Page 1

TVS Diode Arrays (SPA

5678

4321

Pin 1.3

Pin 2.4

Pin 6.8

Pin 5.7

RoHS

GREEN

®

Diodes)

Lightning Surge Protection - SLVU2.8-4 Series

SLVu2.8-4 Series 2.8V 40A TVS Array

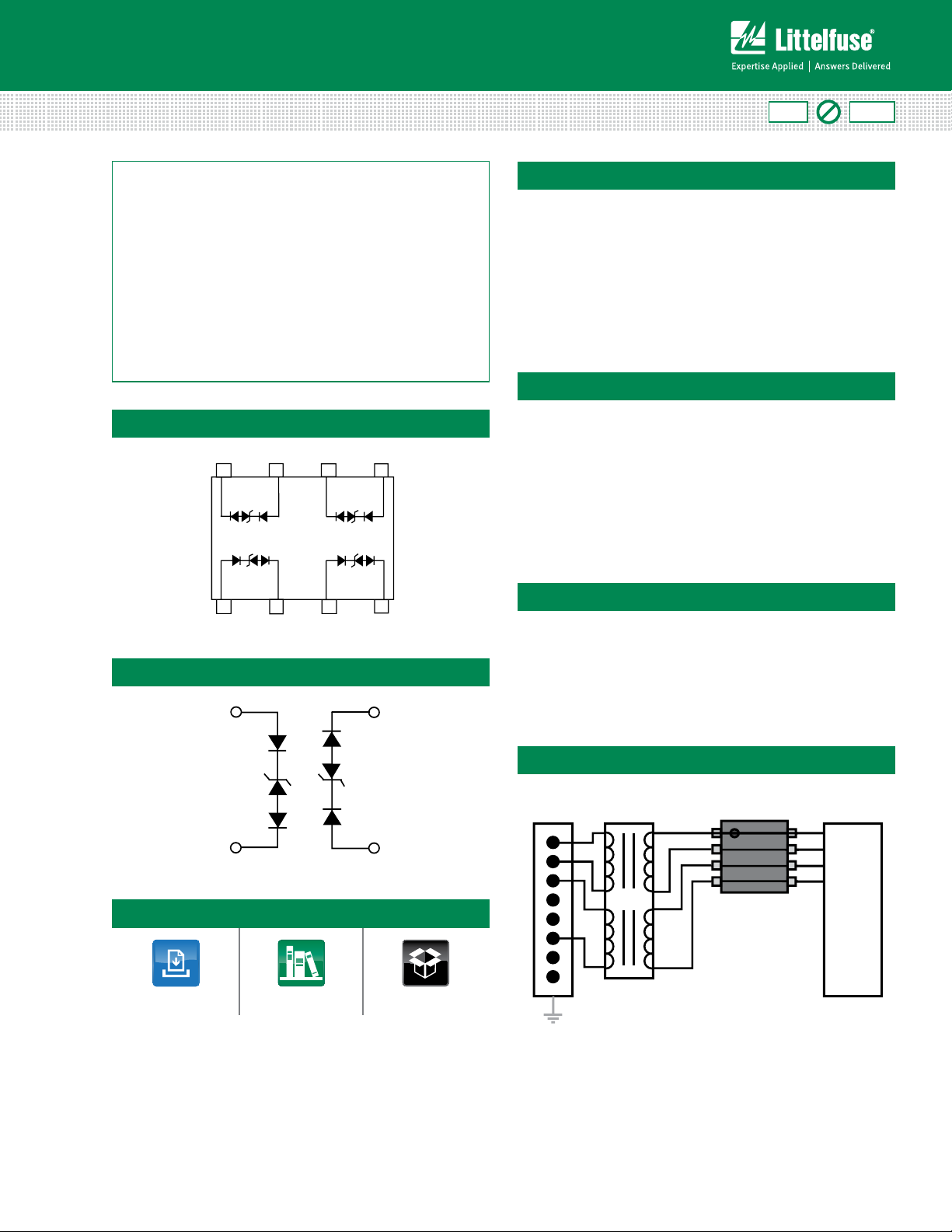

Pinout

Pb

Description

The SLVU2.8-4 was designed to protect low voltage,

CMOS devices from ESD and lightning induced transients.

