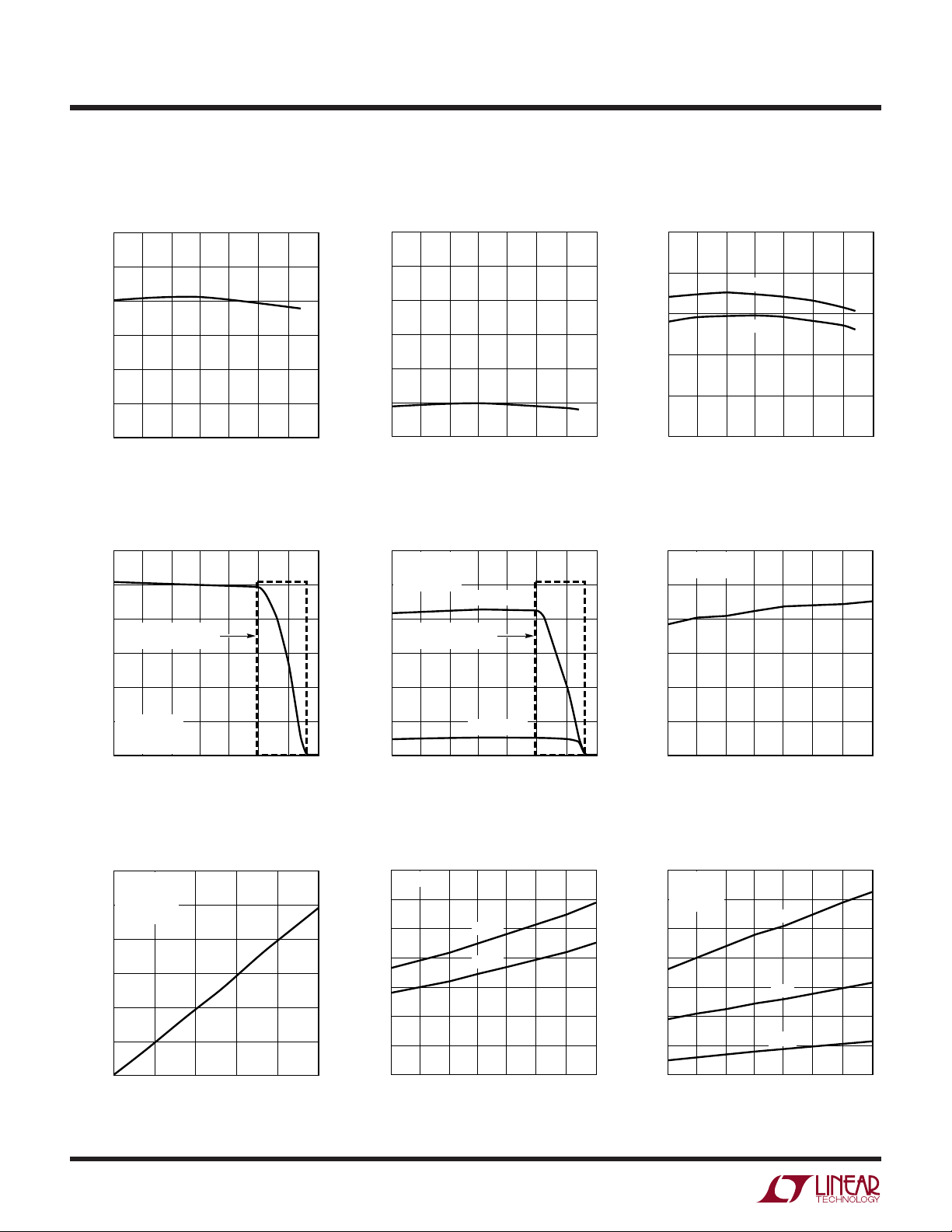

LOAD CURRENT (mA)

60

EFFICIENCY (%)

80

75

70

65

85

90

95

100

3455 TA01b

V

BAT

= 3.6V

SWITCHER 1

V

OUT1

= 1.8V

SWITCHER 2

V

OUT2

= 3.3V

1 10 100 1000

查询LTC3411供应商

LTC3455

Dual DC/DC Converter

with USB Power Manager

FEATURES

■

Seamless Transition between Input Power Sources:

Li-Ion Battery, USB, and 5V Wall Adapter

■

Accurate USB Current Limiting (500mA/100mA)

■

Two High Efficiency DC/DC Converters: Up to 96%

■

Thermal Regulation Maximizes Battery Charge

Rate without Risk of Overheating*

■

Full-Featured Li-Ion Battery Charger

■

Hot Swap™ Output for SDIO and Memory Cards

■

Pin-Selectable Burst Mode® Operation

■

Output Disconnect: All Outputs Discharged to

Ground During Shutdown

■

Available in a 4mm × 4mm × 0.8mm 24-Pin

QFN Package

U

APPLICATIO S

■

Handheld Computers

■

Digital Cameras

■

MP3 Players

and Li-Ion Battery Charger

U

DESCRIPTIO

The LTC®3455 is a complete power management solution

for a variety of portable applications. The device contains

two synchronous step-down DC/DC converters, a USB

power controller, a full-featured Li-Ion battery charger, a

Hot Swap output, a low-battery indicator, and numerous

internal protection features. The LTC3455 provides a

small, simple solution for obtaining power from three

different power sources: a single-cell Li-Ion battery, a USB

port, and a wall adapter. Current drawn from the USB bus

is accurately limited under all conditions. Whenever a USB

or a wall adapter is present, the battery charger is enabled

and all internal power for the device is drawn from the

appropriate external power source. All outputs are discharged to ground during shutdown to provide complete

output disconnect. The device is available in a

4mm × 4mm 24-pin exposed-pad QFN package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Hot Swap is a trademark of Linear Technology Corporation.

Burst Mode is a registered trademark of Linear Technology Corporation.

