FEATURES

■

Synchronous Rectification: Up to 96% Efficiency

■

True Output Disconnect

■

Inrush Current Limiting

■

Very Low Quiescent Current: 12µA

■

Up to 1.5A Continuous Output Current

■

Fixed Frequency Operation Up to 3MHz

■

0.5V to 4.5V Input Range

■

2.4V to 5.25V Adjustable Output Voltage

■

Guaranteed 1V Start-Up

■

Programmable Current Limit

■

Programmable Soft-Start

■

Synchronizable Oscillator

■

Manual or Automatic Burst Mode® Operation

■

Low-Battery Comparator

■

<1µA Shutdown Current

■

1.22V Reference Output Voltage

■

Small (4mm × 4mm) Thermally Enhanced QFN

Package

U

APPLICATIO S

■

Handheld Computers

■

Cordless Phones

■

GPS Receivers

■

Battery Backup Supplies

LTC3421

3A, 3MHz Micropower

Synchronous Boost Converter

with Output Disconnect

U

DESCRIPTIO

The LTC®3421 is a high efficiency, current mode, fixed

frequency, step-up DC/DC converter with true output disconnect and inrush current limiting. The device includes a

0.10Ω N-channel MOSFET switch and a 0.14Ω P-channel

synchronous rectifier. This product has the ability to simply program the output voltage, switching frequency, current limit, soft-start, Burst Mode threshold and loop

compensation with external passive components.

Quiescent current is only 12µA during Burst Mode opera-

tion, maximizing battery life in portable applications. The

oscillator frequency can be programmed up to 3MHz and

can be synchronized to an external clock applied to the

SYNC pin. An open-drain uncommitted low-battery comparator is included. The part maintains operation in

applications with a secondary cell powering the output

voltage during shutdown.

Other features include: 1µA shutdown, antiringing control,

thermal limit and reference output.

The LTC3421 is available in a small 4mm × 4mm QFN

package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a registered trademark of Linear Technology Corporation.

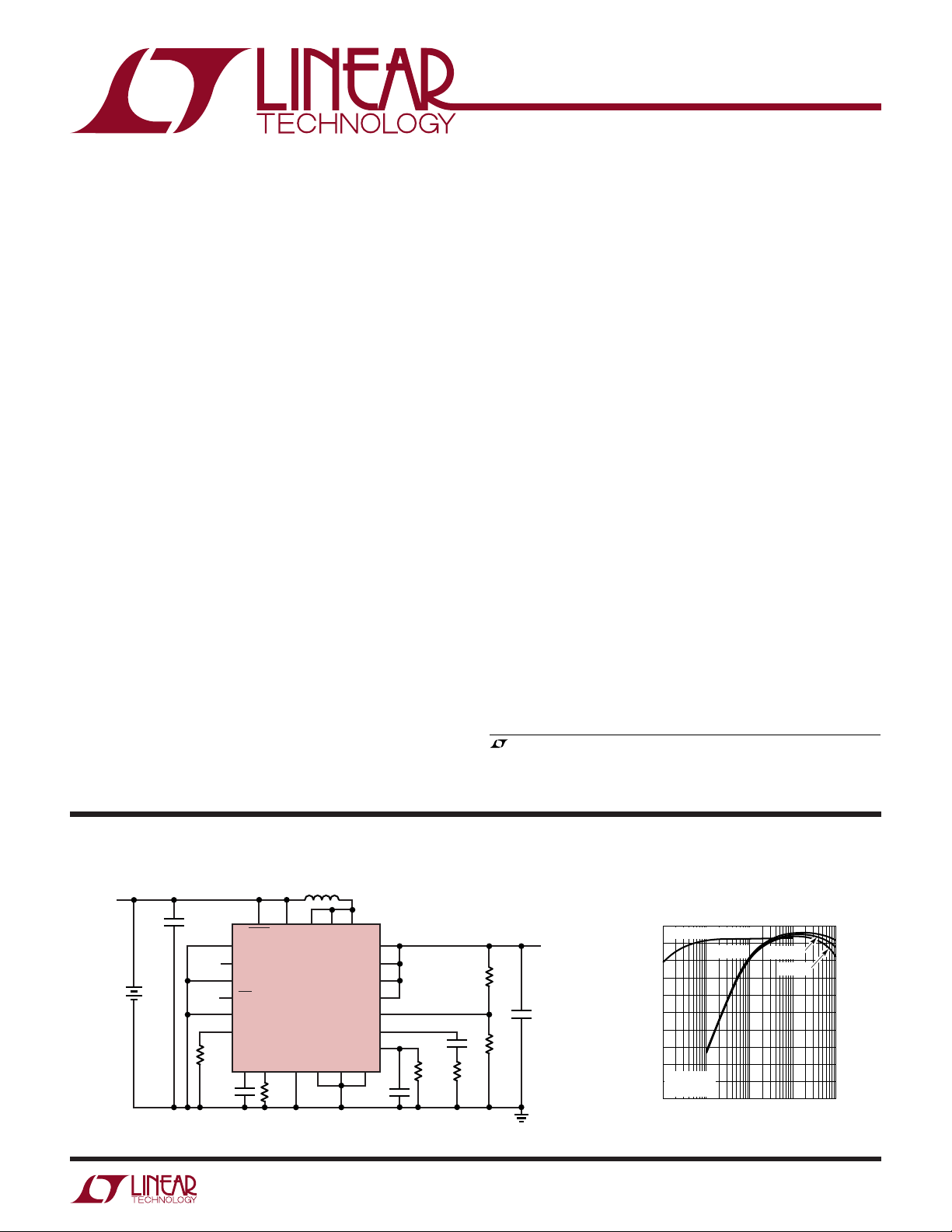

TYPICAL APPLICATIO

V

IN

1.8V TO 3V

*LOCATE COMPONENTS CLOSE TO PINS

C1: TAIYO YUDEN JMK212BJ106MM

2

CELLS

C1*

4.7µF

45.3k

0.1µF

221141516

V

SHDN

REF

LIM

SS R

IN

GND

T

28k

4

ENB

3

V

23

LBI

22

LBO

7

SYNC

8

I

U

L1

4.7µH

SW SW

SW

18

V

OUTS

17

V

OUT

19

V

OUT

20

LTC3421

PGND PGNDPGND

C5: TAIYO YUDEN JMK325BJ226MM

L1: TDK RLF7030T-4R7M3R4

V

OUT

BURST

FB

V

C

1312111056

0.1µF

1

24

9

470pF

20k

100k

340k

200k

C5*

22µF

3421 TA01

V

3.3V

1.2A

OUT

2-Cell to 3.3V Efficiency

100

Burst Mode OPERATION

90

80

70

60

50

40

EFFICIENCY (%)

30

20

V

10

f

0

0.1 10 100 1000

= 3.3V

OUT

= 1MHz

OSC

1

OUTPUT CURRENT (mA)

