Page 1

LCB-I-O Rev B

MULTI-TEMPERATURE

LOOP CONTROL BOARD

INSTRUCTIONS

Models: KB 81 - 286, KBXL 400 -

801, WB 51 - 211, and

WH 55 - 399

WARNING

IMG00116

This manual must only be used

by a qualifi ed heating installer /

service technician. Read all

instructions, including this manual,

the Installation and Operation

Manual, and the Service Manual,

before installing. Perform steps in

the order given. Failure to comply

could result in severe personal

injury, death, or substantial property

damage.

Save this manual for future reference.

Page 2

Contents

1. INTRODUCTION ......................................................... 3

2. COMPONENTS AND HYDRONIC PIPING ................. 4-6

3. WIRING REQUIREMENTS

Line Voltage Connections ............................................ 7

Loop Sensors .............................................................. 7

Mixing Valves .............................................................. 7

Wiring of the Cascade ................................................. 7

4. BOILER PARAMETERS SETUP

Cascade Communication Setup ................................... 10

To Access Cascade Address ....................................... 10

3-Way Valve Setup ....................................................... 10

24-Hour Pump In-Activity Operation ............................. 11

To Set Time for SYS Pump Delay ................................ 11

5. BASIC OPERATION ..................................................... 12

Protections .................................................................. 12

Initial ...................................................................... 12

Error Mode ............................................................ 12

Forced Change ..................................................... 13

Revision Notes ................................................... Back Cover

Hazard defi nitions

The following defi ned terms are used throughout this manual to bring attention to the presence of hazards of various risk levels

or to important information concerning the life of the product.

DANGER

WARNING

CAUTION

CAUTION

NOTICE

DANGER indicates an imminently hazardous situation which, if not avoided, will result in death or serious

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

CAUTION indicates a potentially hazardous situation which, if not avoided, may result in minor or

moderate injury.

CAUTION used without the safety alert symbol indicates a potentially hazardous situation which, if not

avoided, may result in property damage.

NOTICE indicates special instructions on installation, operation, or maintenance that are important but

not related to personal injury or property damage.

2

Page 3

Loop Control Board Instructions

1 Introduction

The information contained in this manual provides installation and operation instructions for the addition of the MultiTemperature Loop Control Board in conjunction with the Lochinvar Knight (KB(N/L) 81-286), Knight XL (KB(N/L) 400 -801),

Wall Mount (WB(N/L) 51-211, WH(N/L) 55-399) boilers.

When connected on the Cascade communication bus to the boiler control, the Multi-Temperature Loop Control Board

(MTLCB) will actively control the water temperature supplied, up to three (3) loops. The MTLCB will control the 3-way mixing

valves and pumps for each of these loops, and provide the actual loop temperatures to the boiler for display.

The MTLCB has been tested, and is in compliance with the following standards:

• CSA Standard C22.2 No 0 - General Requirements - Canadian Electrical Code, Part II

• CSA Standard C22.2 No 24 - Temperature-Indicating & Regulating Equipment

• ANSI/UL 873 - Temperature Indicating and Regulating Equipment

3

Page 4

2 Components and Hydronic Piping

Components

Loop Control Board Instructions

The multi-temperature loop control consists of four (4)

major components in conjunction with the boiler system.

These components are as follows:

• Multi-Temperature Loop Control Board

• Loop Temperature Sensors

• Mixing Valves

• Loop Pumps

In order for the system to work properly the components

listed above must be installed correctly. Reference the

piping illustrations included in this section (FIG.’s 2-1 and

2-2) for suggested guidelines in piping.

NOTICE

1. Multi-Temperature Loop Control Board (MTLCB):

The MTLCB communicates with the boiler’s SMART

SYSTEM control for operation of the mixing valves and

loop pumps to regulate each loop temperature. The

power supply required for the MTLCB is 120 V/60 Hz

at less than 12 amps.

