Page 1

TVS Diode Arrays (SPA

RoHS

GREEN

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

SM Series 400W TVS Diode Array

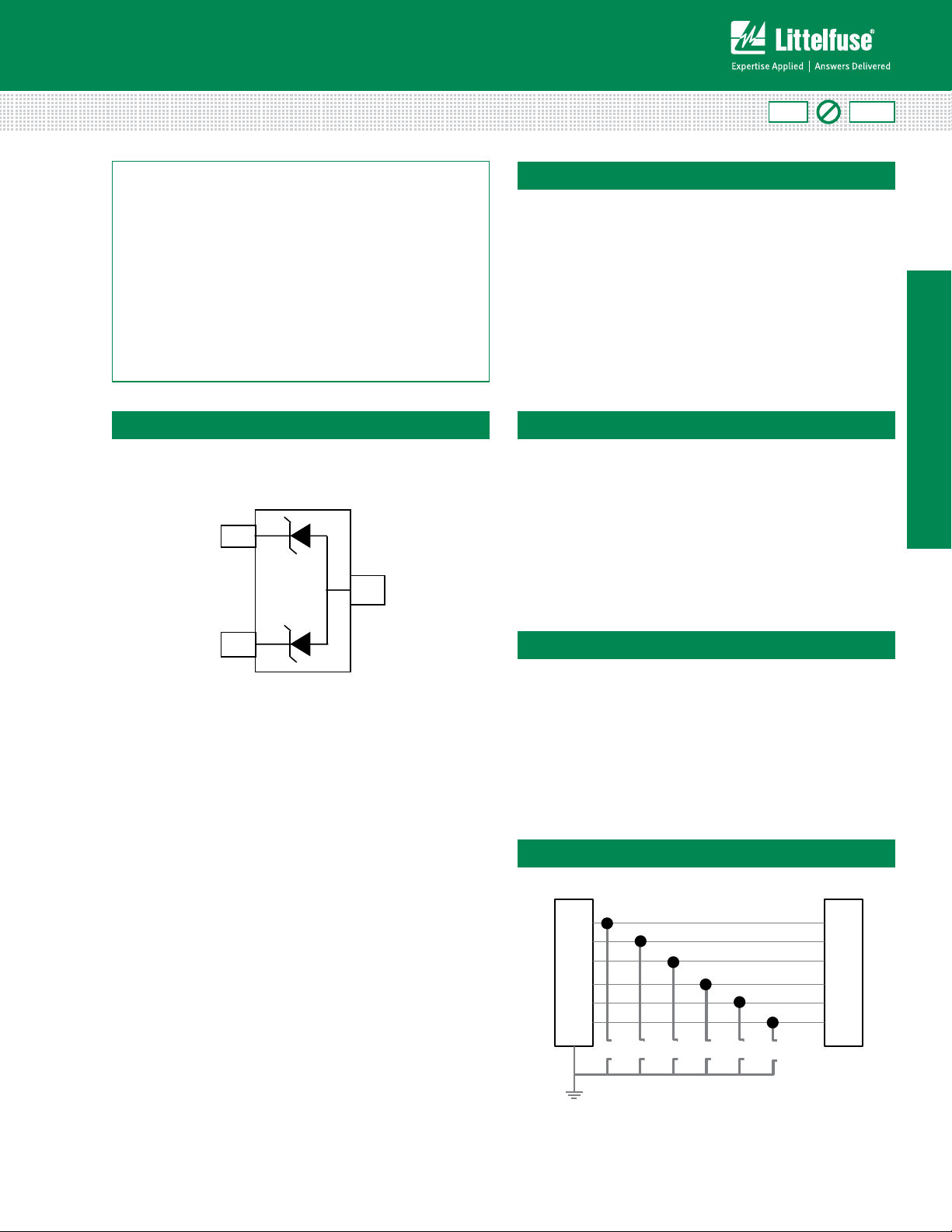

Pinout and Functional Block Diagram

(AEC-Q101 qualied)

1

Pb

Description

The SM series TVS Diode Array is designed to protect

sensitive equipment from damage due to electrostatic

discharge (ESD), electrical fast transients (EFT), and

lightning induced surges.

