LTC2283

www.BDTIC.com/LINEAR

Dual 12-Bit, 125Msps

Low Power 3V ADC

FEATURES

n

Integrated Dual 12-Bit ADCs

n

Sample Rate: 125Msps

n

Single 3V Supply (2.85V to 3.4V)

n

Low Power: 790mW

n

70.2dB SNR, 88dB SFDR

n

110dB Channel Isolation at 100MHz

n

Flexible Input: 1V

n

640MHz Full Power Bandwidth S/H

n

Clock Duty Cycle Stabilizer

n

Shutdown and Nap Modes

n

Data Ready Output Clock

n

Pin Compatible Family

P-P

to 2V

P-P

Range

125Msps: LTC2283 (12-Bit), LTC2285 (14-Bit)

105Msps: LTC2282 (12-Bit), LTC2284 (14-Bit)

80Msps: LTC2294 (12-Bit), LTC2299 (14-Bit)

65Msps: LTC2293 (12-Bit), LTC2298 (14-Bit)

40Msps: LTC2292 (12-Bit), LTC2297 (14-Bit)

n

64-Pin (9mm × 9mm) QFN Package

APPLICATIONS

DESCRIPTION

The LTC®2283 is a 12-bit 125Msps, low power dual 3V

A/D converter designed for digitizing high frequency,

wide dynamic range signals. The LTC2283 is perfect for

demanding imaging and communications applications

with AC performance that includes 70.1dB SNR and 82dB

SFDR for signals at the Nyquist frequency.

Typical DC specs include ±0.4LSB INL, ±0.2LSB DNL. The

transition noise is a low 0.32LSB

A single 3V supply allows low power operation. A separate

output supply allows the outputs to drive 0.5V to 3.6V

logic.

A single-ended CLK input controls converter operation.

An optional clock duty cycle stabilizer allows high performance at full speed for a wide range of clock duty cycles.

A data ready output clock (CLKOUT) can be used to latch

the output data.

L, LT, LTC and LTM are registered trademarks of Linear Technology Corporation. All other

trademarks are the property of their respective owners.

RMS

.

n

Wireless and Wired Broadband Communication

n

Imaging Systems

n

Spectral Analysis

n

Portable Instrumentation

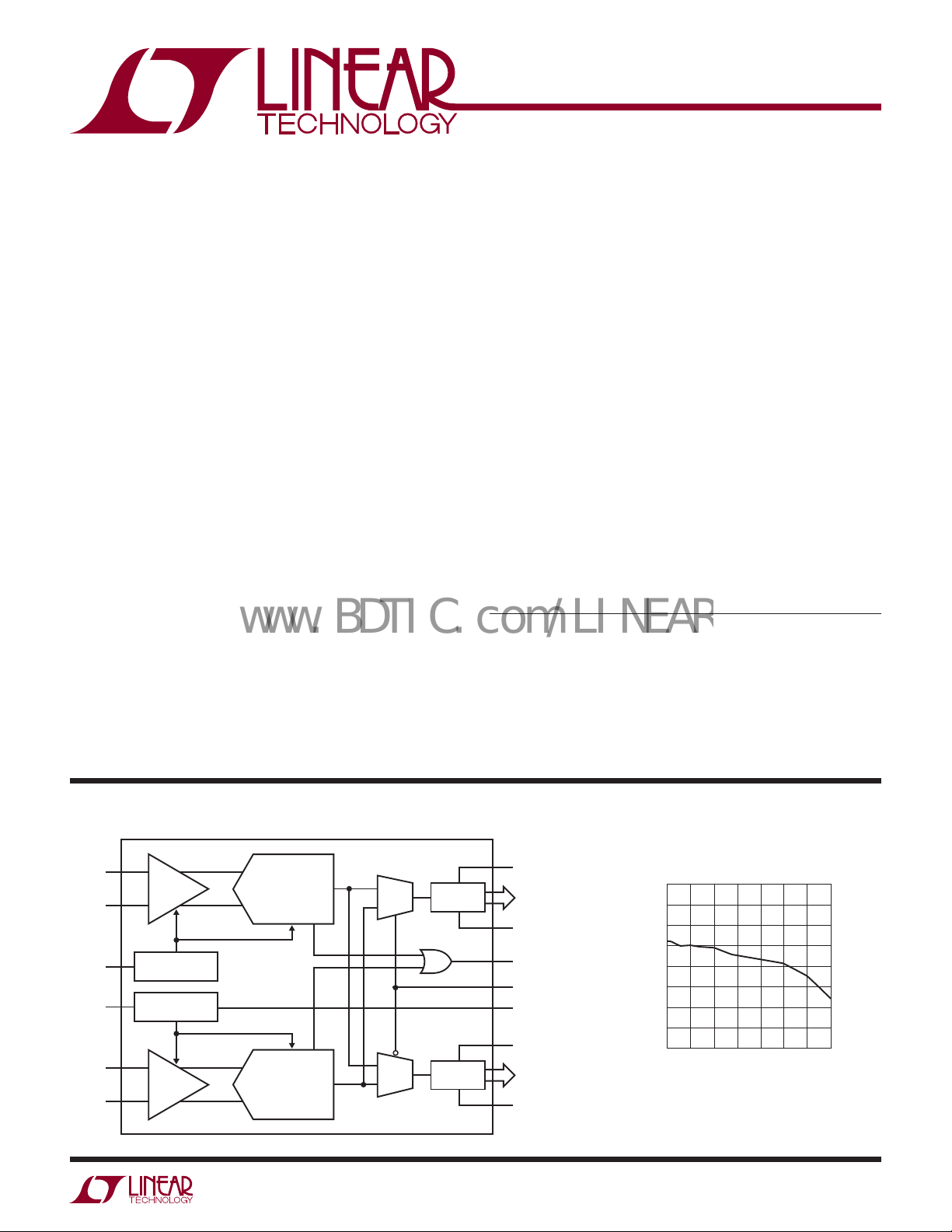

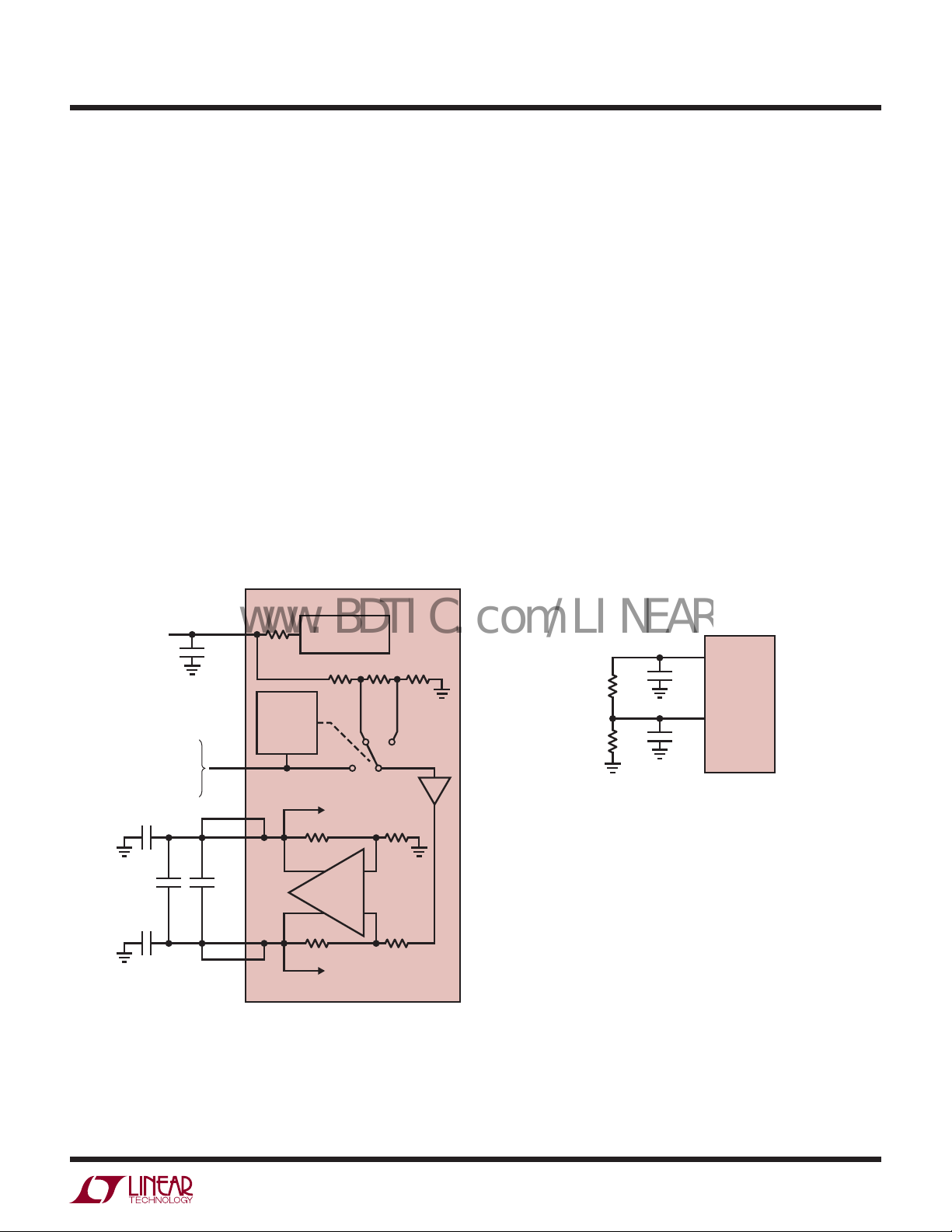

TYPICAL APPLICATION

ANALOG

INPUT A

CLK A

CLK B

ANALOG

INPUT B

+

INPUT

S/H

–

CLOCK/DUTY CYCLE

CONTROL

CLOCK/DUTY CYCLE

CONTROL

+

INPUT

S/H

–

12-BIT

PIPELINED

ADC CORE

12-BIT

PIPELINED

ADC CORE

OUTPUT

DRIVERS

OUTPUT

DRIVERS

2283 TA01

OV

DD

D11A

•

•

•

D0A

OGND

OF

MUX

CLKOUT

OV

DD

D11B

•

•

•

D0B

OGND

SNR vs Input Frequency,

–1dB, 2V Range

73

72

71

70

69

SNR (dBFS)

68

67

66

65

50 100 200

0

150

INPUT FREQUENCY (MHz)

250 300 350

2283 TA01b

2283fb

1

LTC2283

www.BDTIC.com/LINEAR

OVDD = VDD (Notes 1, 2)

Supply Voltage (VDD) ..................................................4V

Digital Output Ground Voltage (OGND) ........–0.3V to 1V

Analog Input Voltage (Note 3) .......–0.3V to (V

Digital Input Voltage ......................–0.3V to (V

Digital Output Voltage ................ –0.3V to (OV

Power Dissipation .............................................1500mW

Operating Temperature Range

LTC2283C ................................................ 0°C to 70°C

LTC2283I.............................................. –40°C to 85°C

Storage Temperature Range ................... –65°C to 150°C

DD

DD

DD

+ 0.3V)

+ 0.3V)

+ 0.3V)

