Versatile TFT LCD Bias Supply and White LED Driver

in a 4mm × 4mm QFN – Design Note 440

Eddy Wells

Introduction

The makers of h andheld medical, industrial and consumer

devices use a wide variety of high resolution, small to

medium sized color TFT LCD displays. The power supply

designers for these displays must contend with shrinking board area, tight schedules, and variations in display

®

type s and feature requirements. T he LTC

3524 simplifi es

the designer’s job by combining a versatile, easily programmed, TFT LCD bias supply and white LED backlight

driver in a low profi le 4mm × 4mm QFN package.

The LTC3524’s 2.5V to 6V input supply range is ideally

suited for portable devices powered from Li-Ion or

multiple alkaline or nickel cells. Both the LCD and LED

drivers operate at 1.5MHz, allowing the use of tiny, low

cost, inductors and capacitors.

The TFT bias portion of the circuit consists of a synchronous boost converter, adjustable between 3V and

6V, providing the main analog V

for the TFT. Low

OUT

current gate drive voltages (VH and VN) are generated

using integrated charge-pump circuits. These low noise

outputs are pr ogrammable to ±20V, allowing optimal bias

for multiple display types and makers. The TFT outputs

are sequenced at power-up and dischar ged at power-down

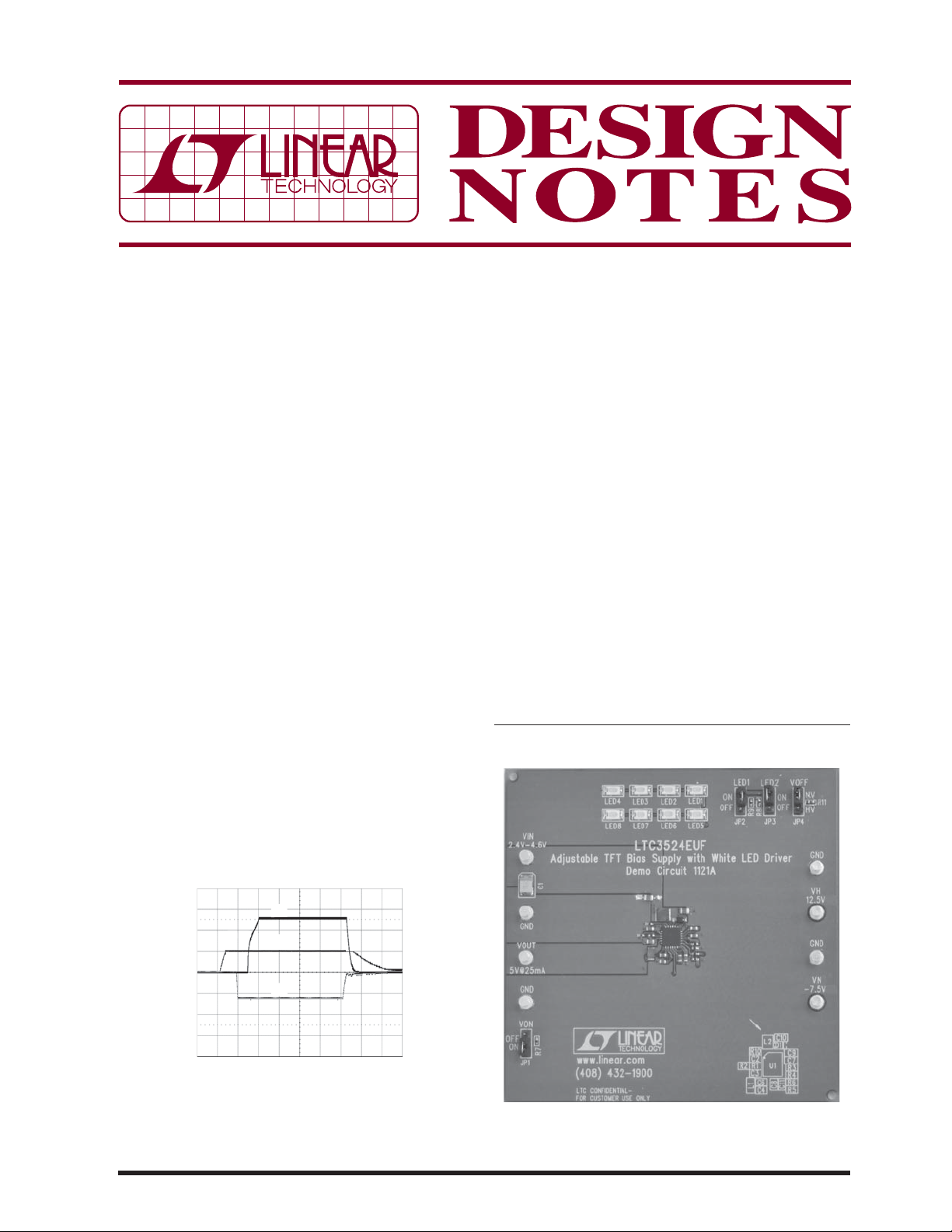

as shown in Figure 1.