The SM series can absorb repetitive ESD strikes above the

maximum level specified in the IEC61000-4-2 international

standard without performance degradation and safely

dissipate up to 24A of 8/20us induced surge current (IEC61000-4-5) with very low clamping voltages.

Features

• ESD, IEC61000-4-2,

±30kV contact, ±30kV air

• EFT, IEC61000-4-4, 50A

(5/50ns)

• Lightning, IEC61000-4-5,

24A (t

=8/20μs, SM05)

P

• Working voltages: 5V,

12V, 15V, 24V and 36V

• Low clamping voltage

• Low leakage current

• AEC-Q101 qualied

(SOT23-3 package)

SM Series

3

2

Life Support Note:

Not Intended for Use in Life Support or Life Saving Applications

The products shown herein are not designed for use in life sustaining or life saving

applications unless otherwise expressly indicated.

Applications

• Industrial Equipment

• Test and Medical

Equipment

• Point-of-Sale Terminals

• Motor Controls

RS-232 Application Example

RS-232 Port

RD

TD

RTS

CTS

DSR

DTR

• Legacy Ports

(RS-232, RS-485)

• Security and Alarm

Systems

Transceiver

IC

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/05/13

Case GND

SM15 (x6)

(bidireconal implementaon)

5

Page 2

TVS Diode Arrays (SPA

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

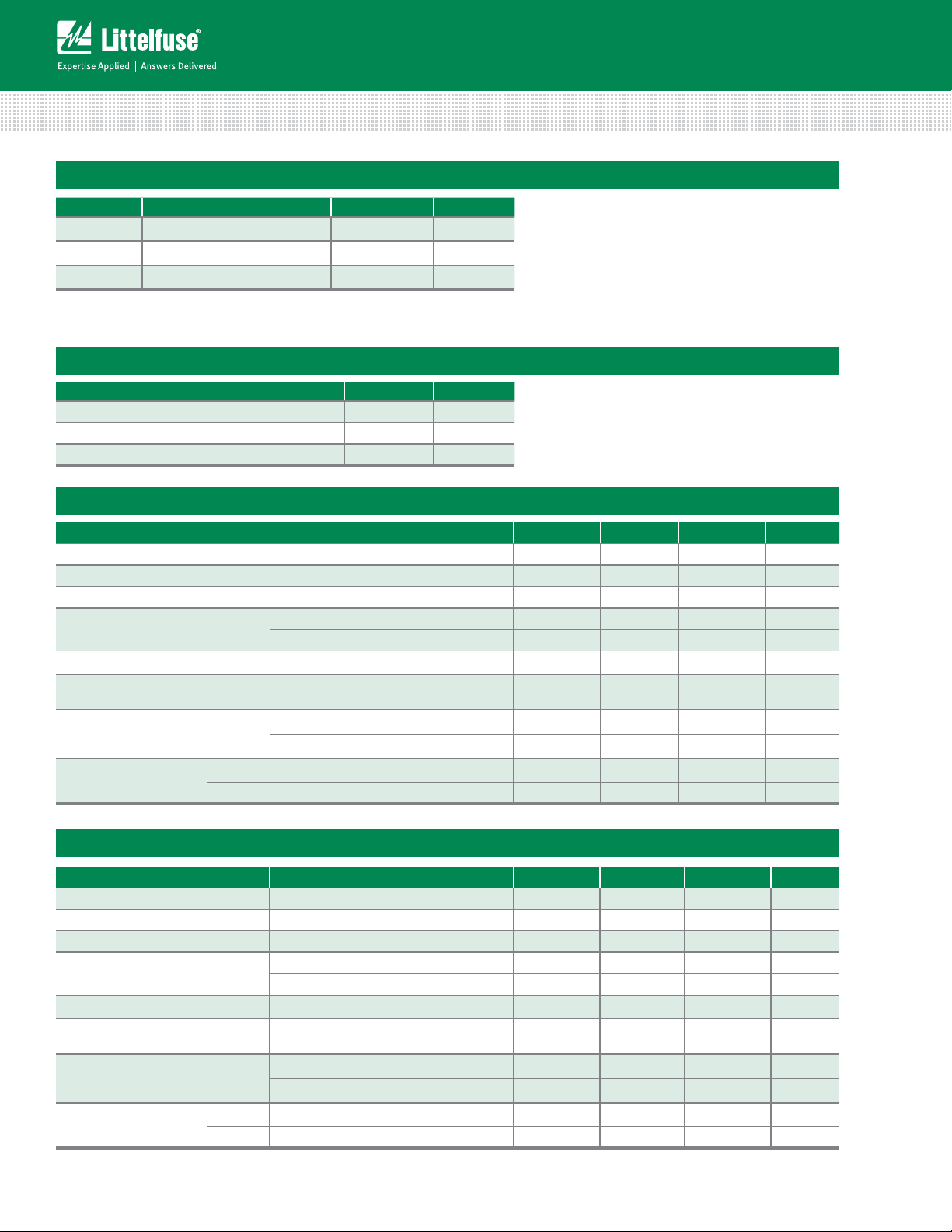

Absolute Maximum Ratings

Symbol Parameter Value Units

P

Pk

T

OP

T

STOR

Notes:

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause permanent damage to the device. This is a stress only rating and operation of

the device at these or any other conditions above those indicated in the operational sections of this specification is not implied.

Peak Pulse Power (tp=8/20μs)

Operating Temperature -40 to 125 °C

Storage Temperature -55 to 150 °C

Thermal Information

Parameter Rating Units

Storage Temperature Range -55 to 150 °C

Maximum Junction Temperature 150 °C