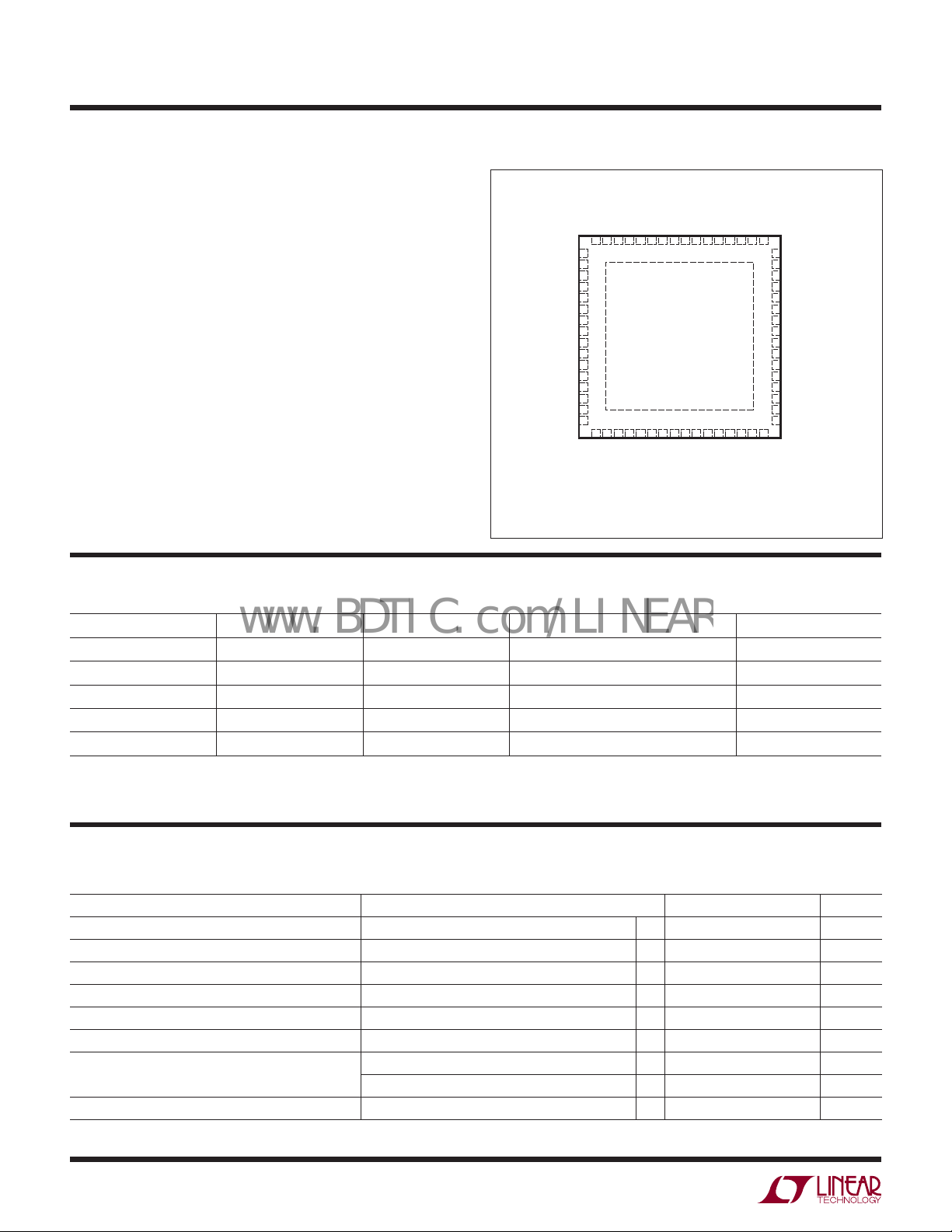

PIN CONFIGURATION ABSOLUTE MAXIMUM RATINGS

TOP VIEW

DD

64 GND

63 VDD62 SENSEA

61 VCMA

60 MODE

59 SHDNA

58 OEA

57 OF

56 DA11

55 DA10

54 DA9

53 DA8

52 DA7

51 DA6

50 OGND

49 OV

A

INA

A

INA

REFHA 3

REFHA 4

REFLA 5

REFLA 6

V

DD

CLKA 8

CLKB 9

V

DD

REFLB 11

REFLB 12

REFHB 13

REFHB 14

–

A

INB

+

A

INB

+

1

–

2

7

65

10

15

16

48 DA5

47 DA4

46 DA3

45 DA2

44 DA1

43 DA0

42 NC

41 NC

40 CLKOUT

39 DB11

38 DB10

37 DB9

36 DB8

35 DB7

34 DB6

33 DB5

18

DD

V

GND 17

SENSEB 19

64-LEAD (9mm × 9mm) PLASTIC QFN

EXPOSED PAD (PIN 65) IS GND AND MUST BE SOLDERED TO PCB

T

NC 24

OEB 23

MUX 21

VCMB 20

SHDNB 22

UP PACKAGE

= 150°C, θJA = 20°C/W

JMAX

NC 25

DB0 26

DB1 27

DB2 28

DB3 29

DB4 30

OGND 31

32

DD

OV

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC2283CUP#PBF LTC2283CUP#TRPBF LTC2283UP 64-Lead (9mm × 9mm) Plastic QFN 0°C to 70°C

LTC2283IUP#PBF LTC2283IUP#TRPBF LTC2283UP 64-Lead (9mm × 9mm) Plastic QFN –40°C to 85°C

LEAD BASED FINISH TAPE AND REEL PART MARKING* PACKAGE DESCRIPTION TEMPERATURE RANGE

LTC2283CUP LTC2283CUP#TR LTC2283UP 64-Lead (9mm × 9mm) Plastic QFN 0°C to 70°C

LTC2283IUP LTC2283IUP#TR LTC2283UP 64-Lead (9mm × 9mm) Plastic QFN –40°C to 85°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges. *The temperature grade is identifi ed by a label on the shipping container.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

The l denotes the specifi cations which apply over the full operating

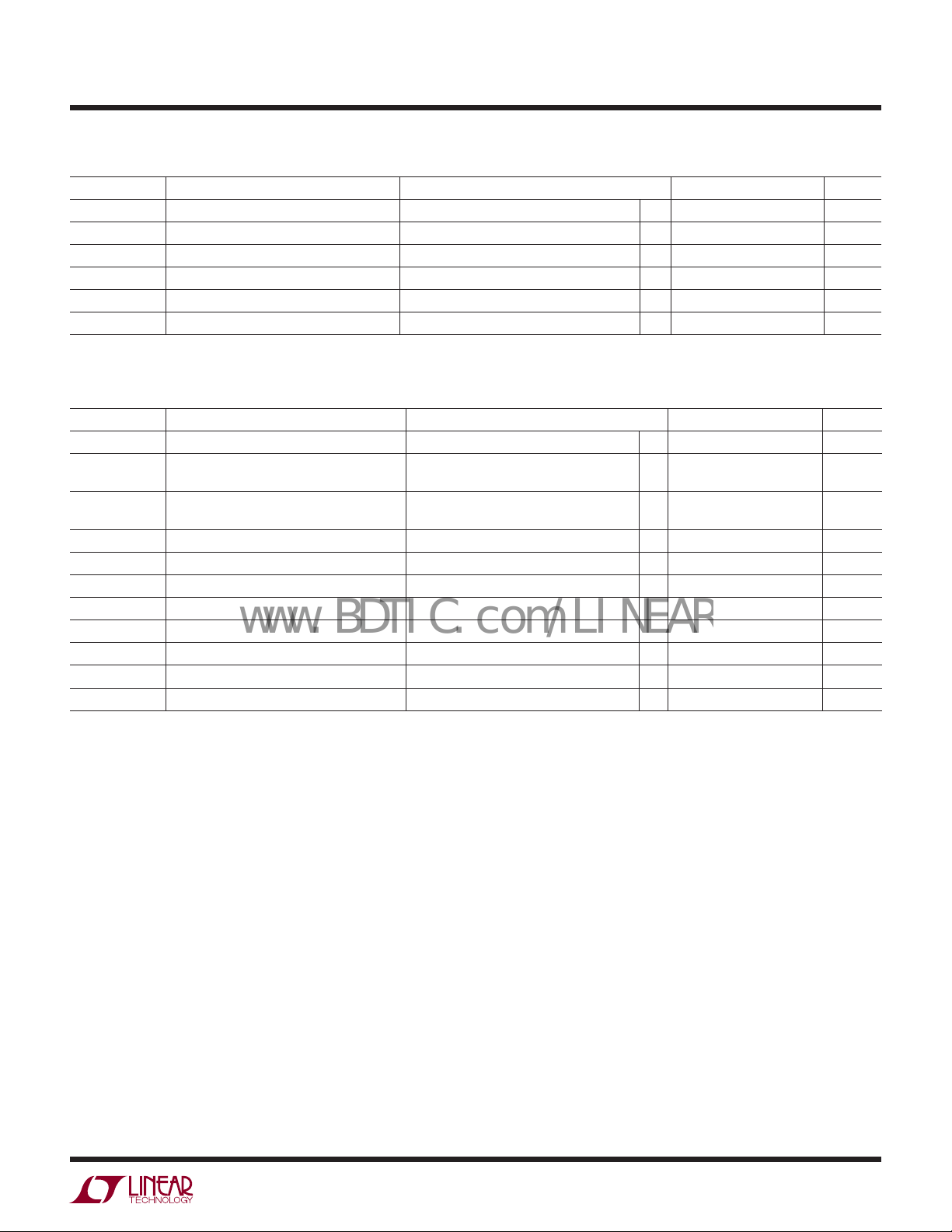

CONVERTER CHARACTERISTICS

temperature range, otherwise specifi cations are at TA = 25°C. (Note 4)

PARAMETER CONDITIONS MIN TYP MAX UNITS

Resolution (No Missing Codes)

Integral Linearity Error Differential Analog Input (Note 5)

Differential Linearity Error Differential Analog Input

Offset Error (Note 6)

Gain Error External Reference

Offset Drift ±10 μV/°C

Full-Scale Drift Internal Reference ±30 ppm/°C

External Reference ±5 ppm/°C

Gain Matching External Reference ±0.3 %FS

2

12 Bits

●

–2 ±0.4 2 LSB

●

–0.9 ±0.2 0.9 LSB

●

–12 ±2 12 mV

●

–2.5 ±0.5 2.5 %FS

●

2283fb

LTC2283

www.BDTIC.com/LINEAR

The l denotes the specifi cations which apply over the full operating

CONVERTER CHARACTERISTICS

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

Offset Matching ±2 mV

Transition Noise SENSE = 1V 0.32 LSB

ANALOG INPUT

The l denotes the specifi cations which apply over the full operating temperature range, otherwise

specifi cations are at TA = 25°C. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

+

V

IN

V

IN,CM

I

IN

I

SENSE

I

MODE

t

AP

t

JITTER

CMRR Analog Input Common Mode Rejection Ratio 80 dB

Analog Input Range (A

Analog Input Common Mode (A

Analog Input Leakage Current 0V < A

SENSEA, SENSEB Input Leakage 0V < SENSEA, SENSEB < 1V

MODE Input Leakage Current 0V < MODE < V

Sample-and-Hold Acquisition Delay Time 0 ns

Sample-and-Hold Acquisition Delay Time Jitter 0.2 ps

Full Power Bandwidth Figure 8 Test Circuit 640 MHz

–

–A

IN

) 2.85V < V

IN

+

–

+A

IN

IN

= 25°C. (Note 4)

A

< 3.4V (Note 7)

DD

)/2 Differential Input Drive (Note 7)

Single Ended Input Drive (Note 7)

+

–

, A

< V

IN

IN

DD

DD

●

●

●

●

●

●

±0.5V to ±1V V

1

0.5

–1 1 μA

–3 3 μA

–3 3 μA

1.5

1.5

RMS

1.9

2

RMS

V

V

DYNAMIC ACCURACY

The l denotes the specifi cations which apply over the full operating temperature range,

otherwise specifi cations are at TA = 25°C. AIN = –1dBFS. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

SNR Signal-to-Noise Ratio 5MHz Input 70.2 dB

30MHz Input 70.1 dB

68 70 dB

●

70 82 dB

●

77 90 dB

●

67 69.6 dB

●

SFDR Spurious Free Dynamic Range

SFDR Spurious Free Dynamic Range

S/(N+D) Signal-to-Noise Plus Distortion Ratio

I

MD

2nd or 3rd Harmonic

4th Harmonic or Higher

Intermodulation Distortion fIN = 40MHz, 41MHz 85 dB

Crosstalk f

70MHz Input

140MHz Input 69.6 dB

5MHz Input 88 dB

30MHz Input 85 dB

70MHz Input

140MHz Input 78 dB

5MHz Input 90 dB

30MHz Input 90 dB

70MHz Input

140MHz Input 90 dB

5MHz Input 69.8 dB

30MHz Input 69.7 dB

70MHz Input

140MHz Input 69.5 dB

= 100MHz –110 dB

IN

2283fb

3

LTC2283

www.BDTIC.com/LINEAR

INTERNAL REFERENCE CHARACTERISTICS

PARAMETER CONDITIONS MIN TYP MAX UNITS

Output Voltage I

V

CM

Output Tempco ±25 ppm/°C

V

CM

Line Regulation 2.85V < VDD < 3.4V 3 mV/V

V

CM

Output Resistance

V

CM

DIGITAL INPUTS AND DIGITAL OUTPUTS

The l denotes the specifi cations which apply over the

= 0 1.475 1.500 1.525 V

OUT

|

I

|

< 1mA

OUT

(Note 4)

4Ω

full operating temperature range, otherwise specifi cations are at TA = 25°C. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

LOGIC INPUTS (CLK, OE, SHDN, MUX)

V

IH

V

IL

I

IN

C

IN

LOGIC OUTPUTS

= 3V

OV

DD

C

OZ

I

SOURCE

I

SINK

V

OH

V

OL

= 2.5V

OV

DD

V

OH

V

OL

= 1.8V

OV

DD

V

OH

V

OL

High Level Input Voltage VDD = 3V

Low Level Input Voltage VDD = 3V

Input Current VIN = 0V to V

Input Capacitance (Note 7) 3 pF

Hi-Z Output Capacitance OE = High (Note 7) 3 pF

Output Source Current V

Output Sink Current V

High Level Output Voltage IO = –10μA

Low Level Output Voltage IO = 10μA

High Level Output Voltage IO = –200μA 2.49 V

Low Level Output Voltage IO = 1.6mA 0.09 V

High Level Output Voltage IO = –200μA 1.79 V

Low Level Output Voltage IO = 1.6mA 0.09 V

OUT

OUT

I

= –200μA

O

I

= 1.6mA

O

DD

= 0V 50 mA

= 3V 50 mA

2V

●

●

–10 10 μA

●

2.995

2.7

●

●

2.99

0.005

0.09 0.4

0.8 V

V

V

V

V

4

2283fb

LTC2283

www.BDTIC.com/LINEAR

The l denotes the specifi cations which apply over the full operating temperature

POWER REQUIREMENTS

range, otherwise specifi cations are at T

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

DD

OV

DD

IV

DD

P

DISS

P

SHDN

P

NAP

The l denotes the specifi cations which apply over the full operating temperature

TIMING CHARACTERISTICS

Analog Supply Voltage (Note 9)

Output Supply Voltage (Note 9)

Supply Current Both ADCs at f

Power Dissipation Both ADCs at f

Shutdown Power (Each Channel) SHDN = H, OE = H, No CLK 2 mW

Nap Mode Power (Each Channel) SHDN = H, OE = L, No CLK 15 mW

range, otherwise specifi cations are at TA = 25°C. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

f

s

t

L

t

H

t

AP

t

D

t

C

t

MD

Pipeline Latency 5 Cycles

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: All voltage values are with respect to ground with GND and OGND

wired together (unless otherwise noted).

