and Equipment,

or applicable provisions of the local building codes.

The distance of the vent terminal from adjacent buildings,

windows that open and building openings MUST comply with

the minimum clearances stated in this manual and the latest

edition of the National Fuel Gas Code, ANSI Z223.1, in

Canada, the latest edition of CAN/CGA Standard B149

Installation Code for Gas Burning Appliances and Equipment.

Vent connection is made directly to the flue outlet opening on

the back of the unit. The connection from the appliance vent to

the stack must be made as direct as possible with no reduction

in diameter.

Negative Draft General Venting Information

The negative draft in the flue of a Category I or II vent

installation must be within the range of a negative 0.02 to 0.08

inches water column to ensure proper operation. All draft

readings are made while the unit is in stable operation

(approximately 2 to 5 minutes). If draft exceeds the maximum

specified, a barometric damper must be installed to regulate

draft. Mount the barometric damper in the vertical flue at least

three feet above the connection to the unit’s flue outlet.

Use the National Fuel Gas Code venting tables to properly size

all vent connectors and stacks for all Category I and II systems.

The vent and accessories, such as firestop spacers, thimbles,

caps, etc., MUST be installed in accordance with the

manufacturer’s instructions. The vent connector and firestop

must provide correct spacing to combustible surfaces and seal

to the vent connector on the upper and lower sides of each floor

or ceiling through which the vent connector passes.

Any vent materials specified must be listed by a nationally

recognized test agency for use as vent material appropriate for

the specified vent category.

Follow the installation instructions from the manufacturer of

the vent material.

Locate units as close as possible to a chimney or gas vent.

When planning the venting system, avoid possible contact with

plumbing or electrical wiring inside walls, ceilings and floors.

Provide adequate clearance from combustibles for the vent

connector and firestop.

Avoid long horizontal runs of the vent pipe, 90° elbows,

reductions and restrictions. Horizontal portions of the venting

system shall be supported to prevent sagging.

Horizontal runs of vent pipe must slope upwards not less than

1/4 inch per foot (21 mm/m) from the appliance to the vent

terminal. Vent systems equipped with a drain tee must slope

upward from the drain to ensure proper removal of any

condensate that may form in the flue.

7

Examine the venting system at least once a year. Check all

joints and vent pipe connections for tightness. Also check

for corrosion or deterioration. Immediately correct any

problems observed in the venting system.

IMPORTANT

TABLE — C

Minimum Flue Pipe & Optional

Air Inlet Pipe Sizes are:

Input Btu/hr Flue Size

Air Inlet

Pipe Size

500,000 7" 5"

750,000 9" 5"

1,000,000 10" 6"

1,300,000 12" 6"

When the appliance is installed as either a Category II or

Category IV vent appliance, unique venting guidelines will

apply. Refer to the appropriate section of the Installation and

Service Manual for specific instructions for Category II or

Category IV vent installations.

WARNING

Category IV General Venting Information

A Category IV venting system operates with a positive pressure

in the vent. This positive pressure is generated by the internal

combustion air blower which operates the combustion process

and also exhaust the flue products from the building. The

Category IV flue from this appliance cannot be combined with

the vent from any other appliance. The Category IV flues from

multiple appliances cannot be combined into a common vent.

The Category IV flue from this appliance must be a dedicated

stack. The flue from this Category IV appliance must have all

vent joints and seams sealed gastight. A Category IV vent

system has specific vent material and installation requirements.

The flue products in the vent system may be cooled below their

dew point and form condensate in the flue. The flue materials

used for a Category IV vent must be resistant to any corrosive

damage from flue gas condensate. The flue from a Category IV

vent system must have a condensate drain with provisions to

properly collect and dispose of any condensate that may occur

in the venting system.

The connection from the appliance vent to the stack or vent

termination outside the building must be made with listed

Category IV vent material and must be as direct as possible.

The Category IV vent and accessories such as firestop spacers,

thimbles, caps, etc., must be installed in accordance with the

vent manufacturer’s instructions. The vent connector and

firestop must provide correct spacing to combustible surfaces

and seal to the vent connector on the upper and lower sides of

each floor or ceiling through which the vent connector passes.

Any vent materials specified must be listed by a nationally

recognized test agency for use as a Category IV vent material.

The venting system must be planned so as to avoid possible

contact with concealed plumbing or electrical wiring inside

walls, floors, or ceilings. Locate the appliance as close as

possible to a chimney or gas vent.

Horizontal portions of the venting system shall be supported to

prevent sagging. Horizontal runs should slope upwards not less

than 1/4 inch per foot from the drain tee installed in the flue to

the vertical portion of the flue or to the vent terminal on

sidewall venting installations. This ensures proper removal of

any condensate that may form in the flue. Follow the

installation instructions from the vent material manufacturer.

Do not use an existing chimney as a raceway if another

appliance or fireplace is vented through the chimney. The

weight of the venting system must not rest on the unit.

Adequate support of the venting system must be provided in

compliance with local codes and other applicable codes. All

connections should be secured and sealed per the vent

manufacturer’s specifications.

Vent connectors serving appliances vented by natural draft shall

not be connected to any portion of the Category IV positive

pressure vent system used by this appliance. Connection of a

negative draft flue into the positive pressure stack from this

appliance may cause flue products to be discharged into an

occupied living space causing serious health injury.

When a Category IV vent system is disconnected for any

reason, the flue must be reassembled and resealed according to

the vent manufacturer’s instructions.

The flue may terminate either vertically at the rooftop or

horizontally on a sidewall. Refer to the specific vent

termination sections for information about recommended vent

termination location and clearances.

