Page 1

Service Manual

15-inch Color Monitor

C1570MNSL/T

Page 2

Service Manual Versions and Revision

No. Version Release Date Revision

1. 1.0 Aug. 30, 2001 Original release

Copyright

Copyright 2001 LiteOn Technology Corp.

All Rights Reserved

This manual may not, in whole or in part, be

copied, photocopied, reproduced, translated, or

converted to any electronic or machine readable

form without prior written permission of LiteOn

Technology Corp.

C1570MNSL/T Service Manual.

Printed in Taiwan.

Trademarks

LiteOn is a registered trademark of LiteOn

Technology Corp.

All other trademarks are the property of their

respective owners.

Page 3

C1570MNSL/T

Table of Contents

1. Precautions.........................................................................................................2

2. Product Specifications .......................................................................................5

3. Operation Theory............................................................................................. 10

4. Alignments and Adjustments ........................................................................... 15

5. Troubleshooting ...............................................................................................19

6. Recommended Spare Parts List....................................................................... 25

7. Block Diagram .................................................................................................27

8. Exploded Diagrams .................................................................................. Inserted

9. PCB Diagrams ......................................................................................... Inserted

11. Schematic Diagrams ................................................................................ Inserted

Page 1

Page 4

C1570MNSL/T

1 Precautions

Follow these safety and servicing precautions to prevent damage and to protect against potential hazards

such as electrical shock and X-rays.

1-1 Safety Precautions

1-1-1 Warnings

1. For safety purpose, do not attempt to modify

the circuit board, and always disconnect the AC

power before performing servicing on the

monitor.

2. Operation of the monitor outside its cabinet or

with the cover removed involves the risk of

shock hazard. Repair work on the monitor

should only be attempted by service personnel

who are thoroughly familiar with all necessary

safety precautions and procedures for working

on high voltage equipment.

3. Do not lift the CRT by the neck. After

completely discharging the high voltage anode,

handle the CRT only when wearing shatterproof

goggles. Try to keep the CRT away from the

body during handling.

4. High voltage should always be kept at the rated

value, no higher. Only when high voltage is

excessive are X-rays capable of penetrating the

shell of the CRT. Operation at high voltages

may also cause failure of the CRT or high

voltage circuitry.

nonmetallic control knobs, insulating materials,

cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor

networks, mechanical insulators, etc.

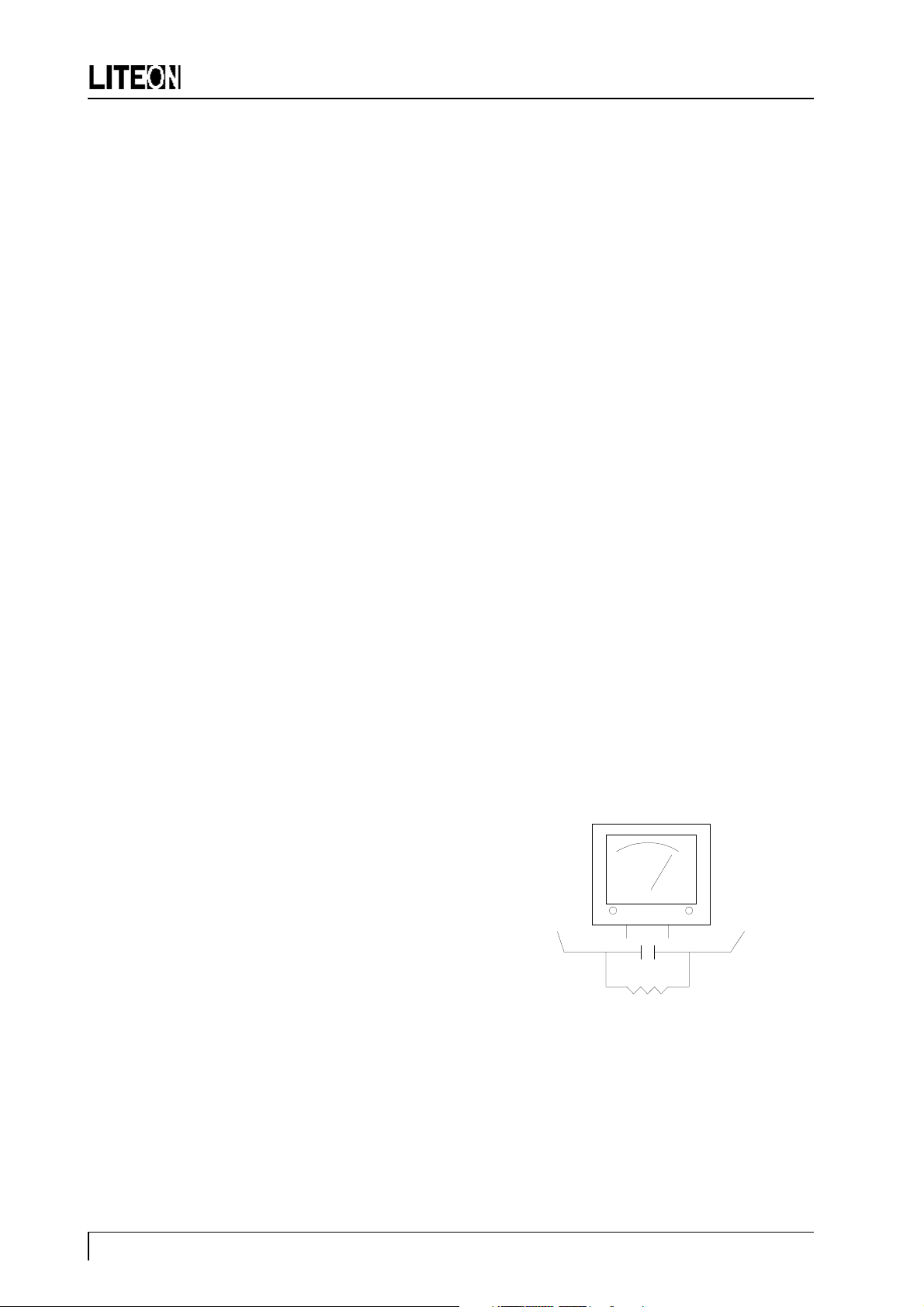

3. AC Leakage Current Check

Always perform the AC Leakage Current

Check on the exposed metal parts, including

metal cabinets, screwheads and control shafts,

as follows:

a) Plug the AC line cord directly into a rated

AC outlet. Do not use an isolation

transformer during the check.

b) Use an AC voltmeter with at least 5000

ohms per volt sensitivity as follows:

Connect a 1500 ohms, 10 watt resistor

paralleled by a 0.15uF AC capacitor in series

with all exposed metal cabinet parts and a

known earth ground, such as electrical

conduct or electrical ground connected to

earth ground, as shown in the Figure 1-1.

Measure the AC voltage across the

combination of resistor and capacitor.

Figure 1-1. Set Up For AC Leakage Current Check

5. The CRT is especially constructed to limit Xray emission to 0.5mR/HR at 300 microamperes

anode current. To ensure continued X-ray

protection, replace the CRT with only the same

or equivalent type as the original, and adjust the

anodes voltage to the designated maximum

rating, never to exceed.

1-1-2 Safety Checks

Before returning the monitor to the user, perform

the following safety checks:

1. Inspect to make certain that each lead dress is

not pinched or that hardware is not lodged

between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as

To kn ow n

earth ground

0.15ufd

1500 ohm 10 watt

To exposed m e tal

cabinet part

c) Reverse the AC plug at the AC outlet and

repeat the steps for AC voltage

measurements for each exposed metal part.

d) Voltage reading must not exceed 0.3 volts

RMS, equivalent to 0.2 milliampere AC. Any

value exceeding this limit ill constitute a

potential shock hazard and must be

corrected immediately.

PrecautionsPage 2

Page 5

C1570MNSL/T

1-1-3 Product Safety Notices

Many electrical and mechanical parts in this chassis have special safety-related characteristics which are

often not evident from visual inspection, the protection afforded by them may not be obtained by replacing

them with components rated for higher voltage, wattage, etc. Before replacing any of these components,

consult the Recommended Spare Parts List given at the end of this manual. Any of the replacements that do

not provide the same safety characteristics may result in shock, fire, X-ray emission or other hazards.