Note 3: When these pin voltages are taken below GND or above V

will be clamped by internal diodes. This product can handle input currents

of greater than 100mA below GND or above V

Note 4: V

drive, unless otherwise noted.

DD

Sampling Frequency (Note 9)

CLK Low Time Duty Cycle Stabilizer Off (Note 7)

CLK High Time Duty Cycle Stabilizer Off (Note 7)

Sample-and-Hold Aperture Delay 0 ns

CLK to DATA Delay CL = 5pF (Note 7)

CLK to CLKOUT Delay CL = 5pF (Note 7)

DATA to CLKOUT Skew (t

MUX to DATA Delay CL = 5pF (Note 7)

Data Access Time After OE↓ C

BUS Relinquish Time (Note 7)

= 3V, f

= 125MHz, input range = 2V

SAMPLE

= 25°C. (Note 8)

A

without latchup.

DD

with differential

P-P

S(MAX)

S(MAX)

Duty Cycle Stabilizer On (Note 7)

Duty Cycle Stabilizer On (Note 7)

– tC) (Note 7)

D

= 5pF (Note 7)

L

Note 5: Integral nonlinearity is defi ned as the deviation of a code from a

straight line passing through the actual endpoints of the transfer curve.

The deviation is measured from the center of the quantization band.

Note 6: Offset error is the offset voltage measured from –0.5 LSB when

the output code fl ickers between 0000 0000 0000 and 1111 1111 1111.

Note 7: Guaranteed by design, not subject to test.

, they

DD

Note 8: V

drive. The supply current and power dissipation are the sum total for both

channels with both channels active.

Note 9: Recommended operating conditions.

DD

= 3V, f

2.85 3 3.4 V

●

0.5 3 3.6 V

●

●

●

1 125 MHz

●

3.8

●

3

●

3.8

●

3

●

1.4 2.7 5.4 ns

●

1.4 2.7 5.4 ns

●

–0.6 0 0.6 ns

●

1.4 2.7 5.4 ns

●

●

●

= 125MHz, input range = 1V

SAMPLE

263 305 mA

790 915 mW

4

500

4

500

4

500

4

500

4.3 10 ns

3.3 8.5 ns

with differential

P-P

ns

ns

ns

ns

2283fb

5

LTC2283

www.BDTIC.com/LINEAR

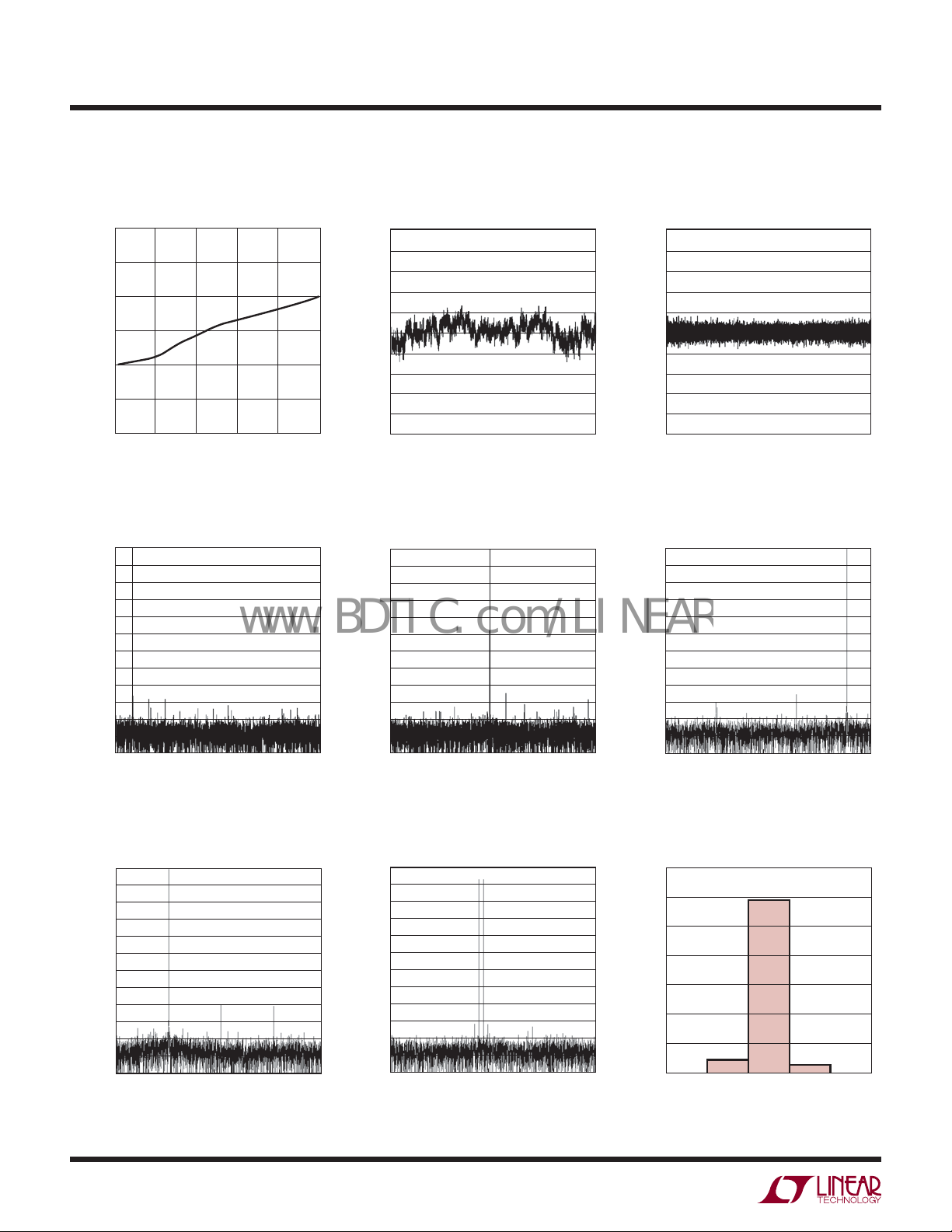

TYPICAL PERFORMANCE CHARACTERISTICS

Crosstalk vs Input Frequency Typical INL, 2V Range, 125Msps Typical DNL, 2V Range, 125Msps

–100

–105

–110

–115

CROSSTALK (dB)

–120

–125

–130

0

20 40 60 80

INPUT FREQUENCY (MHz)

100

2283 G01

1.0

0.8

0.6

0.4

0.2

0

–0.2

INL ERROR (LSB)

–0.4

–0.6

–0.8

–1.0

0

1024 2048 4096

CODE

3072

2283 G02

1.0

0.8

0.6

0.4

0.2

0

–0.2

DNL ERROR (LSB)

–0.4

–0.6

–0.8

–1.0

0

1024 2048 4096

CODE

3072

2283 G03

8192 Point FFT, f

–1dB, 2V Range, 125Msps

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

10 20 30 40 50

FREQUENCY (MHz)

8192 Point FFT, f

–1dB, 2V Range, 125Msps

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

10 20 30 40 50

FREQUENCY (MHz)

= 5MHz,

IN

= 140MHz,

IN

60

2283 G04

60

2283 G07

8192 Point FFT, fIN = 30MHz,

–1dB, 2V Range, 125Msps

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

10 20 30 40 50

FREQUENCY (MHz)

8192 Point 2-Tone FFT,

= 28.2MHz and 26.8MHz,

f

IN

–1dB, 2V Range, 125Msps

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

10 20 30 40 50

FREQUENCY (MHz)

60

2283 G05

60

2283 G08

8192 Point FFT, fIN = 70MHz,

–1dB, 2V Range, 125Msps

0

–10

–20

–30

–40

–50

–60

–70

AMPLITUDE (dB)

–80

–90

–100

–110

–120

0

10 20 30 40 50

FREQUENCY (MHz)

Grounded Input

Histogram, 125Msps

70000

4249

2045

58717

2046

CODE

60000

50000

40000

COUNT

30000

20000

10000

00

0

2044

2562

2047

60

2283 G06

2048

2283 G09

6

2283fb

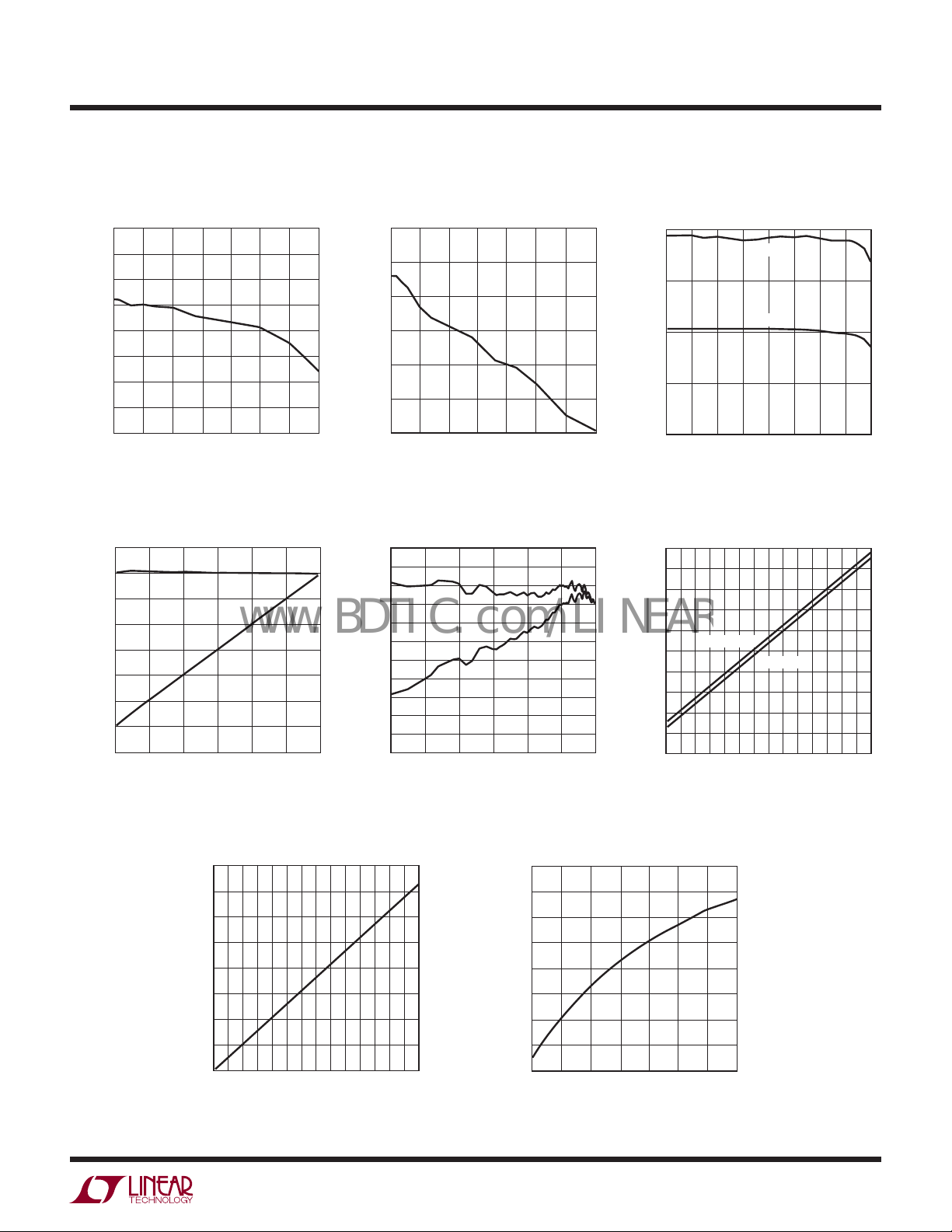

TYPICAL PERFORMANCE CHARACTERISTICS

www.BDTIC.com/LINEAR

LTC2283

SNR vs Input Frequency,

–1dB, 2V Range, 125Msps

73

72

71

70

69

SNR (dBFS)

