Page 1

ILD1000G Installation Handbook

TO PREVENT ELECTRIC SHOCK DO NOT REMOVE THE

Handbook Contents

• Safety

• Introduction

• Quick Start

• Installation

• Overview

• Troubleshooting

• Accessories

• Technical Specifications

• Warranty

• Declaration Of Conformity

SAFETY

This symbol is used to alert the user to important

operating or maintenance instructions.

The Lightning bolt triangle is used to alert the user

to the risk of electric shock.

1. It is important to read these instructions, and to follow them.

2. Keep this instruction manual in an accessible place.

3. Clean only with a dry cloth. Cleaning fluids may effect the equipment.

4. Do not block any ventilation openings. Install in accordance with the

5. Do not install this equipment near any heat sources such as radiators, heating vents

6. WARNING – THIS APPARATUS MUST BE EARTHED / GROUNDED.

7. Only power cords with the correct power connector may be used to maintain safety.

8. Refer all servicing to qualified personnel. Servicing is required when the apparatus

9. WARNING – To reduce the risk of fire or electric shock, do not expose this

manufacturer’s instructions.

or other apparatus that produces heat.

Cables incorporating the UK 13A fused plug, Schuko with earthing contacts and UL

approved “grounding type” are acceptable. These must be plugged into power outlets

which provide a protective earth.

has been damaged in any way, such as a power supply cord or plug is damaged,

liquid has been spilled or objects have fallen into the apparatus, the apparatus has

been exposed to any rain or moisture, does not operate normally or has been

dropped.

apparatus to rain or moisture. The apparatus shall not be exposed to dripping

or splashing and no objects filled with liquids, such as vases, shall be placed

on the apparatus.

Box Contents

1 x ILD1000G

1 x Loop connector

1 x Status socket connector

1 x ‘Installation Handbook’

2 x 1U Rack mounting ears

1 x Power cable

1 x Deaf logo

COVER. THERE ARE NO USER SERVICEABLE PARTS

INSIDE. REFER SERVICING TO QUALIFIED PERSONNEL.

1

Page 2

INTRODUCTION

The ILD1000G Induction loop driver has been designed as a high quality

amplifier for use with conference rooms, stadia, theatres, sports halls,

confidential rooms, lecture halls and cinemas. Depending on a number of

factors regarding the installation of the loop and the set-up of the amplifier

the ILD1000G can provide compliance with IEC60118-4 for areas >1300m2.

Ease of installation and use have been major factors in the design,

combined with optimised performance, and the freedom from R.F.I.

generation.

The ILD1000G has three inputs. A balanced line (INPUT 3), a balanced

microphone (INPUT 1) and one (INPUT 2) which can be configured to either.

For more complex installations, you may need ancillary equipment such as

microphone pre-amplifier(s), adaptor(s) for use with 100V line, or signal

processing units. See Accessories or contact Ampetronic for advice.

QUICK START

For those who have a good appreciation of loop systems, the following is a

very quick guide to setting up the amplifier: All you need is an ac power

source, a signal source and a loop. See ‘Designing Induction Loops’

handbook (supplied) or contact Ampetronic for advice.

Installation

1. Turn all controls fully anti-clockwise.

2. Connect loop cable of appropriate length / gauge.

3. Connect signal input(s).

4. Connect power. See points 6 and 7 in SAFETY section.

5.

If rackmounted remove all rubber feet from units. DO NOT re-fit the

feet fixing screws as this may cause damage and invalidate the

warranty

Operation

6. Switch ON – check green POWER LED flashes during self test and

illuminates continuously when checks are complete.

7. Apply input signal and increase the input control until two green

COMPRESSION LEDs are illuminated on the peaks of the signal.

8. Adjust the CURRENT control until the CURRENT LED illuminate to

achieve the desired peak current.

9. Repeat step 6 for any other inputs used.

10. Listen to the magnetic field produced inside the loop area using a

receiving device (e.g. Ampetronic ILR3), or examine the performance

in more detail with a field strength meter.

