Page 1

Manual Includes:

Safety Information

Operating Instructions

Maintenance Schedule

Tips For Better Operation

Illustrated Parts Breakdown

Please Read and Save These Instructions.

For safety, read all safety and operating instructions prior to operating machine.

OPERATOR’S MANUAL

Model 900 Walk Behind Edger

Little Wonder

®

Page 2

Page 3

TABLE OF CONTENTS

Section 1: General Information

Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Table for BedShaper

®

Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 2: Specifications

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Cutting Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Section 3: Safety Instructions

Before Operating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Safety and Instruction Decals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Section 4: Operating Instructions

Control Identification and Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Adjusting Working Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Starting Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

Stopping Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5-6

Tips for Better Bed Shaping Results . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Section 5: Maintenance

Maintenance Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Illustrated Instructions for Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Adjustment- Dirt Scraper Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

Cleaning- End of Season . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8-9

Section 6: Replacement and Repair Instructions

Replace Drive Belts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Change Disc Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9-10

Transmission . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Gearbox & Differential . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Section 7: Illustrated Parts Breakdown

Main Frame and Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11-12

Blade Frame and Drive Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13-14

Wheel Drive and Guard Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15-16

Operations Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17-18

Little Wonder

®

Page 4

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . .see manufacturers manual

Transmission . . . . . . . . . . . . . . . . .hydrostatic, infinite speed control

Blade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .notched, spring steel

Bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .roller

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .welded, formed steel

Gauge Wheel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .single

Cutting Depth . . . . . . . . . . . . . . . . . . . . . . . . .1" - 4.5" (2.5 - 11.4 cm)

Depth Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .pin, position

To tal Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .43" (109.2 cm)

Total Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .51" (129.5 cm)

Total Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .45" (109.2 cm)

Blade Diameter . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16 1/4" (41.3 cm)

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . .365 lbs. (165 kg)

Section 1

GENERAL INFORMATION

HIGHLIGHTED INFORMATION

Information that is of special importance has been

highlighted with headings in boldface type.

Danger, Warning, and Caution identify safety-

related information and can be further identified

by the safety alert symbol . Important identi-

fies information requiring special attention since it

deals with the possibility of damage to part or

parts of BedShaper

®

machines. Note identifies

information worthy of special attention.

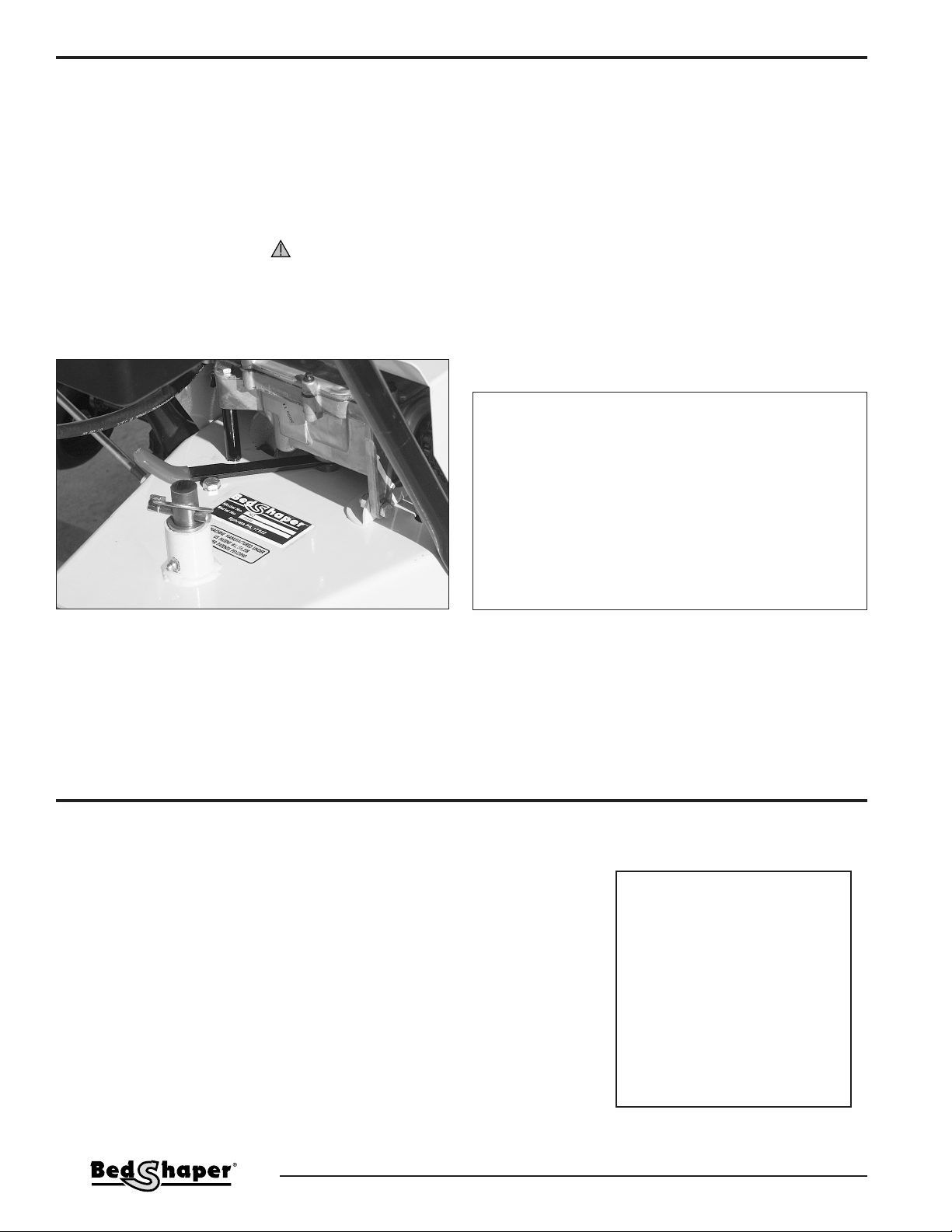

MODEL AND SERIAL NUMBER LOCATION

Both the model number and serial number are

located on the manufacturer’s plate located on

the mainframe of the BedShaper

®

(See Photo 1-1).