Maximum Lead Temperature (Soldering 20-40s) 260 °C

400

W

SM05 Electrical Characteristics (T

OP

=25ºC)

Parameter Symbol Test Conditions Min Typ Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Leakage Current I

Clamp Voltage

Dynamic Resistance

Peak Pulse Current

(8/20µs)

1

2

1

ESD Withstand Voltage

Diode Capacitance

1

RWM

R

LEAK

V

C

R

DYN

Ipp tp=8/20µs 24.0 A

1

V

ESD

C

I/O-GND

C

I/O-I/O

SM12 Electrical Characteristics (T

IPP=1A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 9.8 V

I

=10A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 13.0 V

PP

TLP, tp=100ns, I/O to GND 0.19 Ω

IEC61000-4-2 (Contact Discharge) ±30 kV

IEC61000-4-2 (Air Discharge) ±30 kV

Reverse Bias=0V, f=1MHz 400 pF

Reverse Bias=0V, f=1MHz 350 pF

=25ºC)

OP

IR≤1μA 5.0 V

IR=1mA 6.0 V

VR=5V 1. 0 μA

Parameter Symbol Test Conditions Min Ty p Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Leakage Current I

Clamp Voltage

Dynamic Resistance

Peak Pulse Current

(8/20µs)

ESD Withstand Voltage

Diode Capacitance

1

2

1

1

1

6

RWM

R

LEAK

V

R

IPP=1A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 18.5 V

C

I

=10A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 22.5 V

PP

DYN

TLP, tp=100ns, I/O to GND 0.25 Ω

Ipp tp=8/20µs 1 7. 0 A

V

C

C

ESD

I/O-GND

I/O-I/O

IEC61000-4-2 (Contact Discharge) ±30 kV

IEC61000-4-2 (Air Discharge) ±30 kV

Reverse Bias=0V, f=1MHz 150 pF

Reverse Bias=0V, f=1MHz 120 pF

IR≤1μA 12.0 V

IR=1mA 13.3 V

VR=12V 1. 0 μA

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/05/13

Page 3

TVS Diode Arrays (SPA

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

SM15 Electrical Characteristics (T

OP

=25ºC)

Parameter Symbol Test Conditions Min Ty p Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Leakage Current I

Clamp Voltage

Dynamic Resistance

Peak Pulse Current

(8/20µs)