1-2 Servicing Precautions

Warning: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before performing servicing covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen conflict between the following servicing precautions and any of the safety

precautions, always follow the safety precautions

1. Follow closely the servicing precautions printed on the monitor cabinet and chassis.

2. Always unplug the AC power cord from the AC power source before removing or installing any component

or assembly, disconnecting PCB plugs or connectors and connecting a test component in parallel with a

capacitor.

3. When replacing parts or circuit boards, clamp the lead wires around the component before soldering.

4. When replacing a high wattage resistor (>0.5W metal oxide film resistor) in the circuit board, keep the

resistor about 1 cm (1/2 inch) away from the circuit board.

5. Keep wires away from the high voltage or high temperature components.

6. Keep wires in their original positions so as to minimize interference.

7. Always connect a test instruments ground lead to the instrument chassis ground before connecting the

positive lead; always remove the instruments ground lead last.

After putting the rear cover back and make sure the monitor is working properly, the Hi-Pot &

Ground Continuity tests MUST BE performed before the monitor is returned to user.

1-3 Hi-Pot Test

1. Test Equipment

Puncture test model PM5530 ADT or KIKUSU TOS-8750 voltage tester or equivalent approved equipment.

Note : The test equipment must be calibrated in regular period.

2. Test Setup

a) Apply voltage : DC 2121 VDC

b) Test duration : 3 seconds

c) Cutoff current should be set to 10 mA

3. Test Procedure

a) Unplug power cord from AC source.

b) Put the power switch of the monitor in the ON position.

c) Leave signal cable un-connected.

Precautions

Page 3

Page 6

d) Plug monitor power cord to the Hi Pot tester terminals.

e) Turn on tester and watch the indicator or beeper.

f) If the indicator lamp lighten, or beeper beeps, the test fails.

1-4 Ground Continuity Test

1. Test Equipment

AC low ohm tester TOS-6100 or equivalent approved equipment.

Note : The test equipment must be calibrated in regular period.

2. Test Setup

a) Test duration : 3 seconds

b) Set current limit at 25 A

c) The grounding resistance must be less than 0.1 ohm.

3. Test Procedure

a) Plug the monitor power cord to the tester terminals.

C1570MNSL/T

b) Make sure all connections are well-contacted.

c) Turn on monitor power and tester power.

d) Press Test button.

e) If green light shows up, means test OK.

If red light shows up, means test fails.

f) If the Tester has a digital display, the resistance value must not exceed 0.1 ohm.

Note : Be sure not to touch the metal portion of the signal cable head during testing.

PrecautionsPage 4

Page 7

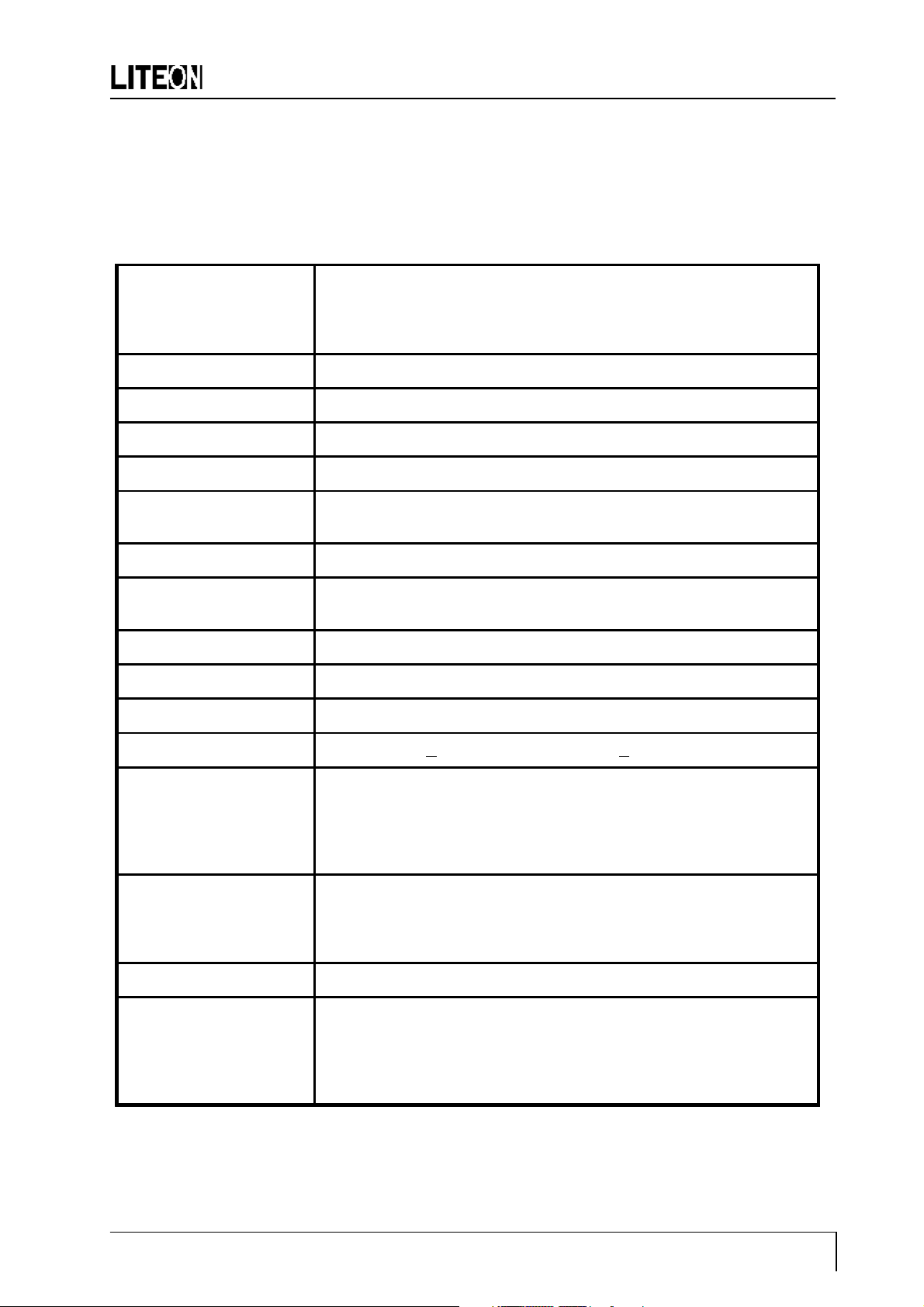

2 Product Specifications

2-1 Specifications

15-inch (13.8-inch Visual image area), sloted mask, 90 degrees

Picture Tube

Scanning Frequency VGA, Super VGA, 1024x768@60/70/72/75/85 Hz

Maximum Resolution 1280 dots (H) x 1024 lines (V) @60Hz refresh rate

Display Area 262 mm (H) x 196 mm (V) typical

Display Characters 80 char. x 60 rows on a 10 x 10 matrix

deflection, dot type black matrix, medium short persistence

pho spho r, d ark tint, non-glare/ anti-static screen, mini-ne ck gun

0.28 mm dot pitch

C1570MNSL/T

Display C olors Analo g

Input

Sync hronizatin Signals S eparate S ync: horizontal/vertical, TTL, positive o r ne gative

Sync hronization

Freque ncies

Signal Connectors 15-pin, D-shell connector

Video Signals Analog : 0.7 Vp-p, RGB positive

Power Input 75 Watts (maximum) AC rated voltage, 100VAC to 240VAC

Misconvergence Center Area : <

User Contro ls Po wer On/O ff, C ontrast, Brightness, Horizontal Size, Horizontal

Service Controls PWB-1603 : power voltage adjust (VR801), high voltage adjust,

Unlimited C olors

Horizontal : 30 to 69 kHz

Vertical : 50 to 120 Hz

0.3 mm; Corner Area : < 0.4mm

Position, Vertical Size, Vertical Position, Pincushion, Trapezoid,

Rotation, Color temperature, Langua ge, Display Frequency,

Dega uss, Re c all, H. Moire,

V. M o ir e

Focus adjust FBT on up VR.

To adjust R-bias, G-bias, B-bias, High voltage and ABL, must

enter the factory mode.

Preset Modes 10 (see Table 2-2. Timing Chart)

o

Environmental

Considerations

Operation temperature : 5

Operation Humidity : 20% to 90% ambient

Storage temperature : -40

Storage Humidity : 10% to 90% (non-condensing)

Altitude : up to 10000feet above sea level

C to 40oC ambient

o

C to 65oC ambient

Note: Above specifications are subject to change without prior notice.

