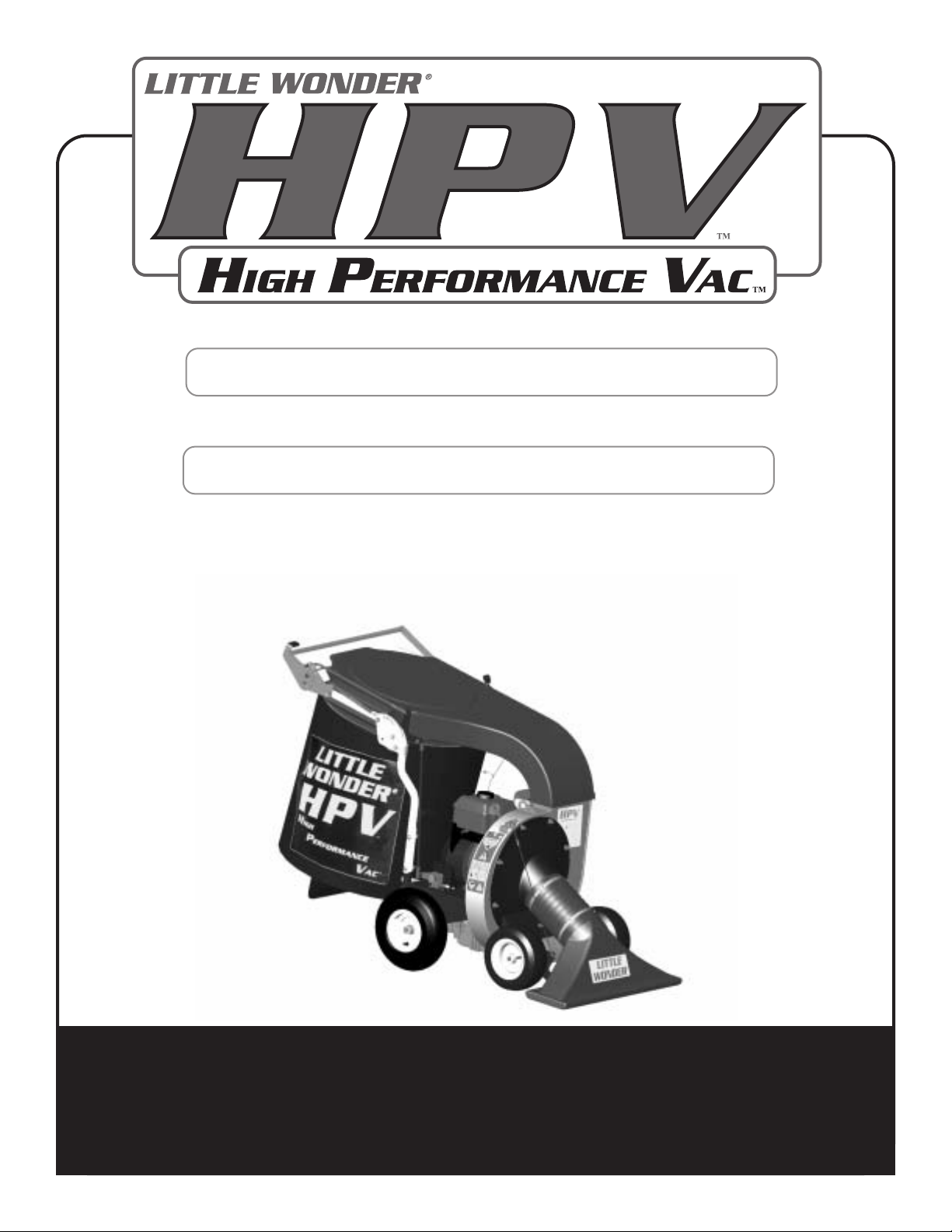

Page 1

© 2008 Little Wonder, Div. of Schiller-Pfeiffer Inc. All Rights Reserved.

ASPIRADORA DE ALTO RENDIMIENTO

ASPIRATEUR HAUTE PERFORMANCE

© 2008 Little Wonder, Division de Schiller Pfeiffer Inc. Tous droits réservés.

© 2008 Little Wonder, División de Schiller - Pfeiffer, Inc. Todos los Derechos Reservados.

Models 5621 and 5631

Modèles 5621 et 5631

Modelos 5621 y 5631

SELF PROPELLED

AUTOTRACTÉ

AUTO-PROPULSADA

Page 2

1

Table of Contents Important Information

A. Introduction

On behalf of everyone at

Little Wonder

, we would like to

thank you for your purchase of a

Little Wonder

High

Performance Vac. This professional debris handling machine

was designed to the highest standards to ensure you many

hours of uninterrupted service.

This manual provides the information necessary for safe and

efficient operation and service. For your safety, it is critically

important that you read and understand this entire manual

before operating your High Performance Vac.

Specifications:

Model Dry Weight Max Rpm

5621 258 lbs. 3400

5631 260 lbs. 3400

B. Service Information

High Performance Vac Unit

Contact your local

Little Wonder

dealer.

Engine

Contact an authorized Briggs & Stratton dealer. Dealers are

listed in the Yellow Pages under “Lawn and Garden Equipment

Supplies”, “Lawn Maintenance” or “Lawn Mowers”. Your

dealer will need to know the model and serial number of your

engine. For their location, please consult the operator’s manual

provided with your engine.

C. Special Safety Information

WARNING DANGER

ATTENTION: THIS SYMBOL POINTS OUT

IMPORTANT SAFETY INSTRUCTIONS

WHEN YOU SEE THIS SYMBOL

HEED ITS WARNING! STAY ALERT!

WARNING DANGER

TO REDUCE THE POTENTIAL FOR ACCIDENTS,

COMPLY WITH THE SAFETY INSTRUCTIONS IN

THIS MANUAL. FAILURE TO COMPLY MAY RESULT

IN SERIOUS PERSONAL INJURY AND OR

EQUIPMENT AND PROPERTY DAMAGE.

WARNING DANGER

THE ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

Important Information

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Service Information . . . . . . . . . . . . . . . . . . . . .1

Special Safety Information . . . . . . . . . . . . . . . .1

Unpackaging

Unpackaging Information . . . . . . . . . . . . . . . . .2

Safety and Warnings

Safety Decals . . . . . . . . . . . . . . . . . . . . . . . . . .2

General Safety Rules

Warnings - "Don’ts" . . . . . . . . . . . . . . . . . . . . .4

Warnings - "Do’s" . . . . . . . . . . . . . . . . . . . . . . .4

Engine/ Fuel Warnings - "Don’ts" . . . . . . . . . .5

Engine/ Fuel Warnings - "Do’s" . . . . . . . . . . . .5

Assembly Instructions

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Speed Controller Setup . . . . . . . . . . . . . . . . . . .7

Put Oil and Gasoline in Engine

Before Starting . . . . . . . . . . . . . . . . . . . . . . . . .8

Use of Lifting Lug . . . . . . . . . . . . . . . . . . . . . .9

Operation

Starting Instructions . . . . . . . . . . . . . . . . . . . . .9

Self-Propelled Setup . . . . . . . . . . . . . . . . . . . . .9

Vacuuming . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Empty Debris Bag . . . . . . . . . . . . . . . . . . . . . .10

Refueling the Engine . . . . . . . . . . . . . . . . . . .10

Storage and Maintenance

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . .11

Removing Blockage in Moving Parts . . . . . . .12

Removing the Fan . . . . . . . . . . . . . . . . . . . . . .12

Changing V-Belt . . . . . . . . . . . . . . . . . . . . . . .12

Part Numbers

HPV Parts Assembly . . . . . . . . . . . . . . . . . . . .13

HPV Parts List . . . . . . . . . . . . . . . . . . . . . . . .14

HPV Engine Assembly . . . . . . . . . . . . . . . . . .15

HPV Deck Assembly . . . . . . . . . . . . . . . . . . .15

HPV Collector Assembly . . . . . . . . . . . . . . . .16

HPV Liner Assembly . . . . . . . . . . . . . . . . . . .17

HPV Nozzle Assembly . . . . . . . . . . . . . . . . . .17

Warranties

Warranty . . . . . . . . . . . . . . . . . . . . . .Back cover

Page 3

2

Unpacking

1. Remove Collector assembly, Nozzle assembly, and

Debris bag from the top section of the package.

2. Remove cardboard insert.

3. Cut away short side of box and fold down.

4. Pull and latch “transaxle engagement lever.”

See page 9.

5. Roll HPV base unit out of box.

P/N 600602

Warning Label

P/N 600605

Warning Label

Caution:

Thrown

objects.

Keep

bystanders

away.

Always wear

eye, ear and

breathing

protection.

Before

performing

any service or

maintenance,

disconnect spark

plug wire. Make

sure throttle is in

STOP position.

Read and

understand the

Owners Manual.

Store your

Owners Manual

in a safe place.

Keep hands and

feet away from

air discharge

areas. Rotating

fan will cause

serious injury.

Safety and Warnings

A. Safety Decals

An important part of the safety system incorporated in this

High Performance Vac are the warnings and informational

decals (labels) found on various parts of the unit.

These decals (labels) must be replaced if they become illegible

due to abrasion, etc.

It is your responsibility to replace the decals (labels) when they

become hard to read. The location of these decals and their

part numbers for ordering are shown on page 3.

WARNING DANGER

IMPROPER USE OR CARE OF THIS HIGH

PERFORMANCE VAC, OR FAILURE TO WEAR PROPER

PROTECTION CAN RESULT IN SERIOUS INJURY.

READ AND UNDERSTAND THE RULES FOR

SAFE OPERATION AND ALL INSTRUCTIONS

IN THIS MANUAL.

WEAR HEARING, EYE, AND BREATHING

PROTECTION.

P/N 600604

Page 4

3

P/N 600604

Safety and Warnings

P/N 600602

Warning Label

P/N 600605

Warning Label

Page 5

4

General Safety Rules

1. Read and understand manual.

2. Wear eye, hearing, and breathing protection, proper

clothing and footwear.

3. While operating the machine always be sure of a safe and

secure operating position, maintain a firm footing and

good balance at all times.

4. Keep area clear of children, pets and bystanders.

5. Never attempt to use an incomplete machine or one fitted

with an unauthorized modification.

6. Avoid contact with and inhalation of harmful fluids, gases,

mists, fumes, and dust.

7. Do not allow children to operate machine.

8. Do not override or remove any safety devices.

12. Keep hands away from hose inlet and discharge chute.

13. Disconnect spark plug before doing any cleaning or

maintenance.

14. Wear gloves to protect your hands.

15. Beware that the machine is loud and, during normal

operation; may interfere with speech communication.

A. Warnings - "Don’ts"

Don’t attempt to remove materials from intake or discharge

when High Performance Vac is running, or fan is rotating.

Don’t install or remove components while High Performance

Vac is running. Turn off engine to make changeover. Be sure

throttle is in the stop position, and the High Performance Vac

has come to a complete stop. Remove the spark plug wire

from the spark plug before removing material.

Don’t attempt to repair High Performance Vac. Have repairs

made by qualified Little Wonder dealer or repairman. See that

only Little Wonder and recommended engine manufacturers

replacement parts are used.

Don’t leave the engine running while the High Performance

Vac is unattended.

Don’t store, spill, or use gasoline near flames or spark

B. Warnings - "Do’s"

Always dress properly. Do not wear loose clothing or jewelry.

They can be caught in moving parts. Use of sturdy gloves,

non-skid footwear and safety glasses are recommended.

