Lochinvar PFN0502PM-F9 Installation Manual

HIGH EFFICIENCY COMMERCIAL BOILERS

DESIGNER’S GUIDE POWER-FIN® WATER HEATER

Up to 87%

Thermal Efficiency

www.Lochinvar.com

Dear Design-Build Contractor / Project Manager / Design Engineer,

At Lochinvar, we have long recognized the importance of innovation to any

product or service. Those who share in this business also face the challenge

of meeting constantly changing needs and energy effi ciency demands.

The designer’s guide you are now holding has been designed to make it more

convenient for you to select the perfect Lochinvar boiler for your projects

and provide correct specifi cations for your teams.

All information has been organized and presented in a succinct, easy-to-use

manner, so you can use and share information confi dently and with minimal

effort.

However, it is important to remember that this guide is not intended to

replace our installation manual. Installers should refer to our installation

manual for specifi c installation instructions and more detail. This guide will

make regular reference to other documents like the Installation & Operation

Manual that are available on the Lochinvar website, www.Lochinvar.com.

We hope this manual will make your work easier and more productive.

Thanks again for specifying the Lochinvar family of quality standard and

custom-built water heaters and boilers.

Sincerely,

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

1 2 3 4 5 6 7

8

Table of Contents

Combustion Air …………..…..……………………… Page 5

Venting ….…………………………………………….. Page 8

Gas ….….…………….……………….………………… Page 21

Water …..……………………..……………………….. Page 23

Electricity & Controls .…………………………….. Page 29

Other Details ..……………………………………….. Page 33

Appendix A ….……..…………………………………. Page 36

Appendix B …………………………………………… Page 41

.

3

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

At Lochinvar, we know that designing a water heater is hard work. Designing a domestic

water heating system is no picnic either. Demands for greater efficiency and elaborate

system control have made systems more complex.

This designers guide will break down the system requirements that match the Power-fin

water heater to assure safe operation, highly efficient heating and long life.

There are five major elements of domestic water heating system

design:

Combustion Air

Air

(See page 5)

Venting

(See page 8)

Electricity

& Controls

Venting

Gas

(See page 21)

Water

Water

Gas

(See page 23)

Electricity

& Controls

(See page 29)

Plus many other important details:

Locations Available Options

(See page 34 for “Location of Unit”) (See page 35 for “Options”)

High Altitude Requirements Suggested Piping Diagram

(See page 35 for “High Altitude Applications”) (See Appendix Section “A”)

4

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

Air

Chapter 1 – Combustion and

Ventilation Air

Everybody’s gotta breathe. Even water heaters need air. Air seems easy enough. You stand in

the equipment room and you breathe comfortably, don’t you? Open a door. Open a window.

This is a big room. There’s lots of air in here for the water heater.

The average person inhales 400 to 500 cubic feet of air in a 24 hour period. A one million Btu/hr

water heater will draw 226.38 cubic feet of air every MINUTE! A 20 by 20 by 8 foot equipment

room holds 3200 cubic feet of air. That’s a volume of air to last you or me over six days. A one

million Btu/hr Power-fin will consume 3200 cubic feet of air in 14 minutes.

Therefore, a good, easy flow of clean air is 100% necessary for clean, efficient combustion. So,

we need to provide a permanent and uninterrupted flow of air to the water heater. The Power-fin

water heater is designed to receive combustion air by one of TWO methods. The water heater

may draw combustion air from the room or have the air ducted directly to the water heater from

an exterior space.

This chapter explains the methods for “air from the room”.

Chapter 2 explains “air ducted directly to the water

heater”. Again, this chapter lists several techniques to

size the air openings that will deliver room air. If there are

other appliances in the room requiring air, their air

requirements must be including when sizing the air

openings.

Provisions for combustion and ventilation air must be

designed and installed in accordance with “Air for

Combustion and Ventilation”, of the latest edition of the National Fuel Gas Code, ANSI Z223.1, (in

Canada, the latest edition of CGA Standard B149 Installation Code for Gas Burning Appliances

and Equipment) or applicable provisions of the local building codes.

NEGATIVE PRESSURE IN THE EQUIPMENT ROOM

It is important to NEVER have a negative pressure on the equipment room. Exhaust fans are

popular in equipment rooms to exchange the air. If the exhaust fan pulls air OUT, then a negative

pressure occurs in the room. The combustion and ventilation air must be sized to supply all the

equipment PLUS the air for the exhaust fan.

COMBUSTION AND VENTILATION AIR SIZING CALCULATIONS

The sizing calculations in this section are based on “Free Area”. The louvers or grill used on the

air openings must have a net free area equal to or greater than the value derived in the

calculations. The Free Area in a louver or grill is defined as the open, unblocked area. The

louvers, grills, mesh, blades, all will block a given amount of space in the louver’s overall

dimension. Consult the louver manufacturer for exact net free area of the louver.

5

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

THE POWER-FIN COMES WITH LOUVER CONTACTS AS STANDARD EQUIPMENT. THE CONTACTS

WILL OPEN AND CLOSE A MOTORIZED LOUVER ON EACH CALL FOR HEAT.

