Page 1

Service Manual

A1454 / A1554NEL

Color Monitor

Page 2

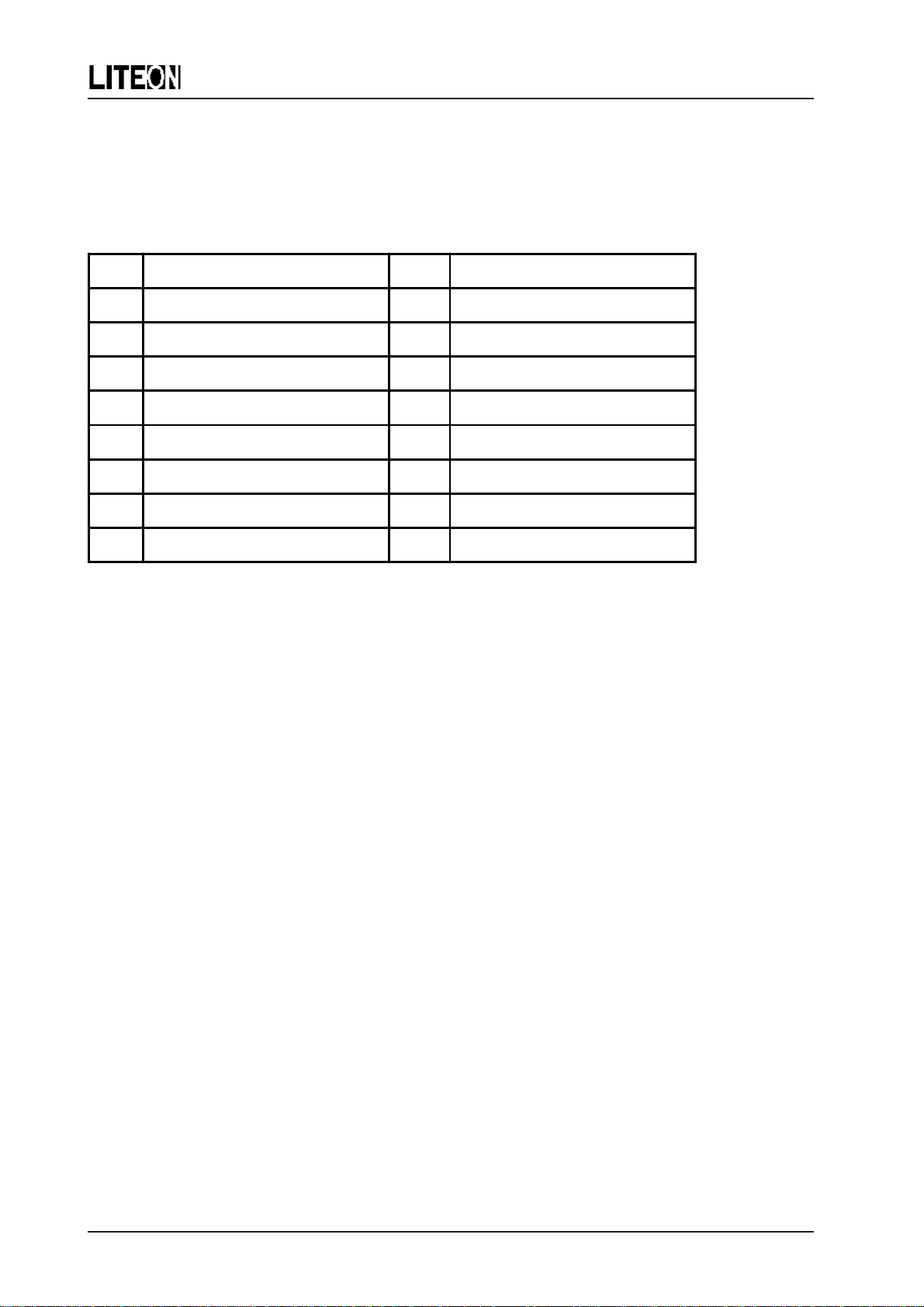

Service Manual V ersions and Revision

No. Vers ion Release Date Revision

1. 1.0 May 28, 1998 Original release

2 1.1 June 19, 1998 4-1- 3 (3)

4-2 - 2 Screen and White Balance Adjustment

6 (15) update model

6 (16) add spare parts

3 1.2 July 8, 1998 2-6 DPMS (Page 9)

3 (Page 10)

Copyright

Copyright 1998 LiteOn T echnology Corp.

All Rights Reserved

This manual may not, in whole or in part, be

copied, photocopied, reproduced, translated, or

converted to any electronic or machine readable

form without prior written permission of LiteOn

T echnology Corp.

A1454 / A1554 NEL Service Manual.

Printed in T aiwan.

T rademarks

LiteOn is a registered trademark of LiteOn

T echnology Corp.

All other trademarks are the property of their

respective owners.

