FEATURES

■

350mA Constant Current Output

■

2.8V to 4V Output Compliance

■

1- or 2-Cell NiMH or Alkaline Input

■

Synchronous Rectification: Up to 90% Efficiency

■

Fixed Frequency Operation: 1.3MHz

■

Low Quiescent Current: <1mA

■

Very Low Shutdown Current: <50µA

■

Open LED Output Limited to 4.7V

■

VIN Range: 1V to 3.2V

■

Dimming Control

■

Undervoltage Lockout to Protect Batteries

■

Low Profile (0.75mm) 3mm × 3mm Thermally

Enhanced 8-Lead DD and S8 Packages

U

APPLICATIO S

■

Portable Lighting

■

Rechargeable Flashlights

LTC3490

Single Cell 350mA

LED Driver

U

DESCRIPTIO

The LTC®3490 provides a constant current drive for 1W

LED applications. It is a high efficiency boost converter

that operates from 1 or 2 NiMH or alkaline cells and

generates 350mA of constant current with up to 4V of

compliance. It contains a 100mΩ NFET switch and a

130mΩ PFET synchronous rectifier. The fixed switching

frequency is internally set to 1.3MHz.

The LTC3490 limits the output voltage to 4.7V if the output

load is disconnected. It also features an analog dimming

capability that reduces the drive current proportional to

the CTRL/SHDN pin voltage. A low-battery logic output

signals when the battery has dropped below 1V/cell. An

undervoltage lockout circuit shuts down the LTC3490

when the battery voltage drops below 0.85V/cell. The

feedback loop is internally compensated to minimize component count.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation.

All other trademarks are the property of their respective owners.

TYPICAL APPLICATIO

Single Cell Minimum Component LED Driver

3.3µH

V

IN

1 NiMH OR

ALKALINE

CELL

ON/OFF

+

1M

LTC3490

CTRL/SHDN

CELLS

GND

LOBAT

SW

CAP

LED

U

350mA

4.7µF

HIGH

CURRENT

LED

3490 TA01

Efficiency vs V

100

I

= 350mA

OUT

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1

1.5

IN

2

VIN (V)

at V

LED

= 3.5V

2.5

3

3490 TA02

3490fa

1

LTC3490

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage (VIN) ................................... –0.3V to 6V