*U.S. Patent 6,522,118

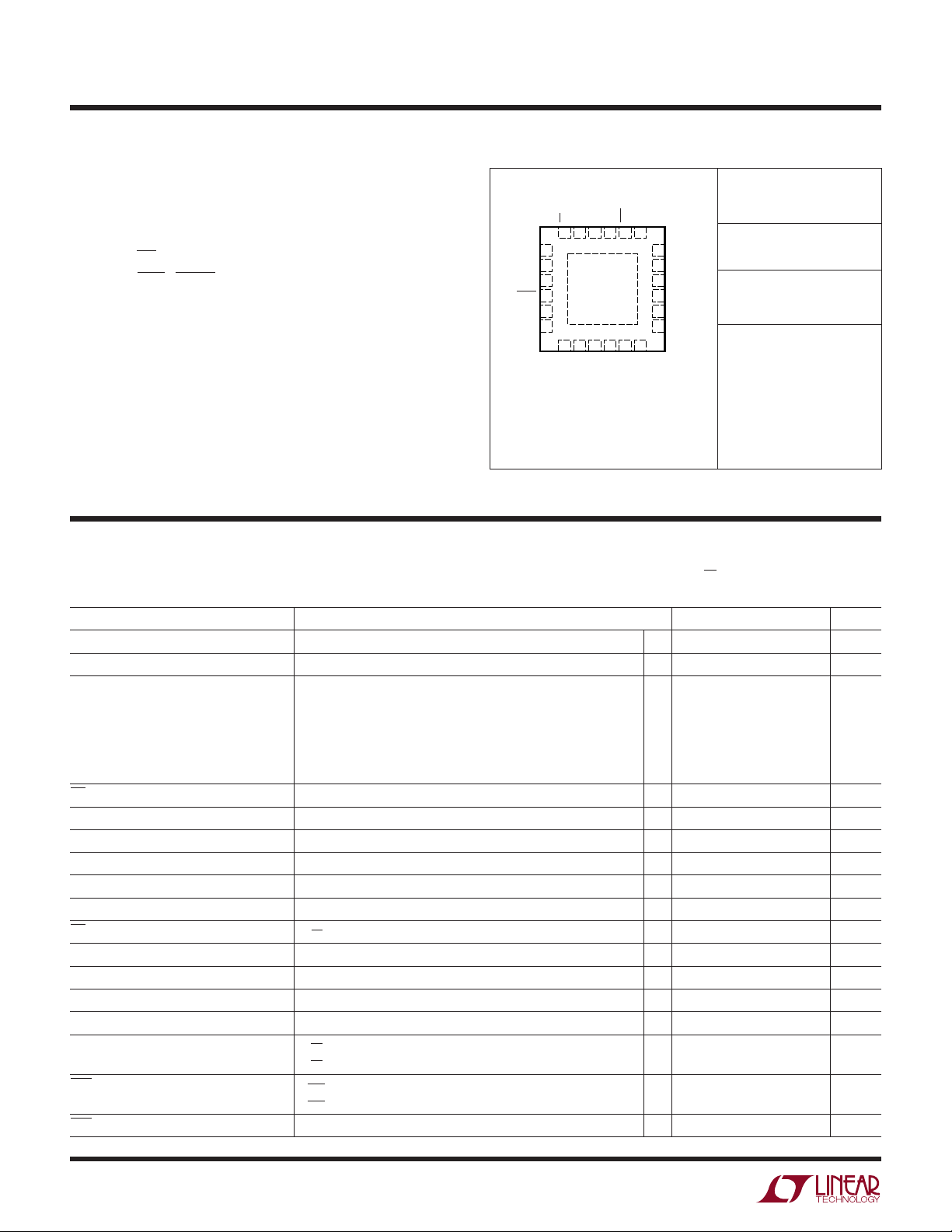

TYPICAL APPLICATIO

USB 5V

1Ω

4.7µF

WALL 5V

1Ω

1µF

SINGLE

CELL Li-ION

3.3V TO 4.2V

USB

CONTROLLER

10µF

3.32k

1.24k

1.8V

+

LBO

V

BAT

2.49M

806k

0.1µF

4.7µF

1k

2.49k

1M

10

11

17

16

8

6

5

4

3

2

9

USB

SUSPEND

USBHP

V

MAX

CHRG

WALLFB

TIMER

PROG

V

BAT

AO

AI

LTC3455

U

MODE

HSON

ON2

PWRON

RST

PBSTAT

HSO

HSI

SW2

FB2

SW1

FB1

GND

3455 TA01a

21

15

19

22

20

23

1M

24

ON

14

13

4.7µH

12

10pF

18

4.7µH

7

10pF

1

25

1M

ON/OFF

µC

1.8V

3.3V, HS

1µF

249k

80.6k

100k

80.6k

3.3V

0.5A

10µF

1.8V

0.4A

10µF

Efficiency

3455f

1

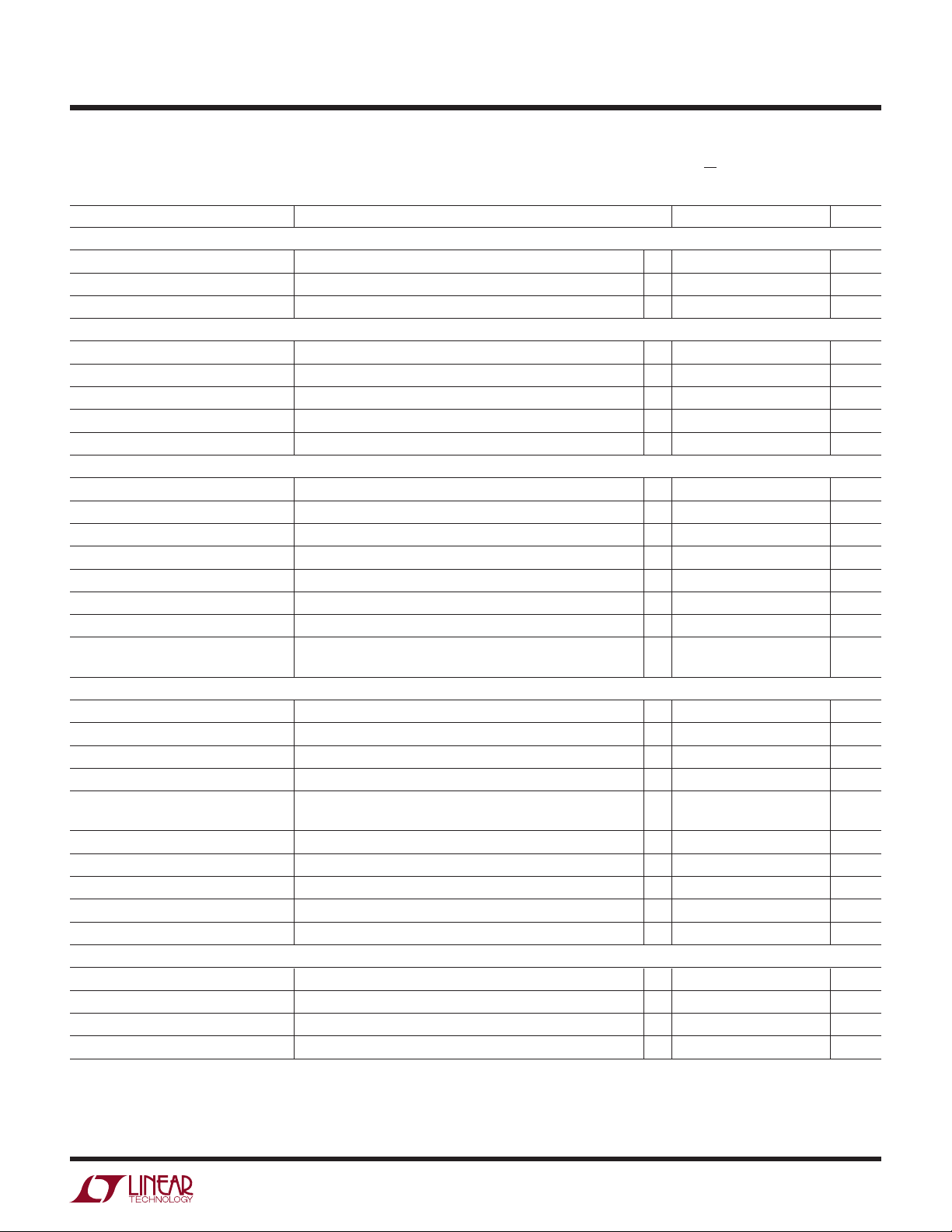

LTC3455

242523 22 21 20 19

7 8 9

TOP VIEW

UF PACKAGE

24-LEAD (4mm × 4mm) PLASTIC QFN

10 11 12

6

5

4

3

2

1

13

14

15

16

17

18

FB1

PROG

TIMER

CHRG

USBHP

SUSPEND

FB2

AO

AI

HSON

HSO

HSI

ON

PBSTAT

PWRON

MODE

RST

ON2

SW1

USB

V

BAT

V

MAX

WALLFB

SW2

ABSOLUTE AXI U RATI GS

(Note 1)

V

BAT

SW1, SW2 Voltages ....................–0.3V to (V

TIMER Voltage.............................–0.3V to (V

PWRON, ON, ON2, HSON Voltages .............–0.3V to 6V

PBSTAT, RST, CHRG, AO Voltages ..............– 0.3V to 6V

HSI, HSO Voltages.......................................–0.3V to 6V

MODE, USBHP, SUSPEND Voltages ............–0.3V to 6V

WALLFB, AI, PROG Voltages .......................–0.3V to 2V

FB1, FB2 Voltages........................................–0.3V to 2V

Junction Temperature........................................... 125°C

Operating Temperature Range (Note 2) .. –40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

V

USB

PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery Undervoltage Lockout Voltage V

Battery Undervoltage Lockout Hysteresis 450 mV

V

BAT

Burst Mode,

PWM Mode, Battery Powered V

USB Powered V

Wall Powered V

Shutdown V

ON Pin Threshold 0.8 1.0 V

PWRON Pin Threshold 0.8 1.0 V

ON2 Pin Threshold 0.8 1.0 V

MODE Pin Threshold 0.8 1.0 V

WALLFB Pin Threshold Voltage WALLFB Rising ● 1.20 1.23 1.26 V

WALLFB Pin Hysteresis 60 mV

ON Pin Pullup Current VON = 1V 2.5 µA

PWRON Pin Pulldown Current V

ON2 Pin Pulldown Current V

MODE Pin Pullup Current V

WALLFB Pin Input Bias Current V

PBSTAT Pin Low Voltage VON = 0V, I

RST Pin Low Voltage I

RST Pulse Duration After FB1 and FB2 in Regulation 200 ms

2

, V

, USB Voltages ...........................–0.3V to 6V

MAX

= 0V, V

Pin Quiescent Current (Note 3)

= 0V unless otherwise noted.

WALLFB

Battery Powered V

WW

W

U

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

+0.3V)

MAX

+0.3V)

MAX

T

= 125°C, θJA = 36°C/W, θJC = 2.5°C/W

JMAX

EXPOSED PAD (PIN 25) IS GND

MUST BE SOLDERED TO PCB

Consult LTC Marketing for parts specified with wider operating temperature ranges.

The ● denotes the specifications which apply over the full operating

= 3.6V, V

BAT

Rising 2.9 3.0 3.2 V

BAT

= V

ON2

= 1V, V

ON2

= 5V, Charger Off 10 20 µA

USB

WALL

PWRON

PWRON

= 1V 2.5 µA

ON2

MODE

WALLFB

= 0V, I

V

ON

= 100µA 0.02 0.10 V

RST

= 1mA 0.20 0.35 V

I

RST

= 1V, Not Switching 110 160 µA

MODE

= 1.5V, V

= 0V, V

= 0V, Not Switching 500 800 µA

MODE

= 4.5V, Charger Off 10 20 µA

MAX

= 0V 2 4 µA

MAX

= 1V 2.5 µA

= 1V 2.5 µA

= 1.35V ● ±1 ±30 nA

= 100µA 0.02 0.10 V

PBSTAT

= 1mA 0.20 0.35 V

PBSTAT

= 3.6V, V

MAX

PWRON

= 2V, V

is open, V

ON

NUMBER

LTC3455EUF

UF PART

MARKING

3455

ON2

= 0V,

3455f

LTC3455

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

V

USB

= 0V, V

= 0V unless otherwise noted.

WALLFB

The ● denotes the specifications which apply over the full operating

= 3.6V, V

BAT

= 3.6V, V

MAX

PWRON

= 2V, V

is open, V

ON

ON2

= 0V,

PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery-V

V

MAX

V

MAX

V

MAX

PMOS

MAX

PMOS Switch On-Resistance 0.15 Ω

Switch Current Limit 2.5 4.0 A

Switch Current Limit at Startup With V

MAX

Rising, V

MAX

= 3V, V

= 3.6V 0.4 0.9 A

BAT

Gain Block

AI Pin Threshold Voltage ● 0.784 0.805 0.826 V

AI Pin/FB2 Pin Voltage Difference V

FB2

– V

AI

–8 0 8 mV

AI Pin Input Bias Current VAI = 0.85V ● ±1 ±25 nA

AO Pin Sink Current VAI = 0.6V, VAO = 1.5V 1.0 1.8 2.5 mA

AO Pin Voltage VAI = 0.6V, IAO = 1mA 0.8 1.2 V

Switching Regulators

FB1, FB2 Voltage ● 0.784 0.805 0.826 V

FB1, FB2 Voltage Line Regulation V

FB1, FB2 Voltage Burst Mode Hysteresis V

FB1, FB2 Pin Input Bias Current V

= 3V to 5V 0.01 %/V

MAX

= 2V 8 mV

MODE

= V

FB1

= 0.85V ● ±1 ±25 nA

FB2

Switching Frequency Both Switchers 1.2 1.5 1.8 MHz

PMOS Switch On-Resistance Both Switchers 0.35 Ω

NMOS Switch On-Resistance Both Switchers 0.45 Ω

PMOS Switch Current Limit Switcher 1 450 600 850 mA

Switcher 2 700 900 1200 mA

USB Power Manager

USB Undervoltage Lockout Voltage From Low to High 3.75 3.90 4.10 V

USB Undervoltage Lockout Hysteresis 150 mV

USB Minimum Voltage to Charge Battery 4.0 V

USB PMOS Switch On-Resistance V

USB Current Limit V

USB Suspend Mode Bias Current V

= 5V 0.5 Ω

USB

V

USB

USB

USB

= 5V, V

= 5V, V

= 5V, V

= 2V ● 440 475 500 mA

USBHP

= 0V ● 60 80 100 mA

USBHP

= 2V 4 20 µA

SUSPEND

SUSPEND Pin Threshold 0.8 1.1 V

USBHP Pin Threshold 0.8 1.1 V

SUSPEND Pin Pulldown Current V

USBHP Pin Pulldown Current V

= 0.5V 2.5 µA

SUSPEND

= 0.5V 2.5 µA

USBHP

Hot Swap Output

Hot Swap PMOS Switch On-Resistance V

Hot Swap PMOS Switch Current Limit V

= 3.3V 0.9 Ω

HSI

= 3.3V, V

HSI

= 2.5V 120 160 mA

HSO

HSON Pin Threshold 0.8 1.1 V

HSON Pin Pulldown Current 2.5 µA

3455f

3

LTC3455

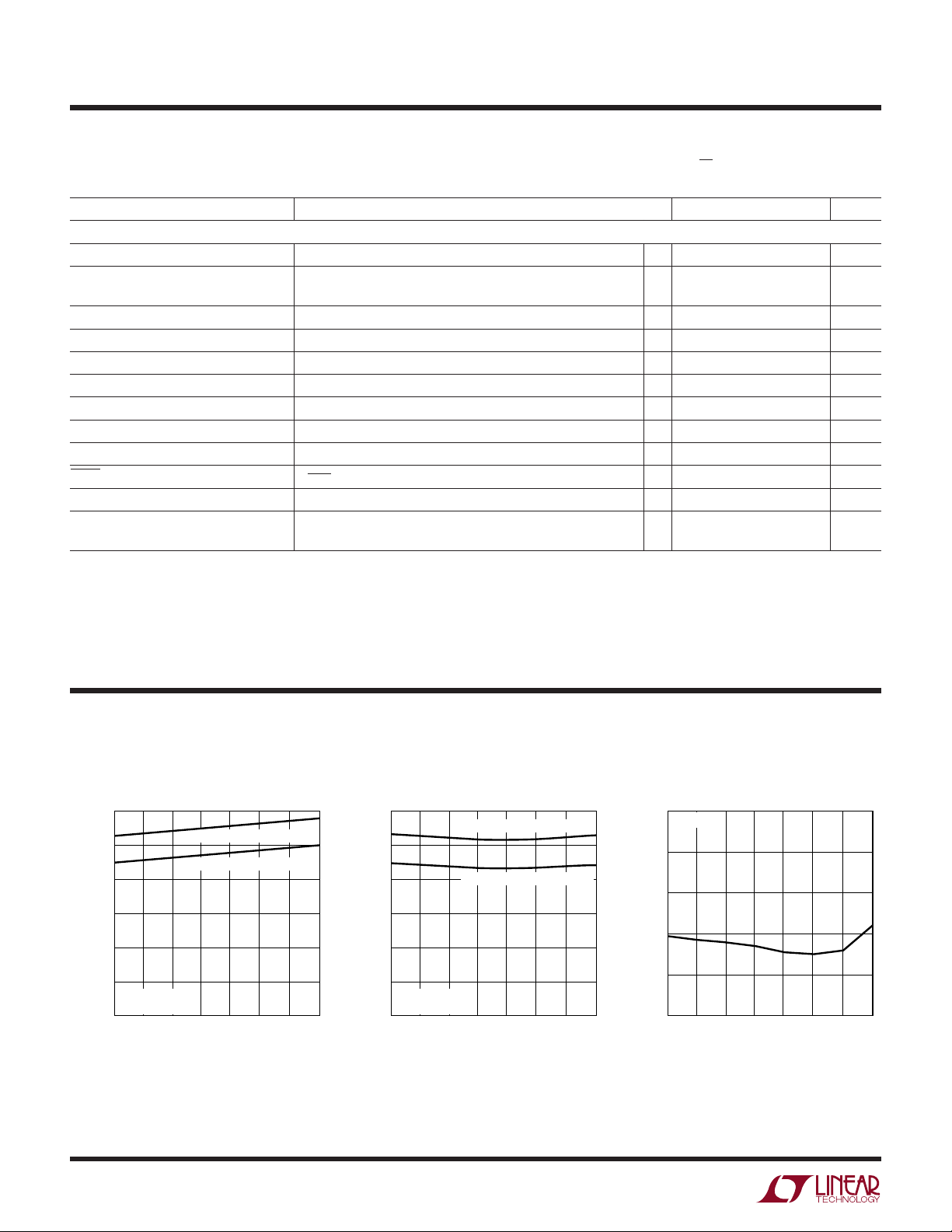

TEMPERATURE (°C)