Always wear ear protectors where possible. Use face filter to

avoid breathing dust.

Always stay alert. Watch what you are doing and use common

sense. Do not operate High Performance Vac when fatigued.

Always keep hands away from air intake and air outlet chute.

Keep both hands on handles when power is on.

Always maintain and examine High Performance Vac with

care. Follow maintenance instructions given in manual.

WARNING DANGER

9. FAN COASTS AFTER THE ENGINE IS TURNED OFF.

WARNING DANGER

DO NOT SMOKE WHEN FILLING FUEL TANK

WARNING DANGER

10. ROTATING FAN. DON’T ATTEMPT TO REMOVE

MATERIALS FROM INTAKE OR DISCHARGE WHEN

UNIT IS RUNNING, OR FAN IS ROTATING.

WARNING DANGER

DO NOT USE THE HIGH PERFORMANCE VAC IF THE

MUFFLER IS DEFECTIVE OR MISSING.

WARNING DANGER

11. DO NOT OPERATE UNIT IF EXCESSIVE VIBRATION

OCCURS; SHUT ENGINE OFF IMMEDIATELY!

REMOVE SPARK PLUG WIRES AND CHECK FOR

DAMAGED IMPELLER, LOOSE IMPELLER BOLT,

LOOSE IMPELLER KEY, OR LODGED

FOREIGN OBJECTS.

Page 6

5

WARNING DANGER

IF THE HIGH PERFORMANCE VAC IS USED

IMPROPERLY OR SAFETY PRECAUTIONS ARE NOT

FOLLOWED, THE USER RISKS SERIOUS INJURY TO

THEMSELVES AND OTHERS.

READ AND UNDERSTAND THE FOLLOWING

BEFORE ATTEMPTING TO OPERATE THIS

HIGH PERFORMANCE VAC.

WARNING DANGER

HANDLE FUEL WITH CARE. IT IS HIGHLY

FLAMMABLE. FUELING A HOT ENGINE OR NEAR

AN IGNITION SOURCE CAN CAUSE A FIRE AND

RESULT IN SERIOUS PERSONAL INJURY AND/ OR

PROPERTY DAMAGE.

D. Engine/ Fuel Warnings - "Do’s"

Always use fresh gasoline. Stale gasoline can cause

difficult starting, poor performance and leakage.

Always pull starter cord slowly until resistance is felt.

Then pull cord rapidly to avoid kickback and prevent

arm or hand injury.

The use of spark arrestor mufflers is required by law in

the state of California (Section 4442 of the California

Public Resources Code), as well as in other states or

municipalities. Federal laws apply on federal lands.

Always handle fuel with care; it is highly flammable.

Never add fuel to a machine with a running or hot

engine. Do not inhale fuel fumes as they are toxic.

The spark ignition system meets all requirements of

the Canadian Interference Causing Equipment

Regulations.

monoxide and other gasses are emitted.

Don’t run engine when electrical system causes spark

outside the cylinder. During periodical checks of the

spark plug, keep plug a safe distance from cylinder to

avoid burning of evaporated fuel from cylinder.

Don’t check for spark with spark plug or plug wire

removed and grounded. Use an approved tester. Sparks

can ignite fumes.

Don’t run engine when the odor of gasoline is present

or other explosive conditions exist.

Don’t operate the unit if gasoline is spilled. Clean up

spill completely before starting engine.

Don’t refuel indoors or in an improperly ventilated

area.

Don’t operate your High Performance Vac if there is

an accumulation of debris around the muffler and

cooling fins.

Don’t touch hot mufflers, cylinders or cooling fins as

contact may cause serious burns.

B. Warnings - "Do’s" Continued

Always store High Performance Vac indoors. When not in use,

store High Performance Vac indoors in a sheltered area

(a dry place) where it’s not accessible to children. The High

Performance Vac, as well as fuel, should not be stored in a

house. Keep throttle in the stop position.

Always be sure High Performance Vac is fully assembled.

Never operate High Performance Vac without all guards and

deflectors in place. Ensure that all nuts, bolts, screws are

installed and properly tightened.

Always keep the throttle in the “stop” position when not in use.

Always keep a safe distance between two or more operators

when working together simultaneously.

C. Engine/ Fuel Warnings - "Don’ts"

Don’t fuel, refuel or check fuel while smoking or near

an open flame or other ignition source. Stop engine and

be sure it is cool before refueling.

Don’t leave the engine running while the High

Performance Vac is unattended. Stop engine before

transporting High Performance Vac from one place to

another.

Don’t start or run this High Performance Vac indoors,

or in an improperly ventilated area as poisonous carbon

Page 7

6

A. Assembly

1. Attach the collector assembly to the base unit:

• Bolt the collector assembly to the frame with 4 sets of

bolts, washer, and nuts

• Slide the rectangular end of the collector over the housing

and mount the flange with 2 sets of washers and nuts

2. Attach the throttle control cable to the handle on the

collector assembly:

• Bolt throttle control lever to handle with washer and nut

• Secure throttle cable to handle with cable ties in 2 places

3. Install the band clamp into the debris bag (wear gloves

when handling band clamp):

• Slide the bracket end of the band clamp through the left

side opening of the sleeve on the debris bag until it

emerges from the right side

• Feed the tail end of the band (on the clasp side) behind

the bracket in the sleeve

• Pinch the wire form on the clasp together and connect it

through 2 holes in the adjustment bracket such that it will

close tightly over the collector

4. Connect the debris bag by placing it over the bottom lip of

the collector and closing the clasp to secure the bag. Adjust

the clasp wire form to the appropriate hole position on the

bracket to insure a tight fit. If the bag will not fit tight within

the range of the 3 adjustment holes, insert the bag seal strap:

• Unhook the wire form from the bracket

• Pull the tail end of the

band back out from

behind the bracket

• Feed one end of the seal

strap behind the metal

band and through the

channel to the other side

• Tuck the other end of

the seal strap behind

the bracket

(overlapping the lead

end of the seal strap)

• Feed the tail end of the

band clamp behind the

bracket (overlap the

seal strap)

• Connect the wire form

to the appropriate holes

in the bracket and

secure the debris bag to

the collector

5. Attach nozzle assembly to

base unit:

• Attach one end of the

hose to the nozzle

assembly with the

bridge clamp

• Slide the other end of

Assembly Instructions

the hose over the edge of the inlet on the front plate

• Hook one side of the nozzle bracket over the front axle

• Bend the other end of the nozzle bracket inward to

hook it over the axle and engage the pins on the wheel

bracket with the slots on the nozzle bracket

• Secure the hose to front plate inlet with the bridge

clamp

• Attach the nozzle cable end fitting through the hole in

the nozzle bracket

6. To remove nozzle assembly (for purposes of storage, or

clearing blockages):

• Turn engine off and disconnect spark plug

• Loosen hose clamp on the front plate with flathead

screwdriver or 5/16 wrench

• Slide hose off of front plate inlet

• Bend one side of nozzle bracket inward and twist the

assembly to remove the hook from the axle

• Twist back and lift to remove the other side of nozzle

bracket from the axle

WARNING DANGER

NEVER RUN OR OPERATE YOUR MACHINE

UNLESS DISCHARGE BAG IS ATTACHED,

AND THE INTAKE NOZZLE IS INSTALLED.

Page 8

7

7. Speed Controller Setup

1.

Attach the Lower Connecting Rod Assembly to the

Lower Bellcrank.

a. Attach Lower Connecting Rod Assembly to the Lower

Bellcrank with a 3/8”-24 Nyloc Nut. Tighten using

9/16” and 1/2” wrenches.

2.

Setup the Speed Controller Mechanism – Critical for

proper operation.

a. Verify that the Self-Locking Acorn Nut is tightened

sufficiently to hold the Upper Connecting Rod

Assembly firmly in place. If not, slightly tighten the

Self-Locking Acorn Nut.

b. Verify the Actuator reversing function by depressing

the Reversing Lever (Red) and then releasing it. It

should work smoothly and, when released, it should

fully return to the “normal” position.

c. If the Actuator does not work smoothly, binds up,

or does not fully return to the “normal” position,

loosen the Self-Locking Acorn Nut slightly and

recheck the operation. Repeat as needed to achieve

proper operation.

d. Depress the Reversing Lever and then press lightly

on the Bail Handle until the Front Face of the Rear

Slot on the Bail Handle just touches

the Actuator

Pin (also refer to picture in step ‘e’ below).

e. The Front Face of the Rear Slot and the Actuator

Pin Bushing should be in contact with each other

and appear as shown below:

f. If the Actuator Pin does not enter into the Rear

Slot as show below, the Upper Connecting Rod

Assembly is too short and must be lengthened.

i. Remove the nut that holds the Rod End to the

Upper Bellcrank.

ii. Disconnect the Rod End from the Upper

Bellcrank.

iii. Adjust the Rod End outwards by unscrewing it

counterclockwise.

iv. Reattach the Rod End to the Upper Bellcrank

and secure it with the nut (hand tightened).

v. Repeat this adjustment as needed to position

the Rear Slot and Actuator Pin as shown in

step ‘e’ above.

Page 9

8

B. Put Oil and Gasoline in Engine

Before Starting

1. Little Wonder recommends using SAE 30 Oil. The use of

multi-viscosity oil will result in high oil consumption and

possible engine damage.

2. Add gasoline to the fuel tank, and you are ready to start.

3. See Engine Operating & Maintenance instructions for

more detail description of type and amount of oil and

gasoline used.

WARNING DANGER

HANDLE FUEL WITH CARE. IT IS HIGHLY

FLAMMABLE. FUELING A HOT ENGINE OR NEAR

AN IGNITION SOURCE CAN CAUSE A FIRE AND

RESULT IN SERIOUS PERSONAL INJURY AND/ OR

PROPERTY DAMAGE.

g. If the Actuator Pin enters into the Rear Slot as

shown below, the Upper Connecting Rod

Assembly is too long and must be shortened.

i. Remove the nut that holds the Rod End to the

Upper Bellcrank.

ii. Disconnect the Rod End from the Upper

Bellcrank.

iii. Adjust the Rod End inwards by screwing it

clockwise.

iv. Reattach the Rod End to the Upper Bellcrank

and secure it with the nut (hand tightened).

v. Repeat this adjustment as needed to position

the Rear Slot and Actuator Pin as shown in

step ‘e’ above.

h. While holding the Reversing Lever down,

gradually press down on the Bail Handle. The

Actuator Pin should engage the Rear Slot smoothly

with minimal or no “snapping” action when the

Bail Handle is depressed. It may be necessary to

readjust the Rod End as described above to finetune this action.

i. Release the Bail Handle. It should return to its full

upright position and the Actuator Assembly should

also return to its “normal” position as shown below:

j. Depress the Bail Handle and verify that the

Actuator Pin smoothly engages the Front Slot on

the Bail Handle.

k. Verify the forward and reverse operations several

times to assure that the set up is correct.

l. Lock the Rod End of the Upper Connecting Rod

Assembly by holding the Rod End in position with

a 1/2” wrench and then tightening the nut with a

9/16” wrench as shown below:

m. Verify that Rod End is straight and not cocked as

depicted below:

n. Remove the standard 3/8”-24 Nut from the Rod

End of the Upper Connecting Rod Assembly and

replace it with the 3/8”-24 Nyloc Nut. Tighten

using both a 9/16” & 1/2” wrench.

Setup of Speed Controller complete.

