Page 1

TVS Diode Arrays (SPA

1

2

1

2

RoHS

GREEN

1

2

®

Diodes)

General Purpose ESD Protection - SP1003 Series

SP1003 Series - 30pF 30kV Unidirectional Discrete TVS

Description

Zener diodes fabricated in a proprietary silicon avalanche

technology protect each I/O pin to provide a high level of

protection for electronic equipment that may experience

destructive electrostatic discharges (ESD). These robust

diodes can safely absorb repetitive ESD strikes at ±30kV

(contact discharge, IEC 61000-4-2) without performance

degradation. Additionally, each diode can safely dissipate

7A of 8/20µs surge current (IEC61000-4-5) with very low

clamping voltages.

Features

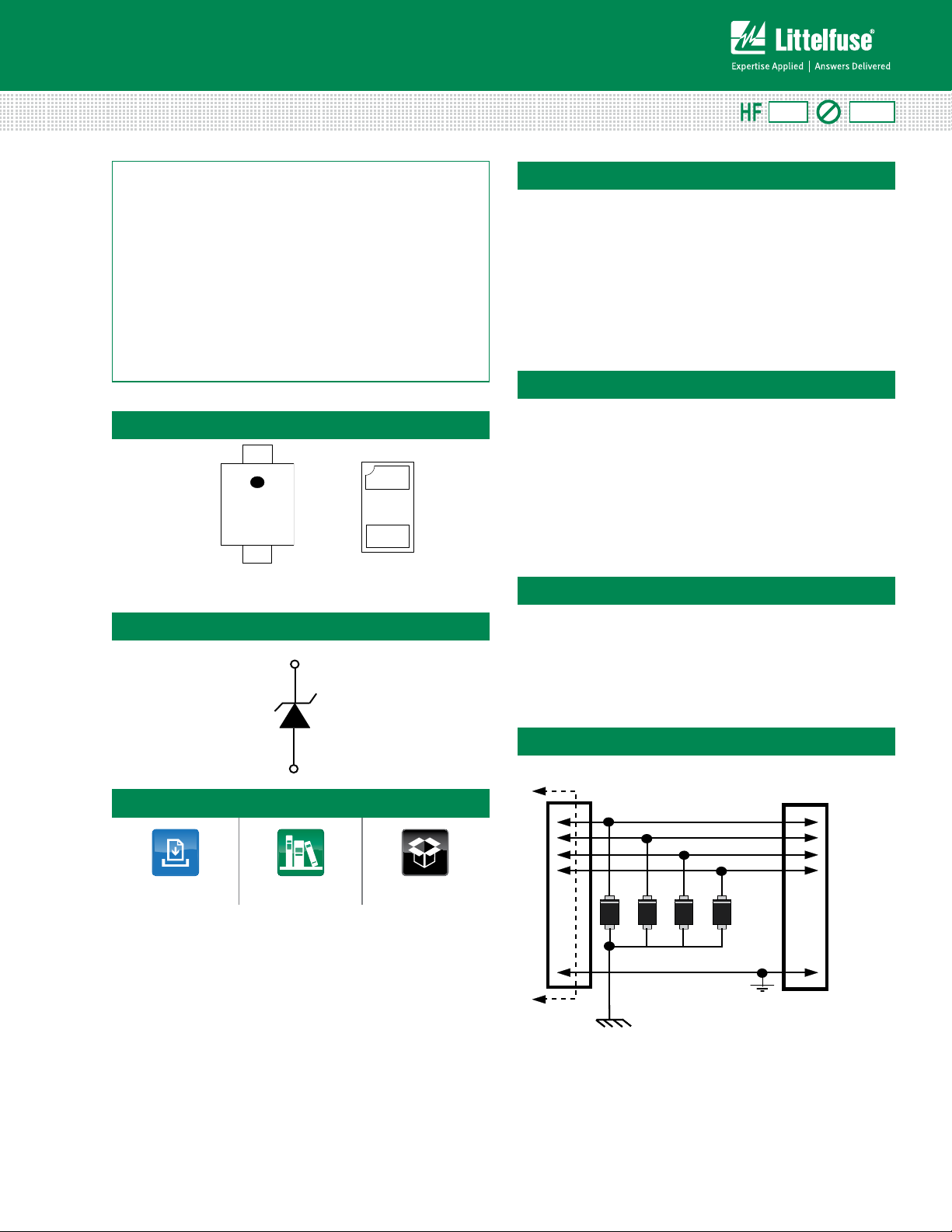

Pinout

• ESD, IEC61000-4-2,

±30kV contact, ±30kV air

• EFT, IEC61000-4-4, 40A

(5/50ns)