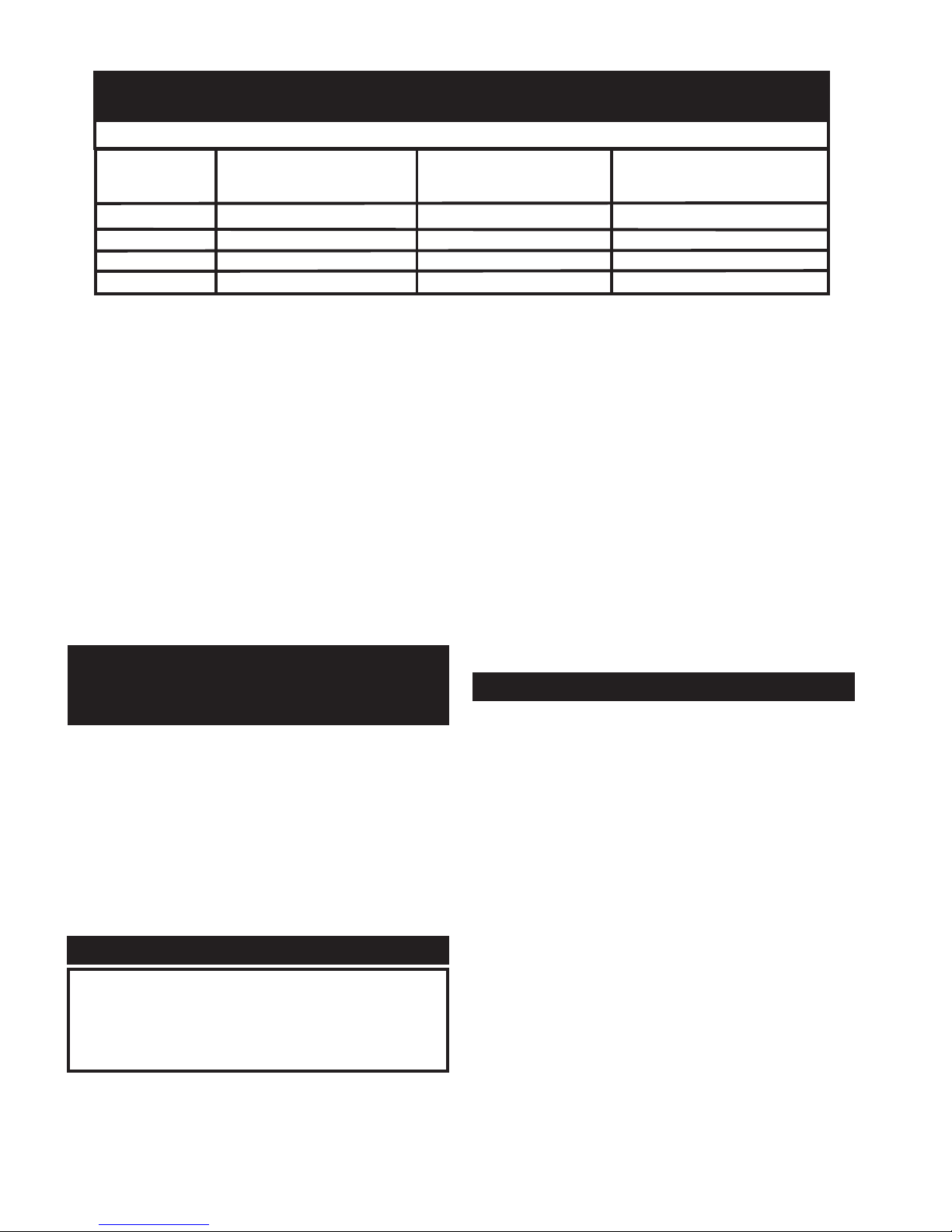

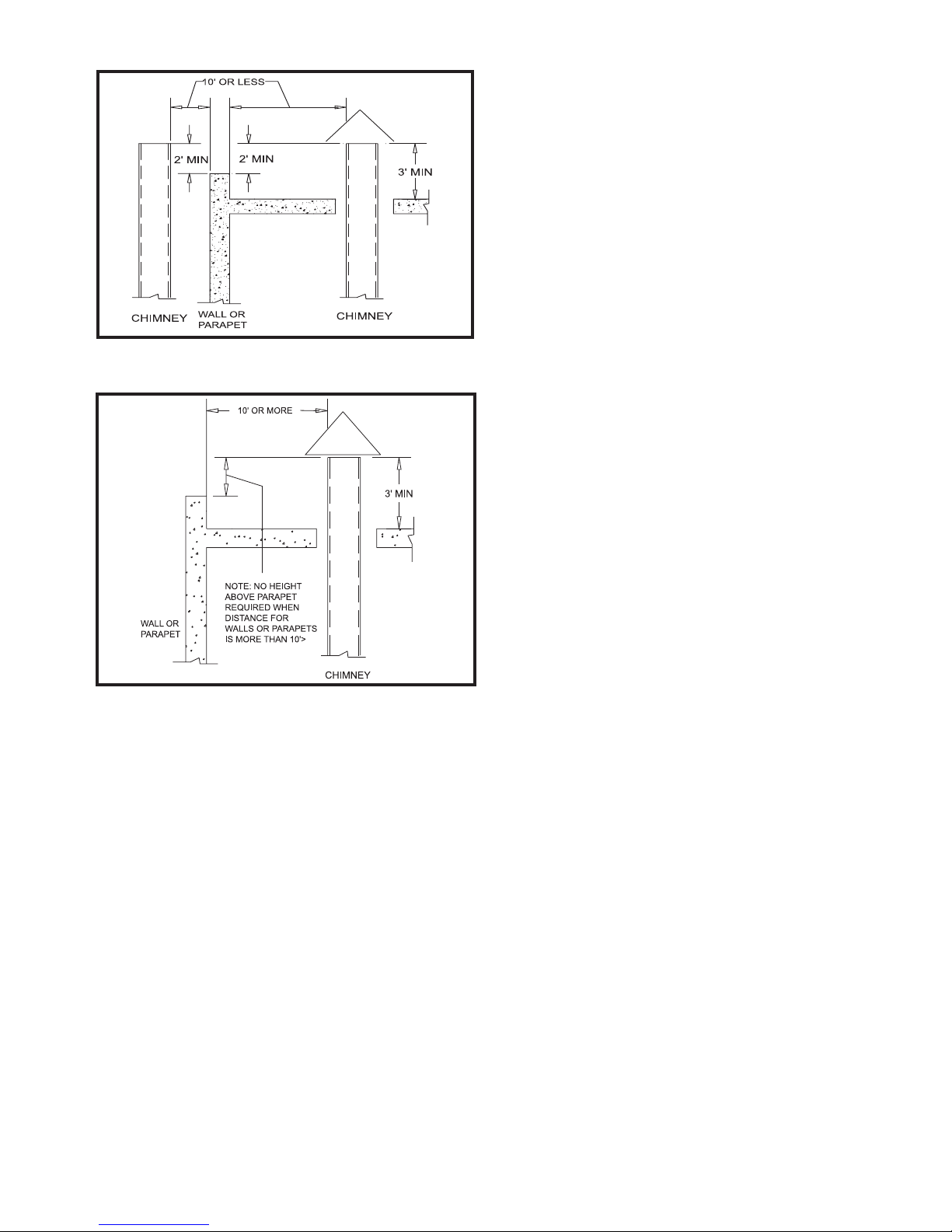

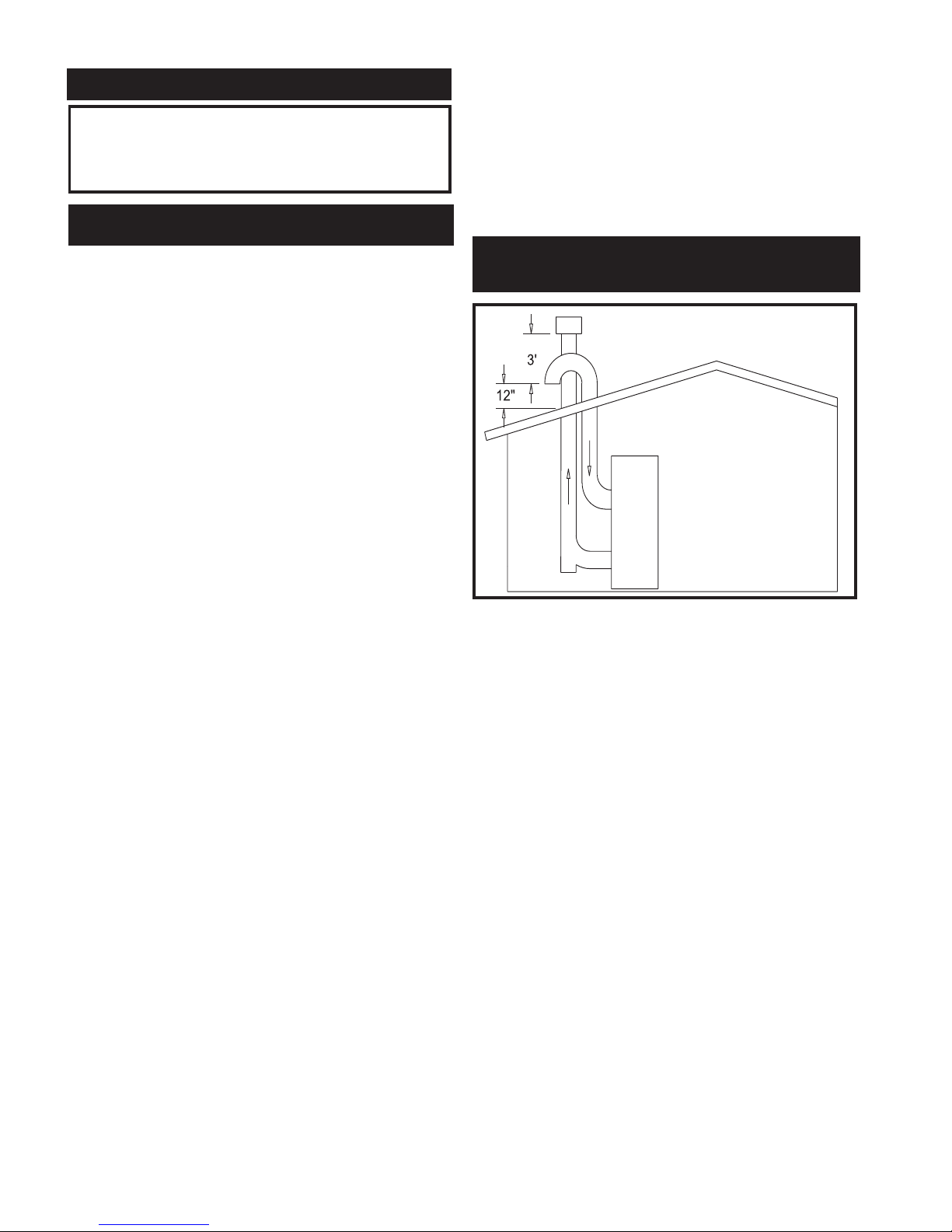

FIG. 7 Vent Termination from Peaked Roof - 10' or Less

from Ridge

FIG. 8 Vent Termination from Peaked Roof More than 10'

from Ridge

The vent terminal should be vertical and exhaust outside the

building at least 2 feet (0.61m) above the highest point of the

roof within a 10 foot (3.05m) radius of the termination.

The vertical termination must be a minimum of 3 feet (0.91m)

above the point of exit.

8

When the appliance is installed as either a Category II or

Category IV vent appliance, unique venting guidelines

will apply. Refer to the appropriate section of the

Installation and Service Manual for specific instructions

for Category II or Category IV vent installations.

WARNING

ROOFTOP VENT TERMINATION

CLEARANCES FOR CATEGORY I, II,

OR IV VERTICAL VENTING SYSTEMS

FIG. 9 Vent Termination from Flat Roof 10' or Less from

Parapet Wall

FIG. 10 Vent Termination from Flat Roof More Than 10'

from Parapet Wall

A vertical termination less than 10 feet (3.05m) from a parapet

wall must be a minimum of 2 feet (0.61m) higher than the

parapet wall.

The vent cap should have a minimum clearance of 4 feet

(1.22m) horizontally from and in no case above or below,

unless a 4 foot (1.22m) horizontal distance is maintained from

electric meters, gas meters, regulators, and relief equipment.

The venting system shall terminate at least 3 feet (0.9m) above

any forced air inlet within 10 feet (3.05m).

The venting system shall terminate at least 4 feet (1.2m) below,

4 feet (1.2m) horizontally from, or 1 foot (30cm) above any

door, window, or gravity air inlet into any building.

Do not terminate the vent in a window well, stairwell, alcove,

courtyard, or other recessed area. The vent cannot terminate

below grade. The bottom of the vent terminal shall be located

at least 12 inches (30cm) above the roof or above normal snow

levels.

To avoid a blocked flue condition, keep the vent cap clear of

snow, ice, leaves, debris, etc.

Flue gases from this appliance may contain large amounts of

water vapor that will form a white plume in winter. Plume

could obstruct window view.

Flue gas condensate can freeze on exterior surfaces or on the

vent cap. Frozen condensate on the vent cap can result in a

blocked flue condition. Flue gas condensate can cause

discoloration of exterior building surfaces. Adjacent brick or

masonry surfaces should be protected with a rust resistant sheet

metal plate.

The manufacturer shall NOT be held liable for any personal

injury or property damage due to ice formation or dislodging of

ice from the vent system or vent termination.

Common Venting Systems

When this appliance is equipped with ON/OFF burner firing

and a Category I flue, the flue may be combined with the flue

from any other negative draft, Category I appliance. Common

venting of multiple negative draft appliances requires that you

MUST install a barometric damper on each unit to regulate

draft. Install per the requirements of the latest edition of the

National Fuel Gas Code, ANSI Z223.1 and/or CAN/CGA-B149

Installation Code.

Common venting systems may be too large when an existing

unit is removed. At the time of removal of an existing

appliance, the following steps shall be followed with each

appliance remaining connected to the common venting system

placed in operation, while other appliances remaining

connected to the common venting system are not in operation.

a.) Seal any unused opening in the common venting system.

b.) Visually inspect the venting system for proper size and

horizontal pitch and determine there is no blockage or

restriction, leakage, corrosion, and other unsafe condition.

c.) Insofar as is practical, close all building doors and windows

and all doors between the space in which the appliances

remaining connected to the common venting system are

located and other spaces of the building. Turn on clothes

dryers and any other appliances not connected to the

common venting system. Turn on any exhaust fans, such

as range hoods and bathroom exhausts, so they will operate

at maximum speed. Do not operate a summer exhaust fan.

