Page 1

OWNER’S

MANUAL

Page 2

Welcome To The World Of Mantis Gardening!

Here’s your new Mantis Edger...

designed for proud homeowners

who want to make their yard look

like a showcase!

With your new Mantis Edger,

you’ll have the neatest edge in the

neighborhood. The patented

cross-blade system cuts through

overgrown grass quickly and easily. It’s ideal for edging in confined

or narrow areas where traditional

wheeled edgers can’t reach.

Once you know how to use your

Mantis Edger correctly, we guarantee you’ll love it. So first, please

read this manual and watch the

enclosed video. They show, step

by step, how to use your edger

safely and how to get the best

edging results.

2

Table of Contents

Safety Rules & Warnings ........................... 3

Safety Decals ............................................. 4

Engine & Fuel Warnings ........................... 4

Assembly ................................................... 6

Edger Diagram ........................................... 7

Mixing Fuel ............................................. 10

Starting Instructions ................................ 11

Additional Information .......................... 12

What to Do Just in Case .......................... 13

Edging Instructions ................................. 14

Blade Replacement .................................. 16

Maintenance ............................................ 17

Storage ...................................................... 20

Troubleshooting Tips .............................. 22

Specifications .......................................... 24

Service Maintenance Guide ..................... 24

Mantis Edger Assembly Layout ............... 26

Engine Parts Assemblies .......................... 28

Limited Warranty Information ............... 32

Page 3

Safety Rules & Warnings

You will notice throughout this Owner’s Manual Safety Rules and Important Notes.

Make sure you understand and obey these warnings for your own protection.

I. Special Safety Information

II. Safety & Warnings

WARNING • DANGER

ATTENTION: THIS SYMBOL POINTS OUT

OUR IMPORTANT SAFETY INSTRUCTIONS.

WHEN YOU SEE THIS SYMBOL,

HEED ITS WARNING! STAY ALERT!

▲

!

▲

!

▲

!

WARNING • DANGER

TO REDUCE THE POTENTIAL FOR ACCIDENTS, COMPLY

WITH THE SAFETY INSTRUCTIONS IN THIS MANUAL.

FAILURE TO COMPLY MAY RESULT IN SERIOUS PERSONAL

INJURY, AND/OR EQUIPMENT AND PERSONAL DAMAGE

▲

!

▲

!

The engine exhaust from this product contains chemicals

known to the State of California to cause cancer, birth defects or other reproductive harm.

▲

!

WARNING:

WARNING • DANGER

IMPROPER USE OR CARE OF THIS

EDGER OR FAILURE TO WEAR PROPER

PROTECTION CAN RESULT IN SERIOUS INJURY.

READ AND UNDERSTAND THE RULES FOR SAFE

OPERATION AND ALL INSTRUCTIONS IN THIS MANUAL.

WEAR HEARING AND EYE PROTECTION.

▲

!

▲

!

3

Page 4

III. Safety Decal Information

An important part of the safety system incorporated

in this edger are the warning and information

decals found on various parts of the edger.

These decals must be replaced in time; it is

your responsibility to replace these decals

when they become hard to read. The

location and part numbers of these

decals are illustrated on page 27.

DIRECTION OF ROTATION

ROTATING BLADE

WARNING • DANGER

IF THE EDGER IS USED IMPROPERLY OR SAFETY PRECAUTIONS ARE NOT

FOLLOWED, THE USERS RISK SERIOUS INJURY TO THEMSELVES AND OTHERS.

READ AND UNDERSTAND THIS MANUAL BEFORE ATTEMPTING TO OPERATE THIS EDGER.

▲

!

▲

!

IV. Warnings - Do’s

Read and understand the owner’s

manual. Pay particular attention

to all sections regarding safety.

Always keep a firm grip on both handles

while the blade is moving and/or the engine is

running. BE AWARE! The blade may coast after

throttle trigger is released. Make sure blade has

come to a stop and engine is off before letting

go of the edger.

Always maintain a firm footing and good

balance. Do not overreach while operating the

edger. Before you start to use the edger, check

the work area for obstacles that might cause

you to lose your footing, balance, or control

of the machine.

Always keep area clear of children, pets,

and bystanders.

Always stay alert. Watch what you are

doing and use common sense. Do not operate

edger when fatigued.

Always dress properly. Do not wear loose

clothing or jewelry, which may get caught in

moving parts. Use sturdy gloves. Gloves reduce

the transmission of vibration to your hands.

Prolonged exposure to vibration can cause

numbness and other ailments. Wear non-skid

footwear to ensure secure and proper footing.

Always wear ear and eye protection.

Eye protection must meet ANSI Z 87.1. To

avoid hearing damage, we recommend hearing

protection be worn whenever using the equipment.

Always keep a safe distance between two

or more people when working together.

Always inspect your edger before each use

and ensure that all handles, guards and fasteners are secure, operating and in place.

Always maintain and examine your edger

with care. Follow maintenance instructions

given in manual.

Always store edger in a sheltered area (a dry

4

100603

100602

100601

Page 5

place) not accessible to children. The edger, as

well as fuel, should not be stored in a house.

V. Warnings - Don’ts

Don’t use edger with one hand. Keep both

hands on handles with fingers and thumbs

encircling the handles, while blade is moving

and engine is running.

Don’t overreach. Keep a good footing at all

times.

Don’t attempt to clear blade while the

engine is on. Never try to remove jammed

material before switching the engine off and

making sure the blade has stopped completely.

Don’t allow children or incapable people

to operate this edger.

Don’t operate while under the influence

of alcohol or drugs.

Don’t attempt to repair this edger.

Have repairs made by a qualified dealer or

repairman. See that only original Mantis

parts are used.

WARNING • DANGER

HANDLE FUEL WITH CARE; IT IS HIGHLY FLAMMABLE. FUELING A HOT ENGINE OR NEAR AN IGNITION

SOURCE CAN CAUSE A FIRE AND RESULT IN SERIOUS PERSONAL INJURY AND/OR PROPERTY DAMAGE.

▲

!

▲

!

VI. Engine/Fuel Warnings - Do’s

Always use fresh gasoline in the fuel mix-

ture. Stale gasoline can cause damage.

Always pull starter cord slowly until

resistance is felt. Then pull cord rapidly to

avoid kickback and prevent arm or hand

injury.

Always operate engine with spark

arrestor installed and operating properly.

The use of spark arrestor mufflers is required by

law in the state of California (Section 4442 of

the California Public Services Code), as well as

in other states or municipalities. Federal laws

apply on federal lands.

VII. Engine/Fuel Warnings - Don’ts

Don’t fuel, refuel or check fuel while

smoking, or near an open flame or other igni-

tion source. Stop engine and be sure it is cool

before refueling.

Don’t leave the engine running while

the edger is unattended. Stop engine before

putting the edger down or transporting from

one place to another.

Don’t refuel, start or run this edger

indoors or in an improperly ventilated area.

Don’t run engine when electrical system

causes spark outside the cylinder. During

periodical checks of the spark plug, keep plug a

safe distance from cylinder to avoid burning of

evaporated fuel from cylinder.

Don’t check for spark with spark plug or

plug wire removed. Use an approved tester.

Don’t crank engine with spark plug

removed unless spark plug wire is disconnected. Sparks can ignite fumes.