VIN = 3V

VIN = 2.4V

VIN = 2V

3421 G02

3421f

1

LTC3421

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

VIN, V

BURST, SHDN, SS, ENB, SW,

LBO, LBI, SYNC Voltages .......................... –0.3V to 6V

Operating Temperature Range

(Notes 2, 5)............................................. –40°C to 85°C

Storage Temperature Range ................. –65°C to 125°C

Lead Temperature (Soldering, 10 sec).................. 300°C

OUT

, V

Voltage ............................ –0.3V to 6V

OUTS

UUW

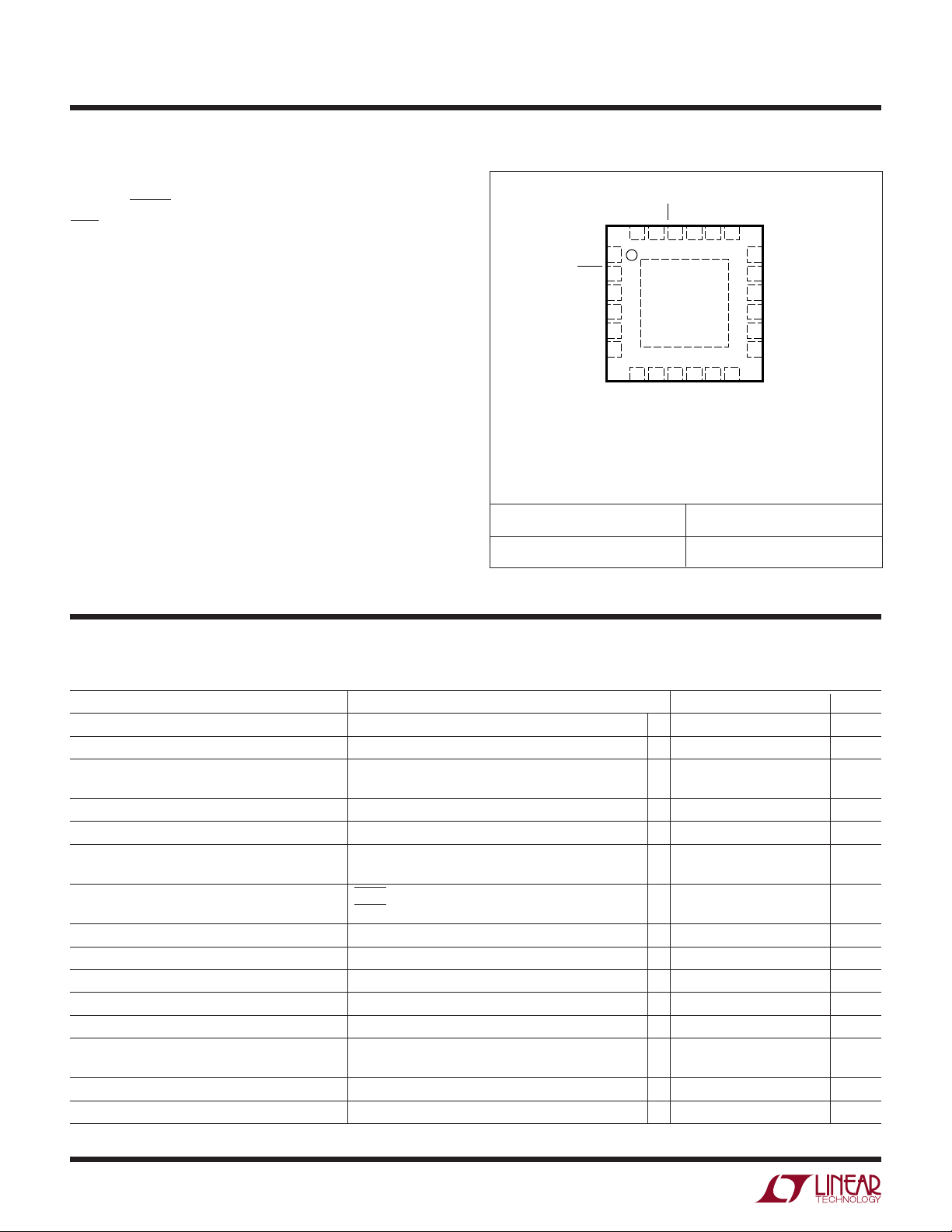

PACKAGE/ORDER I FOR ATIO

TOP VIEW

LBO

VINV

25

10 11 12

GND

BURST

OUTVOUT

18

V

OUTS

V

17

OUT

SW

16

SW

15

SW

14

13

PGND

PGND

PGND

LTC3421EUF

VCLBI

24 23 22 21 20 19

FB

1

SHDN

2

V

3

REF

ENB

4

R

5

T

SS

6

7 8 9

LIM

I

SYNC

24-LEAD (4mm × 4mm) PLASTIC QFN

T

JMAX

= 35°C/W 4 LAYER BOARD, θJC = 2.6°C/W

θ

JA

EXPOSED PAD IS GND (PIN 25) MUST BE SOLDERED TO PCB

UF PACKAGE

= 125°C, θJA = 40°C/W 1 LAYER BOARD,

ORDER PART NUMBER

UF PART MARKING 3421

Consult LTC Marketing for parts specified with wider operating temperature ranges.

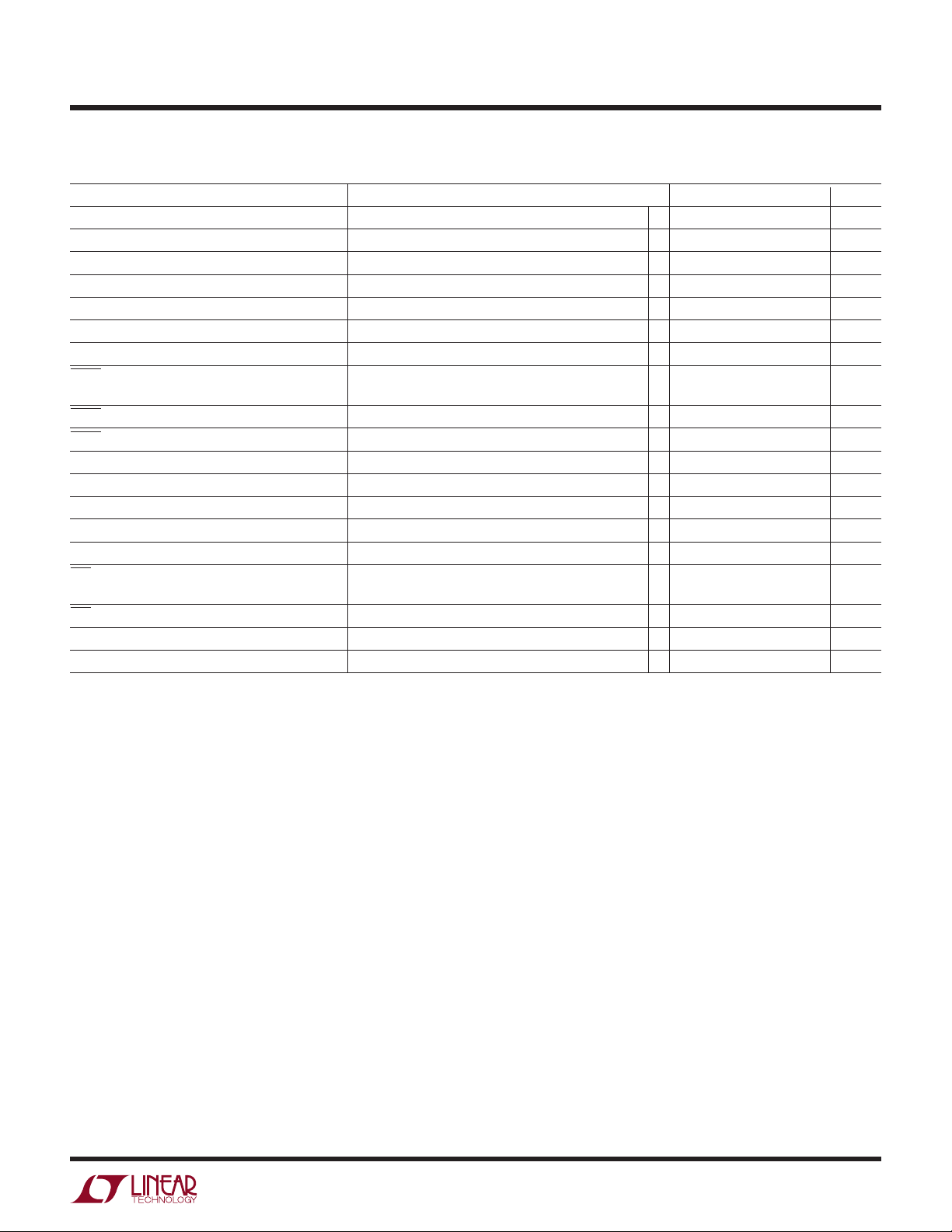

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 1.2V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum VIN Start-Up Voltage I