Close fireplace dampers.

d). Place in operation the appliance being inspected. Follow

the lighting instructions in this manual. Adjust thermostat

so appliance will operate continuously.

e.) Test for spillage at the draft hood / relief opening after five

(5) minutes of main burner operation. Use the flame of a

match or candle, or smoke from a cigarette, cigar, or pipe.

f.) After it has been determined that each appliance remaining

connected to the common venting system properly vents

when tested as above, return doors, windows, exhaust fans,

fireplace dampers, and other gas burning appliances to their

previous conditions of use.

g.) Any improper operation of the common venting system

should be corrected so that the installation conforms to the

latest edition of the National Fuel Gas Code, ANSI Z223.1,

in Canada, the latest edition of CGA Standard B149

Installation Code for Gas Burning Appliances and

Equipment. When resizing any portion of the common

venting system, the common venting system should be

9

resized to approach the minimum size as determined using

the appropriate tables in Appendix G in the latest edition of

the National Fuel Gas Code, ANSI Z223.1, in Canada, the

latest edition of CGA Standard B149 Installation Code for

Gas Burning Appliances and Equipment.

A masonry chimney must be properly sized and lined for the

installation of a high efficiency gas fired appliance. Venting of

a high efficiency appliance into a cold, oversized and unlined

masonry chimney can result in operational and safety problems.

A standard masonry chimney must not be used to vent the

products of combustion from this high efficiency gas fired

appliance.

A masonry chimney must be carefully inspected to determine

its suitability for the venting of flue products.

An unlined chimney must be relined with an approved chimney

liner system when a new appliance is being attached to it. For

appliances with ON/OFF burner firing, metallic liner systems

(Type “B” double-wall, flexible, or rigid metallic liners) are

recommended

For appliances with modulating burner operation, sealed,

metallic, corrosion resistant liner systems (single-wall, doublewall, flexible, or rigid metallic liners) rated for use with a high

efficiency, Category IV appliance must be used.

Corrosion resistant chimney liner systems are typically made

from a high grade of corrosion resistant stainless steel, such as

AL29-4C. The corrosion resistant liner must be properly sized

and fully sealed throughout the entire length contained within

the masonry lined chimney. Both the top and bottom of the

masonry chimney must be capped and sealed to provide a dead

air space around the liner.