Input Voltages (CTRL/SHDN, CELLS) ......... – 0.3V to 6V

Output Voltages (CAP, LED, SW)................ – 0.3V to 6V

/

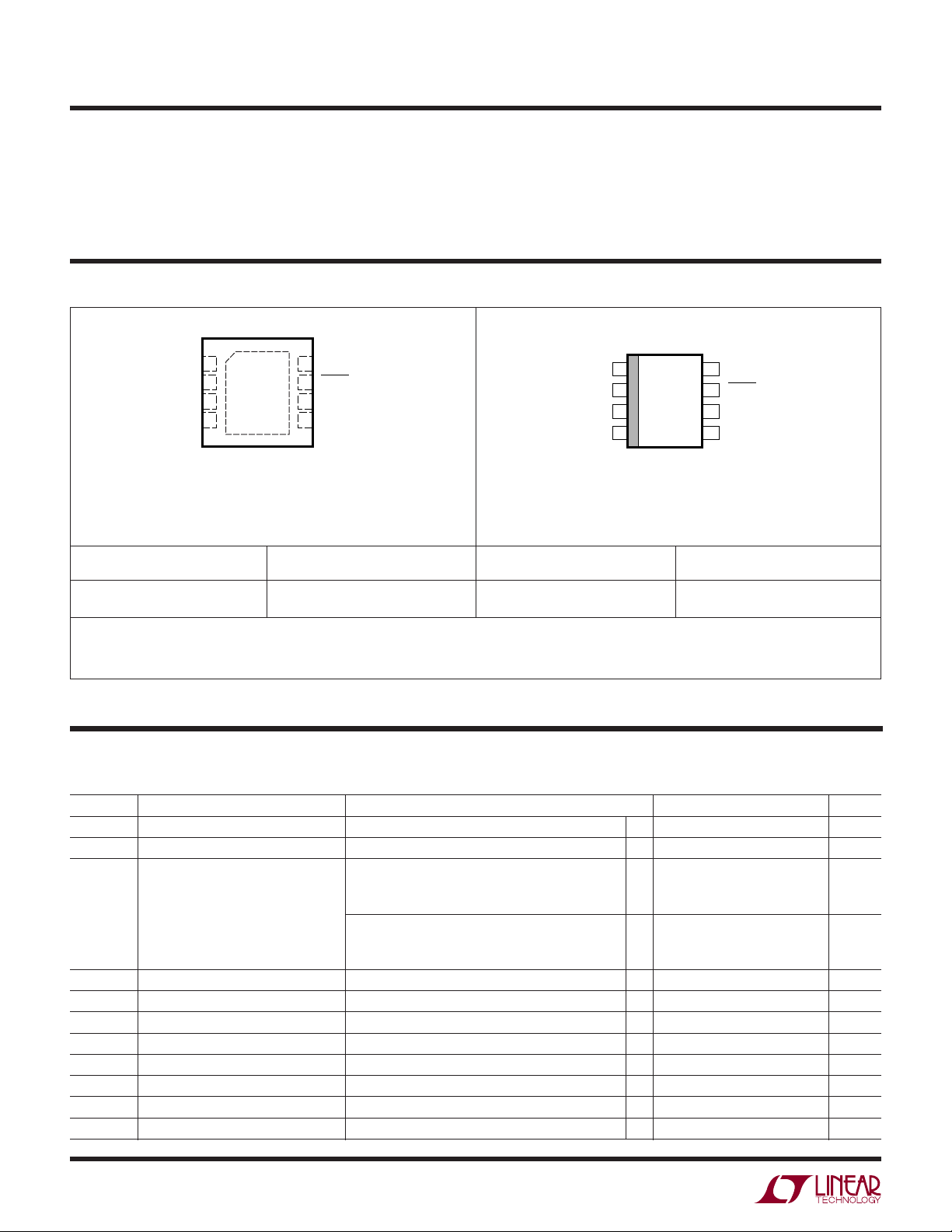

PACKAGE

O

RDER I FOR ATIO

1CELLS

V

2

IN

SW

3

GND

4

8-LEAD (3mm × 3mm) PLASTIC DFN

T

= 125°C, θJA = 43°C/ W (NOTE 4)

JMAX

EXPOSED PAD (PIN 9) IS GND

MUST BE SOLDERED TO PCB (NOTE 5)

ORDER PART NUMBER

LTC3490EDD

TOP VIEW

9

DD PACKAGE

WU

8

CTRL/SHDN

LOBAT

7

CAP

6

LED

5

DD PART MARKING

LBRQ

U

Operating Temperature Range (Note 2) .. –40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

Lead Temperature (Soldering, 10 sec, S8) .......... 300°C

TOP VIEW

CELLS

1

V

2

IN

SW

3

GND

4

S8 PACKAGE

8-LEAD PLASTIC SO

T

= 125°C, θJA = 150°C/ W (NOTE 4)

JMAX

CTRL/SHDN

8

LOBAT

7

CAP

6

LED

5

ORDER PART NUMBER S8 PART MARKING

LTC3490ES8

3490

Order Options

Lead Free: Add #PBF Lead Free Tape and Reel: Add #TRPBF

Lead Free Part Marking: http://www.linear.com/leadfree/

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

Tape and Reel: Add #TR

The ● denotes specifications which apply over the full operating

temperature range, otherwise specifications are TA = 25°C. VIN = 2.5V unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

IN

V

IN(START)

I

LED(MAX)

I

LED(SHDN)

V

LED

V

LED(OVL)

I

IN(SHDN)

I

IN(ACTIVE)

f

SW

I

L(NMOS)

R

ON(NMOS)

Input Supply Range 1 3.2 V

Minimum Start-Up Voltage (Note 3) 0.9 1 V

LED Drive Current V

LED Drive Current in Shutdown V

Output Compliance Voltage

Output Voltage Overvoltage Limit Open LED

Input Current, Shutdown V

Input Current, Active Excluding Load Power 20 30 mA

Switching Frequency

Leakage Current, NMOS Switch 0.1 µA

On-Resistance, NMOS Switch 0.1 Ω

CTRL/SHDN

25°C to 85°C 330 350 370 mA

–40°C to <25°C 310 350 385 mA

V

CTRL/SHDN

25°C to 85°C 337 350 363 mA

–40°C to <25°C 325 345 365 mA

CTRL/SHDN

CTRL/SHDN

= VIN, DD Package

= VIN, S8 Package

= 0V 0.1 1 µA

●

2.8 4 V

●

4.2 4.7 V

= 0V, Excluding Switch Leakage 20 50 µA

●

1.0 1.3 1.6 MHz

3490fa

2

LTC3490

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are T

A

The ● denotes specifications which apply over the full operating

= 25°C. VIN = 2.5V unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

L(PMOS)

R

ON(PMOS)