Page 3

A1454 / A1554 NEL

Table of Contents

1. Precautions................................................................................................. 2

2. Product Specifications .............................................................................. 5

3. Operation Theory ...................................................................................... 9

4. Alignments and Adjustments .................................................................... 13

5. Troubleshooting......................................................................................... 17

6. Recommended Spare Parts List ................................................................ 21

7. Block Diagram .......................................................................................... 23

8. Exploded Diagrams..................................................................................... Inserted

9. PCB Diagrams ............................................................................................ Inserted

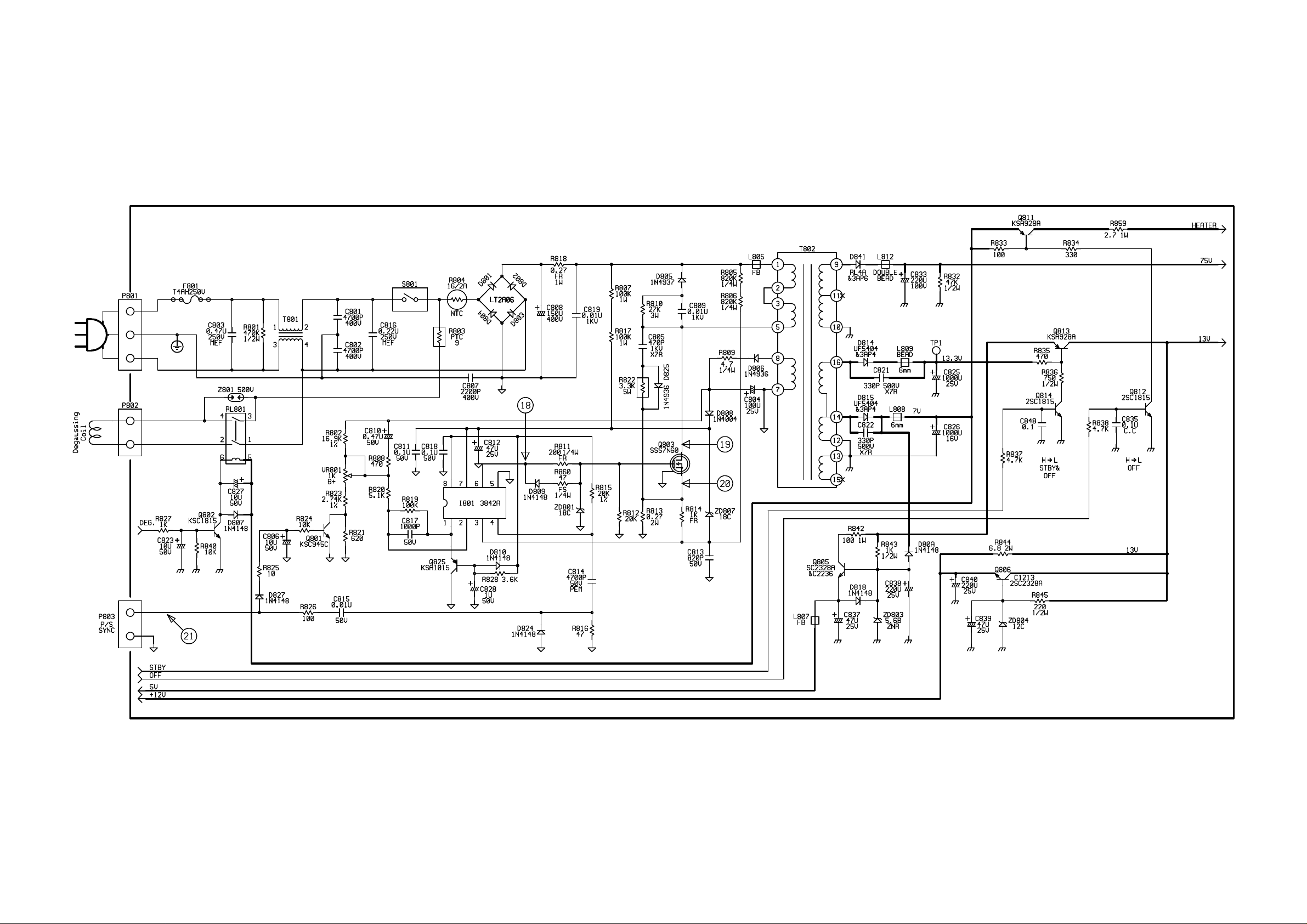

10. Schematic Diagrams................................................................................... Inserted

1

Page 4

A1454 / A1554 NEL

g

1 Precautions

Follow these safety and servicing precautions to prevent damage and to protect against potential hazards

such as electrical shock and X-rays.

1-1 Safety Precautions

1-1-1 Warnings

1. For safety purpose, do not attempt to modify

the circuit board, and always disconnect the AC

power before performing servicing on the

monitor.

2. Operation of the monitor outside its cabinet or

with the cover removed involves the risk of

shock hazard. Repair work on the monitor

should only be attempted by service personnel

who are thoroughly familiar with all necessary

safety precautions and procedures for working

on high voltage equipment.

3. Do not lift the CRT by the neck. After

completely discharging the high voltage anode,

handle the CRT only when wearing shatterproof

goggles. Try to keep the CRT away from the

body during handling.

4. High voltage should always be kept at the rated

value, no higher. Only when high voltage is

excessive are X-rays capable of penetrating the

shell of the CRT. Operation at high voltages

may also cause failure of the CRT or high

voltage circuitry.

nonmetallic control knobs, insulating materials,

cabinet backs, adjustment and compartment

covers or shields, isolation resistor-capacitor

networks, mechanical insulators, etc.

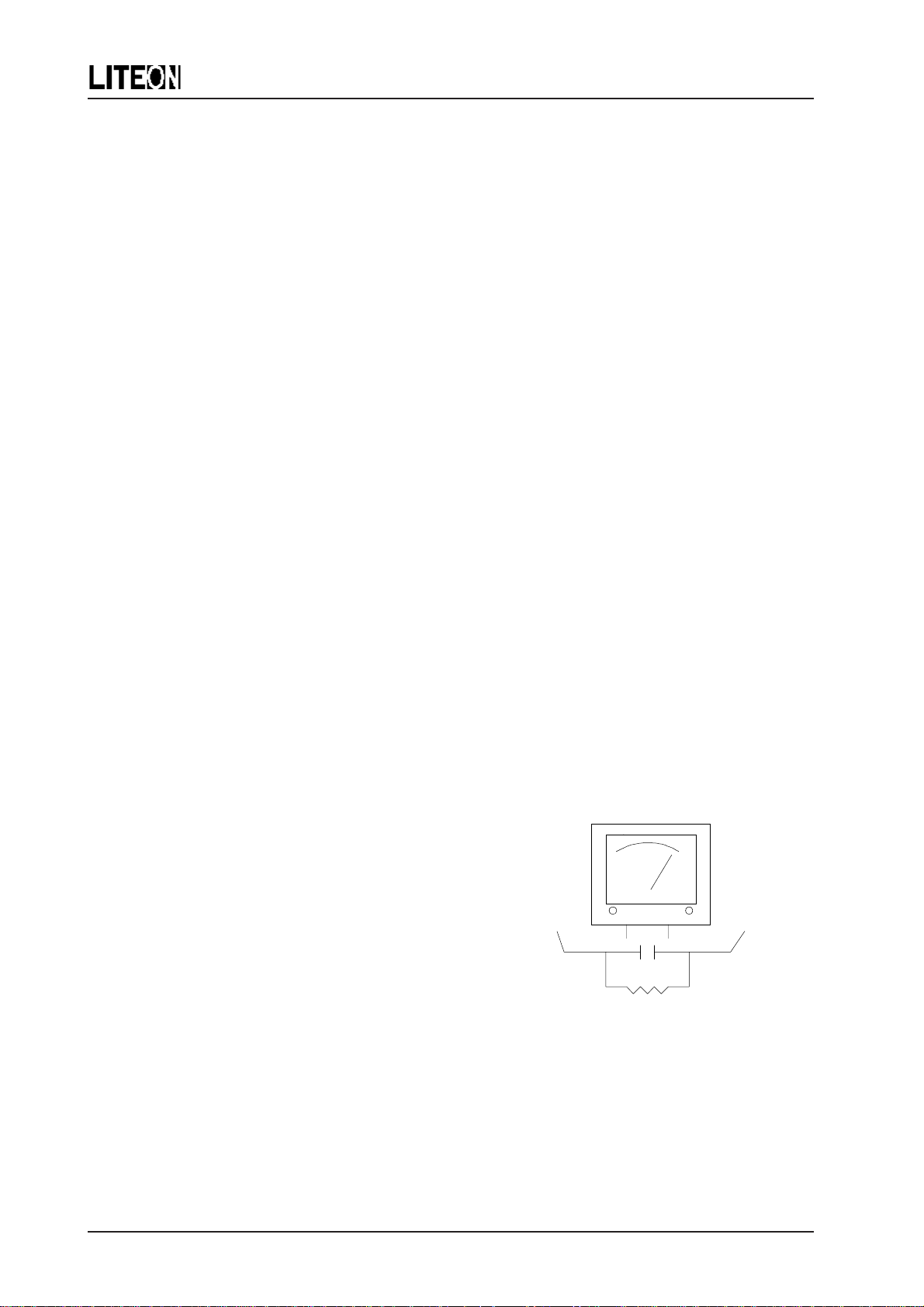

3. AC Leakage Current Check

Always perform the AC Leakage Current

Check on the exposed metal parts, including

metal cabinets, screwheads and control shafts,

as follows:

a) Plug the AC line cord directly into a rated

AC outlet. Do not use an isolation

transformer during the check.

b) Use an AC voltmeter with at least 5000

ohms per volt sensitivity as follows:

Connect a 1500 ohms, 10 watt resistor

paralleled by a 0.15uF AC capacitor in series

with all exposed metal cabinet parts and a

known earth ground, such as electrical

conduct or electrical ground connected to

earth ground, as shown in the Figure 1-1.

Measure the AC voltage across the

combination of resistor and capacitor .

Figure 1-1. Set Up For AC Leakage Current Check

5. The CRT is especially constructed to limit Xray emission to 0.5mR/HR at 300 microamperes

anode current. To ensure continued X-ray

protection, replace the CR T with only the same

or equivalent type as the original, and adjust the

anode’s voltage to the designated maximum

rating, never to exceed.

1-1-2 Safety Checks

Before returning the monitor to the user, perform

the following safety checks:

1. Inspect to make certain that each lead dress is

not pinched or that hardware is not lodged

between the chassis and other metal parts in

the monitor.

2. Inspect all protective devices such as

2 Precautions2

To kn own

earth

round

0.15ufd

1500 ohm 10 w att

To ex posed m e tal

cabinet part

c) Reverse the AC plug at the AC outlet and

repeat the steps for AC voltage

measurements for each exposed metal part.

d) Voltage reading must not exceed 0.3 volts

RMS, equivalent to 0.2 milliampere AC. Any

value exceeding this limit ill constitute a

potential shock hazard and must be

corrected immediately .

Page 5

A1454 / A1554 NEL

1-1-3 Product Safety Notices

Many electrical and mechanical parts in this chassis have special safety-related characteristics which are often

not evident from visual inspection, the protection afforded by them may not be obtained by replacing them

with components rated for higher voltage, wattage, etc. Before replacing any of these components, consult

the Recommended Spare Parts List given at the end of this manual. Any of the replacements that do not

provide the same safety characteristics may result in shock, fire, X-ray emission or other hazards.