Don’t run engine when the odor of gasoline

is present or other explosive conditions exist.

Don’t operate the edger if gasoline is

spilled. Clean up spill completely before starting engine.

Don’t operate your edger if there is an

accumulation of debris around the muffler and

cooling fins.

Don’t touch hot mufflers, cylinders or

cooling fins, as contact may cause serious

burns.

5

Page 6

Assembly

WARNING • DANGER

IMPROPER ASSEMBLY OF THIS EDGER

CAN RESULT IN SERIOUS INJURY.

MAKE SURE TO FOLLOW ALL

INSTRUCTIONS CAREFULLY.

IF YOU HAVE ANY QUESTIONS

ABOUT THE EDGER ASSEMBLY,

CONTACT YOUR LOCAL

AUTHORIZED MANTIS DEALER

▲

!

▲

!

Your Mantis Edger comes partially assembled;

you must install the handlebars and clip in

the throttle cable. The Mantis Edger can be

assembled by one person, but will be easier

with help from a second person. Assembly

will take just a few minutes if you follow the

directions.

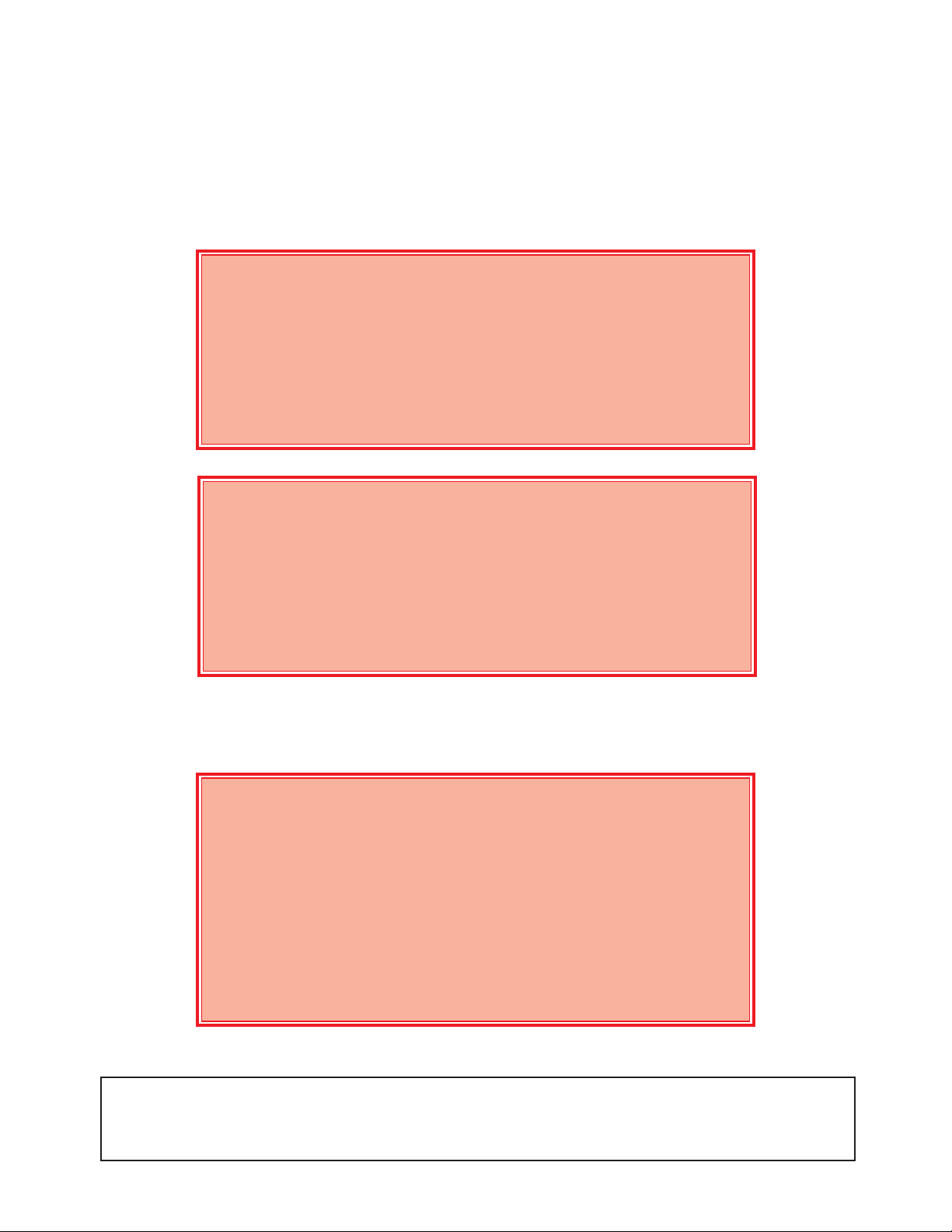

First, take all items out of the carton.

Save the cardboard box to prop up the

engine for ease of assembly.

The list on page 7 shows the parts that come

with your edger. Check to make sure you

have all of them. The bag of hardware

is in the plastic bag containing the Owner’s

Manual and Video.

To assemble your Mantis Edger, you’ll need a

flat head screwdriver. We suggest that you

first install all nuts and bolts only “finger

tight” - that is, one-half to one full turn then, fully tighten after you’ve completed

assembly.

The nuts are self-locking, but you

must use a screwdriver to tighten

them completely.

6

Page 7

KEY # DESCRIPTION QTY PART #

1 Screw M5 x 36 mm 4 100500

2 Nut Nyloc 5mm 4 100501

Main Body 1

44 Handle Right 1 100225

45 Handle Left 1 100226

46 Handle Cross Brace 1 100227

48 Handle Clamp 1 100532

52 Bolt 1/4” x 5.5” 1 100533

53 Knob 1 100232

Mantis Edger Parts List

7

1

1

1

1

2

2

2

46

53

48

52

45

44

see pages 26 & 27 for parts explosion

NOTE: Please use the Part No.