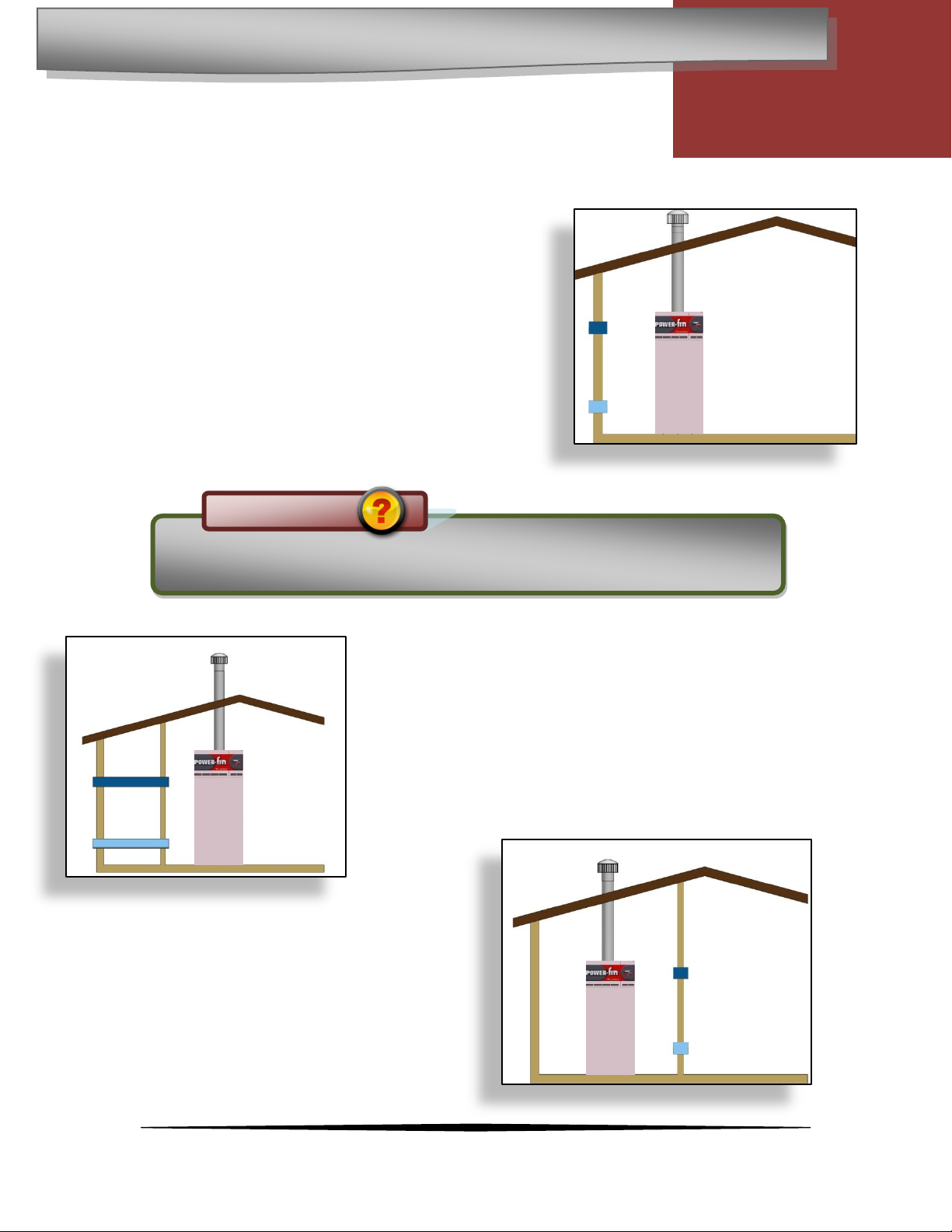

1. COMBUSTION AIR FROM OUTSIDE

If air is taken directly from outside the building with no

duct, provide two permanent openings to the

equipment room:

(a) Combustion air opening, with a minimum free area

of one square inch per 4000 Btu/hr input (5.5 cm² per

kW). This opening must be located within 12" (30 cm)

of the bottom of the enclosure.

(b) Ventilation air opening, with a minimum free area of

one square inch per 4000 Btu/hr input (5.5 cm² per

kW). This opening must be located within 12" (30 cm)

of the top of the enclosure.

2. COMBUSTION AIR THROUGH DUCTS

If combustion and ventilation air is taken from the outdoors using

a duct to deliver the air to the equipment room, each of the two

openings should be sized based on a minimum free area of one

square inch per 2000 Btu/hr (11 cm² per kW) of input.

3. COMBUSTION AIR FROM INTERIOR

SPACE

If air is taken from another interior space,

each of the two openings specified above

should have a net free area of one square

inch for each 1000 Btu/hr (22 cm² per kW) of

input, but not less than 100 square inches

(645 cm²).

6

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

THE COMBUSTION AIR MUST BE FREE OF ANY CONTAMINANTS OR CHEMICAL FUMES. SALTS,

REFRIGERANTS AND SOLVENTS INTRODUCED INTO THE COMBUSTION PROCESS WILL RESULT IN

THE FORMATION OF CORROSIVE ACIDS THAT WILL DAMAGE THE APPLIANCE AND THE VENT.