Product Specifications

Page 5

Page 8

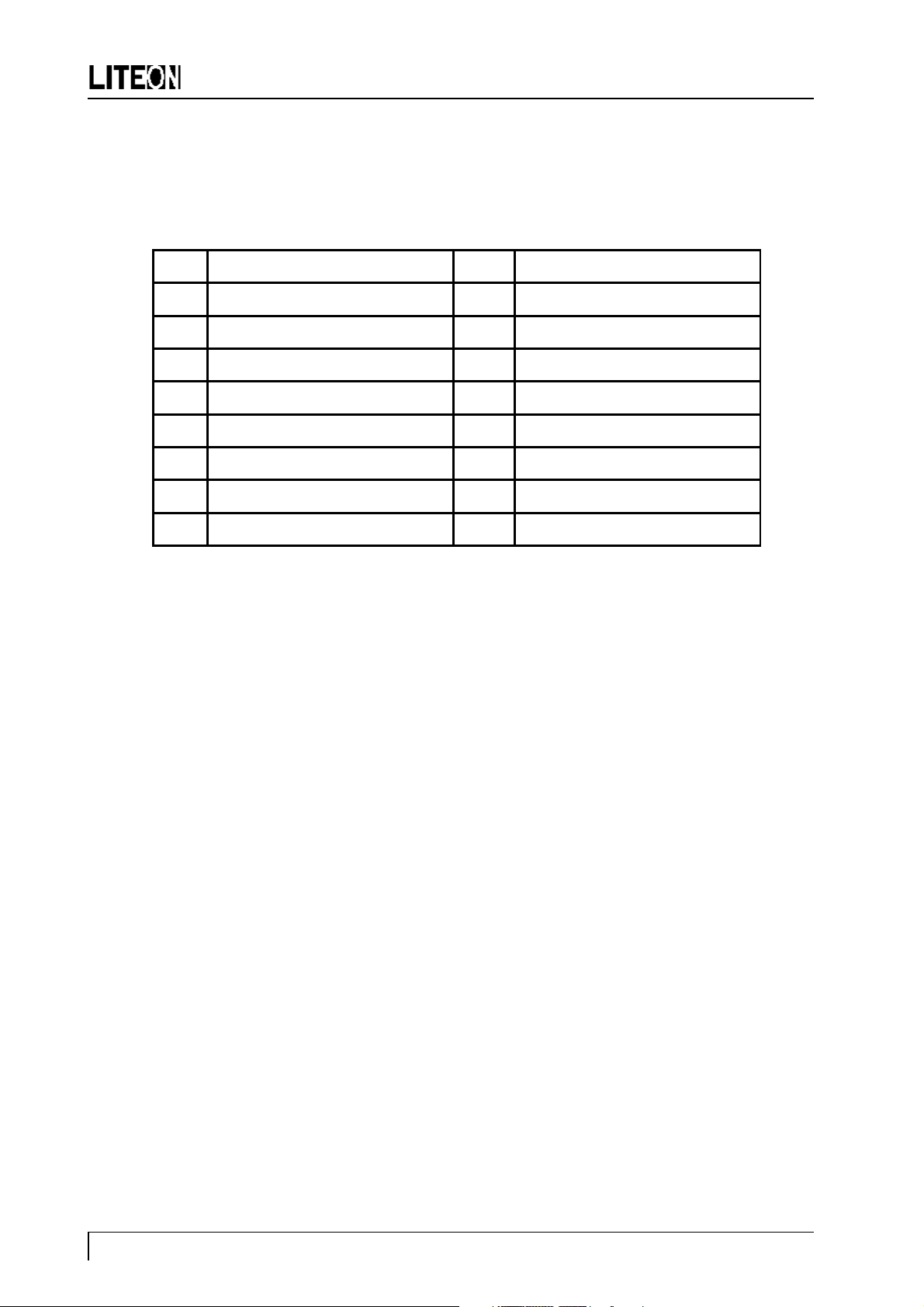

2-2 Signal Cable Pin Connections

Table 2-1. Signal Cable Pin Assignment

Pin Signal Pin Signal

1 Red video 9** +5V

2 Green video 10 Digital Ground

3 Blue video 11 Ground

4 Ground 12 S DA

5* NC 13 H-Sync

6 Red gro und 14 V- Sync

7 Green ground 15 S C L

8Blue ground

C1570MNSL/T

Note * This pin is used for selftest detection. Connect this pin to ground at the PC end.

** For PC 99: This pin will obtain +5V from PC side.

Product SpecificationsPage 6

Page 9

C1570MNSL/T

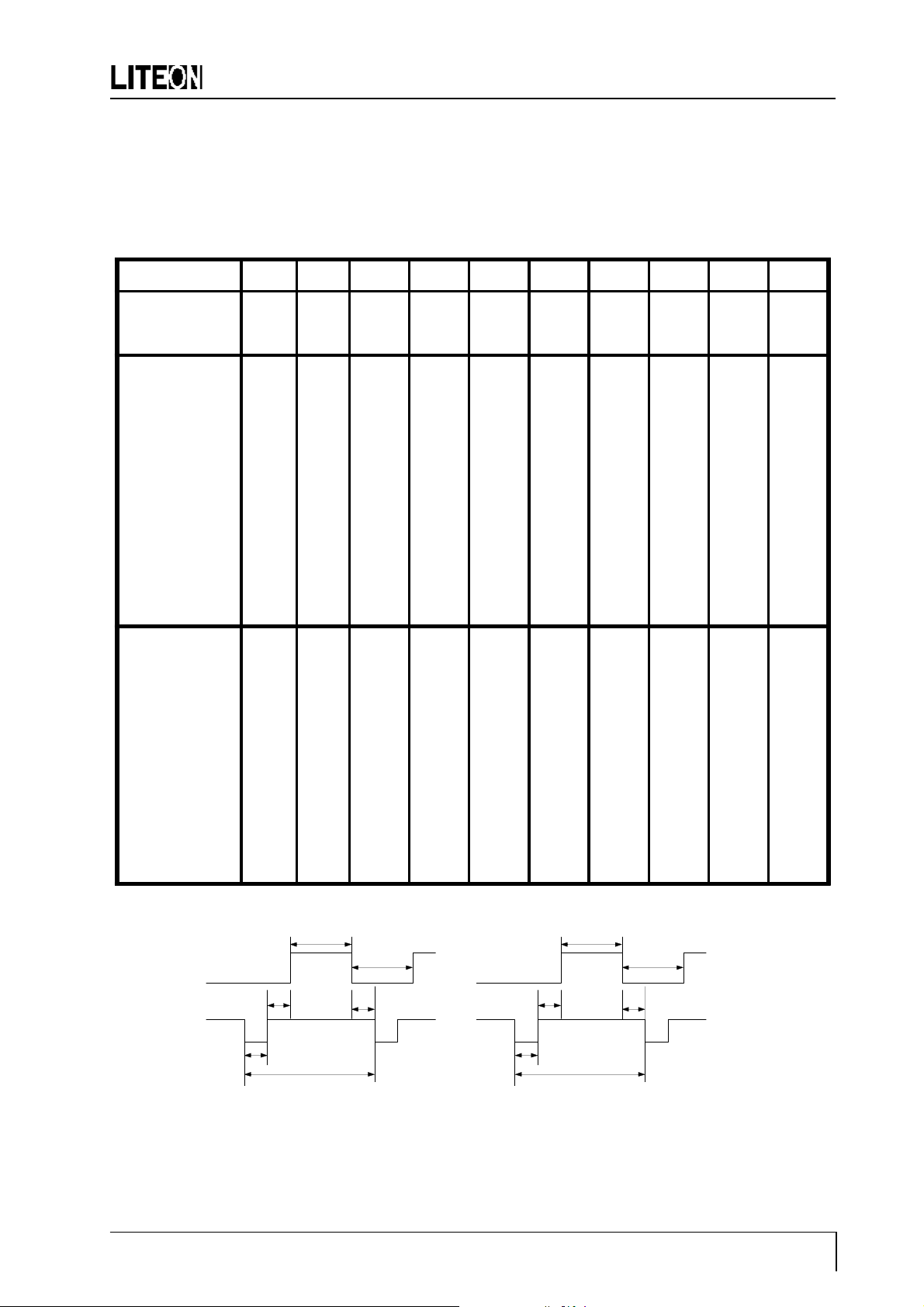

2-3 Timing Chart

This section describes the timings that the computer industry recognizes as standard for computer-generated

video signals.