68

67

66

65

50 100 200

0

150

INPUT FREQUENCY (MHz)

SNR vs Input Level,

= 70MHz, 2V Range, 125Msps

f

IN

80

70

60

50

40

30

SNR (dBc AND dBFS)

20

10

0

–50 –40

–60

dBFS

dBc

–30

INPUT LEVEL (dBFS)

250 300 350

2283 G10

–20

–10

2283 G13

0

SFDR vs Input Frequency,

–1dB, 2V Range, 125Msps

95

90

85

80

SFDR (dBFS)

75

70

65

0

50 100

INPUT FREQUENCY (MHz)

200 300 350

150 250

SFDR vs Input Level,

fIN = 70MHz, 2V Range, 125Msps

110

100

90

80

70

60

50

40

SFDR (dBc AND dBFS)

30

20

10

0

–60

dBFS

dBc

–40 –20–50 –30 –10

INPUT LEVEL (dBFS)

2283 G11

2283 G14

(mA)

I

0

SNR and SFDR vs Sample Rate,

2V Range, f

90

80

70

SNR AND SFDR (dBFS)

60

50

0

20 40 60 80

I

vs Sample Rate,

VDD

= 5MHz, –1dB

IN

SFDR

SNR

SAMPLE RATE (Msps)

100 120 140 160

5MHz Sine Wave Input, –1dB

290

280

270

260

VDD

250

240

230

220

210

200

190

2V RANGE

1V RANGE

20

0

60

40

SAMPLE RATE (Msps)

80

100 120

2283 G12

140

2283 G15

I

vs Sample Rate, 5MHz Sine

OVDD

Wave Input, –1dB, 0VDD = 1.8V SNR vs SENSE, fIN = 5MHz, –1dB

16

14

12

10

(mA)

8

OVDD

I

6

4

2

0

20 40 80

0

60

SAMPLE RATE (Msps)

100 120 140

2283 G16

72

71

70

69

68

SNR (dBFS)

67

66

65

64

0.4

0.5 0.6 0.8

0.7

SENSE PIN (V)

0.9 1.0 1.1

2283 G17

2283fb

7

LTC2283

www.BDTIC.com/LINEAR

PIN FUNCTIONS

+

A

(Pin 1): Channel A Positive Differential Analog

INA

Input.

–

A

(Pin 2): Channel A Negative Differential Analog

INA

Input.

REFHA (Pins 3, 4): Channel A High Reference. Short together and bypass to Pins 5, 6 with a 0.1μF ceramic chip

capacitor as close to the pin as possible. Also bypass to

Pins 5, 6 with an additional 2.2μF ceramic chip capacitor

and to ground with a 1μF ceramic chip capacitor.

REFLA (Pins 5, 6): Channel A Low Reference. Short together and bypass to Pins 3, 4 with a 0.1μF ceramic chip

capacitor as close to the pin as possible. Also bypass to

Pins 3, 4 with an additional 2.2μF ceramic chip capacitor

and to ground with a 1μF ceramic chip capacitor.

(Pins 7, 10, 18, 63): Analog 3V Supply. Bypass to

V

DD

GND with 0.1μF ceramic chip capacitors.

CLKA (Pin 8): Channel A Clock Input. The input sample

starts on the positive edge.

CLKB (Pin 9): Channel B Clock Input. The input sample

starts on the positive edge.

REFLB (Pins 11, 12): Channel B Low Reference. Short

together and bypass to Pins 13, 14 with a 0.1μF ceramic

chip capacitor as close to the pin as possible. Also bypass to Pins 13, 14 with an additional 2.2μF ceramic

chip capacitor and to ground with a 1μF ceramic chip

capacitor.

and a ±0.5V input range. V

selects the internal reference

DD

and a ±1V input range. An external reference greater than

0.5V and less than 1V applied to SENSEB selects an input

range of ±V

(Pin 20): Channel B 1.5V Output and Input Common

V

CMB

. ±1V is the largest valid input range.

SENSEB

Mode Bias. Bypass to ground with 2.2μF ceramic chip

capacitor. Do not connect to V

CMA

.

MUX (Pin 21): Digital Output Multiplexer Control. If MUX

is High, Channel A comes out on DA0-DA11; Channel B

comes out on DB0-DB11. If MUX is Low, the output busses are swapped and Channel A comes out on DB0-DB11;

Channel B comes out on DA0-DA11. To multiplex both

channels onto a single output bus, connect MUX, CLKA

and CLKB together. (This is not recommended at clock

frequencies above 80Msps.)

SHDNB (Pin 22): Channel B Shutdown Mode Selection

Pin. Connecting SHDNB to GND and OEB to GND results

in normal operation with the outputs enabled. Connecting

SHDNB to GND and OEB to V

results in normal operation

DD

with the outputs at high impedance. Connecting SHDNB

to V

outputs at high impedance. Connecting SHDNB to V

and OEB to V

and OEB to GND results in nap mode with the

DD

results in sleep mode with the outputs

DD

DD

at high impedance.

OEB (Pin 23): Channel B Output Enable Pin. Refer to

SHDNB pin function.

NC (Pins 24, 25, 41, 42): Do not connect these pins.

REFHB (Pins 13, 14): Channel B High Reference. Short

together and bypass to Pins 11, 12 with a 0.1μF ceramic

chip capacitor as close to the pin as possible. Also bypass to Pins 11, 12 with an additional 2.2μF ceramic

chip capacitor and to ground with a 1μF ceramic chip

capacitor.

–

A

(Pin 15): Channel B Negative Differential Analog

INB

Input.

+

A

(Pin 16): Channel B Positive Differential Analog

INB

Input.

GND (Pins 17, 64): ADC Power Ground.

SENSEB (Pin 19): Channel B Reference Programming Pin.

Connecting SENSEB to V

selects the internal reference

CMB

8

DB0 – DB11 (Pins 26 to 30, 33 to 39): Channel B Digital

Outputs. DB11 is the MSB.

OGND (Pins 31, 50): Output Driver Ground.

(Pins 32, 49): Positive Supply for the Output Drivers.

OV

DD

Bypass to ground with 0.1μF ceramic chip capacitor.

CLKOUT (Pin 40): Data Ready Clock Output. Latch data

on the falling edge of CLKOUT. CLKOUT is derived from

CLKB. Tie CLKA to CLKB for simultaneous operation.

DA0 – DA11 (Pins 43 to 48, 51 to 56): Channel A Digital

Outputs. DA11 is the MSB.

OF (Pin 57): Overfl ow/Underfl ow Output. High when an

overfl ow or underfl ow has occurred on either Channel A

or Channel B.

2283fb

PIN FUNCTIONS

www.BDTIC.com/LINEAR

LTC2283

OEA (Pin 58): Channel A Output Enable Pin. Refer to

SHDNA pin function.

SHDNA (Pin 59): Channel A Shutdown Mode Selection

Pin. Connecting SHDNA to GND and OEA to GND results

in normal operation with the outputs enabled. Connecting

SHDNA to GND and OEA to V

results in normal operation

DD

with the outputs at high impedance. Connecting SHDNA

to V

outputs at high impedance. Connecting SHDNA to V

and OEA to V

and OEA to GND results in nap mode with the

DD

results in sleep mode with the outputs

DD

DD

at high impedance.

MODE (Pin 60): Output Format and Clock Duty Cycle

Stabilizer Selection Pin. Note that MODE controls both

channels. Connecting MODE to GND selects offset binary

output format and turns the clock duty cycle stabilizer off.

1/3 V

selects offset binary output format and turns the

DD

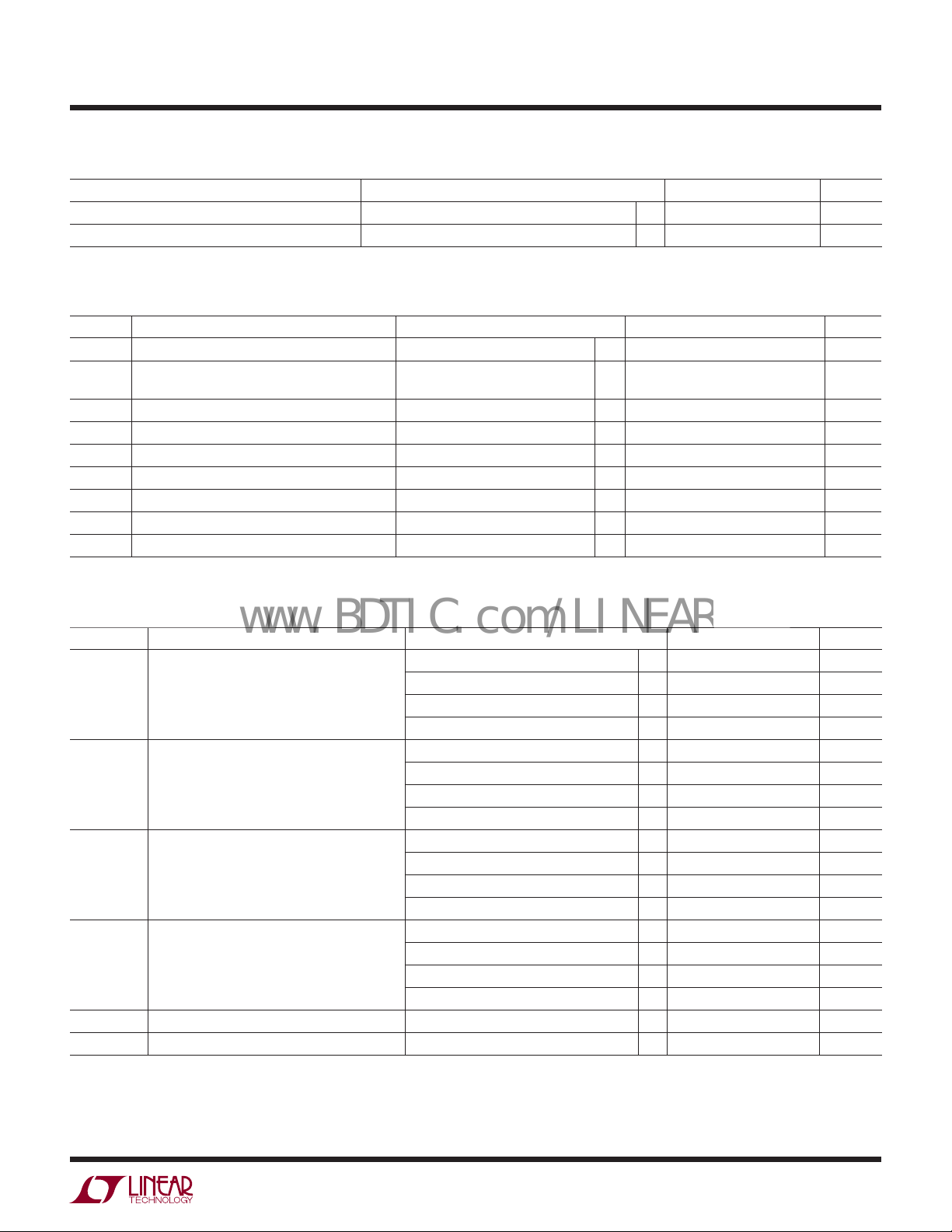

FUNCTIONAL BLOCK DIAGRAM

clock duty cycle stabilizer on. 2/3 VDD selects 2’s complement output format and turns the clock duty cycle stabilizer

on. V

selects 2’s complement output format and turns

DD

the clock duty cycle stabilizer off.

(Pin 61): Channel A 1.5V Output and Input Common

V

CMA

Mode Bias. Bypass to ground with 2.2μF ceramic chip

capacitor. Do not connect to V

CMB

.

SENSEA (Pin 62): Channel A Reference Programming Pin.

Connecting SENSEA to V

and a ±0.5V input range. V

selects the internal reference

CMA

selects the internal reference

DD

and a ±1V input range. An external reference greater than

0.5V and less than 1V applied to SENSEA selects an input

range of ±V

. ±1V is the largest valid input range.

SENSEA

GND (Exposed Pad) (Pin 65): ADC Power Ground. The

Exposed Pad on the bottom of the package needs to be

soldered to ground.