Caution

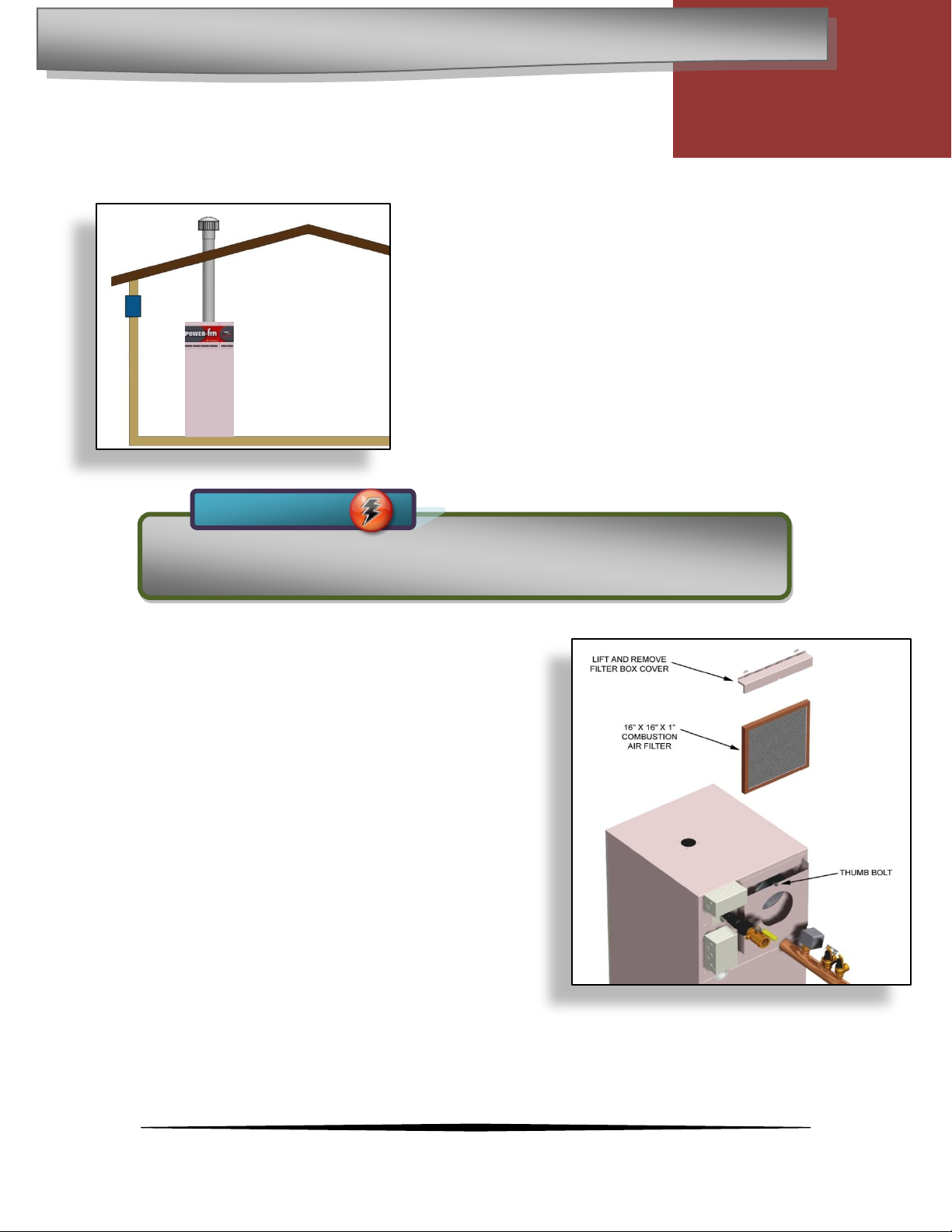

4. DIRECT OUTSIDE AIR, SINGLE OPENING

If a single combustion air opening is provided to bring

combustion air in directly from the outdoors, the opening

must be sized based on a minimum free area of one

square inch per 3000 Btu/hr (7 cm² per kW). This opening

must be located within 12" (30 cm) of the top of the

enclosure.

COMBUSTION AIR FILTER

The Power-fin has a built-in air filter as standard

equipment. Located at the combustion air inlet, the air

filter is provided to help ensure clean air is used for the

combustion process.

The filter size on models 502-1302 is 16" x 12" x 1"

(40.6 cm x 30.4 cm x 2.5 cm) and on models 1501 2001 is 16" x 16" x 1" (40.6 cm x 40.6 cm x 2.5 cm).

You can find these commercially available filters at any

home center or plumbing supply store.

7

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

CATEGORY I

Non-Condensing

Non-Positive Pressure

CATEGORY III

Non-Condensing

Positive Pressure

CATEGORY II

Condensing

Non-Positive Pressure

CATEGORY IV

Condensing

Positive Pressure

SPILLAGE OF FLUE PRODUCTS AND CARBON MONOXIDE EMISSIONS PRODUCED BY THE

COMBUSTION PROCESS CAN CAUSE SEVERE PERSONAL INJURY OR DEATH.

Warning

Venting

Chapter 2 – Venting

Venting is a difficult design element for the installation of a gas fired appliance. It has a variety of

choices, it has several available vent configurations, it has the important rules and regulations

that govern the installation and most important of all, it bears a requirement for human safety.

Lochinvar offers twelve different vent configurations on the Power-fin water heater to meet the

building’s requirements. There are six layouts or footprints across three different vent categories.

They are…

Vertical Vent with Air from the Equipment Room Category I, Category II or Category IV

Vertical Vent with Air from the Rooftop Category I, Category II or Category IV

Vertical Vent with Air from the Sidewall Category I, Category II or Category IV

Sidewall Vent with Air from the Equipment Room Category IV only

Sidewall Vent with Air from the Rooftop Category IV only

Sidewall Vent with Air from the Sidewall Category IV only

That’s a lot of choices. Plus there is an important

new consideration about specifying the correct

Firing Code. Allow me to overexplain.

Part 1

Vent Categories

Here is the traditional vent category diagram, standard throughout the industry. Lochinvar offers

twelve venting options that allow the Power-fin to be installed in any of three categories Category I, Category II and Category IV. Depending upon the “Firing Code” chosen, the Powerfin water heater will be factory trimmed for direct connection either Category I or Category IV

venting. Part 2 explains “Firing Codes” and their relationship to Category I and Category IV.

We’ll explain Category II later.

8

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

The four basic Vent Categories are determined by two characterisitics, Condensation and

Pressure.

CONDENSING VERSUS NON-CONDENSING

The possibility for condensation to form in a stack is based on the temperature of the flue

products. If the temperature of the flue products remains consistantly above dewpoint,

condensation will not form. If the temperature drops below dewpoint, condensation will form.

So how does condensation apply to the Power-fin? Easy. The Power-fin’s firing rate determines

the stack temperature. Depending upon the model, the Power-fin may operate at a high firing

rate producing a high stack temperature to stay above dewpoint or it may modulate down to a low

firing rate producing a low stack temperature that allows the flue gas temperature to drop below

dewpoint. This is explained further in Part 2, “Firing Code”.

POSITIVE VERSUS NON-POSITIVE

Positive or non-positive pressure in the vent is determined by the capacity of the appliance’s

blower AND the diameter of the vent in order to PUSH the flue products. If the same appliance is

connected to a larger diameter stack, the blower CANNOT PUSH the flue products. The positive

pressure goes negative, or non-positive.

So how does pressure apply to the Power-fin? Again, easy. Depending upon the model, the

Power-fin will be factory trimmed for a small vent connection to positive vent or a large vent

connection to non-positive vent. This is explained further in Part 2, “Firing Code”.

Part 2

Firing Codes

The model number for all Lochinvar products has a “Firing Code”.

Example: PFN0752PM-M9

“PFN0752PM” is the basic model number / “-M9” is the Firing Code.