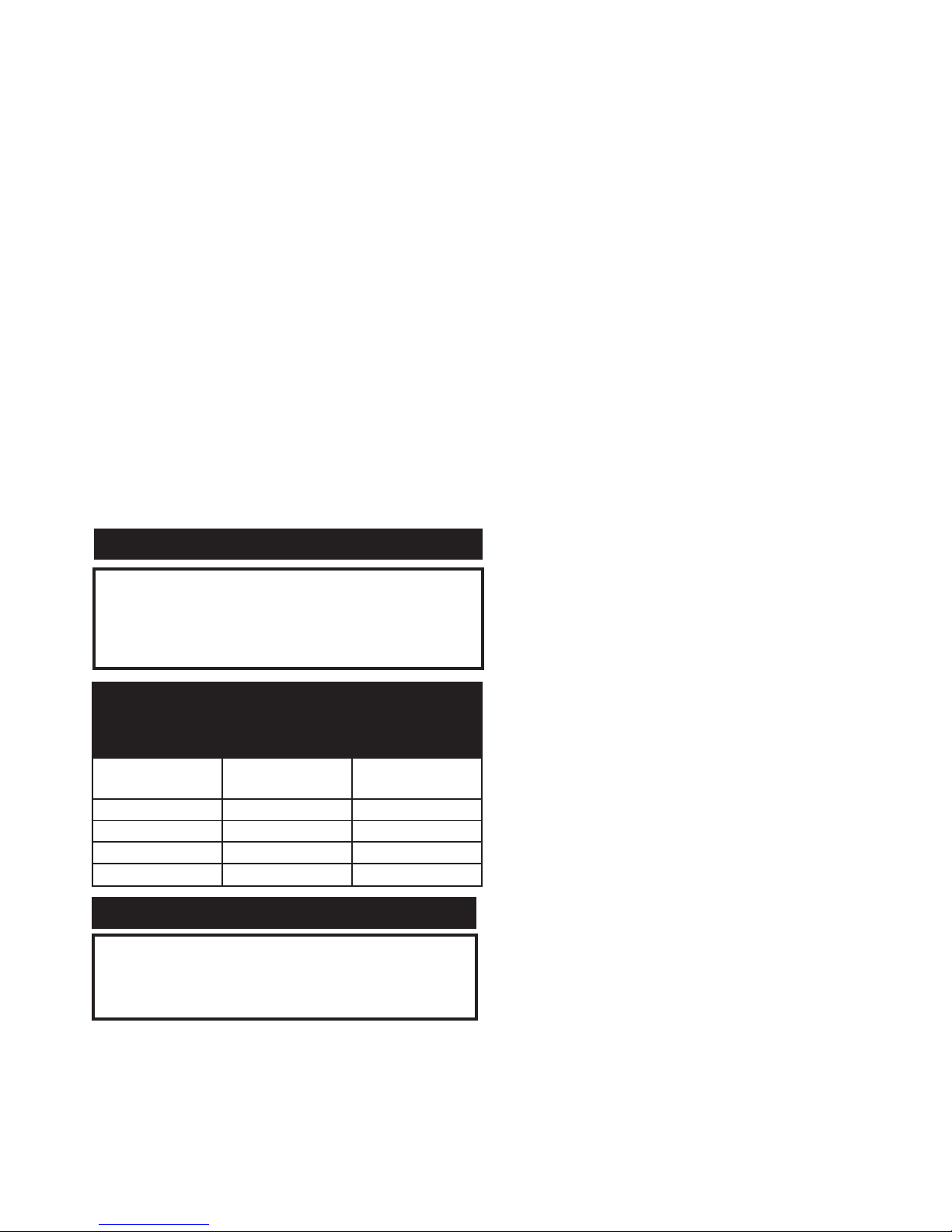

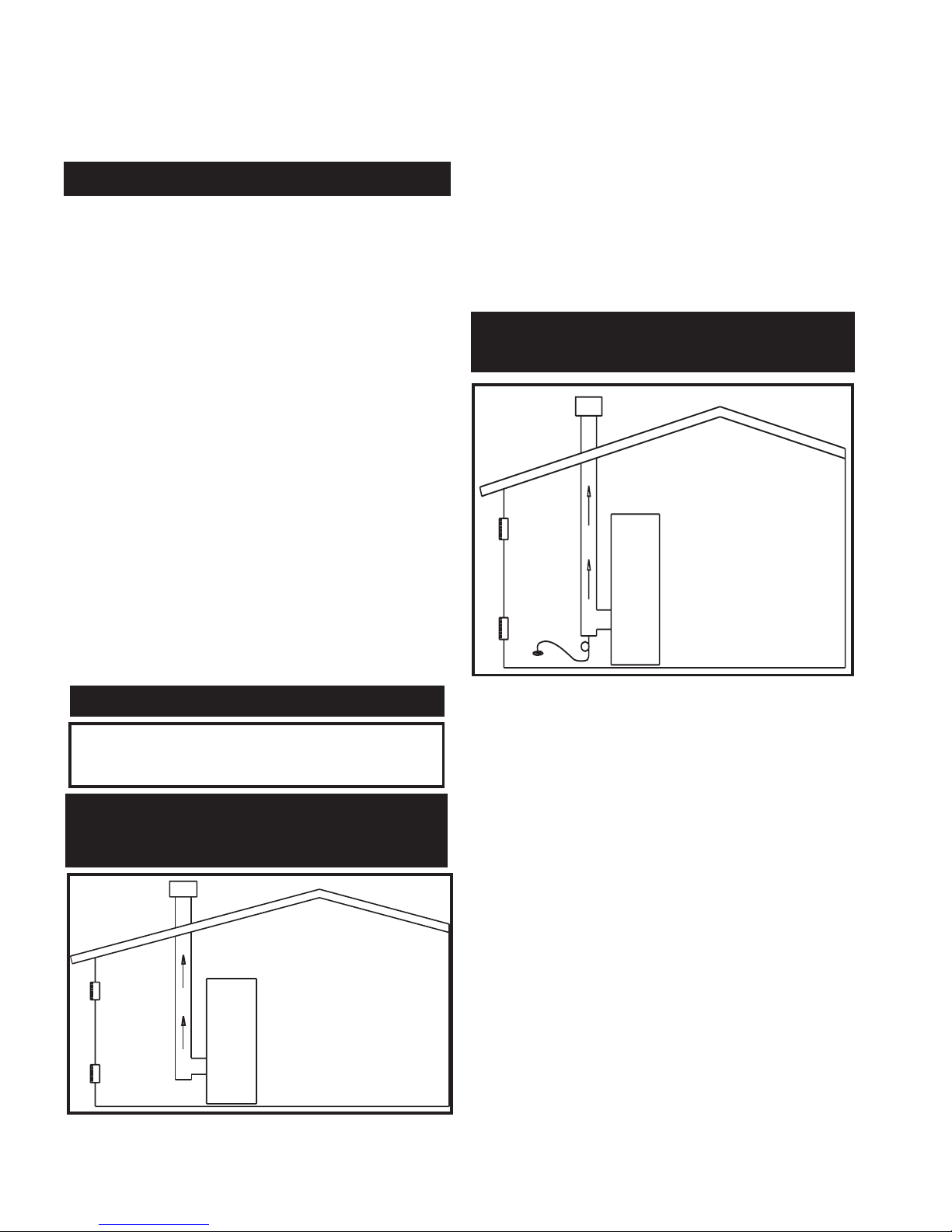

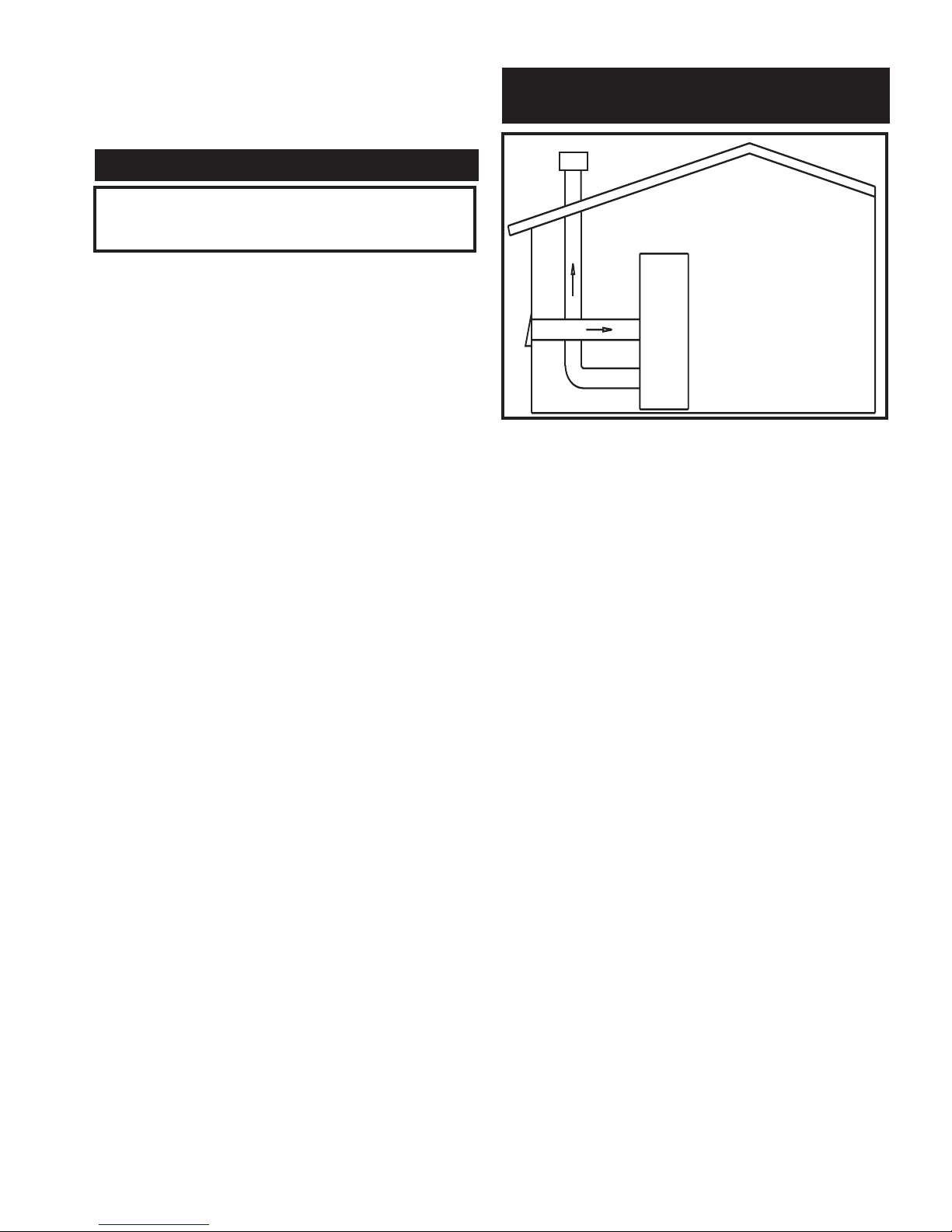

FIG. 11 Conventional Negative Draft Vertical Venting with

Combustion Air Supplied to the Equipment Room

Units that may be vented with a Category I, Type “B” vent

material operate with ON/OFF burner firing. A unit with

ON/OFF burner operation can be identified by the “Category I

and the “F” prefix on the firing controls as noted on the unit’s

rating plate. These are the only units that can be vented with

standard double-wall vent material. See the General Venting

and the Negative Draft General Venting Sections in this

manual. The flue must terminate at the rooftop. Combustion

air is supplied from the equipment room. The installation of the

vent must conform to the latest edition of the National Fuel Gas

Code, ANSI Z223.1, in Canada, the latest edition of CGA

Standard B149 Installation Code for Gas Burning Appliances

and Equipment.

FIG. 12 Vertical Category II Negative Draft Venting with

Combustion Air Supplied to the Equipment Room

Units that must be vented with a Category II corrosion resistant

vent material operate with modulating burner firing. The unit

can be identified by the “Category II” and the “M” prefix on the

firing controls as noted on the unit’s rating plate. Vent

connection is made directly to the back of the unit using an

AL29-4C corrosion resistant vent pipe. See the General

Venting and the Negative Draft General Venting Sections in this

manual. The flue must terminate at the rooftop. Combustion

air is supplied from the equipment room. The modulating

burner may result in flue gas temperatures below their dew

point forming condensate in the flue. The vent materials must

be corrosion resistant. Materials used for a Category IV vent

are also corrosion resistant. The system must maintain a

negative draft within the specified range. Use a barometric

damper if system has excess draft.

Vent Materials: The connection from the vent to the stack or

vertical vent termination outside the building MUST be made

with a listed Category II corrosion resistant vent material (or

equivalent) and must be direct as possible with no reduction in

diameter. Currently there are not any vent manufacturers

producing Category II vent material, a Category IV vent

material may be used to meet material requirements for this

venting option.

10

CONVENTIONAL VERTICAL

CATEGORY I NEGATIVE DRAFT

VENTING SYSTEM

MASONRY CHIMNEY INSTALLATION

Check with local code officials to determine code

requirements or the advisability of using a masonry

chimney with a sealed corrosion resistant liner system.

IMPORTANT

(VERTICAL CATEGORY II NEGATIVE

DRAFT VENTING SYSTEM

Category IV Flue Pipe Materials

Select venting material from the following specified vent

distributors:

Heat-Fab Inc., Saf-T CI Vent with AL29-4C stainless steel

(Call 1-800-772-0739 for nearest distributor)

Protech Systems Inc., Fas N Seal Vent with AL29-4C stainless

steel (Call 1-800-766-3473 for nearest distributor)

Flex-L International Inc., StaR 34 Vent with AL29-4C

stainless steel (Call 1-800-561-1980 for nearest distributor)

Metal-Fab Inc., Corr/Guard Vent with AL29-4C stainless steel

(Call 1-800-835-2830 for nearest distributor)

Z-Flex Z-Vent with AL29-4C stainless steel (Call 1-800-6545600 for nearest distributor)

Or other listed Category IV vent systems suitable for a

condensing, positive pressure gas fired appliance.

A Category IV flue MUST have all vent joints and seams sealed

gastight and have provisions for a drain to properly collect and

dispose of condensate that may occur in the venting system.