The number in the top box is the model number.

The number in the bottom box is the serial number. Please use these numbers when ordering

replacement parts or when obtaining maintenance assistance. Record these numbers in Table

1-1 for easy access.

Fill In Information:

BedShaper

®

Model Number__________________________

BedShaper

®

Serial Number__________________________

Date of Purchase________________________

Dealer Name___________________________

INTENDED USE

BedShaper

®

machines are intended to shape and

edge the perimeter of a landscaped flower bed or

sand trap. It is further intended that the machine

be operated by a trained individual who is familiar

with commercial landscape equipment, standing

behind the machine at the controls.

Section 2

SPECIFICATIONS

Photo 1-1

Table 1-1

LEFT AND RIGHT

Left and right references in this manual are made

from the operator’s position looking in the

direction of travel.

Specifications are subject to change without notification.

1

Repair parts for your

BedShaper

®

are listed in

Section 7, ILLUSTRATED

PARTS BREAKDOWN, and

are available through your

Little Wonder

®

dealer. The

parts list was developed as

a general overview. Contact

your Little Wonder

®

dealer

for the most up to date

information.

Little Wonder

®

Page 5

The safety alert, , means Caution, Warning,

or Danger concerning the operator’s personal

safety. Read, understand, and follow the instructions listed with the safety alert. Failure to heed

these instructions may result in personal injury.

This machine was designed and built with the

operator’s safety as a prime concern. Many features have been included in the attachment to

prevent and protect the operator from personal

injury, but the operator must take safe operation

seriously and take every precaution possible for

safe operation. Failure to follow the safety

instructions contained in this manual may

result in: personal injury, death, damage to

equipment and property.

If you have any questions concerning safety,

operation, maintenance, set-up or product comments, please contact your Little Wonder

®

deal-

er or call Little Wonder

®

at 1-877-596-6337.

BEFORE OPERATING

1. Read, understand, and follow the instructions and contents of this Operator’s Manual

before operating the attachment. Be familiar with

all controls and how to disengage them quickly.

Additional operator’s manuals for the BedShaper

®

are available on request by sending the series and

serial numbers to your Little Wonder Dealer or:

Little Wonder

®

1028 Street Road

Southampton, PA 18966

2. Check area to be edged for foreign objects

which may be thrown by the rotating disc. Pick up

all sticks, stones, wire, and any other debris.

3. Avoid areas that have possible buried hazards. Ask property owner about the presence of

buried hazards before using the BedShaper

®

.

Hazards include: electrical wiring, water pipes,

cable television wire, metal and plastic edging,

irrigation pipes, roots, masonry, metal, and other

items that may cause damage or injury to persons, machine, or property.

4. Never allow children to operate the

BedShaper

®

and tractor. Adults shall not operate

the BedShaper

®

without reading the operator’s

manual.

5. Keep persons, children, and pets clear of

operating machine. Do Not operate the machine

with bystanders in the area.

6. Do not operate the machine while barefoot or

when wearing lightweight footwear. Wear protective footwear, preferably safety work boots and

long pants.

7. Always wear adequate protective clothing. Do

not wear loose fitting clothing that could be

caught in moving parts. Never wear shorts.

8. Safety glasses must be worn by the operator

and may be required by some local ordinances

and insurance policies.

9. Prolonged exposure to loud noise could cause

hearing impairment or loss of hearing. OSHA

approved hearing protection is recommended.

10. Keep all shields and safety devices fastened

and in place. If a shield, safety device or decal is

defective or damaged, repair or replace it before

operating machine.

11. Do not alter safety control lever or safety

devices at all.

12. Never attempt to adjust the machine while the

engine is running. Failure to wait until the engine

and/or driveline comes to a complete stop may

cause injury from moving parts.

13. After operating machine, blade may be hot

enough to cause burns. Allow sufficient time- five

or ten minutes is required- for the blade to cool

before attempting to service, adjust, unclog, or

touch blade.

14. Never by-pass the controls. The blade is

designed to stop if the control lever is not held by

the operator.

15. The machine is to be operated from behind

the handlebars. Never attempt to operate the

machine from anywhere else.

Section 3

SAFETY INSTRUCTIONS

2

Little Wonder

®

Page 6

OPERATION

1. Watch for hidden hazards when operating.

Roots, pipes, wire, sticks and holes can be

encountered quickly. Scout work area and

remove hazards before operating machine.

2. Before adjusting or servicing your BedShaper

®

,

wait for moving parts to come to a complete stop.

MAINTENANCE

1. Disconnect the spark plug wire before servicing or adjusting your BedShaper

®

to prevent

accidental starting.

2. Make sure all fasteners are tight and all shields

are in place and in good condition. Check blade

mounting nut frequently to make sure it is tight.

3. Make only the maintenance adjustments

described in this manual. Any unauthorized

adjustments or modifications to the BedShaper

®

may result in unsafe operating conditions.

4. Never alter or remove any safety devices on the

unit. Safety devices are incorporated into the

design for safe operation.

SAFETY AND INSTRUCTION DECALS

IMPORTANT

Safety and instruction decals are installed at the

factory. If any decals are missing, damaged or

illegible, replacements should be ordered and

installed immediately.

Before Operating, Follow Checklist Below:

• Perform a visual inspection.

• Inspect shields and safety equipment.

• Inspect blade drive belts for proper tension and

alignment.

• Check blade for secure mounting. Gloves

should be worn when handling blade- it may be

sharp enough to cause cuts.

• Adjust blade cutting height.

• Check blade engagement lever with engine running for proper operation. Blade should begin to

turn when handle is approx. 1

1

/2" (3.75 cm) from

being fully seated.

• Perform any maintenance items according to

maintenance chart on page 6.