This collection of letters and numbers has a specific meaning. The Firing Code is important

because it specifies a particular feature set that is factory trimmed to match the planned venting

system. With the correct firing code, Lochinvar will factory trim your water heater to fire at correct

input rate and provide the correct vent connection to meet your needs.

There are THREE basic firing codes. Here’s how they work.

F9 models / Power-fin 0502-1302 only

“F9” means “Full Fire” or 100% Full Fire with no modulation. (No Turndown)

Temperature – Firing at 100% of input rate, the Power-fin 0502-1302-F9 models will always

produce a high stack temperature. Non-Condensing.

Pressure – The Power-fin 0502-1302-F9 models are factory trimmed with a large diameter vent

connection. The blower CANNOT PUSH the flue products through a similarly sized stack

therefore creating a non-positive pressure. Non-Positive Pressure.

F9 models are Category I.

B9 models / Power-fin 1501-2001 only

“B9” means “Bi-level Fire” or 50% to 100% firing rate. (2:1 Turndown)

Temperature – Even firing at the lowest input rate of 50%, the Power-fin 1501-2001-B9 models

will produce a high stack temperature. Non-Condensing.

9

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

CATEGORY I

Non-Condensing

Non-Positive Pressure

F9 or B9 Models

CATEGORY III

CATEGORY II

CATEGORY IV

Condensing

Positive Pressure

M9 Models

Pressure –The Power-fin 1501-2001-B9 models are factory trimmed with a large diameter vent

connection. The blower CANNOT PUSH the flue products through a similarly sized stack

therefore creating a non-positive pressure. Non-Positive Pressure.

B9 models are Category I.

M9 models / Power-fin 0502-2001

“M9” means “Modulating” Fire or 20% to 100% firing rate. (5:1 Turndown)

Temperature – When the Power-fin 0502-2001-M9 models modulate down to their lowest input

rate of 20%, they produce a comparatively low stack temperature that will likely cause

condensation to occur in the stack. Condensing.

Pressure – The Power-fin 0502-2001-M9 models are factory trimmed with a small diameter vent

connection. The blower CAN PUSH the flue products through a similarly sized stack therefore

creating a positive pressure. Positive Pressure.

M9 models are Category IV.

Part 3

Choose your vent configuration

Now, that you know your vent category and the matching Firing Code, it’s time to choose the vent

configuration or system layout. Let’s start with Category IV venting.

Category IV Venting

This is likely to be the most common because it offers modulation and it offers the largest variety

of vent configurations. All six layouts listed on page eight can be installed as Category IV

venting. The following pages offer a diagram of the six layouts, important design information and

a list of the available vent kits that are required to install some of these configurations.

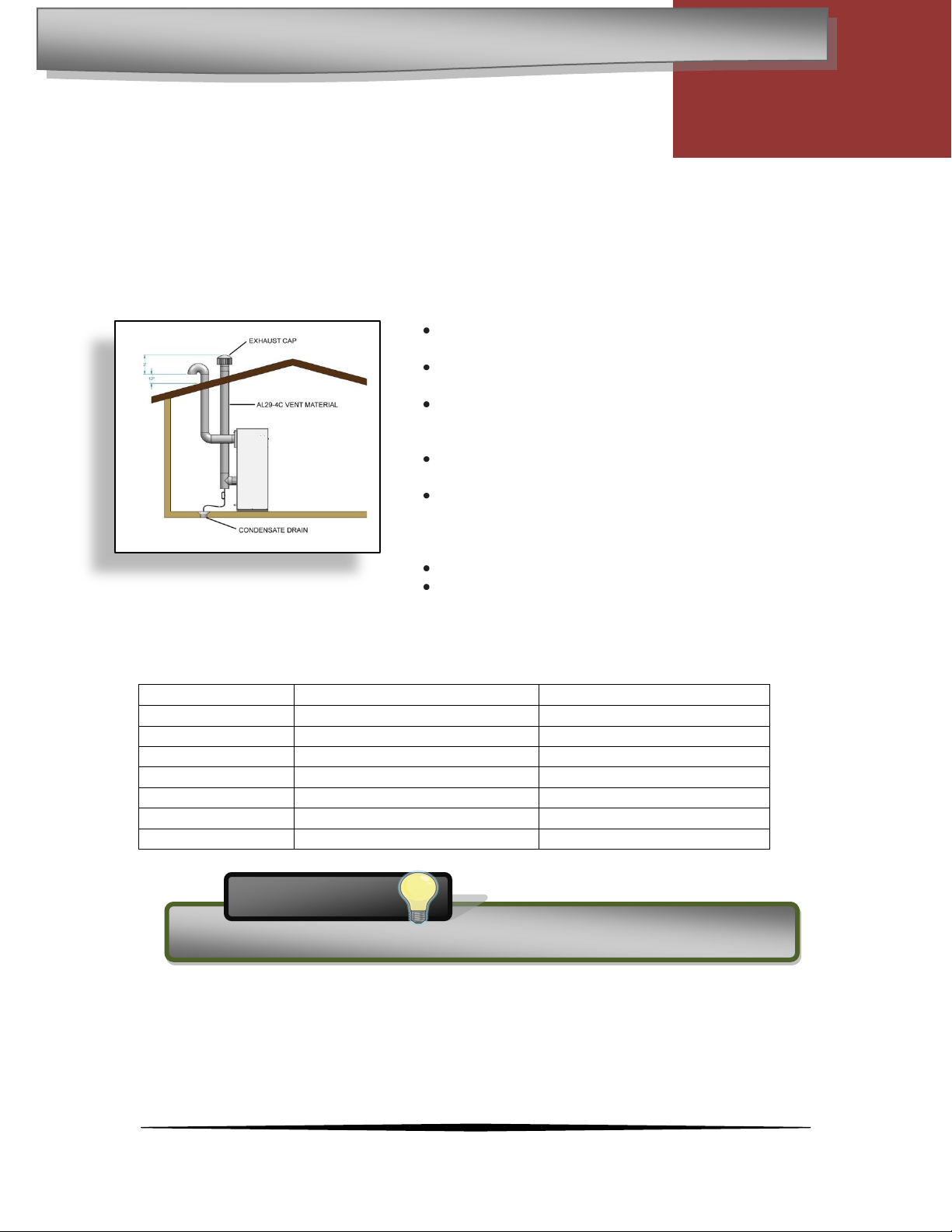

Vertical Vent with Air from the Equipment Room Category IV

Vertical Vent with Air from the Rooftop Category IV

Vertical Vent with Air from the Sidewall Category IV

Sidewall Vent with Air from the Equipment Room Category IV only

Sidewall Vent with Air from the Rooftop Category IV only

Sidewall Vent with Air from the Sidewall Category IV only

10

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

MODEL

CAT IV VENT CONNECTION

PFN0502PM-M9

4"

