L DESIGN FEATURES

R1

1%

R2

1%

VREF

VPG

GND

LTC2931

+

–

0.5V

V3, V4,

V5 OR V6

V

TRIP

R3

1%

R4

1%

LTC2931

V4

VREF

V

TRIP

R4

1%

R3

1%

LTC2931

6-Input Supervisors Offer Accurate

Monitoring and 125°C Operation

by Shuley Nakamura and Al Hinckley

Introduction

The latest trio of power supply supervisors from Linear Technology is ideal

for today’s multi-voltage systems that

require accurate supply monitoring.

The LTC2930, LTC2931, and LTC2932

are 6-input voltage monitors capable of

maintaining 1.5% threshold accuracy

from –40°C to 125°C. The combination of monitored supply voltages is

set by a single pin. Each part offers

16 threshold voltage combinations,

thus meeting the needs of almost

any multi-voltage system. This programmability eliminates the need to

qualify, source and stock unique part

numbers for different threshold voltage

combinations.

The overall architecture and operating specifications of these three

devices are similar, but each has

unique features (see Table 1). The

LTC2930 generates a reset after

any undervoltage event or when the

manual reset input (MR) pulls low. It

is ideal for space-constrained applications as it comes in a compact 3mm

× 3mm 12-lead DFN package. The

LTC2931 includes a watchdog input

(WDI), a watchdog output (WDO) and

user-adjustable watchdog periods to

enable microprocessor monitoring

and control. The LTC2932 can vary

its monitor thresholds from 5% to

12.5%, and a reset disable pin provides margining capability. Both the

LTC2931 and LTC2932 are packaged

in 20-pin TSSOP packages and have

separate comparator outputs, enabling individual supply monitoring

and/or sequencing.

