L DESIGN FEATURES

Li-Ion

0.8V TO 3.6V/400mA

3.3V/25mA

0.8V TO 3.6V/400mA

0.8V TO 3.6V/1A

RST

2

OPTIONAL

0V

T

TO OTHER

LOADS

+

LTC3555/LTC3555-X

TRIPLE

HIGH EFFICIENCY

STEP-DOWN

SWITCHING

REGULATORS

I2C PORT

ALWAYS ON LDO

MEMORY

RTC/LOW

POWER LOGIC

I2C

CORE

I/O

µPROCESSOR

USB/WALL

4.35V TO 5.5V

CHARGE

ENABLE

CONTROLS

USB COMPLIANT

STEP-DOWN

REGULATOR

CC/CV

BATTERY

CHARGER

5

1

2

3

CURRENT

CONTROL

New Family of Integrated Power

Controllers Combine Fast Battery

Charging, PowerPath Control and

Efficient DC/DC Converters in

Less Than 20mm2

Introduction

The quickest way to build an efficient

power system for a battery-powered

portable application is to use an

IC that combines all power control

functions into a single chip, namely a

Power Management Integrated Circuit

(PMIC). PMICs seamlessly manage

power flow from various power sources

(wall adapters, USB and batteries) to

power loads (device systems and the

charging battery), while maintaining

current limits where required (such

as that specified for USB). To this

end, PMICs typically feature built-in

PowerPath™ control, DC/DC conver-

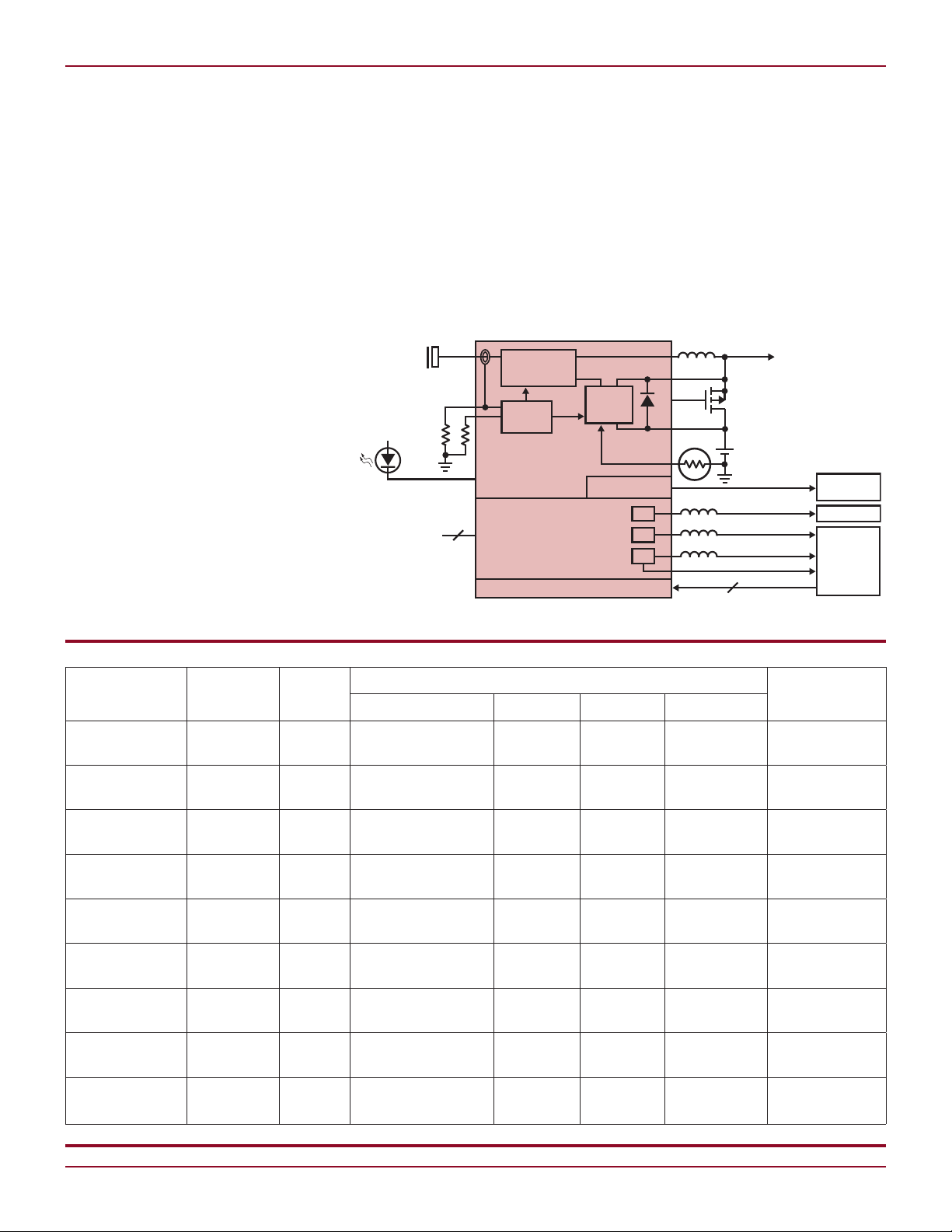

Table 1. Power management ICs with Li-ion/polymer battery chargers

PowerPath

Part Number

LTC3555/-1/-3 Switching I2C 1A, 400mA × 2 25mA

Topology Interface

Figure 1. High efficiency PowerPath manager and triple step-down regulator

Integrated Converters and Load Current Capabilities

by Sam Nork

PackageBuck Buck-Boost Boost LDO