There is a compensating diode in series with each low

voltage TVS to present a low loading capacitance to the

line being protected. These robust structures can safely

absorb repetitive ESD strikes at ±30kV (contact discharge)

per IEC61000-4-2 standard and each structure can safely

dissipate up to 40A (IEC61000-4-5, t

low clamping voltages.

Features

• ESD, IEC61000-4-2,

±30kV contact, ±30kV air

• EFT, IEC61000-4-4, 40A

(5/50ns)

• Lightning, IEC61000-4-5,

40A (8/20μs)

• Low capacitance of 2pF

per line

=8/20μs) with very

P

• Low leakage current of

1μA (MAX) at 2.8V

• SOIC-8 (JEDEC MO-012)

pin configuration allows

for simple flow-through

layout

Functional Block Diagram

Additional Information

Datasheet

Resources

Samples

Applications

• 10/100/1000 Ethernet

• WAN/LAN Equipment

• Switching Systems

• Desktops, Servers, and

Notebooks

Application Example

RJ-45

Connector

J1

J8

Case GND

• Analog Inputs

• Base Stations

SLVU2.8-4

Device is shown

as transparent

for actual footprint

Ethernet

PHY

Tx+

TxRx+

Rx-

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 04/24/13

Page 2

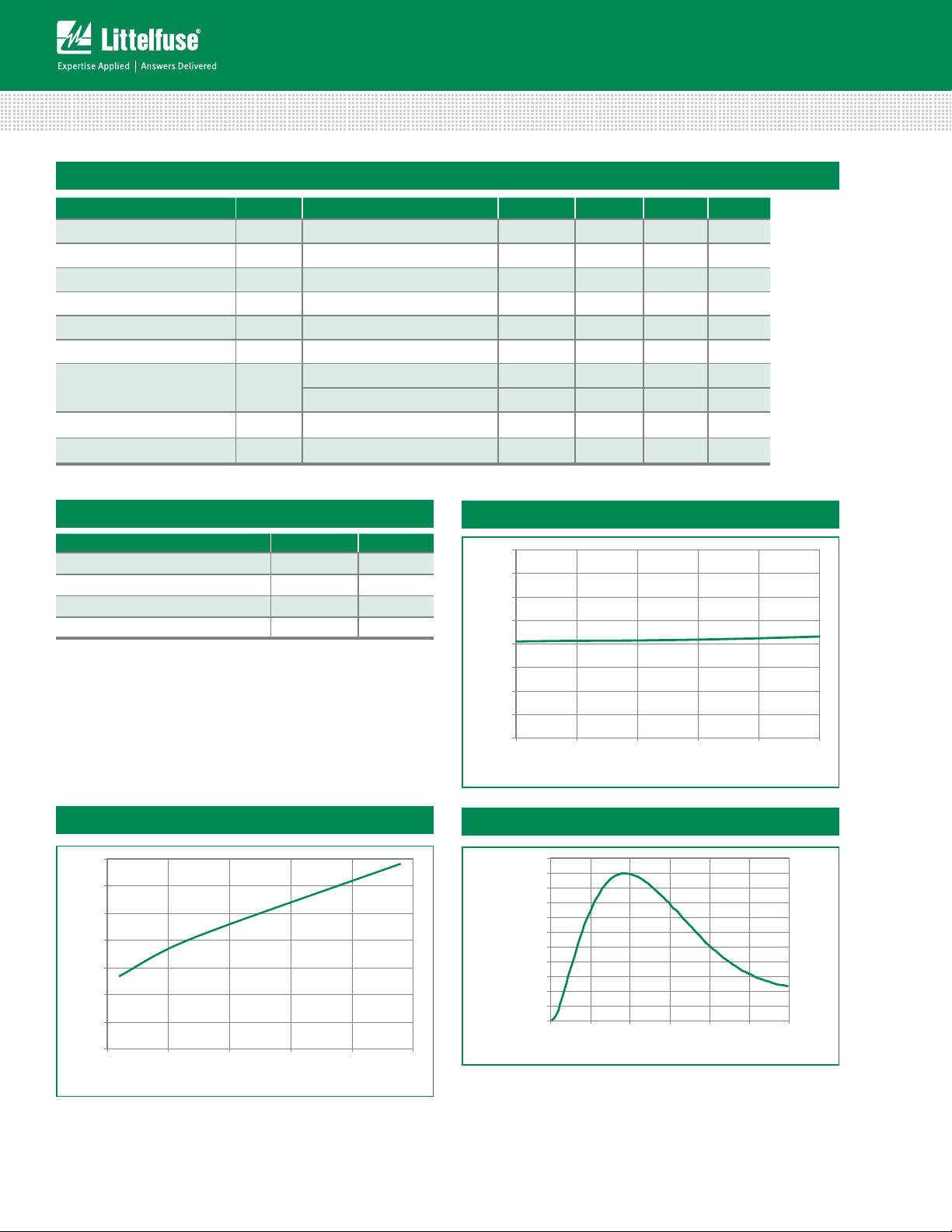

Electrical Characteristics (TOP = 25°C)

0.0

0.5

1.0

1.5

2.0

2.5

3.0

3.5

4.0

0.0 0.5 1.0 1.5 2.0 2.5

DC Bias (V)

Capacitance (pF)

0%

10%

20%

30%

40%

50%

60%

70%

80%

90%

100%

110%

0.0 5.0 10.0 15.0 20.0 25.0 30.0