Feature LTC2930 LTC2931 LTC2932

Configurable Input

Threshold Combinations

Threshold Accuracy 1.5% 1.5% 1.5%

Adjustable Reset Time

Buffered Reference

Individual Comparator

Outputs

Manual Reset

Independent Watchdog

Circuitry

Reset Disable

Supply Tolerance Fixed, 5% Fixed, 5%

Package

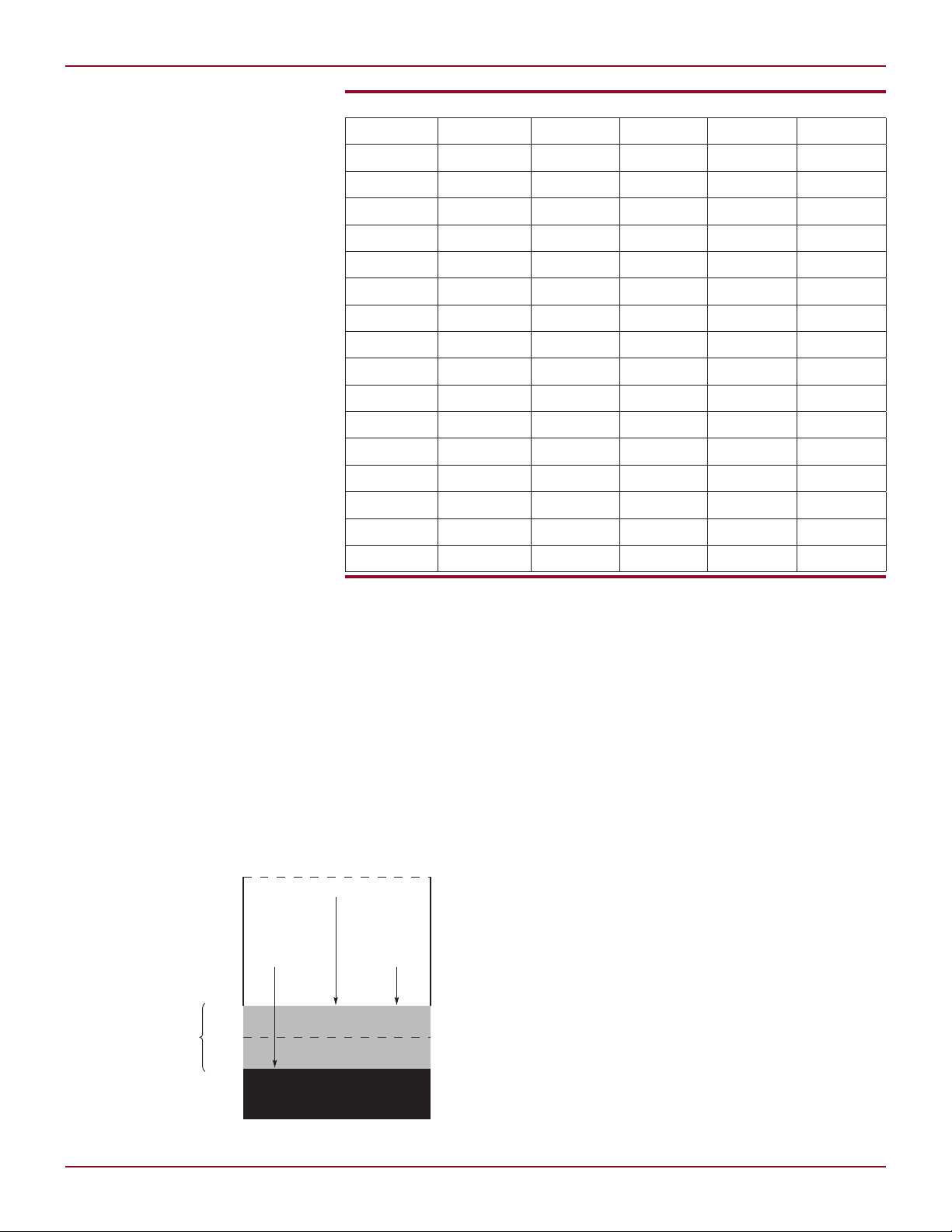

Single Pin Configuration

Makes Life Easy

These supervisors offer an elegant

method of configuring the input voltage thresholds. Figure 1 shows how a

single resistive divider at the VPG pin

sets the supervisor into one of the 16

threshold options shown in Table 2.

See the data sheet for suggested modesetting resistor values.