1-2 Servicing Precautions

Warning: An electrolytic capacitor installed with the wrong polarity might explode.

Caution: Before performing servicing covered by this service manual, read and follow the Safety Precautions

section of this manual.

Note: If unforeseen conflict between the following servicing precautions and any of the safety precautions,

always follow the safety precautions

1. Follow closely the servicing precautions printed on the monitor cabinet and chassis.

2. Always unplug the AC power cord from the AC power source before removing or installing any component

or assembly , disconnecting PCB plugs or connectors and connecting a test component in parallel with a

capacitor.

3. When replacing parts or circuit boards, clamp the lead wires around the component before soldering.

4. When replacing a high wattage resistor (>0.5W metal oxide film resistor) in the circuit board, keep the

resistor about 1 cm (1/2 inch) away from the circuit board.

5. Keep wires away from the high voltage or high temperature components.

6. Keep wires in their original positions so as to minimize interference.

7. Always connect a test instrument’s ground lead to the instrument chassis ground before connecting the

positive lead; always remove the instrument’ s ground lead last.

After putting the rear cover back and make sure the monitor is working properly , the Hi-PoT &

Ground Continuity tests MUST BE performed before the monitor is returned to user.

1-3 Hi-Pot T est

1. T est Equipment

Puncture test model PM5530 ADT or KIKUSU TOS-8750 voltage tester or equivalent approved equipment.

Note : The test equipment must be calibrated in regular period.

2. Test Setup

a) Apply voltage : DC 2100 VDC

b) T est duration : 3 seconds

c) Cutoff current should be set to 3 mA

3. Test Procedure

a) Unplug power cord from AC source.

b) Put the power switch of the monitor in the “ON” position.

c) Leave signal cable un-connected.

Precautions

3

3

Page 6

d) Plug monitor power cord to the Hi Pot tester terminals.

e) Turn on tester and watch the indicator or beeper.

f) If the indicator lamp lighten, or beeper beeps, the test fails.

1-4 Ground Continuity T est

1. T est Equipment

AC low ohm tester TOS-6100 or equivalent approved equipment.

Note : The test equipment must be calibrated in regular period.

2. Test Setup

a) Test duration : 3 seconds

b) Set current limit at 25 A

c) The grounding resistance must be less than 0.1 ohm.

3. Test Procedure

a) Plug the monitor power cord to the tester terminals.

A1454 / A1554 NEL

b) Make sure all connections are well-contacted.

c) Turn on monitor power and tester power.

d) Press “Test” button.

e) If green light shows up, means test OK.

If red light shows up, means test fails.

f) If the T ester has a digital display, the resistance value must not exceed 0.1 ohm.

Note : Be sure not to touch the metal portion of the signal cable head during testing.

4 Precautions4

Page 7

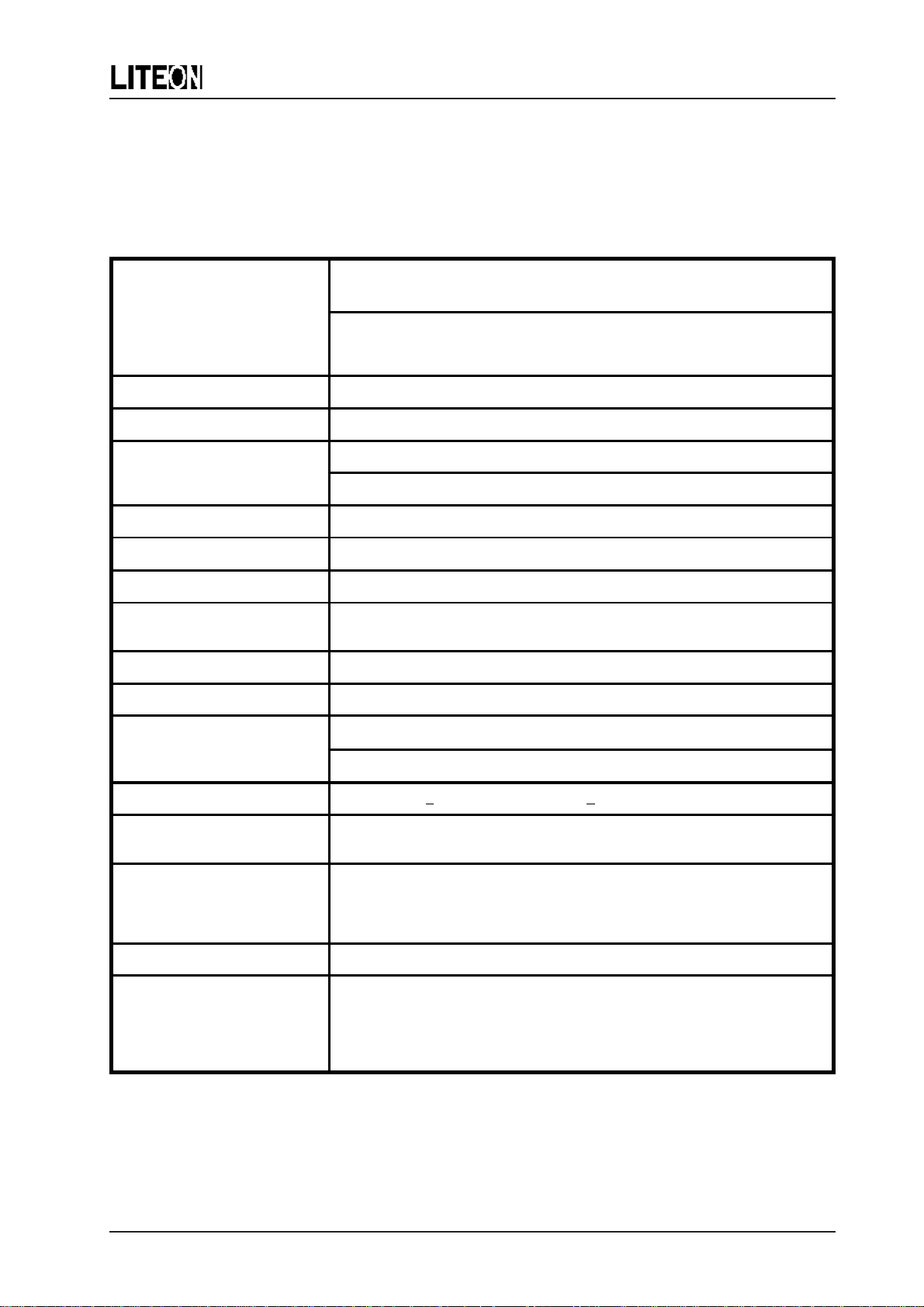

2 Product Specifications

2-1 Specifications

A1454 / A1554 NEL

Picture Tube

Scanning Frequency VGA, Super VGA, 800x600@60/72/75/85 Hz, 1024x768@60 Hz

Maximum Resolution 1024 dots (H) x 768 li nes (V) @60Hz refresh rate

Display Area 14-inch 250 mm (H) x 187 mm ( V) typical

Display Characters 80 char. x 60 rows on a 10 x 10 matrix

Display Colors Analog Input Unlimited Colors

Sync hroni zati n Signal s Se par ate S ync: ho ri zontal /ve rti cal , T TL, pos iti ve o r nega tiv e

Sync hroni zati on Fre quenc ies

Si gnal Co nnecto rs 15 -pi n, D-s hel l co nnecto r

Vi deo Signals Analog : 0.7 Vp-p, RG B p ositive

14-inch (13.3-inch Visual image area),

15-inch (14.0-inch Visual image area)

slote d ma sk, 90 degrees de flectio n, d ot type black matrix, medium s ho rt

persistence phosphor, dark tint, non-glar e/ anti-static screen, 0.28 mm dot

pitch

15-inch 262 mm (H) x 196 mm ( V) typical

Horizontal : 30 to 54 kHz

Vertical : 50 to 120 Hz

Powe r Inp ut

Misconvergence Center Area : <

User Controls Power On/Off, Contrast, Brightness, Vertical Sizs, Vertical Position,

Service Controls PWB-1402 : R-bias (VR910), G-bias (VR940), B-bias (VR970),

Preset Modes 12 (see Tabl e 2-2. Timing Chart)

Environmental Considerations Operati on temperature : 5

14-i nch 7 0 Watts ( nominal ) AC rated vol tage, 100VAC to 264VAC

15-i nch 7 5 Watts ( nominal ) AC rated vol tage, 100VAC to 264VAC

0.3 mm; Corner Area : < 0.4 mm

Horizontal Positi on, Horizontal Size, Pincushion, Trapezoid,

R-gain (VR599), G-gain (VR598)

PWB-1405 : power vol tage adjust (VR801), high voltage ad just (VR80 2),

, focus

o

C to 40oC ambient

o

Storage temperature : 0

Humidity : 5% to 95% ambient

Storage Humidity : 5% to 95% (non-condensi ng)

Altitude : up to 3000m a bove sea l evel

C to 65oC ambient

Note: The above specifications are subject to change without prior notice.