Table 2-2. Timing Chart

Mode 12345678910

H. D ots 720 640 800 640 640 800 1024 800 1024 1024

V. D o t s 400 480 600 480 480 600 768 600 768 768

H -fre q (k H z)

Sync Polarity --+ - -+ -+++

A period us

B Blking us 6.356 6.356 6.4 6.35 5.33 5.172 4.923 4.409 3.657 3.725

C S ync us 3.81 3.81 3.2 2.07 1.556 1.616 2.092 1.138 1.219 1.016

D B.P. us 1.907 1.907 2.2 3.81 2.222 3.232 2.462 2.702 2.235 2.201

E Active us

F F.P. us 0.636 0.636 1 0.51 1.556 0.323 0.369 0.569 0.203 0.508

V-freq (H z) 70.08 59.95 60.32 75 85 75 60 85 75.03 85

Sync Polarity +-+ - -+ -+++

O Period ms 14.27 16.68 16.58 13.33 11.764 13.333 16.67 11.76 13.33 11.77

P Blking ms

Q Sync ms 0.064 0.064 0.106 0.08 0.069 0.064 0.124 0.056 0.05 0.044

R B.P. us

31.47 31.47 37.88 37.5 43.3 46.8 48.36 53.67 60.02 68.68

31.78 31.78 26.4 26.666 23.111 21.333 20.68 18.63 16.66 14.56

25.42 25.42 20 20.32 17.778 16.162 15.75 14.22 13 10.836

1.557 1.43 0.739 0.533 0.67 0.533 0.786 0.578 0.533 0.582

1.08 1.02 0.607 0.407 0.578 0.448 0.6 0.503 0.466 0.524

S Active us 12.71 15.25 15.84 12.8 11.093 12.8 15.88 11.18 12.8 11.18

T F.P. us 0.413 0.35 0.026 0.026 0.023 0.021 0.062 0.019 0.017 0.015

Seperate Sync

Horizontal

C

E

Vid eo

D

Sync

A

B

F

H.Parameters:

A: Period B: Blanking Time

C: Sync Width D: Back Porch

E: Active Time F: Front Porch

Ve r t i c al

I

V.Parameters:

G: Period H: Blanking Time

I: Sync Width J: Back Porch

K: Active Time L: Front Porch

K

Vid eo

J

Sync

G

H

L

Product Specifications

Page 7

Page 10

C1570MNSL/T

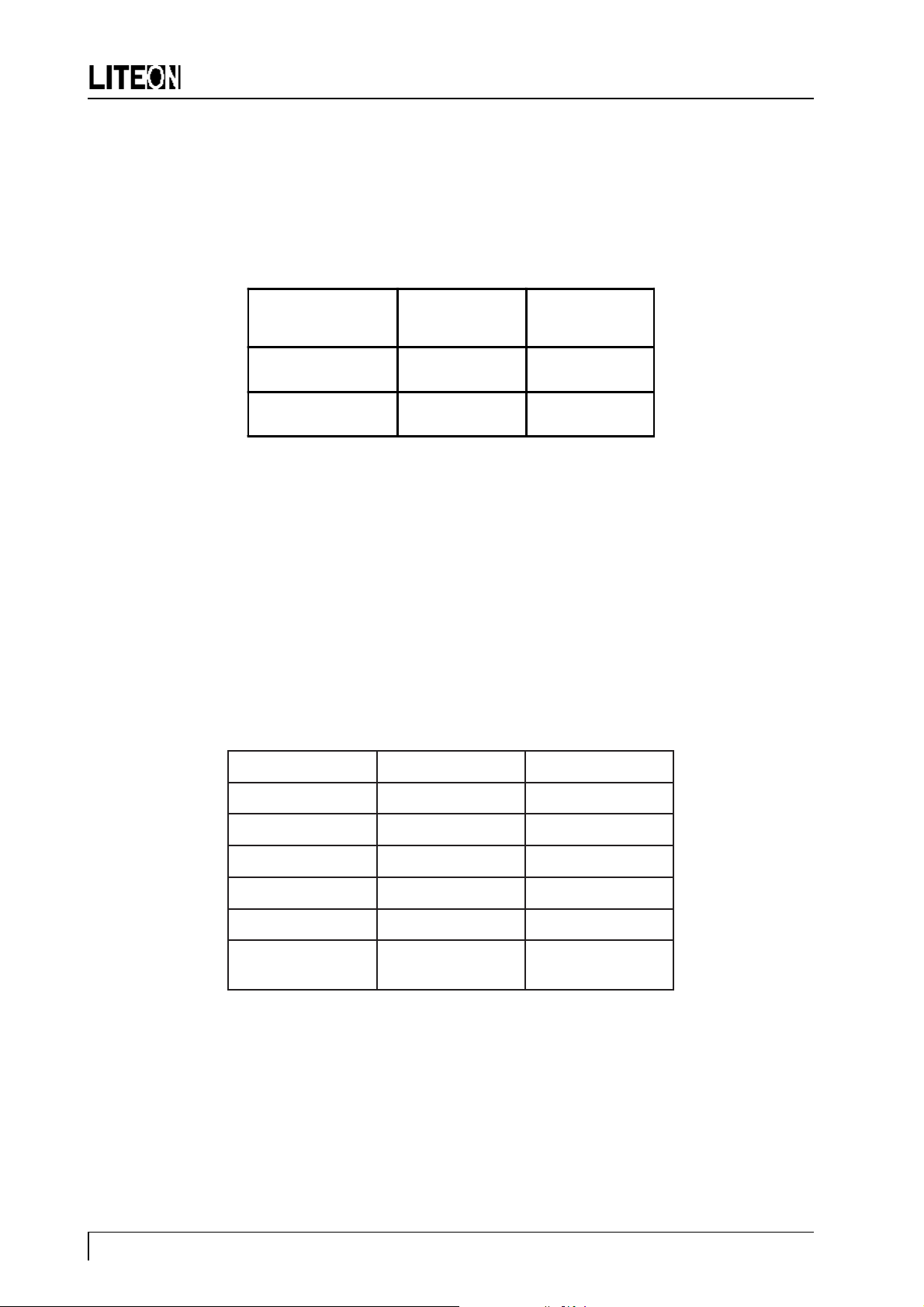

2-4 Power Saving Function

Note: The monitor will be driven into Power Saving mode by the control signal from the display

controller, as indicated by the amber-color power LED.

Table 2-3. Power Saving Function

LE

State Power

Cons umption

D

Light

ON Normal

Active

OFF

<5 watts Amber

*

Green

2-5 TCO Version (Optional)

The monitor meets the TCO 95/99, NUTEK energy saving, electric and magnetic field requirements.

Also it is compliant with TCO 95/TCO 99 labelling scheme.

The emission from magnetic and electric field must comply with the limits specified by the Swedish Board

for Measurement and Testing, commonly known as MPR 1990 recommendations. These limits are summarized in the Table 2-4.

Table 2-4. TCO 95 Emission Requirements

OCT/FLVOCT/FLE

dleiFcitengaMTn52Tn002

dleiFcirtcelEm/V1m/V01

egnaRycneuqerFzHk004~2zH0002~5

eulaVSMRSMR

ecnatsiDmc03mc03

citatsortcelE

laitnetoP

V005-/+V005-/+

The monitor is designed with selected CRT and carefully routed wires around CRT, make sure exactly the

same routing scheme is used when doing CRT replacement.

2-5-1 TCO 95 Version (Optional)

The TCO 95 scheme is for international and environmental labelling of personal computers. The labelling

Product SpecificationsPage 8

Page 11

C1570MNSL/T

scheme was developed as a joint effort by the TCO (The Swedish Confederation of Professional Employ

ees), Naturskyddsforeningen (The Swedish Society for Nature Conservation) and NUTEK (The National

Board for Industry and Technical Development in Sweden).

1)`Scope

TCO 95 touches on ergonomic qualities, emissions (electrical and magnetic fields), energy efficiency and

ecology (with demands for environmental adaptation for both the product and the production processes at

the manufacturing plant).

2) Environmental Requirements

The monitor abides by the environmental demands concerning restrictions on the presence and use of

heavy metals, brominated and chlorinated flame retardants, CFCs (freons), and chlorinated solvents,

among other things. The monitor is also recyclable.