4mm × 5mm

QFN-28

LTC3556 Switching I2C 400mA × 2 1A 25mA

LTC3566 Switching 1A 25mA

LTC3567 Switching I2C 1A 25mA

LTC3586* Switching 400mA × 2 1A 0.8A 20mA

LTC3557/-1 Linear 600mA, 400mA × 2 25mA

Linear Technology Magazine • September 2008

LTC3455 Linear 600mA, 400mA Controller

LTC3558 400mA 400mA

LTC3559/-1 400mA × 2

*For an application of the LTC3586 see “Complete Power Solution for Digital Cameras and Other Complex Compact Portable Applications” in this issue

4

4mm × 5mm

QFN-28

4mm × 4mm

QFN-24

4mm × 4mm

QFN-24

4mm × 6mm

QFN-38

4mm × 4mm

QFN-28

4mm × 4mm

QFN-24

3mm × 3mm

QFN-20

3mm × 3mm

QFN-16

DESIGN FEATURES L

Li-Ion

PGOODALL

0.8V TO 3.6V/400mA

3.3V/25mA

2.5V to 3.3V/1A

0.8V TO 3.6V/400mA

OPTIONAL

0V

T

TO OTHER

LOADS

+

LTC3556

DUAL HIGH EFFICIENCY

BUCKS

HIGH EFFICIENCY

BUCK-BOOST

I2C PORT

ALWAYS ON LDO

MEMORY

CORE

µP

RTC/LOW

POWER LOGIC

HDD/IO

3556 TA01

USB/WALL

4.5V TO 5.5V

CHARGE

I2C

USB COMPLIANT

STEP-DOWN

REGULATOR

CC/CV

BATTERY

CHARGER

SEQ

ENALL

3

1

2

3

40

50

60

70

80

30

20

10

0

90

100

V

IN3

(V)

2.7

EFFICIENCY (%)

3.1

3.5 3.9 4.3 4.7

V

OUT3

= 3.3V

TA = 27°C

I

OUT3

= 200mA

I

OUT3

= 50mA

I

OUT3

= 1000mA

BATTERY VOLTAGE (V)

2.8

0

CHARGE CURRENT (mA)

200

3.2

3.6

3.8

100

700

400

500

600

300

3

3.4

4

4.2

BATTERY CHARGE CURRENT

500mA USB CURRENT LIMIT

EXTRA CURRENT

FOR FASTER CHARGING

V

BUS

= 5V

5X MODE

BATTERY CHARGER PROGRAMMED FOR 1A

sion and battery charging functions.