Minimum VIN Operating Voltage (Note 4) ● 0.5 V

Output Voltage Adjust Range 2.25 5.25 V

Feedback Voltage ● 1.196 1.220 1.244 V

Feedback Input Current VFB = 1.22V 1 50 nA

Quiescent Current—Burst Mode Operation VC = 0V, ENB = 0V (Note 3) 12 20 µA

Quiescent Current—Shutdown SHDN = 0V, ENB = 0V 0.1 1 µA

Quiescent Current—Active (Note 3) 0.6 1.1 mA

NMOS Switch Leakage 0.1 5 µA

PMOS Switch Leakage 0.1 10 µA

NMOS Switch On Resistance 0.1 Ω

PMOS Switch On Resistance 0.14 Ω

NMOS Current Limit I

Max Duty Cycle ● 84 91 %

Min Duty Cycle ● 0%

LOAD

V

= 0V, ENB = 2V (Note 3) 23 50 µA

C

SHDN = 0V, ENB > 1.4V 0.2 2 µA

Resistor = 105k ● 1 1.5 A

LIM

I

Resistor = 36.5k ● 3 4.2 A

LIM

The ● denotes the specifications which apply over the full operating

= 3.3V, RT = 28k, unless otherwise noted.

OUT

< 1mA 0.88 1 V

● 2.40 5.25 V

2

3421f

LTC3421

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 1.2V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Frequency Accuracy ● 0.85 1 1.15 MHz

SYNC Input High ● 2.2 V

SYNC Input Low ● 0.8 V

SYNC Input Current ● 0.01 1 µA

ENB Input High ● 1.2 V

ENB Input Low ● 0.4 V

ENB Input Current ● 1 µA

SHDN Input High V

SHDN Input Low 0.25 V

SHDN Input Current ● 0.01 1 µA

REF Output Voltage ● 1.183 1.22 1.257 V

REF Output Current Range –100 8 µA

Error Amp Transconductance 45 µs

LBI Threshold Falling Edge ● 0.58 0.6 0.62 V

LBI Input Current ● 0.01 1 µA

LBO Low Voltage VIN = 0V, I

LBO Leakage V

SS Current Source VSS = 1V 1.2 2.4 5 µA

BURST Threshold Voltage Falling Edge 0.87 0.97 1.07 V

OUT

V

OUT

V

IN

PGOOD

= 0V, I

The ● denotes the specifications which apply over the full operating

= 3.3V, RT = 28k, unless otherwise noted.

OUT

= 0V (Initial Start-Up) 1.00 V

> 2.4V 0.65 V

= 1mA 12.0 50 mV

SINK

= 20mA 0.25 0.5 V

SINK

= 5.5V 0.01 1 µA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC3421E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the 40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Current is measured into the V

bootstrapped to the output. The current will reflect to the input supply by

(V

) • Efficiency. The outputs are not switching.

OUT/VIN

pin since the supply current is

OUTS

Note 4: Once V

supply.

Note 5: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

is greater than 2.4V, the IC is not dependent on the V

OUT

IN

3421f

3

LTC3421

OUTPUT CURRENT (mA)

0

START VOLTAGE (V)