–50

QUIESCENT CURRENT (µA)

5

4

3

2

1

0

25 75

3455 G03

–25 0

50 100 125

V

BAT

= 3.6V

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. V

V

USB

= 0V, V

= 0V unless otherwise noted.

WALLFB

The ● denotes the specifications which apply over the full operating

= 3.6V, V

BAT

= 3.6V, V

MAX

PWRON

= 2V, V

is open, VON = 0V,

ON

PARAMETER CONDITIONS MIN TYP MAX UNITS

Battery Charger

Regulated Charger V

Charger Current Limit (USB Powered) R

Charger Current Limit (Wall Powered) R

Recharge Battery Voltage Threshold V

Voltage 0°C ≤ TA ≤ 85°C 4.158 4.200 4.242 V

BAT

=2.49kΩ, V

PROG

=2.49kΩ, V

R

PROG

=2.49kΩ, V

PROG

BAT(REGULATED)

= 2V, V

USBHP

= 0V, V

USBHP

= 4.5V, 0°C ≤ TA ≤ 85°C 425 500 575 mA

MAX

– V

RECHARGE

= 5V, 0°C ≤ TA ≤ 85°C 400 470 mA

USB

= 5V, 0°C ≤ TA ≤ 85°C5090mA

USB

150 mV

Trickle Charge Trip Threshold Battery Voltage Rising 2.85 V

Trickle Charge Trip Hysteresis 60 mV

Trickle Charge Current R

PROG Pin Current Internal Pull-Up Current, No R

PROG Pin Voltage R

CHRG Pin Output Low Voltage I

Timer Accuracy C

=2.49kΩ, V

PROG

=2.49kΩ 1.23 V

PROG

= 5mA 0.75 V

CHRG

= 0.1µF ±10 %

TIMER

= 2V 65 mA

BAT

PROG

2 µA

Junction Temperature in 105 °C

Constant Temperature Mode

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3455 is guaranteed to meet specified performance from

Note 3: Quiescent current is pulled from the V

wall power is present, and from the V

pin when either USB or Wall

MAX

power is present.

pin when neither USB or

BAT

0°C to 70°C and is designed, characterized and expected to meet these

extended temperature limits, but is not tested at –40°C and 85°C

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Burst Mode Quiescent Current PWM Mode Quiescent Current Shutdown Quiescent Current

120

100

80

60

40

QUIESCENT CURRENT (µA)

20

V

= 3.6V

BAT

NOT SWITCHING

0

–50

–25 0

BOTH SWITCHERS ENABLED

ONLY SWITCHER 1 ENABLED

50 100 125

25 75

TEMPERATURE (°C)

3455 G01

600

500

400

300

200

QUIESCENT CURRENT (µA)

100

0

–50

V

= 3.6V

BAT

NOT SWITCHING

–25 0

TEMPERATURE (°C)

BOTH SWITCHERS ENABLED

ONLY SWITCHER 1 ENABLED

50 100 125

25 75

3455 G02

3455f

4

UW

TEMPERATURE (°C)

–50

HSO PIN CURRENT LIMIT (mA)

200

150

100

50

0

25 75

3455 G09

–25 0

50 100 125

V

HSI

= 3.3V

V

HSO

= 2.5V

TEMPERATURE (°C)

–50

CURRENT LIMIT (mA)

1000

800

600

400

200

0

25 75

3455 G06

–25 0

50 100 125

SWITCHER 1

SWITCHER 2

TEMPERATURE (°C)

–50

WALLFB TRIP VOLTAGE (V)

1.26

1.24

1.22

1.20

1.18

1.16

1.14

1.12

1.10

25 75

3455 G12

–25 0

50 100 125

FALLING

RISING

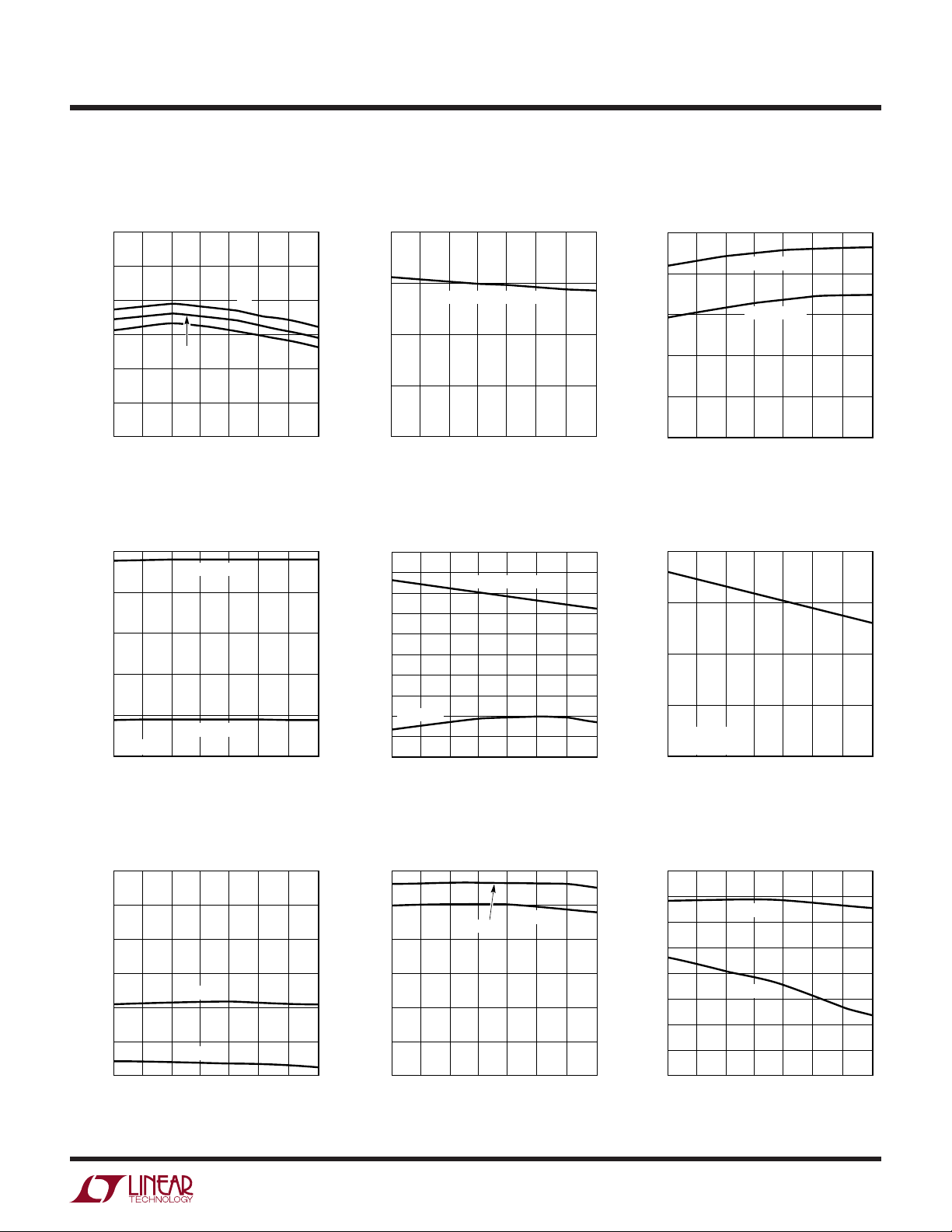

TYPICAL PERFOR A CE CHARACTERISTICS

LTC3455

Feedback Pins (FB1, FB2)

and AI Pin Voltage

815

810

805

800

VOLTAGE (mV)

795

790

785

–50

–25 0

FB2

TEMPERATURE (°C)

AI

FB1

50 100 125

25 75

3455 G04

USB Pin Current Limit V

500

USBHP = 2V

400

300

200

USB PIN CURRENT (mA)

100

0

–50

V

USB

–25 0

= 5V

USBHP = 0V

50 100 125

25 75

TEMPERATURE (°C)

3455 G07

Switching Regulator Oscillator

Frequency Switching Regulator Current Limit

2.0

1.5

1.0

0.5

SWITCHING FREQUENCY (MHz)

0

–50

5.0

4.5

4.0

3.5

3.0

2.5

2.0

CURRENT LIMIT (A)

1.5

MAX

V

1.0

0.5

0

–50

FOR BOTH SWITCHERS

50 100 125

–25 0

Pin Current Limit HSO Pin Current Limit

MAX

STARTUP

–25 0

25 75

TEMPERATURE (°C)

NORMAL OPERATION

50 100 125

25 75

TEMPERATURE (°C)

3455 G05

3455 G08

Battery Undervoltage Lockout USB Undervoltage Lockout WALLFB Trip Voltage

4.00

3.75

3.50

3.25

3.00

BATTERY UVLO (V)

2.75

2.50

–50

–25 0

RISING

FALLING

50 100 125

25 75

TEMPERATURE (°C)

3455 G10

4.00

3.75

3.50

3.25

USB UVLO (V)

3.00

2.75

2.50

–50

–25 0

RISING

TEMPERATURE (°C)

FALLING

50 100 125

25 75

3455 G11

3455f

5

LTC3455

TEMPERATURE (°C)

–50

BATTERY CURRENT (µA)

15.0

10.0

5.0

12.5

7.5

2.5

0

25 75

3455 G18

–25 0

50 100 125

V

BAT

= 4.2V

CHARGER OFF

TEMPERATURE (°C)

–50

R

DS(ON)

1.4

1.2

1.0

0.8

0.6

0.2

0.4

0

25 75

3455 G21

–25 0

50 100 125

HSO

USB

V

MAX

V

HSI

= 3.3V

V

USB

= 5V

V

BAT

= 3.6V

TEMPERATURE (°C)

–50

TRICKLE CHARGE THRESHOLD (V)

3.0

2.9

2.8

2.7

2.6

2.5

25 75

3455 G15

–25 0

50 100 125

FALLING

RISING

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Battery Charger Regulation

Voltage

4.30

4.25

4.20

(V)