Product Specifications

5

5

Page 8

2-2 Signal Cable Pin Connections

Table 2-1. Pin Assignments

Pin Sig nal Pin Sig nal

1 Red video 9 No pin

2 Gr ee n vid eo 1 0 Dig ita l Gr ou nd

3 Blue video 11 Gro und

4 Gr ound 12 SDA

5* Selftest 13 H-Sync

6 Re d gr ound 14 V -Sync /VC L

7 Gr een ground 15 SC L

A1454 / A1554 NEL

8Blue ground

Note: * This pin is used for selftest detection. Connect this pin to ground at the PC end.

6 Product Specifications6

Page 9

A1454 / A1554 NEL

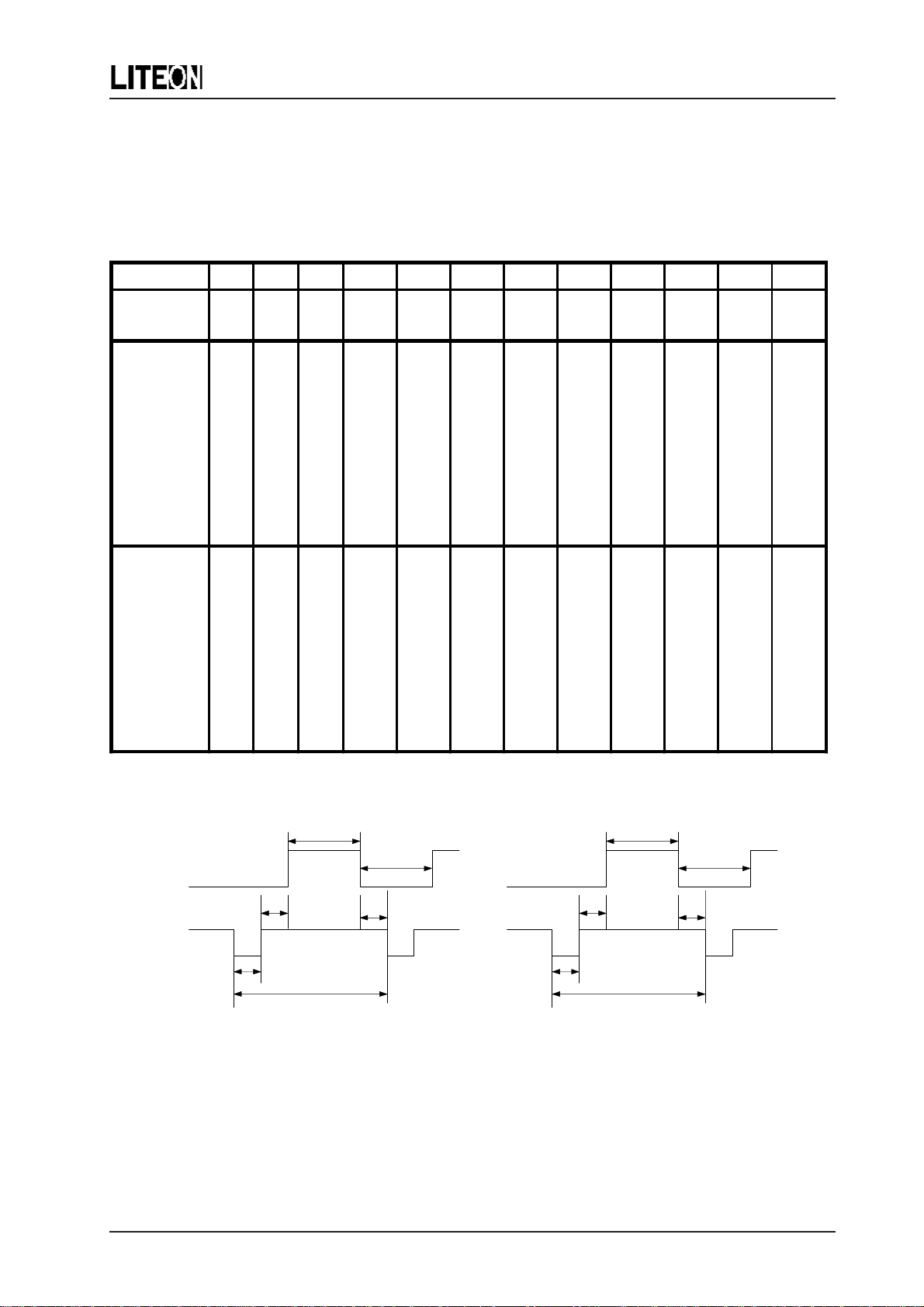

2-3 Timing Chart

This section of the service manual describes the timing that the computer industry recognizes as standard for

computer-generated video signals.

Table 2-2. T iming Chart

Mode 123456789101112

H. Do ts 720 720 640 640 640 800 800 800 800 640 1024 800

V. Dot s 350 400 480 480 480 600 600 600 600 480 768 600

H-freq (k Hz) 31.47 31.47 31.47 37.86 37.5 35.16 37.88 46.875 48.08 43.3 48.36 53.674

Sync Polarity +-- - -+/-+ + + - - +

A Perio d us 31.78 31.78 31.78 26.413 26.666 28.44 26.4 21.333 20.8 23.11 20.677 18.6

B Blking us 6.356 6.356 6.356 6.095 6.35 6.22 6.4 5.172 4.8 5.333 4.923 4.409

C Sy nc us 3.81 3.81 3.81 1.27 2.07 2 3.2 1.616 2.4 1.556 2.09 1.138

D B.P. us 1.907 1.907 1.907 4.06 3.81 3.556 2.2 3.232 1.28 2.222 2.462 2.702

E Acti ve us 25.42 25.42 25.42 20.317 20.32 22.22 20 16.162 16 17.778 15.75 14.222

F F.P. us 0.636 0.636 0.636 0.76 0.51 0.667 1 0.323 1.12 1.556 0.369 0.569

V-freq (H z) 70.08 70.08 59.95 72.81 75 56.25 60.32 75 72.18 85 60 85

Sync Polarity -+- - - +/-+ + + - - +

G Period ms 14.27 14.27 16.68 13.735 13.33 17.78 16.58 13.333 13.87 11.764 16.67 11.8

H Blking ms 3.146 1.557 1.43 1.057 0.533 0.711 0.739 0.533 1.373 0.67 0.786 0.578

I Sync ms 0.064 0.064 0.064 0.079 0.08 0.057 0.106 0.064 0.125 0.069 0.124 0.056

J B.P. ms 1.87 1.08 1.02 0.74 0.407 0.626 0.607 0.448 0.478 0.578 0.6 0.503

K Active ms 11.12 12.71 15.25 12.678 12.8 17.07 15.84 12.8 12.51 11.093 15.88 11.179

L F. P. ms 1.21 0.413 0.35 0.238 0.026 0.0284 0.026 0.021 0.770 0.023 0.062 0.019

Video

A

E

B

F

Sync

H orizontal

D

C

H.Parameters:

A: Period B: Blanking Time

C: Sync Width D:Back Porch

E : Active Time F: Front Porch

Seperate Sync

Ver tic a l

V .Parameters:

G : Period H: Blanking Time

I: Sync W idth J: Back Porch

K: Active Time L: Front Porch

K

Video

J

Sync

I

G

H

L

Product Specifications

7

7

Page 10

A1454 / A1554 NEL

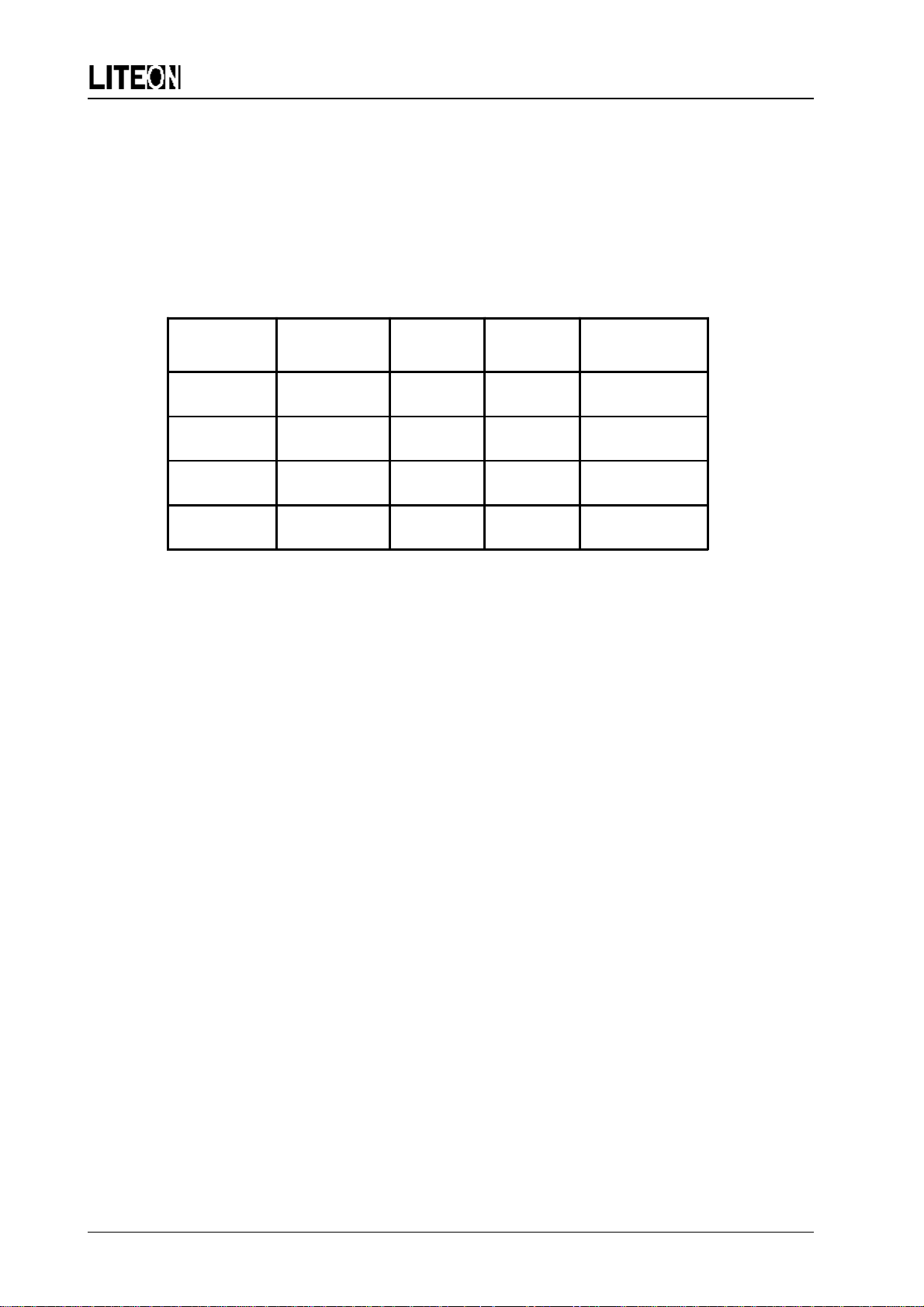

2-4 Display Power Management Signaling (DPMS)

Note: These power-saving states exceed the Environmental Protection Agency (EPA) Energy Star

requirements and the Video Electronics Standard Association (VESA) for Display Power

Management Signaling (DPMS) .

T able 2-3. Display Power Management Signaling (DPMS)

State LED Color H-Sync V-Sync Power

Co ns umptio n

ON Green Pulse Pulse Normal

STANDBY Yellow No Pulse Pulse <15 watts

SUSPEND Yellow Pulse No Pulse <15 watts

OFF Amber No Pulse No Pulse <5 watts

8 Product Specifications8

Page 11

A1454 / A1554 NEL

3 Operation Theory

This is a fully digital multi-sync color monitor that is compliant with DDC1 and 2B Plug and Play VESA

standard and offers the following main features.

3-1 Main Features

1. Simplified design with minimum components.

2

2. The NOVATEK NT68P61A processor-- that has I

brightness-- offers the functions for: (a) Contrast, (b) Brightness, (c) H-size, (d) H-position, (e) V-size, (f)

V-position, (g) Pincushion, and (h) Trapezoid.

C BUS controlled geometric correction, contrast and

In addition, it also offers more functions as: (a) Sync. processor, I/P and O/P, (b) Mute, (c) Power saving

- Suspend & Stand-By , (d) Power saving override, (e) DDC1/2B, (f) I

signal cable (g) CS1/CS2 for linearity and size compensation.

3. Stores up to 12 factory preset modes and offers 6 user modes. Recall factory modes by pressing together

“+” and “-” keys from the front panel. Use “Select” key to select a parameter and “+” and “-” for

adjusting the value of the parameter. User setting data are stored automatically.

4. Powerful PHILIPS TDA4853 and TDA4866 present the following useful functions: (a) Pincushion, (b)

Trapezoid, (c) V-Position, (d) V-Size, (e) Vertical’s “C” and “S” correction -- factory adjust, (f) Pincushion’ s

V. position correction, (g) Corner correction -- factory adjust, (h) Pincushion unbalance correction -factory adjust, (i) Parallelogram distortion -- factory adjust, (j) Moire cancellation -- factory adjust, (k) Xray protection, and (l) Full horizontal plus with vertical auto sync capability .

5. Software controlled auto shut off function activated if fH < = 29 kHz and fH > = 56 kHz.

6. Full range AC input and simplified line filter design.

2

C Bus for auto-alignment through

3-2 Microcontrol Section

1. This monitor uses NOVATEK NT68P61 CPU. It contains a 6502 8-bit CPU core, 256 bytes of RAM

used as working RAM and stack area, 24k bytes of OTP ROM, 14-channel 8 bit PWM D/A converter,

2-channel A/D converters for key detection saving I/O pins, internal H. sync and V. sync signals processor

providing mode detection, and an I2C bus interface. When H/V sync through D-Sub signal cable enter pin

39 and pin 40, the CPU marks frequency polarity detection and calculate and send to H/V sync OUT.

Then CPU reads the data from I703 and write to device 4854 and some DAC in CPU. the above

operation takes about 500 ms.

2. There are 12 factory preset modes and 6 user modes. There are 8 functions, Contrast, Brightness, H.

Size, H. Position, V. Size, V. Position, Pincushion, and Trapezoid, all controlled by panel keys which can

be adjusted by user.

3. The user control parameters are selected in sequence listed as above by LEDs. When pressing “select”,

the function will be selected one by one. When a particular parameter is chosen, use “+” and “-” button

to adjust the value. LED will flash when reaching extreme value, which means the value cannot be

increased or decreased anymore. There are seven functions which can be controlled only by internal

setting. Through internal setting user can modify the factory preset data.

4. The pin 24 and pin 25 are used for ATE and DDC function. The DDC1 and DDC2 are implemented in

CPU. When power on the CPU is initial in DDC1 mode. At DDC1 mode when V. sync in, the data will

be sent out one by one. When SCL is lowized, the CPU will enter the DDC2 mode. In DDC2 mode, after

receiving A0 0 A1, the EDID data will be sent out. When CPU receive C6 as slave address, the CPU will

operate in ATE mode which is used for auto-alignment. After alignment the data will be stored in I703.