V

IH

Leakage Current, PMOS Switch 0.1 µA

On-Resistance, PMOS Switch 0.13 Ω

Input High (CELLS) VIN – 0.4 V

Input High (SHDN) VIN • 0.9 V

V

IL

Input Low (CELLS) 0.4 V

Input Low (SHDN) VIN • 0.2 V

I

IN

K

CTRL

R

ON(LOBAT)

V

IN(LOBAT1)

V

IN(LOBAT2)

V

IN(UVLO2)

Input Current (CTRL/SHDN, CELLS) 0.01 µA

Control Gain, I

LED/VCTRL

On-Resistance, LOBAT Output VIN < V

Input Voltage, Low Battery, 1 Cell V

Input Voltage, Low Battery, 2 Cells V

Input Voltage, Undervoltage Lockout, V

Scales Linearity with VIN, VIN = 1V 500 mA/V

CELLS

CELLS

CELLS

IN(LOBAT)

= 0V

= V

IN

= V

IN

●

●

0.8 1.12 V

●

1.8 2.24 V

●

1.4 1.8 V

300 Ω

2 Cells

V

IN(UVLO1)

Input Voltage, Undervoltage Lockout, V

CELLS

= 0 V

●

0.7 0.9 V

1 Cell

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: The LTC3490 is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C range are

assured by design, characterization and correlation with statistical process

controls.

Note 4: This device includes overtemperature protection intended to

protect the device during momentary overload conditions. The maximum

junction temperature may be exceeded when overtemperature protection

is active. Continuous operation above the specified maximum operating

junction temperature may result in device degradation or failure.

Note 5: The Exposed Pad of the DFN package must be soldered to a

PCB pad for optimum thermal conductivity. This pad must be connected

to ground.

Note 3: The LTC3490 input voltage may drop below the minimum start-up

voltage once the LED voltage has risen above 2.3V.