PFN0752PM-M9

5"

PFN1002PM-M9

6"

PFN1302PM-M9

8"

PFN1501PM-M9

6"

PFN1701PM-M9

7"

PFN2001PM-M9

8"

THIS CONFIGURATION MAY BE INSTALLED AS CATEGORY II. SEE PAGE 17 FOR DETAILS.

Tip

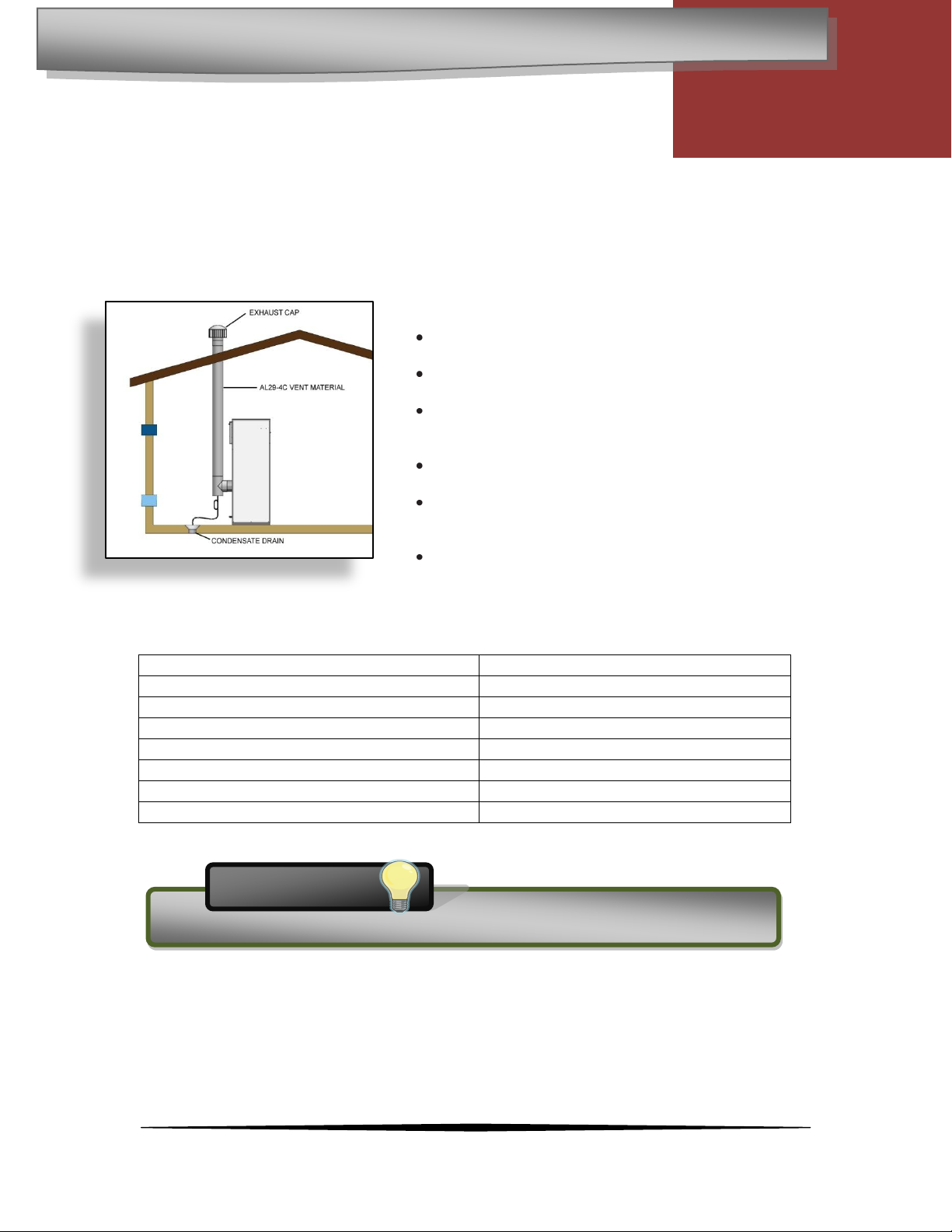

CATEGORY IV VENTING – “M9” FIRING CODE

VERTICAL VENT WITH COMBUSTION AIR FROM EQUIPMENT ROOM.

The flue outlet terminates on the rooftop. The combustion air is drawn

naturally from the equipment room.

BULLET POINTS

Category IV vent material is required, such as

AL29-4C.

All vent joints and seams must be sealed gastight

and may not be common vented.

The vent must have a condensate drain with

provisions to properly collect and dispose of any

condensate that may occur in the vent pipe.

All vent material for this configuration including

vent termination will be obtained locally.

The air is delivered to the equipment room by

means defined in Chapter 1 of this designer’s

guide.

Maximum distance – 50 equivalent feet of vent.

The Category IV Power-fin with a model number that features the M9 (Modulating Fire) Firing

Code will be factory trimmed for Category IV vent connection in the following dimensions.

11

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

MODEL

CAT IV VENT CONNECTION

AIR INLET CONNECTION

PFN0502PM-M9

4"

5"

PFN0752PM-M9

5"

5"

PFN1002PM-M9

6"

6"

PFN1302PM-M9

8"

6"

PFN1501PM-M9

6"

6"

PFN1701PM-M9

7"

7"

PFN2001PM-M9

8"

8"

THIS CONFIGURATION MAY BE INSTALLED AS CATEGORY II. SEE PAGE 17 FOR DETAILS.