Page 10

9

Operation

WARNING DANGER

THE OPERATOR OF THIS HIGH PERFORMANCE

VAC IS RESPONSIBLE FOR ACCIDENTS OR

HAZARDS OCCURRING TO HIMSELF, OTHER

PEOPLE OR THEIR PROPERTY.

WARNING DANGER

ENGINE EMITS CARBON MONOXIDE. DO NOT

OPERATE OR REFUEL IN ENCLOSED AREA.

A. Starting Instructions

1. Perform pre-starting checks (engine oil and gas level, all

safety inspections, etc. Read entire Owners’ Manual for all

pre-starting information.)

2. Release the Transaxle Engagement Lever

3. Make sure Gas Supply Knob (located above Recoil

Starter) is turned to On position.

4. Move Choke Lever (located above and to the left of the

Recoil Starter) to Choke position.

5. Move Throttle Control Lever (located on Left Handlebar)

to Middle Position or Full Position (toward Rabbit symbol.)

6. Pull Recoil Starter Handle slowly until resistance is felt,

then pull firmly to start engine.

7. When engine starts, slowly move Choke Lever to

Open position.

8. Increase Throttle Control Lever to Full Speed if desired.

9. NOTE: If engine is difficult to start: Press Belt Tension

Lever down with your left foot before pulling Recoil

Starter Handle. (This disengages the belt for easier

starting.) When engine starts, slowly release your foot

from the Belt Tension Lever.

WARNING DANGER

DO NOT USE OR SERVICE THE UNIT WHEN IT’S

SUSPENDED FROM THE LIFTING LUG.

WARNING DANGER

FUEL IS EXTREMELY FLAMMABLE. HANDLE IT

WITH CARE. KEEP AWAY FROM IGNITION

SOURCES. DO NOT SMOKE WHILE FUELING

YOUR EQUIPMENT.

C. Use of Lifting Lug

Little Wonder High Performance Vac is supplied with

convenient Lifting Lug that can be used when you need to move

the unit.

B. Self-Propelled Instructions

1. With engine running (and Transaxle Lever in Engage

position) slowly press Bail Handle downward to selfpropel vacuum FORWARD. The farther down you press

the Bail Handle, the faster the speed of the vacuum.

Slowly release the Bail Handle to reduce speed or to stop.

2. To self-propel in Reverse, first press downward on the

Reverse Lever, and (with the Reverse Lever pressed

down) press downward on the Bail Handle. The farther

down you press the Bail Handle, the faster the speed of

the vacuum in REVERSE. Slowly release the Bail Handle

to reduce speed or to stop.

3. Releasing the Bail Handle at any time stops the vacuum

from movement.

RECOIL STARTER HANDLE

tension when starting

BELT TENSION LEVER

Step on to release belt

CHOKE LEVER

THROTTLE CONTROL LEVER

REVERSE LEVER

Release to engage

Press to engage

GAS SUPPLY KNOB

Pull and latch to disengage

reverse mode

TRANSAXLE ENGAGEMET LEVER

BAIL HANDLE

Press to propell

HPV forward or reverse

NOZZLE CONTROL

KNOB

BAND CLAMP

CLASP

HPV Control Levers

Page 11

10

D. Empty Debris Bag

1. Turn off engine and let it come to a complete stop before

removing the debris bag.

2. Roll vacuum to the desired unloading location

(compost pile, curb-side, wooded area, tarp, etc.).

3. Open clasp on band clamp to release bag to the ground.

Avoid dragging bag on surface to prolong bag life.

4. Empty contents of debris bag (handle straps are provided

on the under side of the bag for aid in dumping contents).

5. Reconnect bag to collector.

E. Refueling the Engine

1. Stop engine and allow it to cool for a few minutes before

refueling.

C. Vacuuming

1. Adjust nozzle to desired height by turning the nozzle

control knob, secure position with wing nut.

2. Vacuum debris from lawn or paved surfaces. Vacuum the

following: leaves, small twigs and sticks, acorns, thistles,

seed pods, grass clippings, straw, wood chips, dry mulch,

litter, small cans & bottles, paper products, styrofoam

products.

3. Avoid the following: excessively wet surfaces and debris,

gravel surfaces, large hard objects, rocks, long fibrous

materials (vines, rope, string etc). Do not force anything

into vacuum.

WARNING DANGER

KEEP RECOIL STARTER SCREEN AND ENTIRE

ENGINE CLEAR OF ALL DEBRIS. DO NOT

OPERATE ENGINE WITH AN ACCUMULATION OF

GRASS, DIRT, LEAVES OR OTHER

COMBUSTIBLE MATERIAL NEAR MUFFLER.

WARNING DANGER

DO NOT OPERATE UNIT IF EXCESSIVE

VIBRATION OCCURS; SHUT ENGINE OFF

IMMEDIATELY! REMOVE SPARK PLUG WIRES

AND CHECK FOR DAMAGED IMPELLER,

LOOSE IMPELLER BOLT, LOOSE IMPELLER KEY,

OR LODGED FOREIGN OBJECTS.

Page 12

11

A. Storage

1. After each use, run HPV with the empty bag attached to help clear out any loose material in the housing.

2. When not in use store High Performance Vac in sheltered area (a dry place) not accessible to children. Keep throttle in the

“Stop” position.

3. The High Performance Vac, as well as fuel, should not be stored in a house or poorly ventilated areas.

4. Do not store fuel in the engine’s gas tank longer then

30 days.

Storage and Maintenance

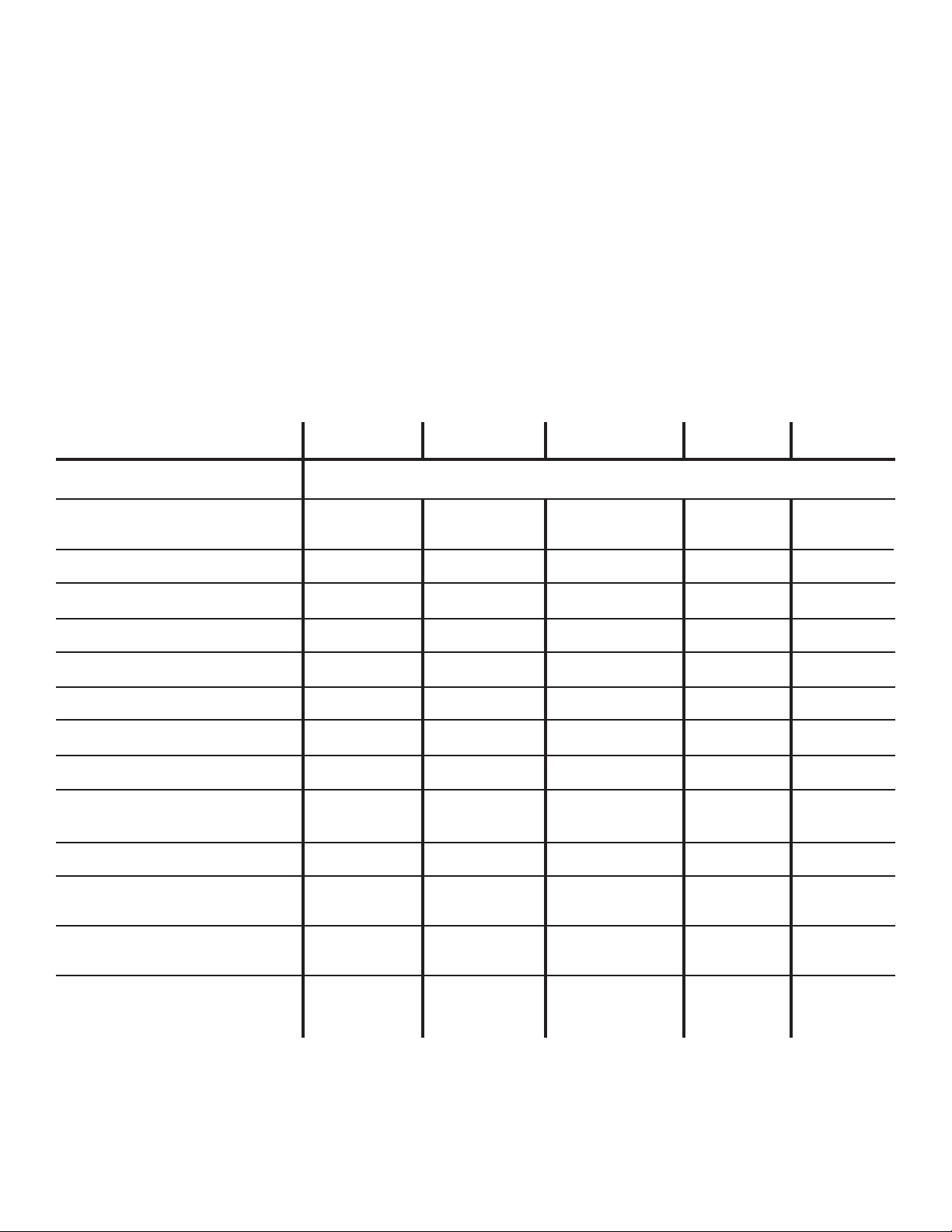

B. Maintenance

After First

8 Hrs of Use

Every

Use

Every

5 Hrs

Every

25 Hours

Every

50 Hours

Area

*Engine

Check muffler area for

accumulation of debris

Check for excessive vibration

Inspect for loose or damaged parts

Inspect for clean intake nozzle

Inspect labels condition

Check oil level

**Oil change

Service air cleaner

Clean and inspect spark plug

arrester

Check tire pressure

Inspect speed control for proper

operation

Check V Belt for excessive wear,

cracks, etc.

Check idler pulleys for smooth

operation

See Engine Manual

* See Engine Operating & Maintenance instructions for more detail maintenance and service schedule.

** Change oil every 25 Hrs if operating under heavy load or high ambient temperature.

Page 13

12

6. Replace damaged or worn fan with a new one. If during

fan removal the key (#915) was removed from the keyway,

reinstall it by applying a few drops of the Loctite 380

instant adhesive (“Black Max” P/N 38050) on the key, and

load the key in the keyway of the shaft. (Cure time is

approx. 1 min.)

7. Use a new bolt (#600524) (add Loctite 242 to new bolt)

and washer (#910527) and complete fan installation.

Insure a secure fit upon re-assembling. Torque bolt to

39-51 Ft. lbs.

E. Changing V-Belt

1. Turn off engine. Remove Spark Plug Wire from Spark

Plug. Chock or block wheels of vacuum to prevent it

from rolling.

2. Remove Debris Bag from vacuum.

3. Remove 3 hex head bolts that attach Belt Guard to

Deck. (Use 7/16” wrench or socket.) Set Belt Guard aside.

Note how V Belt goes around each of 4 pulleys and how

it “twists.”

4. Remove 4 hex head bolts that attach Recoil Starter Cover

to Engine Standoffs. (Use 8 millimeter nut driver, socket or

wrench.) Remove Recoil Starter Cover.

5. Loosen (but do not remove) 2 hex head bolts that attach

Fixed Idler Bracket to Deck. (Use 7/16” wrench or socket.)

This allows clearance for belt to be removed.

6. Press down on Belt Tension Lever and lift V Belt off its

pulley. Release Belt Tension Lever. Remove V Belt from

Engine Pulley.

7. Remove V Belt from large horizontal pulley of transaxle

(under Deck.) Pushing V Belt forward with both hands,

then lifting V Belt up, then pulling V Belt backwards

should remove it from large pulley. Remove V Belt from

under Deck.