Photo 3-1

3

❶ Warning Decal

❷ Danger Decal

➌ Underground Hazard Decal

❶

❷

➌

Little Wonder

®

Page 7

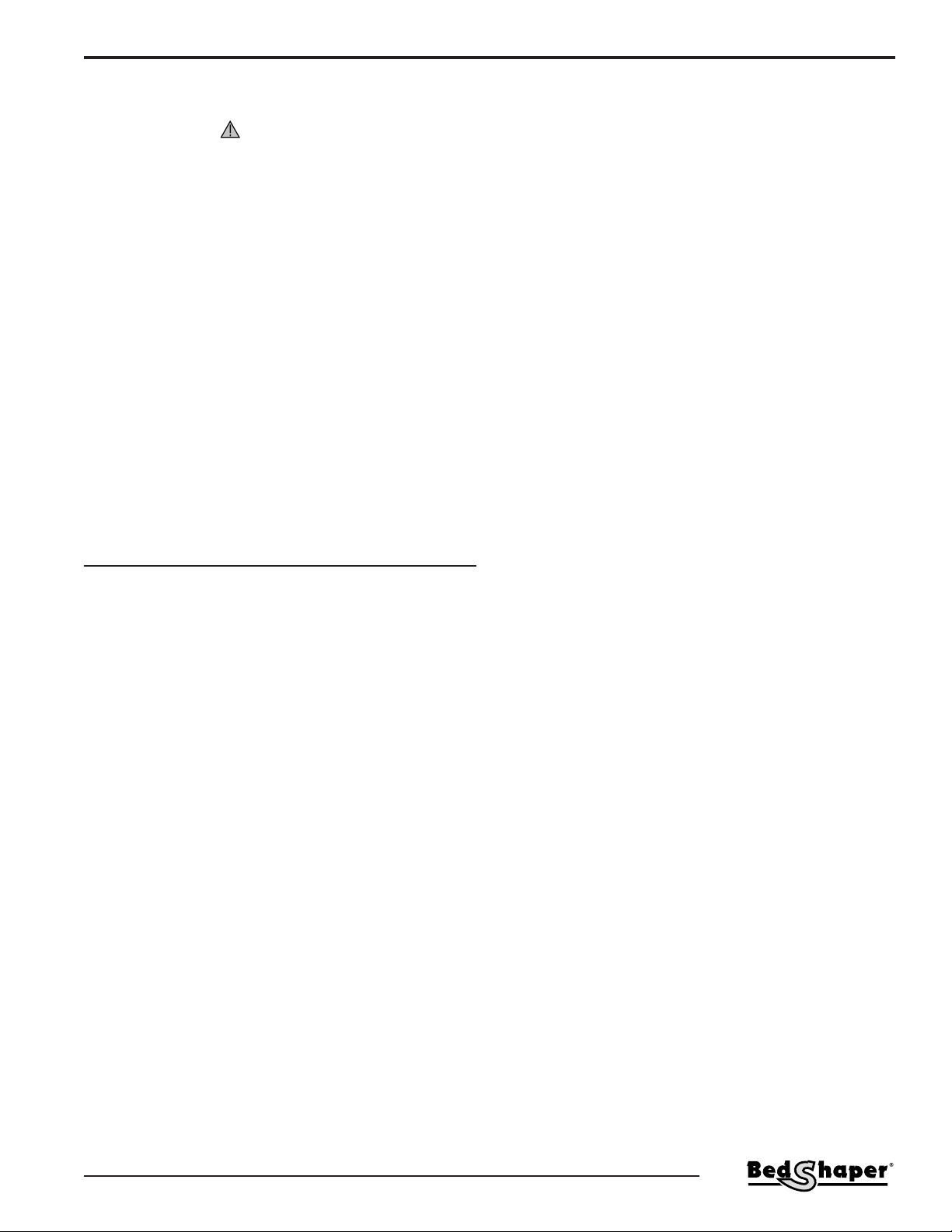

CONTROL IDENTIFICATION AND FUNCTION

Before operating machine, become familiar with

the controls and general operation of the

BedShaper

®

. Know the location, purpose and

operation of the blade engagement lever, speed

control, engine shut off/throttle.

The lift lever is used to raise the blade arm from

the ground for transport. Pulling the lever towards

the operator raises the blade arm to the transport

position. The spring-loaded latch keeps the blade

in the transport position. Releasing the latch and

easing the lever forward will set the blade in the

ground.

The operating speed control is used to propel the

machine in forward and reverse. See “STARTING

OPERATION” for details.