3) Energy Requirements

The monitor also follows the energy requirements that, after a certain period of inactivity, the monitor

shall reduce its power consumption to a lower level in one or more stages.

4) Others

The monitor meets the strict environmental demands for the reduction of electric and magnetic fields,

physical and visual ergonomics and good usability.

Table 2-5. TCO 95 Visual Ergonomics

erutaeFdradnatSnoitpircseD

ytiraeniLsselro%1 ehtotderapmocsworrosnmulocfohtgnelniecnereffiD

.rotinomehtforetnecehthguorhtshtgnelgnidnopserroc

ecnanimuLyalpsiD)tsaelta(2m/dc001

ecnanimuL

ytimrofinU

sselro1:7.1 ehtnihtiwecnanimulnimotxamehtneewtebsioitarehT

.aeraevitcaelohw

2-5-2 TCO 99 Version (Optional)

TCO 99 will append the color temperature and energy efficiency specification, also cover the environmental

requirement.

Product Specifications

Page 9

Page 12

C1570MNSL/T

3 Operation Theory

This is a fully digital controlled multi-sync color monitor that is compliant with DDC1 and 2B Plug and Play

VESA standard and offers the following main features.

3-1 Main Features

1. Simplified design with minimum components.

2. The MYSON MTV212M32 processor-- that has I

brightness-- offers the functions for: (a) Contrast, (b) Brightness, (c) H-size, (d) H-position, (e) V-size, (f)

V-position, (g) Pincushion, and (h) Trapezoid.

2

C BUS controlled geometric correction, contrast and

In addition, it also offers more functions as: (a) Sync. processor, I/P and O/P, (b) Mute, (c) Power saving

OFF mode, (d) Power saving override, (e) DDC1/2B, (f) I

2

C Bus for auto-alignment through signal cable

(g) CS1/CS2/CS3/CS4 for linearity and size compensation.

3. Stores up to MAX. 14 factory preset modes and offers 8 user modes. There are 16 function icons at

OSD. They are controlled by

2 keys on front panel.

1

4. Powerful PHILIPS TDA4863AJ and TDA4841 present the following useful functions: (a) Pincushion,

(b) Trapezoid, (c) V-Position, (d) V-Size, (e) Verticals C and S correction -- factory adjust, (f)

Pincushions V. position correction, (g) Corner correction -- factory adjust, (h) Pincushion unbalance

correction -- factory adjust, (i) Parallelogram distortion -- factory adjust, (j) Moire cancellation, (k) X-ray

protection, and (l) Full horizontal and vertical auto sync capability.

5. Software controlled auto shut off function activated if HF < = 29 kHz and HF > = 70 kHz.

6. Full range AC input and simplified line filter design.

3-2 Microcontrol Section

1. This monitor uses MYSON MTV212M32 CPU. It contains a 8051 8-bit CPU core, 512 bytes of RAM

used as working RAM and stack area, 32k bytes of ROM, 14-channel 8 bit PWM D/A converter, 3channel A/D converters for key detection saving I/O pins, internal H. sync and V. sync signals processor

providing mode detection, and an I2C bus interface. When H/V sync through D-Sub signal cable enter pin

41 and pin 42, the CPU performs frequency / polarity detection and calculate and send to H/V sync OUT.

Then CPU reads the data from EEPROM I703 and transfer to device 4841 and some DAC in CPU,

above operation takes about 500 ms.

2. There allowed MAX. 14 factory preset modes and 8 user modes. There are 11 functions, Contrast,

Brightness, H. Size, H. Position, V. Size, V. Position, Pincushion, and Trapezoid, Rotation, H. Moire, V

Moire, all controlled by OSD icon which can be adjusted by user.

3. C1570MNSL/T Communication Protocal

3.1Monitor Communication Summary

The monitor operates the communication channel in two modes, the Transmit-Only Mode and the BiDirectional Mode.

3.2 Transmit-Only Mode

Like DDC1 is a uni-directional channel from display to host, the device transmits data bits on the SDA pin

in response to a clock signal on the VCLK pin.

3.3Bi-Directional Mode

It is a bi-directional channel between the display and host based on I

2

C protocol.

In this protocol, 2 wires (SDA-serial data, SCL-serial clock) carry information between the devices

Page 10 Operation Theory

Page 13

C1570MNSL/T

connected to the bus, a device that sends data on the bus is defined to be the transmitter, and a device that

receives data from the bus is defined to be the receiver. The bus must be controlled by a master device

that generates the clock (SCL), controls access to the bus and generates the START and STOP conditions,

while the monitor acts as the slave. Data on the I2C bus can be transferred at a rate up to 100KHz.

There are two communicaionts on the monitor in I

* DDC2 mode - The Transmission from the host to the monitor which is a request by reading the EDID.

* ATE mode - The transmission from the host to the monitor which is sending or reading the data of the

device of monitor.

* Note: The devices slave address on I

2

C

Device Slave address on I2C

24C08 A0H

MTV021 7AH

LM1267 DCh

2

C bus.

TDA4841 8Ch

MCU C6h

4. The user control parameters are selected by OSD icons, through 1 & 2 keys, they are detected by

sensing the voltage through R710, R740, R741, R743, R716, R717 to pin 25 and 26 of I701.

3-3 Deflection Section

1. I2C -- autosync deflection controller is TDA4841.

2. The TDA4841 is a high performance and efficient solution for autosync monitors. All functions are

controllable by I

control all functions.

3-3-1 Horizontal Section

1. The oscillator is driven by the currents in R419 and R420. The minimum oscillator frequency is determined

by R419 and the maximum frequency is determined by R420.

2. Horizontal sync goes into pin 15 through R318. And horizontal flyback pulse goes into pin 1 through R401

and bypass filter C403 from pin 6 of FBT.

2

C bus. SDA and SCL signals coming from microprocessor feed to pin 19 and pin 18 to

3. Horizontal driver (pin8) O/P to Q401 via C410.

3-3-2 Vertical Section

1. Vertical sync goes into pin 14 through R317.

2. The free running frequency is determined by R301 and C301.

Operation Theory Page 11

Page 14

C1570MNSL/T

3-3-3 Vertical O/P section

1. The differential output currents from pin 13 of Vout1 and pin 12 of Vout2 can be directly coupled to the

vertical deflection booster pin 7 and pin 6 of TDA4863AJ.

2. The TDA48634J has one output stages which are current driven in opposite phase and operate in combination

with the deflection coil in a half bridge configuration.

3. This IC is powered by two voltage. (+12V at pin 1, -12V at pin 4).

3-3-4 E-W/Trapezoid and H. Width Controls

1. The horizontal O/P stage uses diode modulator D419, D410, C411, C412, L409 and C418 for East-West

(Pincushion) Trapezoid and H. width controls.

2. The scan current is determined by B

+

minus Vm ( the voltage of C418) values and the pincushion control

is accomplished by Q419 by coupling a parabola waveform from pin 11 of TDA4841. The H. width /

corner and trapezoid correction are also accomplished by this pin 11. The DC level controls H. size. The

AC level is combined with side pin and trapezoid corners functions.

3-3-5 X-Ray Protection

1. To avoid X-ray hazard, a DC voltage generated at pin 6 of FBT and rectified by D408, C432 and divided

by R403, R404 and R405 come into pin 2 of TDA4841.

2. If this voltage is higher than 6.39 V, then TDA4841 will be activated to float HUNLOCK (pin17), H.

DRV( pin 8), B DRV (pin 6), VOUT1 (pin 12), VOUT2 (pin13). After that all deflection circuit stop

working.

3-3-6 G1, Blanking and Brightness

1. The vertical blanking signal comes from two ways. One is from pin 2 of I301 (TDA4863AJ), the other is

from vertical sync (pin 34 of I701). These two positive vertical pulses through Q405 amplified and converted

into negative pulse and sent to G1 for vertical blanking.

2. In protection mode or an out-of- range situation HUNLock will send 5 V pulse to saturate Q407, then G1

will go down to -140V. During the mode change, Mute acts as same as HUNLocks.

3. The brightness is controlled by CPU pin 39 through PNP transistor Q407. The lower control voltage

causes Q407 conducts darken to get lighter raster and a higher control voltage causes Q407 conducts

lighter to get lower brightness.