when ordering any parts

Page 8

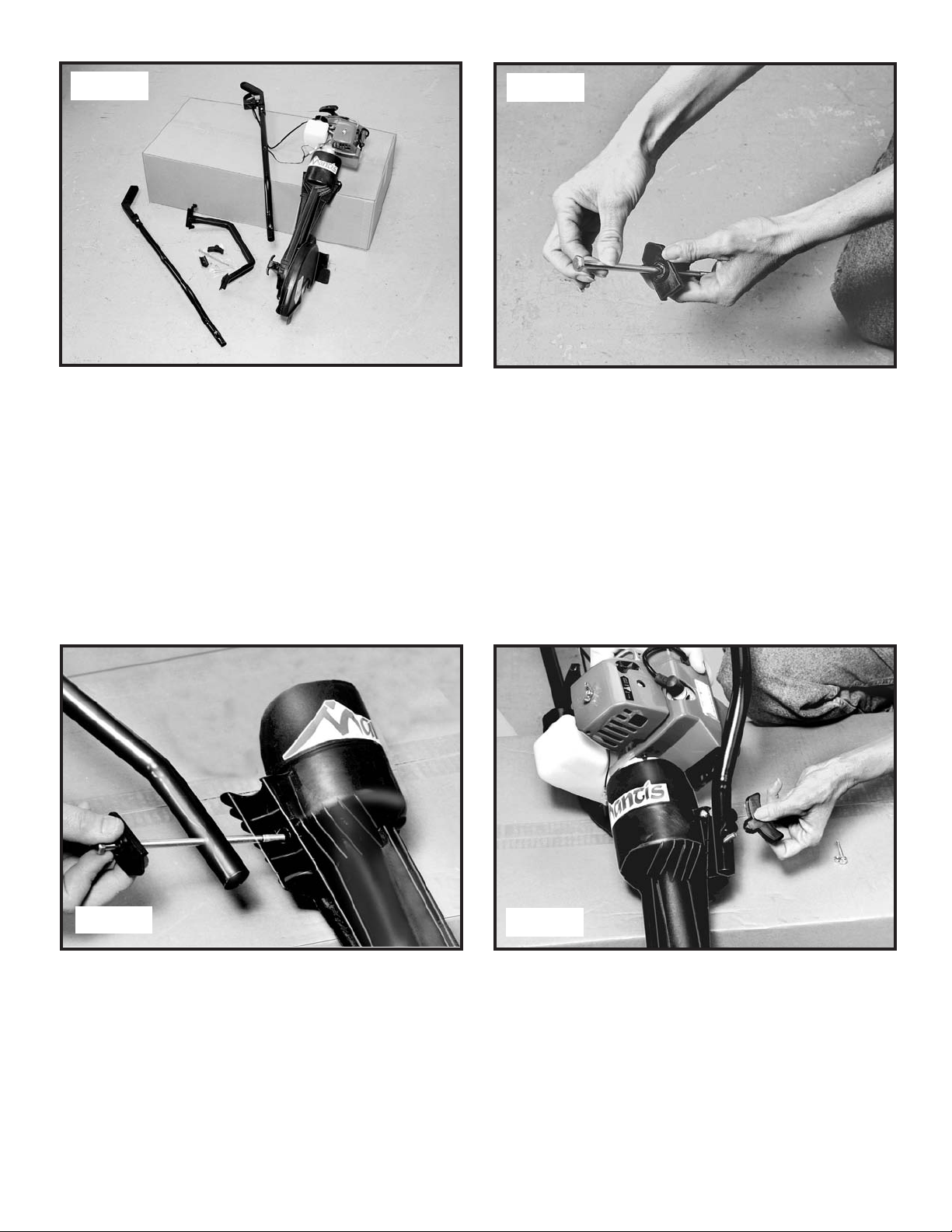

Step 1

Step 2

Step 3

Step 4

Insert the bolt through the right handle (with

the throttle trigger) and through the main

body of the Edger with the point of the plastic washer facing down towards the blades.

After taking all parts out of the carton, turn

the cardboard box over and rest the engine

on top of it for ease of assembly.

Slip the flat handle clamp (key #48) onto the

long bolt (key #52) so that the hex head fits

into the recessed area.

Place the second handle over the bolt that

now protrudes from the other side and secure

it with the large plastic wing nut from the

hardware bag. Do not overtighten the wing

nut.

8

Page 9

Step 5

Step 6

Step 7

Holding the nut in place, tighten the screw

on each side with a flat head screwdriver.

Place the handle cross brace (key #46)

between the handles and lay the throttle

cable and wire into the clips of the righthand handle brace.

Line up the holes in the brace with the holes

in the handle tubing and attach the brace

with one screw (key #1) and one nut (key #2)

on each side.

Your Mantis Edger is now fully assembled!

9

Page 10

Your Mantis Edger comes with a free premeasured bottle of two-cycle engine oil.

Here’s how to mix the oil with the gas.

1. Pour 1/2 gallon of the gasoline into a safe

one gallon container. Do not mix the fuel

and oil in the engine fuel tank.

2. Add the Mantis two-cycle engine oil

(2.6 ounces pre-measured) to the gasoline

and mix. Then add the other 1/2 gallon

of gasoline. (50:1 ratio)

3. Screw the cap onto the gasoline can, and

swirl the can to blend the oil and gas.

4. Carefully pour the fuel mix into the

Mantis Edger’s fuel tank. After putting

the fuel tank’s cap back on, wipe up any

spilled fuel from tank and gasoline can.

IMPORTANT:

Two-cycle fuel separates and ages. Do not

mix more than you will use in a month.

Using old fuel can cause difficult starting

or engine damage. Shake fuel container to

thoroughly mix fuel before each use. Do not

attempt to run your engine on gasoline only;

use the proper fuel mixture.

Fuel Mix and Fueling

WARNING • DANGER

FUEL IS EXTREMELY FLAMMABLE. HANDLE IT WITH CARE. KEEP AWAY FROM

IGNITION SOURCES. DO NOT SMOKE WHILE FUELING YOUR EQUIPMENT.

▲

!

▲

!

Your Mantis Edger is powered by a two-stroke, air cooled

engine which requires a fuel mixture of gasoline and

two-cycle oil.

Use a mixture of 50 parts unleaded regular gasoline and

1 part two-cycle oil (50:1). Use branded 89 octane

(R+M+2) unleaded gasoline or gasohol (max. 10% ethyl

alcohol, or 15% MTBE, no methyl alcohol).

Need more pre-measured engine oil? Contact

your local authorized Mantis dealer.

Remember...

•Always mix two-cycle oil with gasoline

before fueling your edger. Never, ever run

your Edger on gasoline alone. This will ruin

your engine and void all warranties.

• Always use a clean gas can and always use

unleaded gas.

• Never try to mix the oil and gasoline in the

engine fuel tank.

•Always mix gasoline and oil in the proper

proportions: 1 gallon of unleaded gasoline

to 2.6 ounces of two-cycle engine oil.

(50:1 ratio)

IMPORTANT NOTE:

DO NOT use old or stale oil/gasoline

mixture. Always use the proper

oil/ gasoline mixture. If you do not,

your engine will suffer rapid,

permanent damage and you will

void the engine warranty.

10

Page 11

Starting Instructions

To Start Your Mantis Edger for the First Time:

Fill the fuel tank with the proper oil/gasoline mixture

(see previous section). Hand tighten the gasoline cap

until it’s just snug.

Place the start/stop switch into the “start” position

(Picture 1).

Lay the Edger flat on the ground for the following steps.

Pull out the choke button to close the engine choke

(Picture 2).

Locate the purge bulb on the upper right of the

engine, in front of the fuel tank (Picture 3). It sends fuel

into the carburetor for easy starting. Press the purge bulb

until you see fuel flow through the clear fuel return line.

Since you’re starting “cold,” you may need to press six

to eight times. As soon as fuel starts flowing through the

clear fuel line, stop pressing!

Place one foot on the cross-brace, and pull the starter

cord (Picture 4) slowly until resistance is felt. Then give

the recoil starter cord a few short, brisk pulls until the

engine fires. During cold starting, you may need to pull

at least three or four times before the engine fires

(coughs and sputters).

NOTE: When the choke is closed, never pull the cord

more than four or five times. Overpulling may cause

flooding. Also, bear in mind that, when the engine fires,

it only coughs or sputters, and will not run on choke.

Push in the choke button to open the choke (Picture 5)

Then, pull the starter cord again. The engine should

start and run. Let the

engine warm up two to

three minutes before using.