Section 4

OPERATING INSTRUCTIONS

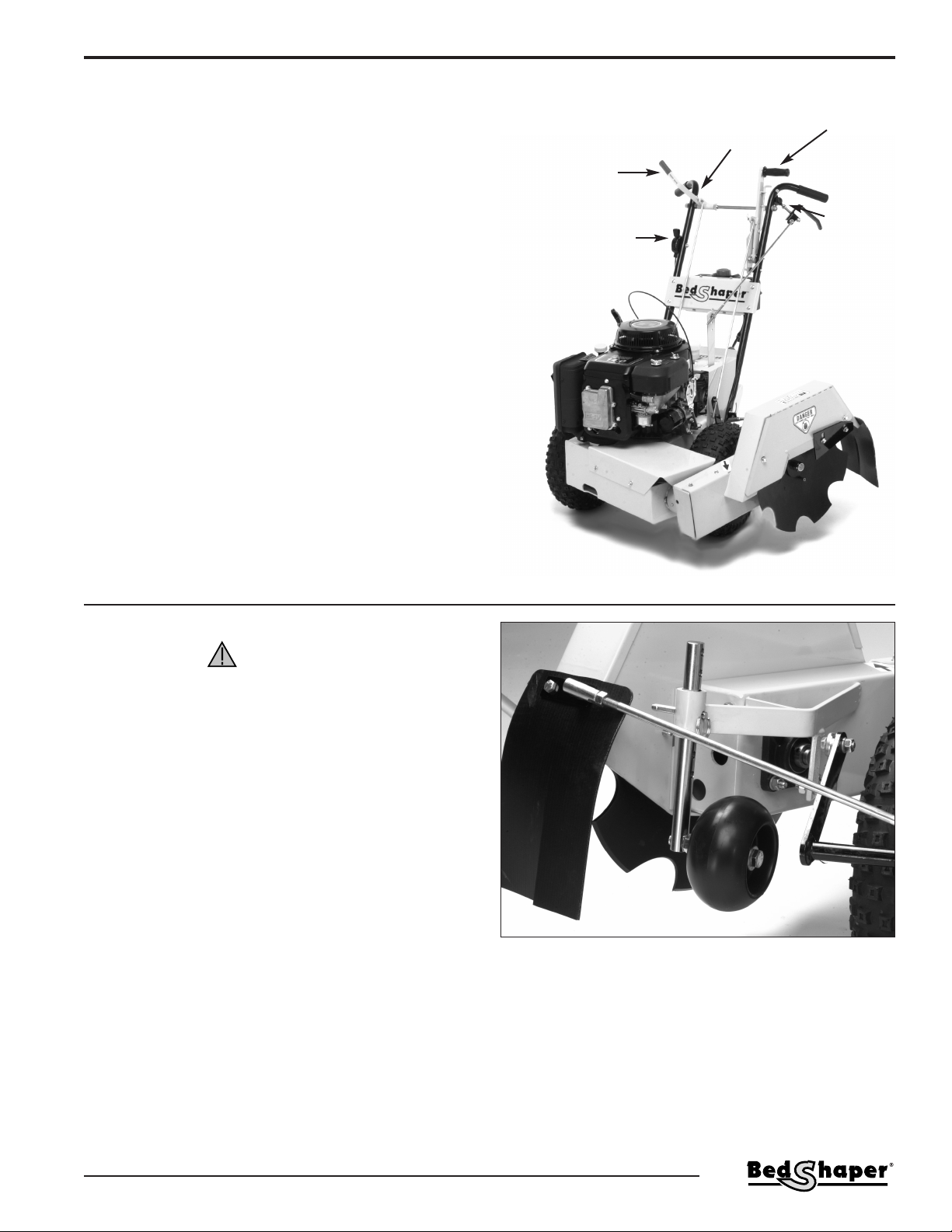

ADJUSTING WORKING DEPTH

Caution

Engine must be stopped

before adjusting working depth.

Blade depth adjustment is controlled by a gauge

wheel (see Photo 4-2). To adjust to a different cutting depth, lift blade arm, remove pin on gauge

wheel, adjust to desired height. Replace pin.

The height of the BedShaper

®

can be adjusted

from 1" to 4.5" (2.5 to 11.4 cm). As a starting point,

with the blade resting on a hard surface, adjust

the gauge wheel so it is 2" (5.1 cm) above the hard

surface. Further adjustments can be made to

accommodate the desired performance.

Photo 4-1

Photo 4-2

4

❶ Blade

Lift Lever

❷ Blade

Engagement

Lever

❹ Throttle

❸ Operating

Speed

Control

❺ On/Off

Rocker Switch

(Kawasaki engine

only)

Little Wonder

®

Page 8

STARTING OPERATION

1. Move throttle to choke position.

(See Photo 4-1 ❹)

2. Start engine. See engine operator’s manual

shipped with your machine.

3. Before engaging blade be sure all bystanders,

especially children and pets, are clear of operating area.

4. Blade should be out of the ground, in transport position.

5. Set engine speed about half throttle. Refer to

the engine operator’s manual which came with

your BedShaper

®

.

6. Engage blade lever. (See Photo 4-1 ➋)

7. Adjust engine speed to full throttle.

8. Smoothly push blade lift lever forward to

lower blade into the ground.

9. Engage operating speed control smoothly to

propel machine forward. (See Photo 4-1 ➌)