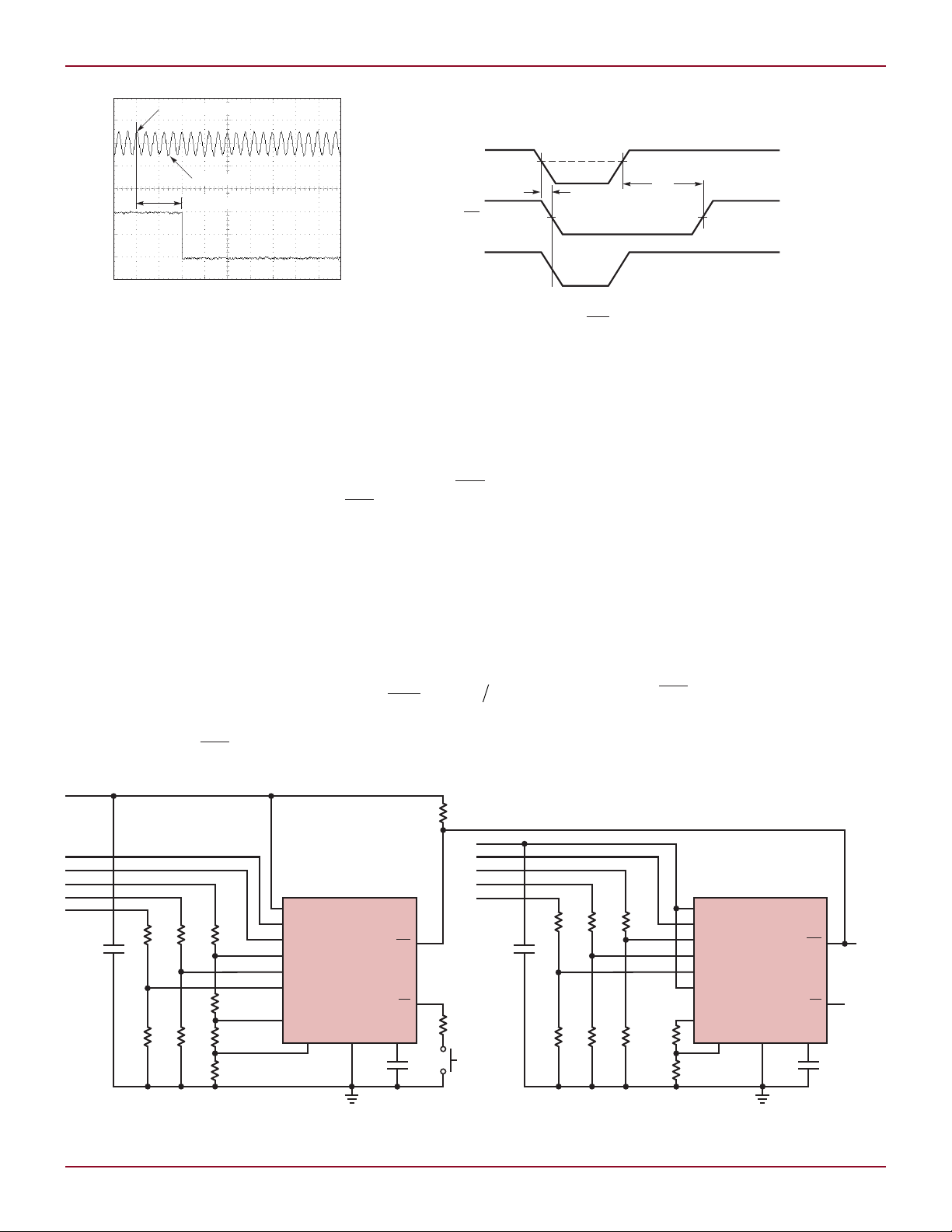

The actual thresholds are set by

integrated precision dividers for 5V,

Table 1. LTC2930, LTC2931, LTC2932 feature summary

16 16 16

L L L

L L L

L L

L

L

User Selectable

5%, 7.5%, 10%, 12.5%

12-lead

3mm × 3mm DFN

20-lead

F Package

3.3V, 3V, 2.5V, 1.8V, and 1.5V supply

monitoring. For other supply values,

uncommitted comparators with 0.5V

thresholds allow virtually any positive

supply to be monitored using a resistive divider, as shown in Figure 2a.

The V4 input also monitors negative

voltages—with the same 1.5% accuracy—using the integrated buffered

reference for offset (see Figure 2b).

20-lead

F Package

L

10

Figure 1. Mode selection

2a. 2b.

Figure 2. Using a resistive divider to set the voltage trip point

Linear Technology Magazine • March 2008

DESIGN FEATURES L

5V

4.75V

4.675V

±1.5%

THRESHOLD

BAND

4.6V

NOMINAL

SUPPLY

VOLTAGE

SUPPLY TOLERANCE

MINIMUM

RELIABLE

SYSTEM

VOLTAGE

IDEAL

SUPERVISOR

THRESHOLD

REGION OF POTENTIAL MALFUNCTION

–5%

–6.5%

–8%

What Does Threshold

Accuracy Mean?

Consider a 5V system with ±5% supply tolerance. The 5V supply may vary

between 4.75V to 5.25V. System ICs

powered by this supply must operate

reliably within this band (and a little

more, as explained below). A perfectly

accurate supervisor for this supply

generates a reset at exactly 4.75V.

However, no supervisor is this perfect.

The actual reset threshold of a supervisor fluctuates over a specified band;

the LTC2930, LTC2931 and LTC2932

vary ±1.5% around their nominal

threshold voltage over temperature

(Figure 3). The reset threshold band

and the power supply tolerance bands

should not overlap. This prevents false

or nuisance resets when the power

supply is actually within its specified

tolerance band.

The L TC 2930, LT C293 1 and

LTC2932 boast a ±1.5% reset thresh-

old accuracy, so a “5%” threshold is

usually set to 6.5% below the nominal

input voltage. Therefore, a typical

5V, “5%” threshold is 4.675V. The

threshold is guaranteed to lie in the

band between 4.750V and 4.600V

over temperature. The powered system must work reliably down to the

low end of the threshold band, or risk

malfunction before a reset signal is

properly issued.