Time (μs)

Percent of I

PP

0

2

4

6

8

10

12

14

0510 15 20 25

Peak Pulse Current-IPP (A)

Clamping Voltage-V

C

(V)

Parameter Symbol Test Conditions Min Typ Max Units

Reverse Standoff Voltage V

Reverse Breakdown Voltage V

Snap Back Voltage V

Reverse Leakage Current I

Clamping Voltage

Clamping Voltage

ESD Withstand Voltage

1

1

1

Dynamic Resistance R

Diode Capacitance

1

Note:

Parameter is guaranteed by design and/or device characterization.

1

V

RWM

BR

SB

LEAK

V

V

ESD

DYN

C

C

C

D

TVS Diode Arrays (SPA

®

Diodes)

Lightning Surge Protection - SLVU2.8-4 Series

IR≤1μA 2.8 V

IT=2μA 3.0 V

IT=50mA 2.8 V

VR=2.8V (Each Line) 1 μA

IPP=5A, tP=8/20μs (Each Line) 7. 0 8.5 V

IPP=24A, tP=8/20μs (Each Line) 13.9 15.0 V

IEC61000-4-2 (Contact) ±30 kV

IEC61000-4-2 (Air) ±30 kV

(VC2 - VC1) / (I

VR=0V, f=1MHz (Each Line)

- I

) (Each Line) 0.4 Ω

PP2

PP1

2.0 2.5 pF

Absolute Maximum Ratings

Parameter Rating Units

Peak Pulse Power (tP=8/20µs) 600 W

Peak Pulse Current (tP=8/20µs) 40 A

Operating Temperature –40 to 125 ºC

Storage Temperature –55 to 150 ºC

CAUTION: Stresses above those listed in “Absolute Maximum Ratings” may cause

permanent damage to the device. This is a stress only rating and operation of the device

at these or any other conditions above those indicated in the operational sections of this

specification is not implied.