4.15

BAT

V

4.10

4.05

4.00

–50

–25 0

25 75

TEMPERATURE (°C)

Charge Current When

Wall-Powered

600

500

400

THERMAL CONTROL

LOOP IN OPERATION

300

50 100 125

3455 G13

Battery Charger Recharge

Threshold

4.30

4.25

4.20

(V)

4.15

RECHARGE

V

4.10

4.05

4.00

–50

–25 0

25 75

TEMPERATURE (°C)

Charge Current When

USB-Powered

600

V

= 3.6V

BAT

= 5V

V

USB

= 2.49k

R

500

PROG

400

THERMAL CONTROL

LOOP IN OPERATION

300

V

50 100 125

= 2V

USBHP

Battery Charger Trickle-Charge

Threshold

3455 G14

Battery Current When

USB- or Wall-Powered

200

V

= 3.6V

100

BAT

BATTERY CHARGE CURRENT (mA)

0

–50

V

MAX

R

PROG

–25 0

= 4.5V

= 2.49k

PROG Pin Voltage

vs Charge Current

1.50

V

= 3.6V

BAT

V

= 4.5V

MAX

= 2.49

R

1.25

PROG

= 25°C

T

A

1.00

(V)

0.75

PROG

V

0.50

0.25

0

0

100 200

50 100 125

25 75

TEMPERATURE (°C)

300

CHARGE CURRENT (mA)

3455 G16

400 500

3455 G19

200

100

BATTERY CHARGE CURRENT (mA)

0

–50

–25 0

R

DS(ON)

V

USBHP

25 75

TEMPERATURE (°C)

for Switching Regulator

Power Switches

0.7

V

= 3.6V

BAT

0.6

0.5

0.4

DS(ON)

R

0.3

0.2

0.1

0

–50

–25 0

NMOS

PMOS

25 75

TEMPERATURE (°C)

= 0V

50 100 125

3455 G17

50 100 125

3455 G20

R

for V

DS(ON)

MAX

PMOS Switches

, USB, and HSO

3455f

6

UUU

PI FU CTIO S

LTC3455

FB1 (Pin 1): Feedback Pin for Switcher 1. Set the output

voltage by connecting feedback resistors to this pin.

PROG (Pin 2): Charge Current Program and Charge Current Monitor Pin. Connect a resistor, R

to ground to program battery charge current.

I

= 1000 • 1.23V / R

BAT

In all modes the voltage on the PROG pin can be used to

measure charge current. PROG has a weak pull-up current

source to turn the charger off if the pin is left open.

TIMER (Pin 3): Timer Capacitor Pin. Connect a capacitor,

C

cycle termination time. The timer starts when USB or wall

power is first present. The timer period is:

Tie TIMER to ground to disable just the internal timer

function. Tie TIMER to V

constant-current-only mode (which disables the timer,

voltage amplifier and trickle charge function).

CHRG (Pin 4): Open-Drain Charge Status Pin. This pin is

pulled low with an internal N-channel MOSFET whenever

the battery charger is enabled, and is forced into a high

impedance state whenever it is disabled.

USBHP (Pin 5): USB High Power Mode Pin. This pin is

used to select the appropriate USB current limit (either

500mA or 100mA). Pull high to select 500mA (high power

mode); low to select 100mA (low power mode).

SUSPEND (Pin 6): USB Suspend Pin. When this pin is

pulled high, the internal USB power controller is disabled

and the USB pin current reduces to less than 20µA.

SW1 (Pin 7): Switch Pin for Switcher 1. Minimize the

length of the metal trace connected to this pin. Place the

inductor for Switcher 1 as close to this pin as possible.

USB (Pin 8): USB Supply Pin. Input current into this pin is

limited to either 100mA or 500mA based on the state of the

USBHP pin. The charger and Switcher 1 will remain alive

whenever USB power is present (when USB pin is above

3.9V and SUSPEND is low).

V

capacitor as close to the device as possible.

, between this pin and ground to set the charge

TIMER

T

(hours) = C

TIMER

(Pin 9): Battery Input Pin. Bypass this pin with a

BAT

PROG

• (3 hours) / (0.1µF)

TIMER

to use the charger in a

MAX

, from this pin

PROG

V

(Pin 10): Max Voltage Pin. This pin is used to power

MAX

the two internal step-down DC/DC converters and is

provided externally to power other devices (i.e. LDOs or

Switchers for LCD bias, white LED backlight drive, etc).

When the LTC3455 is on and neither USB or wall power are

available, an internal PMOS switch connects this pin to the

V

pin. When either USB or wall power is present, they

BAT

provide power to this pin, and the battery charger draws

power from this pin. In shutdown, this pin is discharged to

ground to provide output disconnect.

WALLFB (Pin 11): Wall Power Detection Pin. This pin is

the input to a comparator used to signal the presence of a

5V wall adapter. A resistor divider taken from the wall

adapter input is connected to this pin to tell the LTC3455

when the adapter voltage is high enough to provide power

to the LTC3455. When this pin is higher than 1.23V, the

battery charger is enabled. The 5V wall adapter is connected to the V

WALLFB to ground if a wall adapter is not used.

SW2 (Pin 12): Switch Pin for Switcher 2. Minimize the

length of the metal trace connected to this pin. Place the

inductor for Switcher 2 as close to this pin as possible.

HSI (Pin 13): Hot Swap Input Pin. This pin is connected to

the HSO pin through a current-limited PMOS switch.

HSO (Pin 14): Hot Swap Output Pin. This output is used for

memory cards or other devices that would appear as a

short if they were hot-plugged directly to one of the

outputs (typically the 3.3V output). The current out of this

pin is limited to 160mA.

HSON (Pin 15): Hot Swap Enable Pin. This pin turns on the

PMOS that connects the HSI and HSO pins.

AI (Pin 16): Gain Block Input Pin. This pin is the inverting

input to an amplifier that can be used as a low-battery

detector or as an LDO with the addition of an external PNP

or PMOS. The non-inverting input of the gain block is

connected to the 0.8V internal reference.

AO (Pin 17): Gain Block Output Pin. This pin is an opendrain output, and is pulled low when the AI pin is less than

800mV. This output can be used as a low-battery detector,

or as an LDO with the addition of an external PNP or PMOS.

This pin can sink up to 1mA.

pin through a Schottky diode. Tie

MAX

3455f

7

LTC3455

PI FU CTIO S

UUU

FB2 (Pin 18): Feedback Pin for Switcher 2. Set the output

voltage by connecting feedback resistors to this pin.

ON2 (Pin 19): Enable Pin for Switcher 2. This pin turns on

Switcher 2 only if ON is low or PWRON is high. Switcher

2 cannot be turned on by itself.

RST (Pin 20): Reset Pin. This pin is an open-drain output

that provides a 200ms reset signal during power-up to

initialize a microcontroller.

MODE (Pin 21): Burst Mode Enable Pin. Tie this pin high

to allow Burst Mode operation for the LTC3455. Burst

Mode operation will provide superior efficiency when both

outputs are operating with very low output currents. Tie

this pin to ground to force PWM operation under all load

current conditions. Burst Mode is disabled initially at

startup (for 200ms) and also whenever external power is

available (even if MODE is pulled high).

PWRON (Pin 22): Power-On Pin. Pull this pin high to turn

on the LTC3455. This pin is typically used in conjunction

with the ON and PTSTAT pins, and a momentary-on

switch. Tie PWRON to ground if not used.

PBSTAT (Pin 23): Push-Button Status Pin. This pin is an

open drain output that indicates the state of the ON pin

(which is usually connected to a momentary-on pushbutton) to the microcontroller. This pin follows the state of

the ON pin (PBSTAT goes low when ON is pulled low).

ON (Pin 24): ON Pin. Pull this pin to ground to turn on the

LTC3455. This pin is typically used with a momentary-on

push-button switch to turn on the LTC3455. This pin

would be held low until the PWRON pin is pulled high by

a microcontroller to keep the LTC3455 turned on. If a

momentary-on switch is not used, this pin can be held to

ground to keep on the LTC3455. Leave ON open if not

used. This pin has a weak pull-up current source.

GND (Pin 25 – Exposed Pad): Ground Pin. The exposed

backside pad is the only ground pin for the LTC3455 and

must be soldered to the PC board ground plane for the

device to operate properly.

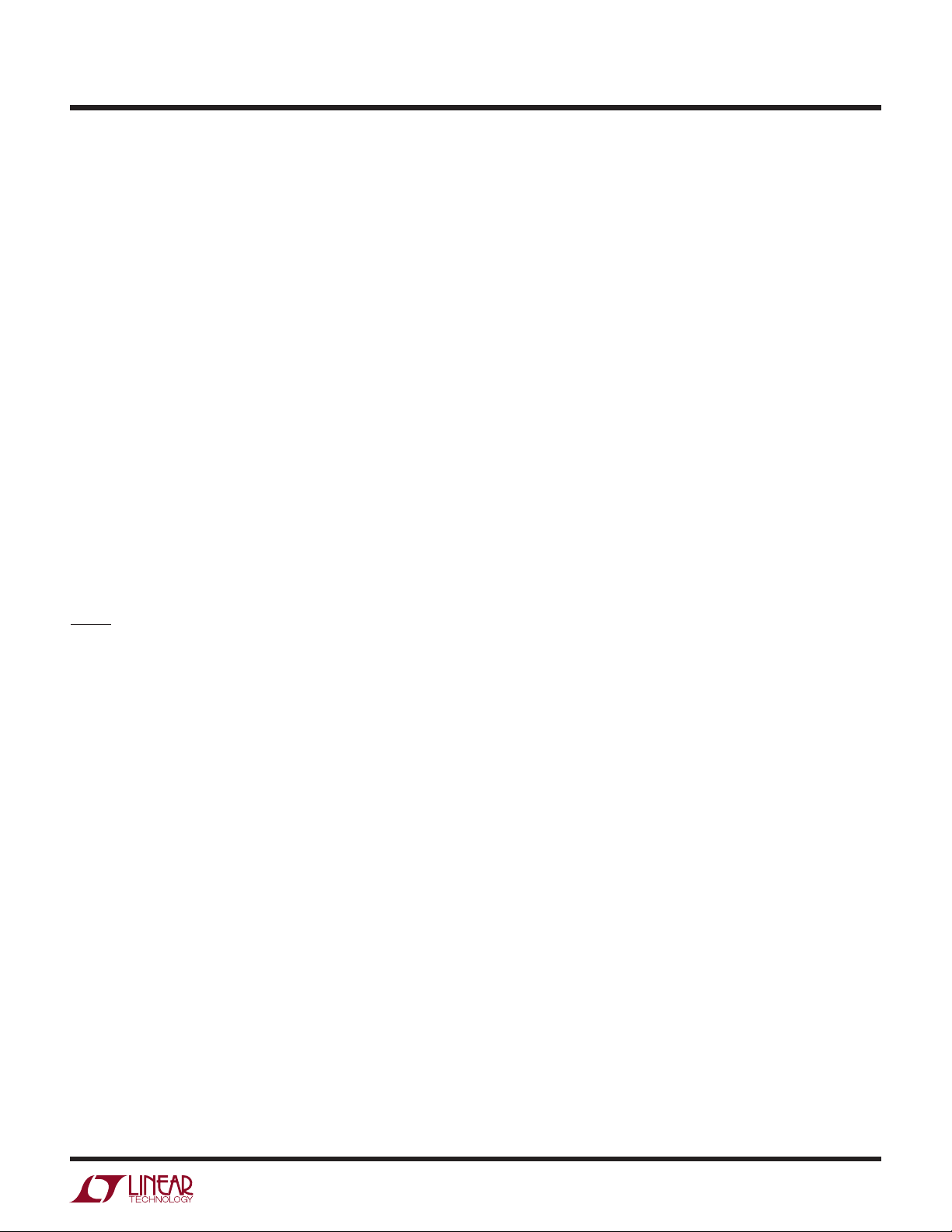

SI PLIFIEDWBLOCK DIAGRA

USB POWER

3.9V TO 5.3V

Li-Ion BATTERY

3.3V TO 4.2V

USE FOR LDO

OR LOW BATTERY

INDICATOR

USB POWER

MANAGER

BATTERY

PMOS SWITCH

BATTERY

CHARGER

GAIN BLOCK

W

V

IS CONNECTED TO THE BEST

MAX

AVAILABLE INPUT POWER SOURCE

(WALL ADAPTER, USB OR BATTERY)

