Page 1

Energy Efficient, Cost Effective Boilers

Lochinvar first introduced Copper-Fin technology to the boiler

industry some 45 years ago. Since then, we’ve continued to refine

and perfect it - adding advanced fan-assisted combustion, hot

surface ignition, a unique gasketless Cop per-Fin heat ex chang er

and space-age insulating materials.

Installation Flexibility and Cost-Savings

With compact sizes that use less floor space than ever before,

all Copper-Fin units are narrow enough to fit through a standard

36” doorway – an ad van tage most commercial boilers can’t provide.

Plus, thanks to special insulating materials, Copper-Fin units require

only 3” clearance from combustible walls. What’s more, our

Stack Frame allows you to install two units in the area

normally required for one. This makes it easier to fit multiple

Copper-Fin boilers into cramped me chan i cal rooms. And you

can even use a smaller diameter vent stack - up to 8” smaller than

typically required for comparable atmospheric boilers - so it saves

money as well as valuable mechanical room space.

Copper-Fin

®

Commercial Gas

Boilers

Unique Copper-Fin Heat Ex chang er

The Lochinvar Copper-Fin boiler design uses a two pass heat

ex chang er. Water is circulated through a row of high ly-efficient,

finned copper tubes. The high rate of water flow creates a scour ing

action that prevents sed i ment and lime-scale buildup, common in

conventional boilers, and the finned copper tubes allow maximum

heat transfer efficiency.To create this special heat transfer capability,

Lochinvar extrudes the fins from thick

wall copper tubing to precise

specifications - ex act ly 7

fins per inch. The result

is an integrallyfinned tube

with a heat

transfer

ratio 9 times

greater than

a plain copper

tube.

Heavy-Duty Gasketless Design

What’s more, advanced casting processes allowed Lochinvar to

develop a unique one-piece header system. This gasketless design

provides enhanced reliability, improved durability and optimum

performance - without the problems or failures common with

O-rings and gaskets.

Meets the Toughest Air Quality Standards

Because of our unique fan-assisted combustion process, the

Copper-Fin exceeds today’s toughest NOx emissions requirements.

An independent certification laboratory test gave us a rating of

less than 20 ppm — corrected to 3% O

cleaner environment.

. And less NOx means a

2

Enhanced to Provide Performance and Serviceability

Our enhanced Copper-Fin models offer the same reliable operation, and

feature a more service friendly design. The down stream test valves and

referenced gas valves are now in the upper deck for easier access, and

the electrical and BMS connections have been repositioned toward the

front of the unit for easier installation.

The gas valves, which are referenced to the sealed combustion chamber,

improve operational performance by monitoring the pressure in the

sealed combustion chamber and adjusting gas flow to maintain the

optimum air/fuel mixture. And the built-in air inlet filter reduces

maintenance and improves performance by trapping dust and airborne

particulates that can foul the burners and blowers. With dual sight

glasses (one on each end), you can easily monitor burner performance

and flame characteristics throughout the entire combustion chamber.

The operator interface panel provides two-stage electronic temperature

control and comprehensive diagnostic status without opening the

control panel. Its user friendly design simplifies service while providing

additional diagnostic information through a series of LEDs.

Vent Cost-Savings

Btu/hr CONVENTIONAL COPPER-FIN

INPUT VENT SIZE VENT SIZE $ S

495,000 10” 6” $ 382

645,000 12” 8” $ 504

745,000 14” 8” $ 829

985,000 16” 10” $ 1,228

1,225,000 16” 12” $ 992

1,435,000 18” 12” $ 1,466

1,795,000 20” 14” $ 1,564

2,065,000 22” 14” $ 2,398

*Comparison based on 25´ vent system using Type “B” double wall vent material,

storm collar and vent cap.