4. The brightness is controled by I701 through I

2

C bus to I501 (LM1267).

3-3-7 Contrast Section

1. Contrast is controlled by I701 through I2C bus to I501 (LM1267) directly.

2. Beam current is detected through T402 (FBT) pin 7, C429, R460, D406 and detected voltage feeding into

Q406, D415, Q409, R530, R532, R454, R471, C529 to control I501 pin 22 voltage. When I501 pin 24

voltage drops below 3.9V, the ABL function will happen.

3-3-8 H/V size breathing compensation

1. Beam current is sensed as above section (4-3-7 item 2) and this voltage routes through R436, Q409,

Page 12 Operation Theory

Page 15

C1570MNSL/T

R459 then through R418 to I401 pin 31 for H. size compensation, through R302 to I401 pin 21 for V size

compensation.

3-3-9 Dynamic focus circuitry

The dynamic focus is applied to improve the corner focus performance.

Horizontal dynamic comes from C413 through R435, C450, T403, R434, C448 and feed to FBT dynamic

focus pin.

3-4 Power Supply Section

3-4-1 AC Rectifier

The circuit can accept 90 V to 264 V AC input through D828~D831 bridge diodes and C808 filtering to get

DC 126 V~364 V for power conversion in T802.

3-4-2 Line Filter

It consists of C859, C860, C803, C816, C848, C852, C807 and T801 and meets EMI regulation.

3-4-3 Power LED Status

1. The LED has 3 leads with common cathode to emit green and amber color light for different power

saving states. It is controlled by CPU.

2. Normal : Green light

Amber LED is off because CPU pin 31 is 1.96V and pin 30 is 0.02V, only green LED is turned on.

3. Off Mode : Amber light

CPU pin 31 is 0.02V and pin 30 is 1.92V, then green is off and amber is illuminated.

3-4-4 Auto Degaussing

When S801 turns on, pin 14 of I701 will send a signal to Q802 and turns on RL801 for degaussing. After 4

seconds, it will turn off RL801 automatically.

3-4-5 PWM Control

1. Start Up

The I801 (MC3842) gets power from R807, R873, C812 and pin 7 voltage reaches 16 V for starting up.

The I801 starts oscillation at 22 kHz, sawtooth on pin 4 and pin 6 output to drive Q803/T802. Once Q803

switching on, D806, C804 set up an 15 V to keep I801 working through D808 auxiliary voltage.

2. Regulation

The DC O/P voltage is proportional to the auxiliary voltage, so I801 pin 2 senses the feedback voltage from

the divider R802, R823, VR801 and R821 to compare with the built-in 2.5 volts reference voltage for error

amplifier operation. Finally pin 6 can modulate the different duty cycle by VR801 setting to achieve

regulation purpose.

3-4-6 Synchronization

1. Normal Mode

Operation Theory Page 13

Page 16

C1570MNSL/T

The sync pulse from FBT (31 kHz~69 kHz) via C815, R826, D824, C814 and R816 to pin 4 of I801 to

keep I801 synchronized with horizontal sync input frequency.

2. Power Saving Modes: Standby/Suspend

Because there is no pulse from FBT, so the free-run frequency is decided by R815 and C814 and the

SMPS works at 22 kHz.

3. Override

The horizontal free run frequency is about 62.5 kHz under override condition, SMPS is synchronized to

this frequency.

3-4-7 O.V.P.

If the auxiliary voltage is higher than zener voltage ZD807 (18 volts) and makes pin 3 of I801 higher than

1 V, pin 6 duty cycle is limited to have the OVP activated.

3-4-8 O.P.P.

The excess current of T802 through Q803, R813 and R814 can develop enough voltage on pin 3 then limit the

power delivered because the pin 6 duty cycle is limited too.

3-4-9 Step Up Power Supply For FBT

1. The B+ of FBT is proportional to horizontal frequency, that is the higher frequency, the higher voltage.

The basic voltage is 55 volts from T802 pin 11 via L811, D813, C824 and the gate control of Q807 comes

from I401 pin 6 via Q808, R4C9 and R855. The duty cycle is controlled by C843, C841, C846, R846, R877

and R856, R857, R839 and D821 combination ratio.

2. The regulation and boost up (from 68 V to 160 V or more, on demand). The H.V. is set at 24.5 kV (zero

beam) by CPU pin 33. The booster comprises Q807, L802, L801, D820, C425 and T802 to offer the

required B+ for different frequency modes.

3-5 Video Amplifier Section

1. RGB signal inputs are terminated by R507, R537 and R567 then pass through the coupling capacitors

C501, C531 and C561 to I501 LM1267 preamplifier.

2. The amplifier RGB signals (0~3 Vpp) are adjusted by I

comes from pin 16 of TDA4841 to set up equal clamp level.

3. The video output stages are amplified by I502 (LM2469).

4. The RGB cathodes cut off are adjusted by I701 through I

5. Under override condition, NO SIGNAL will show up on the screen.

2

C bus from I501, pin 23 is for clamp pulse which

2

C bus.

3-6 OSD (On Screen Display) Circuit

1. The I504 HTV021-21 is OSD IC. The OSD signals are worked by positive vertical pulse from I701 pin 34

that goes to I504 pin 10, and positive horizontal pulse from T402 pin 6 goes through R472, C419, D433 to

I504 pin 5. CPU I701 pin 12, 13 (I2C bus) transfers information to I504 pin 7, 8.

2. The OSD R. G. B signals and blanking signal are terminated at I504 pin 15, 14, 13, and 12 to I501 pin 1,

2, 3, and 4, then the OSD picture appears.

Page 14 Operation Theory

Page 17

C1570MNSL/T

4 Alignments and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor settings.

4-1 General Adjustments

4-1-1 Adjustment Conditions

a) Power Supply

Apply AC 115 V or 220 V

b) Warm-up Time

The monitor must be powered on for 15 minutes before starting any alignment, but requires 30 minutes of

warm-up time for convergence adjustment.

c) Signal Input

1. Video: RGB Analog, 0.7 Vp-p, positive

2. Synchronization: Horizontal and vertical TTL signal, separate, positive or negative

3. All adjustments should be made using a signal of FH = 68.68 kHz, FV = 85 Hz, unless otherwise

defined.

4-1-2 Equipment Required

The following equipments are necessary for adjustment procedures:

1. Volt-ohm-A meter (Sanwa FD-750C or equivalent)

2. 30 kV high voltage probe (HP34111A)

3. Oscilloscope (TEK2235 or equivalent)

4. Minolta Color Analyzer II

5. Signal generator (IBM PC with proper display cards or Chroma 2000)

6. Screwdriver

4-1-3 Switching Power Supply and Regulator Adjustment

a. The regulated B+ control has been preset in the factory and needs no adjustment. However, if any repair

is made on the power supply section, the following readjustment procedures are recommended:

1. Allow the monitor to warm-up for about 15 minutes.

2. Apply VGA (1024 x 768 @ 68.68 kHz/85 Hz) signal to the monitor.

3. Connect a DC voltage meter to TP001 (on the Main board), and adjust VR801 for 12 ± 0.1 Vdc

4. If a fuse is broken during adjustment, remember to replace it with the exact same type of fuse.

b. If necessary, follow the following procedures to enter the factory mode.

1. Press both

2. After turn the power off, this monitor will go back to normal mode.

key and 2 key simultaneously then power ON.

1

Alignments and Adjustments

Page 15

Page 18

C1570MNSL/T

4-2 Alignment Procedures

4-2-1 High Voltage Adjustment

CONDITION

Display image : Crosshatch pattern

PROCEDURE

Connect DC meter to TP002 and adjust by OSD (enter factory mode) to obtain a DC voltage of -145 ± 0.5V

DC for CPT CRT M36AJA93X46 (TCO) or M36AJA83X46 (MPRII).

4-2-2 Screen and White Balance Adjustment

CONDITION

Press

and 2 buttons simultaneously when switching the power On.

1

Display image : No video

PROCEDURE

1 Raster color setting (68.68 KHz Mode)

1-a. Set Brightness (OSD Icon) to max Y=0.9 ± 0.2 FL and 640 V at G2.

1-b Adjust by OSD RGB cutoff icon (enter factory mode), until x=280 ± 5FL, y=280 ± 5FL,

Y=0.9 ± 0.2FL

1-c Adjust Brightness to raster Brightness Y=0.01~0.02 FL.