Follow these steps whenever

you are starting the engine

“cold,” or when the engine has

run dry and you have just

added fuel. Remember, always

use short, brisk pulls. Don’t

give the cord a long, forceful

yank. And, do not let the

cord snap back into the

starter housing.

Picture 1

Picture 2

Picture 3

Picture 4

Picture 5

WARNING

AVOID ACCIDENTAL

BLADE ENGAGEMENT

DO NOT SQUEEZE THE

THROTTLE TRIGGER

WHEN STARTING. MAIN-

TAIN PROPER IDLE

SPEED ADJUSTMENT

(3000-3200 RPM).

▲

!

▲

!

11

Page 12

Starting a Warm Engine

Slide start/stop switch to the START position.

Push choke button into the RUN (open) position.

If there is no fuel in the clear return line, push primer

bulb 3-4 times or until fuel is visible in the line.

Pull starter rope using short pulls, 1/2 to 2/3 of the rope

length.

If engine fails to start in 4 pulls, use “First Time” starting

procedure on page 11.

With engine running and both hands on the handles,

squeeze throttle trigger gradually to increase the engine

speed and engage the blade.

Starting Instructions

...continued...

Never use starting

fluids as they will

cause permanent

engine damage. Using

them will void the

engine warranty.

Before you use the

tiller, read the Safety

& Warning rules on

pages 3-5.

Additional Information

WARNING • DANGER

IF ENGINE DOES NOT STOP WHEN SWITCH

IS PUT IN THE STOP POSITION, RELEASE

THE THROTTLE, ALLOW ENGINE TO IDLE.

PUT THE EDGER DOWN AND PULL

THE CHOKE BUTTON OUT TO COLD

START (CLOSED) POSITION.

CHECK AND RETURN START/STOP

SWITCH TO ON POSITION BEFORE

STARTING ENGINE AGAIN.

▲

!

▲

!

won’t turn unless you squeeze the throttle

lever on the handlebars. And, when you

release the throttle lever, the blade will stop.

A Tip for Extending Your

Engine’s Life

After you start your engine, let your edger

warm up for two to three minutes before you

use it. Then, before you put your tiller away,

let it idle for a minute to give the engine a

chance to cool down.

How to Stop

the Engine

Simply push the

start/stop switch

to “stop” (see

picture). This

will stop the

engine instantly.

If it should ever

fail to do so, just pull out the choke button.

The engine will stop at once.

About the Choke

The choke controls the amount of air drawn

into the engine. Your edger will run only

if the choke is open - that is, if the choke

button is pushed in.

A Special Feature (with the idle

set and the engine running)

Even when the engine is running, the blades

12

Page 13

What To Do Just In Case

If you follow the normal starting procedure, you should

have no problem starting your edger. But, just in case you

do have problems, here’s what to do.

Make sure the start/stop switch is on “start.” You’d be surprised how many people forget to slide the switch into the

“start” position.

If the switch was on “stop” when you pulled the cord, you

may have flooded the engine.

Starting a Flooded Engine

• First, examine the spark plug. Use a 3/4 inch spark plug

wrench (Picture 1).

• Remove the cap over the spark plug.

• Unscrew the spark plug (Picture 2).

If the end of the spark plug is wet, the engine may be

flooded. Make sure the switch is in the stop posi-

tion, disconnect spark plug wire and remove plug.

Use a paper towel or a clean rag to dry the spark

plug, then, with the spark plug out of the engine,

pull the starter cord several times. Shake the fuel

out of the inside of the plug and air dry. Next,

replace the spark plug. Use the wrench to tighten it and

replace the cap. Next, put the switch in the start position

and pull the choke button out. Pull the starter cord three

or four times until the engine coughs or sputters. Open the

choke (push the choke button in) and pull the cord a few

times. The engine should start and run.

Picture 1

Picture 2

Picture 3

WARNING

MAKE SURE THE START/STOP SWITCH IS IN THE

STOP POSITION. KEEP PLUG WIRE AWAY FROM

ENGINE TO AVOID UNINTENTIONAL SPARK.

▲

!

▲

!

IMPORTANT NOTE:

To avoid possible damage to the

Threads, do not try to remove the plug

from a hot aluminum cylinder head.

If the end of the spark plug is dry,

check to see if the fuel line is

blocked. The fuel line runs from

the fuel tank to the carburetor. Pull

it off at the carburetor end. Fuel

should drip slowly from the line.

Wipe off any excess or spilled fuel.

If fuel does not drip from the line,

check the line for any bends or

pinches (Picture 3). Kinks in the

line restrict the flow of fuel to the

engine. Just straighten out the line.

Reconnect. Then follow the normal

starting procedure.

13

Page 14

Here’s Another Way to Start

Your Mantis Edger

If you follow the previous steps and your

engine still won’t start, try this:

1. Slide the switch to “start.”

2. Push the choke button to open the choke.

3. Press the plastic bubble 5 to 6 times.

4. Give the starter cord a few short, quick

pulls. The engine should start and run.

5. If the engine does not start, then pull out

the choke button to close the choke. Pull the

starter cord four to five times. The engine

should sputter and cough.

6. After the engine sputters, push the choke

button in. Then pull the starter cord. The

engine should start and run.

What To Do Just In Case ...continued...

7. If the engine still does not start, repeat

steps 2 through 6.

8. If the engine still does not

start, call your local authorized

Mantis Dealer.

IMPORTANT NOTE:

Never use starting fluids as

they will cause permanent

engine damage. Using them

will void the engine warranty.

Before you use the edger, read

the Safety & Warning rules on

pages 3-5.

Edging Instructions

The Mantis Edger is very easy and simple

to use. For some people, it may take a few

edgings to become an expert.

Thoroughly inspect the area where the edger is to be used

and remove all stones, sticks, wires, and other foreign

objects.

Adjust blade height (Picture 1). With a new blade,

try the second hole closest to the operator.

With both arms fully extended downward (Picture 2), hold

both handle grips firmly. With the engine running, pull

the throttle trigger to increase engine speed to full throttle.

Always run the engine at full throttle when edging.

If blade is not deep enough, or if digging is too deep,

adjust blade height or slightly raise or lower handles to

suit depth required. (Picture 3). However, it is always more

comfortable and relaxed to have arms fully extended

downward.

Picture 1

Picture 2

14

Page 15

As cutting actions begins, push the Mantis Edger forward so that the blade can cut the edge as you move forward. (Picture 4).

Continue at a moderate pace until you are familiar with

the controls and the handling of the Mantis Edger.

If blade jams or stops in the ground, lower handles or

pull back unit and recommence (Picture 5). Control

engine and cutting speed to suit work being done When

cutting efficiently, engine speed should be full throttle

under load.

Edging Along a Concrete Edge

For the position of the blade, align the edge guide on

top of the blade cover with the edge of the concrete. If

the blade hits the concrete, lower the handle and reposition the blade at the side of the concrete. Even if the

grass is growing over the concrete and you cannot see

the edge, you can feel the edge of the concrete

with the rotating blade by slightly tilting the

handles of the edger sideways, away from the

concrete, so that the blade tilts towards the concrete and touches or “kisses” the concrete edge

and acts as a guide (Picture 6). Edger blades are

made from high tensile hardened spring steel and will

last a long time. Once the edge is established, the second

and subsequent times around are very fast.

Sideways Tilting

Lower either the left or right handle to achieve angled

cutting along walls or fences (Picture 7).