UW

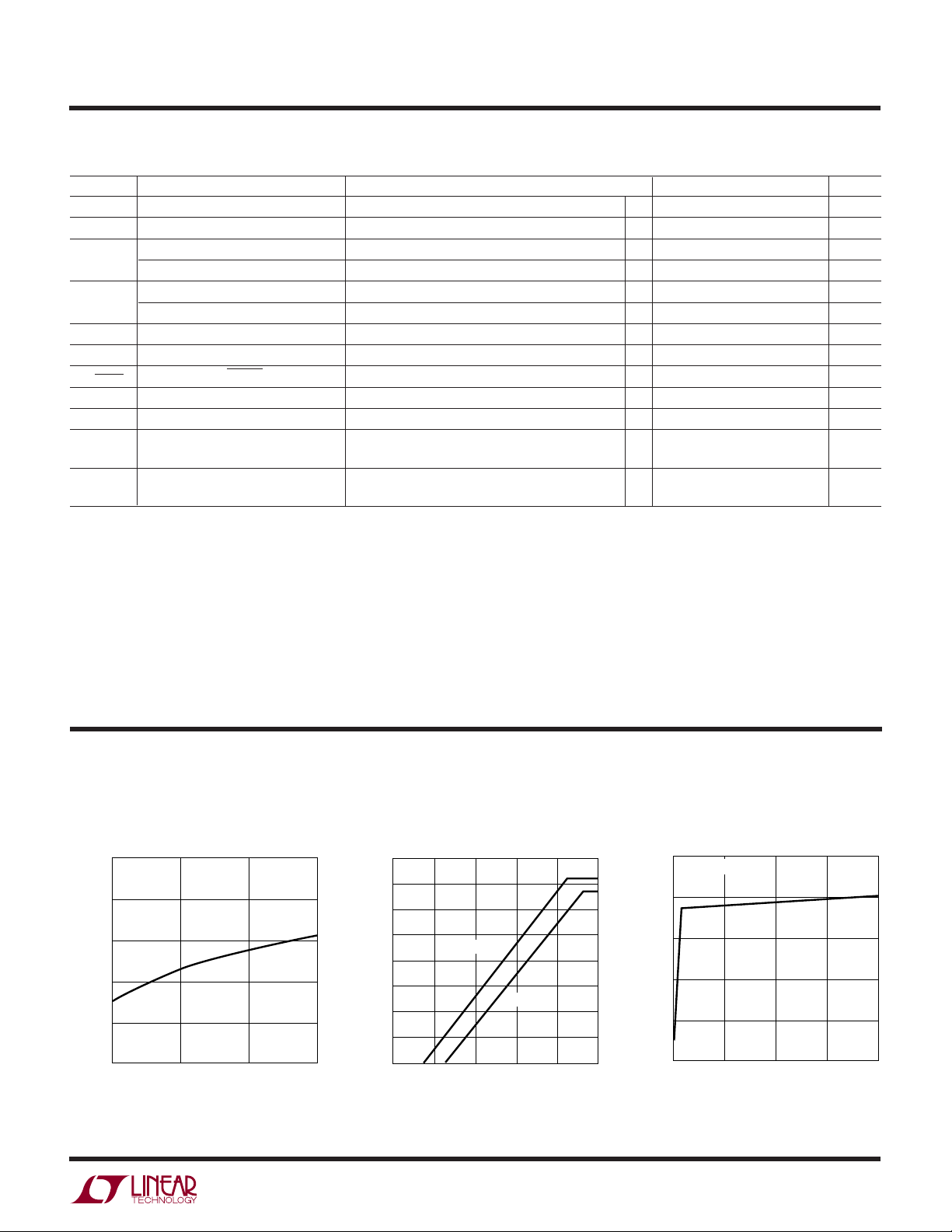

TYPICAL PERFOR A CE CHARACTERISTICS

Oscillator Frequency

vs V

400

350

300

250

(mA)

200

LED

I

150

100

I

LED

50

0

0

CTRL

MAXIMUM

MINIMUM

0.2 0.4 0.8

V

CTRL/VIN

0.6

(V)

vs Temperature

1.400

1.360

1.320

1.280

FREQUENCY (MHz)

1.240

1.200

–50

0

TEMPERATURE (°C)

50

100

3490 G01

3490 G02

I

vs V

LED

375

350

325

(mA)

LED

I

300

275

250

1

1

IN

V

= 3.5V

LED

1.5

2

VIN (V)

2.5

3

3490 G03

3490fa

3

LTC3490

I

LED

(mA)

0

0

EFFICIENCY (%)