Operation Theory

9

Page 12

3-3 Deflection Section

1. I2C -- autosync deflection controller is TDA4853.

A1454 / A1554 NEL

2. The TDA4853 is a high performance and efficient solution for autosync monitors. All functions are

controllable by I

control all functions.

2

C bus. SDA and SCL signals come from microprocessor feed to pin 19 and pin 18 to

3-3-1 Horizontal Section

1. The oscillator is driven by the currents in R419 and R420. The minimum oscillator frequency is determined

by R419 and the maximum frequency is determined by R420.

2. Horizontal sync comes into pin 15 through R318. And horizontal flybok pulse comes into pin 1 through

R401, R402 and by pass filter C403 from pin 6 of FBT for AFC loop.

3. Horizontal driver (pin8) O/P to Q401 via C410.

3-3-2 V ertical Section

1. Vertical sync comes into pin 14 through R317.

2. The free running frequency is determined by R301 and C301.

3-3-3 V ertical O/P section

1. The differential output currents from pin 13 of Vout1 and pin 12 of V out2 can be directly coupled to the

vertical deflection booster pin 1 and pin 2 of TDA4866.

2. The TDA4866 has two output stages which are current driven in opposite phase and operate in combination

with the deflection coil in a full bridge configuration.

3-3-4 E-W/T rapezoid and H. Width Controls

1. The horizontal O/P stage uses diode modulator D419, D423, C411, C412, L409 and C418 for East-West

(Pincushion) Trapezoid and H. width controls.

2. The scan current is determined by B

is accomplished by Darlington pair Q418 and Q419 by coupling a parabola waveform from pin 11 of

TDA4853. The H. width size corner correction and trapezoid are also accomplished by this pin 11.

+

minus Vm ( the voltage of C418) values and the pincushion control

3-3-5 X-Ray Protection

1. T o avoid X-ray hazard, a DC voltage generated by pin 6 of FBT and rectified by D408, C432 and divided

by R403, R404 and R405 come into pin 2 of TDA4853.

2. If this voltage is higher than 6.39 V , then TDA4853 will be activated to float HUNLOCK (pin17), H. DR V(

pin 8), B DR V (pin 6), VOUT1 (pin 12), VOUT2 (pin13). After that all deflection circuit stop working.

3-3-6 G1, Blanking and Brightness

1. The vertical blanking signal comes from two ways. One is from pin 8 of I301 (TDA4866), the other is

from vertical sync (pin 32 of I701). This two positive vertical pulses through Q406 amplified and converted

into negative pulse and sent to G1 for vertical blanking.

2. In protection mode or an out of range situation HUNLock will send 5 V pulse to saturate Q405 and open

Q408 then G1 will go down to -140V. During the mode change, Mute acts as same as HUNLock’s.

3. The brightness is controlled by CPU pin 1 comes into PNP transistor Q408, low voltage causes high

10 Operation Theory

Page 13

A1454 / A1554 NEL

current to get brighter raster, high voltage gets lower brightness.

3-4 Power Supply Section

3-4-1 AC Rectifier

The circuit can accept 90 V to 264 V AC input through D801~D804 bridge diodes and C808 filtering to get

DC 126 V~364 V for power conversion in T802.

3-4-2 Line Filter

It consists of C801, C802, C803, C816 and T801 and meets EMI regulation.

3-4-3 Power LED Status

1. The LED has 3 leads common cathode with green and amber colors for different power saving indications.

It is controlled by CPU.

2. Normal : Green light

Amber LED is off because CPU pin10 is high and pin 9 is low , only green LED is turned on.

3. Standby / Suspend : Y ellow light

CPU pin 9 and pin 10 are low, then green and amber LED are turned on. That is yellow.

4. Off Mode : Amber light

CPU pin 9 is high and pin 10 is low, then green is of f and amber is on.

3-4-4 Auto Degaussing

1. A1454NEL : When SMPS works, the 6.3 V power source is applied to Q802 and CPU let Q802 turn on

a few seconds, then drive the armature of RL801 to perform the degaussing function.

2. A1554NEL : When power switch S801 on, the AC current flows through R862, D816 (D817) and

degaussing coil preforms the degaussing function.

3-4-5 PWM Control

1. Start Up

The I801 gets power from R807, R817, C812 and pin 7 voltage reaches 16 V for starting up. The I801

starts oscillation at 22 kHz, sawtooth on pin 4 and pin 6 output to drive Q803/T802. Once Q803 switches

on, D806, C804 set up an 15 V to keep I801 working through D808 auxiliary voltage.

2. Regulation

The DC O/P voltage is proportional to the auxiliary voltage, so I801 pin 2 senses the feedback voltage

from the divider R802, R823, VR801 and R821 to compare with built-in 2.5 volts reference voltage for

error amplifier operation. Finally pin 6 can modulate the different duty cycle by VR801 setting to achieve

regulation purpose.

Operation Theory

11

Page 14

A1454 / A1554 NEL

3-4-6 Synchronization

1. Normal Mode

The sync pulse from FBT (31 kHz~54 kHz) via C815, R826, D824 and R816 to pin 4 of I801 to keep I801

synchronized with horizontal sync input frequency .

2. Power Saving Modes: Standby/Suspend

Because there is no pulse from FBT, so the free-run frequency is decided by R815 and C814 and the

SMPS works at 22 kHz.

3. Override

The horizontal free run frequency is about 41 kHz under override condition, SMPS is synchronized to this

frequency .

3-4-7 O.V . P .

If the auxiliary voltage is higher than zener voltage ZD807 (18 volts) and makes pin 3 of I801 higher than

1 V, pin 6 duty cycle is limited to have the OVP activated.

3-4-8 O.P.P.

The excess current of T802 through R813 can develop enough voltage to pin 3 then limit the power delivered

because the pin 6 duty cycle is limited too.

3-4-9 Step Up Power Supply For FBT

1. The B+ of FBT is proportional to horizontal frequency , that is higher frequency , higher voltage. The basic

voltage is 75 volts from T802 pin 9 via D840, L812 and the gate control of Q807 comes from I401 pin 6 via

Q808, Q809 and Q810. The duty cycle is controlled by C843, C462, R489, R846 and R856, R857, R858

VR802 combination ratio.

2. The regulation and boost up (from 77 V to 92 V or more, on demand). The H.V. is set at 24.5 kV (zero

beam) by VR802 which senses the secondary O/P from FBT . The booster comprises Q807, L801, D820,

C425 and I802 to offer the required B+ for different frequency modes.

3-5 Video Amplifier Section

1. RGB signal inputs are terminated by R502, R532 and R562 then pass through the coupling capacitors

C501, C531 and C561 to the IC501 MM1375 pre-amplifier .

2. The amplifier RGB signals (0~3 Vpp) are adjusted by VR599 (R), VR598 (G). Pin 9 is for DC contrast

control input, pin 11 is for clamp pulse which comes from pin 16 of TDA4853 to set up the equal clamp

level.

3. The video output stages are cascode amplifiers with buffer of complementary emitter followers, the stray

capacitance is so small that the load resistor R906, R911, R936, R941, R966 and R971 can be 3.6 k ohm

and the power dissipation is minimized.

4. The RGB cathodes cut off are adjusted by VR910, VR940 and VR970.

5. Under override condition, the self test signal is supplied from pin 1 of CPU, the default value is about 1

volt. In this condition, G1 will increase 10 volts then get about 6 FL light out put.

12 Operation Theory

Page 15

A1454 / A1554 NEL

4 Alignments and Adjustments

This section of the service manual explains how to make permanent adjustments to the monitor settings.

4-1 General Adjustments

4-1-1 Adjustment Conditions

a) Power Supply

Apply AC 115 V or 220 V

b) Warm-up T ime

The monitor must be powered on for 15 minutes before starting any alignment, but requires 30 minutes of

warm-up time for convergence adjustment.

c) Signal Input

1. Video: RGB Analog, 0.7 Vp-p, positive

2. Synchronization: Horizontal and vertical TTL signal, separate, positive or negative

3. All adjustments should be made using a signal of FH = 31.468 kHz, FV = 60 Hz, unless otherwise

defined.