Please note that the piping illustrations

(FIG.’s 2-1 and 2-2) are meant to show

system piping concept only, the installer

is responsible for all equipment and

detailing required by local codes.

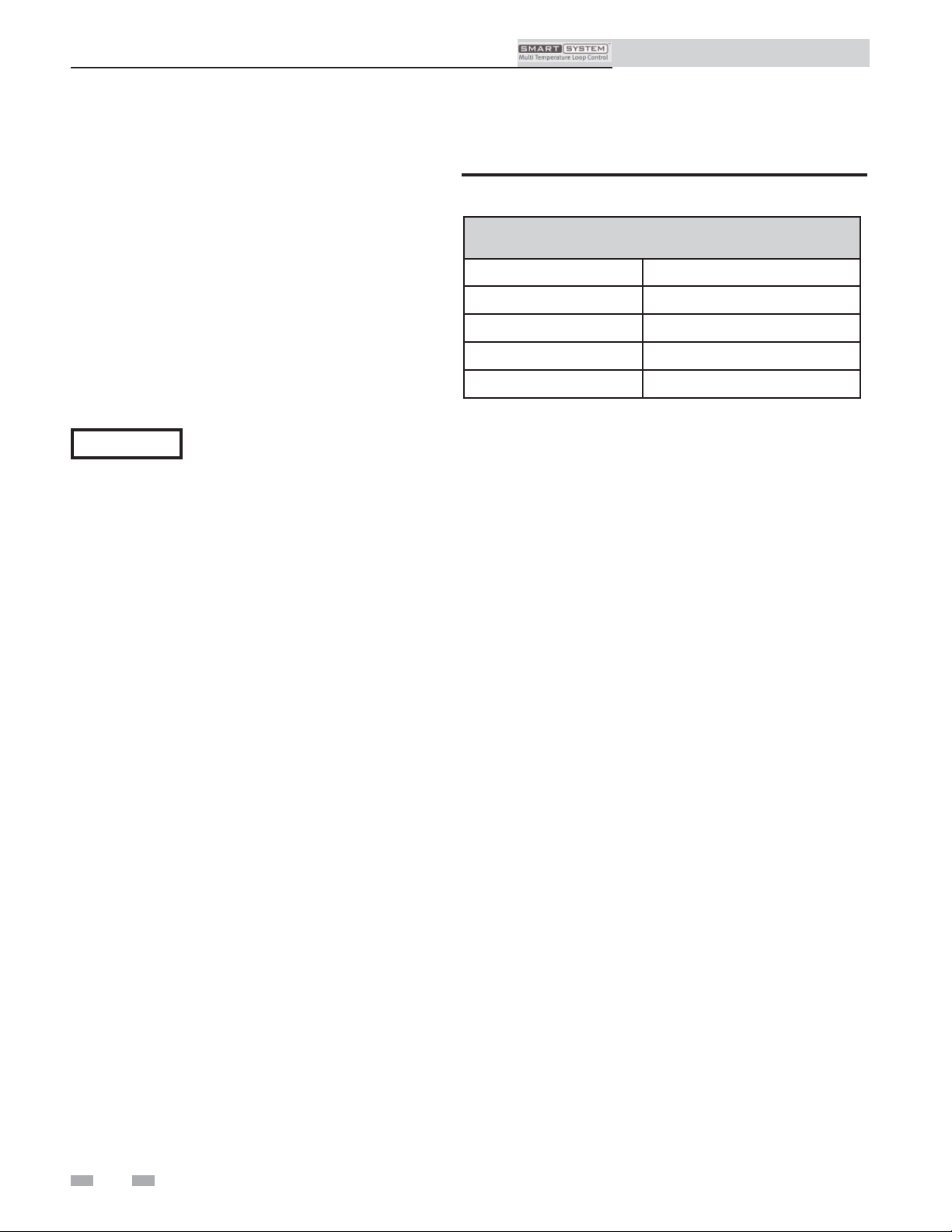

Table 2A 3-Way Valve Requirements

3-Way Valve Requirements

Item Description Limit

Power Supply 24 VAC

Maximum Load .25 Amps

Control Signal 3-Point (Open, Close, Com)

Action Type Floating / Modulating

4. Loop Pumps:

Field supplied. The MTLCB provides 120 VAC power to

operate three (3) loop pumps. The maximum current rating

for each pump cannot exceed 1.8 amps.