11. Adjust MLC control to achieve a flat frequency response.

2

Page 3

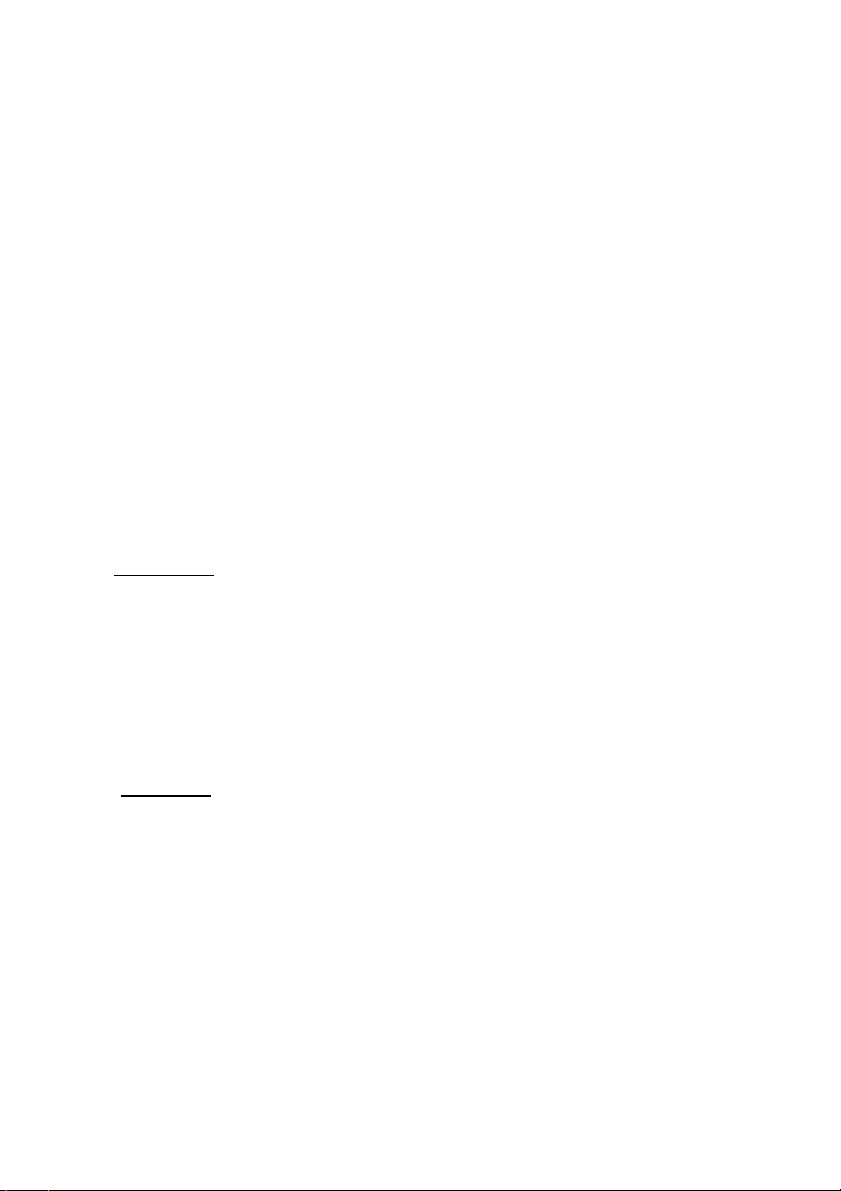

Connections

- (Signal cold)

SOURCE

Connection of 3-pole Plug

CONNECTOR

+ (Signal)

SOURCE

SLEEVE

Connection of 3-pole plug.

RECORDING DEVICE

Connection of 3-pole Plug

INPUT 1 & 2

Screen

+ (Signal hot)

3

1

2

INPUT 3

SLAVE

I/O

Balanced

Unbalanced

Connection of

male XLR

balanced

TIP

RING

SLEEVE

with balanced signals.

Use Twin-screened cable.

TIP

RING

Use Twin-screened cable.

Must be 3m or less.

TIP

RING

SLEEVE

to use Slave I/O socket

for recording output.

+ (Signal hot)

- (Signal cold)

+ (Signal)