SWITCHER 1

SWITCHER 2

HOT SWAP

3455 SBD

5V WALL ADAPTER

V

MAX

USE TO POWER OTHER

DC/DCs AND LDOs

V

OUT1

1.8V TYPICAL

V

OUT2

3.3V TYPICAL

HOT SWAP OUTPUT

3.3V TYPICAL

8

3455f

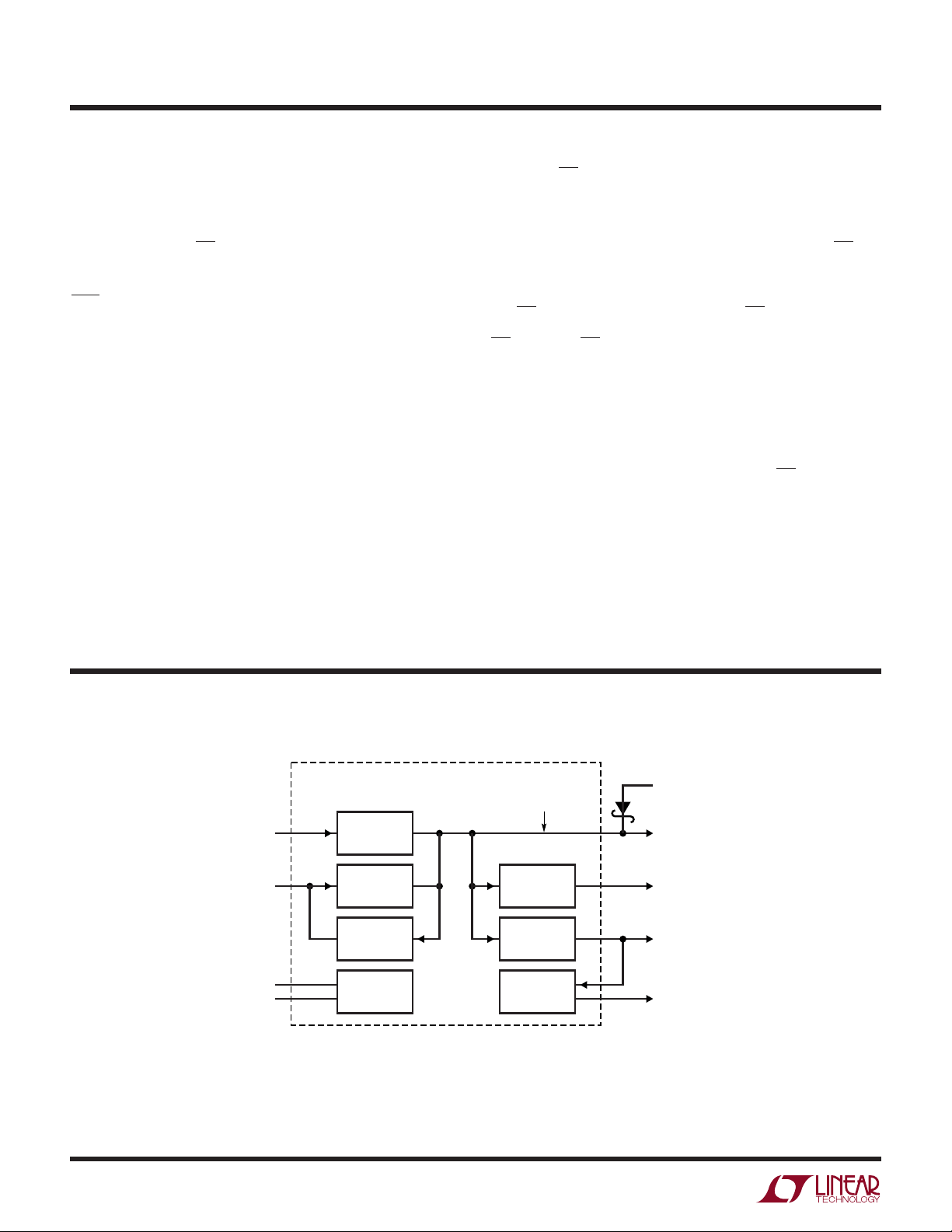

BLOCK DIAGRA

USB

1Ω

4.7µF

SUSPEND

USBHP

CHRG

TIMER

PROG

GND

V

806k

1.8V

PBSTAT

806k

1.8V

PWRON

ON2

MODE

HSON

BAT

RST

8

6

5

4

3

2

25

9

AI

16

AO

17

ON

24

23

22

19

20

21

15

200ms RESET PULSE

BURST MODE ENABLE

CONTROLLER

V

MAX

V

3.3V to 4.2V

µC

USB 5V

USB

1k

0.1µF

2.49k

BAT

2.43M

4.7µF

806k

LBO

ON/OFF

W

USB POWER MANAGER

1 1000

–

REF

+

R

4R

V

+

BAT

3.0V

–

LTC3455

WALL 5V

3.9V

–

+

BATTERY CHARGER

1 1000

–

1.23V

+

2.41R

EXTPWR

BATTERY PMOS SWITCH

+

1.23V

–

11

10

3.32k

WALLFB

1.24k

V

MAX

+

–

PWM

DRIVER

ENABLE

PWM

DRIVER

ENABLE

HOT SWAP

+

SWITCHER 1

SWITCHER 2

4.7µH

SW1

7

100k

FB1

0.8V

0.8V

3455 BD01

1

80.6k

4.7µH

SW2

12

249k

FB2

18

80.6k

HSI

13

HSO

14

–

+

–

+

CHARGE

CONTROL

R

–

0.8V

+

UVLO

EXTPWR

ENABLE

1Ω

1µF

10µF

10µF

10µF

1µF

V

MAX

1.8V

3.3V, HS

3.3V

3455f

9

LTC3455

OPERATIO

U

The LTC3455 is designed to be a complete power management solution for a wide variety of portable systems. The

device incorporates two current mode step-down switching regulators, a full-featured battery charger, a USB

power controller, a Hot Swap output, a low-battery comparator (which can also be configured as an LDO) and

numerous protection features into a single package. When

only battery power is available, the battery PMOS switch

connects the V

both switching regulators (and any other devices powered

from V

). When external power is applied, the LTC3455

MAX

pin to the V

MAX

pin to provide power to

BAT

U

WUU

APPLICATIO S I FOR ATIO

Undervoltage Lockout (UVLO)

If no external power is present, the LTC3455 will start only

if the battery voltage is above 3.0V. This prevents starting

up with a battery that is too close to deep discharge. Once

started, the battery must drop below 2.6V before the

LTC3455 will shut off. This hysteresis is set intentionally

large to prevent the LTC3455 from turning off at an

inappropriate time, like during the read- or write-cycle of

a hard-disk drive (which could potentially damage the

drive). The internal UVLO is meant only as a last chance

safety measure to prevent running the battery voltage too

low and damaging it. An accurate, user-settable lowbattery threshold can be implemented using the gain block

(see the “Gain Block” section for details) which gives the

microcontroller complete control over the timing of a

shutdown due to a low-battery condition.

seamlessly transitions from battery power (a single-cell

Li-Ion cell) to either the USB supply or a wall adapter. The

battery PMOS switch is turned off, the charger is activated

and all internal power for the device is drawn from the

appropriate external power source. Maximum charge current and charge time are programmed using an external

resistor and capacitor, respectively. The USB power manager provides accurate current limiting for the USB pin

under all conditions. The Hot Swap output is ideal for

powering memory cards and other devices that can be

inserted while the system is fully powered.

Whenever the WALLFB pin is above 1.23V, system power

is drawn from the wall adapter via the V

battery charger is active. The 5V wall adapter output is

connected to the V

a resistor divider from the 5V wall input is connected to the

WALLFB pin to signal the LTC3455 that wall power is

present. A higher voltage adapter can also be used, but the

6V maximum rating on the V

additional regulator to step down the voltage.

If USB power is present and above 3.9V (and wall power

is not available), system power is drawn from the USB pin.

The battery charger is active, but charge current will be

held off until the USB pin increases above 4.0V to prevent

the battery charger from further loading down an already

low USB supply. As long as the USB pin stays above 3.9V,

the USB port supplies all other system power.

pin through a Schottky diode, and

MAX

pin requires the use of an

MAX

pin, and the

MAX

If external power is present and the battery voltage is less

than 3.0V, the V

for the LTC3455 to start, and once started, the V

must stay above 3.1V for the device to continue running.

Selecting the Input Power Source

The priority for supplying power to both DC/DC converters, all internal circuitry, and the V

USB, battery.

pin voltage must be greater than 3.9V

MAX

pin is: Wall adapter,

MAX

MAX

pin

10

If the system needs more power than the USB bus can

supply, the charger turns off completely, the USB power

controller becomes a 500mA (or 100mA) current source

and the V

ues to decrease, eventually the battery will provide the

additional current needed. This allows the LTC3455 to

withstand load current transients that briefly require more

power than the USB power supply can provide.

voltage begins to decrease. If V

MAX

MAX

contin-

3455f

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Operation When No Battery Is Present

As long as USB or wall power is available, the LTC3455 will

operate with no battery present, a crucial requirement for

systems with a removable battery. Keep in mind, however,

that if the LTC3455 is USB powered and the battery is not

present, absence of the battery means that there is no

reservoir if the system needs more power than the USB

port can supply. Similarly, if external power is available,

the LTC3455 will operate even if the battery is bad or in

deep-discharge.

The LTC3455 is also a good choice for systems that are

always powered by a USB supply or wall adapter. The

charger can then be used to charge a large capacitor or

backup battery, which can briefly provide power to the

system after the external power has been removed. This

gives the microcontroller enough time to follow proper

shutdown procedures even after the main power source is

abruptly removed. If USB powered, the large capacitor or

backup battery will also be used to provide additional

current if the system briefly needs more power than the

USB bus can provide.

Concerns When Wall Adapter Powered

desirable, but it is not necessarily an easy task. As the

performance of digital cameras, handheld computers, and

MP3 players increases, the power needed to operate them

also increases. The power available from a single USB port

(maximum 2.5W) is barely enough to support the peak

power needed by many full-featured portable devices,

even without the power needed to quickly charge their

batteries.

To further complicate matters, a USB port is not the ideal

power source. Each device can draw a maximum of

500mA (in high power mode), but the voltage provided to

the portable device can vary quite significantly. Although

a USB power supply has a 5V nominal rating, when you

include normal supply variations, cable losses, and transient conditions, the USB voltage showing up at the

portable device is typically much lower—often falling to

only 4V. Since the USB port has a strict current limit of

500mA, this means the amount of power available to the

portable device can be as low as 2W. The reduced USB

voltage also presents problems when trying to fully charge

a single-cell Lithium-Ion battery (that has a 4.2V final

charge voltage) when the USB voltage may itself be below

or near 4.2V.