2. Loop Temperature Sensors:

The loop temperature sensors measure the temperature

of each loop. Each sensor should be placed on the

discharge side of the loop pump as shown in FIG.’s

2-1 and 2-2 on pages 5 and 6 of this manual. Use

only the three (3) NTC thermistor sensors supplied. If a

replacement sensor is needed, order Lochinvar part

number TST2032. For the best reading, the sensor

should be securely fastened to the pipe and insulated.

3. Mixing Valves:

Field supplied. The MTLCB is designed to control

24 VAC fl oating 3-way mixing valves with open and

close signals. These valves have an actuator (motor)

time from full open to full close. The time in seconds

must be consistent across all 3-way valves installed. For

information on programming the mixing valve time

into the boiler, reference Section 4 , Boiler Parameter

Setup. For 3-way valve requirements, reference Table

2A.

4

Page 5

Loop Control Board Instructions

2 Components and Hydronic Piping (continued)

Figure 2-1_Single Boiler Multi-Temperature

PRESSURE

REDUCING VALVE

BACKFLOW

PREVENTER

MAKE

UP

WATER

AIR SEPARATOR

BALL VALVE

(TYPICAL)

DRAIN POINT

(TYPICAL)

LOOP

SENSOR

(TYPICAL)

PRESSURE

GAUGE

SYSTEM

SUPPLY

SENSOR

EXPANSION

TANK

MAY SUBSTITUTE

LOW LOSS HEADER

TEMPERATURE

LOOP #1

NOT TO EXCEED 4 PIPE DIA.

OR MAX. OF 12" APART

Y-STRAINER

(RECOMMENDED)

BOILER

CIRCULATOR

FLOW CHECK

VALVE

TEMPERATURE

LOOP #2

TEMPERATURE

LOOP #3

DOMESTIC

HOT WATER

CIRCULATOR

MIXING VALVES

(TYPICAL)

HOT

WATER

OUT

ANTI-SCALD

MIXING VALVE

COLD

WATER

IN

NOTICE

NOTICE

UNION

(TYPICAL)

TEMPERATURE /

PRESSURE

GAUGE

DRAIN

BOILER

BOILER

INDIRECT

DHW TANK

INDIRECT

DHW

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

A system supply sensor MUST BE installed for proper boiler operation to occur.

5

Page 6

2 Components and Hydronic Piping

Figure 2-2_Single Boiler Multi-Temperature DHW Zoned

Loop Control Board Instructions

PRESSURE

REDUCING VALVE

BACKFLOW

PREVENTER

MAKE

UP

WATER

AIR SEPARATOR

BALL VALVE

(TYPICAL)

DRAIN POINT

(TYPICAL)

LOOP

SENSOR

(TYPICAL)

PRESSURE

GAUGE

SYSTEM

SUPPLY

SENSOR

EXPANSION

TANK

MAY SUBSTITUTE

LOW LOSS HEADER

TEMPERATURE

LOOP #1

NOT TO EXCEED 4 PIPE DIA.

OR MAX. OF 12" APART

Y-STRAINER

(RECOMMENDED)

BOILER

CIRCULATOR

TEMPERATURE

LOOP #2

TEMPERATURE

LOOP #3

MIXING VALVES

(TYPICAL)

DOMESTIC

HOT WATER

CIRCULATOR

FLOW CHECK

VALVE

HOT

WATER

OUT

ANTI-SCALD

MIXING VALVE

COLD

WATER

IN

NOTICE

NOTICE

6

UNION

(TYPICAL)

TEMPERATURE /

PRESSURE

GAUGE

DRAIN

BOILER

INDIRECT

DHW TANK

Please note that these illustrations are meant to show system piping concept only, the installer is responsible

for all equipment and detailing required by local codes.