LOOP

1

2

LOOP

1+

2+

20.00mm

8.00mm

Refer to technical

specifications for connection

details

3

Page 4

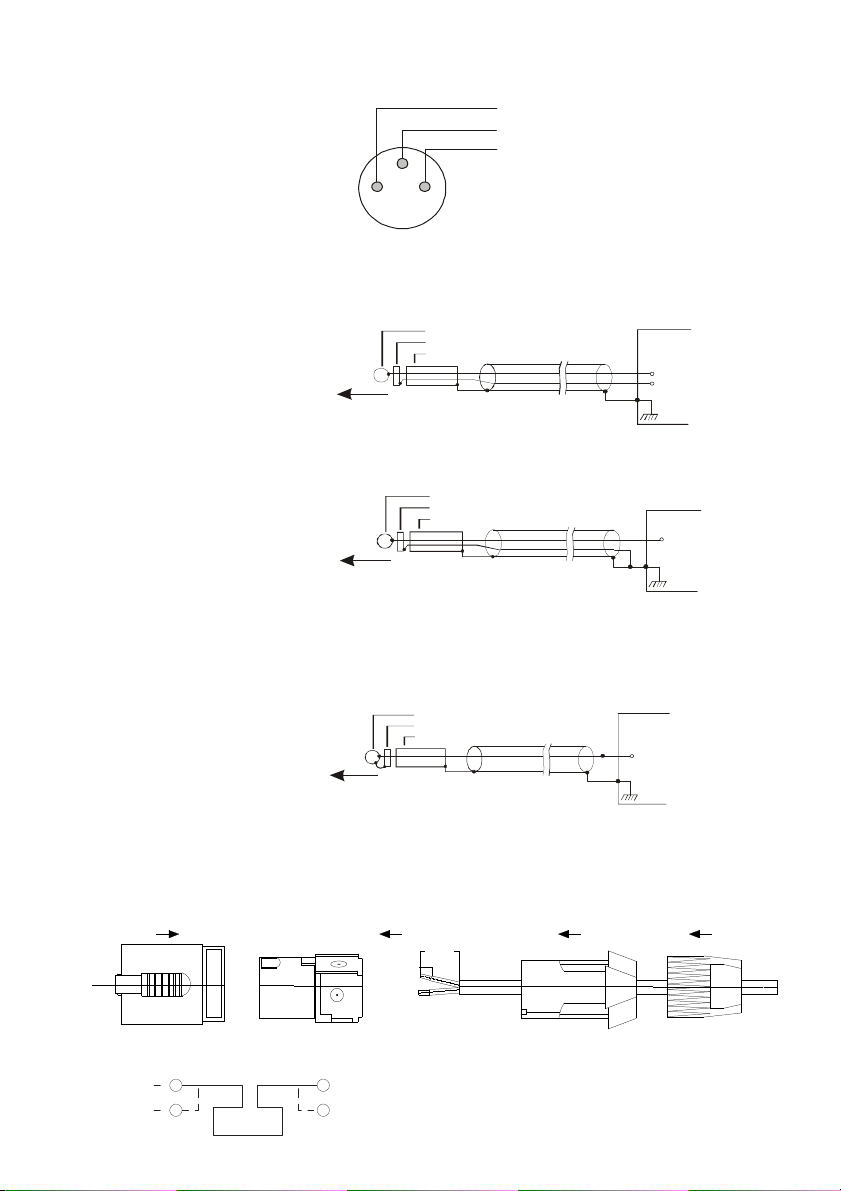

Block Diagram

Must be 3m or less.

Must be 3m or less.

Input 1

Input 2

Phantom

Phantom

Power

Power

Switch

Switch

+15V+15V

Gain Boost

Gain Boost

Compression LEDsCompression LEDs

Input 1 Gain

Overload

Overload

LED

LED

Current LEDsCurrent LEDs

Overheat

Overheat

LED

LED

Loop

Loop

Error

Error

LED

LED

Input 3

230V

or

120V

AC Power

Input 2 Gain

Input 3 Gain

Power

Switch

CompressorCompressor

Power

Supply

Slave

Slave

I/O

I/O

Power

LED

Metal

Metal

Loss

Loss

Correctio n

Correctio n

+15V

-15V

0V

OutputOutput

Current

Monitor

+15V

Use cable supplied.

Use cable supplied.

0V

-15V

Output

Output

15V

150mA

DC

Output

Socket

Loop

Loop

4

Page 5

INSTALLATION

Location

The unit may be free standing or 19” rack mountable using the rack ‘ears’

supplied. Fitting of the ‘ears’ is achieved by removing the two left hand side

for the smaller ‘ear’ and all three right hand side panel screws for the larger

‘ear’. The same screws are then re-used to secure the ‘ears’ in place. (A

PH2 screwdriver will be required). For 19” rack mounting the four rubber

feet must be removed.

The location must provide adequate ventilation for the unit.

An internal fan provides forced ventilation using air vents at the left side

(intake) and rear (exhaust) of the unit. Both of these vents must be

unobstructed for satisfactory cooling. If the unit is installed in an enclosed

environment, sufficient airflow into the enclosure must be provided through

vents fans or other means, such that the units exhaust air is not recycled to

the inlet – causing a reduction in output current or OVERHEAT LED to be

illuminated.

Contact Ampetronic for advice on cooling requirements for your installation.

Tools and Equipment

Small hand tools including a wire stripper and a small flat blade screwdriver

will be required.

An ILR3 loop receiver or a magnetic field strength meter is vital to check

that the loop system is providing the desired level of performance.

A pair of stereo headphones with a 3.5mm jack plug connection is also

useful to monitor the loop signal.

System Requirements

The induction loop cable itself should be already installed according to the

‘Designing Induction Loops’ handbook, or as per specific design instructions

provided by Ampetronic. As a result, a target current should be known,

based on achieving acceptable field strength across the area to be covered.

It is important that the total resistance of loop and feed must be between

0.5Ω and 10Ω (at DC). If this is not achieved, the LOOP ERROR LED will

become illuminated, and the amplifiers output will be disabled. See

Troubleshooting section for details on how correct this, and get your

system working.

The ‘Designing Induction Loops’ handbook contains more details on loop

and feed cables. The correct design and positioning of the actual loop is

vital for satisfactory system performance. If in doubt consult Ampetronic for

advice.