PMICs can be applied in everything

from consumer electronics such as

MP3 players and Bluetooth headsets

to specialized portable medical and

industrial equipment.

Table 1 shows the wide variety of

integrated charger and DC/DC combinations now available from Linear

Technology. The latest additions to

the family, the LTC3555, LTC3556,

LTC3566, LTC3567 and LTC3586, are

primarily targeted toward relatively

high power Li-Ion applications and

contain blocks capable of high efficiency at high current levels. (To see

an application of the LTC3586, see

“Complete Power Solution for Digital

Cameras and Other Complex Compact

Portable Applications” in the Design

Ideas section of this issue.)

The most noteworthy feature of the

new parts is the use of a proprietary

switching PowerPath design, which

improves efficiency over linear power

path or battery fed solutions.

Switching PowerPath Control

Efficiently Harnesses

Available External Power

To speed up charging, some of Linear’s

new PMICs employ a unique current

limited synchronous buck switching charger architecture that uses

more power from the USB or adapter

than other topologies. This is a big

improvement over battery fed and

linear PowerPath control schemes.

(For a more detailed description of

the switching PowerPath architecture,

on” capability if the battery is dead or

missing (as long as the load current

is less than the input current limit).

However, neither a linear charger nor

linear power manager is well-suited

for high current charging due to poor

efficiency under certain conditions.