8. Reverse above steps to replace V Belt. Install V Belt with

the same “twists” that the old V Belt made around the

pulleys. Make sure the “V” side of the V Belt goes into

each pulley. Before replacing Belt Guard or starting

engine, pull Recoil Starter Handle several times to make

sure V Belt rides in the grooves of each pulley.

9. Make sure Belt Tension Lever and return spring operate

smoothly. If it sticks or does not operate smoothly,

lubricate the Belt Tension Lever and its mounting bracket

with a few drops of Motor Oil, or other medium weight

oil. Push Belt Tension Lever down and release it several

times to allow lubrication to penetrate between lever and

mounting bracket. Proper operation of the Belt Tension

Lever and its return spring will insure that your V Belt

will operate properly and last many hours of use.

WARNING DANGER

TURN OFF ENGINE BEFORE YOU DISCONNECT

HOSE, AND MAKE SURE ALL MOVING PARTS

COME TO A COMPLETE STOP.

WARNING DANGER

BE SURE THROTTLE IS IN “STOP” POSITION, AND

FAN HAS COME TO A COMPLETE STOP.

WARNING DANGER

DISCONNECT THE SPARK PLUG WIRES BEFORE

ANY CLEANING OR MAINTENANCE!

WARNING DANGER

WEAR GLOVES, THE CLOG MAY CONTAIN

SHARP MATERIALS.

C. Removing Blockage in Moving Parts

1. Support the housing with 2x4 lumber such that front wheel

are 1” above the ground.

2. Chock the rear wheels with blocks.

3. Remove the nozzle assembly from the front plate.

(See Assembly Instruction 6.)

4. Remove the front wheel assembly.

5. Remove the front plate.

6. Wear gloves and clear out debris from around the impeller

and housing.

D. Directions for removing the Fan

and reinstallation

1. Remove spark plug wire from spark plug.

2. Remove nozzle assembly.

3 Remove front plate assembly.

4. Remove the bolt that secures the fan to the engine

crankshaft.

5. The fan has a 3/4-16 nut welded on the fan hub. Insert a

3/4-16 x 5" long grade 5 (or better) bolt and jack or push

the fan off the engine. (Little Wonder P/N 910505 pressure

screw is recommended.)

Page 14

13

1

4

4x

35

44

4x

46

2

53

4x

4x

31

15

3

31

59

23

21

34

51

43

4x

4x

4x

64

58

48

57

20

CONNECT TO ENGINE

THROTTLE LEVER

45

47

18

19

45

52

2x

2x

46

4x

7

42

33

8

49

40

4x

50

9

52

45

6x

17

16

17

30

14

11

14

63

4x

60

61

62

46

6x

6

22

37

36

54

3x

3x

55

32

56

55

32

15

38

41

56

39

25

46

46

394x

4x

46

29

13

4x

10

5

29

30

12

12

25

28

24

26

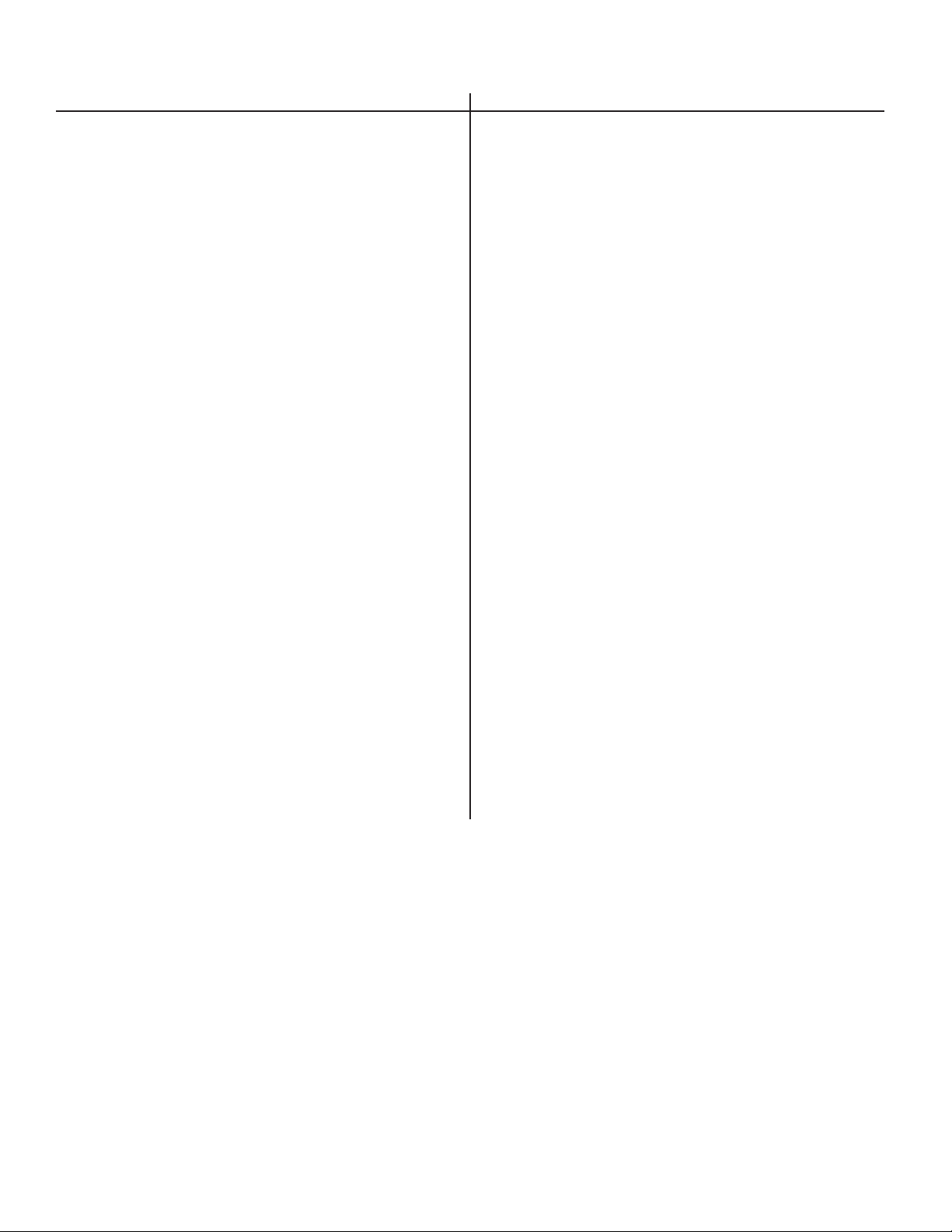

HPV Parts Assembly

Page 15

14

KEY NO.PART NO.DESCRIPTION QTY.

1 SEE DETAIL 6.5 HP ENGINE ASSEMBLY 1

2 SEE DETAIL DECK ASSEMBLY 1

3 600193 TRANSAXLE 1

4 600184 HANDLE MOUNT 1

5 600251 BELT GUARD 1

6 600186 HOUSING - WITH OUT LINER HOLES 1

7 600187 HOUSING - WITH LINER HOLES 1

8 600114 IMPELLER-BALANCED 1

9 600118 FRONT PLATE 1

10 600182 BRACKET, FRONT WHEELS 1

11 600188 AXLE, FRONT 1

12 600137 SPACER, WHEEL 2

13 600257 WEIGHT DISC 4

14 934 WHEEL, 10" 2

15 600195 WHEEL, 13" 2

16 600102 HOSE, NOZZLE, 7"D x 10" LG 1

17 720420 BRIDGE CLAMP, HOSE, 7" D 2

18 600162 KNOB, NOZZLE CONTROL, 5/16-18,

FEMALE 1

19 600104 NOZZLE CONTROL CABLE 1

20 600239 THROTTLE CABLE CONTROL LV

w/ Trans 1

21 600176 BAND CLAMP 1

22 600196 BAG SEAL STRAP 1

23 600177 DEBRIS BAG 1

24 600220 LEVER, DISCONNECT, LV TRANS 1

25 600252 SPRING HANGER 1

26 600548 HAIR PIN, 1/4" SHAFT 1

25 600555 PIN, CLEVIS, 1/2" x 1-1/2" LG 1

28 600556 PIN, HITCH 1

29 600258 COLLAR, 5/8 2

30 312 SNAP RING, 5/8D 2

31 600540 E CLIP 2

32 920532 KEY 3/16 x 3/16 x 1-1/2" LG 2

33 915 KEY, 1/4" SQ x 2" LG 1

K

EY NO.PART NO.DESCRIPTION QTY.

34 600504 BOLT, CARRIAGE, 3/8-16 x 2-1/4, GR.5 4

35 600525 BOLT, CARRIAGE, 3/8-16 x 2" LG 4

36 600537 BOLT, HEX, 1/4-20 x 3/4" LG 3

37 600545 BOLT, HEX, 1/4-20 x 2.5" LG 1

38 942 BOLT, HEX, 5/16-18 x 1-3/4"LG 4

39 600547 BOLT, HEX, 5/16-18 x 2-1/4"LG 5

40 600524 BOLT, 3/8-24 x 1.75" LG 1

41 600546 BOLT, SELF TAP, 5/16-8 x 3/4" LG 1

42 910503 BOLT, SERRATED FLANGE,

5/16-24 x 3/4" LG 4

43 720518 NUT, NYLOCK, 3/8-16 4

44 720594 NUT, SERRATED FLANGE, 3/8-16 4

45 114C NUT, NYLOCK, 5/16-18 9

46 114B NUT, SERRATED FLANGE, 5/16-18 15

47 600507 NUT, WING, 5/16-18 1

48 600506 NUT, NYLOCK, 1/4-20 1

49 910527 WASHER, FAN, FLANGED 1

50 600523 WASHER, 5/16 ID x 3/16 TH 2

51 720516 WASHER, FLAT, 3/8, USS 4

52 720511 WASHER, FLAT, 5/16, USS 8

53 129D WASHER, SPLIT LOCK, 5/16 4

54 600554 WASHER, LOCK, STAR, EXT, 1/4" 3

55 600269 WASHER, THRUST,

OILITE 3/4" ID x 1-1/4" OD x 1/16" TH 2

56 600268 WASHER, THRUST,

OILITE 3/4" ID x 1-1/4" OD x 1/8" TH 6

57 600518 WASHER, 1/4", COLLECTOR 1

58 720411 CABLE TIE, 7.5" 2

59 600521 HARDWARE BAG 1

60 16-102 WARRANTY CARD 1

61 600709 OWNERS MANUAL 1

62 N/A ENGINE MANUAL 1

63 SEE DETAIL NOZZLE ASSEMBLY 1

64 SEE DETAIL COLLECTOR ASSEMBLY 1

HPV Parts List

Page 16

15

HPV Deck Assembly

HPV Engine Assembly

1

5

7

8

3

6

2

4

4x

4x

KEY NO. PART NO. DESCRIPTION QTY.

1 600901 ENGINE, 6.5 HP 1

2 600901 RECOIL, SUPPLIED W/ ENGINE (600901) 1

3 600901 NUT, SUPPLIED W/ ENGINE (600901) 1

4 600901 BOLT, SUPPLIED W/ ENGINE (600901) 4

5 600194 PULLEY, ENGINE 1

6 600249 STANDOFF , ENGINE 4

7 600200 BELT, V, LV W/ TRANS 1

8 600238 KEY, ENGINE PULLEY 1

KEY NO. PART NO. DESCRIPTION QTY.