See next page for connection and set-up.

5

Page 6

Connection and Set-up

It is advised that the loop system is initially set up using a local audio source

such as a CD player, which is not connected into any other system. This

avoids the complication of ground loops and feedback etc, whilst the unit is

set up.

The following procedure describes the installation of a stand alone

ILD1000G, and does not incorporate connection of other ancillary units such

as microphone pre-amps, mixing desks, or signal processing units.

1. Turn all controls fully anti-clockwise.

2. Connect the feed cable from the loop into the NL4 loop connector

supplied as shown:

1

2

Note: Where using a perimeter loop (floor/ceiling level), the feed cable

should be tightly twisted to avoid unwanted stray magnetic fields.

3. Connect the signal inputs appropriately:

Microphones: Suitable dynamic or condenser microphone with balanced

cable feed. Select phantom power as required. Connect to INPUT 1 and

INPUT 2 (with selector switch in the appropriate position) using a 3-pole

XLR plug wired as per Connections drawing.

Line level signals: From other audio equipment such as PA system,

mixing desk or CD player. Connect to INPUT 2 (with selector switch in

the appropriate position) using a 3-pole XLR plug and INPUT 3 using a

3-pole balanced jack plug both wired as per Connections drawing

LOOP

1+

2+

.

You may use either or all three inputs.

Do not run input and output cables close together

The SLAVE I/O must NEVER be used as a separate input. It must only

be used with Ampetronic signal processing equipment or for obtaining a

signal for recording. See Connections for details.

4. Connect AC power to the ILD1000G. See points 6 and 7 in Safety

section.

5. Switch ON. The POWER LED will flash for a few seconds whilst an

internal self-test is performed and the loop resistance is tested. If both

tests are successful, the POWER LED will illuminate continuously and

the unit will be in an operational mode. If the POWER LED continues to

flash, or the LOOP ERROR LED illuminates, consult the

Troubleshooting section.

6. Select one input and apply a suitable audio signal (ideally a CD player

6

Page 7

with music or continuous speech applied to INPUT 3, with no connection

to INPUT 1 or INPUT 2). Turn the associated input control clockwise

until two COMPRESSION LEDs are illuminated on the peaks of the

signal.

7. Turn the CURRENT control clockwise until the target current is achieved

– as indicated by the CURRENT LEDs. Note that consecutive LEDs

illuminate at 3dB intervals. Headphones can be used with the MONITOR

socket to listen directly to the loop current. If high frequency oscillation or

low frequency hum is experienced, consult the Troubleshooting

section.

8. The loop system should now be providing a magnetic field inside the

area of the loop – use the ILR3 or field strength meter to examine its

performance with respect to:

a. Magnetic field strength. This may vary across the coverage due to

layout, metal loss and loop current.

b. Frequency response. Metal losses tend to increase with frequency, and

may require the adjustment of the MLC control.

As a result of this analysis, adjust the CURRENT and set the MLC to

achieve the best sound quality. This should result in adequate magnetic

field strength and a level frequency response in order to satisfy

IEC60118-4. Note: Do NOT adjust the MLC control whilst listening to the

MONITOR socket as this will not give a true indication of the response of

the actual loop.

Once the CURRENT and MLC controls have been adjusted to the

correct level they should NOT need re-adjusting.

9. If not already done so, steps can now be taken to integrate the

ILD1000G into a PA / mixer arrangement following standard audio

techniques. If any unusual effects are experienced refer to the

Troubleshooting section.

Note: Ideally, each input signal level should be set up to achieve 6dB

(one LED) of COMPRESSION with the quietest level of input likely to be

used. This will maximize the dynamic range of the system and ensure

satisfactory performance.

10. Repeat the above procedure for each input used. When adjusting each

input, make sure the signals are removed from the other inputs. This

ensures that all signals are set to equivalent loudness and drive the

compressor properly.