A system supply sensor MUST BE installed for proper boiler operation to occur.

Page 7

3 Wiring Requirements

Loop Control Board Instructions

WARNING

NOTICE

CAUTION

ELECTRICAL SHOCK HAZARD – For

your safety, turn off electrical power supply

before making any electrical connections

to avoid possible electric shock hazard.

Failure to do so can cause severe personal

injury or death.

Wiring must be N.E.C. Class 1.

If original wiring as supplied with boiler

must be replaced, use only type 105°C

wire or equivalent.

Boiler must be electrically grounded as

required by National Electrical Code

ANSI/NFPA 70 – latest edition.

Label all wires prior to disconnection when

servicing controls. Wiring errors can

cause improper and dangerous operation.

Installation must comply with:

1. National Electrical Code and any other national, state,

provincial, or local codes, or regulations.

2. In Canada, CSA C22.1 Canadian Electrical Code Part 1,

and any local codes.

Line voltage connections

1. Connect 120 VAC power wiring to the line voltage

terminal strip in the junction box, as shown in FIG. 3-1

on page 8.

2. Wire the loop pumps (provided by the installer) as shown

in FIG. 3-1.

Loop sensors

1. Install the kit provided loop temperature sensors (see

FIG.’s 2-1 and 2-2).

2. Route the sensor wires through a knockout on the side of

the MTLCB (FIG. 3-1).

3. Connect the loop temperature sensors to the SEN1, SEN2,

and SEN3 terminals on the MTLCB.

Mixing valves

1. Install the mixing valves as shown in FIG.’s 2-1 and 2-2.

2. Route the mixing valve wires through a knockout on the

right side of the MTLCB (FIG. 3-1).

3. Connect the mixing valve wires to terminals MV1, MV2,

and MV3 on the MTLCB.

Wiring of the cascade

Communication between the boiler and the MTLCB

is accomplished using shielded, 2-wire twisted pair

communication cable. Try to keep the cable as short as

possible.

1. Connect one end of the twisted pair wires to Cascade

terminals A and B on the Low Voltage Connection Board

of the boiler (see FIG. 3-2 on page 9).

2. Connect the other end of the twisted pair wires to MTLCB

terminals A and B (FIG. 3-1).

3. Connect the shield wires to one of the shield terminals

on the Low Voltage Connection Board (FIG. 3-2) and the

MTLCB (FIG. 3-1).

NOTICE

The loop pump connections provide 120

VAC power to the pumps at a maximum

current rating of 1.8 amps for each pump.

7

Page 8

3 Wiring Requirements

LOOP SENSOR 1

LOOP SENSOR 2

LOOP SENSOR 3

SEN 2SEN 1

SEN 3

BA

A

B

SHIELD

CASCADE WIRING

VALVE FUSE

1.25 A

5.0 A

P

UMP

F

US

E

P

UM

P

1

P

UM

P

2

P

UM

P

3

N

L

N

N

N

L

L

L

NEUTRAL

LINE

120 V

SUPPLY

LOOP

PUMP 3

LOOP

PUMP 2

LOOP

PUMP 1

FI

E

L

D

S

UP

P

LIE

D

TO

BOILER

3

3-WAY

MIXING

VALVE

2

3-WAY

MIXING

VALVE

1

3-WAY

MIXING

VALVE

CLS

OPN

COM

CLS

OPN

COM

CLS

OPN

COM

FIELD SUPPLIED

COM

CLS

OPN

MV3

OPN

OPN

CLS

CLS

MV2MV1

1

20

VA

C

GND

GROUND

IMG00112

Figure 3-1_Multi-Temperature Loop Control Board (MTLCB)