Picture 3

Picture 4

Picture 5

Picture 6

Picture 7

WARNING

KEEP INSIDE OF BLADE GUARD CLEAN, ESPECIALLY

IN WET CONDITIONS. A CLOGGED GUARD CAN SLOW

DOWN OR STOP BLADE ROTATION AND MAY CAUSE

DAMAGE TO AUTOMATIC SAFETY CLUTCH. ALWAYS

OPERATE BLADE AT FULL THROTTLE WHEN EDGING.

▲

!

▲

!

IMPORTANT NOTE:

The Mantis Edger is equipped with a centrifugal clutch. DO

NOT run edger engine

at low speeds or, if blade is jammed, at

high engine speeds as clutch shoes will

prematurely wear out and cause damage.

15

Page 16

Blade Replacement

1. Stop engine. Unplug the spark plug wire. Clean

area around dust cover and pry debris out with a screwdriver (Picture 1).

2. Through dust cover, place 14mm or 9/16” socket

wrench. On blade end of shaft, place 18mm or adjustable

wrench on blade nut (Picture 2).

3. Unscrew nut counter-clockwise (normal right hand

thread).

4. Remove one small washer, one large washer and two

blades (Picture 3). Before installing blade and washers,

clean all grit and grease. Assemble these parts clean and

dry. Fit large washer, new blades with spiggots of one blade

interlocking with holes on opposite blade, large washer,

two small washers, and nut. Tighten nut.

5. Clean plastic dust cap and housing; press back by gently

tapping into place. Clean inside blade cover of any builtup dirt.

Loose Blade

Follow steps 1 and 2 of Blade Replacement and tighten nut

clockwise.

Picture 1

Picture 2

Picture 3

Picture 4

WARNING

USE ONLY MANTIS BLADES. OTHER BLADES

HAVE LARGER SIZE HOLES (1/2”) WHICH WILL

CAUSE OUT-OF-BALANCE VIBRATIONS WHICH

WILL DAMAGE UNIT AND CAUSE INJURY.

▲

!

▲

!

WARNING

DO NOT RUN ENGINE

WITHOUT BLADE TIGHTENED

TO BLADE SHAFT AS GEAR

DAMAGE WILL OCCUR.

▲

!

▲

!

Lubrication of Gears

There is usually sufficient grease to last at least 4 years or

100 hours of domestic use before topping it up. The grease

in the gear case should be filled up according to use by

adding light, free-flowing grease (available from Mantis,

P/N #9985) through screw hole marked “fill” (Picture 4).

Use a suitable filling gun or squeeze grease pack. Remove

screw marked “bleed.” Squeeze in 3-4 pumps of grease,

until it comes out of the bleed hole. Refit fill screw.

NOTE: Do not use light or heavy gear oil as

it might leak out. If gear case shows leakage,

tighten all screws or replace O-ring. Refill casing.

16

Page 17

Maintenance

Check the Air Filter Often

A wet or dirty air filter can affect the way your engine

starts, performs, and wears. So, it’s a good idea to check

your air filter at least once a month.

If you work in dusty soil, or if you want to be on the

safe side - then check your filter more often (for

instance, before each use). But be sure to replace it at

least once a year, in the spring or fall. Clean or change

it as needed. It is recommended to change the air filter

yearly.

How to Check, Clean, and Change the Air Filter

1. Loosen the wing nut on the side of the air-cleaner

cover (Picture 1).

2. Take off the cover. Make sure to clear the choke

button (Picture 2).

3. The air filter is the felt pad on the inside of the

air-cleaner cover. Check whether it is soiled or moist.

4. If the air filter needs cleaning or no longer fits

properly, remove it. Just lift an edge carefully and “peel”

it out (Picture 3).

5. Use a brush to remove debris from the pad.

6. If the air filter is so dirty that it won’t come clean,

you must replace it or severe engine damage will occur.

Contact your local authorized Mantis dealer.

7. Insert your clean filter inside the air-cleaner cover.

Installing the filter incorrectly will cause engine damage

and void the warranty. Fit the cover back over the air

cleaner (Again, make sure to clear the choke button).

8. Tighten the wing nut to secure the cover.

Picture 1

Picture 2

Picture 3

IMPORTANT!

Make sure filter is “seated” properly in

the cover. The filter must fit snugly inside

the rim that holds the filter into place.

IMPORTANT NOTE:

Please check the lip

on the Air Cleaner

Cover. If the lip is

chipped or cracked, it

should be replaced. This

will prevent dirt from

being ingested through

the carburetor into the

inside of the engine.

17

Page 18

Maintenance ...continued...

Clear Blockages From the Fuel Line and Filter

After you’ve used your Edger for a few seasons, check for

blockages in the fuel tank and fuel filter. Such blockages

can keep your Edger from starting.

Clear any blockages you see in the tank, fuel filter, or

fuel line. Remember: The fuel filter is located inside the

tank (Picture 1). Then, use the normal starting procedure

to start your Edger.

What To Do If Your Engine Idles Too High

What if your engine runs too fast...or if the blades

turn the instant you start the Edger? You may need

to adjust the idle screw ( Picture 2, or Key #25 under

“Carburetor” on page 28) by itself, right below the H

and L screws. Gently turn it counter-clockwise. You’ll

know you’ve adjusted it correctly when the blade does

not turn at low idle.

If you continue to have idle problems, you may need to

adjust the throttle cable.

First, locate the metal triangle at the end of the throttle

cable (Picture 2). The idle screw must touch this triangle.

But, if the throttle cable’s too tight, you’ll see a gap

between the idle screw and the triangle.

To fix this, loosen the top nut that holds the throttle

cable in place (Picture 3) (Use a 10mm wrench or an

adjustable wrench). Then, slide the cable down until you

close the gap between the triangle and the idle screw

(Picture 4). Now, tighten the bottom nut that holds the

throttle cable.

Locate the metal “button” on the triangle. This is the

swivel. The large end of the throttle cable must be inside

the slot in this swivel (Picture 4).

Picture 1

Picture 2

Picture 3

Picture 4

18

idle screw

Page 19

What To Do If Your Engine

Runs “Rough”

If your engine runs “rough” or stalls, you

may need to adjust the carburetor and idle

screws.

If you remove the air-cleaner cover, you’ll see

the two carburetor adjustment screws, next

to the black choke button.

The “RED” screw is the HIGH-speed adjustment...The “WHITE” screw is the low speed

adjustment.

Start the engine and let it run for two to

three minutes. “FLASH” the choke several

times during the warm-up to clear any air

from the fuel system.

Then, stop the engine after it reaches operating temperature.

Now, turn the RED, high-speed screw counter-clockwise all the way to the stop...Then,

turn the WHITE, low-speed screw halfway

between the counter-clockwise and clockwise

stop positions.

Now restart the engine to finish the carburetor adjustment.

Run the engine at full speed two or three

seconds to clear out any excess fuel. Then

return to idle.

Now, accelerate the engine to full throttle

several times to check for a smooth transition

from idle to high speed.

If the engine hesitates, turn the WHITE, lowspeed screw counter-clockwise one-eighth of

a turn. Then, accelerate the engine.

Repeat the adjustment until you get a

smooth transition to high speed.