A

A

V

2.2μF

SENSE

+

IN

INPUT

S/H

–

IN

CM

1.5V

REFERENCE

RANGE

SELECT

FIRST PIPELINED

ADC STAGE

REF

BUF

SECOND PIPELINED

ADC STAGE

DIFF

REF

AMP

REFH

1μF 1μF

THIRD PIPELINED

0.1μF

2.2μF

ADC STAGE

REFL

INTERNAL CLOCK SIGNALSREFH REFL

FOURTH PIPELINED

CLOCK/DUTY

CYCLE

CONTROL

CLK

FIFTH PIPELINED

CONTROL

LOGIC

SHDN

ADC STAGE

OEMODE

ADC STAGE

*OF AND CLKOUT ARE SHARED BETWEEN BOTH CHANNELS.

SIXTH PIPELINED

ADC STAGE

SHIFT REGISTER

AND CORRECTION

OUTPUT

DRIVERS

OGND

2283 F01

•

•

•

OV

DD

OF*

D11

D0

CLKOUT*

Figure 1. Functional Block Diagram (Only One Channel is Shown)

2283fb

9

LTC2283

www.BDTIC.com/LINEAR

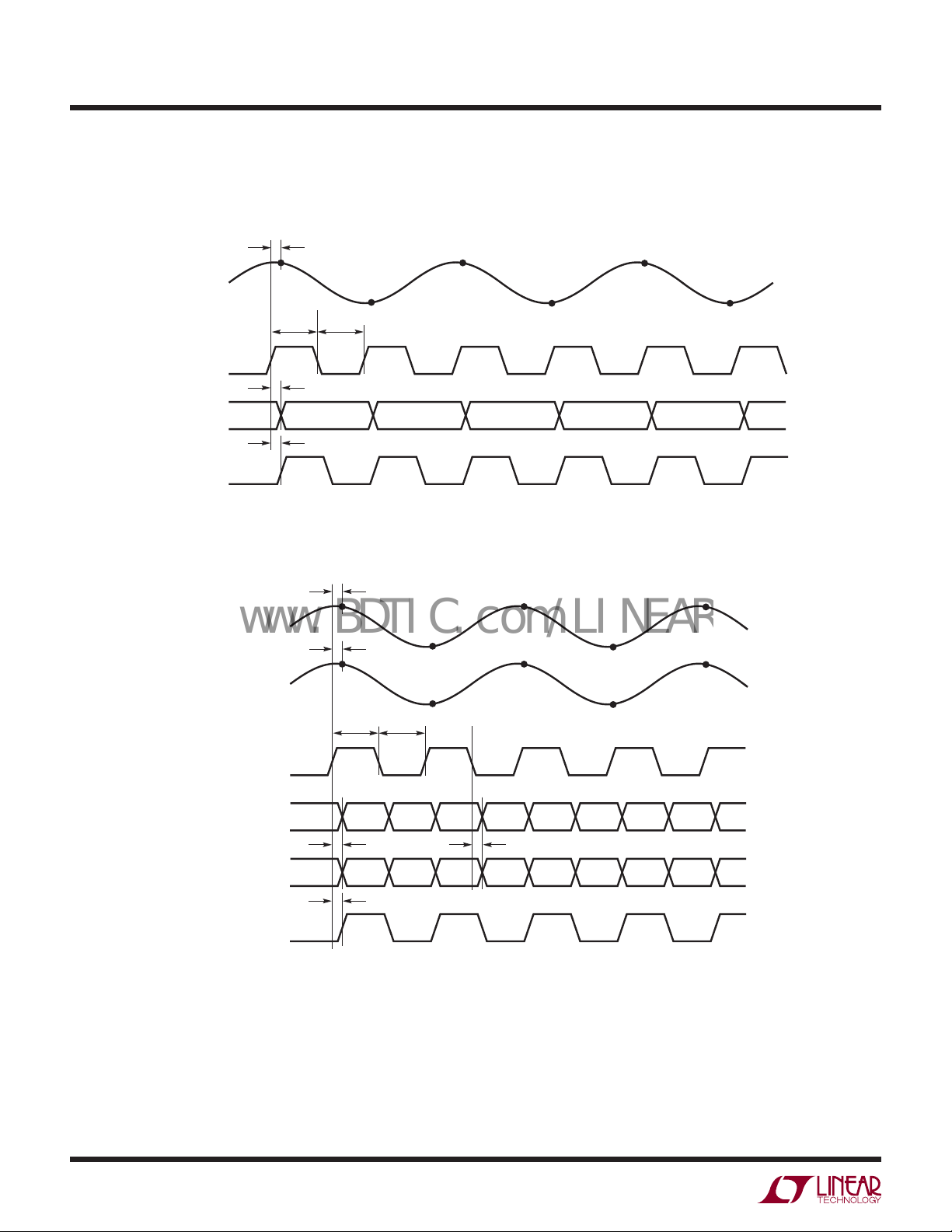

TIMING DIAGRAMS

ANALOG

INPUT

CLKA = CLKB

D0-D11, OF

CLKOUT

N

Dual Digital Output Bus Timing

(Only One Channel is Shown)

t

AP

N + 2

N + 1

t

t

H

L

t

D

N – 5 N

t

C

N – 4 N – 3 N – 2 N – 1

N + 3

N + 4

N + 5

2283 TD01

ANALOG

INPUT A

ANALOG

INPUT B

CLKA = CLKB = MUX

D0A-D11A

D0B-D11B

CLKOUT

Multiplexed Digital Output Bus Timing

t

APA

B – 4

A – 4

t

MD

A + 2

B + 2

A

t

APB

B

t

H

A – 5

t

D

B – 5

t

C

t

L

B – 5

A – 5

A + 1

B + 1

A – 4

B – 4

A – 3

B – 3

B – 3

A – 3

A + 3

B + 3

A – 2

B – 2

B – 2

A – 2

A + 4

B + 4

A – 1

B – 1

2283 TD02

10

2283fb

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

DYNAMIC PERFORMANCE

Signal-to-Noise Plus Distortion Ratio

The signal-to-noise plus distortion ratio [S/(N + D)] is

the ratio between the RMS amplitude of the fundamental input frequency and the RMS amplitude of all other

frequency components at the ADC output. The output is

band limited to frequencies above DC to below half the

sampling frequency.

Signal-to-Noise Ratio

The signal-to-noise ratio (SNR) is the ratio between the

RMS amplitude of the fundamental input frequency and

the RMS amplitude of all other frequency components

except the fi rst fi ve harmonics and DC.

Total Harmonic Distortion

Total harmonic distortion is the ratio of the RMS sum

of all harmonics of the input signal to the fundamental

itself. The out-of-band harmonics alias into the frequency

band between DC and half the sampling frequency. THD

is expressed as:

2fa + fb, 2fb + fa, 2fa – fb and 2fb – fa. The intermodulation distortion is defi ned as the ratio of the RMS value of

either input tone to the RMS value of the largest 3rd order

intermodulation product.

Spurious Free Dynamic Range (SFDR)

Spurious free dynamic range is the peak harmonic or spurious noise that is the largest spectral component excluding

the input signal and DC. This value is expressed in decibels

relative to the RMS value of a full-scale input signal.

Input Bandwidth

The input bandwidth is that input frequency at which the

amplitude of the reconstructed fundamental is reduced

by 3dB for a full scale input signal.

Aperture Delay Time

The time from when CLK reaches midsupply to the instant that the input signal is held by the sample and hold

circuit.

Aperture Delay Jitter

THD= 20log (V22+ V32+ V42+ ...Vn2)/V1

where V1 is the RMS amplitude of the fundamental frequency and V2 through Vn are the amplitudes of the second

through nth harmonics. The THD calculated in this data

sheet uses all the harmonics up to the fi fth.

Intermodulation Distortion

If the ADC input signal consists of more than one spectral

component, the ADC transfer function nonlinearity can

produce intermodulation distortion (IMD) in addition to

THD. IMD is the change in one sinusoidal input caused

by the presence of another sinusoidal input at a different

frequency.

If two pure sine waves of frequencies fa and fb are applied to the ADC input, nonlinearities in the ADC transfer

function can create distortion products at the sum and

difference frequencies of mfa ± nfb, where m and n = 0,

1, 2, 3, etc. The 3rd order intermodulation products are

The variation in the aperture delay time from conversion

to conversion. This random variation will result in noise

when sampling an AC input. The signal to noise ratio due

to the jitter alone will be:

SNR

Crosstalk

Crosstalk is the coupling from one channel (being driven

by a full-scale signal) onto the other channel (being driven

by a –1dBFS signal).

CONVERTER OPERATION

As shown in Figure 1, the LTC2283 is a dual CMOS pipelined

multistep converter. The converter has six pipelined ADC

stages; a sampled analog input will result in a digitized

value fi ve cycles later (see the Timing Diagram section).

For optimal AC performance the analog inputs should be

driven differentially. For cost sensitive applications, the

analog inputs can be driven single-ended with slightly

= –20log (2π • fIN • t

JITTER

JITTER

)

2283fb

11

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

worse harmonic distortion. The CLK input is single-ended.

The LTC2283 has two phases of operation, determined by

the state of the CLK input pin.

Each pipelined stage shown in Figure 1 contains an ADC,

a reconstruction DAC and an interstage residue amplifi er.

In operation, the ADC quantizes the input to the stage and

the quantized value is subtracted from the input by the

DAC to produce a residue. The residue is amplifi ed and

output by the residue amplifi er. Successive stages operate

out of phase so that when the odd stages are outputting

their residue, the even stages are acquiring that residue

and vice versa.

When CLK is low, the analog input is sampled differentially

directly onto the input sample-and-hold capacitors, inside

the “Input S/H” shown in the Block Diagram. At the instant

that CLK transitions from low to high, the sampled input is

held. While CLK is high, the held input voltage is buffered

by the S/H amplifi er which drives the fi rst pipelined ADC

stage. The fi rst stage acquires the output of the S/H during this high phase of CLK. When CLK goes back low, the

fi rst stage produces its residue which is acquired by the

second stage. At the same time, the input S/H goes back to

acquiring the analog input. When CLK goes back high, the

second stage produces its residue which is acquired by the

third stage. An identical process is repeated for the third,

fourth and fi fth stages, resulting in a fi fth stage residue

that is sent to the sixth stage ADC for fi nal evaluation.

Each ADC stage following the fi rst has additional range to

accommodate fl ash and amplifi er offset errors. Results

from all of the ADC stages are digitally synchronized such

that the results can be properly combined in the correction

logic before being sent to the output buffer.

SAMPLE/HOLD OPERATION AND INPUT DRIVE

Sample/Hold Operation

Figure 2 shows an equivalent circuit for the LTC2283 CMOS

differential sample-and-hold. The analog inputs are connected to the sampling capacitors (C

SAMPLE

) through NMOS

transistors. The capacitors shown attached to each input

(C

PARASITIC

) are the summation of all other capacitance

associated with each input.

During the sample phase when CLK is low, the transistors

connect the analog inputs to the sampling capacitors and

they charge to and track the differential input voltage. When

CLK transitions from low to high, the sampled input voltage

is held on the sampling capacitors. During the hold phase

when CLK is high, the sampling capacitors are disconnected

LTC2283

V

DD

15Ω

+

A

A

CLK

IN

V

DD

15Ω

–

IN

Figure 2. Equivalent Input Circuit

C

1pF

C

1pF

V

DD

12

PARASITIC

PARASITIC

C

SAMPLE

3.5pF

C

SAMPLE

3.5pF

2283 F02

2283fb

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

from the input and the held voltage is passed to the ADC

core for processing. As CLK transitions from high to low,

the inputs are reconnected to the sampling capacitors to

acquire a new sample. Since the sampling capacitors still

hold the previous sample, a charging glitch proportional to

the change in voltage between samples will be seen at this

time. If the change between the last sample and the new

sample is small, the charging glitch seen at the input will

be small. If the input change is large, such as the change

seen with input frequencies near Nyquist, then a larger

charging glitch will be seen.

Single-Ended Input

For cost sensitive applications, the analog inputs can be

driven single-ended. With a single-ended input the harmonic distortion and INL will degrade, but the SNR and

+

DNL will remain unchanged. For a single-ended input, A

–

should be driven with the input signal and A

connected to 1.5V or V

CM

.

should be

IN

IN

Common Mode Bias

For optimal performance the analog inputs should be

driven differentially. Each input should swing ±0.5V for the

2V range or ±0.25V for the 1V range, around a common

mode voltage of 1.5V. The V

to provide the common mode bias level. V

output pin may be used

CM

can be tied

CM

directly to the center tap of a transformer to set the DC

input level or as a reference level to an op amp differential

driver circuit. The V

pin must be bypassed to ground

CM

close to the ADC with a 2.2μF or greater capacitor.

Input Drive Impedance

As with all high performance, high speed ADCs, the dynamic

performance of the LTC2283 can be infl uenced by the input

drive circuitry, particularly the second and third harmonics.