1.00

1.05

1.10

200

3421 G09

0.95

0.90

0.80

50

100

150

0.85

1.20

1.15

UW

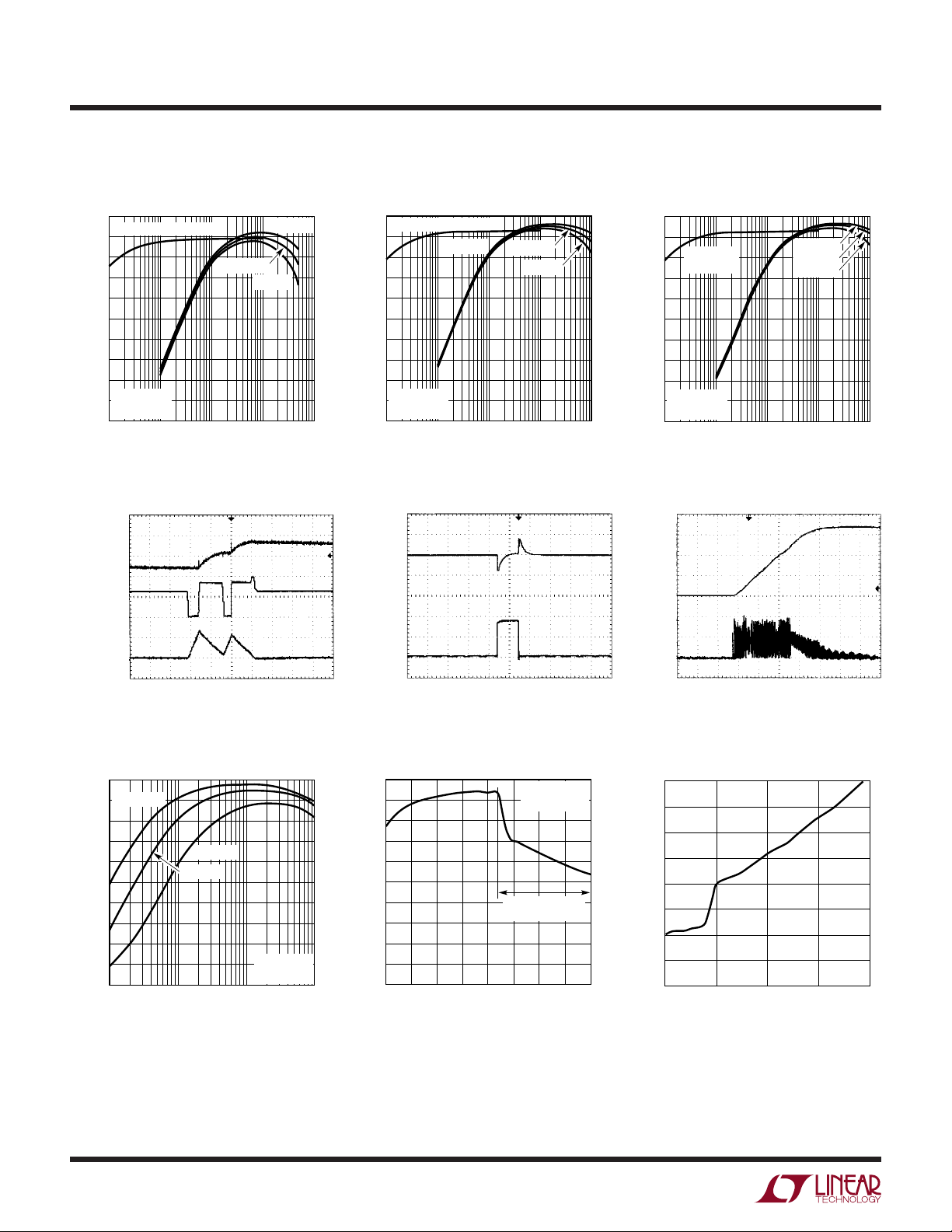

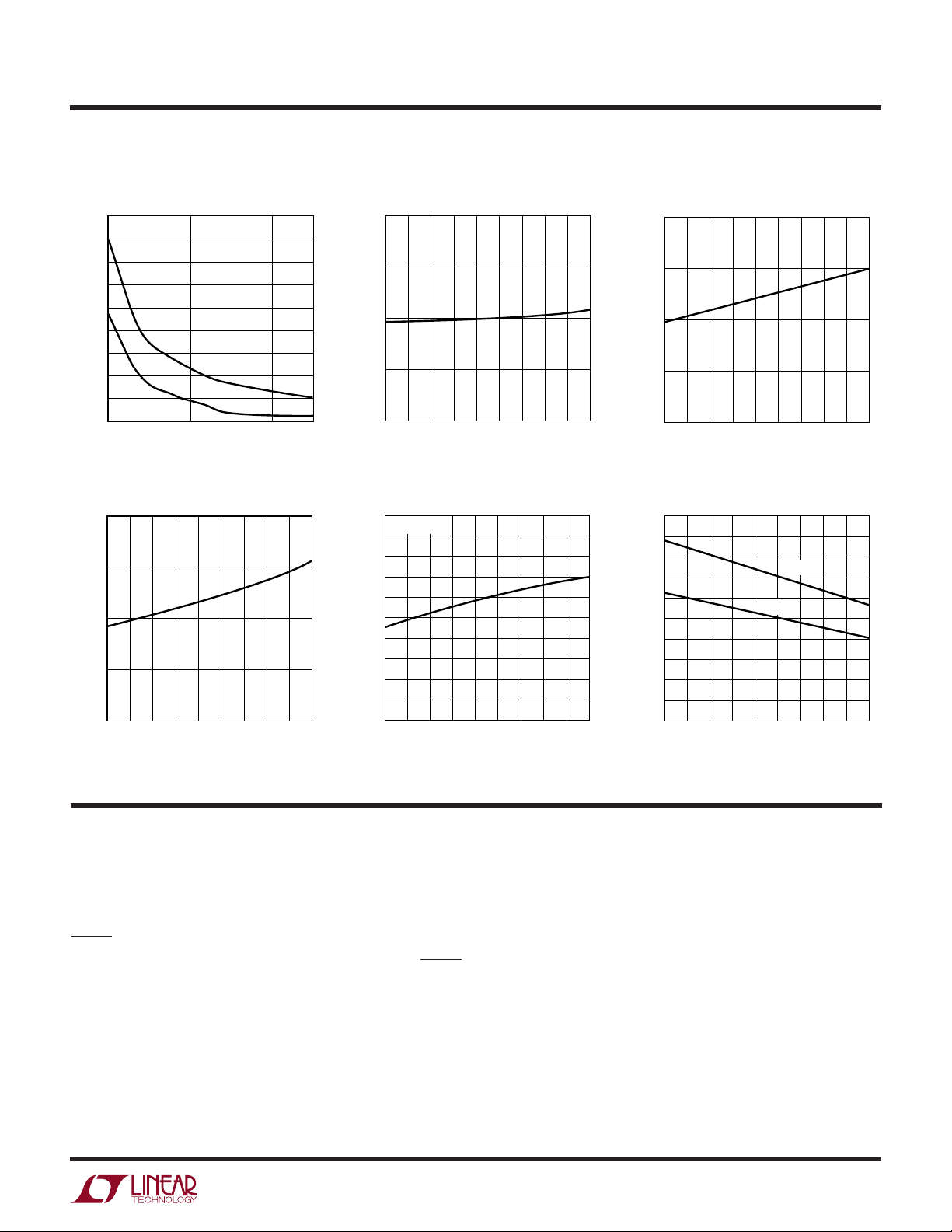

TYPICAL PERFOR A CE CHARACTERISTICS

(TA = 25°C, unless otherwise specified)

Single Cell to 3.3V Efficiency

100

Burst Mode OPERATION

90

80

70

60

50

40

EFFICIENCY (%)

30

20

V

= 3.3V

10

OUT

= 1MHz

f

OSC

0

0.1 10 100 1000

1

OUTPUT CURRENT (mA)

VIN = 1.2V

Burst Mode Operation Load Transient Response Inrush Current Control

V

OUT

50mV/DIV

AC COUPLED

SW

INDUCTOR

CURRENT

0.5A/DIV

VIN = 1.5V

VIN = 1V

3421 G01

2-Cell to 3.3V Efficiency Li-Ion to 5V Efficiency

100

Burst Mode OPERATION

90

80

70

60

50

40

EFFICIENCY (%)

30

20

V

10

OUT

f

OSC

0

0.1 10 100 1000

V

OUT

100mV/DIV

AC COUPLED

600mA

I

OUT

50mA

VIN = 3V

= 3.3V

= 1MHz

1

OUTPUT CURRENT (mA)

VIN = 2.4V

VIN = 2V

3421 G02

100

90

Burst Mode

80

OPERATION

70

60

50

40

EFFICIENCY (%)

30

20

V

= 5V

10

OUT

= 1MHz

f

OSC

0

0.1 10 100 1000

V

OUT

1V/DIV

INDUCTOR

CURRENT

0.5A/DIV

1

OUTPUT CURRENT (mA)

VIN = 4.2V

= 3.6V

V

IN

= 2.7V

V

IN

3421 G03

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

4

2.5µs/DIV

3421 G04

= 2.4V 2.5ms/DIV 3421 G05

V

IN

V

= 3.3V

OUT

= 44µF

C

OUT

Efficiency vs Frequency Efficiency vs V

100

f = 300kHz

f = 3MHz

f = 1MHz

1

10 100 1000

OUTPUT CURRENT (mA)

VIN = 2.4V

V

OUT

= 3.3V

3421 G07

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

1

1.5 2.5

2

INPUT VOLTAGE (V)

IN

PMOS LDO MODE

3

3.5

V

OUT

I

OUT

VIN > V

4

= 3.3V

= 200mA

OUT

4.5

3421 G08

= 0V TO 2.4V 500µs/DIV 3421 G06

V

IN

C

= 44µF

OUT

Start-Up Voltage vs Output Current

5

3421f

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LTC3421

(TA = 25°C, unless otherwise specified)

Burst Mode Threshold vs R

180

160

140

120

100

80

60

OUTPUT CURRENT (mA)

40

20

INTO BURST

0

20

OUT OF BURST

70

R

BURST

BURST

120

(kΩ)

3421 G10

FB Voltage Frequency Accuracy

1.24

1.23

1.22

VOLTAGE (V)

1.21

1.20

–45

–30 –15 0 15

TEMPERATURE (°C)

30 45 60 75 90

3421 G11

Burst Mode Quiescent Current Current Limit Accuracy R

20

15

10

CURRENT (µA)

5

0

–45

–30 –15 0 15

TEMPERATURE (°C)

30 45 60 75 90

3421 G13

1.70

R

LIM

1.65

1.60

1.55

1.50

1.45

1.40

CURRENT (A)

1.35

1.30

1.25

1.20

–30 0

–45

= 105k

–15

TEMPERATURE (°C)

30 90

45

15

60

75

3421 G14

1.03

1.01

0.99

FREQUENCY (MHz)

0.97

0.95

–45

–30 –15 0 15

DS(ON)

0.20

0.18

0.16

0.14

0.12

0.10

0.08

RESISTANCE (Ω)

0.06

0.04

0.02

0

–30 0

–15

–45

TEMPERATURE (°C)

TEMPERATURE (°C)

30 45 60 75 90

PMOS

NMOS

30 90

45

15

3421 G12

60

75

3421 G15

UUU

PI FU CTIO S

FB (Pin 1): Feedback Pin. Connect resistor divider tap

here. The output voltage can be adjusted from 2.4V to

5.25V. The feedback reference voltage is typically 1.220V.