A less accurate supervisor increases

the required system voltage margin

and increases the probability of system

malfunction. The tight ±1.5% accuracy

specification of the LTC2930, LTC2931

Linear Technology Magazine • March 2008

Figure 3. Tight 1.5% threshold accuracy yields high system reliability

Table 2. Voltage threshold modes

V1 (V) V2 (V) V3 (V) V4 (V) V5 (V) V6 (V)

5.0 3.3 2.5 1.8 ADJ ADJ

5.0 3.3 2.5 1.5 ADJ ADJ

5.0 3.3 2.5 ADJ ADJ ADJ

5.0 3.3 1.8 ADJ ADJ ADJ

5.0 3.3 1.8 –ADJ ADJ ADJ

5.0 3.3 ADJ ADJ ADJ ADJ

5.0 3.3 ADJ –ADJ ADJ ADJ

5.0 3.0 2.5 ADJ ADJ ADJ

5.0 3.0 1.8 ADJ ADJ ADJ

5.0 3.0 ADJ ADJ ADJ ADJ

3.3 2.5 1.8 1.5 ADJ ADJ

3.3 2.5 1.8 ADJ ADJ ADJ

3.3 2.5 1.8 –ADJ ADJ ADJ

3.3 2.5 1.5 ADJ ADJ ADJ

3.3 2.5 ADJ ADJ ADJ ADJ

3.3 2.5 ADJ –ADJ ADJ ADJ

and LTC2932 improves the reliability

of the system over supervisors with

wider threshold specifications.

coupling from other signals. If the

monitored voltage is near or at the reset threshold voltage, this noise could

cause spurious resets. Fortunately,

Glitch Immunity =

No Spurious Resets!

Monitored supply voltages are far from

being ideal, perfectly flat DC signals.

Riding on top of these supplies are

high frequency components caused

by a number of sources such as the

output ripple of the power supply or

the LTC2930, LTC2931 and LTC2932

have been designed with this potential

issue in mind, so spurious resets are

of little to no concern.

Some supply monitors overcome

spurious resets by adding hysteresis

to the input comparator. The amount

of applied hysteresis is stated as

a percentage of the trip threshold.

Unfortunately, this degrades monitor

accuracy because the true accuracy

of the trip threshold is now the percentage of added hysteresis plus the

advertised accuracy of the part. The

LTC2930, LTC2931 and LTC2932 do

not use hysteresis, but instead use

an integration scheme that requires

transients to possess enough magnitude and duration to switch the

comparators. This suppresses spurious resets without degrading the

monitor accuracy.

The COMP5 comparator output

response to a “noisy” input on the

LTC2931 is demonstrated in Figure 4.

11

L DESIGN FEATURES

C

t

M

pF ms t

RT

RST

RST

= =

( )

2

500

Ω

•

t

RST

V

RT

V

n

RST

COMP

n

t

UV

300µs PROPAGATION DELAY

–2mV DC STEP APPLIED HERE

500mV

100mV

P–P

V5

100mV/DIV

COMP5

LTC2930

1V

0.9V

–5.2V

1.8V

3.3V

5V

C

RT

47nF

MR

RST

VREF

VPG

GND CRT

V1

V2

V3

V4

V5

V6

121k

1%

R1A

16.2k

1%

R2A

86.6k

1%

100k

1%

10k**

10k

100k

1%

487k

1%

86.6k

1%

68.1k

1%

0.1MF

LTC2930

6V

8V

12V

3V

5V

C

RT

47nF

MANUAL RESET

PUSHBUTTON

t

RST

= 94ms

**OPTIONAL FOR EXTENDED ESD TOLERANCE

MR

RST RESET

VREF

VPG

GND CRT

V1

V2

V3

V4

V5

V6

100k

1%

R1B

40.2k

1%

R2B

59k

1%

100k

1%

100k

1%

2150k

1%

1400k

1%

1020k

1%

0.1MF

Figure 4. Comparator output is

resistant to noisy input voltage

In the example shown, a 500kHz,

100mV

sine wave centered at

P–P

500mV is applied to the V5 input. The

threshold voltage of the adjustable

input, V5, is 500mV. Even though

the signal amplitude goes as low as

450mV, COMP5 remains high. Next,

the DC level of the input is dropped

2mV. In response, COMP5 pulls low

and remains low. As mentioned earlier,

only transients of long enough duration

and magnitude trigger the comparator

output to pull high or low.