Always choose a wall adapter that can provide power for

all load and battery charging requirements. Choosing a

wall adapter with a power rating that is too small will result

in very long charge times and erratic system operation. If

the total current needed (load and battery charging) exceeds what the adapter can provide, the voltage on the

V

pin will begin to droop. If it droops close enough to

MAX

the battery voltage (the V

decreases and eventually reduces to zero. If the load

current is still too much for the wall adapter to provide, the

wall adapter will provide what it can and the battery will

provide the rest. When wall powered, this operation is

intended only for surviving fault conditions and should not

be a normal mode of operation.

Concerns When USB Powered

The popularity of USB (Universal Serial Bus) makes it an

attractive choice for transferring data in a variety of portable devices. Therefore, utilizing the USB port to power

these portable devices while charging their battery is very

pin), the charge current

BAT

The LTC3455 is specifically designed to alleviate these

problems and make the most of the power the USB port

has to offer. See the sections entitled ”Large Transient

Loads when USB powered” and ”Special Charger Features

when USB powered” for more detailed discussions of the

LTC3455’s special USB features.

USB High Power/Low Power/Suspend Modes

There are three basic modes for the USB power manager:

high power, low power, and suspend. High power mode

allows the LTC3455 to draw up to 500mA from the USB

port, and is selected by pulling the USBHP pin high. Low

power mode reduces the allowable current drawn to

100mA, and is selected by pulling the USBHP pin low. The

USBHP pin has a weak internal pulldown current source to

ensure that the LTC3455 always starts up in USB low

power mode. The SUSPEND pin will disable the USB

power manager completely, reducing the USB pin current

to under 20µA.

3455f

11

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Operation in USB Low Power Mode

Most applications that draw power from the USB bus

should be in low power mode only for a brief amount of

time. All devices must be in low power mode (draw no

more than 100mA of current from the USB bus) upon

power-up, and can transition to high power mode (draw

up to 500mA from the USB bus) only after the device has

been given permission to do so by the USB host controller.

The change to high power mode is usually very quick, so

the full 500mA of current is available shortly after connecting to the USB bus. While the LTC3455 will operate when

in low power mode, the amount of power available is so

small that it is difficult or impossible to charge a battery or

even provide enough current to power the rest of the

system. For this reason, USB high power operation should

always be used with the LTC3455.

Handling Large Transient Loads when USB Powered

Many portable devices have nominal loads that can easily

be supported by the USB supply, but they have brief

transient loads that can exceed the maximum available

USB power. The LTC3455 is designed to handle these

overloads while drawing as much power as possible from

the USB port. If the USB bus is providing power but the

LTC3455 (or any other devices connected to the V

needs more total power than the USB bus can supply, the

battery charger turns off completely and the USB power

controller becomes a 500mA (or 100mA) current source

and the V

capacitance connected to the V

voltage begins to decrease. At this point, the

MAX

pin provides the addi-

MAX

tional current needed by the system. As long as the USB

pin stays above 3.9V, the USB bus will continue to provide

as much current as possible. Once the V

below the V

voltage, the battery will provide the addi-

BAT

pin drops just

MAX

tional current needed. This operation allows the LTC3455

to withstand load transients that briefly demand more

power than can be provided by the USB bus.

MAX

pin)

The oscilloscope photographs in Figure 1 show how the

LTC3455 handles load transients when USB powered. The

top photo shows a brief transient load that turns off the

charger but does not dip the V

voltage. The bottom

MAX

photo shows a prolonged transient condition that turns off

the charger and completely dips the V

voltage to the

MAX

point where the battery must provide current. For both

cases, normal operation resumes as soon as the transient

passes.

Extra capacitance can be connected to the V

pin to act

MAX

as a reservoir to help support large transient currents. For

most systems this is not necessary, as the LTC3455

cleanly handles heavy transients. For some designs, however, it may be desirable to use a larger capacitor connected to V

500mA/DIV

500mA/DIV

500mA/DIV

500mA/DIV

500mA/DIV

500mA/DIV

Figure 1. Handling Load Transients when USB Powered

to act as a larger reservoir. Up to 50µF of

MAX

V

MAX

2V/DIV

I

MAX

I

USB

I

BAT

100µs/DIV

USB Maximum Current Condition

V

MAX

2V/DIV

I

MAX

I

USB

I

BAT

100µs/DIV

USB Heavy Over-Current Condition

3455 F01a

3455 F01b

12

3455f

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

ceramic capacitance may be connected to the V

without difficulty. More than 50µ F requires using a capacitor with some ESR or adding some resistance in series

with some of the ceramic capacitance. This is necessary to

ensure loop stability in the battery charger loop when

under USB power.

Using the V

The V

MAX

Pin to Power Other Devices

MAX

pin can be used to provide power for other

devices within the system. This pin is connected to the

battery when no external power is available, and it is

connected to either the USB bus or the wall adapter when

either are available. This ensures that all devices powered

from V

will always draw power from the best available

MAX

input power source.

The internal PMOS connecting V

to the battery is

MAX

current limited to 900mA at startup (to minimize in-rush

current) and to 4A once V

has risen close to the battery

MAX

voltage. Because of the reduced startup current limit, the

turn-on of other devices powered from V

MAX

always be delayed to minimize the currrent initially needed

from the V

pin. The best choice is to enable these

MAX

devices from either switcher output, since the turn-on of

both switchers is always delayed until the V

reached the V

pin voltage. The V

BAT

MAX

MAX

pin is discharged

to ground when the LTC3455 is shut down, so that any

device supplied by V

will have its input grounded

MAX

during shutdown. This ensures output disconnect for all

supply voltages within the system.

pin

MAX

should

pin has

Startup and Shutdown when Battery-Powered

When only battery power is available, the LTC3455 turns

on when either the ON pin is pulled low or the PWRON pin

is pulled high. Either of these pins will keep the device

running, but typically the ON and PWRON pins are used

together to provide turn-on and turn-off using a single

momentary-on push-button switch. Figure 2 shows the

method for using a momentary-on pushbutton to turn the

LTC3455 off and on.

When the momentary-on switch is first pressed, shorting

the ON pin to ground, PBSTAT goes low and the LTC3455

first brings up the V

pin, then enables Switcher 1 to

MAX

power the microcontroller. Once up and running, the

microcontroller provides the PWRON signal to keep the

LTC3455 turned on after the push-button is released.

When the push-button is pressed again to turn off the

device, the PBSTAT pin is pulled low to notify the microcontroller that the push-button has been pressed. The

microcontroller prepares for shutdown then pulls the

PWRON signal low. When the push-button is released, the

ON pin goes high and the LTC3455 turns off. The ON and

PWRON pins enable Switcher 1 (along with all the internal

circuits needed for normal operation), and the ON2 pin

enables Switcher 2. Switcher 2 can only operate when

Switcher 1 is also enabled. The turn-on of both switchers

is always delayed until the V

pin has reached the V

MAX

BAT

pin voltage.

PBSTAT

23

ON

24

PUSH

µC

BUTTON

PWRON

22

ON2

19

Figure 2. Momentary Push-Button Operation

LTC3455

SWITCHER 1

ENABLED

SWITCHER 2

ENABLED

3455 F02

3455f

13

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

19

ON2

23

PBSTAT

24

ON

22

PWRON

9

V

BAT

WALLFB

USB

SUSPEND

+

3V

–

11

+

1.23V

–

8

+

3.9V

–

6

Figure 3. Turn-On Logic Diagram for LTC3455

LTC3455

SWITCHER 2

ENABLED

SWITCHER 1

ENABLED

CHARGER

ENABLED

USB POWER

CONTROLLER

ENABLED

3455 F03

Startup and Shutdown When USB or Wall Powered

Whenever USB or wall power is present (as sensed by the

USB and WALLFB pins), Switcher 1 and the battery

charger will always be enabled. If the LTC3455 is off and

external power is applied, both the charger and Switcher

1 will start independent of the state of the ON and PWRON

pins. This provides maximum battery run-time by always

allowing the battery to charge whenever external power is

available, and ensures that the microcontroller is always

alive when external power is available (this is important for

designs that utilize coulomb-counting or other battery

monitoring techniques). Switcher 2 starts only if ON2 is

also pulled high. Figure 3 shows the turn-on logic diagram

for the LTC3455.

Starting Switcher 2/Power Supply Sequencing

Switcher 2 can operate only when Switcher 1 is also

enabled and in regulation. The ON2 pin can be driven by a

logic signal for independent control of Switcher 2. If both

outputs always operate together, tie the ON2 pin to the

V

pin. This will enable Switcher 2 after the output of

MAX

Switcher 1 has reached 90% of its final value. This powerup delay ensures proper supply sequencing and reduces

the peak battery current at startup. Figure 4 shows the

output sequencing when both switchers are enabled at

startup with the ON2 pin tied to V

switchers is always delayed until the V

the V

pin voltage.

BAT

. The turn-on of both

MAX

pin has reached

MAX

Reset Signal (RST)

A 200ms reset signal (the RST pin is pulled low) is

provided for proper initialization of a microcontroller whenever the LTC3455 is first turned on, either by the ON or

PWRON pins, or by the application of external power. The

RST signal is also pulled low whenever the LTC3455 is in

shutdown, ensuring no false starts for the microcontroller

as the output voltages are rising or collapsing. In the event

of a fault condition the RST pin will be pulled low.

PWRON/ON2

2V/DIV

V

MAX

2V/DIV

V

(1.8V)

OUT1

2V/DIV

V

(3.3V)

OUT2

2V/DIV

100µs/DIV

Figure 4. Sequencing for Switcher 1 and 2 Outputs

3455 F04

14

3455f

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Low or Bad Battery Protection (200ms Timeout)

The 200ms reset timer is also used to prevent starting the

LTC3455 when there is insufficient external power or

insufficient battery voltage to regulate the outputs. When

first turned on, the internal 200ms timer starts. If only

Switcher 1 is enabled (ON2 is low) and its output does not

reach 90% of its final value within 200ms, Switcher 1 is

shut down even if the ON pin is held low or if the PWRON

pin is held high (the V

is low or PWRON is high). This automatic shutdown

feature prevents possible damage to a defective or

overdischarged Li-Ion battery. If ON2 is tied to V

that Switcher 2 is also turned on at startup, then both

outputs must reach 90% of their final values within 200ms.

Once the output(s) are in regulation, the timer is reset for

a full 200ms.

Schottky Diode Selection/WALLFB Resistor Selection

pin will remain on as long as ON

MAX

MAX

so

Three good diode choices are the MBRM110E (1A, 10V),

MBR120ESF (1A, 20V), and the MBRA210E (2A, 10V). All

are available in very small packages from ON Semiconductor (www.onsemi.com), have reverse leakage currents

under 1µ A at room temperature, and have forward drops

of around 500mV at their maximum rated current

(1A or 2A).

V

10

V

MAX

LTC3455

WALLFB

Figure 5. Schottky Leakage Current Path

11

I

LEAKAGE

MAX

WALL 5V

3.32K

1.24K

3455 F05

Switching Regulator General Information

When a 5V wall adapter is used, power is provided to the

V

pin through a Schottky diode. The most important

MAX

specification in picking this diode is its reverse leakage

current. When the LTC3455 is turned on but wall power is

not present, the Schottky will leak current to ground

through the WALLFB resistor divider (see Figure 5). This

leakage current should be minimized (by picking an appropriate low-leakage Schottky diode) as it can dramatically

reduce Burst Mode efficiency at light loads. In addition, a

high leakage current can also false trip the WALLFB pin

and turn on the LTC3455 even if wall power is not

available. To help prevent this false turn-on, use the

WALLFB resistor values shown in Figure 5.