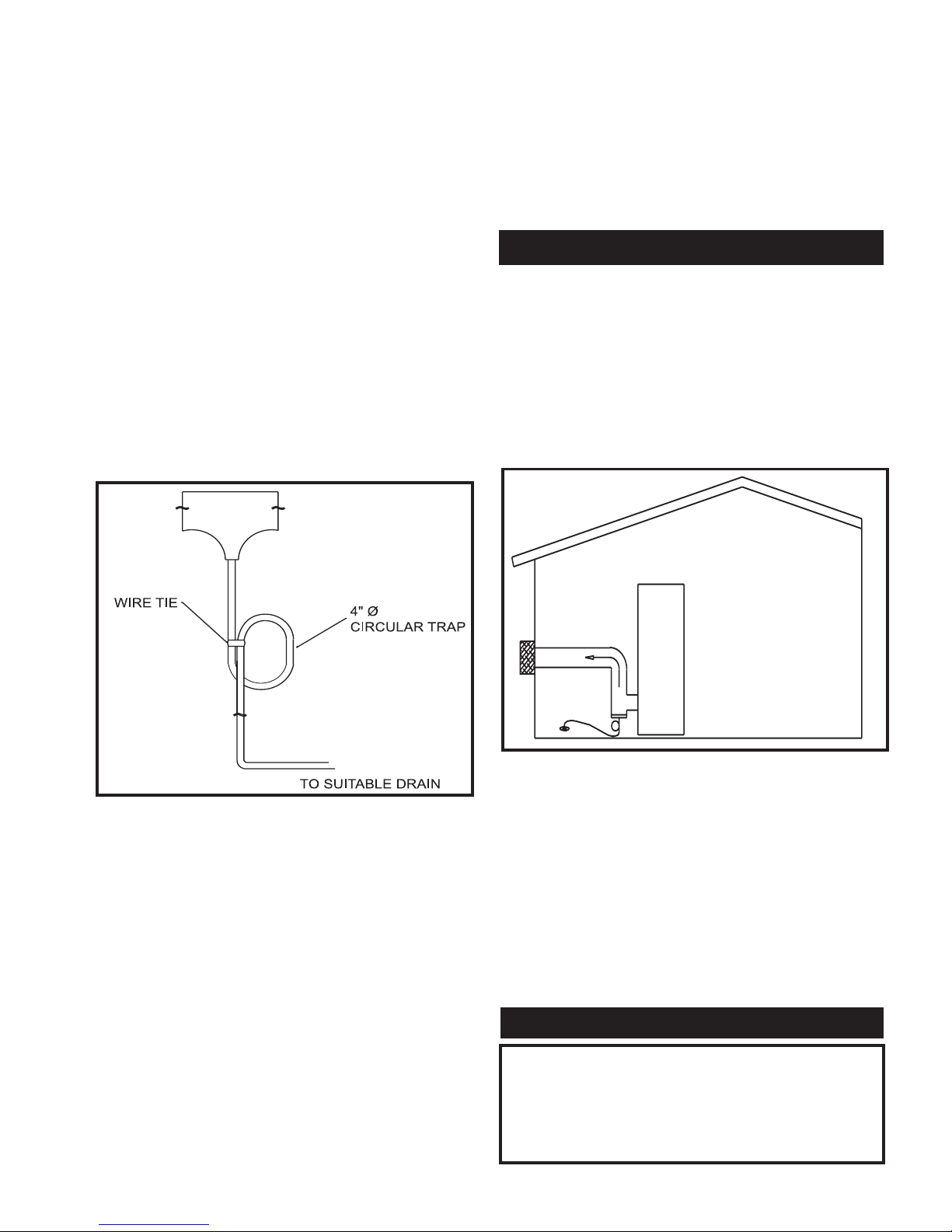

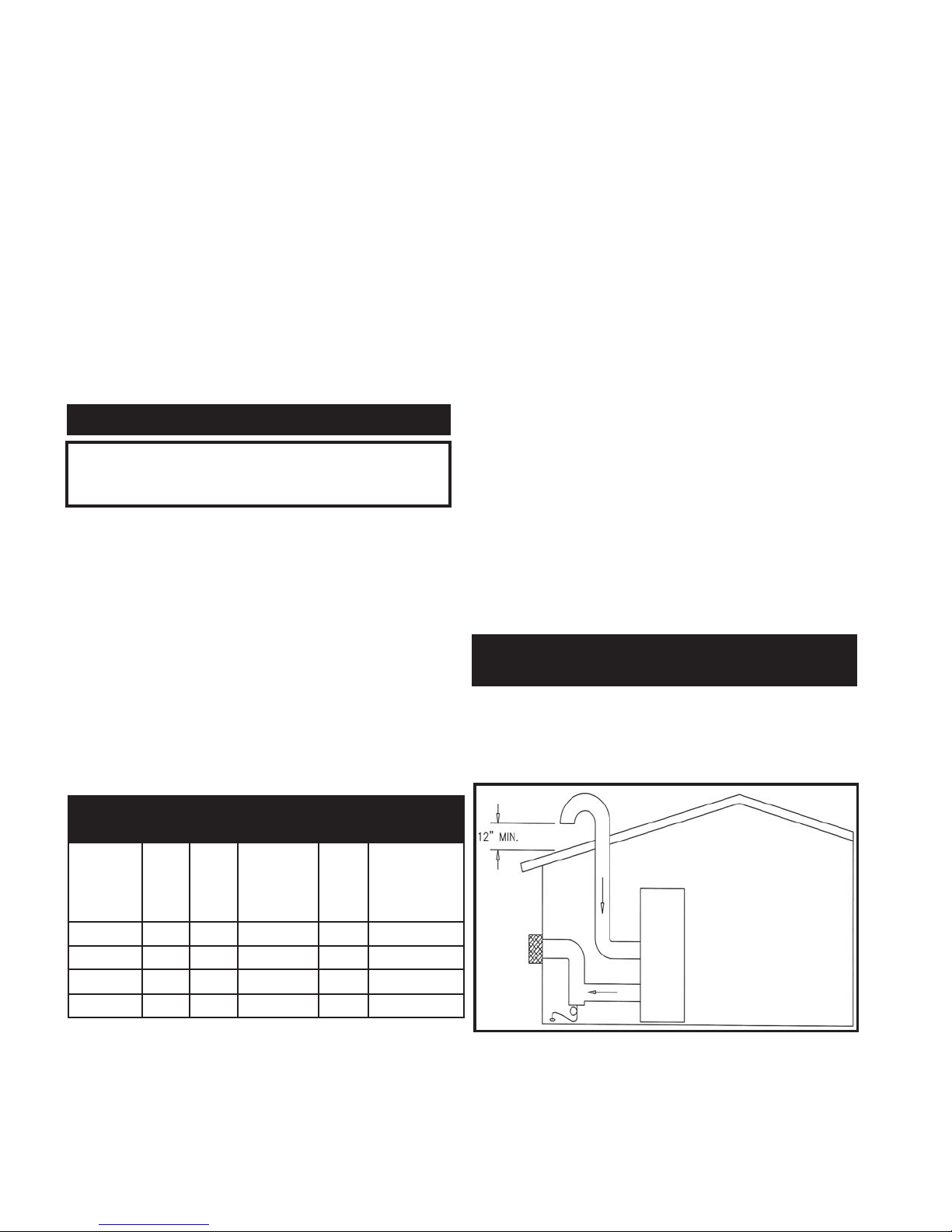

Drain Tee Installation

FIG. 13 Drain Tee Installed in Category II or IV Venting

The drain tee should be installed at the point where the flue

turns vertical for a rooftop termination or as one of the first

fittings in a horizontal flue connector that will terminate on a

sidewall. Ensure that horizontal portions of the vent are

properly sloped to allow condensate to be evacuated at the

drain tee. Plastic drain tubing, sized per the vent manufacturer’s

instructions, shall be provided as a drain line from the tee. The

drain tubing must have a trap provided by a 4" (10.2cm)

diameter circular trap loop in the drain tubing. Prime the trap

loop by pouring a small quantity of water into the drain hose

before assembly to the vent. Secure the trap loop in position

with nylon wire ties. Use caution not to collapse or restrict the

condensate drain line with the nylon wire ties. The condensate

drain must be routed to a condensate neutralization system or a

suitable drain for disposal. Ensure that the drain from the

condensate tee is not exposed to freezing temperatures. See

“Freeze Protection” for more information.

Common Venting System

You can combine the flue with the vent from other negative

draft Category II appliances ONLY. The vent from other

Category I appliances CANNOT be combined with the flue

from Category II appliances unless the entire vent system for

all units use Category IV vent materials. A barometric damper

must be installed on each unit when common venting multiple

negative draft Category II appliances.

This vent option is only available on units with modulating

burner firing. The unit can be identified by the “Category IV”

and the “M” prefix on the firing controls as noted on the unit’s

rating plate.

This venting system option uses the unit’s internal combustion

fan to force the flue products out of a sidewall vent cap

assembly. The unit’s internal fan generates a positive draft

pressure to exhaust the flue products. Combustion air is drawn

from the equipment room (see the Combustion and Ventilation

Air Requirements section).

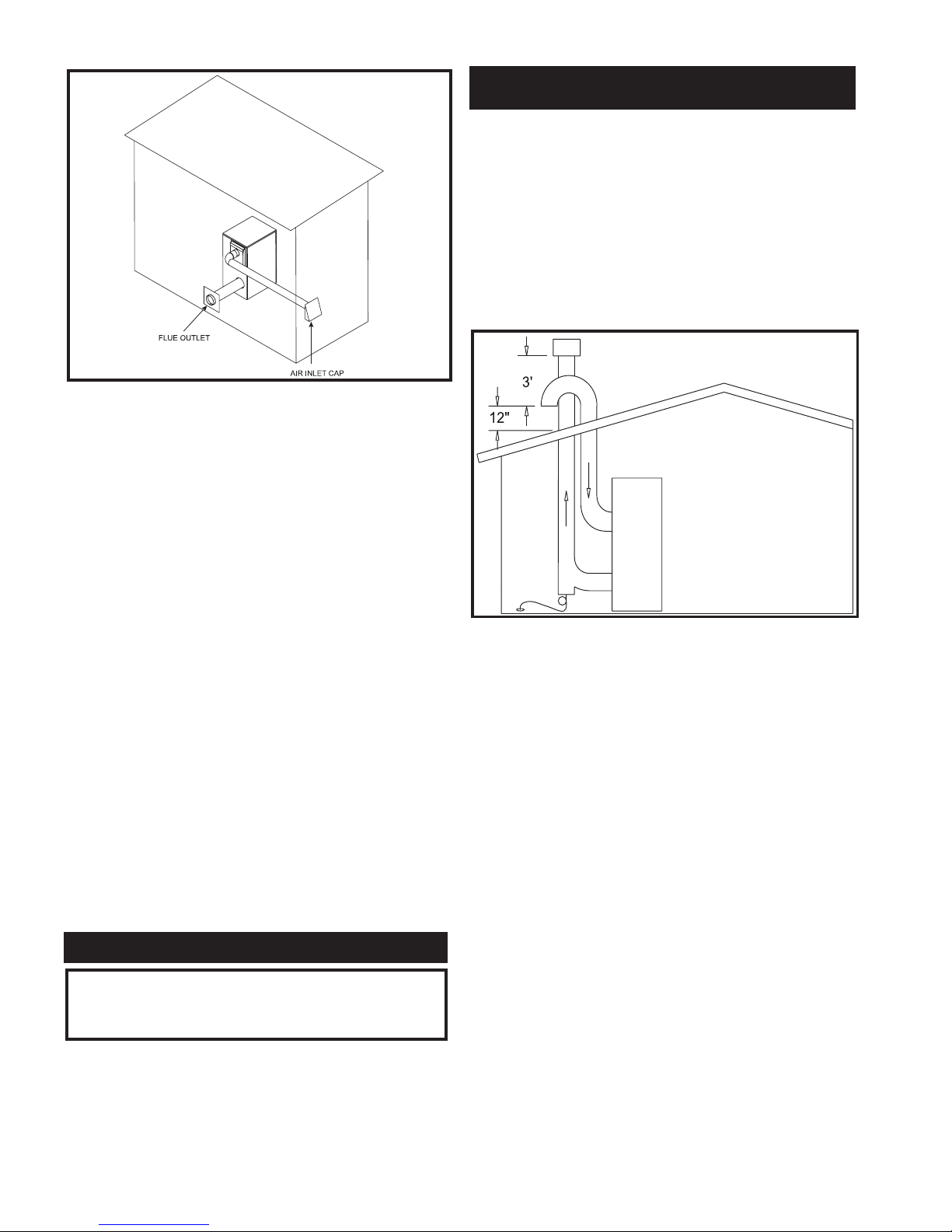

FIG. 14 Sidewall Venting Installation

The connection from the appliance flue outlet to the sidewall

vent cap MUST be made with listed type Category IV vent

materials and accessories. See Category IV flue pipe material

specifications. The installer must supply suitable vent pipe

material. The sidewall vent cap is available from the appliance

manufacturer as a vent kit.

Alternate Sidewall Vent Kits with reduced vent sizes are also

approved and available from the manufacturer. These kits

include a vent reducer, as well as a reduced diameter vent cap.

See Table D for Standard and Alternate Sidewall Vent Kit

numbers. Each appliance must have a dedicated flue with no

other appliance interconnected to any part of the dedicated flue.

11

SIDEWALL VENTING

The Category IV flue from this appliance CANNOT be

combined with the vent from any other appliance. The

Category IV flue from this appliance must be a dedicated

stack and the flue from this appliance must have all vent

joints and seams sealed gastight. A Category IV vent system

has specific vent material and installation requirements.

WARNING

Maximum Vent Length

The installed length of the Category IV flue from the appliance

to the point of termination, outside of the building must not

exceed a maximum of 50 equivalent feet (15.2m) in length.