Loop Control Board Instructions

8

Page 9

Loop Control Board Instructions

3 Wiring Requirements (continued)

Figure 3-2_Terminal Strip Connections to the Boiler’s Low Voltage Connection Board (Knight/Knight XL shown

below for illustration purposes)

IMG00103

LOW VOLTAGE CONNECTION BOARD

ENABLE

CONTACTS

9

Page 10

Loop Control Board Instructions

4 Boiler Parameters Setup

Once the wiring requirements of all the MTLCB components are complete, the next step is to adjust the following parameters

through the boiler’s display:

• Cascade Address

• Loop Temperature Settings

• 3-Way Valves

• Pumps

Power ON the boiler and place into Shutdown Mode, leaving the MTLCB powered OFF. With the boiler in Shutdown Mode,

all calls for heat are disabled and the parameters listed above can be adjusted.

Cascade communication setup

When the MTLCB is used with a single boiler, the boiler must

be programmed as a Cascade Leader by setting its Cascade address to 0.

Figure 4-1_Cascade Screen

To access cascade address:

1. While on the Menu Selection Screen, select [CONTROL

MODES].

2. In the Control Modes Menu (FIG. 4-1), select [CASCADE

ADDRESS] and set to [0].

3. Press the RIGHT SELECT [SAVE] key.

4. Press the [HOME] key to exit and download all parameters.

To adjust the set points for each space heat/loop, reference the Service Manual for a detailed explanation.

The 3-Way Mixing Valve Time can be accessed as shown below:

3-way valve setup

NOTICE

1. Press and hold the LEFT SELECT [MENU] key.

2. Enter the pass code.

3. Scroll down and select [TEMPERATURE SETTINGS].

4. Scroll down and select 3-Way Valve Time by pressing the NAVIGATION dial (FIG. 4-10.

5. Scroll to the intended value.

6. Press the RIGHT SELECT [SAVE] key.

7. Exit one level.

Please note that the brackets ([]) denote screen status.

Once all the parameters have been adjusted for the application, power ON the MTLCB. TX and RX LED’s will light up to signify

data is being sent and received from the boiler’s control. With successful communication, the SH1, SH2, and SH3 temperatures

can be read with a clockwise rotation of the NAVIGATION dial (see FIG. 4-3). If successful communication does not occur,

reference FIG. 4-1 for set up of the Cascade address.

Figure 4-2_SH1, SH2, and SH3 Screen

Figure 4-3_3-Way Valve Time Screen

10

Page 11

4 Boiler Parameters Setup (continued)

Figure 4-4_System Pump Delay Screen

Loop Control Board Instructions

24-hour pump in-activity operation

In the event there is not a call for heat in 24 hours, the loop pump will operate for the time of the system pump delay setting.

To set time for SYS PUMP DELAY:

1. While still on the Menu Selection Screen, scroll down and select [CIRCULATION PUMPS] by pressing the NAVIGATION

dial.

2. In the CIRCULATION PUMPS Menu (FIG. 4-4), select [SYS PUMP DELAY], scroll to the intended time value and press the

RIGHT SELECT [SAVE] key.

11

Page 12

5 Basic Operation

Loop Control Board Instructions

The MTLCB serves as the controlling device for up to three

(3) individual loops, branching off the system loop of a space

heating system. It will control each loop pump and mixing

valve position in order to satisfy the set point for that loop.

By installing the sensors (provided in kit) on the pipe, after the

pump, a mixed temperature is relayed to the boiler display.

Each thermostat input to the boiler should receive a loop

temperature feedback for proper operation. Using this input,

the MTLCB operates the 3-way valve to the correct position

for mixed water supply. The pump will run continuously

with the valve positioning until the thermostat set point is

met or a Protection Mode is active.

When demands of more than one loop are active, the system

set point is maintained at the highest space heat set point

enabled. All enabled loops are actively satisfi ed together, with

up to three (3) different set points mixing down for each set

point temperature below the system.