Adjustable Reset Timeout Period

for Varied Application Needs

Each of the supervisors includes an

adjustable reset timeout period, t

RST

.

Once all the inputs are above their

threshold values, the reset timer is

started (Figure 5). RST stays low for

Figure 5. RST timing diagram

the duration of t

and remains low

RST

as long as the time between transients

is less than the reset timeout. In other

words, the reset timeout prevents supply transients with frequencies greater

than 1/t

from causing undesired

RST

toggling at the RST output. Keeping

RST low during these supply transients

suppresses spurious resets.

The reset timeout period is adjustable to accommodate a variety of

microprocessor applications. Configure the reset timeout period, t

RST

, by

connecting a capacitor, CRT, between

the CRT pin and GND. The value of

this capacitor is determined by

Leaving the CRT pin unconnected

generates a minimum reset timeout of

approximately 25µs. Maximum reset

timeout is limited by the largest available low leakage capacitor.

Additional Glitch Filtering

Even though all six comparators

have built-in glitch filtering, adding

bypass capacitors on the V1 and V2

inputs is recommended, because of

these two, the input with the higher

voltage functions as VCC for the entire

chip. Additional filter capacitors may

be added to the V3, V4, V5 and V6

inputs if needed to suppress troublesome noise.

Open-Drain Reset

The RST outputs on the LTC2930,

LTC2931 and LTC2932 are opendrain and contain weak pull-up

current sources to the V2 voltage.

Figure 6. Wired-OR system reset

12

Linear Technology Magazine • March 2008

DESIGN FEATURES L

COMP1 COMP2 COMP3 COMP4 COMP5 COMP6

LTC2932

12V (9.6V THRESHOLD)

12V

SUPPLY

STATUS

DONE

2.5V

–5.2V

1.8V

3.3V

5V

365k1%487k

1%

5V

10k 10k

10k

0.1MF

t

RST

= 9.4ms

4.7nF

RDIS

T0

T1

VPG

GND

CRT

V1

V2

V3

V4

V5

RST

V6

VREF

SYSTEM

LOGIC

10k

LT3028

V

IN

3.3V

V

OUT

SHDN

LTM4600

V

IN

V

OUT

RUN

10k

LT3028

V

IN

1.8V

V

OUT

SHDN

10k

LTC3704

V

IN

–5.2V

V

OUT

RUN/UVLO

10k

LT3028

V

IN

2.5V

V

OUT

SHDN

100k1%121k

1%

1820k

1%

100k

1%

R1

16.2k

1%

R2

86.6k

1%

LTC2950-1

V

IN

INT

PB

KILL

EN

The open-drain structure provides

many advantages. For instance, each

of these outputs can be externally

pulled-up to voltages higher than V2

using a pull-up resistor. This facilitates

the use of multiple devices operating

under different I/O voltages. In addition, multiple open-drain outputs can

be configured in a “wired-OR” format

where the outputs are tied together.

Figure 6 showcases two LTC2930

supervisors, whose open-drain RST

outputs are tied together and pulledup to 5V via a 10k pull-up resistor.

If one RST output pulls low due to a

reset event, it sinks current and pulls

the other output low.

Linear Technology Magazine • March 2008

13

multi-voltage systems where it is

important to know which particular

supply has failed.

The individual comparator outputs

also allow power supply sequencing.

Figure 7 shows the LTC2932 in a

5-supply power-up sequencer. As

an input reaches its threshold, the

respective comparator output pulls

high and enables the next DC/DC

converter.

The LTC2950-1 is used to provide

pushbutton control for the sequencer.