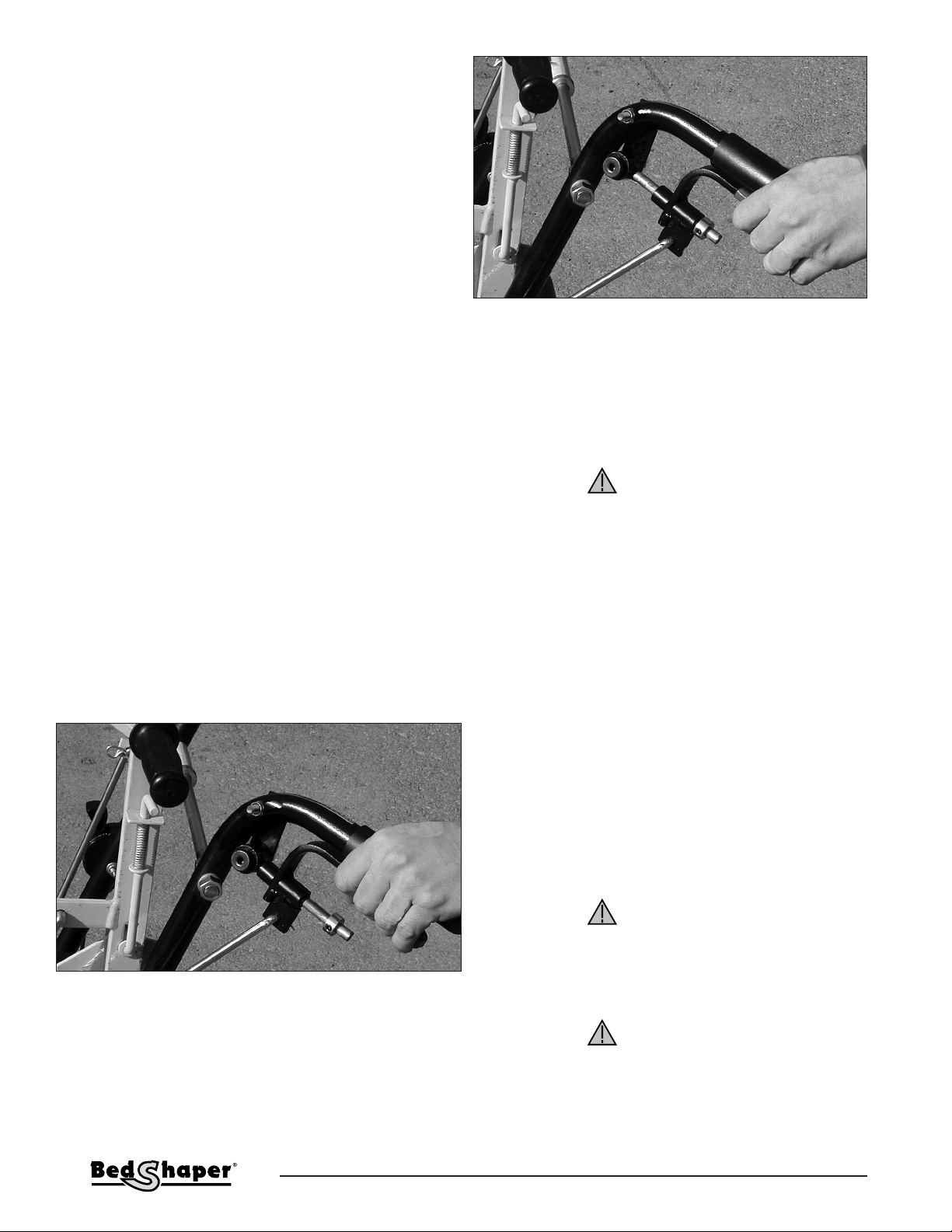

10. Operating speed is achieved by sliding the

control handle forward. Then slowly engage

(squeeze) the lever as shown in Photo 4-3.

11. Transport speed is achieved by sliding the

control handle rearward. Then slowly engage

(squeeze) the lever as shown in Photo 4-4.

12. Reverse is achieved by pushing the control

handle forward (away from your body), and

should only be used with the blade disengaged.

Important: Do not override blade engagement

lever spring loaded safety shutoff.

Caution

Observe conditions behind you before moving

the machine in reverse, making sure you have a

clear path to walk backwards into. Engage lever in

reverse slowly to maintain control over the

machine at all times.

STOPPING OPERATION

1. Release operating speed control lever

(See Photo 4-1 ❸) to stop forward travel.

2. Pull back on blade lift lever (See Photo 4-1 ❶).

3. Release blade engage lever (See Photo 4-1 ❷).

4. Reduce engine speed to an idle.

5. Press On/Off toggle switch to off position if

equipped, or move throttle lever to off position to

shut off engine. (See Photo 4-1 ❺)

Caution

Always remove spark plug wire when leaving

machine unattended. This prevents children and

unauthorized operators from starting and operating unit.

Caution

If blade strikes a stationary object while operating,

disengage blade engagement lever immediately.

Stop engine. Disconnect spark plug wire, and open

blade shield. Inspect machine thoroughly for damage. Make sure that blade is securely tightened.

5

Photo 4-3

Photo 4-4

Little Wonder

®

Page 9

Caution

Never operate the machine at transport speed or

in reverse with the blade engaged or serious bodily injury or machine damage could occur.

TIPS FOR BEST BED SHAPING RESULTS

Blade Life: Conditions will vary, but blade life will

be about 10 hours of operation. Wear will be

noticeable on the notches of the blade. The

sharper and deeper the notches, the better the

cut. Blade speed and soil conditions affect wear.

Replace the blade when worn. Do not attempt to

sharpen or recut notches. This may result in

operator injury.

Soil Conditions: Bed shaping will require the

least amount of time, power and blade wear when

the soil is damp. Pre-wetting the soil may be an

option. The sod will cut cleaner and the remaining

sod strip will stay intact for easier cleanup if

damp.

Pre-Marking: Pre-mark the area to be shaped with

marking paint or lime to ensure a consistent

straight or curved edge. Never use solid objects

or string as markers as these items may be

thrown by the blade or wrap around the blade

shaft.

Multiple Passes and Cutting Width: When establishing a new bed or redesigning an existing bed,

it is recommended that multiple passes be made.

To facilitate removal of sod strips, the passes

should be less than 3" (7.6 cm) in width.

Speed: A slow walking pace is good for safe operation and accuracy, while maintaining efficiency.

Buried Hazards: be constantly aware of the possibility of buried hazards. Check with property

owners about possible hazards before using the

BedShaper

®

. A little time spent investigating an

area may prevent costly mistakes.

Cutting New Beds: First, mark area to show the

new bed outline. Then make first cut approximately 1" (2.5 cm) inside the outer border.

Operate unit in counter clockwise direction,

widening radius 3" (7.6 cm) in each rotation until

desired bed size is achieved.

Clogging: If clogging occurs, disengage the

blade engagement lever. Stop engine, make sure

that all moving parts have come to a stop.

Disconnect spark plug wire. Raise blade arm lift

lever. Remove the two bolts which hold the

hinged blade shield in place. Swing shield into

servicing position.

Danger

If unclogging is required, use a dowel or other

such object to unclog the blade and shield.

When finished unclogging, swing shield back

into place and fasten securely with bolts. Check

blade nut to insure it is tight.

Danger

Never attempt to operate machine without blade

shield securely fastened.

Caution

Hot Blade: allow blade to cool before servicing.

Blade may be hot enough to cause burns.

6

Little Wonder

®

Page 10

7

ILLUSTRATED INSTRUCTIONS

FOR MAINTENANCE

Warning

Before any maintenance or adjustment to

BedShaper

®

is performed, always remember to:

stop engine. Disconnect spark plug wire and

allow components to cool before servicing.

Clean Blade Shield:

1. Make sure blade is cool.

2. Remove two cover bolts from blade shield.

Open hinged shield.

3. Remove debris from shield and behind blade

with a dowel or similar object. Never use handblade may be sharp.

4. Close shield back into position. Securely fasten

shield with two bolts. Never operate without

shield securely fastened.