7

Page 8

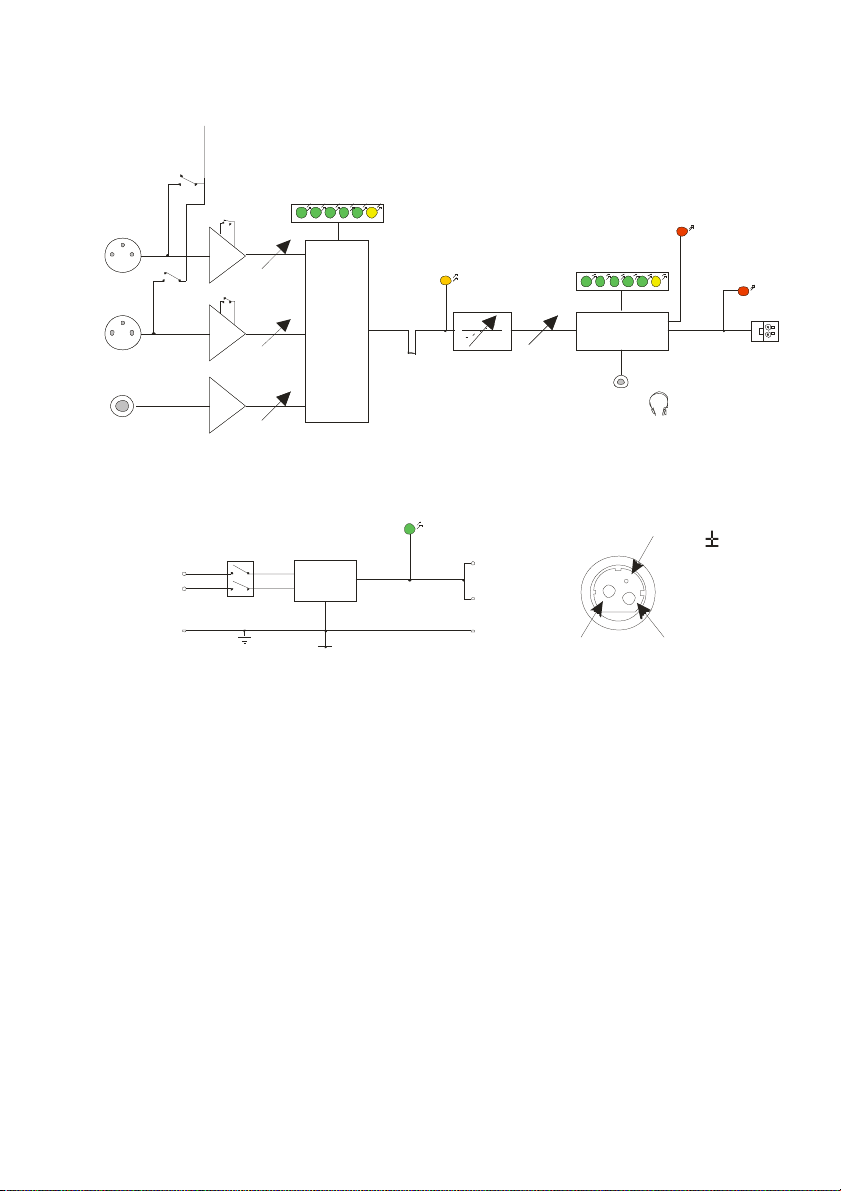

OVERVIEW

COMPR ESSION

dB

INPUT 1

1111

INPUT 1, INPUT 2 and INPUT 3: Screwdriver adjustable controls which set

INPUT 2 INPUT 3

INDUCTION LOOP DRIVER ILD1000G

AC POWER

INPUT 230V

45 - 65Hz

Power: 120W

Fuse: T 1.25A L

Serial Nº

6 1 2 18 24 30 36

CAUTION

RISK OF ELECTRIC SHOCK

DO NOT OPEN

Designed and Engineered in the UK

ML C CURRENT

CURRENT

2.3 3.3 4 .6

A pea k

6.5

9.2 1 3

the level of input signals.

2222

COMPRESSION: Shows the amount of gain reduction in decibels (dB) that

is applied to the input signal(s).

3333

MLC: Screwdriver adjustable control which compensates for the frequency

dependant effects of metal.

4444

CURRENT: Screwdriver adjustable control which sets the level of output

current delivered into the loop.

5555

CURRENT: Indicates the peak current delivered into the loop.

6666

MONITOR: 3.5mm jack socket for use with stereo headphones to listen

directly to the signal being delivered into the loop.

7777

OVERLOAD, OVERHEAT and LOOP ERROR: Warning LEDs, see

Troubleshooting section.

8888

POWER: LED to indicate power is applied to the unit.

9999

I/O: Power switch.

8

MO NITOR

Page 9

0

OVE R

OVE R

LO OP

LOAD

HEAT

ERR OR

POWE R

INDUCTION

LOOP DRIVER

IL D

1000G

I

STATUS

SLAV E I/O

INPU T 3

INPU T 2

SINGLE – TURN

LOOP ONLY

Loop resistance

Min:0.5 Max:3.0Ω Ω

For details consult

instructions or

www.ampetronic.com

1

2

1+

2+

LOOP

AC POWER: Standard 3-pole IEC320 connector containing primary fuse

LOO P OU TPUT

±1 5V

15 0mA

DC

OUTPU T

for the unit.

LOOP OUTPUT: Neutrik ‘Speakon’ High current connection to the loop

cable.

±15V 150mA DC OUTPUT: 3-pin mini DIN connection for ancillary units.

STATUS: Connection to relay contacts providing remote fault indication

SLAVE I/O: 3 pole 6.4mm jack insert point for use with ancillaries.

INPUT 3: 3 pole 6.4mm jack socket for balanced line level inputs.