4-1-2 Equipment Required

The following equipments are necessary for adjustment procedures:

1. Volt-ohm-A meter (Sanwa FD-750C or equivalent)

2. 30 kV high voltage probe (HP3411 1A)

3. Oscilloscope (TEK2235 or equivalent)

4. Minolta Color Analyzer II

5. Signal generator (IBM PC with proper display cards or Chroma 2000)

6. Screwdriver

4-1-3 Switching Power Supply and Regulator Adjustment

The regulated B+ control has been preset in the factory and needs no adjustment. However, if any repair is

made on the power supply section, the following readjustment procedures are recommended:

1. Allow the monitor to warm-up for about 15 minutes.

2. Apply VGA (1024 x 768 @ 48.36 kHz/60 Hz) signal to the monitor.

3. Connect a DC voltage meter to D814 “-” (TP1 on the control PCB), and adjust VR801 for 13.3 + 0.2

V DC, 13.3 - 0 V DC.

4. If a fuse is broken during adjustment, remember to replace it with the exact same type of fuse.

Alignments and Adjustments

13

Page 16

A1454 / A1554 NEL

4-2 Alignment Procedures

4-2-1 High V oltage Adjustment

CONDITION

Display image : Crosshatch pattern

PROCEDURE

Connect DC meter to TP3 and adjust VR802 to obtain a DC voltage of 152 ± 1V DC for CPT CRT

M34AF A83x8. (M36AES83x-1)

4-2-2 Screen and White Balance Adjustment

CONDITION

Press “+”, “-” and “Select” buttons simultaneously when switching the power “On”.

Drive VRs : VR598, VR599

Bias VRs : VR910, VR940, VR970

Display image : No video

PROCEDURE

1-a. 14” Set brightness to -35 V at G1 and G2=530 V contrast to maximum.

or

15” Set brightness to -35 V at G1 and G2=600 V contrast to maximum.

1-b Adjust VR910, VR940 and VR970 to maximum.

1-c Adjust VR940 to raster just distinguish for green gun.

1-d Adjust brightness to raster light outpert to get 0.9 ~ 1.1 FL.

1-e Adjust VR910 to get x=280 ± 5 and VR970 to get y=280 ± 5

CONDITION

Display image : 50 mm x 50 mm white block pattern

PROCEDURE

2-a. Set brightness to cut-off and G1=-35 V

2-b Adjust contrast to get about 43 FL.

2-c. Adjust VR598 for y=0.311 and then adjust VR599 for x=0.281.

2-d Check item 2-b and 2-c again. If not, then adjust contrast VR to get 43 ± 1 FL light outpert.

CONDITION

Display image : Full white pattern

PROCEDURE

3-a. Set brightness to cut-off and contrast to maximum.

3-b. Adjust VR402 to 28FL +2/-0 FL.

4-a. Check the white balance in the VGA mode at 5 FL and 28 FL.

4-b. Repeat all the procedure in 4-2-2 section until the best white balance is obtained, then power off.

14 Alignments and Adjustments

Page 17

A1454 / A1554 NEL

4-2-3 Focus Adjustment

CONDITION

Display image : “e” character pattern

PROCEDURE

1. Set brightness and contrast used for a normal display.

2. Adjust the static focus control on the high voltage resistor block to obtain the best focus over the entire

display area.

4-2-4 Static Convergence Adjustments

Static convergence involves alignment of the red, blue and green lines in the center area of the display .

Note : The monitor requires 30 minutes of warm-up time for convergence adjustment.

CONDITION

Display image : Crosshatch pattern

W arm-up Time : 30 minutes

PROCEDURE

1. Set brightness and contrast to display a well-defined pattern.

2. Ensure the convergence magnet rings are correctly positioned on the CRT.

Figure 4-1. Convergence Magnets on the CR T

1

11

+

P

8 7 6 5 4 3 2

10

1) Setup Bolt 2) Bow Magnet 3) Band 4) 2-Pole Magnet

5) Spacer 7) Spacer

9) Holder

6) 4-Pole Magnet

9

11) Tabs10) Band

3. Rotate the individual rings of 4-pole convergence magnets by changing the spacing between the 2 tabs to

converge the vertical red and blue lines at the center of the screen.

CRT

FRONT

8) 6-Pole Magnet

4. Rotate the pair of rings of 4-pole convergence magnets by maintaining spacing between the 2 tabs to

converge the horizontal red and blue lines at the center of the screen.

5. Rotate the individual rings of 6-pole convergence magnets by changing the spacing between the 2 tabs to

converge the vertical red, blue and green lines.

6. Rotate the pair of rings of 6-pole convergence magnets by maintaining spacing between the 2 tabs to

converge the horizontal red, blue and green lines.

7. Repeat the steps from 3~6 until the best convergence is obtained.

Alignments and Adjustments

15

Page 18

Figure 4-2. 4-pole and 6-pole Magnets Movement

Blue Red

A1454 / A1554 NEL

Red/

Blue Gree n

Blue

Red

4-pole magn ets

movement

Red/

Blue

Green

6-pole magn ets

movement

Note : The 4-pole magnets and the 6-pole magnets interact, making dot movement complex.

4-2-5 Degaussing

Degaussing is required when poor color impurity appears on the screen. This monitor uses an automatic

degaussing circuit that is activated when the power is on. The automatic degaussing will be fully functional

after the monitor has been in operation for 20 minutes.

The degaussing effect is confined to the picture tube since the coils are mounted at the back of the tube.

Should any part of the chassis or cabinet becomes magnetized, it is necessary to degauss the affected area

with a manual degaussing coil.

4-2-6 Manual Degaussing

1. Apply line voltage to the degaussing coil and move it in a rotary motion over the front, sides, and top of the

monitor . The coil should be kept away from the rear of the monitor to avoid damaging the magnetic neck

components.

2. Slowly rotate and move the coil away from the monitor to about 6 feet beyond the point where no effect

on the CR T will be noticeable.

For proper degaussing, it is essential that the field be gradually reduced by moving the coil slowly away from

the monitor . The degaussing coil must never be shut off or disconnected while near the monitor, as this would

introduce a strong field instead of canceling the effect of the stray fields.