Subtract 5 feet (1.5m) of equivalent length for each 90° elbow

installed in the vent. Subtract 2 1/2 feet (0.7m) of equivalent

length for each 45° elbow installed in the vent.

All connections should be secured and sealed per the vent

manufacturer’s specifications.

Vent connectors serving appliances vented by natural draft shall

not be connected to any portion of the Category IV positive

pressure vent system used by this appliance. Connection of a

negative draft flue into the positive pressure stack from this

appliance may cause flue products to be discharged into an

occupied living space causing serious health injury.

When a Category IV vent system is disconnected for any

reason, the flue must be reassembled and resealed according to

the vent manufacturer’s instructions.

The flue for a sidewall venting system must terminate

horizontally on a sidewall. See specific information concerning

vent termination location for recommended clearances and

location.

The sidewall vent cap kit includes the wall penetration

assembly and the discharge screen assembly. All required

Category IV vent pipe and fittings must be purchased locally.

The installed sidewall vent cap assembly may be painted to

match the exterior décor.

The opening through the wall for installation of the sidewall

vent cap must provide an air space clearance of 2 inches

(5.1cm) around the flue pipe. The diameter of the opening for

installation of the sidewall cap will be 4 inches (10.2cm) larger

(minimum) than the nominal diameter of the installed vent pipe

to the sidewall cap.

The sidewall cap is installed from the outside and mounted to

the wall with four (4) screws or wall anchors. Seal under the

screw heads with caulking. Install the screen assembly using

the stainless steel screws provided in the kit. Install the

Category IV vent pipe from the appliance to the vent cap. The

installed vent pipe must protrude at least 2 inches (5.1cm) into

the screen area beyond the thimble portion of the sidewall cap

assembly. See detailed instructions packed with the sidewall

vent kit.

Follow all requirements in the Category IV General Venting

Information section for proper installation and for venting flue

products to the outdoors. See the Combustion and Ventilation

Air Requirements section to ensure that adequate combustion

and ventilation air is supplied to the equipment room. All other

general installation requirements must be followed.

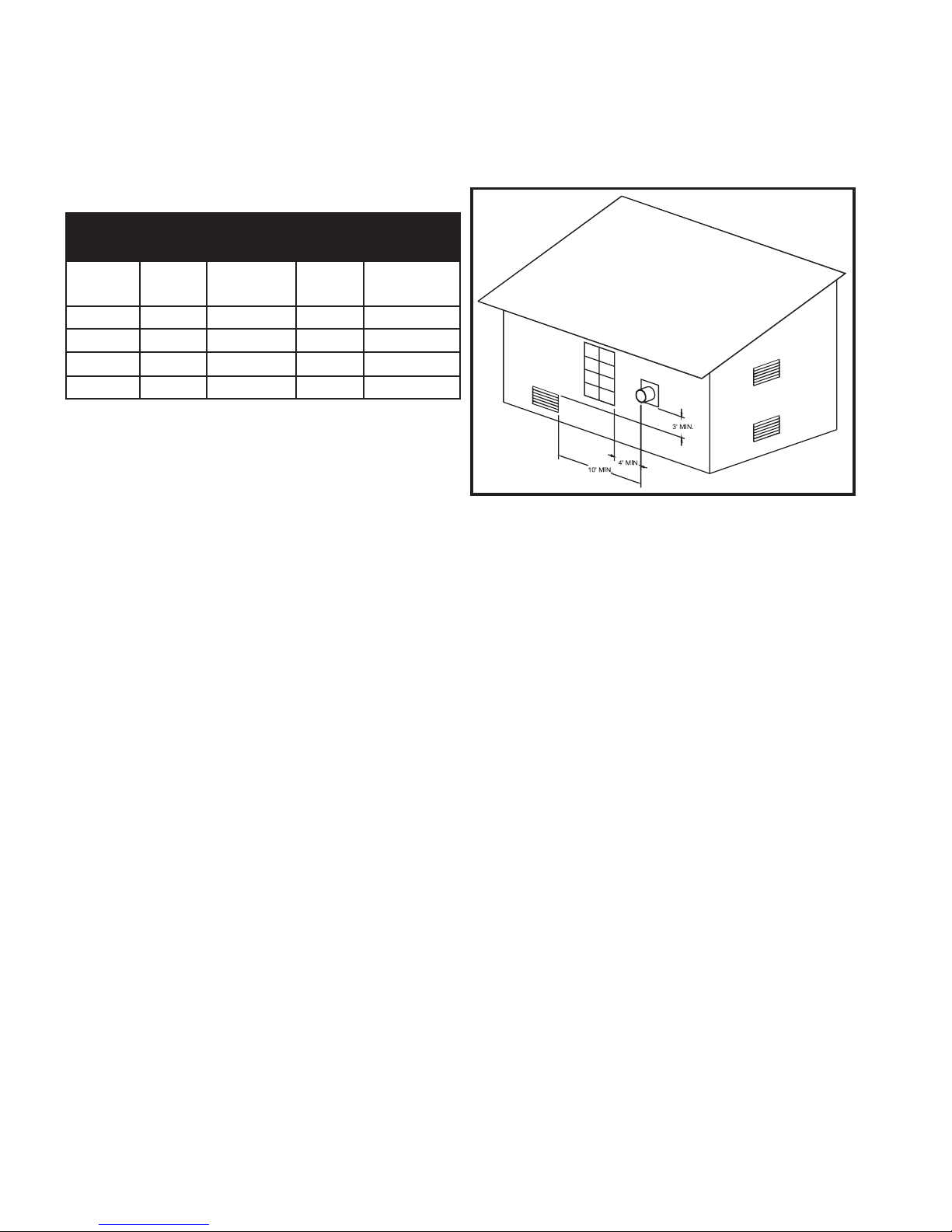

Location of a Sidewall Vent Termination

Follow all requirements in the General Venting section.

FIG. 15 Sidewall Venting Installation with Clearances from

Vent Cap

The vent cap shall terminate at least 3 feet (0.91m) above any

forced air inlet within 10 feet (3.05m).

The vent shall terminate at least 4 feet (1.22m) below, 4 feet

(1.22m) horizontally from or 1 foot (0.30m) above and 2 feet

(0.60m) horizontally from any door, window, or gravity air inlet

to the building.

The sidewall vent termination must be at least 8 feet (2.4m)

horizontally from any combustion air intake located above the

sidewall termination cap.

Do not terminate the vent in a window well, stairwell, alcove,

courtyard, or other recessed area. The vent cannot terminate

below grade.

The vent shall not terminate directly above a public walkway

due to the normal formation of water vapor in the combustion

process. Horizontal terminations must not be located over areas

of pedestrian or vehicular traffic.

The vent system shall terminate at least 1 foot (0.30m) above

grade, above normal snow levels and at least 7 feet (2.13m)

above grade when located adjacent to public walkways.

The vent terminal shall not be installed closer than 3 feet

(0.91m) from an inside corner of an L-shaped structure.

The vent cap should have a minimum clearance of 4 feet

(1.22m) horizontally from and in no case above or below,

unless a 4 foot (1.22m) horizontal distance is maintained from

electric meters, gas meters, regulators and relief equipment.

Flue gas condensate can freeze on exterior walls or on the vent

cap. Frozen condensate on the vent cap can result in a blocked

flue condition. Some discoloration to exterior building surfaces

can be expected. Adjacent brick or masonry surfaces should be

protected with a rust resistant sheet metal plate.

12

TABLE — D

Sidewall Vent Kits

Input

Btu/hr

Flue

Size

Sidewall

Vent Kit

Alt. Flue

Size

Alt. Sidewall

Vent Kit

500,000 7" SVK3027 4" SVK3056

750,000 9" SVK3049 5" SVK3057

1,000,000 10" SVK3029 6" SVK3058

1,300,000 12" SVK3050 8" SVK3059

The sidewall vent system must use the sidewall vent cap kit

provided by the appliance manufacturer for installation on a

sidewall termination.

The sidewall vent cap MUST be purchased as a kit from the

appliance manufacturer to ensure proper operation. Locally

purchased or fabricated sidewall vent caps should not be used.

Direct Vent and DirectAire Vent Systems are installed with

specific flue pipe material requirements based on the type of

firing controls used on the unit. Direct Vent and DirectAire

systems both use a separate combustion air pipe to the outdoors.

The Direct Vent System terminates both the flue and

combustion air inlet in the same pressure zone. The DirectAire

Vent System may terminate the flue and combustion air inlet in

different pressure zones. The flue outlet and combustion air

intake may terminate with either a sidewall or a rooftop

termination based on the specific venting option selected.

Follow all requirements for the specific venting option selected

to determine vent material requirements and proper installation

to discharge the flue products vertically or horizontally to the

outdoors. All other general installation requirements must be

followed.

The Direct Vent and DirectAire Vent Systems require the

installation of an additional pipe to supply combustion air from

outdoors directly to the appliance.

Length of Air Inlet Pipe

The maximum total length of the sidewall or vertical rooftop

combustion air inlet pipe as installed from the appliance to the

air inlet cap must not exceed 50 equivalent feet (15.2m) in

length. Subtract 5 feet (1.52m) of equivalent length for each

90° elbow installed in the air inlet pipe system. Subtract

2 1/2 feet (0.7m) of equivalent length for each 45° elbow

installed in the air inlet pipe system. Do not exceed limits for

the combustion air inlet piping lengths.

Air Inlet Pipe Materials

The air inlet pipe(s) must be sealed. Choose acceptable

combustion air inlet pipe materials from the following list:

PVC, CPVC or ABS (5" or 6" I.D.)*

Dryer Vent or Sealed Flexible Duct (not recommended

for rooftop air inlet)

Galvanized steel vent pipe with joints and seams

sealed as specified below.

Type “B” double-wall vent with joints and seams

sealed as specified below.

*Plastic pipe may require an adapter (not provided) to

transition between the air inlet connection on the

appliance and the plastic air inlet pipe.