CONDITION

Display image : 50 mm x 50 mm white block pattern

PROCEDURE

2 6500

0

K color temperature setting

2-a. Set Brightness to cutoff and Contrast to maximum.

2-b Move cursor on OSD to choose color temperature icon.

2-c. Press

key to G gain then adjust G gain = 75 value, then adjust B, R to y=329±5, x=313±5.

2

2-d Adjust Contrast to set y=45±1.5FL

2-e Check x=313±5, y=329±5.

3 9300

0

K color temperature setting

3-a. Set Brightness to cutoff and Contrast to maximum.

3-b Move cursor on OSD to choose color temperature icon.

3-c. Press

key to G gain then adjust G gain = 80 value, then adjust B, R to y=298±5, x=283±5.

2

3-d Adjust Contrast to set Y=45±1.5FL

3-e Check x=283±5, y=298±5.

Page 16 Alignments and Adjustments

Page 19

4 Full white ABL setting

CONDITION

Display image : full white pattern

4-a Set Brightness to cutoff and Contrast to maximum.

4-b. Adjust OSD ABL icon until Y=30 ± 1FL.

4-c. Check the white balance at 5FL and 28FL.

4-d. Repeat all the procedures in 4-2-2 section until the best white balance is obtained.

4-2-3 Focus Adjustment

CONDITION

Display image : e character pattern

PROCEDURE

1. Set Brightness to cutoff and Contrast to maximum.

2. Adjust center VR at T402 (static focus VR) to make horizontal line clear.

3. Repeat above procedures to get best focus.

C1570MNSL/T

4-2-4 Static Convergence Adjustments

Static convergence involves alignment of the red, blue and green lines in the center area of the display.

Note : The monitor requires 30 minutes of warm-up time for convergence adjustment.

CONDITION

Display image : Crosshatch pattern

Warm-up Time : 30 minutes

PROCEDURE

1. Set Brightness and Contrast to display a well-defined pattern.

2. Ensure the convergence magnet rings are correctly positioned on the CRT.

Figure 4-1. Convergence Magnets on the CRT

1

11

+

P

CRT

FRONT

1) Setup Bolt 2) Bow Magnet 3) Band 4) 2-Pole Magnet

5) Spacer 7) Spacer

9) Holder

Alignments and Adjustments

6) 4-Pole Magnet

8 7 6 5 4 3 2

10

9

8) 6-Pole Magnet

11) Tabs10) Band

Page 17

Page 20

C1570MNSL/T

3. Rotate the individual rings of 4-pole convergence magnets by changing the spacing between the 2 tabs to

converge the vertical red and blue lines at the center of the screen.

4. Rotate the pair of rings of 4-pole convergence magnets by maintaining spacing between the 2 tabs to

converge the horizontal red and blue lines at the center of the screen.

5. Rotate the individual rings of 6-pole convergence magnets by changing the spacing between the 2 tabs to

converge the vertical red, blue and green lines.

6. Rotate the pair of rings of 6-pole convergence magnets by maintaining spacing between the 2 tabs to

converge the horizontal red, blue and green lines.

7. Repeat the steps from 3~6 until the best convergence is obtained.

Figure 4-2. 4-pole and 6-pole Magnets Movement

Red/

Bl u e Re d

Bl u e Gr e en

Blue

Red

4-pole magnets

movem e nt

Red/

Blue

Green

6-pole magnets

movem e nt

Note : The 4-pole magnets and the 6-pole magnets interact, making dot movement complex.

4-2-5 Degaussing

Degaussing is required when poor color impurity appears on the screen. This monitor uses an automatic

degaussing circuit that is activated when the power is on. The automatic degaussing will be fully functional

again after the monitor has been in operation for 20 minutes.

The degaussing effect is confined to the picture tube since the coils are mounted at the back of the tube.

Should any part of the chassis or cabinet becomes magnetized, it is necessary to degauss the affected area

with a manual degaussing coil.

4-2-6 Manual Degaussing

1. Apply line voltage to the degaussing coil and move it in a rotary motion over the front, sides, and top of the

monitor. The coil should be kept away from the rear of the monitor to avoid damaging the magnetic neck

components.

2. Slowly rotate and move the coil away from the monitor to about 6 feet beyond the point where no effect

on the CRT will be noticeable.

For proper degaussing, it is essential that the field be gradually reduced by moving the coil slowly away from

the monitor. The degaussing coil must never be shut off or disconnected while near the monitor, as this would

introduce a strong field instead of canceling the effect of the stray fields.

Page 18 Alignments and Adjustments

Page 21

5 Troubleshooting

5-1 No Raster

C1570MNSL/T

No Raster

Measure

voltage of B+ at

T402 pin 3 on

PWB-MAIN

Yes

Check DC

B+ line, Q808,

Q402, Q807, T402

0 V

Short Circuit

at load?

No

Check AC I/P

on C808

YES

Check

I801, Q803,

R814, R813,

R876, R811,

R818, ZD807,

D825

Grid 1, Grid 2, etc.

NO

Check D828,

D829, D830,

D831, T801,

R891, F801

Normal

(68 V, 31.5 kHz)

Check voltage of

cathode, heater,

High

(75 V or more)

Check I401,

R858, R857,

R856, R839

Troubleshooting

Page 19

Page 22

5-2 OSD Abnormal

C1570MNSL/T

OSD Abnormal

Check I504

pin 9, 4 is 5V and pin 5,

7, 8, 10 missing?

No

Check R518,

R519, R520

OK?

Yes

Check P503 OK?

Yes

No

No

Put on

I504

Replace them

Replace it

Yes

Replace I504

Page 20 Troubleshooting

Page 23

5-3 Function Key Abnormal

Function Key Abnormal

C1570MNSL/T

Check I701 and

I703 missing?

No

Power

ON/OFF again and

check X701, oscillator

OK?

Yes

Check

I703 EEPROM content

OK?

Yes

Yes

No

No

Put on

I701, I703

Replace X701

Replace I703 or do

ATE again

Troubleshooting

Replace I701 and check

uP OK?

No

Check

pin 8 of I701

is 5V?

No

Replace R730, Q701

Yes

Yes

Replace I701

Check

pin 4 of I701

Page 21

Page 24

5-4 No Vertical Scan (Raster is one horizontal line)

No Vertical Scan

C1570MNSL/T

Check I301 voltage of

pin 3 is 12V, pin 4

is -12V?

Yes

Check

pin 5 O/P waveform at

I301

Yes

Check

pin 7, 6 of I301

wavefrom

No

No

No

Ckeck or replace

R316, I301, R320

Check

R313, R305,

R308, R311

Replace I401

Still no vertical scan

Check or replace CRT

Page 22 Troubleshooting

Page 25

5-5 Out of Horizontal Synchronization

Out of Horizontal

Synchronization

C1570MNSL/T

Horizontal

sync present at

pin 15 of I401

Yes

Check

I401 pin 8 H. output

frequency & pin 29

waveform

Yes

Check Q401,

T401, Q402,

R424, D401

5-6 Out of Vertical Synchronization

No

No

Check or replace

the signal cable or

H. sync pin 41

of I701.

Check or replace

I401, C406

Out of Vorizontal

Synchronization

Vorizontal

sync present at

pin 14 of I401

Yes

Check

I401 pin 24 waveform

Yes

Check I401 pin 13 & pin 12.

No

No

Check signal cable

& V. sync pin 42

of I701.

Check or replace

C301, I401,

Troubleshooting

Page 23

Page 26

5-7 R.G.B. Video Amplifier Abnormal

RGB Video AMP Abnormal

C1570MNSL/T

Check

waveform at I501 pin 20, 19

and 18

Yes

Check

I502 pin 1, 2 , 3 collector

voltage (normally about 72V)

& waveform

Yes

Video signal present at the

pin of the CRT R.G.B.

Cathode

Yes

Check or replace the

No

signal cable or I501

No

Check I502

Defective cut-off circuit

(DC restore)

Page 24 Troubleshooting

Page 27

C1570MNSL/T

6 Recommended Parts List

Note:1. The components identified by mark are critical for X-ray safety. Replace these with

exactly the same parts specified.

2 . There is only OTP IC at the model beginning (FPR stage or before). When it put in mass

production and there must be Mask coming out. Please check BOM to get the last release part

number and related information.