SHDN (Pin 2): Shutdown Pin. Less than 0.25V on this pin

shuts down the IC. The IC is enabled when the SHDN

voltage is greater than 1V. Once V

hysteresis is applied to the pin (–500nA out of the pin)

allowing it to operate at a logic high while the battery can

drop to 0.5V.

V

(Pin 3): Buffered 1.22V Reference Output. This pin

REF

can source up to 100µA and sink up to 8µA. This pin must

be decoupled with a 0.1µF capacitor for stability.

is above 2.2V,

OUT

ENB (Pin 4): Reference Output (V

Comparator Enable. When ENB = Low, the V

) and Low-Battery

REF

output and

REF

low-battery comparator are disabled, which lowers the

quiescent current by 5µA. When ENB = High, the V

REF

output and the low-battery comparator are enabled. During shutdown, if the ENB = High and the output voltage is

pulled up to greater than 2.5V from a secondary source

such as a coin cell through a Schottky diode, the V

REF

output and low-battery comparator becomes powered

from the output voltage and enabled.

3421f

5

LTC3421

UUU

PI FU CTIO S

RT (Pin 5): Connect a resistor to ground to program the

oscillator frequency according to the formula:

OSC

28 100,

=

R

T

is in kHz and RT is in kΩ.

OSC

f

where f

SS (Pin 6): Soft-Start Pin. Connect a capacitor from this

pin to ground to set the soft-start time according to the

formula:

t(ms) = CSS(µF) • 320

The nominal soft-start charging current is 2.5µA. The

active range of SS is from 0.8V to 1.6V.

SYNC (Pin 7): Oscillator Synchronization Pin. A clock

pulse width of 100ns to 2µs is required to synchronize the

internal oscillator. If not used SYNC should be grounded.

I

(Pin 8): Current Limit Adjust Pin. Connect a resistor

LIM

from this pin to ground to set the peak current limit threshold for the N-channel MOSFET according to the formula

(note that this is the peak current in the inductor):

GND (Pin 10): Signal Ground Pin. Connect to ground plane

near the RT resistor, error amp compensation components and feedback divider.

PGND (Pins 11 to 13): Source Terminal of Power Internal

N-Channel MOSFET.

SW (Pins 14 to 16): Switch Pin for Inductor Connection.

For applications where V

SW to V

or to a snubber circuit is required to maintain

OUT

> 4.3V, a Schottky diode from

OUT

absolute maximum rating for SW. (see Application Circuits for 5V).

V

(Pins 17, 19 and 20): The output of the synchronous

OUT

rectifier and bootstrapped power source for the IC. A

ceramic bypass capacitor is required to be very close to

the V

V

OUTS

and PGND pins of the IC.

OUT

(Pin 18): V

Sense Pin. Connect V

OUT

OUTS

directly to

an output filter capacitor. The top of the feedback divider

network should also be tied to this point.

VIN (Pin 21): Input Supply Pin. Connect this pin to the

input supply and decouple with at least a 4.7µF ceramic

capacitor.

LIM

150

=

R

I

where I is in amps and R is in kΩ.

BURST (Pin 9): Burst Mode Threshold Adjust Pin. A

resistor/capacitor combination from this pin to ground

programs the average load current at which automatic

Burst Mode operation is entered, according to the formula:

R

BURST

where R

C

BURST

where C

BURST

BURST(MIN)

2

=

I

BURST

is in kΩ and I

CV

•

OUT OUT

≥

,10 000

and C

BURST

are in µF.

OUT

is in amps.

For manual control of Burst Mode operation, ground the

BURST pin to force Burst Mode operation or connect it to

V

to force fixed frequency PWM mode. Note that the

OUT

BURST pin must not be pulled higher than V

OUT

.

LBO (Pin 22): Open-Drain Output. This pin pulls low when

the LBI input is below 0.6V. The open-drain output can

sink up to 20mA. During Burst Mode operation LBO is only

active during the time the IC wakes up to service the

output.

LBI (Pin 23): Low-Battery Comparator Input. Typical

threshold voltage is 0.6V with 30mV hysteresis. This

function is enabled when the ENB pin is high. The lowbattery comparator will operate off VIN or V

, whichever

OUT

is greater.

VC (Pin 24): Error Amp Output. A frequency compensation

network is connected from this pin to ground to compensate the loop. See the section Compensating the Feedback

Loop for guidelines.

Exposed Pad (Pin 25): Ground. This pin must be soldered

to the PCB and is typically connected through the power

GND plane.

3421f

6

BLOCK DIAGRA

W

+

LTC3421

1V TO 4.5V

21

V

IN

ANTIRING

VINV

ANTICROSS

CONDUCTION

CURRENT

LIMIT

SHDN

ENB

V

REF

SHUTDOWN

1.22V REF

2%

THERMAL

REG/SHDN

PWM

LOGIC

2

V

4

OUT

3

14

15

16

SW

SW

DD

NMOS

SW

I

SENSE

AMP

PMOS

V

IN

WELL

SWITCH

+

–

I

ZERO

AMP

V

18

OUTS

V

OUT

17

V

OUT

19

V

OUT

20

R1

V

OUT

2.40V TO 5.25V

+

I

LIM

BURST

8

SS

6

FB

1

V

C

24

9

R

C1

C

SS

R2

C

P

R

Z

SLEEP

OFF

–

–

CURRENT

COMP

+

++

Σ

Burst Mode

CONTROL

1%

ERROR

AMP

I

LIMIT

150k/R

+

–

=

C1

1.22V

I/3000

+

SYNC

R1

R2

0.97V/1.05V

–

LBO

22

13

3421 BD

3421f

EXPOSED

PAD

25

–

+

–3%

BURST

COMP

+

3%

–

PGND

PGND12PGND

11

R

T

SYNC

LBI

0.6V/

OSC

V

–

+

INVOUT

ENB

SLOPE COMP

GND

10

5

7

IN

23

0.63V

UV

OV

7

LTC3421

OPERATIO

U

LOW VOLTAGE START-UP

The LTC3421 includes an independent start-up oscillator

designed to start-up at input voltages of 0.85V typical. The

frequency and peak current limit during start-up are internally controlled. The device can start-up under some load

(see graph of Start-Up Current vs Input Voltage). Softstart and inrush current limiting are provided during startup as well as normal mode. The same soft-start capacitor

is used for each operating mode.

When either VIN or V

normal operating mode. Once the output voltage exceeds

the input by 0.3V, the IC powers itself from V

of VIN. At this point the internal circuitry has no dependency on the VIN input voltage, eliminating the requirement for a large input capacitor. The input voltage can drop

as low as 0.5V without affecting circuit operation. The

limiting factor for the application becomes the availability

of the power source to supply sufficient energy to the

output at the low voltages and the maximum duty cycle,

which is clamped at 91% typical.

exceeds 2.25V, the IC enters

OUT

instead

OUT

Oscillator

The frequency of operation is set through a resistor from

the RT pin to ground. An internally trimmed timing capacitor resides inside the IC. The oscillator can be synchronized with an external clock applied to the SYNC pin. When

synchronizing the oscillator, the free running frequency

must be set to an approximately 30% lower frequency

than the desired synchronized frequency.

Current Sensing

Lossless current sensing converts the peak current signal

to a voltage to sum in with the internal slope compensation. This summed signal is compared to the error amplifier output to provide a peak current control command for

the PWM. The slope compensation in the IC is adaptive to

the input voltage and output voltage. Therefore, the converter provides the proper amount of slope compensation

to ensure stability, but not an excess to cause a loss of

phase margin in the converter.

Error Amplifier

LOW NOISE FIXED FREQUENCY OPERATION

Shutdown

The part is shut down by pulling SHDN below 0.3V, and

activated by pulling the pin initially above 1V and maintaining a high state down to 0.5V. Note that the SHDN pin can

be driven above VIN or V

than the absolute maximum rating.