Figure 2: Clamping Voltage vs. I

PP

Figure 1:

Capacitance vs. Reverse Voltage

Figure 3: Pulse Waveform

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 04/24/13

Page 3

TVS Diode Arrays (SPA

t

R

R

o

C

e

T

T

®

Diodes)

Lightning Surge Protection - SLVU2.8-4 Series

Product Characteristics

Lead Plating Matte Tin

Lead Material Copper Alloy

Lead Coplanarity 0.0004 inches (0.102mm)

Substitute Material Silicon

Body Material Molded Epoxy

Flammability UL 94 V-0

Notes :

1. All dimensions are in millimeters

2. Dimensions include solder plating.

3. Dimensions are exclusive of mold flash & metal burr.

4. All specifications comply to JEDEC SPEC MO-203 Issue A

5. Blo is facing up for mold and facing down for trim/form, i.e. reverse trim/form.

6. Package surface matte finish VDI 11-13.

Soldering Parameters

Reflow Condition Pb – Free assembly

- Temperature Min (T

Pre Heat

- Temperature Max (T

- Time (min to max) (t

Average ramp up rate (Liquidus) Temp

(T

) to peak

L

to TL - Ramp-up Rate 5°C/second max

T

S(max)

Reflow

- Temperature (T

- Temperature (t

Peak Temperature (T

L

) 60 – 150 seconds

L

) 260

P

Time within 5°C of actual peak

Temperature (t

)

p

Ramp-down Rate 5°C/second max

Time 25°C to peak Temperature (TP) 8 minutes Max.

Do not exceed 260°C

T

P

T

L

T

S(max)

t

PreheatPrehea

S

Temperature

T

S(min)

) 150°C

s(min)

) 200°C

s(max)

) 60 – 180 secs

s

5°C/second max

) (Liquidus) 217°C

+0/-5

20 – 40 seconds

t

P

Ramp-up

amp-up

t

L

°C

Critical Zone

ritical Zon

L to TP

to

T

Ramp-down

amp-d

25

time to peak temperature

Package Dimensions — Mechanical Drawings and Recommended Solder Pad Outline

Package SOIC-8

Pins 8

JEDEC MS-012

Millimetres Inches

L

o

F

Recommended

Soldering Pad Outline

(Reference Only)

A 1.35 1.75 0.053 0.069

A1 0.10 0.25 0.004 0.010

A2 1.25 1.65 0.050 0.065

B 0.31 0.51 0.012 0.020

c 0.17 0.25 0.007 0 .010

D 4.80 5.00 0.189 0.197

E 5.80

E1 3.80 4.00 0.150 0.157

e 1.27 BSC 0.050 BSC

L 0.40

Min Max Min Max

6.20

1.27

0.228

0.016

Time

0.244

0.050

© 2013 Littelfuse, Inc.

Specifications are subject to change without notice.

Revised: 04/24/13

Page 4

TVS Diode Arrays (SPA

SLVU2.8 B

T

G

Series

Package

B = SOIC-8

No. of channels

T= Tape & Reel

-4

G= Green

U2.8-4

U

2.8

Product Series

U = SLVU2.8

Voltage Level

-4

No. of channels

®

Diodes)

Lightning Surge Protection - SLVU2.8-4 Series

Part Numbering System

Embossed Carrier Tape & Reel Specification — SOIC Package

User Feeding Direction

Pin 1 Location

Part Marking System

Ordering Information

Part Number Package Marking Min. Order Qty.

SLVU2.8-4BTG SOIC-8 U2.8-4 2500

Symbol

E 1.65 1.85 0.065 0.073

F 5.4 5.6 0.213 0.22

P2 1.95 2.05 0.077 0.081

D 1. 5 1.6 0.059 0.063

D1 1.50 Min 0.059 Min

P0 3.9 4.1 0.154 0.161

10P0 40.0 ± 0.20 1.574 ± 0.008

W 11. 9 12.1 0.468 0.476

P 7. 9 8.1 0.311 0.319

A0 6.3 6.5 0.248 0.256

B0 5.1 5.3 0.2 0.209

K0 2 2.2 0.079 0.087

t 0.30 ± 0.05 0.012 ± 0.002

Millimetres Inches

Min Max Min Max

Specifications are subject to change without notice.

© 2013 Littelfuse, Inc.

Revised: 04/24/13

Loading...

Loading...