Source impedance and reactance can infl uence SFDR. At

the falling edge of CLK, the sample-and-hold circuit will

connect the 3.5pF sampling capacitor to the input pin and

start the sampling period. The sampling period ends when

CLK rises, holding the sampled input on the sampling

capacitor. Ideally the input circuitry should be fast enough

to fully charge the sampling capacitor during the sampling

period 1/(2F

ENCODE

); however, this is not always possible

and the incomplete settling may degrade the SFDR. The

sampling glitch has been designed to be as linear as possible to minimize the effects of incomplete settling.

For the best performance, it is recommended to have a

source impedance of 100Ω or less for each input. The

source impedance should be matched for the differential

inputs. Poor matching will result in higher even order

harmonics, especially the second.

Input Drive Circuits

Figure 3 shows the LTC2283 being driven by an RF transformer with a center tapped secondary. The secondary

center tap is DC biased with V

, setting the ADC input

CM

signal at its optimum DC level. Terminating on the transformer secondary is desirable, as this provides a common

mode path for charging glitches caused by the sample and

hold. Figure 3 shows a 1:1 turns ratio transformer. Other

turns ratios can be used if the source impedance seen

by the ADC does not exceed 100Ω for each ADC input.

A disadvantage of using a transformer is the loss of low

frequency response. Most small RF transformers have

poor performance at frequencies below 1MHz.

V

CM

2.2μF

ANALOG

INPUT

0.1μF T1

1:1

T1 = MA/COM ETC1-1T

RESISTORS, CAPACITORS

ARE 0402 PACKAGE SIZE

Figure 3. Single-Ended to Differential

Conversion Using a Transformer

25Ω

25Ω

25Ω

0.1μF

25Ω

12pF

+

A

IN

LTC2283

–

A

IN

2283 F03

2283fb

13

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

V

CM

2.2μF

A

12pF

A

+

IN

LTC2283

–

IN

2283 F04

ANALOG

INPUT

HIGH SPEED

DIFFERENTIAL

AMPLIFIER

+

+

CM

–

–

25Ω

25Ω

Figure 4. Differential Drive with an Amplifi er

V

CM

2.2μF

12pF

+

A

IN

LTC2283

–

A

IN

2283 F05

ANALOG

INPUT

0.1μF

1k

1k

25Ω

25Ω

0.1μF

Figure 5. Single-Ended Drive

Figure 4 demonstrates the use of a differential amplifi er to

convert a single ended input signal into a differential input

signal. The advantage of this method is that it provides

low frequency input response; however, the limited gain

bandwidth of most op amps will limit the SFDR at high

input frequencies.

Figure 5 shows a single-ended input circuit. The impedance

seen by the analog inputs should be matched. This circuit

is not recommended if low distortion is required.

The 25Ω resistors and 12pF capacitor on the analog

inputs serve two purposes: isolating the drive circuitry

from the sample-and-hold charging glitches and limiting

the wideband noise at the converter input.

For input frequencies above 70MHz, the input circuits of

Figure 6, 7 and 8 are recommended. The balun transformer

gives better high frequency response than a fl ux coupled

center tapped transformer. The coupling capacitors allow

the analog inputs to be DC biased at 1.5V. In Figure 8, the

series inductors are impedance matching elements that

maximize the ADC bandwidth.

V

CM

2.2μF

ANALOG

INPUT

0.1μF

T1

0.1μF

T1 = MA/COM, ETC 1-1-13

RESISTORS, CAPACITORS

ARE 0402 PACKAGE SIZE

25Ω

25Ω

12Ω

0.1μF

12Ω

8pF

+

A

IN

–

A

IN

Figure 6. Recommended Front End Circuit for

Input Frequencies Between 70MHz and 170MHz

V

CM

2.2μF

ANALOG

INPUT

0.1μF

T1

0.1μF

T1 = MA/COM, ETC 1-1-13

RESISTORS, CAPACITORS

ARE 0402 PACKAGE SIZE

25Ω

25Ω

0.1μF

+

A

IN

–

A

IN

Figure 7. Recommended Front End Circuit for

Input Frequencies Between 170MHz and 300MHz

V

CM

2.2μF

ANALOG

0.1μF

INPUT

T1

0.1μF

T1 = MA/COM, ETC 1-1-13

RESISTORS, CAPACITORS, INDUCTORS

ARE 0402 PACKAGE SIZE

25Ω

25Ω

0.1μF

8.2nH

8.2nH

A

IN

A

IN

Figure 8. Recommended Front End Circuit for

Input Frequencies Above 300MHz

+

–

LTC2283

2283 F06

LTC2283

2283 F07

LTC2283

2283 F08

14

2283fb

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

Reference Operation

Figure 9 shows the LTC2283 reference circuitry consisting

of a 1.5V bandgap reference, a difference amplifi er and

switching and control circuit. The internal voltage reference

can be confi gured for two pin selectable input ranges of

2V (±1V differential) or 1V (±0.5V differential). Tying the

SENSE pin to V

pin to V

selects the 1V range.

CM

selects the 2V range; tying the SENSE

DD

The 1.5V bandgap reference serves two functions: its

output provides a DC bias point for setting the common

mode voltage of any external input circuitry; additionally,

the reference is used with a difference amplifi er to generate the differential reference levels needed by the internal

ADC circuitry. An external bypass capacitor is required

for the 1.5V reference output, V

. This provides a high

CM

frequency low impedance path to ground for internal and

external circuitry.

LTC2283

4Ω

V

TIE TO V

DD

TIE TO V

CM

RANGE = 2 • V

0.5V < V

1.5V

FOR 2V RANGE;

FOR 1V RANGE;

1μF

SENSE

SENSE

FOR

< 1V

CM

2.2μF

SENSE

REFH

1.5V BANDGAP

REFERENCE

1V 0.5V

RANGE

DETECT

AND

CONTROL

BUFFER

INTERNAL ADC

HIGH REFERENCE

The difference amplifi er generates the high and low

reference for the ADC. High speed switching circuits are

connected to these outputs and they must be externally

bypassed. Each output has two pins. The multiple output

pins are needed to reduce package inductance. Bypass

capacitors must be connected as shown in Figure 9. Each

ADC channel has an independent reference with its own

bypass capacitors. The two channels can be used with the

same or different input ranges.

Other voltage ranges between the pin selectable ranges

can be programmed with two external resistors as shown

in Figure 10. An external reference can be used by applying its output directly or through a resistor divider to

SENSE. It is not recommended to drive the SENSE pin

with a logic device. The SENSE pin should be tied to the

appropriate level as close to the converter as possible. If

the SENSE pin is driven externally, it should be bypassed

to ground as close to the device as possible with a 1μF

ceramic capacitor. For the best channel matching, connect

an external reference to SENSEA and SENSEB.

1.5V

12k

0.75V

12k

Figure 10. 1.5V Range ADC

V

CM

2.2μF

SENSE

1μF

LTC2283

2283 F10

Input Range

2.2μF

1μF

0.1μF

REFL

DIFF AMP

INTERNAL ADC

LOW REFERENCE

2283 F09

Figure 9. Equivalent Reference Circuit

The input range can be set based on the application.

The 2V input range will provide the best signal-to-noise

performance while maintaining excellent SFDR. The 1V

input range will have better SFDR performance, but the

SNR will degrade by 4dB. See the Typical Performance

Characteristics section.

Driving the Clock Input

The CLK inputs can be driven directly with a CMOS or

TTL level signal. A sinusoidal clock can also be used

along with a low jitter squaring circuit before the CLK pin

(Figure 11).

2283fb

15

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

CLEAN

BEAD

0.1μF

CLK

SUPPLY

LTC2283

2283 F11

4.7μF

FERRITE

1k

50Ω

0.1μF

1k

NC7SVU04

SINUSOIDAL

CLOCK

INPUT

Figure 11. Sinusoidal Single-Ended CLK Drive Figure 12. CLK Drive Using an LVDS or PECL to CMOS Converter

The noise performance of the LTC2283 can depend on the

clock signal quality as much as on the analog input. Any

noise present on the clock signal will result in additional

aperture jitter that will be RMS summed with the inherent

ADC aperture jitter.

In applications where jitter is critical, such as when digitizing high input frequencies, use as large an amplitude

as possible. Also, if the ADC is clocked with a sinusoidal

signal, fi lter the CLK signal to reduce wideband noise and

distortion products generated by the source.

CLEAN

FERRITE

BEAD

0.1μF

CLK

0.1μF

SUPPLY

LTC2283

CLK

FERRITE

BEAD

2283 F12

LTC2283

2283 F13

V

CM

4.7μF

100Ω

IF LVDS USE FIN1002 OR FIN1018.

FOR PECL, USE AZ1000ELT21 OR SIMILAR

ETC1-1T

5pF-30pF

DIFFERENTIAL

CLOCK

INPUT

Figure 13. LVDS or PECL CLK Drive Using a Transformer

It is recommended that CLKA and CLKB are shorted together and driven by the same clock source. If a small time

delay is desired between when the two channels sample

the analog inputs, CLKA and CLKB can be driven by two

different signals. If this delay exceeds 1ns, the performance

of the part may degrade. CLKA and CLKB should not be

driven by asynchronous signals.

Figures 12 and 13 show alternatives for converting a

differential clock to the single-ended CLK input. The use

of a transformer provides no incremental contribution

to phase noise. The LVDS or PECL to CMOS translators

provide little degradation below 70MHz, but at 140MHz will

degrade the SNR compared to the transformer solution.

The nature of the received signals also has a large bearing on how much SNR degradation will be experienced.

For high crest factor signals such as WCDMA or OFDM,

where the nominal power level must be at least 6dB to

8dB below full scale, the use of these translators will have

a lesser impact.

The transformer in the example may be terminated with

the appropriate termination for the signaling in use. The

use of a transformer with a 1:4 impedance ratio may be

desirable in cases where lower voltage differential signals

are considered. The center tap may be bypassed to ground

through a capacitor close to the ADC if the differential

signals originate on a different plane. The use of a capacitor at the input may result in peaking, and depending

on transmission line length may require a 10Ω to 20Ω

ohm series resistor to act as both a low pass fi lter for

high frequency noise that may be induced into the clock

line by neighboring digital signals, as well as a damping

mechanism for refl ections.

Maximum and Minimum Conversion Rates

The maximum conversion rate for the LTC2283 is 125Msps.

The lower limit of the LTC2283 sample rate is determined

by droop of the sample-and-hold circuits. The pipelined

architecture of this ADC relies on storing analog signals on

2283fb

16

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

small valued capacitors. Junction leakage will discharge

the capacitors. The specifi ed minimum operating frequency

for the LTC2283 is 1Msps.

Clock Duty Cycle Stabilizer

An optional clock duty cycle stabilizer circuit ensures high

performance even if the input clock has a non 50% duty

cycle. Using the clock duty cycle stabilizer is recommended

for most applications. To use the clock duty cycle stabilizer,

the MODE pin should be connected to 1/3V

or 2/3VDD

DD

using external resistors.

This circuit uses the rising edge of the CLK pin to sample

the analog input. The falling edge of CLK is ignored and

the internal falling edge is generated by a phase-locked

loop. The input clock duty cycle can vary from 40% to

60% and the clock duty cycle stabilizer will maintain a

constant 50% internal duty cycle. If the clock is turned off

for a long period of time, the duty cycle stabilizer circuit

will require a hundred clock cycles for the PLL to lock

onto the input clock.

For applications where the sample rate needs to be changed

quickly, the clock duty cycle stabilizer can be disabled. If

the duty cycle stabilizer is disabled, care should be taken to

make the sampling clock have a 50% (±5%) duty cycle.

DIGITAL OUTPUTS

Digital Output Buffers

Figure 14 shows an equivalent circuit for a single output

buffer. Each buffer is powered by OV

and OGND, isolated

DD

from the ADC power and ground. The additional N-channel

transistor in the output driver allows operation down to

low voltages. The internal resistor in series with the output

makes the output appear as 50Ω to external circuitry and

may eliminate the need for external damping resistors.

As with all high speed/high resolution converters, the

digital output loading can affect the performance. The

digital outputs of the LTC2283 should drive a minimal

capacitive load to avoid possible interaction between the

digital outputs and sensitive input circuitry. For full speed

operation the capacitive load should be kept under 10pF.

Lower OV

voltages will also help reduce interference

DD

from the digital outputs.

LTC2283

OV

DD

0.5V

OGND

TO 3.6V

0.1μF

TYPICAL

DATA

OUTPUT

DATA

FROM

LATCH

OE

V

DD

PREDRIVER

LOGIC

V

DD

OV

DD

43Ω

Table 1 shows the relationship between the analog input

voltage, the digital data bits, and the overfl ow bit. Note that

OF is high when an overfl ow or underfl ow has occurred

on either Channel A or Channel B.