Sealing of Type “B” double-wall vent material or galvanized

vent pipe material used for air inlet piping on a sidewall or

vertical rooftop Combustion Air Supply System:

a. Seal all joints and seams of the air inlet pipe using either

Aluminum Foil duct tape meeting UL Standard 723 or

181A-P or a high quality UL Listed silicone sealant such as

those manufactured by Dow Corning or General Electric.

b. Do not install seams of vent pipe on the bottom of horizontal

runs.

c. Secure all joints with a minimum of three sheet metal screws

or pop rivets. Apply Aluminum Foil duct tape or silicone

sealant to all screws or rivets installed in the vent pipe.

d. Ensure that the air inlet pipes are properly supported.

The PVC, CPVC, or ABS air inlet pipe should be cleaned and

sealed with the pipe manufacturer’s recommended solvents and

standard commercial pipe cement for the material used. The

PVC, CPVC, ABS, Dryer Vent or Flex Duct air inlet pipe

should use a silicone sealant to ensure a proper seal at the

appliance connection and the air inlet cap connection. Dryer

vent or flex duct should use a screw type clamp to seal the vent

to the appliance air inlet and the air inlet cap. Proper sealing of

the air inlet pipe ensures that combustion air will be free of

contaminants and supplied in proper volume.

When a sidewall or vertical rooftop combustion air supply

system is disconnected for any reason, the air inlet pipe must be

resealed to ensure that combustion air will be free of

contaminants and supplied in proper volume.

13

Appliances that are shut down or will not operate may

experience freezing due to convective airflow in the air inlet

pipe connected to the appliance.

WARNING

DIRECT VENT AND DIRECTAIRE

VENT SYSTEMS

When the appliance is installed as either a Category II or

Category IV vent appliance, unique venting guidelines will

apply. Refer to the appropriate section of the Installation and

Service Manual for specific instructions for Category II or

Category IV vent installations.

WARNING

Using vent or air intake materials other than those specified,

failure to properly seal all seams and joints or failure to

follow vent pipe manufacturer’s instructions can result in

personal injury, death or property damage. Mixing of

venting materials will void the warranty and certification of

the appliance.

WARNING

The use of double-wall vent or insulated material for the

combustion air inlet pipe is recommended in cold climates

to prevent the condensation of airborne moisture in the

incoming combustion air.

NOTE

A DirectAire vent system uses a flue to the sidewall or rooftop

with a separate combustion air pipe to the outdoors. The

DirectAire vent system may terminate the flue and the

combustion air inlet pipe in different pressure zones in any one

of four configurations. These are: (1) The flue on the rooftop

and combustion air intake on the sidewall. (2) Both the flue

and air inlet terminated on the rooftop using a Category I flue

for units with ON/OFF burner firing. (3) The flue terminated

on the sidewall and combustion air from the rooftop. (4) The

flue terminated on the sidewall and the combustion air intake

on a sidewall other than the sidewall where the flue is located.

All appliances are shipped from the factory with a flue outlet

that allows the connection of Category I or Category IV venting

systems. Check the vent category rating on your unit to ensure

that proper vent material is used. The optional DirectAire vent

systems require the installation of specific venting materials

that are purchased locally. Rooftop termination caps for flue

products and combustion air must be purchased locally.

Sidewall termination caps for flue products and combustion air

must be purchased from the manufacturer. The sidewall caps

for combustion air and flue products are available as vent kits.

The following is a detailed explanation of the installation

requirements for each venting system, components used, and

part numbers of vent kits for each model.

Follow all requirements for the type of vent materials used with

your unit.

A Category I or II vertical flue must follow the requirements in

the Vertical Negative Draft Venting sections. A Category IV

flue must follow the requirements under the Category IV

General Venting Information section. All other general venting

installation requirements must be followed.

The DirectAire vent system always requires the installation of

an additional pipe to supply combustion air from outdoors

directly to the appliance. The air inlet pipe must use one of the

materials specified in the Air Inlet Pipe Materials section.

Combined Combustion Air Inlet Points for DirectAire

Systems Only

The air inlet pipes from multiple appliances can be combined

to a single common connection if the common air inlet pipe has

a cross sectional area equal to or larger than the total area of all

air inlet pipes connected to the common air inlet pipe.

[Example: two 5" (12.7cm) air inlet pipes (19.63 in

2

(126.6 cm2) area each) have a total area of 39.26 in2(253.3 cm2)

requires an 8" (20.3 cm) (50.26 in2area) 324.3 cm2) common

air inlet pipe.] The air inlet point for multiple boiler air inlets

must be provided with an exterior opening which has a free

area equal to or greater than the total area of all air inlet pipes

connected to the common air inlet. This exterior opening for

combustion air must connect directly to the outdoors. The total

length of the combined air inlet pipe must not exceed a

maximum of 50 (15.2m) equivalent feet. You must deduct the

restriction in area provided by any screens, grills or louvers

installed in the common air inlet point. Screens, grills, or

louvers installed in the common air inlet can reduce the free

area of the opening from 25% to 75% based on the materials

used.

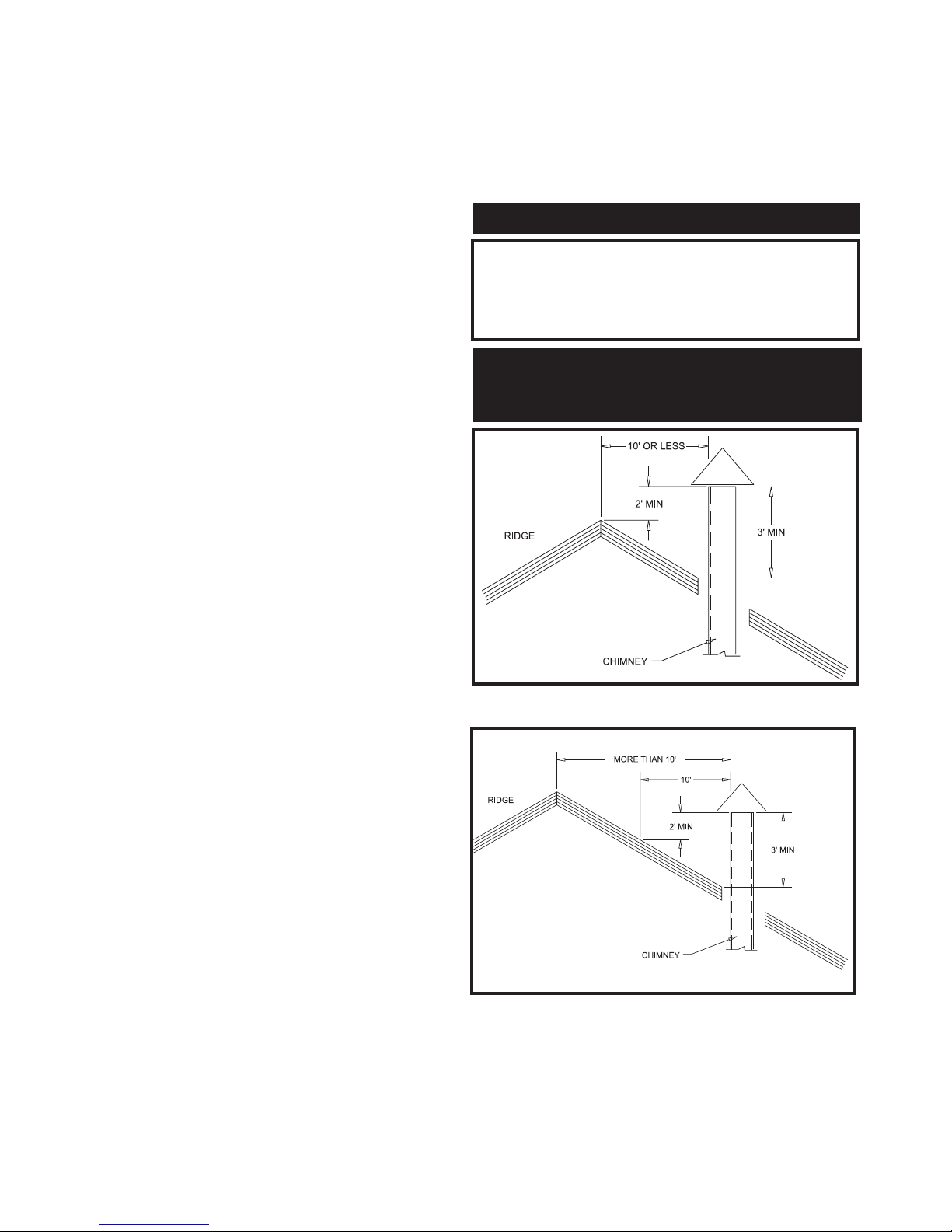

FIG. 16 Vertical DirectAire Installation with Rooftop

Combustion Air Inlet

This venting option is only for units that operate with single

stage ON/OFF burner firing. These units will be marked as

Category I and have an “F” prefix on the firing controls as

noted on the rating plate. This venting option uses a Category

I, Type “B” double-wall vent material terminated at the rooftop

and a separate combustion air pipe also terminating at the

rooftop. The flue must be installed per all requirements in the

Conventional Vertical Negative Draft Venting section for a

Category I vent. Follow all requirements in the Conventional

Vertical Negative Draft Venting section for the materials

required to ensure that flue products are properly vented

vertically to the outdoors. All other general installation

requirements must be followed. The flue outlet and

combustion air intake terminate in the same pressure zones, but

because of the use of a Category I flue it does not meet the

specifications for a Direct Vent System.

The maximum installed length of the flue pipe from the

appliance to the termination cap is limited only by the

requirement to maintain a negative draft within the limits

specified in the Negative Draft General Venting Information

section.

Air Inlet Pipe Materials

A DirectAire Vent System always requires the installation of an

additional pipe to supply combustion air from outdoors directly

to the appliance. The air inlet pipe must use one of the

materials specified in the Air Inlet Pipe Materials section.

14

Failure to properly seal all joints and seams as required in

the air inlet piping may result in flue gas recirculation,

spillage of flue products and carbon monoxide emissions

causing severe personal injury or death.

DANGER

DIRECTAIRE VENT SYSTEMS

VERTICAL DIRECTAIRE VENTING

WITH ROOFTOP COMBUSTION AIR

In cold climates, the use of Type “B” double-wall vent pipe or

an insulated single-wall pipe is recommended to help prevent

moisture in the cool incoming air from condensing and leaking

from the inlet pipe.