1

2

1

ESD Withstand Voltage

Diode Capacitance

1

RWM

R

LEAK

V

C

R

DYN

Ipp tp=8/20µs 12.0 A

1

V

ESD

C

I/O-GND

C

I/O-I/O

SM24 Electrical Characteristics (T

IPP=1A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 24.0 V

I

=10A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 30.0 V

PP

TLP, tp=100ns, I/O to GND 0.30 Ω

IEC61000-4-2 (Contact Discharge) ±30 kV

IEC61000-4-2 (Air Discharge) ±30 kV

Reverse Bias=0V, f=1MHz 100 pF

Reverse Bias=0V, f=1MHz 75 pF

=25ºC)

OP

IR≤1μA 15.0 V

IR=1mA 16.7 V

VR=15V 1. 0 μA

Parameter Symbol Test Conditions Min Ty p Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Leakage Current I

Clamp Voltage

Dynamic Resistance

Peak Pulse Current

(8/20µs)

ESD Withstand Voltage

Diode Capacitance

1

2

1

1

R

1

V

C

C

RWM

R

LEAK

V

IPP=1A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 36.0 V

C

I

=5A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 42.0 V

PP

DYN

TLP, tp=100ns, I/O to GND 0.50 Ω

Ipp tp=8/20µs 7. 0 A

IEC61000-4-2 (Contact Discharge) ±30 kV

ESD

I/O-GND

I/O-I/O

IEC61000-4-2 (Air Discharge) ±30 kV

Reverse Bias=0V, f=1MHz 65 pF

Reverse Bias=0V, f=1MHz 50 pF

IR≤1μA 24.0 V

IR=1mA 26.7 V

VR=24V 1. 0 μA

SM Series

SM36 Electrical Characteristics (T

OP

=25ºC)

Parameter Symbol Test Conditions Min Ty p Max Units

Reverse Standoff Voltage V

Reverse Voltage Drop V

Leakage Current I

Clamp Voltage

Dynamic Resistance

Peak Pulse Current

(8/20µs)

1

2

1

ESD Withstand Voltage

Diode Capacitance

Note:

1

Parameter is guaranteed by design and/or device characterization.

2

Transmission Line Pulse (TLP) with 100ns width and 200ps rise time.

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/05/13

1

RWM

R

LEAK

V

R

IPP=1A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 52.0 V

C

I

=4A, tp=8/20µs, Pin 1 or Pin 2 to Pin 3 62.0 V

PP

DYN

TLP, tp=100ns, I/O to GND 0.65 Ω

Ipp tp=8/20µs 5.0 A

1

V

ESD

C

I/O-GND

C

I/O-I/O

IEC61000-4-2 (Contact Discharge) ±30 kV

IEC61000-4-2 (Air Discharge) ±30 kV

Reverse Bias=0V, f=1MHz 50 pF

Reverse Bias=0V, f=1MHz 40 pF

IR≤1μA 36.0 V

IR=1mA 40.0 V

VR=36V 1. 0 μA

7

Page 4

TVS Diode Arrays (SPA

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Percent of I

PP

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

Non-Repetitive Peak Pulse Power vs. Pulse Time

10

(kW)

pk

1

0.1

Peak Pulse Power - P

0.01

0.11 10 100 1000

Pulse Duration - tp (µs)

Pulse Waveform

Power Derating Curve

110

100

90

80

PP

70

60

50

40

30

20

% of Rated Power I

10

0

0255075100 125150

o

Ambient Temperature - T

(

C)

A

SM05 Transmission Line Pulsing(TLP) Plot

20

18

16

14

12

10

TLP Current (A)

8

6

4

2

0

024681012

SM05

TLP Voltage (V)

SM12 Transmission Line Pulsing(TLP) Plot

20

18

16

14

12

10

TLP Current (A)

8

8

6

4

2

0

0510 15 20 25

SM12

TLP Voltage (V)

SM15 Transmission Line Pulsing(TLP) Plot

20

18

16

14

12

10

TLP Current (A)

8

6

4

2

0

0510 15 20 25 30

SM15

TLP Voltage (V)

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/05/13

Page 5

TVS Diode Arrays (SPA

t

R

R

o

C

e

T

L

T

P

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

SM24 Transmission Line Pulsing(TLP) Plot

20

18

16

14

12

10

TLP Current (A)

8

6

4

2

0

0510 15 20 25 30 35 40

SM24

TLP Voltage (V)

Soldering Parameters

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (min to max) (ts) 60 – 180 secs

Average ramp up rate (Liquidus) Temp

(T

) to peak

L

to TL - Ramp-up Rate 3°C/second max

T

S(max)

Reflow

- Temperature (TL) (Liquidus) 217°C

- Temperature (tL) 60 – 150 seconds

Peak Temperature (TP) 260

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 6°C/second max

Time 25°C to peak Temperature (T

Do not exceed 260°C

) 150°C

s(min)

) 200°C

s(max)

3°C/second max

+0/-5

°C

20 – 40 seconds

) 8 minutes Max.