Soft-Start

The soft-start time is programmed with an external capacitor to ground on the SS pin. An internal current source

charges it with a nominal 2.5µA. The voltage on the SS pin

(in conjunction with the external resistor on the I

is used to control the peak current limit until the voltage on

the capacitor exceeds 1.6V, at which point the external

resistor sets the peak current. In the event of a commanded shutdown or a thermal shutdown, the capacitor is

discharged automatically. Note that Burst Mode operation

is inhibited during the soft-start time.

as long as it is limited to less

OUT

LIM

pin)

The error amplifier is a transconductance amplifier, with

its positive input internally connected to the 1.22V reference and its negative input connected to FB. A simple

compensation network is placed from COMP to ground.

Internal clamps limit the minimum and maximum error

amplifier output voltage for improved large-signal transient response. During sleep (in Burst Mode operation),

the compensation pin is high impedance; however, clamps

limit the voltage on the external compensation network,

preventing the compensation capacitor from discharging

to zero during the sleep time.

Current Limit

The programmable current limit circuit sets the maximum

peak current. This clamp level is programmed with a

resistor from I

current limit is automatically set to a nominal value of 0.6A

peak for optimal efficiency.

LIM

150

=

I

to ground. In Burst Mode operation, the

LIM

R

t(ms) = CSS(µF) • 320

8

where I is in amps and R is in kΩ.

3421f

OPERATIO

LTC3421

U

Zero Current Amplifier

The zero current amplifier monitors the inductor current to

the output and shuts off the synchronous rectifier once the

current is below 50mA typical, preventing negative inductor current.

Antiringing Control

The antiringing control places a resistor across the

inductor to damp the ringing on the SW pin in discontinuous conduction mode. The LCSW ringing (L = inductor,

CSW = capacitance on SW pin) is low energy, but can

cause EMI radiation.

V

REF

The internal 1.22V reference is buffered and brought out

to REFOUT. It is active when the ENB pin is pulled high

(above 1.4V). For stability, a minimum of a 0.1µF capacitor

must be placed on the pin. The output can source up to

100µA and sink up to 8µA. For the lowest possible quies-

cent current in Burst Mode operation, the reference output

should be disabled by grounding the ENB pin.

increasing the output capacitance. Another method of

reducing Burst Mode ripple is to place a small feedforward capacitor across the upper resistor in the V

feedback divider network.

During Burst Mode operation, the VC pin is disconnected

from the error amplifier in an effort to hold the voltage on

the external compensation network where it was before

entering Burst Mode operation. To minimize the effects of

leakage current and stray resistance, voltage clamps limit

the min and max voltage on VC during Burst Mode operation. This minimizes the transient experienced when a

heavy load is suddenly applied to the converter after being

in Burst Mode operation for an extended period of time.

For automatic operation, an RC network should be connected from BURST to ground. The value of the resistor

will control the average load current (I

Burst Mode operation will be entered and exited (there is

hysteresis to prevent oscillation between modes). The

equation given for the capacitor on BURST is for the

minimum value to prevent ripple on BURST from causing

the part to oscillate in and out of Burst Mode operation at

the current where the mode transition occurs.

BURST

) at which

OUT

Burst Mode OPERATION

Burst Mode operation can be automatic or user controlled.

In automatic operation, the IC will automatically enter

Burst Mode operation at light load and return to fixed

frequency PWM mode for heavier loads. The user can

program the average load current at which the mode

transition occurs using a single resistor.

The oscillator is shut down in this mode, since the on time

is determined by the time it takes the inductor current to

reach a fixed peak current and the off time is determined

by the time it takes for the inductor current to return to

zero.

In Burst Mode operation, the IC delivers energy to the

output until it is regulated and then goes into a sleep mode

where the outputs are off and the IC is consuming only

12µA of quiescent current. In this mode, the output ripple

has a variable frequency component with load current and

will be typically 2% peak-peak. This maximizes efficiency

at very light loads by minimizing switching and quiescent

losses. Burst Mode ripple can be reduced slightly by

R

BURST

where R

where C

In the event that a sudden load transient causes FB to

deviate by more than 4% from the regulation value, an

internal pull-up is applied to BURST, forcing the part

quickly out of Burst Mode operation. For optimum transient response when going between Burst Mode operation

and PWM mode, the mode should be controlled manually

by the host. This way PWM mode can be commanded

before the load step occurs, minimizing output voltage

droop. For manual control of Burst Mode operation, the

RC network can be eliminated. To force fixed frequency

PWM mode, BURST should be connected to V

force Burst Mode operation, BURST should be grounded.

C

BURST

BURST

BURST(MIN)

2

=

I

BURST

is in kΩ and I

CV

•

OUT OUT

≥

,10 000

and C

BURST

are in µF.

OUT

is in amps.

OUT

. To

3421f

9

LTC3421

OPERATIO

U

Simplified Diagram of Automatic Burst Mode Control Circuit

V

CC

1mA I

–

V

REF

–4%

FB

1

+

–

REF

+

V

±1%

UV

ERROR AMP/

SLEEP COMP

24

SSDONE

V

C

R

COMP

C

COMP

TO

MODULATOR

CLAMP

0.5V TO 1V

9

0.9V/

1.1V

BURST

R

B

/3000

OUT

SSDONE

–

+

C

B

SLEEP

MODE

1 = Burst Mode

OPERATION

0 = PWM MODE

3421 TA03

The circuit connected to BURST should be able to sink or

source up to 2mA. Note that Burst Mode operaton is

inhibited during start-up and soft-start.

Note that if VIN is above V

– 0.3V, the part will exit Burst

OUT

Mode operation and the synchronous rectifier will be

disabled.

Note that if the load applied during forced Burst Mode

operation exceeds the current that can be supplied, the

output voltage will start to droop and the part will automatically come out of Burst Mode operation and enter fixed

frequency mode, raising V

. The maximum current that

OUT

can be supplied in Burst Mode operation is given by:

10

I

O MAX

()

=

2

055

VV

+

1

•

–

()

OUT IN

V

IN

in amps

.

OUTPUT DISCONNECT AND INRUSH LIMITING

The LTC3421 is designed to allow true output disconnect

by eliminating body diode conduction of the internal

P-channel MOSFET rectifier. This allows V

to go to zero

OUT

volts during shutdown without drawing any current from

the input source. It also allows for inrush current limiting

at turn-on, minimizing surge currents seen by the input

supply. Note that to obtain the advantages of output

3421f

OPERATIO

LTC3421

U

disconnect, there must not be any external Schottky

diodes connected between the SW pins and V

OUT

.

Note: Board layout is extremely critical to minimize voltage overshoot on the SW pins due to stray inductance.

Keep the output filter capacitors as close as possible to the

WUUU

APPLICATIO S I FOR ATIO

COMPONENT SELECTION

V

24 23 22 21 20 19

LBI LBO VINV

V

C

FB

1

2

SHDN

3

V

REF

4

ENB

R

5

T

SS

6

I

LIM

SYNC

BURST GND PGND PGND

7 8 9 10 11 12

OUTVOUT

V

OUTS

V

PGND

OUT

SW

SW

SW

V

OUT

18

17

16

15

14

13

3421 F01

Figure 1. Recommended Component Placement. Traces Carrying

High Current are Direct (PGND, SW, V

). Trace Area at FB and

OUT

VC are Kept Low. Lead Length to Battery Should be Kept Short.