10

30

40

50

100

70

100

200

3490 G05

20

80

90

60

300

400

VIN = 2.4V

VIN = 1.2V

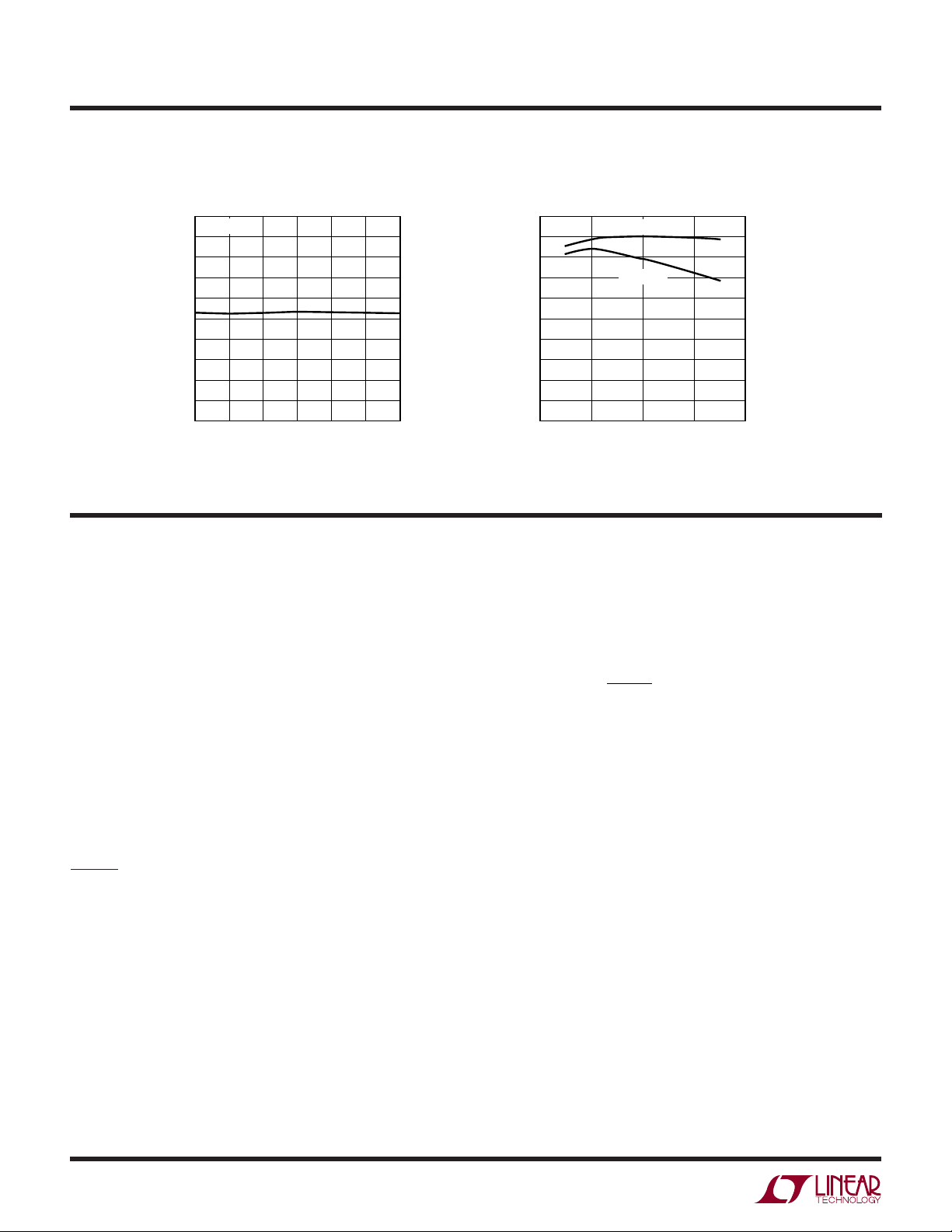

UW

TYPICAL PERFOR A CE CHARACTERISTICS

I

360

358

356

354

352

(mA)

350

LED

I

348

346

344

342

340

LED

VIN = 2.4V

2.8

vs V

3 3.2

LED

3.4 3.6 3.8

V

(V)

LED

4

3490 G04

Efficiency vs I

LED

PI FU CTIO S

U

UU

CELLS (Pin 1): A logic input to set the low-battery and

undervoltage shutdown thresholds. A logic low (tied to

GND) will set the thresholds for 1 cell. A logic high (tied to

VIN) will set the thresholds for 2 cells.

(Pin 2): Supply Voltage.

V

IN

SW (Pin 3): Switch Input. Connect this pin to an external

inductor from V

IN

.

GND (Pin 4): Circuit Ground.

LED (Pin 5): Output Drive Current to LED.

CAP (Pin 6): Filter Capacitor. A 4.7µF low ESR capacitor

should be tied to this pin.

LOBAT (Pin 7): Low active, open-drain logic output indicating a low-battery condition.

4

CTRL/SHDN (Pin 8): Analog Control Voltage and Shutdown. When V

• 0.2 < V

IN

< VIN • 0.9, the LED drive

CTRL

current varies according to the formula:

⎛

I

LED

When V

500 0 2•–.

=

CTRL

V

⎜

⎝

> VIN • 0.9, the LED drive current is clamped

at 350mA. When V

CTRL

V

IN

CTRL

⎞

mA

⎟

⎠

< VIN • 0.2, then the part is in low

power shutdown.

Exposed Pad (Pin 9, DD Package): Ground. This pin must

be soldered to the PCB to provide both electrical contact

to ground and good thermal contact to the PCB.

3490fa

LTC3490

U

U

W

FU CTIO AL DIAGRA

–

V

IN

2

+

GATE

CONTROL

DRIVERS

PWM

LOGIC

START-UP

AND

LIMIT

P BODY

CONTROL

OSCILLATOR

3

SW

SENSE

OVERVOLTAGE

DETECT

AMP

CAP

6

0.1Ω

19.2Ω

+

–

250k

LED

5

–

+

V

/2

REF

40k

8

1

CTRL/

SHDN

CELLS

DIMMING

–

AMP

+

I

REF

GND

4

BATTERY

MONITOR

SHUTDOWN

LOBAT

7

3490 FD

3490fa

5

LTC3490

OPERATIO

U

The LTC3490 is a high efficiency, constant current source

for 1W high intensity white LEDs. These high intensity

LEDs require a fixed current of 350mA with a voltage

compliance of 2.8V to 4V.

The LTC3490 operates with 1 or 2 NiMH or alkaline cells.

It functions as a boost converter with a current sense resistor providing the control feedback. If the battery voltage

is greater than the required LED compliance, it will cycle

off periodically to maintain the correct average current. It

features a low voltage start-up circuit that will start with an

input voltage of only 1V. Once the drive voltage exceeds

2.3V, the circuit operates from the drive voltage.

All of the loop compensation is internal; only the main filter

capacitor is needed for stable operation.

Dimming Function

During normal operation with the CTRL/SHDN pin connected to V

350mA. The drive current can be reduced by changing the

voltage on the CTRL/SHDN pin.

For VIN • 0.2 < V

proportional to V

ometer from V

, the LED drive current is controlled at

IN

< VIN • 0.9, the LED current is

CTRL

CTRL/VIN

to control the current without sensitivity

IN

. This allows a simple potenti-

to the battery voltage. The LED drive current is given by the

formula:

⎛

V

500 0 2•–.