power, but charging/powering from

the USB host is complicated by the

host’s 2.5W limit. To take advantage of

the limited USB power, all components

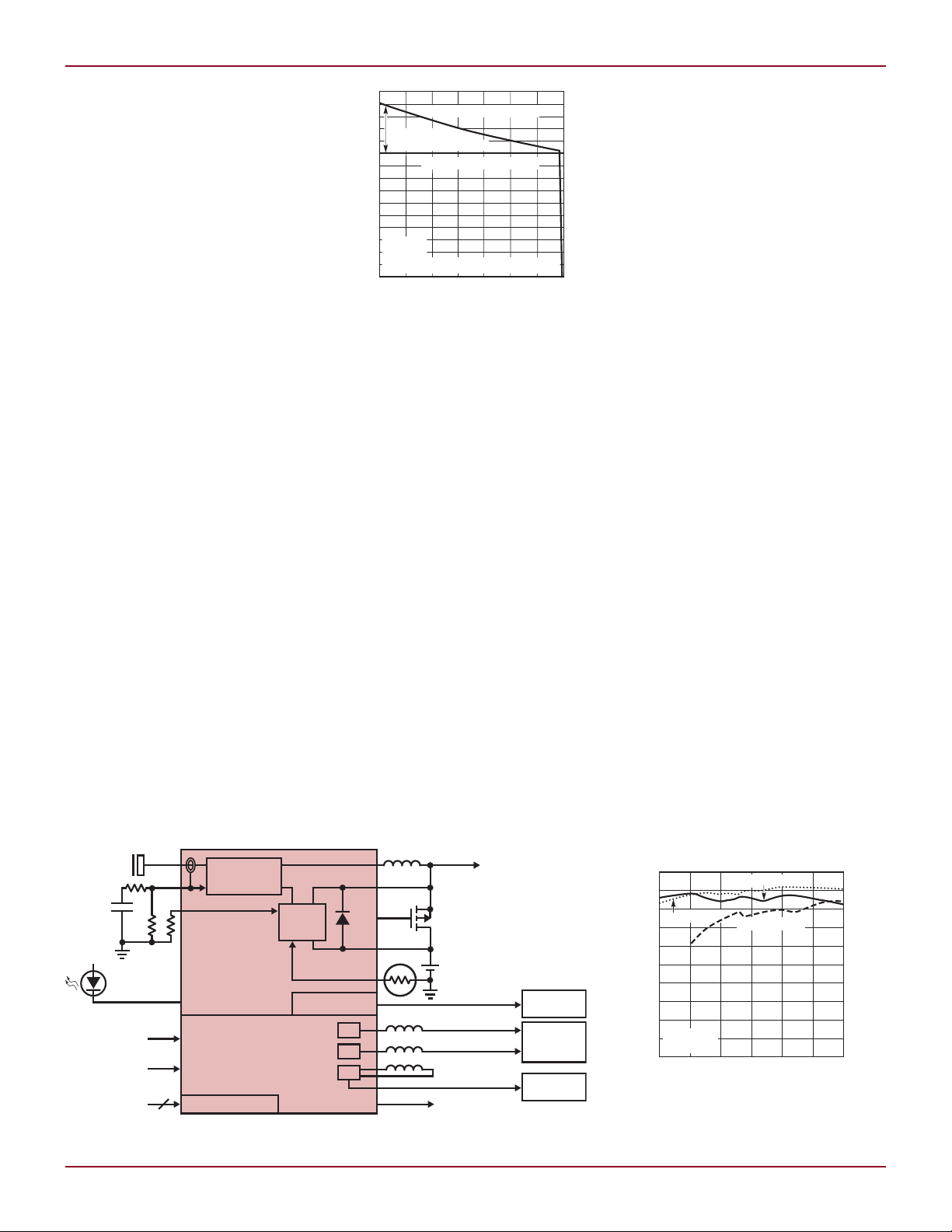

Figure 2. Switching power manager charge

current vs battery voltage with a 500mA input

current limit. Peak charge current = 700mA.

in the power path must be as efficient

as possible.

is a battery-tracking (Bat-Track™)

see the cover article in the June 2008

issue of Linear Technology magazine

titled “Speed Up Li-ion Battery Charging and Reduce Heat with a Switching

PowerPath Manager.”)

For instance, portable products

with large capacity batteries (1Ahr

plus) face a direct tradeoff between

charge time and charger power dissipation—especially when a linear

charging method is used. At relatively

low charge currents, a linear charger

dissipates a modest amount of power,

but at currents required to quickly

charge high capacity batteries, a linear

charger can dissipate 2W or more.

A switching PowerPath topology is

an improvement over the commonly

synchronous buck design with logic

programmable input current limit to

ensure USB compatibility. When USB

or adapter power is available, the

LTC35xx power manager generates a

V

The 300mV difference voltage is sufficient to keep the battery charger

just out of dropout and deliver the

programmed charge current at high

efficiency. As with linear power managers, the load current is provided first,

and current that is left over is directed

to the battery. Input current limit is

controlled via an external resistor to

set absolute current and two logic

pins to control the ratio (e.g. 100mA,

500mA, 1A and Suspend).

used linear PowerPath topology, and

both are an improvement over battery

fed applications. A linear PowerPath

powers the application directly from

an external source rather than from

the battery itself and provides “instant

with a completely discharged battery

is achievable vs 60% or so for a linear

charger. Or said another way, the

switching power path dissipates only

50% of the power dissipated by a linear

USB is now a common source of

A key attribute in these new PMICs

supply equal to V

OUT

+ 300mV.

BAT

Charging efficiency of over 80%

Linear Technology Magazine • September 2008

Figure 3. 1A buck-boost efficiency vs VIN (LTC3556, LTC3566/7, LTC3586)

5

GND

ILIM

DECODE

LOGIC

I2C PORT

SWAB1

V

IN1

V

C1

FB1

DV

CC

SCL

EN1

CHRGEN

CHRGEN

SDA

1A, 2.25MHz

BUCK-BOOST

REGULATOR

ENABLE

MODE

SWCD1

V

OUT1

D/A

4

6, 12, 17, 25

V

IN4

LTC3586

L

SW4

R1 C

OUT

C

PL

R2

V

OUT4

FB4

Li-Ion

FAULT

0.8V TO 3.6V/400mA

5V/800mA

3.3V/20mA

2.5V to 3.3V/1A

0.8V TO 3.6V/400mA

OPTIONAL

0V

T

TO OTHER

LOADS

+

LTC3586

DUAL HIGH EFFICIENCY

BUCKS

HIGH EFFICIENCY

BUCK-BOOST

HIGH EFFICIENCY

BOOST

ALWAYS ON LDO

MEMORY/

CORE µP

RTC/LOW

POWER LOGIC

I/O

SYSTEM

USB/WALL

4.5V TO 5.5V

CHARGE

I

LIM

USB COMPLIANT

STEP-DOWN

REGULATOR

CC/CV

BATTERY

CHARGER

MODE

EN

2

4

1

2

AUDIO/

MOTOR

4

3

CURRENT

CONTROL

L DESIGN FEATURES

charger under worst case conditions.