VIN and V

Ceramic Capacitors Should be as Close to the IC

OUT

Pins as Possible

Inductor Selection

The high frequency operation of the LTC3421 allows the

use of small surface mount inductors. The minimum

inductance value is proportional to the operating frequency and is limited by the following constraints:

3

L

and L

>>

VV V

IN MIN OUT MAX IN MIN

f

•–

()

() ( ) ()

••

f Ripple V

OUT MAX

()

IN

GND

MULTIPLE VIAS

TO GROUND

PLANE

V

pins and use very low ESR/ESL ceramic capacitors,

OUT

tied to a good ground plane. In V

a Schottky diode is required from the switch nodes to V

> 4.3V applications,

OUT

OUT

to limit the peak switch voltage to less than 6V unless

some form of external snubbing is employed. (See 5V

Applications section.)

where

f = Operating Frequency in MHz

Ripple = Allowable Inductor Current Ripple (Amps

Peak-Peak)

V

V

= Minimum Input Voltage

IN(MIN)

OUT(MAX)

= Maximum Output Voltage

The inductor current ripple is typically set to 20% to 40%

of the maximum inductor current.

For high efficiency, choose an inductor with high frequency core material, such as ferrite, to reduce core loses.

The inductor should have low ESR (equivalent series

resistance) to reduce the I2R losses and must be able to

handle the peak inductor current without saturating. Molded

chokes or chip inductors usually do not have enough core

to support peak inductor currents in the 1A to 4A region.

To minimize radiated noise, use a toroidal or shielded

inductor. See Table 1 for suggested inductor suppliers and

Table 2 for a list of capacitor suppliers.

Table 1. Inductor Vendor Information

SUPPLIER PHONE FAX WEB SITE

Coilcraft (847) 639-6400 (847) 639-1469 www.coilcraft.com

Coiltronics (561) 241-7876 (516) 241-9339

Murata USA: USA: www.murata.com

(814) 237-1431 (814) 238-0490

(800) 831-9172

Sumida USA: USA: www.sumida.com

(847) 956-0666 (847) 956-0702

Japan: Japan:

81-3-3607-5111 81-3-3607-5144

TDK (847) 803-6100 (847) 803-6296 www.component.tdk.com

TOKO (847) 297-0070 (847) 669-7864 www.toko.com

3421f

11

LTC3421

WUUU

APPLICATIO S I FOR ATIO

Output Capacitor Selection

The output voltage ripple has two components to it. The

bulk value of the capacitor is set to reduce the ripple due

to charge into the capacitor each cycle. The maximum

ripple due to charge is given by:

IV

•

V

RBULK

=

PIN

CVf

••

OUT OUT

where IP = peak inductor current.

The ESR (equivalent series resistance) is usually the most

dominant factor for ripple in most power converters. The

ripple due to capacitor ESR is simply given by:

V

where C

RCESR

ESR

= IP • C

ESR

= capacitor series resistance.

Low ESR capacitors should be used to minimize output

voltage ripple. For surface mount applications, AVX TPS

series tantalum capacitors, Sanyo POSCAP or Taiyo Yuden

ceramic capacitors are recommended. For through-hole

applications, Sanyo OS-CON capacitors offer low ESR in a

small package size.

In some layouts it may be necessary to place a 1µF low ESR

ceramic capacitor as close to the V

and GND pins as

OUT

possible.

Input Capacitor Selection

The input filter capacitor reduces peak currents drawn

from the input source and reduces input switching noise.

Since the IC can operate at voltages below 0.5V once the

output is regulated, the demand on the input capacitor is

much less. In most applications 1µF per amp of peak input

current is recommended. Taiyo Yuden offers very low ESR

ceramic capacitors, for example the 1µF in a 0603 case

(JMK107BJ105MA).

Table 2. Capacitor Vendor Information

SUPPLIER PHONE FAX WEB SITE

AVX (803) 448-9411 (803) 448-1943 www.avxcorp.com

Sanyo (619) 661-6322 (619) 661-1055 www.sanyovideo.com

TDK (847) 803-6100 (847) 803-6296 www.component.tdk.com

Murata USA: USA: www.murata.com

(814) 237-1431 (814) 238-0490

(800) 831-9172

Taiyo Yuden (408) 573-4150 (408) 573-4159 www.t-yuden.com

Operating Frequency Selection

There are several considerations in selecting the operating

frequency of the converter. The first is, which are the sensitive frequency bands that cannot tolerate any spectral

noise? The second consideration is the physical size of the

converter. As the operating frequency goes up, the inductor and filter capacitors go down in value and size. The trade

off is in efficiency since the switching losses due to gate

charge are going up proportional with frequency.

Another operating frequency consideration is whether the

application can allow “pulse skipping.” In this mode, the

minimum on time of the converter cannot support the duty

cycle, so the converter ripple will go up and there will be

a low frequency component of the output ripple. In many

applications where physical size is the main criterion,

running the converter in this mode is acceptable. In applications where it is preferred not to enter this mode, the

maximum operating frequency is given by:

f

MAX NOSKIP

where t

ON(MIN)

=

•

Vt

OUT ON MIN_()

Hz

= minimum on time = 120ns.

–

VV

OUT IN

Thermal Considerations

To deliver the power that the LTC3421 is capable of, it is

imperative that a good thermal path be provided to

dissipate the heat generated within the package. This can

be accomplished by taking advantage of the large thermal

pad on the underside of the IC. It is recommended that multiple vias in the printed circuit board be used to conduct

heat away from the IC and into a copper plane with as much

area as possible. In the event that the junction temperature gets too high, the peak current limit will automatically

be decreased. If the junction temperature continues to rise,

the part will go into thermal shutdown, and all switching

will stop until the temperature drops.

VIN > V

Operation

OUT

The LTC3421 will maintain voltage regulation when the

input voltage is above the output voltage. This is achieved

by terminating the switching on the synchronous PMOS

and applying VIN statically on the gate. This will ensure the

3421f

12

WUUU

f

V

IL

RHPZ

IN

OUT

=

π

2

2• • •

APPLICATIO S I FOR ATIO

LTC3421

volts • seconds of the inductor will reverse during the time

current is flowing to the output. Since this mode will

dissipate more power in the IC, the maximum output

current is limited in order to maintain an acceptable

junction temperature.

–

125

T

I

OUT MAX

()

=

•.–

40 1 5

VV

()

()

IN OUT

A

+

where TA = ambient temperature.

For example at VIN = 4.5V and V

= 3.3V, the maximum

OUT

output current is 370mA.

Short Circuit

The LTC3421 output disconnect feature allows output short

circuit while maintaining a maximum set current limit. The

IC has incorporated internal features such as current limit

and thermal shutdown for protection from an excessive

overload or short circuit. In applications that require a prolonged short circuit, it is recommended to limit the power

dissipation in the IC to maintain an acceptable junction

temperature. The circuit in Figure 2 will limit the maximum

current during a prolonged short by reducing the current

limit value in a short circuit by disconnecting R2 with the

N-channel MOSFET switch. R3 and C1 provide a soft-start

function after a short circuit. Resistor R1 lowers the current limit value as VIN rises, maintaining a relatively constant power. The current limit equation for the circuit in

Figure 2 is given by:

Closing the Feedback Loop

The LTC3421 uses current mode control with internal

adaptive slope compensation. Current mode control eliminates the 2nd order filter due to the inductor and output

capacitor exhibited in voltage mode controllers, and simplifies it to a single pole filter response. The product of the

modulator control to output DC gain and the error amp

open-loop gain gives the DC gain of the system:

V

GG

=

G

DC EA

G

CONTROL

CONTROL_OUTPUT

V

•,2

I

OUT

IN

=≈

••

G

EA

2000

V

REF

OUT

The output filter pole is given by:

I

f

FILTER POLE

where C

=

_

is the output filter capacitor.

OUT

OUT

••

π

VC

OUT OUT

The output filter zero is given by:

f

FILTER ZERO

where R

_

ESR

=

•• •

2

is the capacitor equivalent series resistance.