I

=

LED

When V

at 350mA.

Open-Circuit Protection

Since this is a boost converter attempting to drive a current into the load, an open or high impedance load will cause

the regulator loop to increase the output voltage in an effort to achieve regulation. To protect the device, maximum

output voltage is limited to 4.7V under all conditions.

Undervoltage Sense and Protection

The undervoltage lockout prevents excessive inductor

peak current and protects the batteries from deep discharging which can damage them. The low-battery indicator allows the end user to be made aware that the batteries

are nearing the end of their useful life.

CTRL

CTRL

⎜

⎝

V

IN

> VIN • 0.9, the LED drive current is clamped

⎞

⎟

⎠

mA

6

3490fa

WUUU

APPLICATIO S I FOR ATIO

LTC3490

The LTC3490 requires only four external components to

operate: an inductor, an output capacitor, a switch and a

pull-down resistor. The inductor is nominally set at 3.3µH

and the capacitor at 4.7µF. Optional components include

an input capacitor and dimming resistors.

COMPONENT SELECTION

Inductor Selection

The high frequency operation of the LTC3490 allows the

use of small surface mount inductors. The minimum

inductance value is proportional to the operating frequency and is limited by the following constraints:

3

LfH

≥

and

VV V

IN MIN OUT MAX IN MIN

≥

L

•–

() ( ) ()

()

••

f Ripple V

OUT MAX

()

H

where:

f = Operating Frequency (Hz)

Ripple = Inductor Current Ripple (A)

V

V

= Minimum Input Voltage (V)

IN(MIN)

OUT(MAX)

= Maximum Output Voltage (V)

The inductor current ripple is typically set to 20% to 40%

of the inductor current.

The peak inductor current is given by:

where:

= Input Voltage (V)

V

IN

= Output Voltage (V)

V

OUT

I

= LED Drive Current (A)

OUT

= Input Current = V

I

IN

= R

R

P

R

= R

N

of the PFET Switch (Ω)

DSON

of the NFET Switch (Ω)

DSON

OUT/VIN

• I

OUT

(A)

For high efficiency, choose an inductor with a high frequency core material, such as ferrite, to reduce core

losses. The inductor should have low ESR (equivalent

2

series resistance) to reduce the I

R losses and must be

able to handle the peak inductor current at full load without

saturating. In single cell applications, the inductor ESR

must be below 25mΩ to keep the efficiency up and

maintain output current regulation. Dual cell applications

can tolerate significantly higher ESR (up to 75mΩ) with

minimal efficiency degradation. Molded chokes or chip

inductors usually do not have enough core to support the

peak inductor currents in the 1A to 2A region. If radiated

noise is an issue, use a toroid, pot core or shielded bobbin

inductor to minimize radiated noise. See Table 1 for a list

of suggested inductors. Look closely at the manufacturers

data sheets; they specify saturation current differently.

Table 1. Inductor Information

INDUCTOR PART NUMBER ESR (mΩ) SATURATION CURRENT (A)

TOKO A918CY-3R3M 47 1.97

TYCO DN4835-3R3M 58 2.15

TDK SLF7045T-3R3M2R5 20 2.5

II

=

LPK OUT

()

+

VIRRI

+

OUT OUT P N IN

VV V

()

IN OUT IN

•••2

LfV

•–•

–•

VRI

IN N IN

–

OUT

Output Capacitor Selection

The output capacitor value and equivalent series resistance (ESR) are the primary factors in the output ripple.

The output ripple is not a direct concern for LED drive as

the LED will operate at the average current value. However

the peak pulsed forward current rating of the LED must not

be exceeded to avoid damaging the LED.

3490fa

7

LTC3490

WUUU

APPLICATIO S I FOR ATIO

The output ripple voltage has two primary components.

The first is due to the value of the capacitor and is given by:

IV

•

VR

CAP

LPK IN

=

CV f

••

OUT

The second is due to the capacitor ESR:

VR

= I

LPK

• R

ESR

ESR

The LED current ripple and peak pulsed current are calculated by:

IR

LED

II

PPFC OUT

VR VR

=

RR

=+

•

CAP ESR

IR

+

LE

DD

SENSE LED

2

where:

R

R

= Internal Sense Resistor = 0.1Ω

SENSE

= Dynamic Impedance of the LED

LED

Component values will be calculated for 1 or 2 NiMH cells

and assumes the end-of-charge voltage to be 0.9V per cell.

The operating frequency is assumed to be 1MHz, the

worst-case low frequency. The allowed inductor ripple

current is 0.31A. Table 3 shows a summary of the key

parameters.