BedShaper

®

Maintenance Chart- Service Intervals

Item Daily 25 Hrs. Yearly Page

Visual Inspection ■

Engine Refer to Engine Manual

Clean Blade Shield ■ 6

Check Wear on Blade ■ 7

Lubricate Blade Arm Zerk Grease Fittings ■ 7

Check Drive Belts ■ 8

Lubricate Blade Shaft & Axle Bearings ■ 8

Chain Tension ■ 8

End of Season Cleaning ■ 8

Table 5-1

Section 5

MAINTENANCE

Little Wonder

®

Page 11

Check Wear of Blade

1. Make sure blade is cool enough to handle

(always wear gloves when handling blade).

2. Look for any excessive wear, chipping and

abnormal wear. Replace if necessary (see section

6).

3. Check tightness of nut. Never operate

machine when nut is not properly tightened. Nut

should be tightened to 100 ft. lbs (13.8 kg/m).

Check Blade Drive Belt

1. Remove blade (see “change blade”, page 8).

2. Remove bolts from belt drive shield. Remove

shield.

3. Check condition of belt for excessive wear,

fraying and abnormal conditions.

4. Replace with new belt, if necessary (see section 6).

5. Reinstall belt drive shields, fasten securely

with bolts.

6. Replace blade per instructions.

Lubricate Blade Shaft & Axle Bearings (x4)

(Photo 5-1)

1. Locate and clean fittings. ➋ & ➌

2. Pump fittings full of grease using a hand

pump.

Important

Do not overfill. Too much pressure will damage

bearing seals.

Lubricate Blade Arm Zerk Grease Fittings

1. Locate and clean fittings on both sides of arm.

(Photo 5-1) ➊.x2

2. Pump fittings full of grease using a hand

pump.

ADJUSTMENT- DIRT SCRAPER GAP (PHOTO 5-2)

1. Allow blade time to cool.

2. Raise BedShaper

®

blade lift lever into trans-

port position.

3. Examine gap between blade and dirt scraper.

Note: recommended gap is

1

/2" (1.3 cm).

4. Adjust gap, if necessary. Loosen the two bolts

which secure dirt scraper. Adjust gap to

1

/2" (1.3

cm). Snug bolts.

5. Rotate blade at least one full revolution. Check

to see that blade does not contact dirt scraper. If

contact is made, repeat step and increase gap.

Important: dirt scraper must not contact rotating

blade.

6. Tighten bolts on dirt scraper securely.

CLEANING- END OF SEASON

1. Remove bolts from all shields.

2. Tilt or remove shields so that internal parts of

machine are exposed.

Photo 5-1

Photo 5-2

8

❶

❷

➌

Little Wonder

®

Page 12

9

3. Remove dirt and debris from machine using

compressed air.

Important

Always use eye protection when cleaning the

machine.

4. Wash machine with a mild soap and water to

remove dirt and grease.

5. Allow machine to dry thoroughly.

6. Lubricate all fittings with grease and perform

all maintenance checks to prevent corrosion and

to ready machine for new season.

7. Install all shields. Tighten bolts securely.

8. Cover machine with a protective covering.

Store in a dry place.

REPLACE DRIVE BELTS

Replace Blade Arm Drive Belt (Photo 6-1)

1. Follow all instructions for checking blade drive

belt (page 7).

2. Pull idler pulley down to take tension off belt

(photo 6-1).

3. Remove old belt and replace.

4. Reverse step 3.

5. Replace belt cover and blade.

Replace Main Drive Belts

1. Tilt machine forward sufficiently to gain access

to belts on underside of unit.

2. Place a block under rear wheel to keep

machine in raised position safely.

3. Loosen idler mount bolt and slide idler to left.

4. Remove and replace belt.

5. Slide idler to right to tension belt and tighten

idler mount bolt.

6. Remove blocking and tilt machine to ground.

7. Turn engine over slowly to allow engine oil to

return to its sump.

Transmission Drive Chain Adjustment (Photo

6-2). Access chain adjuster block as shown in figure 6-2.

Chain should be snug for proper operation.

Adjust by loosening tension block and sliding

rearward. Do not over tighten chain. Rotate drive

by hand to ensure chain is not over tensioned at

any one spot.

CHANGE DISC BLADE (Photo 6-3)

1. Remove bolts securing the hinged blade

shield. Swing shield into servicing position.

2. Keep blade from turning by inserting a vise grip

between a notch of the blade and the shield bracket.

Section 6

REPLACEMENT AND REPAIR INSTRUCTIONS

Photo 6-1

Photo 6-2

Little Wonder

®

Page 13

3. Wire brush the exposed threads and remove

the nut from the shaft. Remove washer. Remove

the blade from the shaft.

4. Install the new blade on the shaft and align

with the two guide pins. Replace lock nut each

time or shaft damage will occur.

5. Block blade using vise grips as shown. Tighten

nut to 100 ft. lbs. (13.8 kg/m) torque.

6. Tilt hinged shield into position. Install two bolts

and tighten securely.

Transmission

The transmission requires no servicing or maintenance. Oil level in the reservoir should be at the

lower reservoir mark when cold and will be at the

upper reservoir mark when hot.

The machine can be towed manually by disengaging the hydrostatic transmission. To tow, move the

lever to the left and over the Hex bolt head to “tow

position” as shown in figure 6-4. To re-engage,

move the lever to the “run postion”.

Gearbox & Differential

The gearbox and differential require no servicing

or maintenance.

Photo 6-3

10

Safety shield shown open.