1 600199 DECK, LV W/ TRANS 1

2 600231 BELLCRANK, DECK 1

3 600244 BRACKET, BELLCRANK, DECK 1

4 600264 BRACKET, IDLER, WELDMENT 1

5 600266 LINK, BELLCRANK, WELDMENT 1

6 600219 STRAP, TORQUE, LV 1

7 600204 BRACKET, MOUNT, TENSION 1

8 600203 BRACKET, TENSION 1

9 600555 PIN, CLEVIS, 1/2" X 1-1/2" LG 1

10 600556 PIN, HITCH 1

11 600270 BUSHING, FLANGED, 1/2" ID X 5/8" OD X 1/2" LG 2

12 600224 PULLEY, IDLER, LV 2

13 600201 BEARING, NEEDLE, 1/2" ID X 11/16" OD 4

14 600253 SPRING, PULLEY, IDLER 1

15 600526 BOLT, SHOULDER, 1/2" X 1-1/4" LG 3

16 600537 BOLT, HEX, 1/4-20 X 3/4" LG 6

17 129C BOLT, HEX, 5/16-18 X 3/4" LG 1

18 600536 BOLT, SHOULDER, 3/8" X 3/8" LG 1

19 114B NUT, SERRATED FLANGE, 5/16-18 2

20 600541 NUT, THIN JAM, 3/8-16 3

21 600554 WASHER, LOCK, STAR, EXT, 1/4" 6

22 600558 SHIM, SHOULDER BOLT, 1/2" OD X .015 TH 2

23 600557 WASHER, BELVILLE SPRING 3/8 ID X 5/8 OD 2

Page 17

16

KEY NO. PART NO. DESCRIPTION QTY.

1 600101 DISCHARGE COLLECTOR 1

2 600130 HANDLE 1

3 600142 FLANGE CLAMP PLATE 1

4 600138 FLANGE ANGLE-COLLECTOR 1

5 600242 BRACKET, BELLCRANK, HANDLE 1

6 600206 BELLCRANK, HANDLE 1

7 600215 BAIL HANDLE 1

8 600211 REVERSE LEVER 1

9 600271 CAP, REVERSE LEVER 1

10 600161 HOOK STRIP 1

11 600605 WARNING LABEL - DEBRIS BAG 1

12 600260 SPRING, RETURN CONTROL 1

13 600237 SPRING, TORSION, BAIL 1

14 600210 ROD, CONTROL, UPPER 1

15 600209 ROD, CONTROL, LOWER 1

16 20950 SWIVEL ASSEMBLY 3/8-24 3

17 600552 BOLT, HEX, 1/4-20 X 2" LG 2

18 600545 BOLT, HEX, 1/4-20 X 2.5" LG 3

19 600544 BOLT, HEX, 5/16-18 X 2"LG 1

20 600543 BOLT, HEX, 5/16-18 X 3.5"LG 1

21 600551 BOLT, SHOULDER, 5/16 DIA X 3/8" LG 1

22 600506 NUT, NYLOCK, 1/4-20 6

23 114C NUT, NYLOCK, 5/16-18 2

24 600542 NUT, NYLOCK, 3/8-24, YELLOW ZINC 3

25 114B NUT, SERRATED FLANGE, 5/16-18 2

26 600528 NUT, THIN JAM, 3/8-24 5

27 600549 NUT, ACORN, 1/4-20, SELF LOCKING 1

28 600550 NUT, ACORN, 3/8-24, SELF LOCKING 1

29 600518 WASHER, 1/4", COLLECTOR 7

30 396 WASHER, LOCK, 1/4", SPLIT 1

31 720510 WASHER, FLAT, 1/4, USS 5

32 720511 WASHER, FLAT, 5/16, USS 6

33 600259 BUSHING,ACTUATOR 1

34 600246 BUSHING, FLANGED, DRYLIN MFI-0608-04 2

35 600262 SPACER, OILLITE, 1/4" ID X 3/8" OD X 3/8" LG 2

36 600241 BUSHING, FLANGED, OILLITE, 5/16 ID X 7/16 OD X3/8" LG 2

37 600263 SPACER, OILLITE, 5/16" ID X 3/8" OD X 3/8" LG 1

38 600256 SPACER, OILITE, 5/16 ID X 5/8 OD X 1.25" LG 2

HPV Collector Assembly

Page 18

17

HPV Liner Assembly

KEY NO. PART NO. DESCRIPTION QTY.

1 600187 HOUSING ASSEMBLY, WITH LINER HOLES 1

2 600175 LINER 1

3 720592 FLANGE BOLT, 5/16-18 X 1" LG 10

4 720511 WASHER, FLAT, 5/16, USS 10

5 114C NUTS, NYLOCK, 5/16-18 10

KEY NO. PART NO. DESCRIPTION QTY.

1 600100 NOZZLE 1

2 600133 NOZZLE CLAMP PLATE ASSEMBLY 1

3 600183 NOZZLE BRACKET, VER. 2" 1

4 114B NUT, SERRATED FLANGE, 5/16-18 3

HPV Nozzle Assembly

(MODELS 5611 & 5631 ONLY)

Page 19

LITTLE WONDER

®

DIVISION OF SCHILLER-PFEIFFER, INCORPORATED

1028 STREET ROAD, P.O. BOX 38

SOUTHAMPTON, PA 18966

PHONE 877-596-6337 • FAX 215-357-8045

www.littlewonder.com

Specifications, descriptions, and illustrative material in this literature are as accurate as known at the time of publication, but are subject to change without notice.

1 YEAR LIMITED SERVICE & WARRANTY POLICY

FOR HIGH PERFORMANCE VAC

The

Little Wonder

High Performance Vac is guaranteed against defects in material

and workmanship for a period of ONE YEAR from date of purchase, when used for

RESIDENTIAL SERVICE, or COMMERCIAL SERVICE. Any

Little Wonder

High

Performance Vac or part found to be defective within the warranty period is to be returned

to any registered Little Wonder Dealer.

Engines for all gasoline powered products are warranted separately by the engine

manufacture for a period of one year. Therefore, there are no warranties made, expressed or

implied, for engines of gasoline powered products by

Little Wonder

.

Transportation charges for parts and units submitted for replacement under this warranty

must be borne by the purchaser.

THIS WARRANTY shall not be effective if the product has been subject to misuse,

negligence or accident, or if the product has been repaired or altered outside of our

Southampton factory in any respect which affects its condition or operation.

Little Wonder

shall not be liable for any special indirect or consequential damages

arising from defective equipment. Any implied warranty, including merchantability of

fitness for a particular purpose, shall not extend beyond the written warranty period.

THIS WARRANTY shall only be effective if the enclosed Warranty/Registration card is

properly filled out and returned to

Little Wonder

, Div. of Schiller-Pfeiffer, Inc. at time

of purchase.

877-LWONDER

WARNING DANGER

THE ENGINE EXHAUST FROM THIS PRODUCT

CONTAINS CHEMICALS KNOWN TO THE STATE OF

CALIFORNIA TO CAUSE CANCER, BIRTH DEFECTS

OR OTHER REPRODUCTIVE HARM.

Page 20

1

Table des matières Informations importantes

A. Introduction

De la part de tout le personnel de

Little Wonder

, nous

tenons à vous remercier de votre achat d’un aspirateur haute

performance

Little Wonder

. Cet appareil de ramassage

des déchets a été conçu suivant les normes les plus strictes afin

de vous assurer de nombreuses heures d’utilisation sans

incident.

Ce manuel contient les informations nécessaires à une

utilisation et un entretien sûrs et efficaces. Pour votre sécurité,

il est extrêmement important que vous lisiez et compreniez le

manuel dans son intégralité avant d’utiliser l’appareil.

Caractéristiques techniques :

Modèle Poids à sec Rotation maxi.

5621 258 lbs./117 kg 3400

5631 260 lbs./118 kg 3400

B. Informations sur l’entretien

Aspirateur haute performance

Faire appel au revendeur local

Little Wonder

.

Moteur

Faire appel à un revendeur agréé Briggs & Stratton. Vous

trouverez une liste des revendeurs dans les Pages jaunes, sous

les rubriques « Fournitures de matériel de pelouses et

jardins », « Entretien des pelouses » ou « Tondeuses à

gazon ». Le revendeur aura besoin de connaître le modèle et le

numéro de série de votre moteur. Pour leur emplacement,

veuillez consulter le manuel d’utilisation fourni avec votre

moteur. Faire appel à un revendeur agréé Briggs & Stratton.

Vous trouverez une liste des revendeurs dans les Pages jaunes,

C. Informations particulières sur la sécurité

AVERTISSEMENT DANGER

ATTENTION : CE SYMBOLE ATTIRE VOTRE ATTENTION

SUR D’IMPORTANTES CONSIGNES DE SÉCURITÉ.

LORSQUE VOUS VOYEZ CE SYMBOLE,

TENEZ COMPTE DE L’AVERTISSEMENT ! SOYEZ

VIGILANT !

AVERTISSEMENT DANGER

POUR RÉDUIRE LES RISQUES D’ACCIDENTS,

RESPECTER LES CONSIGNES DE SÉCURITÉ

FIGURANT DANS CE MANUEL. LE NON-RESPECT DE

CES CONSIGNES PEUT ENTRAÎNER DES DOMMAGES

CORPORELS ET MATÉRIELS GRAVES.

AVERTISSEMENT DANGER

L’ÉCHAPPEMENT DU MOTEUR DE CE PRODUIT

CONTIENT DES PRODUITS CHIMIQUES DÉCLARÉS

PAR L’ÉTAT DE LA CALIFORNIE RESPONSABLES DE

CANCER, MALFORMATIONS CONGÉNITALES OU

AUTRES ANOMALIES DE LA REPRODUCTION.

Informations importantes

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Informations sur l’entretien . . . . . . . . . . . . . . .1

Informations particulières sur la sécurité . . . . .1

Déballage

Informations sur le déballage . . . . . . . . . . . . . .2

Sécurité et avertissements

Décalcomanies de sécurité . . . . . . . . . . . . . . . .2

Consignes générales de sécurité

Avertissements – Ce qu’il ne faut pas faire . . .4

Avertissements – Ce qu’il faut faire . . . . . . . . .4

Avertissements concernant le moteur et le

carburant – Ce qu’il ne faut pas faire . . . . . . . .5

Avertissements concernant le moteur et le

carburant – Ce qu’il faut faire . . . . . . . . . . . . . .5

Consignes d’assemblage

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

Réglage de la commande de vitesse . . . . . . . . .7

Plein d’huile et d’essence avant le démarrage .8

Utilisation de l’oreille de levage . . . . . . . . . . . .9

Consignes d’utilisation

Starting Instructions . . . . . . . . . . . . . . . . . . . . .9

Réglage du mode autotracté . . . . . . . . . . . . . . .9

Passage de l’aspirateur . . . . . . . . . . . . . . . . . .10

Vidage de sac à déchets . . . . . . . . . . . . . . . . .10

Remplissage du réservoir de carburant . . . . . .10

Rangement et entretien

Rangement . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

Élimination des blocages dans les pièces

mobiles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Démontage du ventilateur . . . . . . . . . . . . . . . .12

Remplacement de la courroie trapézoïdale . . .12

Nomenclature des pièces

Nomenclature des assemblages HPV . . . . . . .13

Nomenclature des pièces HPV . . . . . . . . . . . .14

Ensemble moteur HPV . . . . . . . . . . . . . . . . . .15

Ensemble de la plate-forme HPV . . . . . . . . . .15

Ensemble collecteur HPV . . . . . . . . . . . . . . . .16

Chemise HPV . . . . . . . . . . . . . . . . . . . . . . . . .17

Tête d’aspiration HPV . . . . . . . . . . . . . . . . . .17

Garanties

Garantie . . . . . . . . . . . . . . . . .Couverture arrière

Page 21

2

Déballage

1. Enlever le collecteur, la tête d’aspiration et le sac à déchets

de la partie supérieure de l’emballage.