After the pushbutton is pressed, the

LTC2950-1 pulls the RUN pin of the

LTM4600 high. Subsequently, the

LTM4600 generates a 5V output which

Figure 7. Five supply 12.5% tolerance power-up sequencer with pushbutton

Comparator Outputs Enable

Individual Supply Monitoring

and Sequencing Support

Real-time comparator outputs on both

the LTC2931 and LTC2932 indicate

the status of the individual inputs.

Similar to the RST output, the comparator outputs are also open-drain

and have weak pull-up current sources

to the V2 voltage.

While RST pulls low when an

undervoltage event occurs on any of

the monitored supplies, a comparator

output pulls low only when its counterpart input is below its threshold

voltage. The ability to monitor the

status of each supply is useful in

L DESIGN FEATURES

t

RST

t

WP

t < t

RST

t

WD

t

WD

RST

WDI

WDO

t

RST

t

RST

t

WD

A. UNDERVOLTAGE EVENT OCCURS, RST PULLS LOW, WDO PULLS HIGH, AND RST TIMER STARTS.

B. RST TIMES OUT (ALL INPUT VOLTAGES BECOME GOOD BEFORE RST TIMEOUT), t

RST

, THEN WATCHDOG TIMER STARTS.

C. WATCHDOG TIMES OUT, tWD, AND WDO PULLS LOW. RST TIMER STARTS.

D. WDI TRANSITION OCCURS BEFORE RST TIMEOUT. WDO PULLS HIGH AND WDO TIMER STARTS.

E. WDI TRANSITION OCCURS WHILE WDO IS HIGH. WATCHDOG TIMER CLEARS AND RESTARTS.

F. WATCHDOG TIMES OUT. WDO PULLS LOW AND RST TIMER STARTS.

G. RST TIMES OUT. WDO PULLS HIGH AND WATCHDOG TIMER STARTS.

A B C D E F G

t

RST

t

RST

t

MRW

V

RT

V

n

RST

MR

t

UV

t

MRD

C

t

M

pF ms t

WT

WD

WD

= =

( )

2050Ω

•

supplies power to each of the four

DC/DC converters.

Three Supervisor Flavors

LTC2930: Manual Reset (MR)

Forces RST Low

Use the manual reset input (MR) on

the LTC2930 to issue a forced reset,

independent of input voltage levels. A

10µA (typical) internal current source

pulls the MR pin to VCC. A logic low on

this pin pulls RST low. When the MR

pin returns high, RST returns high

after the selected reset timeout period

has elapsed, assuming all six voltage

inputs are above their thresholds

(Figure 8). The input-high threshold

on the MR pin is 1.6V (max), allowing

the pin to be driven by low voltage

logic as well.

LTC2931: Monitor a Microprocessor

with the Watchdog Function

The LTC2931’s independent watchdog

circuitry monitors a microprocessor’s

activity. The microprocessor is required to change the logic state of the

WDI pin on a periodic basis in order to

clear the watchdog timer. The LTC2931

consists of a watchdog input (WDI), a

watchdog output (WDO) and a timing

pin (CWT), which allows for a user

adjustable watchdog timeout period.

Figure 9 illustrates the watchdog timer

and its relationship to the reset timer

and WDI.

The watchdog timeout period is

adjustable and can be optimized for

software execution. The watchdog

Figure 8. MR timing diagram

timeout period, tWD, is adjusted by

connecting a capacitor, CWT, between

the CWT pin and ground. The value of

this capacitor is determined by

Leaving the CWT pin unconnected

generates a minimum watchdog timeout of approximately 200µs. Maximum

watchdog timeout is limited by the largest available low leakage capacitor.