Table 1. Output Codes vs Input Voltage

+

A

(2V Range) OF

>+1.000000V

+0.999512V

+0.999024V

+0.000488V

0.000000V

–0.000488V

–0.000976V

–0.999512V

–1.000000V

<–1.000000V

–

– A

IN

IN

1

0

0

0

0

0

0

0

0

1

D11 – D0

(Offset Binary)

1111 1111 1111

1111 1111 1111

1111 1111 1110

1000 0000 0001

1000 0000 0000

0111 1111 1111

0111 1111 1110

0000 0000 0001

0000 0000 0000

0000 0000 0000

D11 – D0

(2’s Complement)

0111 1111 1111

0111 1111 1111

0111 1111 1110

0000 0000 0001

0000 0000 0000

1111 1111 1111

1111 1111 1110

1000 0000 0001

1000 0000 0000

1000 0000 0000

2283 F14

Figure 14. Digital Output Buffer

Data Format

Using the MODE pin, the LTC2283 parallel digital output

can be selected for offset binary or 2’s complement format.

Connecting MODE to GND or 1/3V

output format. Connecting MODE to 2/3V

selects offset binary

DD

or VDD selects

DD

2’s complement output format. An external resistor divider

can be used to set the 1/3V

or 2/3VDD logic values.

DD

Table 2 shows the logic states for the MODE pin.

2283fb

17

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

Table 2. MODE Pin Function

MODE PIN OUTPUT FORMAT

0 Offset Binary Off

1/3V

2/3V

V

DD

DD

DD

Offset Binary On

2’s Complement On

2’s Complement Off

CLOCK DUTY

CYCLE STABILIZER

Overfl ow Bit

When OF outputs a logic high the converter is either

overranged or underranged on channel A or channel B.

Note that both channels share a common OF pin, which

is not the case for slower pin compatible parts such as

the LTC2282 or LTC2294. OF is disabled when channel A

is in sleep or nap mode.

Output Clock

The ADC has a delayed version of the CLKB input available

as a digital output, CLKOUT. The falling edge of the CLKOUT

pin can be used to latch the digital output data. CLKOUT

is disabled when channel B is in sleep or nap mode.

Output Driver Power

Sleep and Nap Modes

The converter may be placed in shutdown or nap modes to

conserve power. Connecting SHDN to GND results in normal

operation. Connecting SHDN to V

and OE to VDD results

DD

in sleep mode, which powers down all circuitry including

the reference and typically dissipates 1mW. When exiting

sleep mode it will take milliseconds for the output data

to become valid because the reference capacitors have to

recharge and stabilize. Connecting SHDN to V

and OE

DD

to GND results in nap mode, which typically dissipates

30mW. In nap mode, the on-chip reference circuit is kept

on, so that recovery from nap mode is faster than that

from sleep mode, typically taking 100 clock cycles. In both

sleep and nap modes, all digital outputs are disabled and

enter the Hi-Z state.

Channels A and B have independent SHDN pins (SHDNA,

SHDNB). Channel A is controlled by SHDNA and OEA,

and channel B is controlled by SHDNB and OEB. The

nap, sleep and output enable modes of the two channels

are completely independent, so it is possible to have one

channel operating while the other channel is in nap or

sleep mode.

Separate output power and ground pins allow the output

drivers to be isolated from the analog circuitry. The power

supply for the digital output buffers, OV

, should be tied

DD

to the same power supply as for the logic being driven.

For example, if the converter is driving a DSP powered

by a 1.8V supply, then OV

should be tied to that same

DD

1.8V supply.

can be powered with any voltage from 500mV up to

OV

DD

3.6V. OGND can be powered with any voltage from GND

up to 1V and must be less than OV

will swing between OGND and OV

. The logic outputs

DD

.

DD

Output Enable

The outputs may be disabled with the output enable pin,

OE. OE high disables all data outputs including OF. The

data access and bus relinquish times are too slow to

allow the outputs to be enabled and disabled during full

speed operation. The output Hi-Z state is intended for use

during long periods of inactivity. Channels A and B have

independent output enable pins (OEA, OEB).

Digital Output Multiplexer

The digital outputs of the LTC2283 can be multiplexed onto

a single data bus if the sample rate is 80Msps or less. The

MUX pin is a digital input that swaps the two data busses. If MUX is High, channel A comes out on DA0-DA11;

channel B comes out on DB0-DB11. If MUX is Low, the

output busses are swapped and channel A comes out

on DB0-DB11; channel B comes out on DA0-DA11. To

multiplex both channels onto a single output bus, connect

MUX, CLKA and CLKB together (see the Timing Diagram

for the multiplexed mode). The multiplexed data is available on either data bus — the unused data bus can be

disabled with its OE pin.

Grounding and Bypassing

The LTC2283 requires a printed circuit board with a clean,

unbroken ground plane. A multilayer board with an internal

ground plane is recommended. Layout for the printed

circuit board should ensure that digital and analog signal

lines are separated as much as possible. In particular, care

2283fb

18

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

should be taken not to run any digital track alongside an

analog signal track or underneath the ADC.

High quality ceramic bypass capacitors should be used at

the V

tors must be located as close to the pins as possible. Of

particular importance is the 0.1μF capacitor between REFH

and REFL. This capacitor should be placed as close to the

device as possible (1.5mm or less). A size 0402 ceramic

capacitor is recommended. The large 2.2μF capacitor between REFH and REFL can be somewhat further away. The

traces connecting the pins and bypass capacitors must be

kept short and should be made as wide as possible.

The LTC2283 differential inputs should run parallel and

close to each other. The input traces should be as short

as possible to minimize capacitance and to minimize

noise pickup.

Heat Transfer

Most of the heat generated by the LTC2283 is transferred

from the die through the bottom-side Exposed Pad and

package leads onto the printed circuit board. For good

electrical and thermal performance, the Exposed Pad

should be soldered to a large grounded pad on the PC

board. It is critical that all ground pins are connected to

a ground plane of suffi cient area.

Clock Sources for Undersampling

Undersampling is especially demanding on the clock

source, and the higher the input frequency, the greater the

sensitivity to clock jitter or phase noise. A clock source that

degrades SNR of a full-scale signal by 1dB at 70MHz will

degrade SNR by 3dB at 140MHz, and 4.5dB at 190MHz.

In cases where absolute clock frequency accuracy is

relatively unimportant and only a single ADC is required,

a 3V canned oscillator from vendors such as Saronix

or Vectron can be placed close to the ADC and simply

connected directly to the ADC. If there is any distance to

the ADC, some source termination to reduce ringing that

, OVDD, VCM, REFH, and REFL pins. Bypass capaci-

DD

may occur even over a fraction of an inch is advisable.

You must not allow the clock to overshoot the supplies or

performance will suffer. Do not fi lter the clock signal with

a narrow band fi lter unless you have a sinusoidal clock

source, as the rise and fall time artifacts present in typical

digital clock signals will be translated into phase noise.

The lowest phase noise oscillators have single-ended

sinusoidal outputs, and for these devices the use of a fi lter

close to the ADC may be benefi cial. This fi lter should be

close to the ADC to both reduce roundtrip refl ection times,

as well as reduce the susceptibility of the traces between

the fi lter and the ADC. If the circuit is sensitive to closein phase noise, the power supply for oscillators and any

buffers must be very stable, or propagation delay variation

with supply will translate into phase noise. Even though

these clock sources may be regarded as digital devices, do

not operate them on a digital supply. If your clock is also

used to drive digital devices such as an FPGA, you should

locate the oscillator, and any clock fan-out devices close to

the ADC, and give the routing to the ADC precedence. The

clock signals to the FPGA should have series termination at

the driver to prevent high frequency noise from the FPGA

disturbing the substrate of the clock fan-out device. If you

use an FPGA as a programmable divider, you must re-time

the signal using the original oscillator, and the re-timing

fl ip-fl op as well as the oscillator should be close to the

ADC, and powered with a very quiet supply.

For cases where there are multiple ADCs, or where the

clock source originates some distance away, differential

clock distribution is advisable. This is advisable both from

the perspective of EMI, but also to avoid receiving noise

from digital sources both radiated, as well as propagated in

the waveguides that exist between the layers of multilayer

PCBs. The differential pairs must be close together and

distanced from other signals. The differential pair should

be guarded on both sides with copper distanced at least

3x the distance between the traces, and grounded with

vias no more than 1/4 inch apart.