The diode forward voltage drop should be around 500mV

or less at its maximum rated current to allow charging

even when the wall adapter voltage is lower than normal.

Some manufacturers have recently introduced Schottky

diodes optimized for a very low forward drop, but their

reverse leakage currents can be more than 100µ A at room

temperature, and over 1mA at high temperatures. These

diodes are not recommended for use with the LTC3455,

but if they are used operation at high temperature should

be checked thoroughly to avoid problems due to excessive

diode leakage current.

The LTC3455 contains two 1.5MHz constant-frequency

current mode switching regulators that operate with efficiencies up to 96%. Switcher 1 provides up to 400mA at

1.5V/1.8V (to power a microcontroller core), and Switcher

2 provides up to 600mA at 3V/3.3V (to power microcontroller I/O, memory and other logic circuitry). Both converters support 100% duty cycle operation (low dropout

mode) when the input voltage drops very close to the

output voltage, and both are capable of operating in Burst

Mode operation for highest efficiencies at light loads

(Burst Mode operation is pin selectable). Switcher 2 has

independent ON/OFF control, but operates only when

Switcher 1 is also enabled and in regulation. If both are

enabled at power-up, Switcher 2 is allowed to turn on only

after Switcher 1 has reached 90% of its final value. This

power-up delay ensures proper supply sequencing and

reduces the peak battery current at startup. If the output of

Switcher 1 drops to below 85% of its programmed output

voltage, Switcher 2 will turn off. This ensures that any

problems with the core supply will shut down the rest of

the sytem.

3455f

15

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Switching Regulator Inductor Selection

Many different sizes and shapes of inductors are available

from numerous manufacturers. Choosing the right inductor from such a large selection of devices can be overwhelming, but following a few basic guidelines will make

the selection process much simpler. To maximize efficiency, choose an inductor with a low DC resistance. Keep

in mind that most inductors that are very thin or have a very

small volume typically have much higher core and DCR

losses, and will not give the best efficiency.

Choose an inductor with a DC current rating at least 1.5

times larger than the maximum load current to ensure that

the inductor does not saturate during normal operation.

Table 1 shows several inductors that work well with the

LTC3455. These inductors offer a good compromise in

current rating, DCR and physical size. Consult each manufacturer for detailed information on their entire selection of

inductors.

Switching Regulator Output Capacitor Selection

Low ESR (equivalent series resistance) ceramic capacitors should be used at both switching regulator outputs.

Only X5R or X7R ceramic capacitors should be used

because they retain their capacitance over wider voltage

and temperature ranges than other ceramic types. A 10µ F

output capacitor is sufficient for most applications. Table

2 shows a list of several ceramic capacitor manufacturers.

Consult each manufacturer for detailed information on

their entire selection of ceramic capacitors. Many manufacturers now offer very thin (<1mm tall) ceramic capacitors ideal for use in height-restricted designs.

Table 2. Recommended Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (803) 448-9411 www.avxcorp.com

Murata (714) 852-2001 www.murata.com

TDK (888) 835-6646 www.tdk.com

Table 1. Recommended Inductors

Max Max

Inductor L I

Type (µH) (A) (Ω) (mm) Manufacturer

DB318C 4.7 0.86 0.1 1.8 Toko

10 0.58 0.18 1.8 (847)297-0070

CLS4D09 4.7 0.75 0.19 1 Sumida

10 0.5 0.37 1 (847)956-0666

CDRH3D16 4.7 0.9 0.11 1.8 Sumida

10 0.55 0.21 1.8

SD12 4.7 1.29 0.12 1.2 Cooper

10 0.82 0.28 1.2 (561)752-5000

ELT5KT 4.7 1 0.2 1.2 Panasonic

10 0.68 0.36 1.2 (408)945-5660

DC

DCR Height

www.toko.com

www.sumida.com

www.cooperet.com

www.panasonic.com

V

Pin Capacitor Selection

BAT

For the V

pin, a 4.7µ F to 10µF ceramic capacitor is the

BAT

best choice. Only X5R or X7R ceramic capacitors should

be used.

V

Pin Capacitor Selection

MAX

For the V

pin, a 10µF ceramic capacitor is the best

MAX

choice. Only X5R or X7R ceramic capacitors should be

used. Do not use less than 10µF on this pin. For some

designs it may be desirable to use a larger capacitor

connected to V

to act as a reservoir when the LTC3455

MAX

is USB powered. Up to 50µ F of ceramic capacitance may

be connected to the V

pin without difficulty. More than

MAX

50µ F requires using a capacitor with some ESR (like a

Tantalum or OS-CON) or adding some resistance in series

with some of the ceramic capacitance. This is necessary

to ensure loop stability in the battery charger loop when

under USB power.

16

3455f

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

USB Pin and Wall Adapter Capacitor Selection

Caution must be exercised when using ceramic capacitors

to bypass the USB pin or the wall adapter input. High

voltage transients can be generated when the USB or wall

adapter is hot plugged. When power is supplied via the

USB bus or wall adapter, the cable inductance along with

the self resonant and high Q characteristics of ceramic

capacitors can cause substantial ringing which can easily

exceed the maximum voltage pin ratings and damage the

LTC3455. Refer to Linear Technology Application Note 88,

entitled “Ceramic Input Capacitors Can Cause Overvoltage

Transients” for a detailed discussion of this problem. The

long cable lengths of most wall adapters and USB cables

makes them especially susceptible to this problem. Even

if this ringing is not large enough to damage the part, it can

couple to the V

outputs) and be mistaken as loop instability. To bypass the

USB pin and the wall adapter input, add a 1Ω resistor in

series with a ceramic capacitor to lower the effective Q of

the network and greatly reduce the ringing. A tantalum,

OS-CON, or electrolytic capacitor can be used in place of

the ceramic and resistor, as their higher ESR reduces the

Q, thus reducing the voltage ringing. Use 4.7µ F to 10µ F for

the USB pin, and 1µF or larger for the wall adapter input.

pin (and to the switching regulator

MAX

Burst Mode™ Operation

For highest efficiencies at light loads, both DC/DC converters are capable of operating in Burst Mode. In this mode,

energy is delivered to the outputs in shorts bursts, which

minimizes switching losses and quiescent-current losses.

Output voltage ripple is slightly higher in this mode, but

efficiency is greatly improved. As shown in Figure 7, the

efficiency at low load currents increases significantly

when Burst Mode operation is used.

100

Burst Mode

3.3V

90

80

1.8V

70

Burst

Mode

60

50

EFFICIENCY (%)

40

30

20

Figure 7. PWM and Burst Mode Efficiency

1.8V

PWM Mode

1

3.3V

PWM Mode

V

= 3.6V

BAT

10 100 1000

LOAD CURRENT (mA)

3455 F07

Programming Switching Regulator Output Voltage

The output voltage for each switching regulator is programmed using a resistor divider from the output connected to the feedback pins (FB1 and FB2):

R

2

VV

=+

08 1

OUT

.•

R

1

Typical values for R1 are in the range of 80k to 400k.

V

OUT

R2

R1

3455 F06

GND

1, 18

25

FB1, FB2

LTC3455

Figure 6. Setting the Output Voltage

Tie the MODE pin to V

to always allow automatic Burst

MAX

Mode operation. Even when the MODE pin is high, the

LTC3455 will only enter Burst Mode when the load current

is low. For many noise-sensitive systems, Burst Mode

operation might be undesirable at certain times (i.e. during

a transmit or receive cycle of a wireless device), but highly

desirable at others (i.e. when the device is in low-power

standby mode). The MODE pin can be used to enable or

disable Burst Mode operation at any time, offering both

low-noise and low-power operation when they are needed

the most. Burst Mode is disabled initially at startup (for the

first 200ms) and also whenever external power is available, even if the MODE pin is pulled high.

Figure 8 shows the switching waveforms for switcher 1

(both PWM mode and Burst Mode Operation) with VIN =

3.6V, V

Burst Mode is a registered trademark of Linear Technology Corporation.

= 1.8V, and I

OUT1

OUT1

= 25mA.

3455f

17

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Burst Mode

V

SW1

2V/DIV

V

OUT1

50mV/DIV

AC COUPLED

I

L1

100mA/DIV

V

SW1

2V/DIV

V

OUT1

10mV/DIV

AC COUPLED

I

L1

100mA/DIV

Figure 8. Burst Mode and PWM Mode Waveforms

5µs/DIV

PWM Mode

1µs/DIV

Soft-Start for each Switcher

Soft-start is accomplished by gradually increasing the

peak inductor current for each switcher. This allows each

output to rise slowly, helping minimize the battery in-rush

current. Figure 9 shows the battery current during startup.

A soft-start cycle occurs whenever each switcher first

turns on, or after a fault condition has occurred (thermal

shutdown or UVLO).

3455 F08a

3455 F08b

In-Rush Current Limiting

When the LTC3455 is battery-powered, an internal 0.15Ω

PMOS switch connects the battery (V

pin) to the V

BAT

MAX

pin to provide power for both switchers and other internal

circuitry. This PMOS switch is turned off in shutdown, and

the V

pin discharges to ground, providing output

MAX

disconnect for all outputs. At startup, this PMOS must first

charge up any capacitance present on the V

pin to the

MAX

battery voltage. To minimize the in-rush current needed

from the battery, the PMOS switch is current-limited to

900mA and both switchers are disabled while the V

voltage is ramping up. Once V

reaches the battery

MAX

MAX

voltage, the PMOS current-limit increases to 4A and both

switchers are allowed to turn on. Figure 9 shows the

startup battery current for the LTC3455, which stays wellcontrolled while V

is ramping up and while both

MAX

switchers outputs are rising.

Battery Charger General Information

The battery charger and Switcher 1 will always be enabled

whenever USB or wall power is present (as sensed by the

USB and WALLFB pins). This ensures that the battery can

be charged and that the microcontroller is alive whenever

external power is available. For some applications, it may

be undesirable for the charger to become active immediately when external power is applied. For such applications, an NMOS switch can be used to disconnect the

R

resistor and allow the PROG pin to float high,

PROG

turning off the charger. In this manner, charging occurs

only when allowed by the microcontroller.

V

OUT1

V

OUT2

500mA/DIV

18

V

MAX

2V/DIV

(1.8V)

2V/DIV

(3.3V)

2V/DIV

I

BAT

100µs/DIV

Figure 9. In-Rush Current at Startup

3455 F09

The LTC3455 battery charger is a constant-current, constant-voltage charger. In constant-current mode, the maximum charge current is set by a single external resistor.

When the battery approaches the final float voltage, the

charge current begins to decrease as the charger switches

to constant-voltage mode. The charge cycle is terminated

only by the charge timer.

3455f

LTC3455

U

WUU

APPLICATIO S I FOR ATIO

Charge and Recharge Cycles

When external power is first applied, a new charge cycle is

always initiated. The battery will continue charging until

the programmed charge time is reached. If the battery

voltage is below 4.05V at the end of this cycle, the

LTC3455 will start a new charge cycle. This action will

continue until the battery voltage exceeds the 4.05V threshold. This operation is typically seen only when charging

from USB power. Because the charge current can vary

dramatically when the LTC3455 is USB powered, it takes

considerably longer to charge a battery using the USB

supply (as compared to a wall adapter). If the timer

capacitor is chosen correctly, the battery should be fully

charged on one cycle when wall power is available.

If the battery is above the 4.05V threshold when a charge

cycle has expired, charging will stop. At this point, a

recharge cycle is initiated if any of the following occurs:

The battery voltage drops below 4.05V, external power is

removed and reapplied, the PROG pin is floated temporarily, or the SUSPEND pin is temporarily pulled high (if the

LTC3455 is under USB power).