AVINGS*

Page 2

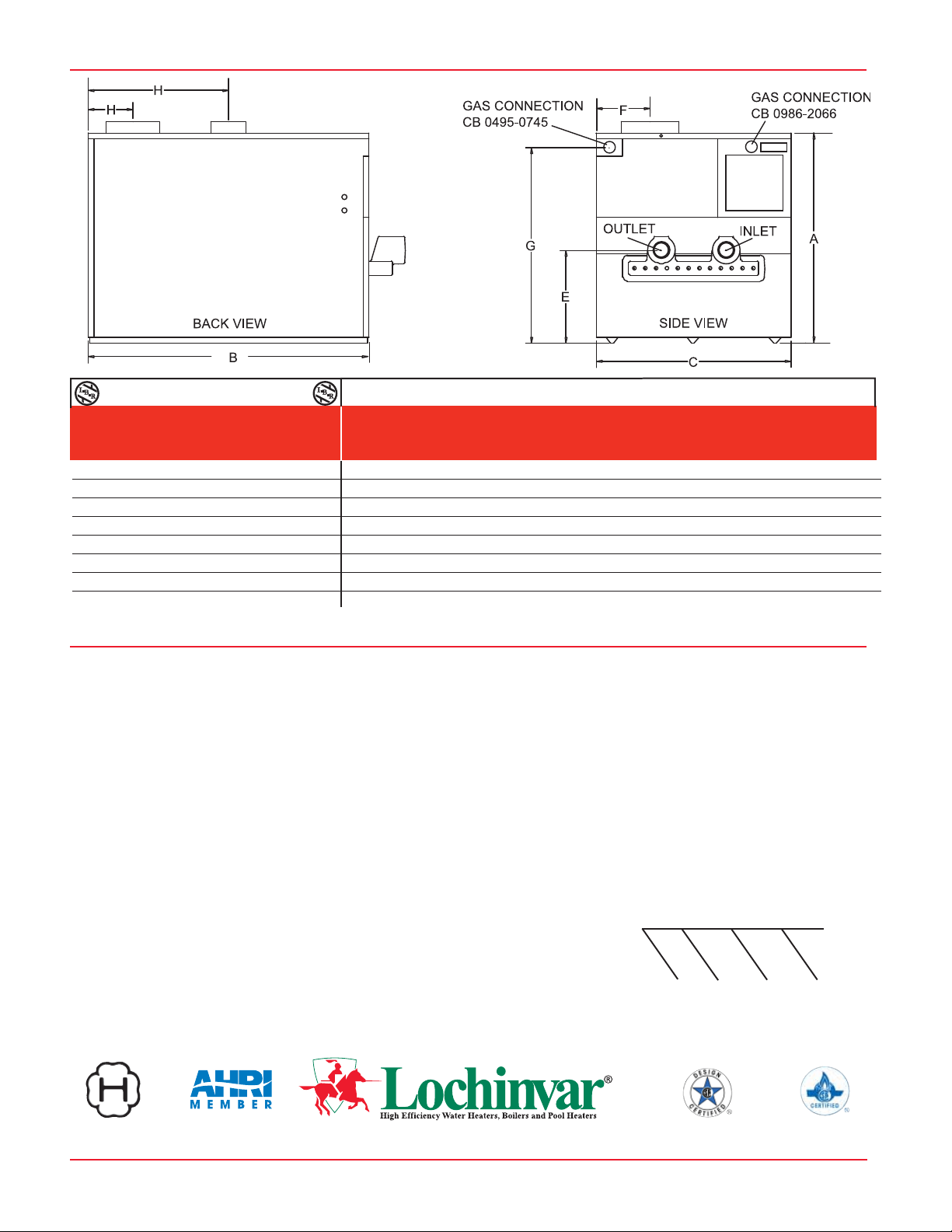

Copper-Fin® Boiler Dimensions & Specifications

Copper-Fin Heating Boiler Dimensions & Spec i fi ca tions

Input Heating Net

Model Max Thermal Capacity I=B=R Gas Vent Shipping

Number MBH Efficiency MBH MBH A B C E F G H Conn. Size Weight

CBN0495 495 81% 401 349 33-1/4” 45-1/4” 22-1/4” 12-1/2” 9-1/2” 30-3/4” 22-3/4” 1-1/4” 6” 440

CBN0645 645 81% 522 454 33-1/4” 56-3/4” 22-1/4” 12-1/2” 9-1/2” 30-3/4” 22-1/4” 1-1/4” 8” 510

CBN0745 745 81% 603 524 33-1/4” 64” 22-1/4” 12-1/2” 9-1/2” 30-3/4” 31-1/4” 1-1/4” 8” 550

CBN0986 985 81% 798 694 36” 48-1/4” 33-1/2” 15-3/4” 9-1/2” 33-3/4” 8” 2” 10” 845

CBN1256 1,255 81% 1,017 884 36” 58-1/2” 33-1/2” 15-3/4” 10-1/2” 33-3/4” 9” 2” 12” 905

CBN1436 1,435 81% 1,162 1,010 36” 68-3/4” 33-1/2” 15-3/4” 10-1/2” 33-3/4” 9” 2” 12” 1050

CBN1796 1,795 81% 1,454 1,264 36” 82-1/4” 33-1/2” 15-3/4” 11” 33-3/4” 10” 2” 14” 1193

CBN2066 2,065 81% 1,673 1,455 36” 92-1/2” 33-1/2” 15-3/4” 11” 33-3/4” 10” 2” 14” 1350

Notes: Change ‘N’ to ‘L’ for LP gas models. Water connections for models CB 0495-745 are 2” NPT on 6-1/2” centers.

No deration on LP models. Water connections for models CB 0986-2066 are 2-1/2” NPT on 11-1/4” centers.

Performance data based on manufacturer test results.

Standard Features

• 81% Thermal Efficiency

• Electronic Temperature Control

• Fan Assisted Combustion

• Sealed Combustion Chamber

• Stainless Steel Burners

• Low NOx Operation Exceeds the most