2283fb

19

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

DD

OV

DD

QDV

DD

OV

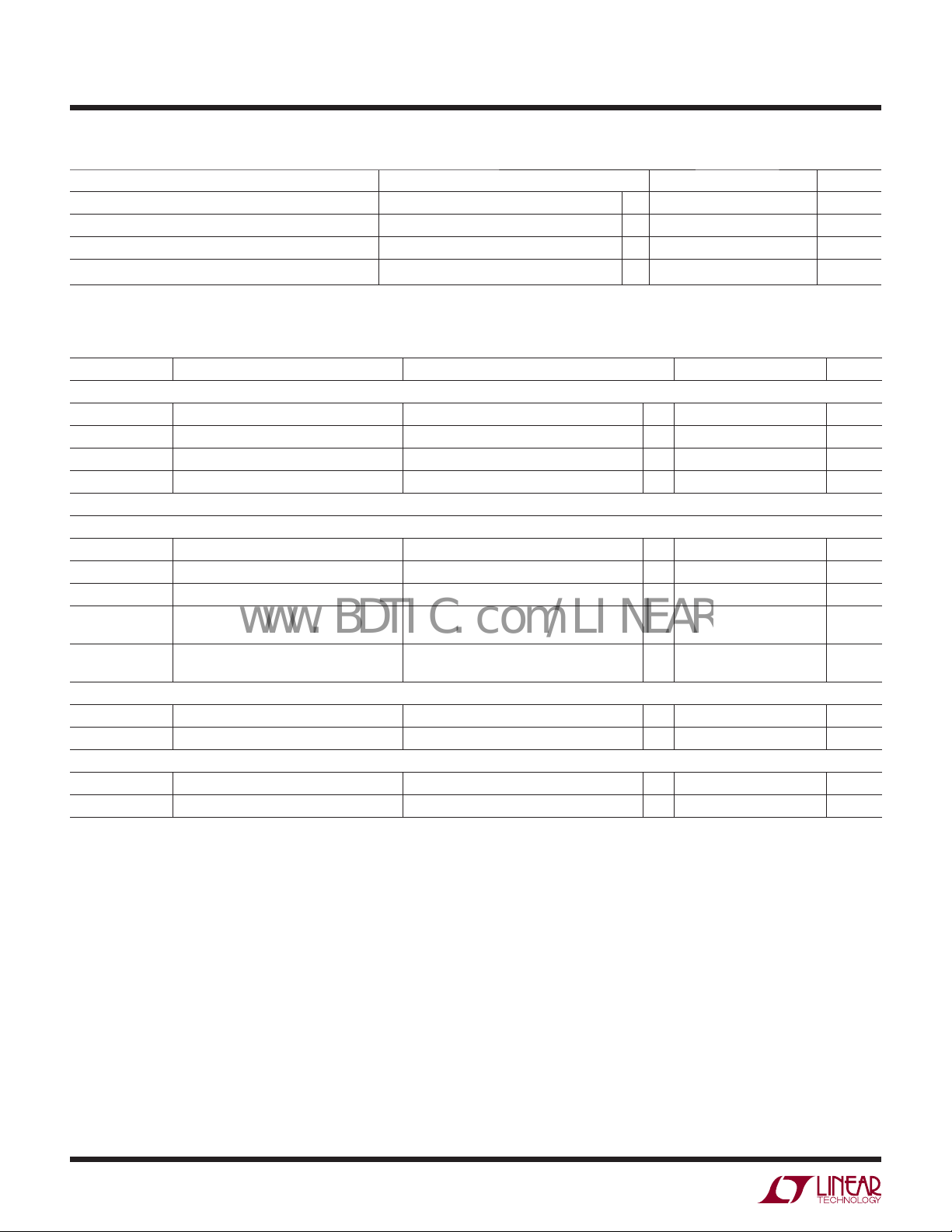

Evaluation Circuit Schematic of the LTC2283

1

3579111315171921232527293133353739

J1

EDGE-CON-100

246

8

101214161820222426283032343638

R42

1k

U2

21

20191817161514

B1

B0

FXLH42245MPX

CCB

V

CCB

V

CCA

124 23

V

A1

A0

3456789

DD

V

JP1 MODE

12

DD

V

B2

DD

2/3V

R11kR21kR3

JP2 SENSEA

2

B3

B7

B5B4B6

PAD

EXPOSED

A3A2A4A5A6A7OE

10

C2

2.2μF

C1

DD

GND

1/3V

34

56

78

1k

DD

CM

V

V

EXT REF

12

34

DD

V

E1

T/R

GND GND GNDGND

22

0.1μF

C44

0.1μF

56

EXT

REF A

CCINVSS

SCL

R34

B5B4B6

PAD

μF

0.01

2

GND

C48

C47

C41

C40

DD

3VE5PWR

V

C45

+

R25

C36

100μF

4.7k

DD

5

QDV

2

B7

10

22

105k

E4

GND

0.1μF

0.1μF

0.1μF

0.1μF

4.7μF

6.3V

OPT

V

R37

4.99k

R36

4.99k

U5

24LC025

C46

0.1μF

R35

100k

C24

0.1μF

1

2

3

4

U4

NC7SV86P5X

T/R

GND GND GNDGND

11 12 13 25

C50

10μF

6.3V

DD

QDV

R40

105k

C49

3

4

ADJ

BYP

OUT

U13

IN

LT1761ES5-BYP

15

DD

V

1μF

C51

C55

0.1μF

C54

0.1μF

DD

QDV

C53

0.1μF

C52

0.1μF

GND

876

V

A0A1A2

123

μF

0.01

GND

DD

QDV

R33

4.7k

CCIN

VSSSCL

SDA

V

ENABLE

41434547495153555759616365676971737577

42444648505254565860626466687072747678

40

U9

21

20191817161514

B3

B1

B0

B2

B7

DD

FXLH42245MPX

CCB

V

QDV

CCB

V

DD

CCA

124 23

V

OV

11 12 13 25

R5

CMA

V

J2

*

T1

C3

R4

ANALOG

DD

V

*

0.1μF

OPT

INPUT A

R6

123

5

3456789

DD

OV

C5

0.1μF

49

50

51

52

53

54

55

56

57

58

59

60

61

62

63

64

C4

0.1μF

C6

*

24.9Ω

R7

••

4

24.9Ω

B5B4B6

PAD

EXPOSED

A3A2A4A5A6A7OE

A1

A0

484746454443424140393837363534

DD

OV

OGND

DA8

DA9

DA10

DA11

DA12

DA13

OF

OEA

VCMA

DD

V

GND

123456789

R8

C7

DA7

SHDNA

MODE

+

A

R9

0.1μF

INA

51Ω

DA6

SENSEA

–

INA

A

C9 1μF

*

CMA

V

C12

C8

DA5

REFHA

4.7μF

L1

0.1μF

DA4

REFHA

C11

C10

6.3V

BEAD

0.1μF

V

DA3

REFLA

2.2μF

DD

10

DA2

DA1

REFLA

VDDCLKA

C13 1μF

C14

DD

V

2

T/R

GND GND GNDGND

22

DA0

DB13

CLKOUT

U1

LTC2283

CLKB

VDDREFLB

10111213141516

C18 1μF

DD

V

0.1μF

C15

0.1μF

R10

1k

C19

J3

CLOCK

U10

DD

FXLH42245MPX

QDV

DD

124 23

OV

11 12 13 25

DB9

DB12

DB11

DB10

–

REFLB

REFHB

REFHB

C21

0.1μF

C20

2.2μF

C17

0.1μF

3

5

24

R15

0.1μF

R14

INPUT

21

20191817161514

B1

B0

B2

CCB

V

CCB

V

CCA

V

A1

A0

3456789

33

DB8

DB7

OV

DD

OV

32

OGND

31

DB6

30

DB5

29

DB4

28

DB3

27

DB2

26

DB1

25

DB0

24

OEB

23

SHDNB

22

MUX

21

VCMB

20

SENSEB

19

DD

V

18

GND

17

+

INB

INB

A

A

C23 1μF

R39

DD

V

R32

OPT

U3

NC7SVU04

1k

49.9Ω

B3

B5B4B6

PAD

EXPOSED

A3A2A4A5A6A7OE

10

C25

0.1μF

DD

C27

0.1μF

DD

V

*

1k

R18

T2

C29

R17

J4

ANALOG

7981838587899193959799

808284868890929496

U11

21

DD

V

*

R22

••

5

DD

QDV

DD

OV

V

24.9Ω

CM

20191817161514

B0

FXLH42245MPX

CCB

V

CCB

V

CCA

124 23

V

A0

3456789

DD

OV

U12

LT1761ES5-BYP

DD

V

C35

EXT REF

34

56

E2

CMB

EXT

V

*

R24

C34

R23

51Ω

CMB

V

C33

0.1μF

B7

0.1μF

OPT

2

T/R

22

C28

CMB

V

*

INPUT B

GND GND GNDGND

2.2μF

DD

V

JP3 SENSEB

C31

R20

24.9Ω

123

4

11 12 13 25

12

98

100

B3

B1

B2

EXPOSED

A3A2A4A5A6A7OE

A1

C37

10μF

6.3V

R25

105k

C38

3

4

ADJ

BYP

OUT

IN

15

1μF

C39

0.1μF

REF B

DD

OV

0.1μF

E3

DD

V

R38

4.99k

5

CC

WP

SCL

4

R41

100k

2

*VERSION TABLE

2283 AI01

SDA

SDA

A3

< 70MHz

< 70MHz

< 70MHz

< 140MHz

IN

IN

IN

IN

INPUT FREQUENCY

1MHz < A

1MHz < A

1MHz < A

70MHz < A

T1, T2

MABAES0060

MABAES0060

MABAES0060

MABA-007159-000000

8pF

12pF

12pF

12pF

C6, C31

24.9Ω

24.9Ω

24.9Ω

12.4Ω

R5, R9, R18, R24

125

125

125

125

Msps

1012141012

BITS

U1

LTC2281IUP

LTC2283IUP

LTC2285IUP

LTC2281IUP

DC1098A-A

DC1098A-B

DC1098A-C

DC1098A-D

ASSEMBLY TYPE

< 140MHz

< 140MHz

IN

IN

70MHz < A

70MHz < A

MABA-007159-000000

MABA-007159-000000

8pF

8pF

12.4Ω

12.4Ω

125

125

14

LTC2283IUP

LTC2285IUP

DC1098A-F

DC1098A-E

2283fb

20

APPLICATIONS INFORMATION

www.BDTIC.com/LINEAR

LTC2283

Silkscreen Top

Top Side

2283fb

21

LTC2283

www.BDTIC.com/LINEAR

APPLICATIONS INFORMATION

Inner Layer 2 GND Inner Layer 3 Power

Bottom Side

22

2283fb

PACKAGE DESCRIPTION

www.BDTIC.com/LINEAR

LTC2283

UP Package

64-Lead Plastic QFN (9mm × 9mm)

(Reference LTC DWG # 05-08-1705)

0.70 ±0.05

7.15 ±0.05

7.15 ±0.05

0.25 ±0.05

0.50 BSC

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

APPLY SOLDER MASK TO AREAS THAT ARE NOT SOLDERED

9 .00 ± 0.10

(4 SIDES)

PIN 1 TOP MARK

(SEE NOTE 5)

7.50 REF

(4 SIDES)

8.10 ±0.05 9.50 ± 0.05

PACKAGE OUTLINE

0.75 ± 0.05

R = 0.10

TYP

7.50 REF

(4-SIDES)

R = 0.115

7.15 ± 0.10

TYP

PIN 1

CHAMFER

C = 0.35

6463

0.40 ± 0.10

1

2

NOTE:

1. DRAWING CONFORMS TO JEDEC PACKAGE OUTLINE MO-220 VARIATION WNJR-5

2. ALL DIMENSIONS ARE IN MILLIMETERS

3. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.20mm ON ANY SIDE, IF PRESENT

4. EXPOSED PAD SHALL BE SOLDER PLATED

5. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE TOP AND BOTTOM OF PACKAGE

6. DRAWING NOT TO SCALE

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.200 REF

0.00 – 0.05

7.15 ± 0.10

(UP64) QFN 0406 REV C

0.25 ± 0.05

0.50 BSC

BOTTOM VIEW—EXPOSED PAD

2283fb

23

LTC2283

www.BDTIC.com/LINEAR

TYPICAL APPLICATION

PART NUMBER DESCRIPTION COMMENTS

LTC1748 14-Bit, 80Msps, 5V ADC 76.3dB SNR, 90dB SFDR, 48-Pin TSSOP Package

LTC1750 14-Bit, 80Msps, 5V Wideband ADC Up to 500MHz IF Undersampling, 90dB SFDR

LTC1993-2 High Speed Differential Op Amp 800MHz BW, 70dBc Distortion at 70MHz, 6dB Gain

LTC1994 Low Noise, Low Distortion Fully Differential Input/Output

Amplifi er/Driver

LTC2208 16-Bit, 130Msps, 3.3V ADC, LVDS Outputs 1250mW, 77.1dB SNR, 100dB SFDR, 64-Pin QFN Package

LTC2220 12-Bit, 170Msps, 3.3V ADC, LVDS Outputs 890mW, 67.7dB SNR, 84dB SFDR, 64-Pin QFN Package

LTC2224 12-Bit, 135Msps, 3.3V ADC, High IF Sampling 630mW, 67.6dB SNR, 84dB SFDR, 48-Pin QFN Package

LTC2242-12 12-Bit, 250Msps, 2.5V ADC, LVDS Outputs 740mW, 65.4dB SNR, 84dB SFDR, 64-Pin QFN Package

LTC2254 14-Bit, 105Msps, 3V ADC, Lowest Power 320mW, 72.4dB SNR, 88dB SFDR, 32-Pin QFN Package

LTC2255 14-Bit, 125Msps ADC, 3V ADC, Lowest Power 395mW, 72.5dB SNR, 88dB SFDR, 32-Pin QFN Package

LTC2280 10-Bit, Dual, 105Msps, 3V ADC, Low Crosstalk 320mW, 61.6dB SNR, 85dB SFDR, 64-Pin QFN Package

LTC2282 12-Bit, Dual, 105Msps, 3V ADC, Low Crosstalk 540mW, 70.1dB SNR, 88dB SFDR, 64-Pin QFN Package

LTC2284 14-Bit, Dual, 105Msps, 3V ADC, Low Crosstalk 540mW, 72.4dB SNR, 88dB SFDR, 64-Pin QFN Package

LTC2286 10-Bit, Dual, 25Msps, 3V ADC, Low Crosstalk 150mW, 61.8dB SNR, 85dB SFDR, 64-Pin QFN Package

LTC2287 10-Bit, Dual, 40Msps, 3V ADC, Low Crosstalk 235mW, 61.8dB SNR, 85dB SFDR, 64-Pin QFN Package

LTC2288 10-Bit, Dual, 65Msps, 3V ADC, Low Crosstalk 400mW, 61.8dB SNR, 85dB SFDR, 64-Pin QFN Package

LTC2289 10-Bit, Dual, 80Msps, 3V ADC, Low Crosstalk 422mW, 61.6dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2290 12-Bit, Dual, 10Msps, 3V ADC, Low Crosstalk 120mW, 71.3dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2291 12-Bit, Dual, 25Msps, 3V ADC, Low Crosstalk 150mW, 71.4dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2292 12-Bit, Dual, 40Msps, 3V ADC, Low Crosstalk 235mW, 71.4dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2293 12-Bit, Dual, 65Msps, 3V ADC, Low Crosstalk 400mW, 71.3dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2294 12-Bit, Dual, 80Msps, 3V ADC, Low Crosstalk 422mW, 70.6dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2295 14-Bit, Dual, 10Msps, 3V ADC, Low Crosstalk 120mW, 74.4dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2296 14-Bit, Dual, 25Msps, 3V ADC, Low Crosstalk 150mW, 74.5dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2297 14-Bit, Dual, 40Msps, 3V ADC, Low Crosstalk 235mW, 74.4dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2298 14-Bit, Dual, 65Msps, 3V ADC, Low Crosstalk 400mW, 74.3dB SNR, 90dB SFDR, 64-Pin QFN Package

LTC2299 14-Bit, Dual, 80Msps, 3V ADC, Low Crosstalk 444mW, 73dB SNR, 90dB SFDR, 64-Pin QFN Package

LT5512 DC-3GHz High Signal Level Downconverting Mixer DC to 3GHz, 21dBm IIP3, Integrated LO Buffer

LT5514 Ultralow Distortion IF Amplifi er/ADC Driver with Digitally

Controlled Gain

LT5515 1.5GHz to 2.5GHz Direct Conversion Quadrature Demodulator High IIP3: 20dBm at 1.9GHz, Integrated LO Quadrature Generator

LT5516 800MHz to 1.5GHz Direct Conversion Quadrature Demodulator High IIP3: 21.5dBm at 900MHz, Integrated LO Quadrature Generator

LT5517 40MHz to 900MHz Direct Conversion Quadrature Demodulator High IIP3: 21dBm at 800MHz, Integrated LO Quadrature Generator

LT5522 600MHz to 2.7GHz High Linearity Downconverting Mixer 4.5V to 5.25V Supply, 25dBm IIP3 at 900MHz, NF = 12.5dB,

Low Distortion: –94dB at 1MHz

450MHz to 1dB BW, 47dB OIP3, Digital Gain Control

10.5dB to 33dB in 1.5dB/Step

50Ω Single Ended RF and LO Ports

Linear Technology Corporation

24

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

2283fb

LT 1207 REV B • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2006

Loading...

Loading...