Table 3. Summary of Key Parameters

PARAMETER 1-CELL 2-CELL UNITS

L

MIN

Choose L 3.3 3.3 µH

I

IN

I

LPK

Choose C 4.7 4.7 µF

Cap ESR 5 5 mΩ

VR

CAP

VR

ESR

IR

LED

I

PPFC

2.2 3.2 µH

1.56 0.78 A

1.93 0.96 A

0.09 0.09 V

0.01 0.005 V

0.10 0.09 A

0.40 0.39 A

where:

Low ESR capacitors should be used to minimize output

ripple. Ceramic X5R or X7R type capacitors are recommended. See Table 2 for a list of component suppliers.

Table 2. Capacitor Information

CAPACITOR PART NUMBER DESCRIPTION

TDK C2012X5R0J475K 4.7µF, 6.3V, X5R in 0805

AVX 1210ZC475MAT 4.7µF, 10V, X7R in 1210

Taiyo Yuden CELMK316BJ475ML 4.7µF, 10V, X7R in 1206

Input Capacitor Selection

Most battery-powered applications do not need an input

capacitor. In supply-powered applications or battery applications with long leads to the battery, a low ESR 3.3µF

capacitor reduces switching noise and peak currents.

Design Example

The example will use a Lumileds DS25 white LED. The key

specifications are:

V

(at IF= 350mA) = 3.4 ±0.6V

F

I

is the peak inductor current

LPK

VR

is the ripple voltage due to the output capacitor

CAP

value

is the ripple voltage due to the output capacitor

VR

ESR

ESR

is the LED current ripple

IR

LED

I

is the LED peak pulsed forward current

PPFC

PC Board Layout Checklist

Keep the inductor and output capacitor as close to the IC

as possible. Make traces as short and wide as is feasible.

Parasitic resistance and inductance reduce efficiency and

increase ripple.

Keep resistance in the battery connections as low as

possible. In single cell applications, only 0.1Ω in the

battery connections will have a dramatic effect in efficiency and battery life. I2R losses can exceed 100mW and

the converter operates lower on the efficiency curve.

R

= 1Ω

LED

Peak Pulsed Forward Current = 0.5A

8

3490fa

WUUU

APPLICATIO S I FOR ATIO

LTC3490

Red Luxeon LEDs

The red, red-orange and amber Luxeon LEDs have a lower

forward voltage than the white, blue and green LEDs. Since

the LTC3490 internal circuitry is powered from the output,

it requires a minimum LED voltage of 2.5V for reliable

operation. The minimum forward voltage on the red LEDs

U

TYPICAL APPLICATIO S

2-Cell Adjustable Amplitude LED Driver

3.3µH

V

IN

LTC3490

CTRL/SHDN

CELLS

GND

2 NiMH OR

ALKALINE

CELLS

ON/OFF

+

+

1M

is only 2.31V. The LTC3490 requires an additional 190mV

for proper operation. In non-dimming applications, this can

be accomplished with a 0.6Ω resistor in series with the

LED. The resistor voltage drops too low in dimming applications, so a Schottky diode is recommended to keep

sufficient voltage at the output at lower currents.

SW

CAP

LED

LOBAT

4.7µF

LUMILEDS

LUXEON

LXHL-BW02

1 NiMH OR

ALKALINE

CELL

3490 TA03

Soft Turn-Off LED Driver

3.3µH

LTC3490

GND

SW

CAP

LED

LOBAT

350mA

4.7µF

LUMILEDS

LUXEON

LXHL-BW02

3490 TA04

V

IN

ON/OFF

+

CTRL/SHDN

1µF

1M

CELLS

3490fa

9

LTC3490

U

TYPICAL APPLICATIO S

Luxeon Red LED Driver Without Dimming

3.3µH

1 NiMH OR

ALKALINE

CELL

1 NiMH OR

ALKALINE

CELL

ON/OFF

V

IN

+

CTRL/SHDN

1M

CELLS

LTC3490

GND

SW

CAP

LED

LOBAT

0.6Ω

4.7µF

LUMILEDS

LUXEON

LXHL-BD03

3490 TA06

Luxeon Red LED Driver with Dimming

3.3µH

ON/OFF

V

IN

+

1M

CTRL/SHDN

CELLS

LTC3490

GND

SW

CAP

LED

LOBAT

4.7µF

MBRM120E

LUMILEDS

LUXEON

LXHL-BD03

3490 TA07

10

Efficiency vs VIN with Red LED

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1

RESISTOR

1.5

2

VIN (V)

SCHOTTKY

2.5

3

3490 G06

3490fa

PACKAGE DESCRIPTIO

U

DD Package

8-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1698)