2. Enlever le séparateur en carton.

3. Découper et replier vers le bas la paroi latérale courte de la

boîte.

4. Tirer et verrouiller le levier d’enclenchement de la boîtepont. Voir page 9.

5. Faire rouler la base de l’aspirateur hors de la boîte.

N° de référence 600602

Décalcomanie

d’avertissement

N° de référence 600605

Décalcomanie d’avertissement

Attention :

Projection

d’objets.

Garder les

spectateurs à

l'écart.

Toujours

porter des

éléments de

protection de

la vision, de

l’ouïe et de la

respiration.

Avant d'effectuer

quelque

intervention de

service ou

d'entretien que ce

soit, débrancher le

fil de bougie.

S'assurer que

l'accélérateur est à

la position d'arrêt.

Il importe de lire

et de

comprendre le

manuel

d’utilisation.

Garder le

manuel

d’utilisation en

lieu sûr.

Garder les

mains et les

pieds à l'écart

des décharges

d’air. Le

ventilateur

rotatif cause des

blessures graves.

Sécurité et avertissements

A. Décalcomanies de sécurité

Les décalcomanies d'avertissement et d'information qu'on

trouve sur différentes parties de cet aspirateur constituent une

partie importante du système de sécurité.

Ces décalcomanies (ou étiquettes) doivent être remplacées si

elles deviennent illisibles par suite d’abrasion ou pour toute

autre raison.

Vous devez les remplacer lorsqu’elles deviennent difficiles à

lire. Leur emplacement et leur numéro de référence pour la

commande sont indiqués à la page 3.

AVERTISSEMENT DANGER

POUR ÉCARTER LES RISQUES DE BLESSURE GRAVE,

UTILISER ET ENTRETENIR CET ASPIRATEUR DE FAÇON

APPROPRIÉE ET PORTER UNE PROTECTION ADAPTÉE.

LIRE ET COMPRENDRE LES CONSIGNES DE SÉCURITÉ ET

TOUTES LES INSTRUCTIONS CONTENUES DANS CE

MANUEL.

PORTER DES ÉLÉMENTS DE PROTECTION DE L’OUÏE, DE

LA VISION ET DE LA RESPIRATION.

N° de référence

600604

NE PAS FAIRE FONCTIONNER L’APPAREIL

LORSQUE SON SAC N’EST PAS EN

PLACE.

ARRÊTER LE MOTEUR ET LE LAISSER S’IMMOBILISER

COMPLÈTEMENT AVANT DE RETIRER LE SAC.

ASPIRATEUR HAUTE PERFORMANCE

LA ROTATION DES LAMES PEUT

PROVOQUER DES BLESSURES

GRAVES. MAINTENIR TOUTES LES

PARTIES DU CORPS À L’ÉCART.

EMPÊCHER LES OBJETS GROS OU

DURS D’ENTRER DANS L’APPAREIL.

À UTILISER POUR LE RAMASSAGE DE

L’HERBE, DES FEUILLES ET DES

DÉCHETS.

NE PAS UTILISER L’APPAREIL

SANS SA TÊTE D’ASPIRATION

ET DISPOSITIF DE MISE EN SAC

OU SANS SON TUYAU

D’ASPIRATION ET TUYAU DE

REFOULEMENT.

Page 22

3

N° de référence

600604

Sécurité et avertissements

N° de référence

600602

Décalcomanie

d’avertissement

N° de référence 600605

Décalcomanie d’avertissement

ASPIRATEUR HAUTE PERFORMANCE

Page 23

4

Consignes générales de sécurité

1. Prendre le temps de lire et de comprendre ce manuel.

2. Porter des éléments. de protection de la vision, de l’ouïe et

de la respiration, ainsi que des chaussures et vêtements

adaptés

3. Pendant le fonctionnement de l’appareil, veiller à toujours

se trouver dans une position sure en conservant à tout

moment une posture ferme et un bon équilibre.

4. Éviter de travailler en présence d’enfants, d’animaux

domestiques et de curieux.

5. Ne jamais tenter d’utiliser un appareil qui est incomplet ou

qui a fait l’objet d’une modification non autorisée.

6. Éviter le contact et l’inhalation des liquides, brouillards,

poussières et gaz dangereux.

7. Ne pas autoriser les enfants à utiliser l’appareil.

8. Ne pas contourner ni enlever les dispositifs de sécurité.

12. Maintenir les mains à l’écart de l’orifice d’entrée du tuyau

et de la goulotte d’éjection.

13. Débrancher la bougie avant tout nettoyage ou entretien.

14. Porter dans gants pour la protection des mains.

15. Être conscient du fait que l’appareil est bruyant et peut

empêcher la communication de la parole pendant son

fonctionnement normal.

A. Avertissements – Ce qu’il ne faut pas faire

Ne pas essayer d’enlever des matières prises dans le collecteur

ou l’éjecteur lorsque l’appareil est en fonctionnement ou

lorsque le ventilateur tourne.

Ne pas installer de constituants, ni en enlever, pendant le

fonctionnement de l’appareil. Ne pas oublier d’arrêter le

moteur avant tout changement de configuration. S'assurer que

l'accélérateur est en position d'arrêt et que l’appareil est

complètement arrêté. Débrancher le fil de bougie avant

d’enlever toute matière.

Ne pas essayer de réparer cet appareil. Confier les réparations

à un revendeur Little Wonder ou technicien qualifié. S'assurer

que seules des pièces de rechange Little Wonder et des pièces

de rechange recommandées par le constructeur du moteur sont

utilisées.

Ne pas laisser le moteur en marche pendant que l’appareil est

sans surveillance.

Ne pas stocker, renverser ni utiliser d’essence à proximité

d’une flamme ou d’une source d’étincelles.

B. Avertissements – Ce qu’il faut faire

S’habiller adéquatement. Ne pas porter de vêtements flottants

ni de bijoux. Ils peuvent être happés par les pièces en

mouvement. L'utilisation de gants robustes, de chaussures

antidérapantes et de lunettes de sécurité est recommandée.

Toujours porter des protecteurs auditifs lorsque cela est

possible. Utiliser un filtre facial pour ne pas respirer la

poussière.

Rester toujours vigilant. Faire attention à ce que l’on fait et

faire preuve de discernement. Ne pas utiliser l’appareil

lorsqu’on est fatigué.

Maintenir en toutes circonstances les mains à l’écart de la prise

d’air et de la goulotte d’éjection. Maintenir les deux mains sur

le guidon lorsque l’appareil est en marche.

Entretenir et examiner systématiquement l’appareil avec

beaucoup de soin. Suivre les instructions d’entretien données

dans le manuel.

AVERTISSEMENT DANGER

9. LE VENTILATEUR CONTINUE À TOURNER PENDANT

UN MOMENT APRÈS L’ARRÊT DU MOTEUR.

AVERTISSEMENT DANGER

NE PAS FUMER PENDANT LE REMPLISSAGE DU

RÉSERVOIR DE CARBURANT.

AVERTISSEMENT DANGER

10. VENTILATEUR TOURNANT. NE PAS ESSAYER

D’ENLEVER DES MATIÈRES PRISES DANS LE

COLLECTEUR OU L’ÉCHAPPEMENT LORSQUE

L’APPAREIL EST EN FONCTIONNEMENT OU

LORSQUE LE VENTILATEUR TOURNE.

AVERTISSEMENT DANGER

NE PAS UTILISER L’APPAREIL SI LE SILENCIEUX EST

ENDOMMAGÉ OU ABSENT.

AVERTISSEMENT DANGER

11. NE PAS FAIRE FONCTIONNER L’APPAREIL S’IL

VIBRE DE MANIÈRE EXCESSIVE ; ARRÊTER

IMMÉDIATEMENT LE MOTEUR ! DÉBRANCHER LE FIL

DE BOUGIE ET DÉTERMINER SI LE ROTOR EST

ENDOMMAGÉ, SI UN DE SES BOULONS EST

DESSERRÉ, SI SA CLAVETTE EST LÂCHE OU SI UN

CORPS ÉTRANGER S’EST LOGÉ DANS L’APPAREIL.

Page 24

5

AVERTISSEMENT DANGER

SI L’APPAREIL EST UTILISÉ DE MANIÈRE

INAPPROPRIÉE OU SI LES CONSIGNES DE

SÉCURITÉ NE SONT PAS SUIVIES, L’UTILISATEUR

S’EXPOSE ET EXPOSE LES AUTRES À UN RISQUE

DE BLESSURE GRAVE.

PRENDRE LE TEMPS DE LIRE ET DE COMPRENDRE

CE QUI SUIT AVANT DE FAIRE FONCTIONNER CET

APPAREIL.

AVERTISSEMENT DANGER

MANIPULER LE CARBURANT AVEC PRÉCAUTION.

IL EST TRÈS INFLAMMABLE. POUR ÉCARTER LES

RISQUES D’INCENDIE ET DE DOMMAGES

CORPORELS ET MATÉRIELS GRAVES, NE PAS

REMPLIR LE RÉSERVOIR SI LE MOTEUR EST

CHAUD OU S’IL SE TROUVE À PROXIMITÉ D’UNE

SOURCE D’INFLAMMATION.

D. Avertissements concernant le moteur

et le carburant – Ce qu’il faut faire

Toujours utiliser de l’essence fraîche. L’utilisation

d’essence viciée peut causer un démarrage difficile, un

mauvais fonctionnement et des fuites.

Tirer le cordon du démarreur lentement jusqu'à ce

qu'une résistance se fasse sentir. Tirer ensuite le cordon

rapidement pour éviter les rebonds et prévenir des

blessures au bras ou à la main.

L’utilisation de silencieux à pare-étincelles est requise

par la loi de l’État de la Californie (article 4442 du

Code des ressources publiques de la Californie), ainsi

que dans d’autres États et municipalités. La loi fédérale

américaine s’applique sur les territoires fédéraux

américains.

Manipuler le carburant avec précaution ; il est très

inflammable. Ne jamais ajouter de carburant dans le

réservoir d’une machine dont le moteur est chaud ou en

marche. Ne pas inhaler les vapeurs de carburant, car

elles sont toxiques.

Le système d’allumage par étincelle satisfait toutes

les exigences des règlements canadiens sur le

matériel causant des interférences.

il émet du monoxyde de carbone et autres gaz toxiques.

Ne pas faire fonctionner le moteur si le système

d’allumage provoque des étincelles à l'extérieur du

cylindre. Durant les vérifications périodiques de la

bougie, maintenir la bougie à une distance suffisante du

cylindre pour éviter d’enflammer le carburant

s’évaporant du cylindre.

Ne pas vérifier la production d’étincelles avec la bougie

ou le fil de bougie enlevé et mis à la terre. Utiliser un

dispositif d’essai homologué. Les étincelles peuvent

enflammer les vapeurs d’essence.

Ne pas faire fonctionner le moteur en présence d’une

odeur d'essence ou autre possibilité d’explosion.

Ne pas faire fonctionner la machine en cas de présence

d’un déversement d’essence. Nettoyer complètement

l'essence déversée avant de mettre le moteur en marche.