P

SM36 Transmission Line Pulsing(TLP) Plot

t

S

SM36

TLP Voltage (V)

Ramp-up

PreheatPrehea

amp-up

t

P

t

L

20

18

16

14

12

10

TLP Current (A)

8

6

4

2

0

0510 15 20 25 30 35 40 45 50 55

T

P

T

L

T

S(max)

Temperature

T

S(min)

25

time to peak temperature

Product Characteristics

Critical Zone

ritical Zon

L to TP

to

T

Ramp-down

amp-d

Time

SM Series

Lead Plating

Matte Tin

Lead Material Copper Alloy

Ordering Information

Lead Coplanarity 0.0004 inches (0.102mm)

Part Number Package Marking Min. Order Qty.

SM05-02HTG SOT23-3 M05 3000

SM12-02HTG SOT23-3 M12 3000

SM15-02HTG SOT23-3 M15 3000

SM24-02HTG SOT23-3 M24 3000

SM36-02HTG SOT23-3 M36 3000

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 12/05/13

Substitute Material Silicon

Body Material Molded Epoxy

Flammability UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

5. Package surface matte finish VDI 11-13.

9

Page 6

TVS Diode Arrays (SPA

GENERAL INFORMATION

1. 3000 PIECES PER REEL.

2. ORDER IN MULTIPLES OF FULL REELS ONLY.

3. MEETS EIA-481 REVISION "A" SPECIFICATIONS.

USER DIRECTION OF FEED

PIN 1

SOT23-3 (8mm POCKET PITCH)

8.4mm

180mm

14.4mm

13mm

60mm

ACCESS HOLE

8mm TAPE AND REEL

P

b

0

N

M

xx

Mxx

®

Diodes)

General Purpose ESD Protection - SM05 through SM36

Part Marking System

Package Dimensions — SOT23-3

3

E

E1

2

D

A

A1

L1

Recommended Pad Layout

P

C

502B

1

e

e1

Part Numbering System

–

02

T

G

SM

TVS Diode Arrays

®

(SPA

Diodes)

Series

Working

Voltage

Number of

Channels

Package SOT23-3

Pins 3

JEDEC TO-236

Millimeters Inches

Min Max Min Max

A 0.89 1. 1 2 0.035 0.044

A1 0.01 0.1 0.0004 0.004

b 0.3 0.5 0.012 0.020

c 0.08 0.2 0.003 0.008

D 2.8 3.04 0.110 0.120

M

0

N

E 2.1 2.64 0.083 0.104

E1 1. 2 1. 4 0.047 0.055

e 0.95 BSC 0.038 BSC

e1 1.90 BSC 0.075 BSC

L1 0.54 REF 0.021 REF

M 2.29 .090

N 0.95 0.038

O 0.78 .030TYP

P 0.78 .030TYP

H

G= Green

T= Tape & Reel

Package

H: SOT23-3

Embossed Carrier Tape & Reel Specification — SOT23-3

10

Symbol

Millimetres Inches

Min Max Min Max

E 1.65 1.85 0.065 0.073

F 3.40 3.60 0.134 0.142

P2 1.90 2.10 0.075 0.083

D 1.40 1.60 0.055 0.063

P0 3.90 4.10 0.154 0.161

W 7.70 8.30 0.303 0.327

P 3.90 4.10 0.154 0.161

A0 3.05 3.25 0.120 0.128

B0 2.67 2.87 0.105 0.113

K0 1. 1 2 1.32 0.044 0.052

t 0.22 0.24 0.009 0.009

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 12/05/13

Loading...

Loading...