• Lightning, IEC61000-4-5,

7A (8/20µs)

• Low leakage current of

100nA (MAX) at 5V

Pb

• Tiny SOD723/ SOD882

(JEDEC MO-236) package

saves board space

• Fits solder footprint of

industry standard 0402

(1005) devices

• AEC-Q101 qualied

(SOD882 package)

SOD723 SOD882

Functional Block Diagram

Additional Information

Datasheet

Resources

(AEC-Q101 qualied)

Samples

Applications

• Mobile phones

• Smart phones

• PDAs

• Portable navigation

devices

Application Example

Low-speed port

Low-speed port

Outside World

(4) SP1003-01

Shield

Shield

Ground

Ground

• Digital cameras

• Portable medical devices

I/O port

I/O port

Controller

Controller

B1

B1

B2

B2

B3

B3

B4

B4

Signal

Signal

Ground

Ground

Life Support Note:

Not Intended for Use in Life Support or Life Saving Applications

The products shown herein are not designed for use in life sustaining or life saving

applications unless otherwise expressly indicated.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/22/13

Page 2

TVS Diode Arrays (SPA

®

Diodes)

General Purpose ESD Protection - SP1003 Series

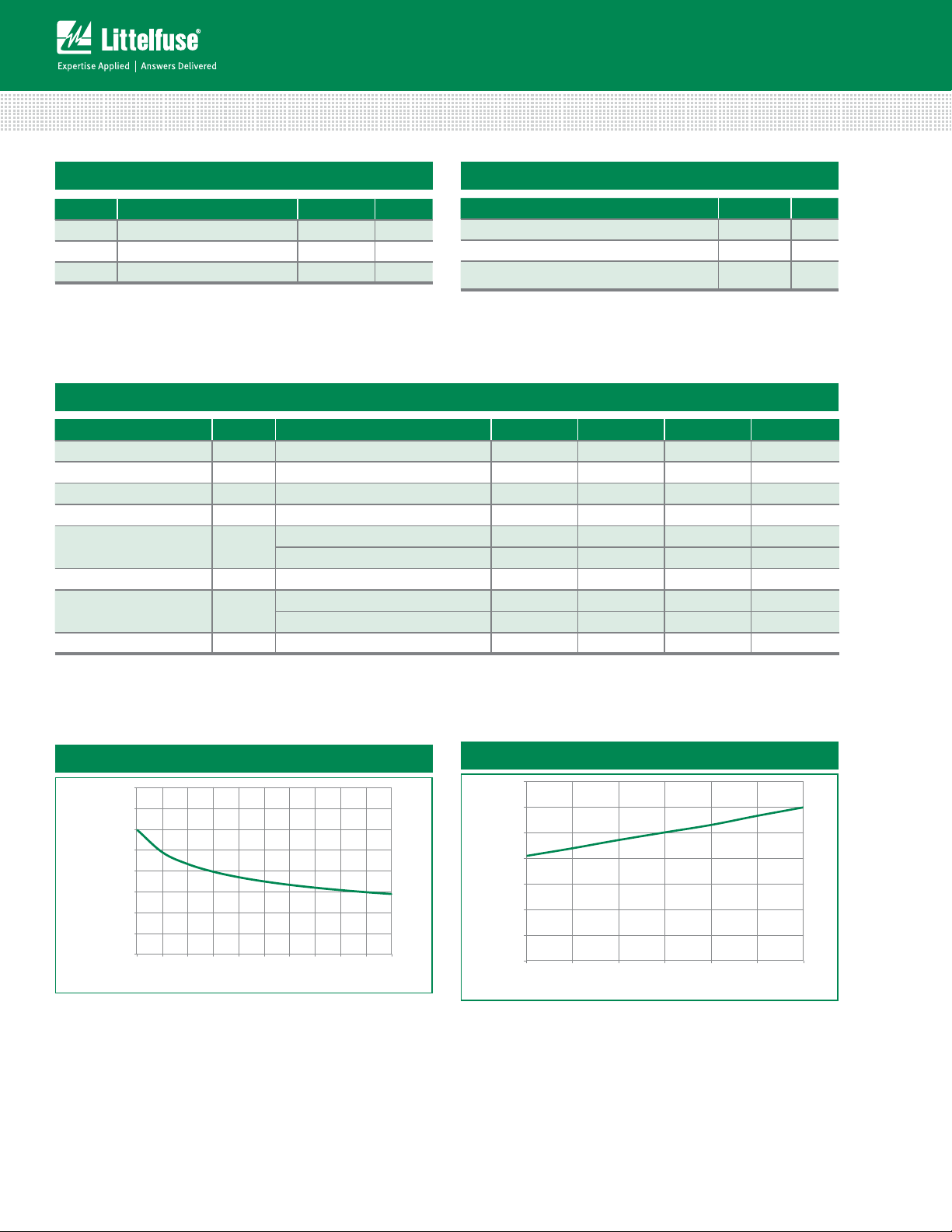

Absolute Maximum Ratings

Symbol Parameter Value Units

I

PP

T

OP

T

STOR

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specification is not implied.

Electrical Characteristics (T

Forward Voltage Drop V

Reverse Voltage Drop V

Reverse Standoff Voltage V

Reverse Leakage Current I

Clamp Voltage

Dynamic Resistance R

ESD Withstand Voltage

Diode Capacitance

Note: 1 Parameter is guaranteed by design and/or device characterization.

Peak Pulse Current (tp=8/20μs) 7. 0 A

Operating Temperature –40 to 125 °C

Storage Temperature –55 to 150 °C

=25ºC)

OP

Parameter Symbol Test Conditions Min Typ Max Units

F

R

RWM

LEAK