INPUT 2: XLR socket for balanced MIC/line level signals

LINE/MIC: Mode select switch for input 2.

GAIN BOOST: Gain selector switch for input 2 (ON = +15dB).

PHANTOM: Phantom selector switch for input 2.

INPUT 1: XLR socket for balanced MIC signals

GAIN BOOST: Gain selector switch for input 1 (ON = +15dB).

PHANTOM: Phantom selector switch for input 1.

9

INPU T 1

Page 10

TROUBLESHOOTING

POWER LED not illuminated

• Check that the power switch is toggled to the ON (I) position.

• Check fuse continuity. A 20mm fuse is incorporated into the AC

POWER inlet. It is necessary to remove the power cord before

extracting the fuse holder. Test the continuity of the fuse using a

multimeter. A spare fuse is provided in the fuse holder

Any replacement fuse MUST be of the same rating and type as

printed on the rear of the unit.

POWER LED flashing continuously

Amplifier has failed self test and is in safe mode. No signal will be fed

into the loop. Switch the unit off, remove all connections except the loop

and power connections, turn all front panel controls to minimum and

switch back on. If the problem persists, contact Ampetronic for advice.

COMPRESSION LEDs not illuminating

Check input connections.

Ensure that the appropriate front panel control (INPUT1, INPUT2 or

INPUT3) is turned up. Check there is sufficient signal level for the

required input.

CURRENT LEDs not illuminating

There are many possible causes for this:

• Check the COMPRESSION LEDs are illuminating.

• Check that the CURRENT control is turned up sufficiently.

• Check the LOOP ERROR, or OVERHEAT LEDs are not illuminated.

• Ensure the POWER LED is illuminated and not flashing.

• Remove any connection from the SLAVE I/O socket.

• Check that the loop cable is connected, terminated correctly and

inserted into the LOOP OUTPUT socket.

• Check the loop is not open circuit, short circuit, or connected to

earth (see instability or high frequency noise section of

Troubleshooting)

• Switch the unit off and turn back on.

Note: You can listen to the actual loop signal by using a pair of

headphones plugged into the monitor socket.

10

Page 11

OVERLOAD LED illuminated

Indicates too much current is being delivered into the loop or that the

output voltage is clipping. Occasional lighting of this indicator is normal

on peaks of signal.

• Remove any connection to the SLAVE I/O.

• Turn down the CURRENT control to avoid running too much current

or causing the output voltage to clip.

• Check the loop is not open circuit, short circuit, or connected to

earth (see instability or high frequency noise section of

Troubleshooting)

• Check the loop is within specified limits.

OVERHEAT LED illuminated

Indicates that the internal heatsink is too hot. Loop current is not

delivered.

• Ensure that the unit is installed in a location with sufficient

ventilation

• Check that nothing is blocking the free flow of air through the vents

at the side and back of the unit.

• Check the loop is not open circuit, short circuit, or connected to

earth (see instability or high frequency noise section of

Troubleshooting)

LOOP ERROR LED illuminated

Indicates the loop cable connected to the unit is outside specification.

is important that the total resistance of loop and feed must be between 0.5Ω

and 10Ω (at DC). If this is not achieved, the LOOP ERROR LED may

illuminate and the amplifiers output will be disabled.

Important: Once the cause of any loop error has been established the unit

will need to be restarted. Turn the power OFF - wait 5 seconds, and switch

ON.

It

• Check that the loop cable is connected, terminated correctly and

inserted into the LOOP OUTPUT socket. Restart the amplifier as

above.

• Ensure the DC resistance is acceptable -

between 0.5Ω and 10Ω

. In

all case the amplifier will need to be restarted once the problem is

solved.

Note: Meter leads can easily measure 0.2

Ω, and should be factored out.

• If the loop is open circuit - it may have been cut somewhere and will

11

Page 12

require investigation and potentially re-laying.

• If the loop is high resistance >10Ω - check all connections and re-

tighten, there may be something loose.

• Check for short circuits in the loop connector.

• If the loop is just very low resistance, fold a defined length (see below)

of 0.5mm² cable in half and twist it together neatly – using a hand drill

can be helpful. Coil this loosely on the forearm and bind it so that it

does not come un-coiled. Then connect the two ends in series with the

low resistance loop to ensure that the unit will always turn on, but the

system performance is un-affected. 5m of 0.5mm² wire will add

approximately 0.15 Ω to loop resistance. Use an appropriate length to

ensure the loop resistance exceeds 0.5Ω.

Note: High or low resistance loops can be encountered in a venue with

a pre-installed loop, which was designed for use with an old loop driver

which might be being replaced. Before using this loop ensure that the

existing loop will allow the system to perform to an acceptable level by

checking it’s layout details in the ‘Designing Induction loops’ handbook.

Low magnetic field strength

Due to insufficient CURRENT or excessive metal loss.

May require a special loop design to achieve acceptable performance,

contact Ampetronic for advice.