Photo 6-4

Little Wonder

®

Page 14

Main Frame and Drive Assembly

11

D

2

1A

1

20

19

18

11

17

16

14

14A

13

12

10

9

8

7

7A

7B

4

5

6

15

3

Section 7

ILLUSTRATED PARTS BREAKDOWN

Page 15

Main Frame and Drive Assembly

12

1 22192 1 Deck Assembly

20966 1 3/16” grease zerk, self tapping

18129 1 Spacer 1” x 5/8” x 1/4”

1A 20901 4 Engine spacers

2 22218 1 Engine, Briggs & Stratton, 10.5 HP

20918 1 Engine, Honda, 13 HP

22167 1 Engine, Kawasaki, 13 HP

20901 4 Spacer (Honda & Briggs engine)

3 21099 1 Hydrostatic transmission

22142 5 Shim

22089 1 Reservoir

22084 1 Angle Mount

22088 1 Adapter

22103 1 RTN spring

22047 1 Tow lever

18413 1 Grip tow lever

22045 4 Pipe spacer

4 22022 1 Pulley

90603 1 key

22046 5/16” x 4 1/4” CSH

90063 Cap screw 5/16” x 11/4”

5 22170 1 Belt, hydrostatic drive

6 18038 1 Pulley, hydrostatic drive

90027 2 3/16” x 3/8” set screw

7 18020 1 Idler hydrostatic drive

90041 1 3/8” x 2 3/4” carriage bolt

90033 1 3/8” lock washer

90030 1 3/8” hex nut

7A 20947 1 Spacer

7B 18050 2 Belt guide

90044 1 3/8” x 1” cap screw, gr 5

90033 1 3/8” lock washer

90030 1 3/8” hex nut

Item # Part # Qty Description

8 18053 1 Key

9 18040 1 Pulley, blade drive

90027 1 3/8” set screw

10 18006 1 Idler pulley, blade drive

90038 1 3/8” x 1 3/4” cap screw, gr 5

90033 1 3/8” lock washer

90030 1 3/8” hex nut

11 20948 1 Idler pulley, blade drive

90038 1 3/8” x 1 3/4” cap screw, gr 5

90033 1 3/8” lock washer

90030 1 3/8” hex nut

90071 2 Shim

12 18201 1 Belt, blade drive

13 18418 1 Arm, blade belt tensioner

14 18004 2 Bushing

14A 18002 1 Bolt, shoulder

90033 1 3/8” lock washer

90030 1 3/8” hex nut

15 18003 1 Pulley, gearbox drive

16 18008 1 Hub

90015 3 1/4” x 1 1/4” cap screw, gr 5

90011 3 1/4” lock washer

17 18054 1 Key, woodruff

18 18047 1 Spring, tension

19 18502 1 Blade drive gearbox

90053 2 5/16” x 1 1/2” cap screw, gr 5

90052 2 5/16” lock washer

90048 2 5/16” hex nut

20 18405 1 Gearbox cover

20994 3 1/4” x 3/4” screw, self tapping

Item # Part # Qty Description

Page 16

Blade Frame and Drive Assembly

13

GEAR

C

L

BOX

1

2

3

5

6

7

8

9

9A

10

11

12

13

14

15

16

17

18

19

20

21

22

2323

2

25

26

Page 17

Blade Frame and Drive Assembly

14

1 18401 1 Arm, blade

20966 2 3/16” grease fitting, drive in

2 18025 2 Bearing & lock collar assembly

90036 4 3/8” x 1 1/2” cap screw, gr 5

90033 4 3/8” lock washer

90030 4 3/8” hex nut

22184 2 set screw

20966 2 3/16” grease fittings

3 18101 1 pin, detent

5 18103 1 Wheel, gauge

90008 2 1/2” x 4 1/4” cap screw, gr 5

90029 2 3/8” flat washer

6 18426 1 Shank

7 18098 1 Eye bolt

90052 1 5/16” lock washer

90048 1 5/16” hex nut

8 18018 1 Spring, tension

9 22190 1 Shaft

9A 90602 1 Key

10 18060 1 Washer, blade

11 18061 1 Nut

12 90102 2 Roll pin

13 19233 1 Blade

Item # Part # Qty Description

14 21056 1 Hub & pulley, blade drive

18465 1 Dust seal

15 18022 1 Bolt, shoulder

90033 1 3/8” lock washer

90030 1 3/8” hex nut

16 18020 1 Idler, blade drive

90038 1 3/8” x 1 3/4” cap screw, gr 5

90033 1 3/8” lock washer

90030 1 3/8” hex nut

17 90605 1 Key

18 18302 1 Pulley, gearbox driven

90053 1 5/16” x 1 1/2” cap screw, gr 5

90046 1 5/16” flat washer

19 18131 1 Collar, split/with screw

20 22130 1 Spacer

21052 1 Shim

21 18134 1 Bushing, bronze

22 18019 1 Idler arm

23 20902 2 Bushing

25 22172 1 Belt, blade drive

26 20949 1 Snap ring

Item # Part # Qty Description

Page 18

Wheel Drive and Guard Assembly

15

1

1A

2

3

4

5

5A

6

2

8

9

10

11

12

11

13A

13

14

14A

15

16

16A

17

17

18

19

22

21A

21

16

16A

19

20

Page 19

Wheel Drive and Guard Assembly

16

1 18125 1 Fork

1A 18129 2 Spacer

2 18128 2 Bushing

20966 1 3/16” grease fitting

3 18127 1 Wheel, caster

90074 1 1/2” x 5 1/2” cap screw, gr 5

90003 1 1/2” hex nut

4 18130 1 Sleeve

5 18307 1 Chain tensioner

5A 18309 1 Spring washer

90064 1 5/16” x 1 1/4” carriage bolt

90048 1 5/16” hex nut

90052 1 5/16” lock washer

6 22059 1 Trans. spocket

22142 1 Shim

22083 1 Clip

8 18124 1 Lynch pin

9 22054 1 Transmission cover

20994 4 1/4” x 3/4” self tapping screw

10 20952 1 Mounting bracket

90040 1 3/8” x 1” cap screw, gr 5

90033 1 3/8” lock washer

90030 1 3/8” hex nut

11 20950 2 Ball joint

90031 4 3/8” hex nut, fine thread

12 20951 1 Support rod

13 18205 1 Mud flap

13A 18206 1 Mud flap clamp

90019 1 1/4” x 3/4” cap screw, gr 5

90009 1 1/4” flat washer

Item # Part # Qty Description

90010 1 1/4” hex nut

14 18408 1 Blade scraper outer

18462 1 Blade scraper inner

14A 21053 2 Nutsert, 5/16”