A second nonsynchronous boost converter gener ates the

voltage required to regulate one or two LED strings at

up to 25mA each. LED current can be adjusted by either

analog or digital means, optimizing the TFT display for

varying ambient light conditions. Each string is independently enabled and can contain 1 to 5 LEDs in series.

Internal circuitry maintains equal current in the strings,

even when the forward voltage drops of the LEDs do not

match. Open LED protection is provided to prevent the

output from exceeding 24V.

3-Output TFT Supply with Digitally Dimmed LED

Backlight

A LTC3524-based TFT and backlight solution for a 4 to 6

inch LCD is shown in Figure 2. High frequency operation

of the power components and the QFN package shrinks

the total converter footprint to approximately 120mm

2

(single sided).

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

VH

V

OUT

5V/DIV

VN

5ms/DIV

Figure 1. LTC3524 TFT LCD Supply Sequencing

at Power-Up and Power-Down

05/08/440

DN4EW F01

DN4EW F02

Figure 2. LTC3524-Based LCD and White LED Supply

The circuit schematic is shown in Figure 3. The TFT bias

portion of the circuit provides a 5V, 25mA output for the

TFT drivers as well as 12.5V and –7.5V outputs with up

to 2mA for the gate bias. These voltages are programmed

using the FBVO, FBH, and FBN pins respectively.

As shown in Figure 1, these outputs are sequenced with

, V N , t h e n V H p o w e r e d , a s r e q u i r e d b y m o s t d i s p l a y s .

V

OUT

The output s are actively discharged w hen ELCD is brought

low, removing voltage from the display.

The white LED backlight for the Figure 3 circuit consists

of two strings with four series LEDs. The LEDs are

driven from the high side with the LTC3524, allowing the

strings to terminate at ground, reducing the number of

wires required to power the display. With R

PROG

= 100k,

each LED is regulated to 20mA. Maximum power for the

backlight is approximately 600mW, assuming a forward

voltage around 3.6V per element.

25mA

12.5V

2mA

+

Li-Ion

–

5V

10μF

10V

0.47μF

324k

0.47μF

220k

0.1μF

2.2μF

1M

2M

SW1

V

OUT

FBVO

VNIN

V2x

2

C

C2

VH

FBH

CH

+

–

+

0.1μF

Figure 3. Complete TFT and LED Solution

CH

IN

LTC3524

–

GND

3.3μH10μH

SW2V

VLED

LED2

LED1

PROG

ELED2

ELED1

ELCD

FBN

VN

+

C

N

0.1μF

10μF

100k for 20mA

470k

1M

DN4EW F03

V

IN

V

OUT

–7.5V

2mA

0.47μF

E

AND

LED1

E

LED2

I

BOOST

LED

INDUCTOR

V

LED2

LED

12.5V

12V

500μs/DIV

5V/DIV

200mA/DIV

10V/DIV

10V/DIV

DN4EW F04

Figure 4. Burst Dimming Waveforms

Effi ciency results for this design are given in Figure 5

with a 3.6V input. The LCD effi ciency curve shows the

performance of the synchronous boost converter with

at 5V and varying load current. This curve includes

V

OUT

the no load quiescen t current of the ch arge-pumps, which

are powered from V

OUT

.

Analog dimming of the LEDs can be implemented by

adjusting the current through the PROG pin. Effi ciency

for analog dimming is shown in Figure 5. Effi ciency with

PWM dimming would remain close to 78% over a wide

dimming range.

100

VIN = 3.6V

90

LCD

80

EFFICIENCY (%)

70

60

5

V

OUT

OR LED STRING CURRENT (mA)

LED

10

15

20

25

DN4EW F05

Dimming is achieved by changing the duty cycle of a 200Hz

power signal applied to the LED strings. The frequency is

high enough to prevent visually detectable fl ickering, but

low enough to allow a better than 100:1 dimming range.

Dimming is implemented by simply connecting a microprocessor controlled port to ELED1 and ELED2. Scope

waveforms at 50% duty cycle are shown in Figure 4.

Data Sheet Download

www.linear.com

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

●

(408) 432-1900

FAX: (408) 434-0507 ● www.linear.com

Figure 5. LCD Bias and LED Effi ciency

Conclusion

The LTC3524 shrinks and simplifi es the design of small

to medium sized TFT LCDs by combining the LCD supply

and LED driver in a single compact package. LCD bias

voltages and LED currents are programmable, making

it possible to simplify parts stock by using the LTC3524

for a wide variety of displays.

For applications help,

call (408) 432-1900, Ext. 3222

dn440f LT/TP 0508 246K • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2008

Loading...

Loading...