Cleaning the Muffler Screen

1. Take out the spark plug.

2. Remove the red cylinder cover (Key #19)

which is held on by two Phillips-head screws.

(Key #18).

3. You will see the metal screen fixture, held

on by 3 more Phillips-head screws (Key #26).

Remove the fixture.

4. Behind the fixture (Key #25) will be the

muffler lid (Key #24) and muffler lid gasket

(Key #23). The screen sits in the gasket.

5. If the screen (Key #22) is clogged with

deposits, it needs to be cleaned. Use carburetor cleaner, and any brush that is not metal.

Brush the screen until you are able to see

through it.

6. If the screen remains plugged after

attempts at cleaning, it must be replaced.

Maintenance

...continued...

19

Page 20

Storage

Each fall - or before you store your Mantis Edger for any

long period - be sure to take these measures:

1. Do not store your Edger with fuel still in it. Even under

ideal conditions, stored fuel containing ethanol or MTBE

can start to go stale in 30 days. And, since stale fuel has a

high gum content, it can clog the carburetor, which will,

in turn, restrict fuel flow. So, when you’re ready to

store your Edger, or will not be using it for more

than 2 weeks, drain the fuel tank completely. (Picture 2).

2. Next, restart the engine to make sure no fuel is left in

the carburetor. Then run the engine until it stops. This will

prevent gum deposits forming inside of the carburetor and

possible engine damage..

3. Disconnect the spark plug wire and remove the spark

plug. (Use a 19mm or 3/4” spark plug wrench.) Pour about

a teaspoon of clean, air-cooled oil through the spark plug

hole into the combustion chamber (Picture 3). Slowly pull

the starter cord two or three times to coat the inside of the

cylinder wall.

4. Inspect the spark plug and, if necessary, clean it. If you

need to replace it, buy a NGK-BPM7Y.

5. Install the spark plug, but leave the spark plug wire

disconnected.

6. Clean the air filter as described on page 17.

7. Clean dirt, grass, and other materials from the entire

machine.

8. Wipe the blade with oil or spray it with WD-40 to

prevent rusting.

9. Oil the throttle cable and all visible moving parts

(Do not remove the engine cover).

Picture 1

Picture 2

Picture 3

WARNING

DO NOT STORE IN AN AREA WHERE FUEL FUMES MAY

ACCUMULATE AND REACH A FLAME OR SPARK

▲

!

▲

!

20

Page 21

Storage ...continued...

10. Order new parts to replace any that are badly worn

or broken. Just contact your local authorized Mantis dealer.

But do it early, so you’ll have the parts well before the next

season.

11. Store your Edger - in an upright position - in a clean,

dry place (Picture 1, previous page).

12. Do you have any fuel left over from last season?

Dispose of it properly. Buy fresh oil and gasoline next

season.

How to Prepare Your Mantis Edger for Restarting

In the spring, when you take your Edger out of storage,

remove the spark plug. Pull the starter cord three or four

times to clean oil from the combustion chamber (Picture

1). Wipe oil from the spark plug. Place the spark plug back

into the cylinder. Re-connect the spark plug wire back on

the spark plug. Then, follow on steps on pages 10 and 11

to refuel and restart your Edger.

Again, Check the Carburetor

If your Edger won’t restart in the spring - or if it lacks its

usual power - the carburetor may need attention. Follow

the steps on page 18 for adjusting the H and L screws

(Picture 2).

Check the Spark Plug Too

If your Edger won’t restart or if it lacks full power, the

spark plug may be at fault. Check to see if the plug is

fouled with oily black deposits. Clean or replace it if it is.

(Picture 3).

Also, check whether the center electrode is rounded at the

end, or if the ground electrode is worn. If either is the case,

you should replace it with a NGK-BPM7Y spark plug. Use a

19mm or a 3/4” spark plug wrench to install it. Adjust the

plug gap .025 to .028 inches (0.6 to 0.7 mm).

Caution: Do not overtighten the spark plug.

The correct torque is 18 to 22 ft.-lbs. (24-30 n.m.).

Picture 1

Picture 2

Picture 3

IMPORTANT NOTE:

To avoid possible damage to the threads, do

not try to remove the

plug from a hot aluminum cylinder head.

21

Page 22

Troubleshooting Tips

Problem

Engine fails to start

Engine hard to start.

Engine misses.

Engine overheats.

Cause

Start/Stop switch is in Stop

position.

No fuel in tank.

Fuel strainer clogged.

Fuel line clogged.

Spark plug shorted or fouled.

Spark plug is broken (cracked

porcelain or electrodes broken)

Ignition lead wire shorted, broken

or disconnected from spark plug.

Ignition inoperative.

Water in gasoline or stale fuel

mixture.

Too much oil in fuel mixture.

Engine under or over choked.

Carburetor out of adjustment.

Gasket leaks (carburetor or cylinder

base gasket).

Weak spark at spark plug.

Dirt in fuel line or carburetor.

Carburetor improperly adjusted.

Spark plug fouled, broken, or

incorrect gap setting.

Weak or intermittent spark at

spark plug.

Insufficient oil in fuel mixture.

Air flow obstructed.

Solution

Move switch to start.

Fill tank

Replace strainer.

Clean fuel line.

Install new spark plug.

Replace spark plug.

Replace lead wire or attach to

spark plug.

Contact your nearest

Authorized Mantis Dealer

Drain entire system and refill

with fresh fuel.

Drain and refill with correct

mixture.

If flooded by overchoking,

proceed according to instructions in operation section. If

underchoked, move choke

lever to closed position and

crank two or three times.

See “Carburetor Adjustment”.

Replace gaskets.

Contact nearest Authorized

Mantis Dealer.

Remove and clean.

See “Carburetor Adjustment”.

Clean or replace spark plug -

set gap to .024-.028 in.

(0.6-0.7mm)

Contact your nearest

Authorized Mantis Dealer.

Mix fuel as described in

starting instructions.

Clean flywheel cylinder fins

and screen.

22

Page 23

Solution

Clean or replace air filter.

See “Carburetor Adjustment.”

Clean carbon from muffler.

Remove muffler, rotate engine

until the piston is at top of

cylinder. With a wooden

scraper or blunt tool, remove

all carbon from exhaust

ports. Be careful not to

scratch or damage piston

or cylinder walls. Blow out

all loose carbon with com-

pressed air. Install muffler

and gasket.

Clean Spark Arrestor.

Contact nearest Authorized

Mantis Dealer.

Replace with plugs specified for

engine.

Contact nearest Authorized

Mantis Dealer.

See “Carburetor Adjustment.”

Remove dust and dirt from

between fins.

Clean.

Cut less deep. Check that

blades are rotating. Edge at

full throttle.

Tighten bladenut.

Push choke to OFF position.

Tighten screws.

Replace O-ring.

Refill with correct grade grease.

See page X.

Refill with lubricant.

Reassembly parts correctly.

Cause

Air filter clogged.

Carburetor out of adjustment.

Muffler clogged.

Clogged exhaust ports.

Spark Arrestor clogged.

Poor compression.

Spark plugs in incorrect heat range.

Bearings, piston ring or cylinder

walls are worn.

Carburetor adjustment too “lean.”

Engine overheats.

Blade cover filled with dirt/grass.

Clutch slipping.

Loose bladenut.

Choke partly on.

Loose screws.