No. Location Part Number Description

1 Q401 6421002705 TR NPN KSD1616A G TA

2 C808 6312615102 ALU uF 150 400V F 85C 25x40

3

4 D814 6412017910 DIODE EGP30G

5 D815 D820 6412004117 DIODE UF2004M T52 2A/400V 50nS

6 F801 6851504053 FUSE TIME LAG H-BRK 4A/250V

7 I301 6442026401 IC TDA4863AJ 9P (PHILIPS)

8 I401 6442030000 IC TDA4841 32P SDIP (PHILIPS)

9 I501 6442031500 IC LM1267NA 24P SDIP (NS)

10 I701 6448016400 IC MTV212MS32 42P PDIP OTP MYSON

11 I703 6448015710 IC 24LC08B/P (MICROCHIP)

12 I801 6442022010 IC KA3842AC 8P PDIP SAMSUNG

13 L404 6111504130 COIL CHOKE 5mH K DR10x16 LY3B

14 L405 6119006600 COIL LINEAR

15 L406 6111806131 COIL CHOKE 80uH DRWW 10x16 LY3B

D828 D829

D830 D831

6412010917 DIODE RL206 T52 2A/800V

16 L409 6111165131 COIL CHOKR L=105uH K DRWW 16x18

17 Q402 6421003210 TR NPN 2SC5339 (TOSHIBA)

18 Q419 6422006000 TR NPN 2SD2012 TO-220(IS)

19

20 Q803 6426006700 FET N-CHNL SSS 7N60 A SAMSUNG

21 Q807 6426006301 FET N-CHNL IRFS634B FAIRCHILD

22 R803 6203080017 POSISTOR & OHM DGC2R08M

Q420 Q421

Q430

6426006401 FET N-CHNL IRFS630B FAIRCHILD

Recommended Spare Parts List

Page 25

Page 28

C1570MNSL/T

No. Location Part Number Description

23 R804 6201160022 THERMISTOR 16 OHM 2A P=7.5 TKS

24 R818 6221122857 MOF OHM 0.22 1W J HOR

25 R852 6221233852 MOF OHM 0.33 2W J HOR

26 T401 6135000801 XFRMER HOR DRIVE THD-1008A EI19

27 T402 6133070210 FBT TFB-7021 SAMPO (MPRII)

28 T403 6136001200 (CPT) XFRMER DYNAMIC TDF-1012 EI19LSE

29 T801 6138001603 LINE FILTER TLF-1016C 16mHET28

30 T802 6131052700 XFRMER PWR TPW-1089 EE40 LSE

31 X701 6449006900 CRYSTAL HC49/U 12MHZ 20PF

32 T402 6133070211 FBT TFB-7021A (TCO)

33 T802 6131052710 XFRMER POWER-TPW 1089-EE40 HJC

Page 26 Recommended Spare Parts List

Page 29

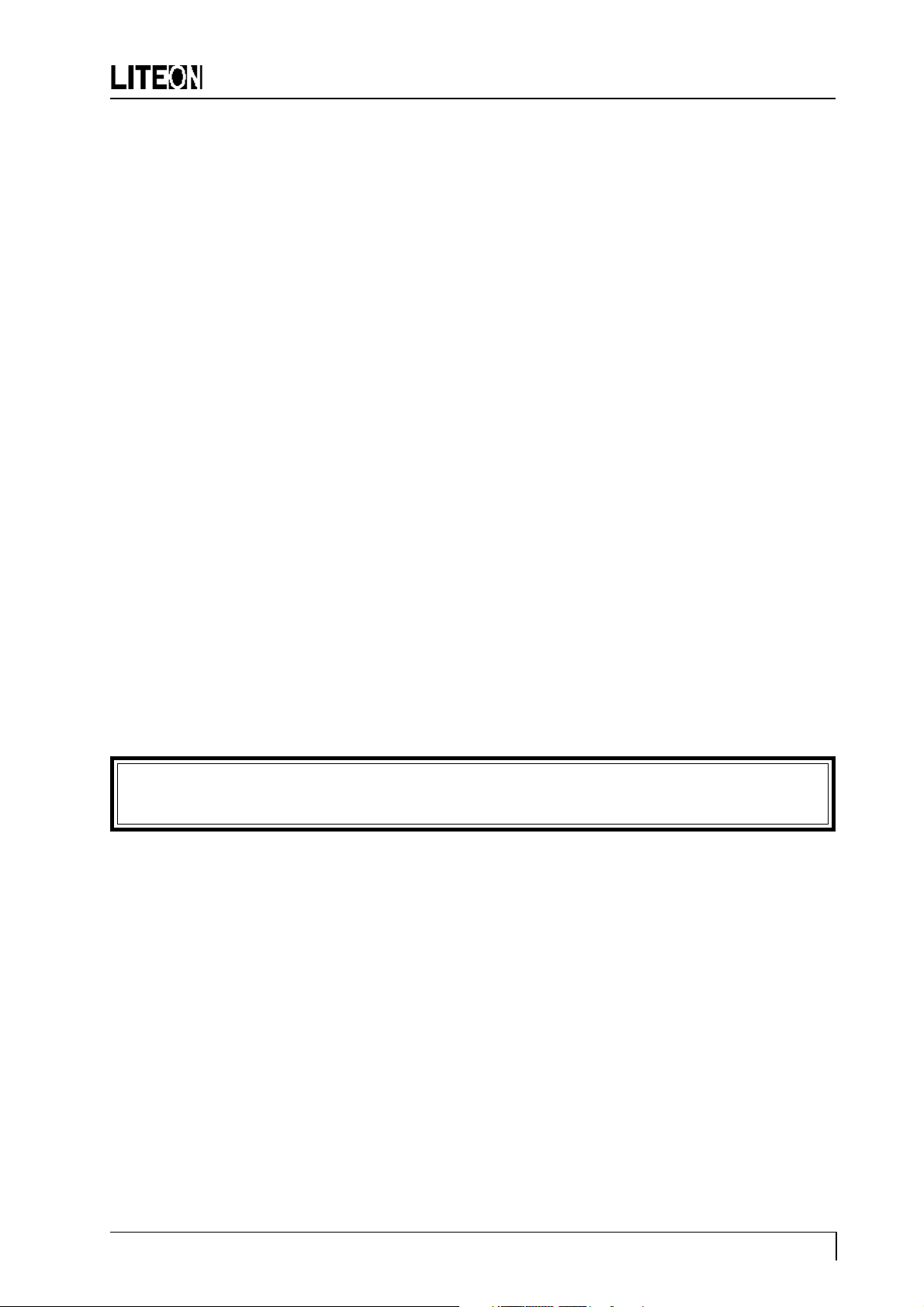

7 Block Diagram

C1570MNSL/T

SDA

SCL

P501

I501

LM1267

R

G

B

5V

OSD MTV021

I701

MTV212M32

I504

ABL

I502

Video AMP

LM 2469

SDA 1

SCL 1

I401

TDA4841

I503

LM2479

BLANKING

CKT

12V

V

H

RG

R

GG

G

BG

B

H

V

5V

SG

P702

O/R

LED

OSD

BLK

KEY

CONTROL

R

G

B

PRE AMP

RGB

O/R

V

H

SDA

SCL

G

G1

ABL

BRIGHTNESS

CONTROL &

SPOT KILLER

H

DRIVER

SCL1

R

B

SDA1

C-LBL

R844

V-TTL

H

OUT

H-FLB

GND

5V

6.3V

12V

75V

115V

GND

P503

24.5KV

HFLB

-130V

640V

FBT

6.6KV

115V

DIODE

MODULATE

40V

RESET

CKT

E2PROM

I703

LINE

FILTER

BRIGHTNESS

DEG

CKT

BRIDGE

DIODE

5V

Q701

LOW VOLTAGE

DROP DOWN

SMPS

POWER

O/P

TRANS

T802

VERTICAL

O/P

I301

STEP

UP

dynamic

foucus

CKT

650V

+H

-H

+V

D.Y

-V

TDA4863

AJ

XRP

12.5V

Q813

Q811

75V

Block Diagram

Page 27

Page 30

Page 31

Page 32

Page 33

Page 34

Page 35

LITE-ON TECHNOLOGY CORP.

5 F, No. 16, Sec. 4, Nanking E. Road, Taipei, Taiwan

Tel: 886-2-25706999 Fax: 886-2-25706888

URL:// www.liteontc.com.tw

Printed in Taiwan

Loading...

Loading...