0.675 ±0.05

R = 0.115

TYP

LTC3490

0.38 ± 0.10

85

3.5 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

2.38 ±0.05

(2 SIDES)

0.50

BSC

8-Lead Plastic Small Outline (Narrow .150 Inch)

.050 BSC

PIN 1

TOP MARK

(NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-1)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON TOP AND BOTTOM OF PACKAGE

S8 Package

(Reference LTC DWG # 05-08-1610)

.045 ±.005

8

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

0.00 – 0.05

.189 – .197

(4.801 – 5.004)

NOTE 3

7

6

1.65 ± 0.10

(2 SIDES)

5

0.25 ± 0.05

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

14

0.50 BSC

(DD8) DFN 1203

.245

MIN

.030

±

.005

TYP

RECOMMENDED SOLDER PAD LAYOUT

.010 – .020

(0.254 – 0.508)

.008 – .010

(0.203 – 0.254)

NOTE:

1. DIMENSIONS IN

2. DRAWING NOT TO SCALE

3. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .006" (0.15mm)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

× 45°

.016 – .050

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.160

±

.005

0°– 8° TYP

.228 – .244

(5.791 – 6.197)

.053 – .069

(1.346 – 1.752)

.014 – .019

(0.355 – 0.483)

TYP

.150 – .157

(3.810 – 3.988)

NOTE 3

1

3

2

4

.004 – .010

(0.101 – 0.254)

.050

(1.270)

BSC

SO8 0303

3490fa

11

LTC3490

TYPICAL APPLICATIO

U

LED Driver Drops to 20% Amplitude on Low-Battery Detect

3.3µH

1 NiMH OR

ALKALINE

CELL

ON/OFF

1M

1M

432k

+

V

IN

CTRL/SHDN

CELLS

LTC3490

GND

SW

CAP

350mA/70mA

LED

LOBAT

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT®1618 Constant Current, Constant Voltage 1.4MHz, VIN: 1.6V to 18V, V

High Efficiency Boost Regulator Packages

LT1932 Constant Current, 1.2MHz, High Efficiency White VIN: 1V to 10V, V

LED Boost Regulator

LT1937 Constant Current, 1.2MHz, High Efficiency White VIN: 2.5V to 10V, V

LED Boost Regulator Packages

LTC3205 High Efficiency, Multi-Display LED Controller VIN: 2.8V to 4.5V, V

LTC3216 1A Low Noise, High Current LED Charge Pump with VIN: 2.9V to 4.4V, V

Independent Flash/Torch Current Control

LTC3402 2A, 3MHz Micropower Synchronous Boost Converter VIN: 0.85V to 5V, V

MS/EDD Packages

LTC3453 500mA Synchronous Buck-Boost High Current LED VIN: 2.7V to 5.5V, V

Driver in QFN

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Efficiency VIN: 2.7V to 16V, V

White LED Boost Regulator with Integrated Schottky

Diode

LT3466 Dual Constant Current, 2MHz, High Efficiency VIN: 2.7V to 24V, V

White LED Boost Regulator with Integrated Schottky

Diode

LT3479 3A, Full-Featured DC/DC Converter with Soft-Start VIN: 2.5V to 24V, V

and Inrush Current Protection Packages

ThinSOT is a trademark of Linear Technology Corporation.

OUT(MAX)

4.7µF

LUMILEDS

LUXEON

LXHL-BWO2

3490 TA05

= 34V, IQ = 1.8mA, ISD < 1µA, MS/EDD

OUT(MAX)

= 34V, IQ = 1.2mA, ISD < 1µA, ThinSOT Packages

= 34V, IQ = 1.9mA, ISD < 1µA, ThinSOTTM/SC70

OUT(MAX)

= 6V, IQ = 50µA, ISD < 1µA, QFN24 Package

OUT(MAX)

= 5.5V, IQ = 300µA, ISD < 2.5µA, DFN Package

OUT(MAX)

= 5V, IQ = < 38µA, ISD < 1µA,

OUT(MAX)

= 5.5V, IQ = 0.6mA, ISD < 6µA, QFN Package

OUT(MAX)

= 34V, IQ = 1.9mA, ISD < 1µA, ThinSOT Package

OUT(MAX)

= 40V, IQ = 5mA, ISD < 16µA, DFN Package

OUT(MAX)

= 40V, IQ = 6.5mA, ISD < 1µA, DFN/TSSOP

OUT(MAX)

12

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3490fa

LT 0606 REV A • PRINTED IN THE USA

© LINEAR TECHNOLOGY CORPORATION 2005

Loading...

Loading...