NOTICE

Once a thermostat demand is enabled, the pump will run

for one (1) minute to stabilize loop temperature before

opening to system water. Note: For smaller systems, the

use of Ramp Delay is recommended to prevent short cycling

and extend runtime. At this time the 3-way valve will adjust,

open to a calculated initial position based on the differential

of the sensed temperature and set point. The MTLCB will

continue to raise the mixed temperature of the loop toward its

individual set point, while continuously relating to the loop’s

sensor input by a specifi c algorithm.

At the end of a loop demand cycle, the pump powers off, and

the valve will move to the fully closed position.

At the beginning of successful

communication, all 3-way valves will see

a signal to close 125% of the time value

entered in the General Setup Section,

FIG. 4-3 on page 10.

Protections

Initial

In the event the sensed temperature continues to exceed the

set point (set point + offset - 2°F, but within the set point +

20°F) for a given loop, a Protection Mode is entered to stop

excessive temperatures from being reached. To prevent the

loop temperature from exceeding this range, the following

stages are enacted:

1. The pump active on the loop exceeding the set point

temperatures is powered off.

2. The mixing valve is adjusted from the current position,

plus 25% to the closed position.

3. The pump is powered ON for two (2) minutes.

4. If the temperature has not dropped below the [set point +

offset - 2°F], the pump is turned OFF.

The control will automatically reset the demand as active once

the sensor input is below the [set point + offset - 2°F].

Error Mode

If the sensed temperature rises above set point + 20°, the

display of the boiler will present the sensor input with an

exclamation mark (ex. 128°F!). The following protection

algorithm will begin to prevent a lockout of the loop:

1. If running, the pump will immediately power off and the

3-way valve is adjusted 125% in the closed direction.

2. Once the close signal ends, the pump is powered back on

for two (2) minutes. Within this time, the sensed

temperature must drop below [set point + offset] or the

pump will be powered off.

3. As a result, the temperature will drop below [set point +

offset] and the error code (ex. 128°F!) is removed.

With the Initial and Error Mode Protections, the valve is fully

closed to reduce the loop temperature by preventing continued

hot water supply from the system. If the temperature sensed

is not reduced within the steps listed above, the MTLCB will

lockout this loop until temperatures below [set point + offset]

are reached. During these scenarios, ensure the physical

movement of the 3-way valve in the event the system needs

to be repaired.

12

Page 13

5 Basic Operation (continued)

Forced Change

It is necessary for the MTLCB to sense a temperature change

of 2°F within the time of a call for heat and the initial

position of the 3-way valve. This is a two-fold protection

where the MTLCB protects the loop from continued normal

operation when it cannot calculate the sensitivity of the valve

movement needed.

As a secondary operation, the sequence below protects

the loop when the loop temperature sensor is connected

to the MTLCB but not installed properly, not installed, or

malfunctioning.

1. With a call for heat the pump turns on.

2. The 3-way valve moves to the initial open position after the

pump is on for one (1) minute.

3. If after three (3) minutes the initial position does not

create a 2°F change in sensed temperature, the 3-way

valve is moved to the closed position.

Loop Control Board Instructions

4. After two (2) minutes of closure, the 3-way valve is

opened to the initial position.

5. Repeat Steps #3 and #4.

6. Once the 3-way valve is moved to the closed position, the

loop is locked out for the duration of the call for heat.

7. The lockout continues for 30 minutes after the call for heat

has ended.

8. After 30 minutes, the next call for heat will begin at Step

#1.

Please note, the fi rst two (2) steps are normal operation and

at Step #3, if a 2°F change in temperature is not sensed, the

protection process will begin. If at any point a 2°F change is

sensed, normal operation will resume.

13

Page 14

NOTES

14

Page 15

NOTES

15

Page 16

Revision Notes: Revision A (ECO #C08954)

initial release.

Revision B (ECO C10236) refl ects the update of

the control image in Figure 3-1 on page 8.

LCB-I-O Rev B

04/12

Loading...

Loading...