Broken O-ring.

Grease too thin or oil used.

No lubricant in gearcase.

Loose bladenut or gear adjustment

incorrect.

Problem

Engine lacks power.

Engine noisy or

knocking.

Engine stalls under

load.

Cutting blade does not

turn when operating.

Gear case leaking.

Noisy gears.

Troubleshooting Tips

...continued...

23

Page 24

Engine Specifications

Dry Weight

Type of Engine

Rotation

Bore

Stroke

Spark Plug

Fuel

Fuel Oil Ratio

Gasoline

Displacement

Exhaust System

Carburetor

Ignition System

Starter

Oil

Fuel Tank Capacity

Starter System Clutch

2.5kg - 5 lbs., 10 ounces

Air cooled, two stroke, single cylinder, gasoline engine

Clockwise, viewed from TOP

32.2 mm (1.268 inches)

26.0 mm (1.04 inches)

NGK BPM7Y

Premixed two stroke fuel

50:1 ratio with Mantis oil

Unleaded (see page X)

21.2 cc (1.294 cu. in.)

Spark arrestor muffler

ZAMA diaphragm model C1U type

Flywheel magneto, capacitor discharge ignition type

Automatic rewind type

Designated, two-stroke, air-cooled engine oil

0.4 liter (13.57 oz.)

Automatic rewind starter Centrifugal type

Service Maintenance Guide

Frequency

Daily or every 4 hours of use

Every 3 months or 100 hours of use

Every 3 months of 100 hours of use

6 months or 300 hours of use

6 months or 300 hours of use

Yearly or 600 hours of use*

Before use

Monthly

Yearly

After Use

Before Use

Before Use

Before Use

Before Use

Before Use

Monthly

Monthly

Every 3 months or 100 hours of use

With each refueling

No maintenance

For coil and flywheel

Maintenance

Clean

Replace

Clean

Replace

Check/Rebuild

Replace

Inspect/Clean

Inspect/Clean

Check Grease

Inspect/Clean/Lubricate

Inspect/Repair

Inspect/Tighten/Replace

Inspect/Replace

Inspect/Replace

Inspect/Replace

Inspect/Replace

Inspect/Replace

Replace

Check

Clean

Replace

Area

Air Filter

Spark Plug

Carburetor

Cooling System

Muffler (Spark Arrestor)

Gear Housing

Blades

Fuel Leaks

Fasteners

Labels

Handles

Guards/Safety Devices

Fuel Line

Starter Rope

Fuel Strainer

Choke

Ignition System

24

Page 25

NOTES:

25

Page 26

26

MANTIS EDGER PARTS LIST

KEY # PART # DESCRIPTION

33 100217 Blade Cover Lid

34 100218 Wheel

35 100219 Wheel Arm

36 100220 Height Adjustment Pin

37 100221 Handle Height Adjustment

38 100222 Shield Edger Body

39 100529 Screw 5.5mm

41 100223 Wheel Bushing RH

42 100224 Wheel Bushing LH

43 100531 Nut Clutch Drum

44 100225 Handle Right

45 100226 Handle Left

46 100227 Handle Cross Brace

47 100228 Throttle Trigger assembly

48 100532 Handle Clamp

49 100229 Grip Right Handle w/o Throttle

50 100230 Housing Throttle

51 100231 Grip Left Handle

52 100533 Bolt 1/4” x 5.5"

53 100232 Knob

54 100233 Main Shaft

55 100234 Main Body

56 100235 Clutch Housing

57 100236 Dust Plug

58 100702 Instruction Book Mailorder

59 100237 Switch Wire

61 100601 Motor Warning Label

62 100200 Throttle Cable

63 4078 Nut Jam M6 Hex

64 4079 Washer Lock Internal M6

65 380E-4B1E Engine

66 100608 Mantis Edger Label

KEY # PART # DESCRIPTION

1 100500 Screw M5 x 36mm

2 100501 Nut Nyloc 5mm

3 100100 Bearing with seal 12 x 32 x 10

4 100101 “O” ring 64 x 1.75mm

5 9985 Grease

6 100102 Felt Seal

7 100203 Blades, Mantis Edger

8 100108 Blade Drum

9 100109 Blade Shaft Drive

10 100506 Blade Washer Small

11 100507 Blade Washer Large

12 100111 Crown Gear Spacer

13 100602 Warning Label “Blade Cover” (P)

14 100603 Warning Label Handle (P)

15 100513 Nut M12 x 1.75

16 100122 Pinion L/E

17 100515 Screw M5 x 39 S/thread

18 100521 Self Screw Thread M5 x 19

19 100204 Spring Throttle Lock

20 100205 Spring Throttle Trigger

21 100206 Tab Connector 45 degree

22 100534 Washer Pinion .050

23 100208 Gear, Crown

24 100209 Trigger Throttle

25 100210 Throttle Interlock

26 100211 Switch Slide

27 100212 Spring Adj. Arm

28 100528 Washer Wheel Arm

29 100213 Debris Deflector

30 100214 Spring Debris Deflector

31 100215 Debris Deflector Limiter

32 100216 Blade and Bearing Cover

NOTE: Please use the Part No.

when ordering any parts

Page 27

39

37

27

36

31

12

10

39

17

28

15

7

39

50

20

19

33

39

32

52

39

x6

13

48

13

45

44

59

39

1

14

49

1

51

43

47#

56

35

57

38

9

55

3

3

23

4

25

#47

5

58

24

26

6

21

2

2

46

8

11

41

34

42

29

53

54

3

3

1

1

22

16

2

30

39

10

18

10

2

11

MANTIS EDGER PARTS BREAKDOWN

27

63

64

62

66

66

65

61

Page 28

SV-4B1E Engine Parts

Carburetor

Air Cleaner & Muffler

28

KEY PART QTY DESCRIPTION

NO. NO.

12520013122 1 Carburetor Asy

Includes the following:

1 12534405360 2 Screw

2 12536308560 1 Ring

3 12538108660 1 Pump, Purge

4 12531005360 2 Screw

5 12538305360 1 Base, Purge

6A B1Diaphragm, Metering

7A B1Gasket, Metering

8 12533942030 1 Screw

9A 1Pen, Metering Arm

10 A 1 Lever, Metering

11 A 1 Spring, Metering Lever

12 A 1 Valve, Inlet Needle

13 A 1 Plug, Welch

14 12531649030 1 Valve, Throttle

15 12531413930 1 Screw

16 12531813120 1 Needle, Low Speed

17 12532909860 1 Cap, Limiter L.L.

18 12532013310 1 Needle, High Speed

19 12532939030 1 Cap, Limiter H.S.

20 12532713930 1 Clip

KEY PART QTY DESCRIPTION

NO. NO.

21 12537242030 1 Swivel

22 12531713310 1 Shaft, Throttle

23 12531342030 1 Spring, Throttle Return

24 12537813930 1 Piece, Friction

25 12533306960 1 Screw, Idle Adjust

26 12533306960 2 Screw

27 12532412820 1 Cover, Pump

28 A B 1 Gasket, Fuel Pump

29 A B 1 Diaphragm, Fuel Pump

30 A 1 Strainer

31 12537649030 1 Nozzle, Main Check Valve

32 12532715130 1 Clip

33 12533406560 1 Spring, Adjust Screw

A 12530012820 1 Rebuild Kit

B 12530320560 1 Gasket/Diaphragm Kit

KEY PART QTY DESCRIPTION

NO. NO.