Tip

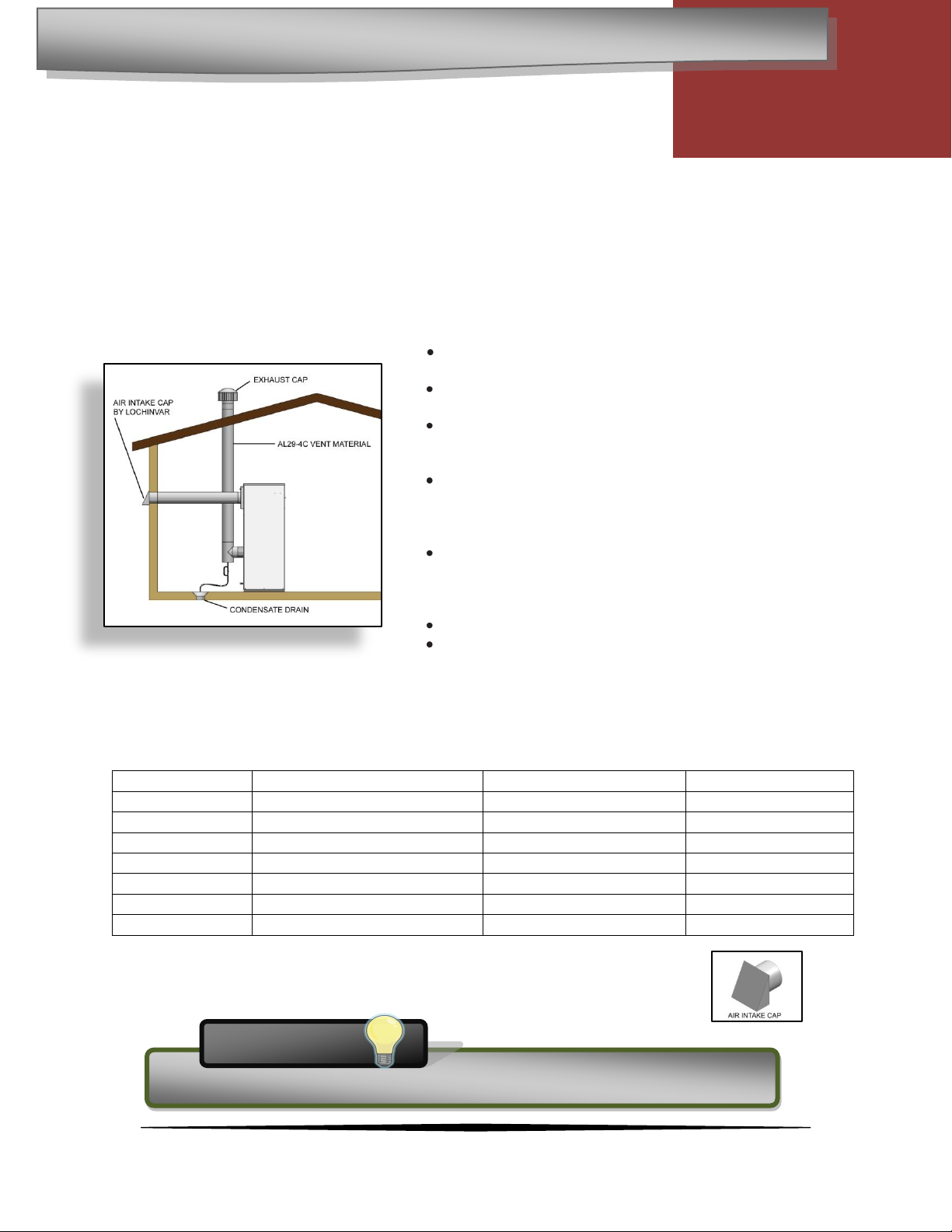

CATEGORY IV VENTING – “M9” FIRING CODE

VERTICAL VENT WITH COMBUSTION AIR FROM THE ROOFTOP.

The flue outlet terminates on the rooftop. The combustion air is ducted to

the appliance from outdoors through the rooftop. This is true Direct Vent

with the flue termination and the air inlet port in the same pressure zone.

BULLET POINTS

Category IV vent material is required, such as

AL29-4C.

All vent joints and seams must be sealed gastight

and may not be common vented.

The vent must have a condensate drain with

provisions to properly collect and dispose of any

condensate that may occur in the vent pipe.

All other vent material for this configuration

Including vent termination will be obtained locally.

The air is delivered to the appliance via a separate

duct. The air intake material can be galvanized

pipe, PVC, CPVC or ABS and must be sealed

airtight.

Maximum distance – 50 equivalent feet of vent.

Maximum distance – 50 equivalent feet of air intake.

The Category IV Power-fin with a model number that features the M9 (Modulating Fire) Firing

Code will be factory trimmed for Category IV vent and air inlet connections in the following

dimensions.

12

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

MODEL

CAT IV VENT CONNECTION

AIR INLET CONNECTION

SAK KIT NUMBER

PFN0502PM-M9

4"

5"

SAK3003

PFN0752PM-M9

5"

5"

SAK3003

PFN1002PM-M9

6"

6"

SAK3004

PFN1302PM-M9

8"

6"

SAK3004

PFN1501PM-M9

6"

6"

SAK3004

PFN1701PM-M9

7"

7"

SAK3005

PFN2001PM-M9

8"

8"

SAK3006

THIS CONFIGURATION MAY BE INSTALLED AS CATEGORY II. SEE PAGE 17 FOR DETAILS.

Tip

CATEGORY IV VENTING – “M9” FIRING CODE

VERTICAL VENT WITH COMBUSTION AIR FROM THE SIDEWALL

(DirectAire).

The flue outlet terminates on the rooftop. The combustion air is ducted to

the appliance from outdoors through the sidewall. This is not true Direct

Vent with the flue termination and the air inlet port in different pressure

zones.