Ne pas faire le plein de carburant à l'intérieur ou dans

un endroit mal aéré.

Ne pas faire fonctionner l’appareil en cas

d'accumulation de déchets autour du silencieux ou des

ailettes de refroidissement.

Pour éviter les brûlures graves, ne pas toucher les

silencieux, ailettes de refroidissement ou cylindres

chauds.

B. Advertencias – “Hacer siempre” –

continuación

Ranger l’appareil à l’intérieur. Lorsqu’il n’est pas utilisé,

conserver l’appareil dans un endroit abrité (au sec) où il n’est

pas accessible aux enfants. L’appareil et le carburant ne

doivent pas être rangés à l'intérieur d’une habitation. Garder

l'accélérateur en position d'arrêt.

Vérifier toujours que l’appareil est complètement assemblé. Ne

jamais le faire fonctionner si les protections et les déflecteurs

ne sont pas en place. S'assurer que tous les écrous, boulons et

vis sont à leur place et bien serrés.

Garder toujours l'accélérateur en position d'arrêt lorsque

l’appareil n'est pas en usage.

Garder une distance sûre entre plusieurs opérateurs qui

travaillent ensemble.

C. Avertissements concernant le moteur

et le carburant – Ce qu’il ne faut pas faire

Ne pas faire le plein de carburant ni en vérifier le

niveau lorsque l’on fume ou qu’on se trouve à proximité

d’une flamme nue ou autre source d’inflammation.

Arrêter le moteur et s’assurer qu’il est froid avant de

refaire le plein.

Ne pas laisser le moteur en marche pendant que

l’appareil est sans surveillance. Arrêter le moteur avant

de transporter l’appareil d’un endroit à un autre.

Ne pas mettre cet appareil en marche ni le faire

fonctionner à l’intérieur ou dans un endroit mal aéré car

Page 25

6

Consignes d’assemblage

AVERTISSEMENT DANGER

NE JAMAIS FAIRE FONCTIONNER L’APPAREIL SI LE

SAC À DÉCHETS N’EST PAS EN PLACE OU SI LA

TÊTE D’ASPIRATION N’EST PAS INSTALLÉE.

A. Assemblage

1. Fixer le collecteur sur la base :

• Boulonner le collecteur sur le châssis à l’aide des 4 jeux

de boulons munis de leur rondelle et de leur écrou.

• Faire glisser l’extrémité rectangulaire du collecteur sur le

châssis et en fixer la bride à l'aide des 2 rondelles et des 2

écrous fournis.

2. Fixer le câble de commande de l’accélérateur sur le guidon

du collecteur :

• Monter le levier de commande de l’accélérateur sur le

guidon à l’aide du boulon, de la rondelle et de l’écrou

fournis.

• À l’aide de deux attaches, fixer le câble de l’accélérateur

sur le guidon.

3. Installer le collier de serrage dans le sac à déchets (manipuler

le collier de serrage en se protégeant les mains avec des

gants) :

• Introduire l’extrémité du collier de serrage comportant la

pièce d’attache à trois trous dans l’ouverture gauche du

manchon du sac à déchets et faire coulisser le collier

jusqu’à ce que l’extrémité ressorte par l’ouverture droite.

• Alimenter l’extrémité de queue du collier (du côté du

fermoir) derrière la pièce d’attache dans le manchon.

• Rapprocher les broches du dispositif de verrouillage en

les pinçant et les brancher sur deux de la pièce d’attache

de manière à obtenir un serrage ferme sur le collecteur.

4. Fixer le sac à déchets en le plaçant sur la lèvre inférieure du

collecteur et en refermant le fermoir. Placer les broches dans

les trous appropriés de la pièce d’attache de manière à

obtenir un bon serrage. S’il est impossible d’obtenir un bon

serrage avec les trois trous disponibles, insérer la bande de

scellement :

• Décrocher les broches de la pièce d’attache.

• Sortir l’extrémité de queue du collier de serrage de

derrière la pièce

d’attache.

• Insérer une des

extrémités de la bande

de scellement derrière

le collier métallique et

dans le manchon

jusqu’à ce qu’elle

ressorte de l’autre côté

du manchon.

• Placer l’autre extrémité

de la bande de

scellement derrière la

pièce d’attache (par

chevauchement de

l’extrémité avant de la

bande de scellement).

• Insérer l’extrémité de

queue du collier de

serrage derrière la pièce

d’attache (par

chevauchement de la

bande de scellement).

• Brancher les broches

dans les trous

appropriés de la pièce

d’attache de manière à

fixer solidement le sac

à déchets sur le

collecteur.

5. Fixer la tête d’aspiration

sur la base :

• À l’aide d’un collier de

raccordement, fixer une

des extrémités du tuyau

sur la tête d’aspiration.

• Faire coulisser l’autre extrémité du tuyau sur le rebord

de l’alimentation sur le capot avant.

• Accrocher une des extrémités du support de la tête

d’aspiration sur l’essieu avant.

• Courber l’autre extrémité du support de la tête vers

l’intérieur jusqu’à ce qu’il s’accroche sur l’essieu et

engager les goupilles de support de roues dans les

logements du support de la tête.

• À l’aide d’un collier de raccordement, fixer le tuyau

sur l’admission du capot avant.

• Fixer le raccord de l’extrémité du câble de la tête

d’aspiration par le trou du support de la tête.

6. Dépose de la tête d’aspiration (pour le rangement ou le

nettoyage des blocages) :

• Arrêter le moteur et débrancher le fil de la bougie.

• À l’aide d’un tournevis plat ou d’une clé 5/16 de po,

desserrer le collier de raccordement du tuyau au capot

avant.

• En le faisant glisser, séparer le tuyau de l’admission

sur le capot avant.

• Courber une des extrémités du support de la tête

d’aspiration vers l’avant et faire pivoter l’ensemble

pour le décrocher de l’essieu.

• Pour décrocher de l’essieu l’autre extrémité du support

de la tête d’aspiration, faire pivoter dans l’autre sens et

soulever.

ENSEMBLE COLLECTEUR

CÂBLE DE L’ACCÉLÉRATEUR

SACHET DE MATÉRIEL

ATTACHES DE

CÂBLE

COLLIER DE

SERRAGE

BANDE DE

SCELLEMENT

SAC À DÉCHETS

DISPOSITIF DE

VERROUILLAGE À BROCHES

EXTRÉMITÉ

DE QUEUE

COLLIER DE SERRAGE

PIÈCE D’ATTACHE

ENSEMBLE TÊTE D’ASPIRATION

SUPPORT DE LA TÊTE D’ASPIRATION

TUYAU

OREILLE DE LEVAGE

ADMISSION SUR LE

CAPOT AVANT

CÂBLE DE LA TÊTE

D’ASPIRATION

SUPPORT DE

ROUES

COLLIERS DE

RACCORDEMENT

FERMOIR

ÉLÉMENTS DE VISSERIE 1/4 PO

ÉLÉMENTS

DE VISSERIE

5/8 PO

ÉLÉMENTS DE VISSERIE 3/8 PO

TRINGLE DE RACCORDEMENT

INFÉRIEURE

LEVIER COUDÉ SUPÉRIEUR

TRINGLE DE RACCORDEMENT

SUPÉRIEURE

Page 26

7

7. Réglage de la commande de vitesse

1. Fixation de la tringle de raccordement inférieure sur le

levier coudé inférieur.

a. À l’aide d’un écrou Nyloc de 3/8 po, fixer la tringle

de raccordement inférieure sur le levier coudé

inférieur. Serrer à l’aide de clés de 9/16 et de 1/2

pouce.

2. Régler la commande de vitesse – opération essentielle pour

un bon fonctionnement.

a. Vérifier que l’écrou borgne autobloquant est

suffisamment serré pour maintenir solidement la

tringle de raccordement supérieure. Dans le cas

contraire, le resserrer légèrement.

b. Vérifier le fonctionnement d’inversion de l’actionneur

en appuyant sur le levier (rouge) d’inversion du sens

de la marche puis en le relâchant. Le mécanisme doit

fonctionner sans à coup et revenir complètement à la

position de marche normale lorsqu’on relâche le

levier.

c. Si l’actionneur fonctionne avec des à-coups, se

coince ou ne revient pas complètement à la

position normale, desserrer légèrement l’écrou

borgne et vérifier de nouveau le fonctionnement

du mécanisme. Répéter l’opération jusqu’à

obtention d’un bon fonctionnement.

d. Appuyer sur le levier d’inversion du sens de la

marche, puis appuyer légèrement sur l’anse de

propulsion jusqu’à ce que la face avant de la

glissière arrière de l’anse soit juste au contact de

la broche d’activation (se reporter également à la

figure de l’étape « e » ci-dessous).

e. La face avant de la glissière arrière et la douille de

la broche d’activation doivent se toucher et

présenter la configuration indiquée ci-dessous :

f. Si la broche d’activation ne pénètre pas dans la

glissière arrière comme le montre la figure cidessous, la tringle de raccordement supérieure est

trop courte et doit être rallongée.

i. Enlever l’écrou maintenant l’extrémité de la

tringle sur le levier coudé supérieur.

ii. Décrocher l’extrémité de la tringle du levier

coudé supérieur.

iii. Rallonger l’extrémité de la tringle en la

dévissant dans le sens contraire des aiguilles

d’une montre.

iv. Reconnecter l’extrémité de la tringle sur le

levier coudé supérieur et la fixer à l’aide de

l’écrou (juste serré à la main).

v. Répéter ce réglage le cas échéant pour

configurer la glissière arrière et la broche

d’activation comme le montre la figure à

l’étape « e » ci-dessus.

Tringle de raccordement inférieure

Tringle de raccordement supérieure

Levier coudé supérieur

Tringle de raccordement inférieure

Levier coudé inférieur

Écrou borgne

Levier d’inversion du

sens de la marche

Levier d’inversion

actionné

Levier d’inversion

relâché

Actionneur en position

normale

Actionneur en position de

marche arrière

Actionneur en position

normale

Enlever l’écrou

Rallonger

Serrer l’écrou à la main

Face avant de la glissière

arrière

Douille de la broche

d’activation

Levier d’inversion actionné

Anse de propulsion

Glissière arrière Broche d’activation

Page 27

8

AVERTISSEMENT DANGER

MANIPULER LE CARBURANT AVEC PRÉCAUTION.

IL EST TRÈS INFLAMMABLE. POUR ÉCARTER LES

RISQUES D’INCENDIE ET DE DOMMAGES

CORPORELS ET MATÉRIELS GRAVES, NE PAS

REMPLIR LE RÉSERVOIR SI LE MOTEUR EST

CHAUD OU S’IL SE TROUVE À PROXIMITÉ D’UNE

SOURCE D’INFLAMMATION.

B. Plein d’huile et d’essence avant le

démarrage

1. Little Wonder recommande l’utilisation d’huile SAE 30.

L’utilisation d’huile à viscosité multiple provoquerait une

forte consommation d’huile et endommagerait le moteur.

2. Après remplissage du réservoir d’essence, l’appareil est

prêt à être mis en marche.