Vertical Combustion Air Inlet

The air inlet cap for the vertical rooftop inlet is assembled from

components purchased locally. The air inlet cap consists of two

90° elbows installed at the point of termination for the air inlet

pipe. The first 90° elbow is installed on the rooftop at the

highest vertical point of the air inlet pipe and turned horizontal;

the second 90° elbow is installed on the horizontal outlet of the

first elbow and turned down. A 90° elbow and a 90° street

elbow may be used to make this assembly. If a straight piece of

pipe is used between the two elbows, it should not exceed 6"

(51mm) in length. The termination ell on the air inlet must be

located a minimum of 12" (0.30m) above the roof or above

normal levels of snow accumulation.

Location of a Rooftop Air Inlet Cap

The point of termination for the combustion air inlet cap MUST

be at least 3 feet (0.91m) below any point of flue gas

termination (vent cap) if it is located within a 10 foot (3.05m)

radius of the flue outlet. Use care to ensure that the 90° ell

assembly is properly installed on the air inlet pipe. The

assembled combustion air cap assembly used MUST

adequately protect the combustion air inlet from wind and

weather.

The combustion air inlet cap must not be installed closer than

10 feet (3.05m) from an inside corner of an L-shaped structure.

The termination point of the combustion air inlet cap must be

installed at least one foot (0.30m) above the rooftop and above

normal snow levels.

The combustion air cap assembly used MUST adequately

protect the combustion air inlet from wind and weather.

Combustion air supplied from outdoors must be free of

contaminants (see Combustion and Ventilation Air). To prevent

recirculation of flue products into the combustion air inlet,

follow all instructions in this section.

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in incomplete

combustion and potentially hazardous levels of carbon

monoxide in the flue products. This will cause operational

problems with the heater and possible spillage of flue products

that can cause personal injury, death, or property damage.

For clearances between multiple air inlet caps, see the Multiple

Vertical Direct Vent Installation section.

FIG. 17 Vertical DirectAire Installation with Sidewall

Combustion Air Inlet

Vertical DirectAire vent systems are installed with the flue

terminating at the rooftop and a separate combustion air pipe at

the sidewall to the outdoors. The flue outlet and combustion air

intake terminate in different pressure zones.

Flue Requirements - ON/OFF Burner Operation

This unit, which operates with an on/off burner firing, may be

vented to the rooftop with a Type “B” vent material. These

units will be marked as Category I and have an “F” prefix on

the firing controls as noted on the rating plate. The flue must

be installed per all requirements in the Conventional Vertical

Negative Draft Venting section for a Category I vent. Follow all

requirements in the Conventional Vertical Negative Draft

Venting section for the materials required to ensure that flue

products are properly vented vertically to the outdoors. All

other general installation requirements must be followed.

Flue Requirements - Modulating Burner Operation

A unit, which operates with a modulating burner firing, may be

vented to the rooftop with a Category II vent material or

equivalent (Category IV) vent material. These units will be

marked as Category II and have an “M” prefix on the firing

controls as noted on the rating plate. The flue must be installed

per all requirements in the Vertical Category II Negative Draft

Venting section using a Category II corrosion resistant flue or

equivalent. Follow all requirements in the Vertical Category II

Negative Draft Venting section for the Category II materials

required to ensure that flue products are properly vented

vertically to the outdoors. All other general installation

requirements must be followed.

Alternate vertical venting with reduced vent sizes is also

approved by the manufacturer. Refer to Table E - Vertical

DirectAire Vent Kits for the alternate flue sizes approved and

the vent reducer part number available from the manufacturer.

When using the reduced vent size the vent will become a

positive pressure vent requiring the use of Category IV vent

material. Follow all requirements in the Category IV General

Venting Information section for proper installation and for

15

Appliances that are shut down or will not operate may

experience freezing due to convective airflow in the air inlet

pipe connected to the appliance.

CAUTION

VERTICAL DIRECTAIRE WITH

SIDEWALL COMBUSTION AIR

venting flue products to the outdoors. All other general

installation requirements must be followed.

The maximum installed length of the Category IV flue from the

appliance to the point of termination must not exceed 50

equivalent feet in length. Subtract 5 feet of equivalent length

for each 90° elbow installed in the vent. Subtract 2 1/2 feet of

equivalent length for each 45° elbow installed in the vent.

Air Inlet Pipe Materials

A DirectAire Vent System always requires the installation of an

additional pipe to supply combustion air from outdoors directly

to the appliance. The air inlet pipe must use one of the

materials specified in the Air Inlet Pipe Materials section.

In cold climates, the use of Type “B” double-wall vent pipe or

an insulated single-wall pipe is recommended to help prevent

moisture in the cool incoming air from condensing and leaking

from the inlet pipe.

Sidewall Combustion Air Inlet

The air inlet cap for the sidewall air inlet must be purchased

from the appliance manufacturer.

The part numbers for the required sidewall air inlet cap kit are

listed by unit size. The appliance manufacturer, in accordance

with CSA International/CGA requirements, must furnish the

sidewall air inlet cap. Each kit includes the special combustion

air inlet cap for installation on an exterior sidewall for

operation of a single appliance only.

Flue piping from the appliance to the rooftop termination may

be increased to 8 inches or 10 inches based on field availability

of 7 inch and 9 inch flue material.

Location of a Sidewall Air Inlet Ca\p

Incorrect installation and/or location of the air inlet cap can

allow the discharge of flue products to be drawn into the

combustion process on the heater. This can result in incomplete

combustion and potentially hazardous levels of carbon

monoxide in the flue products. This will cause operational

problems with the heater and possible spillage of flue products

that can cause personal injury, death, or property damage.

The termination point of the sidewall air inlet must be installed

a minimum of 12 inches (0.30m) above ground level and above

normal levels of snow accumulation.

The point of termination for the sidewall combustion air inlet

cap MUST be located a minimum of 3 feet (0.91m)

horizontally and 12 inches (0.30m) below any point of flue gas

termination (vent cap) if it is located within a 10 foot (3.05m)

radius of the flue outlet.

The sidewall combustion air inlet cap MUST NOT be installed

above the sidewall flue outlet if it is located within a 10 foot

(3.05m) radius of the flue outlet.

The sidewall combustion air inlet cap must not be installed

closer than 10 feet (3.05m) from an inside corner of an

L-shaped structure.

The sidewall combustion air cap assembly used MUST

adequately protect the combustion air inlet from wind and

weather.

The sidewall combustion air inlet cap and the rooftop flue gas

outlet are located in different pressure zones in a DirectAire

system.

Combustion air supplied from outdoors must be free of

contaminants (see Combustion and Ventilation Air). To prevent

recirculation of flue products into the combustion air inlet,

follow all instructions in this section.

For clearances between multiple vent caps, see the Multiple

Horizontal Direct Vent Installation section.

This vent option is only available on units with modulating

burner firing. The unit can be identified by the “Category IV”

and the “M” prefix on the firing controls as noted on the unit’s

rating plate.

FIG. 18 Horizontal DirectAire Installation with Rooftop

Combustion Air Inlet

The Horizontal DirectAire System terminates the flue at the

sidewall using Category IV vent materials and a combustion air

inlet pipe to draw air from the rooftop. Horizontal DirectAire

16

Appliances that are shut down or will not operate may

experience freezing due to convective airflow in the air inlet

pipe connected to the appliance.

CAUTION

TABLE — E

Vertical DirectAire Vent Kits

Input

Btu/hr

Flue

Size

Alt.

Flue

Vent

Reducer

Alt.

Inlet

Pipe

Size

DirectAire

Inlet

Sidewall

Cap Size Kit

500,000 7" 4" DRH2435 5" SAK3003

750,000 9" 5" DRH2436 5" SAK3003

1,000,000 10" 6" DRH2437 6" SAK3000

1,300,000 12" 8" DRH2438 6" SAK3000

HORIZONTAL DIRECTAIRE WITH

VERTICAL COMBUSTION AIR

Vent Systems are installed with the flue outlet and combustion

air intake located in different pressure zones.

Follow all requirements in the Sidewall Venting and

Category IV General Venting Information sections for proper

installation and for venting flue products horizontally out a

sidewall to the outdoors. All other general installation

requirements must be followed.

Air Inlet Pipe Materials

A DirectAire Vent System always requires the installation of an

additional pipe to supply combustion air from outdoors directly

to the appliance. The air inlet pipe must use one of the

materials specified in the “Air Inlet Pipe Materials” section.

In cold climates, the use of Type “B” double-wall vent pipe or

an insulated single-wall pipe is recommended to help prevent

moisture in the cool incoming air from condensing and leaking

from the inlet pipe.

The termination point for the flue products must follow the

clearance requirements in the Sidewall Venting section for use

with Category IV venting.

The flue and air inlet duct sizes for a Horizontal DirectAire

Installation with Rooftop Combustion Air Inlet are listed by

unit size. The sidewall vent cap must be purchased from the

appliance manufacturer as a vent kit. This venting option uses

the sidewall venting kit with the combustion air inlet system

constructed from materials purchased locally by the installer.

Alternate sidewall vent kits with reduced vent sizes are also

approved and available from the manufacturer. These kits

include a vent reducer, as well as a reduced diameter vent cap.

See Table F for Standard and Alternate Sidewall Vent Kit

numbers. All required Category IV vent pipe and fittings must

be purchased locally. The installed sidewall vent cap assembly

may be painted to match the exterior dècor.

Vertical Combustion Air Inlet

FIG. 19 Air Inlet Cap for Rooftop Termination

Follow the vertical combustion air inlet material and location

requirements as listed in the Vertical DirectAire Venting and

Rooftop Combustion Air section.

The rooftop combustion air inlet cap and the sidewall flue gas

outlet are located in different pressure zones in a DirectAire

Vent System.

This vent option is only available on units with modulating

burner firing. The unit can be identified by the “Category IV”

and the “M” prefix on the firing controls as noted on the unit’s

rating plate.

This vent system is installed with a Category IV flue and a

separate combustion air pipe to the outdoors. The Horizontal

DirectAire System terminates the flue at the sidewall and the

combustion air on a sidewall other than the sidewall where the

flue is located. The sidewall flue outlet and sidewall

combustion air intake terminate in different pressure zones.

17