Instability or high frequency noise

1. It is possible for the loop cable to be grounded under fault conditions,

resulting in instability which may sound like high frequency noise,

buzz or whistling. The results of this type of fault are unpredictable

and may appear as any combination of the front panel indication

errors.

This fault is easy to determine. Simply unplug the loop cable from the

amplifier and test with a resistance meter between either of the loop

wires and a good earth point such as a metal radiator. There should

be an infinitely high reading i.e. no connection at all. Any reading

indicates a failure of the loop cable insulation and you will need to

either repair or replace the loop cable.

2. Instability can be caused by using poor quality signal cables, long

unbalanced (2-wire) signal runs to the inputs, or by running input

cables in close proximity with the loop wire over an appreciable

distance. Loop amplifiers are capable of delivering high currents at

audio frequencies. If the loop cable is run close to sensitive signal

cables it may be possible to induce a signal back into the input of the

amplifier causing feedback. Cable runs and loop wires should be

kept well apart from each other. To avoid interference maintain a

12

Page 13

separation of at least 300mm.

3. Instability can cause the amplifier to run hot and may result in the

OVERHEAT LED illuminating.

Interference

1. Background magnetic field signals or interference may be present in

any location and may not be anything to do with the loop system.

Monitor this with a loop receiver (such as an ILR3). If the interference

is still present with the loop system switched off, then you need to

locate and eliminate the source of the interference before switching

the loop system back on

2. Magnetic fields can induce currents into any low impedance

electrical path or loop. Audio or video systems with multiple earths

may experience pick up of the loop signal. Check entire sound

system for evidence of loop signal, and trace source of pick up.

3. Under certain circumstances, the loop signal may appear as jagged

lines or hum bars on a CCTV picture. This could be due to running

CCTV (low impedance unbalanced 2-wire circuit) cables in close

proximity to the loop cable. Separate the loop cables to reduce the

effect.

4. Remote (and apparently unconnected) PA systems can sometimes

pick up loop signals. This is usually because the loop cable becomes

damaged (see point 1 of Instability) or induces signals into the

remote system through long unbalanced cables. Always run long

audio signal cables as 3-wire balanced circuits and keep away from

loop cables.

5. See also point 1 of Instability

Failed AC power fuse in rear of unit

Unplug the loop and AC power supply from amplifier, and replace the

failed fuse with the spare fuse in AC power input fuse tray.

Reconnect the AC power supply and switch on. If the fuse fails

again, return the unit to Ampetronic for evaluation - it may well be

covered under warranty, which will be invalidated by removing the

cover. If the fuse does not fail a 'loop error' may be indicated, but

shows that the unit is working correctly. Re-connect the loop and

switch the power off then on again to reset loop error.

If the fuse fails when the loop is re-connected to the unit, then the

loop could be shorted to electrical mains (and building) earth. This

can happen even if no audio signal is present, as the short to earth is

likely to cause an instability / oscillation / feedback condition to

develop. A loop cable short to earth most commonly occurs where

13

Page 14

flat copper tape is installed on a metal-clad raised access flooring

system. If the insulation on the flat copper tape is abraded (for

example by a piece of metal swarf trapped below the copper tape),

the conductor could short to the earthed tiles.

When installing on raised access floors, it is advisable to insulate

beneath the flat copper tape installation using Ampetronic PWT or

similar tape.

The loop short to earth may only be completed when a person steps

on the tape in the affected location, which can create significant

difficulties when diagnosing the cause of fuse failure. Contact

Ampetronic for further advice if a unit is suffering recurring but

untraceable failure of the rear panel fuse.

ACCESSORIES

Details of all products and services provided by Ampetronic can be found at

www.ampetronic.co

Wall mount brackets are available for mounting the amplifier on the wall

with appropriate fixings

Microphone pre-amplifiers

Signal processing units are available for use with low spill array systems.

Input adaptors for a range of applications such as 100V line audio and low

Z speaker systems are available.

14

Page 15

TECHNICAL SPECIFICATIONS

INPUTS

INPUT 1;

INPUT 2;

INPUT 3;

AC POWER;

COMPRESSION (AGC)

OUTPUTS

Slave I/O;

LOOP OUTPUT;

Input figures quoted at maximum front panel gain

control setting.

Balanced, XLR connector. 15V

phantom

Suitable source impedance

Input impedance

Sensitivity

Overload

Balanced, XLR connector. 15V

phantom.

Suitable source impedance

Input impedance

Sensitivity

Overload

Balanced line level. 6.4mm jack.