BULLET POINTS

Category IV vent material is required, such as

AL29-4C.

All vent joints and seams must be sealed gastight

and may not be common vented.

The vent must have a condensate drain with

provisions to properly collect and dispose of any

condensate that may occur in the vent pipe.

The sidewall exhaust cap must be provided by

Lochinvar. See table below for kit part numbers.

All other vent material for this configuration will be

obtained locally.

The air is delivered to the appliance via a separate

duct. The air intake material can be galvanized

pipe, PVC, CPVC or ABS and must be sealed

airtight.

Maximum distance – 50 equivalent feet of vent.

Maximum distance – 50 equivalent feet of air

The Category IV Power-fin with a model number that features the M9 (Modulating Fire) Firing

Code will be factory trimmed for Category IV vent and air inlet connections in the following

dimensions. The table also includes the kit part numbers for the sidewall exhaust caps which

must be used.

intake.

The main component in Sidewall Air Intake Kit is the Sidewall Air Intake Cap.

13

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

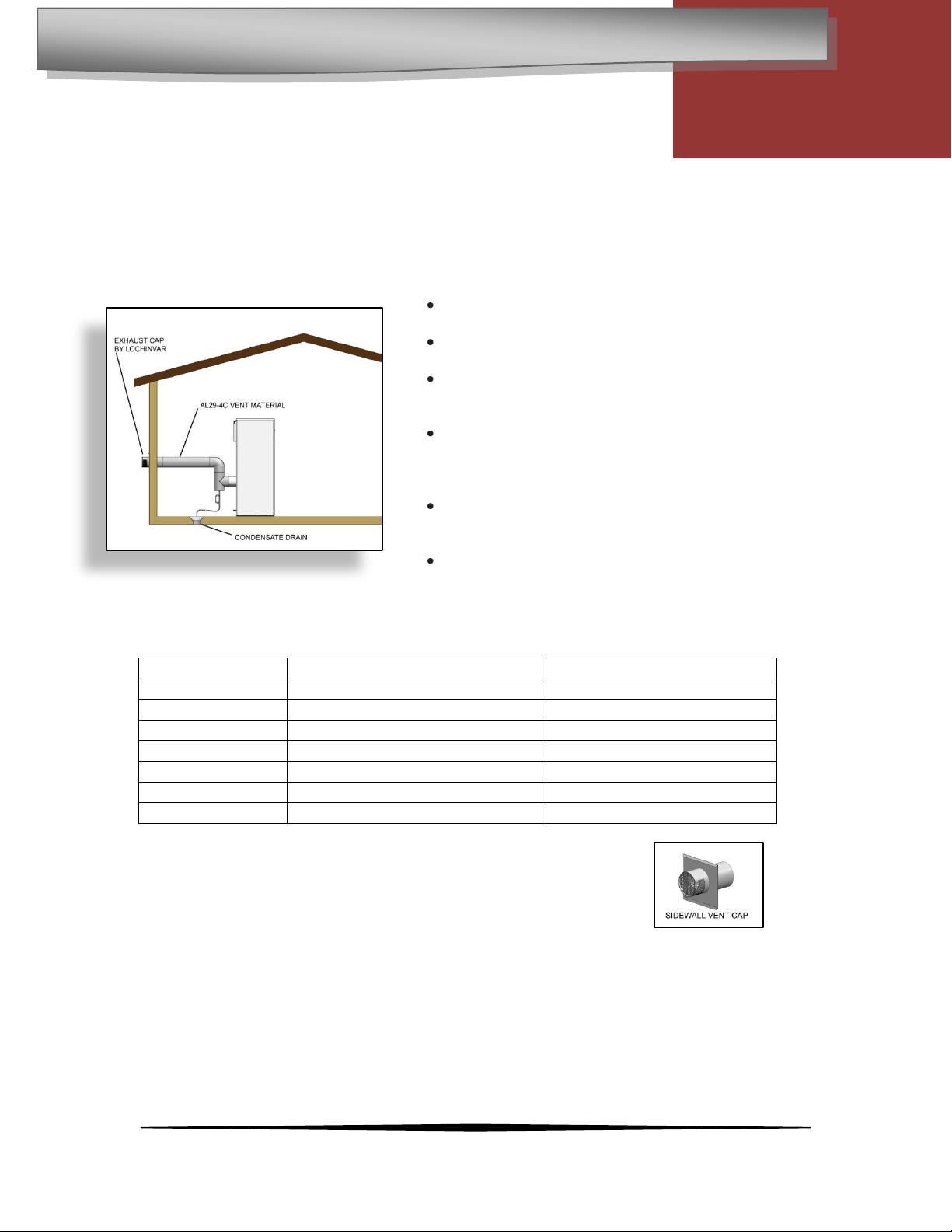

MODEL

CAT IV VENT CONNECTION

SVK KIT NUMBER

PFN0502PM-M9

4"

SVK3069

PFN0752PM-M9

5"

SVK3070

PFN1002PM-M9

6"

SVK3018

PFN1302PM-M9

8"

SVK3068

PFN1501PM-M9

6"

SVK3018

PFN1701PM-M9

7"

SVK3019

PFN2001PM-M9

8"

SVK3068

CATEGORY IV VENTING – “M9” FIRING CODE

SIDEWALL VENT WITH COMBUSTION AIR FROM EQUIPMENT ROOM.

The flue outlet terminates out the sidewall. The combustion air is drawn

naturally from the equipment room.

BULLET POINTS

Category IV vent material is required, such as

AL29-4C.

All vent joints and seams must be sealed gastight

and may not be common vented.

The vent must have a condensate drain

with provisions to properly collect and dispose of

any condensate that may occur in the vent pipe.

The sidewall exhaust cap must be

provided by Lochinvar. See table below for kit part

numbers. All other vent material for this

configuration will be obtained locally.

The air is delivered to the equipment room by

means defined in Chapter 1 of this designer’s

guide.

Maximum distance - 50 equivalent feet of vent.