LTC2932: Margining Capabilities

and Wider Threshold Tolerances

In high reliability system manufacturing and testing, it is important to

verify that the components will con-

Table 3. LTC2932 Tolerance Selection

T0 T1

TOLERANCE

(%)

Low Low 5 1.210

Low High 7.5 1.175

High Low 10 1.146

High High 12.5 1.113

V

REF

(V)

tinue to operate at or below the rated

power supply tolerance. Verification

usually involves margining the power

supplies, running their outputs at or

beyond rated tolerances. The LTC2932

is designed to complement such testing

in two ways. First, the RST output can

be disabled by pulling RDIS low. In this

state, the RST output remains high

despite any undervoltage events which

may occur during margining tests. This

does not affect the individual supply

monitoring, which is independent of

the logic state of RDIS. Second, lowering the trip thresholds can increase

supply headroom to match the margining ranges. This is simply a matter of

changing the two tolerance selection

inputs, T0 and T1, to adjust the global

supply tolerance to 5%, 7.5%, 10%, or

12.5% (see Table 3).

Automotive Application

The ease of implementation, wide

operating temperature range, and

low supply current requirements for

the LTC2930, LTC2931 and LTC2932

supervisors make them ideal for

automotive applications. Figure 10

14

Figure 9. Watchdog timing diagram

Linear Technology Magazine • March 2008

OUT

SENS

SNS

GATE OUT

WDI

WDO

IRF3710 IRF3710

LT4356DE-1

LTC2931

LTC3780

BUCK-BOOST CONVERTER

6V to 30V IN / 12V, 5A OUT

LT3010-5

100k

100k 100k 100k 100k 100k 100k

100k

100k

WDI

WDO

100k

R1A

59k

R2A

40.2k

2150k

4.99k

59k

383k

845k

10Ω10Ω

R5

10K

1M

V

CC

A

OUT

IN+

µP

UNREGULATED12V REGULATED 12V

FLT

FB

COMP1

COMP2

COMP3

COMP4

COMP5

COMP6

V2

V3

V4

V5

V6

RST

VREF

3.3V

2.5V

1.8V

5V

VPG

IN

GND

TMR

GND

LOWBAT

SHDN

SHDN

0.1µF

CTMR

0.1µF

1µF1µF

GND

CRT

C

RT

5V

5V

BATTERY

5V

100k

5V

5V

µP I/O

µP I/O

POWER

SYSTEMS

“ALWAYS ON”

ELECTRONICS

2N3904

1N4148

T0

RDIS

T1

100k

2150k

100k

100k 100k 100k 100k

100k

R1B

66.5k

R2B

34.8k

511k

COMP1

COMP3

COMP4

COMP5

COMP6

V3

V5

V6

RST

VREF

2.5V

5V

3.3V

VPG

5V

µP I/O

µP I/O

POWER

SYSTEMS

“IN CABIN”

ELECTRONICS

100k

MODE 5

845k

MODE 6

LTC2932

CWT

V1

C

WT

GND

CRT

C

RT

5V

V1

V2

V4

0.1µF

0.1µF

R

SENSE

4mΩ

DESIGN FEATURES L

Figure 10. The LTC2931 and LTC2932 in an automotive application

is a block diagram schematic of an

automotive application that uses

the LTC2931 and LTC2932. It was

designed to highlight and utilize the

features of these parts beyond simple

voltage monitoring. The voltage monitors are powered by the LT3010-5,

a fixed 5V micropower linear regulator. Voltage transient protection

is provided by the LT4356DE-1

Linear Technology Magazine • March 2008

overvoltage protection regulator and

inrush limiter.

In a typical automotive power system, a distinction is made between

“Always On” and “In Cabin” electronics. “Always On” systems include

critical electronics that deal with the

safety and security of an automobile

and, as the name implies, are always

on. “In Cabin” electronics pertain to

comfort and entertainment accessories used in automobiles. In the

event the battery is low, for instance,

the in cabin electronics are turned off

to preserve and siphon power to the

critical path.

In this automotive application, power for the always on critical electronics

is generated by the LTC3780 buck

continued on page 34

15

L DESIGN IDEAS

LTC4357

GND

IN OUT

V

DD

GATE

Si4874DY

V

IN

12V

MMBD1205

C

LOAD

V

OUT

12V

10A

LTC4357 with a FDB3632 MOSFET

to replace the Schottky diode.

When the solar panel is illuminated

by full sunlight, it charges the battery.