Input impedance

Sensitivity

Overload

Standard IEC inlet

Mains supply voltage

Frequency

Power

Fuse

Inrush current

Compression of signal in dB shown on six front

panel LEDS

Input range

Output range

Min. input level for AGC

Attack time

Decay time

MIC Line

Normal Boost Normal Boost

≤600Ω

1kΩ

-55dBu

-19dBu

≤600Ω

8700Ω

-55dBu

-24dBu

-

-

-

≤600Ω

1kΩ

-70dBu

-34dBu

≤600Ω

8700Ω

-70dBu

-39dBu

-

-

-

-

-

-

8700Ω

-30dBu

1dBu

1MΩ

-30dBu

5dBu

-

-

-

8700Ω

-45dBu

-14dBu

-

-

-

230V (115V)

45–65 Hz

120 W (EN60065 test into square loop)

T 1.25A L (T 2.5A L) - relevant

approvals.

15A (30A)

>36dB

±1dB across input range

Depends on input used (see sensitivity)

8ms

2s

external processors. (out-tip, in-ring, sleevegnd).

connected internally as are 1- & 2- to allow ‘starquad’ method of cable connection).

Current in Amps peak indicated via six LEDs at 3

dB intervals. PPM style processing for display

Insert point for connecting Ampetronic

Source impedance

Input impedance

Output signal level

Max cable length

NL4 speakon (1+ & 2+

Voltage

Current into a single turn loop.

Absolute max short term peak current.

THD +N

Frequency response (loop current)

Metal Loss correction

Attack

Decay

15

220Ω

100kΩ

1.5Vpk

1m

45V peak (31.8V

13A peak (9.2A

RMS

RMS

)

)

>19A

<0.2% @1kHz

80Hz to 6.5kHz ±1.5dB at low level

Adjustable 0 to 3dB per octave (gain

@1kHz remains constant)

4.7ms

1s

Page 16

±15V DC

OUTPUT

;

Max cable length

Status Socket;

PROTECTION

F

EATURES

Clipping

Cooling;

PHYSICAL

Weight;

Dimensions;

Environmental;

Accessories supplied;

Power Mini DIN connector

The status socket consists of a

pair of isolated contacts (plug supplied as

standard).

Amplifier or load fault

Amplifier and load OK

Contact rating

Dielectric strength (coil – contact)

; Any clipping detected is shown on the

front panel OVERLOAD LED. If clipping persists

(>8s of continuous clipping) amplifier will

shutdown and restart.

Threshold

Output DC offset; If DC offset is detected

amplifier will shutdown and restart

threshold

Overheat; (internal heatsink);

Output level reduction

Output mute (illuminates OVERHEAT)

Any of the above faults also cause the status

relay contacts to open.

Current limit; Also provides indication via

OVERLOAD LED

Loop resistance testing; Checks the resistance

of the load on startup is within limits. POWER

LED flashes during this period. The LOOP

ERROR LED illuminates and output maybe

muted if load is outside limits

Startup time

Min resistance

Max resistance

internal variable speed fan. Intake on

left side, exhaust on rear panel

Fan noise

Amplifier thermal emissions

±15V @ 150mA max.

3m

Open

Closed

DC 2A, 28V, 60W

AC 0.5A, 125V, 60VA

1000Vac 50/60Hz

93% of peak output voltage (time

delays applied to prevent nuisance

tripping)

±0.7V DC

88 to 92°C (3dB max)

92°C (output returns at approx. 60°C)

Approx. 20A pk

8s approx.

0.5Ω

10Ω

33dBA at 1m no load

42dBA at 1m EN60065 test signal into

std. square loop load

100W (EN60065 test into square loop)

Width

Height

Depth

Ingress Protection

Operating temperature range

Relative humidity

Rackmount brackets

Mains lead

Loop connector

Status socket connector

3.7kg

430 mm

44 mm

220mm

IP20

0 – 35°C

20 – 90%

Long one for transformer (right hand)

side

Region specific

Neutrik NL4 speakon

Screw terminal plug

16

Page 17

WARRANTY

This product carries a five year parts and labour warranty from date of

shipment from Ampetronic. To qualify for the five year warranty, the product

must be registered at www.ampetronic.co (products/warranty), without

which the warranty will be valid for two years only.

The warranty could be invalidated if the instructions in this handbook are

not followed correctly, or if the unit is misused in any way.

DECLARATION OF CONFORMITY

Manufacturer: Ampetronic Ltd.

U

Farndon Road

Newark

NG24 4XB.

Declares that the product:

Description: Induction Loop Driver

Type name: ILD1000G

Conforms to the following Directive(s) and Norm(s):

Directive 2004/108/EC

EMC: EN55103-1 : 2009+A1:2012 Emission

EN55103-2 : 2009 Immunity

Directive 2006/95/EC

Safety: EN60065 : 2002+A12:2011

Directive 2011/65/EU RoHS

Date: January 2016

J.R. Pieters

Managing Director

Ampetronic Ltd.

nit 2, Trentside Business Village

UP15101-9

17

Page 18

blank

18

Page 19

blank

19

Page 20

blank

20

Loading...

Loading...