1

1

1

V

C

DYN

V

ESD

C

D

TLP, tp =100ns, 1/O to GND 0.25 Ω

IEC61000-4-2 (Contact Discharge) ±30 kV

IEC61000-4-2 (Air Discharge) ±30 kV

IF = 10mA 0.8 1. 2 V

IR=1mA 6.0 7. 8 8.5 V

IR≤1µA 5.0 V

VR=5V 100 nA

Ipp=6A tp=8/20µs 11. 4 V

I

=7A tp=8/20µs 12.0 V

pp

Reverse Bias=0V 30 pF

Thermal Information

Parameter Rating Units

Storage Temperature Range –55 to 150 °C

Maximum Junction Temperature 150 °C

Maximum Lead Temperature

(Soldering 20-40s)

260 °C

Capacitance vs. Reverse Bias

40.0

35.0

30.0

25.0

20.0

15.0

Capacitance (pF)

10.0

5.0

0.0

0.0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

DC Bias (V)

Clamping Voltage vs. I

14.0

12.0

)

10.0

C

8.0

6.0

4.0

Clamp Voltage (V

2.0

0.0

1 2 3 4 5 6 7

PP

Peak Pulse Current-IPP (A)

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 11/22/13

Page 3

TVS Diode Arrays (SPA

t

R

o

C

e

T

L

T

P

Temperature (ºC)

®

Diodes)

General Purpose ESD Protection - SP1003 Series

Transmission Line Pulsing (TLP) Plot

20

18

16

14

12

10

8

6

TLP Current (A)

4

2

0

024681012141618

TLP Voltage (V)

Pulse Waveform

110%

100%

90%

80%

70%

PP

60%

50%

Percent of I

40%

30%

20%

10%

0%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Leakage vs. Temperature

35.0

30.0

25.0

20.0

15.0

10.0

Leakage Current (nA)

5.0

0.0

0 10 20 30 40 50

Soldering Parameters

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (min to max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

) to peak

L

to TL - Ramp-up Rate 3°C/second max

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (T

Do not exceed 260°C

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/22/13

) 150°C

s(min)

) 200°C

s(max)

3°C/second max

+0/-5

°C

20 – 40 seconds

) 8 minutes Max.