15 18406 1 Blade/belt cover

90009 4 1/4” flat washer

90010 4 1/4” hex nut

16 22033 2 Tire & wheel assembly

90028 3 3/4” flat washer

16A 20949 2 Snap ring

17 18055 2 Key

18 18414 1 Spacer

19 18316 2 Bearing, axle

90075 4 7/16” x 1 1/2” cap screw, gr 5

90076 4 7/16” lock washer

90077 4 7/16” hex nut

20966 2 Grease fitting

20 18415 1 Spacer

21 18501 1 Differential unit

21A 20932 1 Differential sprocket

22 22066 1 Chain, drive with #41 connector link

Item # Part # Qty Description

Page 20

Control Assembly

17

D

B e dB e d

h a p e rh a p e r

1

1A

2A

2

2B

2C

3

4

5

6

6A

18

19

14

15A

15

16

17

15B

7

7A

9A

8

9

10

11

13

24

24

25

26

26

27

28

30

28

26

31

32

33

32

35

40- Decal set (not shown)

Page 21

Control Assembly

18

Item # Part # Qty Description

1 18402 1 Handle, left

90040 2 3/8” x 1” cap screw, gr 5

90033 2 3/8” lock washer

90030 2 3/8” hex nut

1A 18114 2 Grip, handle bar

2 18413 1 Lever, blade engage

2A 18115 1 Grip, red

2B 18110 2 Bushing, nylon

2C 18109 1 Set collar

31Throttle control

18318 1 Briggs - Throttle control

22141 1 Honda - Throttle control

22208 1 Kawasaki - Throttle control

4 18424 1 Rod, blade engage

90046 1 5/16” flat washer

20974 1 1/8” x 1 1/2” hairpin cotter

5 22104 1 Handle support

90013 4 Carriage bolt

90011 4 1/4” lock washer

90012 4 1/4” nut

6 18403 1 Handle, right

90040 2 3/8” x 1” cap screw, gr 5

90033 2 3/8” lock washer

90030 2 3/8” hex nut

6A 18412 1 Handle bar

90002 2 1/2” flat washer

90003 4 1/2” hex nut

7 18422 1 Lever, blade lift

Item # Part # Qty Description

7A 19256 1 Grip, blade lift

8 18120 1 Spring, latch

9 18421 1 Latch rod

9A 18023 1 Push nut

10 18423 1 Quadrant

22155 1 Depth control version

11 18416 1 Rod, blade lift

90046 1 5/16” flat washer

20974 1 1/8” x 1 1/2” hairpin cotter

13 18430 1 Spacer, quadrant

14 20909 1 Plate, tank (except B. & S.)

20994 2 1/4” x 3/4” self tap. screw

15 20906 1 Fuel tank (except B. & S.)

15A 20905 1 Fuel cap (except B. & S.)

15B 22173 1 Fuel line (except B. & S.)

22174 4 Line clamps

16 20983 1 Fuel filter

17 20908 1 Fuel valve (except B. & S.)

18 22087 1 Handle, hydrostatic

22086 1 Slide rod

22144 1 Bushing

22173 2 Set collar

22124 1 Tab, mounting

22113 2 Set collar hydro control

19 22057 1 Rod, hydro

90046 1 5/16” flat washer

90021 1 1/8” x 1” cotter pin

22 20954 1 Grip - red

Item # Part # Qty Description

24 20950 1 Ball Joint

25 22205 1 Lift rocker assembly

90028 1 3/4” flat washer

90024 1 3/16” x 1 1/2” cotter pin

26 18113 1 Swivel

90040 2 5/16” flat washer

90066 2 1/8” x 1” cotter pin

27 18427 1 Spacer, rocker

28 18118 2 Bushing

30 22048 1 Lever, travel control

31 18112 1 Shoulder bolt

32 20902 2 Bushing

33 18021 1 Bell crank

35 22058 1 Rod, blade engage

90046 1 5/16” flat washer

90066 1 1/8” x 1” cotter pin

40 20904 1 Decal set, model 900

41 18033 1 Rod end

Page 22

19

Little Wonder

®

Page 23

Page 24

Little Wonder

®

LITTLE WONDER®

DIVISION OF SCHILLER-PFEIFFER, INCORPORATED

1028 STREET ROAD, P.O. BOX 38

SOUTHAMPTON, PA 18966

PHONE 877-596-6337 • FAX 215-357-8045

www.littlewonder.com

Specifications, descriptions, and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice.

P/N 70001

3/04

2 YEAR LIMITED SERVICE & WARRANTY POLICY

All Little Wonder BedShapers

®

are guaranteed against defects in material and workmanship

for a period of TWO YEARS from date of purchase, when used for RESIDENTIAL SERVICE, or

COMMERICIAL SERVICE. Any Little Wonder BedShaper

®

or part found to be defective

within the warranty period is to be returned to any registered Little Wonder dealer.

Engines for all gasoline powered products are warranted separately by the engine manufacture.

Therefore, there are no warranties made, expressed or implied, for engines for gasoline powered

products by Little Wonder.

Transportation charges for parts and units submitted for replacement under this warranty must be

borne by the purchaser.

THIS WARRANTY shall not be effective if the product has been subject to misuse, negligence or

accident, or if the product has been repaired or altered outside of our Southampton factory or

authorized repair facility in any respect which affects its condition or operation.

Little Wonder shall not be liable for any special indirect or consequential damages arising

from defective equipment. Any implied warranty, including merchantability of fitness for a particular purpose, shall not extend beyond the written warranty period.

THIS WARRANTY shall only be effective if the enclosed Warranty/Registration card is properly

filled out and returned to Little Wonder, Div. of Schiller-Pfeiffer, Inc. at time of purchase.

877-LWONDER

Loading...

Loading...