A shunt regulator absorbs any excess

charging current to prevent overcharging. If the forward current is greater

than 25mV/R

fully enhanced and the voltage drop

rises according to R

I

). In darkness, or in the event of

LOAD

a short circuit across the solar panel

or a component failure in the shunt

regulator, the output voltage of the

solar panel will be less than the battery voltage. In this case, the LTC4357

shuts off the MOSFET, so the battery

will not discharge. The current drawn

from the battery into the LTC4357’s

OUT pin is only 7µA at 12V.

Protecting Against

Reverse Inputs

In automotive applications, the

LTC4357 inputs can be reversed.

An additional component, shown in

Figure 3, prevents the MOSFET from

turning on and protects the LTC4357.

, the MOSFET is

DS(ON)

• (I

DS(ON)

BATTERY

+

Figure 3. –12V Reverse input protection blocks reverse input voltage to the load

With a reverse input, the diode connected to system ground is reverse

biased. The GND pin is pulled by the

second diode to within 700mV of the

reverse input voltage. Any loading

or leakage current tends to hold the

output near system ground, biasing

the LTC4357 in the blocking condition.

If the output is held up at +12V by a

backup source or stored charge in

the output capacitor, roughly double

the input voltage appears across the

MOSFET. The MOSFET is off and held

in the blocking state.

Conclusion

The LTC4357 ideal diode controller can

replace a Schottky diode in many applications. This simple solution reduces

both voltage drop and power dissipation, thereby shrinking the thermal

layout and reducing power loss. Its

wide 9V to 80V supply operating range

and 100V absolute maximum rating

accommodate a broad range of input

supply voltages and applications,

including automotive, telecom and industrial. A dual version, the LTC4355,

is available in 4mm × 3mm DFN-14

or SSOP-16 packages.

L

LTC293x, continued from page 15

boost regulator and monitored by the

LTC2931. The LTC3780 is protected

from transients by the LT4356DE-1

and is capable of delivering full power

to the load with a supply voltage as low

as 6V. The LTC2931 is configured to

monitor four fixed and two adjustable

voltages, including two independent

5V supplies. 1.5% voltage monitoring accuracy is guaranteed over the

entire operating temperature range.

Additionally, each voltage monitoring channel has its own comparator

output that can be used by the microprocessor to identify a fault condition.

The comparator outputs are pulled up

to the 5V bus that powers both voltage monitoring devices. The LTC2931

has an adjustable watchdog timer,

which allows the LTC2931 to report

a malfunctioning microprocessor to

the rest of the system.

The unregulated battery voltage

and power supplies delivered to the in

cabin electronics are monitored by the

LTC2932. This application monitors

34

34

the unregulated battery voltage, and

the COMP4 output alerts the system

to a low battery condition, allowing the

system to enter a standby or power

save mode.

The L TC2932 also provides a

mechanism to override a reset or fault

condition. This is accomplished by

pulling the RDIS pin low. With RDIS

pulled low, the RST output pulls up

to the V2 input voltage. Since V2 is

tied to V1, the reset high level is 5V.

The RDIS function allows the system

to have flexibility in controlling the

power sources without generating system faults. Additionally, the LTC2932

allows real time setting of the voltage

monitoring threshold. This could be

useful when changes in loading or

environment make for predictable

supply variances.

Conclusion

The LTC2930, LTC2931 and LTC2932

can each monitor six supplies, saving

valuable board area in space con-

strained applications. The LTC2930 is

available in a 3mm × 3mm DFN, while

the LTC2931 and LTC2932 are available in 20-pin TSSOP packages.

All include design-time saving features for multi-voltage applications.

Voltage thresholds are accurate to

±1.5%, guaranteed over the entire

–40°C to 125°C temperature range.

This translates directly to simplified

power supply design, as threshold

accuracy must be accounted for in

the entire power supply tolerance

budget.

Comparator glitch immunity eliminates false resets, with no effect on the

high accuracy of the monitor. These

devices support a variety of voltage

combinations, easily set with only a

few external components. The reset

timeout period is also adjustable with

a single capacitor.

Lastly, the features which differ entiate the LTC2930, LTC2931 and

LTC2932 give users the flexibility to

choose one for any application.

Linear Technology Magazine • March 2008

L

Loading...

Loading...