1 13001042032 1 Gasket, Intake

2 90023805020 2 Screw 5 x 20

3 17851004560 1 Rod, Choke

4 13030104560 1 Case, Air Cleaner

5 17881005230 1 Grommet

6 13041005360 1 Bracket, Air Cleaner

7 90024205057 2 Screw 5 x 57

8 89012140630 1 Label, Choke

9 90052800005 1 Nut, Wing

10 13032611521 1 Cover, Air Cleaner

11 13031004560 1 Filter, Air

12 17851504560 1 Shutter, Choke

13 17851600830 1 Spacer

14 12520013122 1 Carburetor Assy

15 13001642031 1 Gasket, Intake

KEY PART QTY DESCRIPTION

NO. NO.

16 13001742031 1 Insulator

17 90050000005 2 Nut 5

20 14580011821 1 Muffler Asy

(Includes Items 21-26)

21 14551042031 2 Gasket, Muffler

(Included In Kit 88900045131)

22 14586240630 1 Screen, Muffler

23 14586642031 1 Gasket, Muffler Lid

(Included In Kit 88900045131)

24 14587642030 1 Lid, Muffler

25 14586306960 1 Fixture, Screen

26 90024204010 3 Screw 4 x 10

27 90010505050 2 Bolt 5 x 50

28 90060000005 2 Washer 5

29 14587105360 1 Cover, Muffler

NOTE: Please use the Part No.

when ordering any parts

Page 29

SV-4B1E Engine

Fuel Tank

Block

Starter, Pawl Catcher & Clutch

29

KEY PART QTY DESCRIPTION

NO. NO.

18 90027505015 3 Screws 5x15

19 90060300005 3 Washers

20 13100511820 1 Tank, Fuel

21 13201011520 1 Pipe 3x5x210

22 13130056430 1Valve, Check

23 13011100530 1 Clip, Pipe

24 13131244330 1 Pipe 3x 5x 70

25 13201049030 1 Pipe 3x6x50

26 13211546730 1 Grommet, Fuel

27 13201309820 1 Clip

28 13120507320 1 Strainer, Fuel

29 13100453530 1 Cap Asy, Fuel Tank

(Includes Item 30)

30 13101655830 1 Gasket, Fuel Cap

KEY PART QTY DESCRIPTION

NO. NO.

1 177200 12820 1 Starter Asy

2 17722042030 1 Spring, Rewind

3 17721544430 1 Drum, Starter

4 17723644330 1 Screw

51Rope Starter

(Use Bulk Rope

99944400040

3 x 890 (.12 x 33.5)

6 17722742030 1 Guide, Rope

7 17728811120 1 Grip, Starter

8 90023804016 4 Screw 4x16

9 90060500008 1 Washer, Spring 8

10 90016204022 2 Bolt 4 x 22

11 15660152130 1 Coil, Ignition

12 99944500071 1 Spark Plug BPM-7Y

13 15901103432 1 Coil, Spark Plug

14 15901201620 1 Cap, Spark Plug

15 15611004920 1 Bushing

16 15680105360 1 Flywheel

17 17720212220 1 Pawl Asy, Starter

(Includes Items 18 & 19)

18 17723442030 2 Spring, Pawl Return

19 17721844330 2 Pawl, Starter

20 90060000005 1 Washer 5

21 90060500005 1 Washer, Spring 5

22 90011505025 1 Bolt 5x25

23 90023804014 4 Screw 4x14

24 61022311520 1 Case Clutch

25 17501004633 1 Drum, Clutch

26 90023806012 1 Screw 6x12

27 17501411520 1 Washer, Clutch

28 17504404630 1 Washer, Clutch

29 90080836000 1 Bearing, Ball 6000

30 90060000010 1 Washer 10

31 17501904630 1 Plate, Clutch

32 17500007531 1 Clutch Asy

(Includes Items 33-35)

33 17500905131 2 Shoe, Clutch

34 17501805130 2 Spring, Clutch

35 17501605020 1 Hub, Clutch

36 16202152830 1 Lead, Ignition

KEY PART QTY DESCRIPTION

NO. NO.

1 10020411520 1Crankcase kit

(Includes Items 2-6)

2 10021242030 2 Seal, Oil

3 10021503930 2 Pin, Dowel

41Gasket, Crankcase

(Included in Kit 88900045131)

5 90081036201 2 Bearing, Ball 620

6 90016205028 3 Bolt 5x28

7 10010013120 1Crankshaft Asy

8 61032502730 1 Key, Woodruff

9 10000048732 1 Piston, Kit

(Includes Items 10-14)

10 10001105330 2 Ring, Piston

11 10001504630 2 Circlip, Piston Pin

12 10001411520 2 Spacer, Piston Pin

13 10001251230 1 Bearing, Needle

14 10001311520 1 Pin, Piston

15 10101044332 1 Gasket, Cylinder Base

(Included in Kit 889000045131)

16 10101106562 1 Cylinder

17 90016205022 2 Bolt 5x22

18 90023804018 2 Screw 4x18

19 10150612820 1Cover, Cylinder

NOTE: Please use the Part No.

when ordering any parts

Page 30

NOTES:

30

Page 31

31

NOTES:

Page 32

LIMITED WARRANT Y INFORMATION

FOR THE MANTIS EDGER

MANTIS extends only to the original

consumer purchaser a limited warranty

against defects in materials and workmanship for a period of two years from

date of purchase. This warranty covers

all portions of the MANTIS Edger.

MANTIS will repair or, at its option,

replace any defective part or parts of the

product free of charge. In the event of

a defect or malfunction, the purchaser

must return the product to an authorized

Mantis dealer.

MANTIS assumes no responsibility in

the event that the product was assembled

or used in contravention of any assembly,

care, safety, or operating instructions

contained in the Owner’s Manual; was not

used with reasonable care; or was used for

other than normal and intended purposes.

MANTIS MAKES NO EXPRESS WARRANTIES

OR REPRESENTATION EXCEPT THOSE

CONTAINED HEREIN. THE DURATION OF

ANY IMPLIED WARRANTY, INCLUDING

MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE, IS LIMITED TO THE

DURATION OF THE EXPRESS WARRANTY.

MANTIS DISCLAIMS ALL LIABILITY FOR

INDIRECT AND/OR CONSEQUENTIAL

DAMAGES. SOME STATES DO NOT ALLOW

LIMITATIONS ON HOW LONG AN IMPLIED

WARRANTY LASTS AND/ OR DO NOT

ALLOW THE EXCLUSION OR LIMITATION

OF INCIDENTAL OR CONSEQUENTIAL

DAMAGES, SO THAT ABOVE LIMITATIONS

AND EXCLUSIONS MAY NOT APPLY TO

YOU. THIS WARRANTY GIVES YOU SPECIFIC LEGAL RIGHTS, AND YOU MAY ALSO

HAVE OTHER RIGHTS WHICH VARY FROM

STATE TO STATE.

MANTIS

1028 Street Road

Southampton, PA 18966

(215) 355-9700

Specifications, descriptions, and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice.

P/N 100707

©MANTIS 5/00

Printed in USA

Loading...

Loading...