16 Alignments and Adjustments

Page 19

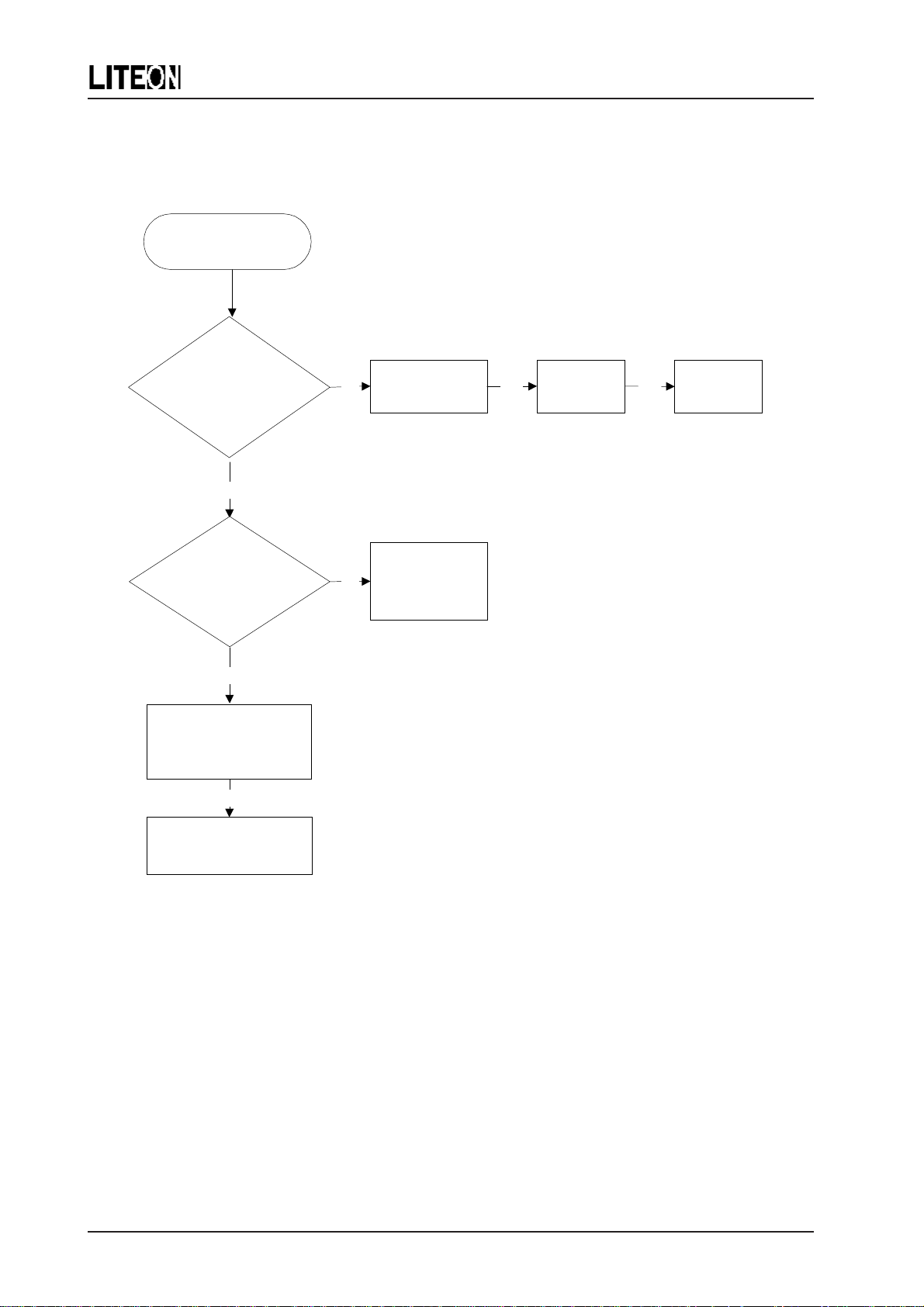

5 T roubleshooting

5-1 No Raster

A1454 / A1554 NEL

No Raster

Measure

voltage of B+ at

T402 pin 3 on

PWB-MAIN

0 V

Short Circuit

at load?

Yes

Check DC B+ line,

Q807, F801

Normal

(83 V, 31.5 kHz)

Check voltage of

No

Check AC I/P

on T801

I801, R813,

R805, R809,

Q803, D806,

D808, D813,

D814, D815, D810

cathode, heater,

Grid 1, Grid 2,

Yes

Check

High

(100 V or more)

Check I401,

Q402, Q401

etc.

No

Check

D801, D802,

D803, D804

T r oubleshooting

17

Page 20

5-2 Function Key Abnormal

Function Key Abnormal

A1454 / A1554 NEL

Check I701 and

I702 missing?

No

Power

ON/OFF again and

check X701,

oscillator OK?

Yes

Check

I702 EEPROM

content OK?

Yes

Yes

No

No

Put on

I701, I702

Replace X701

Replace I702 or

do ATE again

Replace I701 and

check uP OK?

Yes

Replace Q702

No

Replace I701

18 T roubleshooting

Page 21

5-3 Vertical Scan (Raster is one horizontal line)

Vertical Scan Abnormal

A1454 / A1554 NEL

Check voltage of

pin 3 at I301

(about 14 V)

Yes

Check

pin 4 or pin 6

waveform at I301

Normal

Check R311 short ?

No

Abnormal

Ckeck or replace

I301.

Check pin 12 &

pin 13 waveform

at I401

OK

Replace I301

T r oubleshooting

Still no vertical scan

Check or replace CRT

19

Page 22

5-4 R.G.B. Video Amplifier Abnormal

RGB Video AMP

Abnormal

A1454NEL

Check

the waveform at the I501

pin 17, pin 14, pin 20

Yes

Check

I902, Q932, Q962

collector voltage (normally

about 75V)

Yes

Video signal present at

the pin of the CRT

R.G.B. Cathode

Yes

No

No

(pin8, pin19)

Check I501,

R.G.B. O/P

voltage Q901,

Q931, Q961

Check B+

Yes

Check the

waveform at

pin 1, 3, 6

Yes

Check I501

Defective cut-off circuit

(DC restore)

20 T roubleshooting

Page 23

A1454NEL

6 Recommended Parts List

Note: The components identified by “ “ mark are critical for X-ray safety. Replace these with only

the same parts specified.

No. Location Part Number D e scription M odel

1

C417 6326239443 MPP uF 0.39 250V H F P=22.5HJC both

2

C808 6312615102 ALU uF 150 400V F 85C 25x31 both

D801 D802

3

D803 D804

4

D814 D815 6412002027 DIO DE FUF 5404AMP T52 3A/400V both

5

D820 6412002017 DIODE UF3004M T52 3A/400V 50nS both

6

D841 6412018400 DIODE SM- 3AP6 3A/600V O RIGIN both

6412010907 DIODE LT2A06 T52 2A/800V both

7

F801A 6851504050 FUSE TIME LAG H-BRK 4A/250V both

8

I301 6442012300 IC TDA4866 9P (PHILIPS) both

9

I401 6442022500 IC TDA4853 32P SDIP PHILIPS both

10

I501 6442021400 IC MM1375 22P SDIP (MITSUMI) both

11

I701 6448012200 IC NT68P61A 40P PDIP (NOVATEK) both

12

I702 6448007900 IC 24C04A/P (MIC ROCHIP) both

13

I801 6442022000 IC KA3842A 8P PDIP SAM SUNG both

14 L404 6111504130 COIL C HOK E 5mH K DR10x16 both

15 L405 6119004900 C OIL LINEAR TLN-1049 A1554

16 L405 6119004103 C OIL LINEAR TLN-1041 (C) A1454

17 L409 6111185131 COIL C HOK E L=188uH DR10x20 both

18 Q 402 6421003200 TR N PN 2SC 5339 (TOSHIBA) both

Q421 Q430

19

Q807

6426006400 FET N-C HNL IRFS630A SAMSUNG both

20

Q803 6426006700

21

R403 6224230124 MF KO HM 30.1 1/4W F A1454

22

R403 6224290914 MF KO HM 9.09 1/4W F T26 A1554

23

R404 6224286624 MF KO HM 86.6 1/4W F A1454

Recommended Spare Parts List

FET N- CHNL SSS7N60A

(SAMS UN G)

both

21

Page 24

A1454 / A1554 NEL

N o. Location Part Numbe r D escription M odel

24

R404 6224228024 M F KO HM 28 1/4W F T26 A1554

25

R405 6224216924 M F KO HM 16.9 1/4W F A1454

26

R405 6224256014 M F KO HM 5.6 1/4W F T26 A1554

27

R803 6203090002 PO SISTOR 9 O HM Q 2PIN PITC H=10 A1554

28

R804 6201160011 THERMISTOR 16 O HM 2A P=5 UEI both

29

R818 6220327852 FS O HM 0.27 1W J HO R both

30 R862

31 T401

32 T402

33 T801

34 T802 6131041900 X'FRM ER PW R TPW -1064 EE40 DEI both

35 X701 6449000700 CRYSTAL HC 49/U 8M HZ 50ppm 7pF both

6203090017

6135000103 X'FRM ER H OR DRIVE THD-1001(D) both

6133054020 F BT TFB-5402 C F1095 LIEN CHAN G both

6138001621 LINE FILTER TLF -1016A 16mH AXIS both

PO SISTOR 9 OHM

C3R9R0Q 27AWLSN

A1454

22 Recommended Spare Parts List

Page 25

Page 26

Page 27

Page 28

Page 29

Page 30

Page 31

LITE-ON TECHNOLOGY CORP.

5 F, No. 16, Sec. 4, Nanking E. Road, Taipei, Taiwan

T el: 886-2-25706999 Fax: 886-2-25706888

URL:// www.liteontc.com.tw

Printed in Taiwan

Loading...

Loading...