The Category IV Power-fin with a model number that features the M9 (Modulating Fire) Firing

Code will be factory trimmed for Category IV vent connection in the following dimensions. The

table also includes the kit part numbers for the sidewall exhaust caps which must be used.

The main component in Sidewall Vent Kit is the Sidewall Exhaust Cap.

14

LOCHINVAR CORPORATION

300 MADDOX SIMPSON PKWY

LEBANON, TN 37090

www.lochinvar.com

Designer’s Guide / Power-fin Water Heater

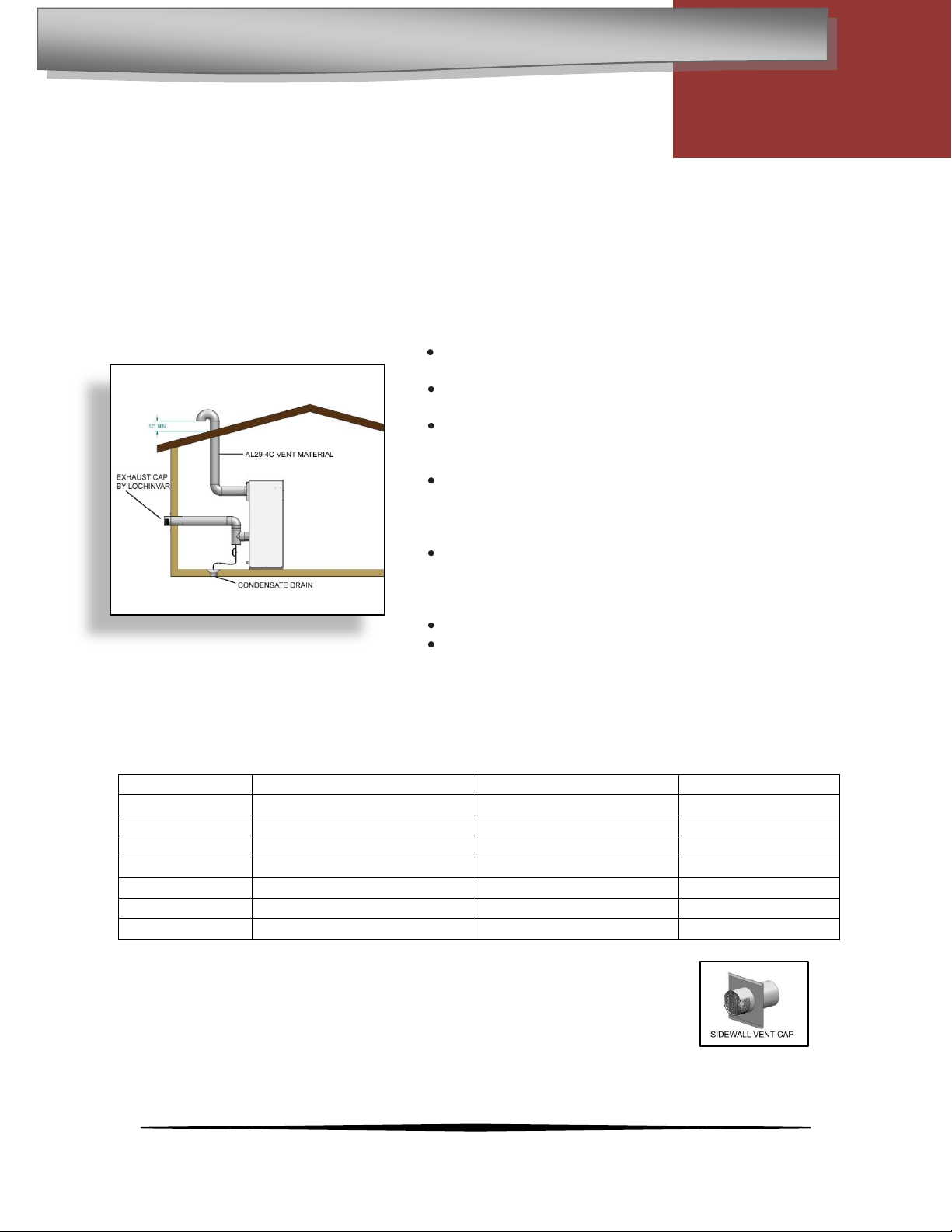

MODEL

CAT IV VENT CONNECTION

AIR INLET CONNECTION

SVK KIT NUMBER

PFN0502PM-M9

4"

5"

SVK3069

PFN0752PM-M9

5"

5"

SVK3070

PFN1002PM-M9

6"

6"

SVK3018

PFN1302PM-M9

8"

6"

SVK3068

PFN1501PM-M9

6"

6"

SVK3018

PFN1701PM-M9

7"

7"

SVK3019

PFN2001PM-M9

8"

8"

SVK3068

CATEGORY IV VENTING – “M9” FIRING CODE

SIDEWALL VENT WITH COMBUSTION AIR FROM THE ROOFTOP

(DirectAire).

The flue outlet terminates out the sidewall. The combustion air is ducted

to the appliance from outdoors through the rooftop. This is not true Direct

Vent with the flue termination and the air inlet port in different pressure

zones.

BULLET POINTS

Category IV vent material is required, such as

AL29-4C.

All vent joints and seams must be sealed gastight

and may not be common vented.

The vent must have a condensate drain with

provisions to properly collect and dispose of

any condensate that may occur in the vent pipe.

The sidewall exhaust cap must be provided by

Lochinvar. See table below for kit part numbers.

All other vent material for this configuration will be

obtained locally.

The air is delivered to the appliance via a separate

duct. The air intake material can be galvanized

pipe, PVC, CPVC or ABS and must be sealed

airtight.

Maximum distance - 50 equivalent feet of vent.

Maximum distance - 50 equivalent feet of air intake.

The Category IV Power-fin with a model number that features the M9 (Modulating Fire) Firing

Code will be factory trimmed for Category IV vent and air inlet connections in the following

dimensions. The table also includes the kit part numbers for the sidewall exhaust caps which

must be used.

The main component in Sidewall Vent Kit is the Sidewall Exhaust Cap.

15

Loading...

Loading...