Programming Charge Current

The maximum charge current is programmed using one

external resistor connected between the PROG pin and

GND (use the closest 1% resistor value):

Capacitance on the PROG pin should be minimized to

ensure loop stability when in constant-current mode. Do

not place a capacitor directly from the PROG pin to ground.

Adding an external R-C network (see Figure 10) allows the

monitoring of average, rather than instantaneous, battery

charge current. Average charge current is typically of

more interest to the user, especially when the LTC3455 is

USB powered, as the battery charge current varies significantly with normal load transients.

LTC3455

PROG

10k

C

FILTER

2

PROG

GND

25

Figure 10. Monitoring Average Charge Current

R

CHARGE

CURRENT

MONITOR

CIRCUITRY

3455 F10

Programming the Battery Charger Timer

An external capacitor on the TIMER pin sets the total

charge time. When this timer elapses the charge cycle

terminates and the CHRG pin assumes a high impedance

state. The total charge time is programmed as:

T

(hours) = C

TIMER

• (3 hours) / (0.1µF)

TIMER

Trickle Charge and Defective Battery Detection

R

= 1000 • 1.23V / I

PROG

BAT

If only USB power is used (no wall adapter), select the

R

value to be 2.49kΩ (or larger) to set the maximum

PROG

charge current at 500mA. If a wall adapter is also used,

I

CHARGE

R

can be programmed up to 1A (with a 1.24kΩ

value), and the USB power manager will automati-

PROG

cally throttle back the charge current to below 500mA

when under USB power.

Monitoring Charge Current

The voltage on the PROG pin is an accurate indication of

the battery charge current under all charging conditions.

I

= 1000 • 1.23V / R

BAT

PROG

If the battery voltage is below 2.85V at the beginning of the

charge cycle, the charger goes into trickle charge mode,

reducing the charge current to 10% of its programmed

full-scale value. If the low battery voltage remains for one

quarter of the programmed total charge time, the battery

is assumed to be defective, the charge cycle is terminated,

and the CHRG pin goes to a high impedance state. This

fault is cleared if any of the following occurs: The battery

voltage rises above 2.85V, external power is removed and

reapplied, the PROG pin is floated temporarily, or the

SUSPEND pin is temporarily pulled high (if the LTC3455 is

under USB power). The device will still operate normally

from USB or wall power even if the charger has turned off

due to a trickle-charge timeout.

3455f

19

LTC3455

V

USB

(V)

3.75

0

CHARGE CURRENT (mA)

100

200

300

400

500

4.00

4.25 4.50 4.75

3455 F12

5.00 5.25

I

BAT

USB HIGH POWER MODE

V

BAT

= 3.6V

U

WUU

APPLICATIO S I FOR ATIO

Battery Charger Thermal Limit

An internal thermal limit reduces the charge current if the

die temperature attempts to rise above approximately

105°C. This protects the LTC3455 from excessive temperature, and allows the user to push the limits of the

power handling capability of a given circuit board without

risk of damaging the LTC3455. Another benefit of the

thermal limit is that charge current can be set according to

typical, not worst-case, ambient temperatures for a given

application with the assurance that the charger will automatically reduce the current under worst-case conditions.

CHRG Status Output

The CHRG pin is pulled low with an internal N-channel

MOSFET whenever the battery charger is enabled, and is

forced into a high impedance state whenever it is disabled.

This NMOS device is capable of driving an external LED.

This pin does not provide any C/10 information.

As the USB voltage drops below 4.5V, the charge current

gradually reduces (and eventually shuts off around 4V).

This helps prevent “chattering” and stability problems

when using long, resistive USB cables. Figure 12 shows

this reduction in charge current.

Figure 12. Charge Current vs USB Voltage

Special Charger Features while USB Powered

The LTC3455 has several special features that help make

the most of the power available from the USB power

supply. The internal USB power controller automatically

throttles back the battery charge current to help keep the

total system current under the strict 500mA/100mA USB

limit. The graph in Figure 11 shows how charge current,

I

, decreases as the current needed for the rest of the

BAT

system increases (both switchers and all other external

devices pull current from the V

current, I

pin). The total USB

MAX

, always stays below 500mA.

USB

500

I

400

300

200

100

CHARGE AND USB CURRENT (mA)

–100

Figure 11. Charge Current vs Total System Current

0

USB HIGH POWER MODE

= 5V

V

USB

= 3.6V

V

BAT

0

100

TOTAL SYSTEM CURRENT (mA)

USB

I

BAT

200 300 400

500 600

3455 F11

Because the charge current can vary dramatically when

the LTC3455 is USB powered, battery charging can take

considerably longer using the USB supply (as compared

to a wall adapter).

Constant-Current-Only Charger/Disabling the

Charger␣ Timer

To use the charger in a constant-current-only mode,

connect the TIMER pin to V

to disable the timer,

MAX

voltage amplifier, and trickle charge function. To disable

only the timer function and leave all others intact, connect

the TIMER pin to GND. Since the charge cycle is terminated only by the charge timer, external charge termination is required when using either of these methods. Use

an external NMOS to float the PROG pin and disable

charging.

Constant-current-only mode is a good choice for systems

that are always powered by a USB supply or wall adapter,

and the charger can be used to charge a super-cap or

backup battery. Disabling the voltage amplifier allows the

super-cap/backup battery to charge up fully to the available USB or wall adapter voltage.

3455f

20

LTC3455

1.8V

LBO

17

1M

LOW-BATTERY

DECTECTOR

V

BAT

16

2.49M

806k

3.3V

17

100k

3455 F14

LDO

2.5V

16

169k

100pF

80.6k

AO

LTC3455

AI

AO

LTC3455

AI

10µF

U

WUU

APPLICATIO S I FOR ATIO

Hot Swap Output

A current limited Hot Swap output is provided for powering memory cards or other external devices that can be

hot-plugged into the system. Typically connected to the

3.3V supply, this output provides isolation to prevent the

external device from disturbing the 3.3V supply when

inserted. The Hot Swap output can only operate when the

LTC3455 is on, and is enabled using the HSON pin. If this

hot-plugging protection is not needed, this output can be

used as a load switch for other devices within the system.

The HSO pin is discharged to ground when the LTC3455

is shut down.

Gain Block

The LTC3455 contains a gain block (pins AI and AO) that

can be used as either a low-battery indicator, or as an LDO

with the addition of an external PNP. Both circuits are

shown in Figure 13. The LDO is convenient for applications

needing a third output (possibly a low current 2.5V or a

quiet 3V supply). The AO pin can sink around 1mA, which

typically limits the LDO current to 100mA or less (due to

the current gain of the PNP). An external PMOS can be

used for the LDO, but a much larger output capacitor is

needed to ensure stability at light loads.

The gain block is alive whenever switcher 1 is enabled, and

is turned off during shutdown to minimize battery drain.

This means that the low-battery detector will not report a

low-battery condition until the LTC3455 is turned on. This

Figure 13. Low-Battery Detector and LDO Using the Gain Block

is not a problem for most applications since the LTC3455

usually powers the microcontroller and all other intelligence in the system.

PCB Layout Considerations

As with all DC/DC converters, careful attention must be

paid to the printed circuit board (PCB) layout and component placement. The V

capacitor, V

BAT

capacitor, and

MAX

both inductors must all be placed as close as possible to

the LTC3455. These components, along with both DC/DC

converter output capacitors, should be placed on the same

side of the circuit board as the LTC3455, with their

connections made on that top layer. Place a local, unbroken ground plane below these components that is tied to

the exposed pad of the LTC3455. The exposed pad (pin 25)

must be soldered to the PCB (to system ground) for proper

operation.

U

TYPICAL APPLICATIO S

Standalone USB Power Supply

with Temporary Backup Power

Although designed primarily for Li-Ion powered portable

applications, the LTC3455 is also a good choice for

systems that are always powered by a USB supply or wall

adapter. The battery charger can then be used to charge up

a large capacitor or backup battery, which briefly provides

power to the system after the external power has been

removed. This gives the microcontroller enough time to

follow proper shutdown procedures when the main power

source is abruptly removed. Figure 14 shows a standalone

power supply for USB high power applications (500mA

maximum USB current) using the LTC3455. The total

system power should be kept below 1.8W to ensure clean

operation even under worst-case USB conditions. With

the resistor values shown, the low-battery indicator (AI

and AO pins) triggers when the V

pin voltage drops to

MAX

4V, notifying the microcontroller of an impending dropout

condition. The 1MΩ resistor connected between the AI

3455f

21

LTC3455

TYPICAL APPLICATIO S

U

USB 5V

4.7µF

1Ω

C6

1.8V

DROPOUT

V

MAX

USB

CONTROLLER

C5

10µF

V

C4

4700µF

10k

82.5k

20k

8

USB

6

SUSPEND

5

USBHP

10

V

MAX

LTC3455

4

CHRG

11

WALLFB

3

MAX

TIMER

2

PROG

2.49k

9

V

BAT

17

AO

1M

16

AI

C1, C2, C3, C5, C6: X5R OR X7R CERAMIC

L1, L2: TOKO DB318C

ALL RESISTORS 1%

MODE

HSON

ON2

PWRON

RST

PBSTAT

HSO

HSI

SW2

FB2

SW1

FB1

GND

3455 TA02

21

15

19

22

20

23

24

ON

14

13

12

18

7

1

25

Figure 14. Standalone USB Power Supply with

Temporary Backup Power

1M

L2, 4.7µH

10pF

L1, 4.7µH

10pF

1M

ON/OFF

µC

1.8V

3.3V, HS

C3

1µF

249k

80.6k

100k

80.6k

3.3V

0.4A

C2

10µF

1.8V

0.2A

C1

10µF

USB 5V

1Ω

C6

4.7µF

WALL 5V

1Ω

C7

1µF

SINGLE

CELL Li-ION

3.3V TO 4.2V

C1 TO C8: X5R OR X7R CERAMIC

L1, L2: TOKO DB318C

D1: ON SEMI MBRM110E

ALL RESISTORS 1%

USB

CONTROLLER

C5

D1

10µF

3.32k

1.24k

+

C8, 0.1µF

C4

4.7µF

1k

2.49k

10

11

8

6

5

4

3

2

9

USB

SUSPEND

USBHP

V

MAX

CHRG

WALLFB

TIMER

PROG

V

BAT

LTC3455

MODE

HSON

ON2

PWRON

RST

PBSTAT

HSO

HSI

SW2

FB2

SW1

FB1

GND

ON

AO

AI

3455 F15

21

15

19

22

20

23

24

14

17

13

12

16

18

7

1

25

1M

C3

1µF

L2, 4.7µH

100pF

L1, 4.7µH

10pF

1M

3.3V, HS

1k

Figure 15. LTC3455 Application with 3.3V Output Current

Increased to 1.2A

ON/OFF

µC

249k

2.49k

80.6k

100k

80.6k

1.8V

M1

FDN304P

OR

Si2305DS

V

MAX

3.3V

1.2A

C2

2x10µF

1.8V

0.4A

C1

10µF

and AO pins provides 150mV of hysteresis (the dropout

indicator stays low until the V

4.15V). A 4700µ F backup capacitor connected to the V

pin rises back above

MAX

BAT

pin briefly provides power to the system after the USB

supply has been removed, and also helps support transient loads that slightly exceed the USB current limit.

Connecting this large capacitance to the V

pin has

BAT

several advantages. It provides a large energy reservoir

that is isolated from both the USB pin (the USB specification limits capacitance on the USB supply pin to 10µF or

less) and the V