1

RC

π

ESR OUT

A troublesome feature of the boost regulator topology is

the right-half plane zero (RHP) and is given by:

I

LIMIT

where I

06 06

=

R

is in Amps; R

LIMIT

Figure 2. Current Limit Foldback Circuit for

Extended Short Conditions

.

LIM

I

LIM

8

R

LIM

100k

V

–

VN2222

IN

TO V

–.

R

1

IN

R1

1M

R2

50k

250

•

and R1 are in kΩ.

LIM

R3

10k

C1

0.1µF

3421 F02

TO V

OUT

At heavy loads this gain increase with phase lag can occur

at a relatively low frequency. The loop gain is typically

rolled off before the RHP zero frequency.

The typical error amp compensation is shown in Figure 3.

The equations for the loop dynamics are as follows:

f

POLE

f

ZERO

f

POLE

≈

1

2206

≈

1

2

≈

2

2

1

π

•• •

eC

1

π

•• •

RC

ZC

1

π

•• •

RC

ZC

which is extremely close to DC

C

1

1

2

3421f

13

LTC3421

WUUU

APPLICATIO S I FOR ATIO

U

TYPICAL APPLICATIO

5V Applications

ERROR

AMP

+

–

1.22V

FB

1

V

C

24

Figure 3

V

OUT

R1

R2

C

R

Z

C

C1

C2

3421 F03

When the output voltage is programmed above 4.3V it is

necessary to add a Schottky diode either from SW to

V

, or to a snubber network in order to maintain an

OUT

acceptable peak voltage on SW. The Schottky to the

V

2.7V TO

4.2V

Li-Ion

IN

C1*

10µF

+

*LOCATE COMPONENTS CLOSE TO PINS

C1: TAIYO YUDEN JMK212BJ106MM

C5: TAIYO YUDEN JMK325BJ226MM

23

22

R1

60k

C2

0.1µF

SHDN

4

ENB

3

V

REF

LBI

LBO

7

SYNC

8

I

LIM

SS R

L1

3µH

221141516

SW SW

V

IN

LTC3421

GND

T

PGND PGNDPGND

R2

28k

SW

V

BURST

D1: MOTOROLA MBR0520L

L1: SUMIDA CDRH6D28-3R0

M1: ZETEX ZXM61P025

OUTS

V

OUT

V

OUT

V

OUT

FB

V

C

1312111056

0.1µF

D1*

18

17

19

20

1

24

9

C3

C4

470pF

R3

10k

R4

100k

output will provide a peak efficiency improvement but will

negate the output disconnect feature. If output disconnect

is required, the Schottky to an active snubber network is

suggested as shown in Figure 4.

M1

R5

1.13M

R6

365k

C6*

1µF

C5*

22µF

×2

3421 F04

100

V

OUT

5V

1A

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

Li-Ion to 5V Efficiency

Burst Mode

OPERATION

V

= 5V

OUT

= 1MHz

f

OSC

0.1 10 100 1000

1

OUTPUT CURRENT (mA)

VIN = 4.2V

= 3.6V

V

IN

= 2.7V

V

IN

3421 G03

14

Figure 4. Lithium-Ion to 5V at 1A Application with an Active Snubber Circuit

3421f

PACKAGE DESCRIPTIO

LTC3421

U

UF Package

24-Lead Plastic QFN (4mm × 4mm)

(Reference LTC DWG # 05-08-1697)

0.70 ±0.05

4.50 ± 0.05

3.10 ± 0.05

2.45 ± 0.05

(4 SIDES)

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

4.00 ± 0.10

(4 SIDES)

PIN 1

TOP MARK

(NOTE 5)

NOTE:

1. DRAWING PROPOSED TO BE MADE A JEDEC PACKAGE OUTLINE MO-220 VARIATION (WGGD-X)—TO BE APPROVED

2. ALL DIMENSIONS ARE IN MILLIMETERS

3. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE, IF PRESENT

4. EXPOSED PAD SHALL BE SOLDER PLATED

5. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON THE TOP AND BOTTOM OF PACKAGE

6. DRAWING NOT TO SCALE

0.25 ±0.05

0.50 BSC

PACKAGE OUTLINE

0.75 ± 0.05

2.45 ± 0.10

(4-SIDES)

0.200 REF

0.00 – 0.05

BOTTOM VIEW—EXPOSED PAD

R = 0.115

TYP

0.23 TYP

(4 SIDES)

24

23

0.38 ± 0.10

1

2

(UF24) QFN 0603

0.25 ± 0.05

0.50 BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

3421f

15

LTC3421

TYPICAL APPLICATIO

U

Single Cell to 3.3V at 500mA with Secondary Cell Backup During Shutdown. LOWBAT and V

L1

R2

28k

V

IN

LTC3421

GND

4.7µH

SW SW

SW

V

OUTS

V

V

V

BURST

PGND PGNDPGND

OUT

OUT

OUT

FB

V

1312111056

0.1µF

18

17

19

20

1

24

C

9

C3

470pF

R3

40k

V

IN

1V TO 1.5V

1 CELL

PRIMARY CELL

C1*

4.7µF

301k

+

604k

*LOCATE COMPONENTS CLOSE TO PINS

C1: TAIYO YUDEN JMK212BJ106MM

0.1µF

LOW BAT

OUTPUT

R1

60k

0.1µF

221141516

SHDN

4

ENB

3

V

REF

23

LBI

22

LBO

7

SYNC

8

I

LIM

SS R

T

C2

C5: TAIYO YUDEN JMK325BJ226MM

L1: TOKO A916CY-4R7M

D1

+

C4

REF

3V

SECONDARY CELL

R4

100k

Single Cell to 3.3V Efficiency

100

Burst Mode OPERATION

90

80

70

60

50

40

EFFICIENCY (%)

30

20

V

= 3.3V

10

OUT

= 1MHz

f

OSC

0

0.1 10 100 1000

1

OUTPUT CURRENT (mA)

VIN = 1.5V

VIN = 1.2V

VIN = 1V

3421 G01

Output are Enabled

V

OUT

3.3V

500mA

R5

340k

C5*

22µF

R6

200k

3421 TA05

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1371/LT1371HV 3A (ISW), 500kHz, High Efficiency Step-Up DC/DC VIN: 2.7V to 30V, V

Converters DD, TO220-7, S20

LTC3400/LTC3400B 600mA (ISW), 1.2MHz, Synchronous Step-Up DC/DC 92% Efficiency, VIN: 0.85V to 5V, V

Converters I

: <1µA, ThinSOT

SD

LTC3401 1A (ISW), 3MHz, Synchronous Step-Up DC/DC Converter 97% Efficiency, VIN: 0.5V to 5V, V

I

: <1µA, MS10

SD

LTC3402 2A (ISW), 3MHz, Synchronous Step-Up DC/DC Converter 97% Efficiency, VIN: 0.5V to 5V, V

: <1µA, MS10

I

SD

LTC3425 5A (ISW), 8MHz, 4-Phase Synchronous Step-Up 95% Efficiency, VIN: 0.5V to 4.5V, V

DC/DC Converter 8MHz, Low Ripple in QFN

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

: 35V/42V, IQ: 4mA, ISD: <12µA,

OUT(MAX)

OUT(MAX)

OUT(MAX)

LINEAR TECHNOLOGY CORPORATION 2003

: 5V, IQ: 19µA/300µA,

OUT(MAX)

: 5.5V, IQ: 38µA,

: 5.5V, IQ: 38µA,

: 5.25V, IQ: 12µA,

OUT(MAX)

LT/TP 1103 1K PRINTED IN USA

3421f

Loading...

Loading...