The LTC35xx switching power managers can charge at up to 1.2A max

and provide seamless switchover to

battery power when the external power

is removed. In USB applications, the

constant power (vs constant current)

nature of the switching PowerPath

controller makes it possible to charge

with more than 500mA from a fixed

500mA USB input source, as shown

in Figure 2.

Higher Current Chargers Go

Hand-In-Hand with Higher

Current Regulators

An obvious companion to a high

performance battery charger is a corresponding set of DC/DC regulators

with similar peak current handling

and high efficiency. As shown in Table

1, the latest PMICs offer between one

and four DC/DCs of varied topologies

with peak currents reaching 1A. The

new parts provide a variety of specific

options to meet the high performance

needs of specific applications.

Need a Buck-Boost?

Not a Problem…

Most high end portable products need

a minimum of three key power supplies: one for the µP core (~1.0V–1.5V),

one for memory (~1.8V), and one for

the I/O and main system supply

(~3.3V). The LTC3555 covers all three

with its built-in three synchronous

bucks. However, some applications,

particularly the more feature-rich variety, face occasional high peak power

transients during wireless transmissions or when a hard drive spins up.

The effective voltage of the battery

drops during these transient currents

due to the battery series resistance

Figure 5. Boost converter application circuit

6

Figure 4. The LTC3586 is a high efficiency PowerPath controller, alwayson LDO, dual buck, buck-boost, plus boost—all in a 4mm × 6mm package

(BSR), trace impedance or power path

losses. This poses a problem for the

3.3V supply, which can drop out of

regulation even if the battery is still

significantly charged. In such cases,

a buck-boost regulator can save the

day by riding through such battery

transients—maintaining regulation

as if nothing happened. Several new

PMICs contain buck-boost DC/DCs

specifically for this purpose. As shown

in Figure 3, the PMIC buck-boosts can

provide a high efficiency 3.3V output

with an input that ranges from 2.7V

to 5.5V.

The LTC3566 and LTC3567 products include a 1A buck-boost supply

in addition to a high performance

Figure 6. The LTC3567 I/O and DC/DC output voltage control interface

switching PowerPath controller as cornerstone high performance building

blocks. The LTC3556 ups the integration further by including two 400mA

buck regulators to accompany the

charger and buck-boost supply. The

LTC3586 contains all of the blocks of

the LTC3556, but ups the integration

one step further…

Need an Additional 5V Boost?

The LTC3586 Has It Covered

While the buck-boost regulators are

capable of regulating a 5V supply,

some applications require both. To

meet this need, the LTC3586 includes

not only a full complement of low voltage regulators, it also includes a high

continued on page 15

Linear Technology Magazine • September 2008

DESIGN FEATURES L

the range of 1.4V to 3.3V. If possible,

using a lower OV

can reduce power

DD

consumption. The termination scheme

is largely based on the receiver. When

choosing the OV

voltage, refer to the

DD

receiver’s data sheet to terminate the

CML lines properly.

CML uses true double termination.

Generally, LVDS is only terminated at

the receiver, which means that any

signal reflection back to the source

reflects back to the receiver with little

attenuation. This limits the data rate

and trace length that LVDS can drive.

The truly differential nature of CML

radiates less energy than LVDS and

CMOS signals, allowing devices to be

in closer proximity to antennas, mixers or other sensitive analog front end

systems. CML also has common mode

termination. This gives CML a better

common mode behavior than LVDS.

LVDS is only terminated differentially,

which does not reject any common

mode signal that may appear on the

transmission line—another limiting

factor in LVDS signaling.