Stringent Air Quality Requirements

• ASME Copper Finned Tube

Heat Exchanger

• 160 psi Working Pressure

• Gasketless Heat Exchanger Design

• Pump Relay w/ Delay

• Down Stream Test Valve

• Referenced Gas Valves

• Loch-Heat Ceramic Tile

Combustion Chamber

• Hot Surface Ignition

• Adjustable High Limit w/ Manual Reset

• ASME Pressure Relief Valve

• Temperature & Pressure Gauge

• Flow Switch

• 24 Volt Control System

• BMS Terminal Strip

• Combustion Air Filter (CB 986-2066)

• Freeze Protection

• 10 Year Limited Warranty on Heat

Exchanger (See warranty for details)

Optional Equipment

• Alarm Bell

• Contacts on any Failure

• Contacts for Air Louvers

• Cupro-Nickel Heat Exchanger

• High & Low Gas Pressure Switch

w/ Manual Reset

• Outdoor Reset Control

• Manual Reset Low Water Cut-Off

w/ test

• Stack Frame

• MP2 Sequencer

Available Firing Systems

M9 Hot Surface Ignition with

Electronic Supervision (Standard)

M13 GE GAP/FM/CSD1

M7 California Code

Venting

• Outdoor Vent Cap

Registered under U.S. Patent # 5,989,020

For Ease In Ordering

By Model Number

CB N 0495 M9

NAT. GAS

MODEL

This boiler is a 495,000 Btu/hr,

natural gas Copper-Fin.

It has M9 firing controls

B

tu/hr INPUT

FIRING

CONTROLS

Lochinvar Corporation • 300 Maddox Simpson Pkwy • Lebanon, TN 37090 • 615-889-8900 / Fax: 615-547-1000

CBN-06 (Revised CBN-06 9/08)

www.Lochinvar.com

FG-5M-3/10-Printed in U.S.A.

Loading...

Loading...