3. Consulter les instructions sur le fonctionnement et

l’entretien du moteur pour une description plus détaillée

des types et quantités d’huile et d’essence à utiliser.

g. Si la broche d’activation pénètre dans la glissière

arrière comme le montre la figure ci-dessous, la

tringle de raccordement supérieure est trop longue

et doit être raccourcie.

i. Enlever l’écrou maintenant l’extrémité de la

tringle sur le levier coudé supérieur.

ii. Décrocher l’extrémité de la tringle du levier

coudé supérieur.

iii. Raccourcir l’extrémité de la tringle en la

vissant dans le sens des aiguilles d’une

montre.

iv. Reconnecter l’extrémité de la tringle sur le

levier coudé supérieur et la fixer à l’aide de

l’écrou (juste serré à la main).

v. Répéter ce réglage le cas échéant pour

configurer la glissière arrière et la broche

d’activation comme le montre la figure à

l’étape « e » ci-dessus.

h. Tout en maintenant abaissé le levier d’inversion du

sens de la marche, appuyer progressivement sur

l’anse de propulsion. Lorsqu’on appuie sur l’anse

de propulsion, la broche d’activation doit s’engager

sans à-coups dans la glissière arrière, avec

pratiquement aucun déclic. La mise au point de ce

mécanisme peut nécessiter le réglage de

l’extrémité de la tringle décrit ci-dessus.

i. Relâcher l’anse de propulsion. Elle doit repasser à

la position complètement relevée et l’actionneur

doit également repasser à sa position normale, telle

qu’illustrée ci-dessous :

j. Appuyer sur l’anse de propulsion et vérifier que la

broche d’activation s’enclenche sans à-coups dans

la glissière avant de l’anse.

k. Vérifier plusieurs fois le fonctionnement en marche

avant et marche arrière pour assurer que le réglage

est correct.

l. Verrouiller l’extrémité de la tringle de raccordement

supérieure en la maintenant en place à l’aide d’une

clé de 1/2 pouce tout en serrant l’écrou à l’aide

d’une clé de 9/16 de pouce comme le montre la

figure ci-dessous :

m. Vérifier que l’extrémité de la tringle est bien droite

et non dans la position incorrecte illustrée cidessous.

n. Enlever l’écrou ordinaire 3/8”-24 de l’extrémité de

la tringle de raccordement supérieure et le

remplacer par l’écrou Nyloc 3/8”-24. Serrer à l’aide

de clés de 9/16 et de 1/2 pouce.

Le réglage de la commande de vitesse est terminé.

Enlever l’écrou

Serrer l’écrou à la main

Raccourcir

Enlever l’écrou

Position de la broche

d’activation et de la glissière

arrière en marche arrière

pleins gaz

Position de la

broche d’activation

et de la glissière

avant pour marche

avant pleins gaz

Écrou Nyloc

Correct - Straight Incorrect - Cocked

Page 28

9

Consignes d’utilisation

AVERTISSEMENT DANGER

L’UTILISATEUR DE CET APPAREIL EST

RESPONSABLE DES ACCIDENTS OU DES DANGERS

ENVERS LUI-MÊME, LES AUTRES ET POUR LES

BIENS MATÉRIELS.

AVERTISSEMENT DANGER

LE CARBURANT EST EXTRÊMEMENT

INFLAMMABLE. LE MANIPULER AVEC

PRÉCAUTION. LE GARDER À L’ÉCART DE TOUTE

SOURCE D’INFLAMMATION. NE PAS FUMER

DURANT LE REMPLISSAGE DU RÉSERVOIR.

AVERTISSEMENT DANGER

LE MOTEUR ÉMET DU MONOXYDE DE CARBONE. NE PAS

FAIRE FONCTIONNER L’APPAREIL NI REMPLIR SON

RÉSERVOIR D’ESSENCE DANS UN ENDROIT CONFINÉ.

A. Instructions de démarrage

1. Réaliser toutes les vérifications préalables au démarrage

(niveaux d’huile moteur et d’essence, etc. Pour les

renseignements concernant les activités préalables au

démarrage, lire complètement le Manuel de l’utilisateur.)

2. Désenclencher le levier d’enclenchement de la boîte-pont.

3. Vérifier que le bouton d’alimentation d’essence (situé audessus du démarreur à rappel) est sur la position Ouvert

(ON).

4. Placer le levier du volet de départ (situé au-dessus et à

gauche du démarreur à rappel) sur la position Fermé

(Choke).

5. Placer le levier de l’accélérateur (situé sur la gauche du

guidon) sur la position intermédiaire ou sur la position

pleins gaz (vers le symbole du lapin).

6. Tirer lentement sur le démarreur à rappel jusqu’à

apparition d’une résistance, puis tirer énergiquement pour

faire démarrer le moteur.

7. Après démarrage du moteur, pousser lentement le levier du

volet de départ sur la position Ouvert (Open).

8. Le cas échéant, faire passer le levier de l’accélérateur sur

la position pleins gaz.

9. Nota. – Si le moteur démarre difficilement, appuyer avec

le pied gauche sur le levier de commande de tension de la

courroie avant de tirer la poignée du démarreur à rappel.

(Cela débraye la courroie pour faciliter le démarrage.)

Après démarrage du moteur, éliminer doucement la

pression du pied sur le levier de commande de tension de

la courroie.

C. Utilisation de l’oreille de levage

L’aspirateur haute performance Little Wonder est doté d’une

oreille de levage pratique qu’on peut utiliser pour le déplacer.

AVERTISSEMENT DANGER

NE PAS FAIRE FONCTIONNER NI ENTRETENIR

L’APPAREIL LORSQU’IL EST SUSPENDU PAR

L’OREILLE DE LEVAGE.

B. Instructions concernant le mode autotracté

1. Le moteur étant en marche (et le levier de la boîte-pont

étant en position embrayée) appuyer lentement sur l’anse

de propulsion pour faire AVANCER l’aspirateur. Plus on

appuie sur l’anse de propulsion, plus la vitesse augmente.

Pour réduire la vitesse ou arrêter, relâcher lentement l’anse

de propulsion.

2. Pour faire reculer la machine, abaisser d’abord le levier

d’inversion du sens de la marche, puis (le levier

d’inversion étant maintenu en position abaissée) appuyer

sur l’anse de propulsion. Plus on appuie sur l’anse de

propulsion, plus la vitesse de MARCHE ARRIÈRE de

l’aspirateur est importante. Pour réduire la vitesse ou

arrêter, relâcher lentement l’anse de propulsion.

3. À tout moment, le relâchement de l’anse de propulsion

arrête le mouvement de l’aspirateur.

RECOIL STARTER HANDLE

tension when starting

BELT TENSION LEVER

Step on to release belt

CHOKE LEVER

THROTTLE CONTROL LEVER

REVERSE LEVER

Release to engage

Press to engage

GAS SUPPLY KNOB

Pull and latch to disengage

reverse mode

TRANSAXLE ENGAGEMET LEVER

BAIL HANDLE

Press to propell

HPV forward or reverse

NOZZLE CONTROL

KNOB

BAND CLAMP

CLASP

Commande de l’aspirateur HPV

POIGNÉE DU DÉMARREUR

À RAPPEL

BOUTON DE

COMMANDE DE

LA TÊTE

D’ASPIRATION

LEVIER

D’INVERSION DU

SENS DE LA

MARCHE

Appuyer pour

passer en marche

arrière

ANSE DE

PROPULSION

Appuyer pour

propulser la machine

vers l’avant ou

l’arrière

FERMOIR DU

COLLIER DE

SERRAGE

LEVIER D’EMBRAYAGE DE LA

BOÎTE-PONT

Tirer et verrouiller pour débrayer

Relâcher pour embrayer

LEVIER DE L’ACCÉLÉRATEUR

BOUTON D’ALIMENTATION D’ESSENCE

LEVIER DU

VOLET DE

DÉPART

LEVIER DE COMMANDE DE

TENSION DE COURROIE

Appuyer avec le pied pour

débrayer la courroie pendant

le démarrage

Page 29

10

D. Vidage du sac à déchets

1. Arrêter le moteur et le laisser revenir complètement au

repos avant d’enlever le sac à déchets.

2. Faire rouler l’aspirateur jusqu’à l’endroit de décharge

désiré (tas de compost, bord du trottoir, zone boisée,

bâche, etc.)

3. Pour libérer le sac à déchets sur le sol, ouvrir le fermoir du

collier de serrage. Pour ne pas réduire la durée de vie du

sac, éviter de le traîner sur le sol.

4. Vider le contenu du sac à déchets (des sangles-poignées se

trouvent à la partie inférieure du sac pour en faciliter le

vidage).

5. Replacer le sac sur le collecteur.

E. Remplissage du réservoir d’essence

1. Arrêter le moteur et le laisser refroidir quelques minutes

avant de remplir le réservoir d’essence.

C. Passage de l’aspirateur

1. Régler la tête d’aspiration à la hauteur désirée en tournant

le bouton de commande, puis fixer sa position à l’aide de

l’écrou à oreilles.

2. Aspirer les déchets de la pelouse ou de la surface

artificielle. On peut aspirer les matières suivantes :

feuilles, brindilles et rameaux, glands, chardons, gousses,

tontes de gazon, paille, copeaux, paillis sec, litière, petites

canettes et bouteilles, articles en papier et articles en

mousse de polystyrène.

3. Ne pas utiliser en présence des conditions suivantes :

surfaces et déchets trop mouillés, surfaces couverte de

gravier, gros objets durs, pierres, longs objets fibreux

(liane, corde, ficelle, etc.) Ne pas faire entrer un objet de

force dans l’aspirateur.

AVERTISSEMENT DANGER

MAINTENIR LA GRILLE DU LANCEUR ET TOUT LE

MOTEUR EXEMPTS DE TOUT DÉCHET. NE PAS

FAIRE FONCTIONNER LE MOTEUR EN PRÉSENCE

D’UNE ACCUMULATION D’HERBE, DE SALETÉ, DE

FEUILLES OU AUTRE MATIÈRE COMBUSTIBLE

PRÈS DU SILENCIEUX.

AVERTISSEMENT DANGER

NE PAS FAIRE FONCTIONNER L’APPAREIL S’IL

VIBRE DE MANIÈRE EXCESSIVE ; ARRÊTER

IMMÉDIATEMENT LE MOTEUR ! DÉBRANCHER LE

FIL DE BOUGIE ET DÉTERMINER SI LE ROTOR EST

ENDOMMAGÉ, SI UN DE SES BOULONS EST

DESSERRÉ, SI SA CLAVETTE EST LÂCHE OU SI UN

CORPS ÉTRANGER S’EST LOGÉ DANS L’APPAREIL.

Page 30

11

A. Rangement

1. Après chaque utilisation, faire fonctionner l’appareil avec le sac à déchet vide de manière à éjecter toutes les matières éparses qui

pourraient se trouver à l’intérieur.

2. Lorsqu’il n’est pas utilisé, conserver l’appareil dans un endroit abrité (au sec) qui n’est pas accessible aux enfants. Garder

l'accélérateur en position d'arrêt.

3. L’appareil et le carburant ne doivent pas être rangés à l'intérieur d’une habitation ou d’un endroit confiné.

4. Ne pas garder le carburant dans le réservoir de l’appareil pendant plus de 30 jours.

Rangement et entretien

B. Entretien

Après les 8 premières

heures d’utilisation

À chaque

utilisation

Toutes les

5 heures

Toutes les

25 heures

Toutes les

50 heures

Domaine

*Moteur

Vérifier l’absence d’une accumulation de déchets à

proximité du silencieux.

Vérifier que l’appareil ne vibre pas de manière excessive.

Vérifier qu’aucune pièce n’est desserrée ou endommagée.

Vérifier la propreté de la tête d’aspiration.

Vérifier la condition des décalcomanies.

Vérifier le niveau d’huile.

**Changer l’huile.

Nettoyer le filtre à air.