CML Power Consumption

With a constant 16mA of bias current

and a voltage swing of 800mV differential, CML logic consumes a moderate

amount of power. For an equal data

rate, CML logic consumes less total

power than PECL and LVPECL. A

single CML driver uses more power

than a single LVDS driver, but only

marginally more that the three pairs

of LVDS drivers required for a typical

LVDS serial bus.

8B/10B Encoding Makes for

Simple Connection

The 8B/10B encoding process results

in an average DC offset of zero, allowing

the data to be routed through transformers or fiber channel transceivers

that can provide isolation between

the digital and analog realm. 8B/10B

encoding also does not require a framing signal or a data clock, whereas

both are required in traditional serial

communication. 8B/10B encoding

transmits data over a single pair of

data lines, whereas a typical serial

ADC requires three or more pairs,

and a typical parallel ADC can require

more than 16 pairs.

The complexity of decoding 8B/10B

lies in the receiver. Fortunately Xilinx,

Altera and Lattice have solutions to

receive data from the LTC2274 and

decode the 8B/10B data, simplifying

the collection of 8B/10B data. Other

8B/10B decoding solutions may be

available. The FPGA required to receive

data from the LTC2274 must be able

to receive high speed serial transmissions of 2GHz or more.

Conclusion

Without sacrificing resolution or

sample rate, the LTC2274 delivers full

16-bit performance at 105Msps over

a single pair of transmission lines,

greatly simplifying layout and saving

valuable board space. This mitigates

interaction with other circuitry in

software defined radio, base station or

industrial applications which involve

many channels of an ADC routed to

one FPGA.

L

LTC35xx, continued from page 6

power synchronous boost converter

(Figure 5).

The fully integrated boost in the

LTC3586 can regulate up to a 5V output with up to 800mA from a battery

voltage as low as 3V. The regulator has

built in output disconnect making it

well-suited for USB OTG supplies or

for powering motors in printer and

camera applications. The current

mode synchronous boost is internally

compensated and operates at a fixed

2.25MHz switching frequency. Pulseskipping at low loads achieves low

noise output for driving high power

audio circuits.

I2C, Programmable

Sequencing and Easy I/O

Despite the progress in new cutting

edge features and design, one old

problem does not go away: power

supply control. Power supplies require

startup and power down sequencing,

fault detection/reporting/handling

and voltage and operating mode adjustments. Getting it all right can be

a system control nightmare depending

on the complexity and limitations of

the power supply circuits.

The LTC35xx family provides very

simple and flexible control of all essential power supply functions. The

LTC3566 and LTC3586 employ dedicated I/O control pins for enabling,

disabling and changing DC/DC

operating modes. Voltages on these

parts are fixed and set with external resistor dividers. The LTC3555,

LTC3556 and LTC3567 accommodate

either I2C control or simple I/O pins

to control the supplies. The LTC3556

provides a three-state SEQ pin to allow the power up sequence of its three

DC/DC converters to be programmed

via pin-strapping. Those parts with

I2C V

maximum V

control power-up at their

OUT

(as determined by the

OUT

FB servo point and external dividers)

when enabled via simple I/O, and

can independently reduce V

OUT

by as

much as 50% in equal 16-step increments via I2C.

All DC/DC converters in all the

PMICs discussed here can survive

an indefinite output fault. The parts

all provide a RST output and all converters are actively pulled down in

shutdown to ensure proper power-up

sequencing. The LTC3586 contains an

additional fault handing feature that

automatically powers down all DC/DC

converters whenever a valid fault is

detected. In short, the entire family

is designed for simple, flexible and

trouble-free control and operation.

Conclusion

Linear Technology’s latest PMIC

products improve the performance

and simplify the design of a wide variety of portable power management

applications. Instead of kitchen sink

alternatives with large packages,

Linear Technology offers a number of

devices with various feature mixes in

small packages. These new PMICs are

simple to use, highly integrated and

high performance, allowing for shorter

design times, greater PCB flexibility,

and better power/thermal management than traditional solutions.

L

Linear Technology Magazine • September 2008

15

Loading...

Loading...