P

t

T

P

t

Ramp-upRamp-up

PreheatPrehea

S

T

L

T

S(max)

Temperature

T

S(min)

25

time to peak temperature

P

t

L

Critical Zone

ritical Zon

L to TP

to

T

Ramp-down

amp-d

Time

Page 4

TVS Diode Arrays (SPA

L

b

Recommended Soldering Pad Layout

SP

1003

* T

G

E: SOD882

01

X

SOD882

Product ID

Pin 1

or C

C

®

Diodes)

General Purpose ESD Protection - SP1003 Series

Part Numbering System

–

TVS Diode Arrays

®

(SPA

Diodes)

Series

Number of Channels

-01 = 1 Channel

Part Marking System

Package Dimensions — SOD723

D

E

HE

Recommended Solder Pad Layout

A

c

G= Green

T= Tape & Reel

Package

D: SOD723

1.10

[0.043]

Millimeters (Inches)

0.45

[0.018]

0.50

[0.020]

Product Characteristics

Lead Plating Pre-Plated Frame or Matte Tin

Lead Material Copper Alloy

Lead Coplanarity 0.0004 inches (0.102mm)

Substitute Material Silicon

Body Material Molded Epoxy

Flammability UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte nish VDI 11-13.

Ordering Information

Part Number Package Marking Min. Order Qty.

SP1003-01DTG SOD723 or 8,000

SP1003-01ETG SOD882 or 10,000

Symbol

A 0.46 0.65 0.018 0.026

b 0.23 0.35 0.009 0.014

c 0.08 0.13 0.003 0.005

D 0.90 1. 10 0.035 0.043

E 0.58 0.64 0.023 0.025

HE 1.37 1.47 0.054 0.058

L 0.15 0.25 0.006 0. 010

Millimeters Inches

Min Max Min Max

c

c

c

c

SOD723

Package Dimensions — SOD882

Package SOD882

Symbol

JEDEC MO-236

Millimeters Inches

Min Typ Max Min Typ Max

A 0.90 1. 0 0 1. 1 0 0.035 0.039 0.043

B 0.50 0.60 0.70 0.020 0.024 0.028

C 0.40 0.50 0.60 0.016 0.020 0.024

D 0.45 0.018

E 0.20 0.25 0.35 0.008 0.010 0.012

F 0.45 0.50 0.55 0.018 0.020 0.022

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 11/22/13

Page 5

TVS Diode Arrays (SPA

KO

AO

A1

ØD1

P

ØD

W

E

F

BO

B1

t

PO

P2

User Feeding Direction

Pin 1 Location

®

Diodes)

General Purpose ESD Protection - SP1003 Series

Embossed Carrier Tape & Reel Specification — SOD723

Embossed Carrier Tape & Reel Specification — SOD882

User Feeding Direction

Pin 1 Location

Symbol

E 1.65 1.85 0.064 0.072

F 3.40 3.60 0.134 0.142

D1 0.45 0.55 0.017 0.021

D 1.50 - - 0.060 - -

PO 3.90 4.10 0.153 0.161

10PO 40.0± 0.20 1.570±0.010

W 7.90 8.20 0.311 0.322

P2/P 1.90 2.10 0.074 0.082

AO 0.60 0.80 0.024 0.032

A1 0.33 REF 0.010 REF

BO 1.61 1.81 0.063 0.071

B1 1.10 REF 0.040 REF

KO 0.54 0.78 0.021 0.031

t - - 0.21 - - 0.008

Symbol

A 0.65 0.70 0.026 0.028

B 1. 10 1.20 0.043 0.047

C 0.50 0.60 0.020 0.024

dØ 1.40 1.60 0.055 0.063

E 1.65 1.85 0.065 0.073

F 3.40 3.60 0.134 0.142

P0 3.90 4.10 0.154 0.161

P 1.90 2.10 0.075 0.083

P1 1.90 2.10 0.075 0.083

W 7.90 8.10 0.311 0.319

Millimetres Inches

Min Max Min Max

Millimetres Inches

Min Max Min Max

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 11/22/13

Loading...

Loading...