Linear Technology LTC1873 Datasheet

FEATURES

LTC1873

Dual 550kHz Synchronous

2-Phase Switching Regulator

Controller with 5-Bit VID

U

DESCRIPTIO

■

Two Independent PWM Controllers in One Package

■

Side 1 Output Is Compliant with Intel Desktop

VRM 8.4 Specifications (Includes 5-Bit VID DAC)

■

1.3V to 3.5V Output Voltage with 50mV/100mV Steps

■

Two Sides Run Out-of-Phase to Minimize C

■

All N-Channel External MOSFET Architecture

■

No External Current Sense Resistors Required

■

Precison Internal 0.8V ±1% Reference

■

550kHz Switching Frequency Minimizes External

IN

Component Size

■

Very Fast Transient Response

■

Up to 25A Output Current per Channel

■

Low Shutdown Current: < 100µA

■

Small 28-Pin SSOP Package

U

APPLICATIO S

■

Microprocessor Core and I/O Supplies

■

Multiple Logic Supply Generator

■

High Efficiency Power Conversion

■

Chipset Power Supply

The LTC®1873 is a dual switching regulator controller optimized for high efficiency with low input voltages. It includes

two complete, on-chip, independent switching regulator controllers. Each is designed to drive a pair of external

N-channel MOSFETs in a voltage mode feedback, synchronous buck configuration. The LTC1873 includes digital output voltage adjustment on side 1 that conforms to the Intel

Desktop VID specification. A constant-frequency, true PWM

design minimizes external component size and cost and

optimizes load transient performance. The synchronous buck

architecture automatically shifts to discontinuous and then to

Burst ModeTM operation as the output load decreases, ensuring maximum efficiency over a wide range of load currents.

The LTC1873 features an onboard reference trimmed to 1%

and delivers better than 1.5% regulation at the converter

outputs over all combinations of line, load and temperature.

Each channel can be enabled independently; with both channels disabled, the LTC1873 shuts down and supply current

drops below 100µA.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

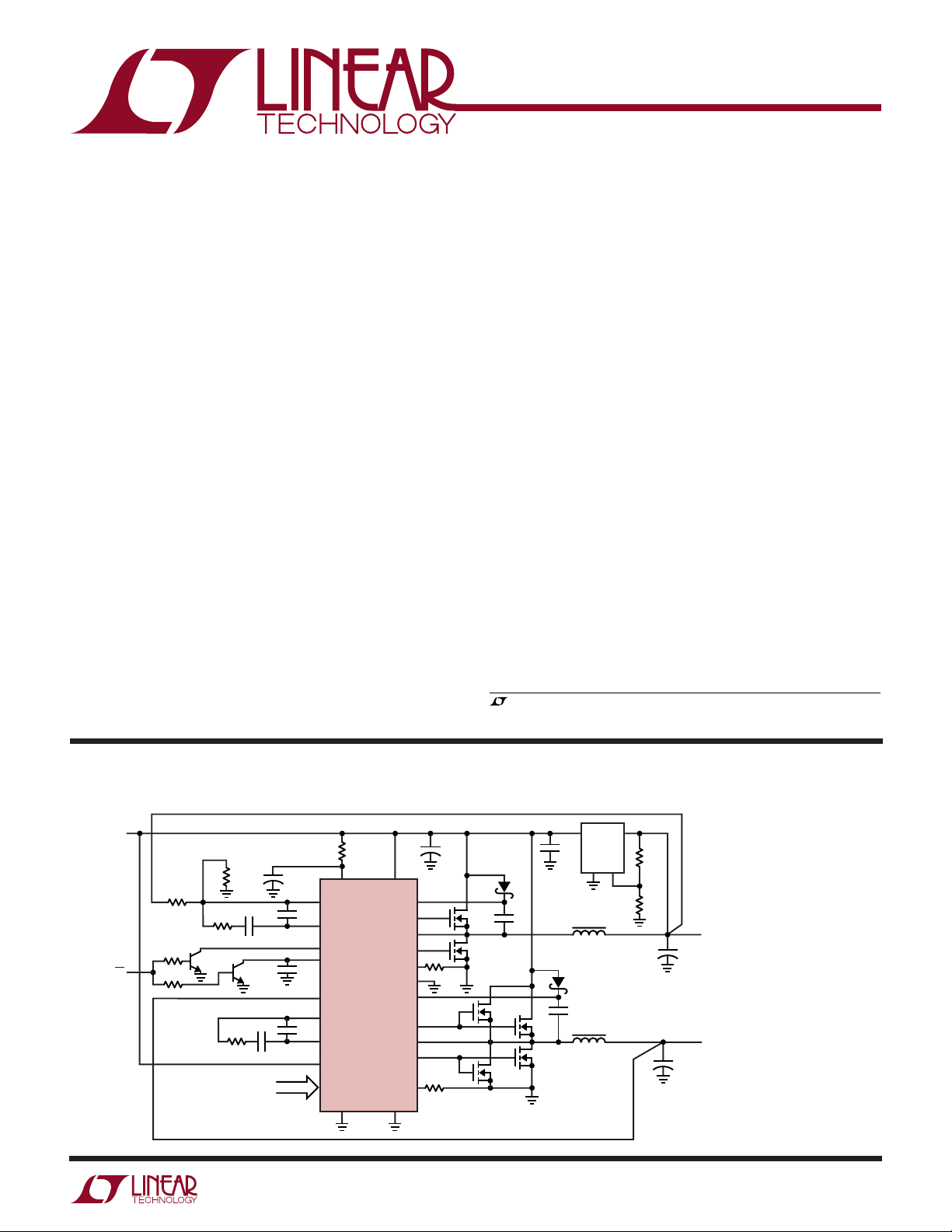

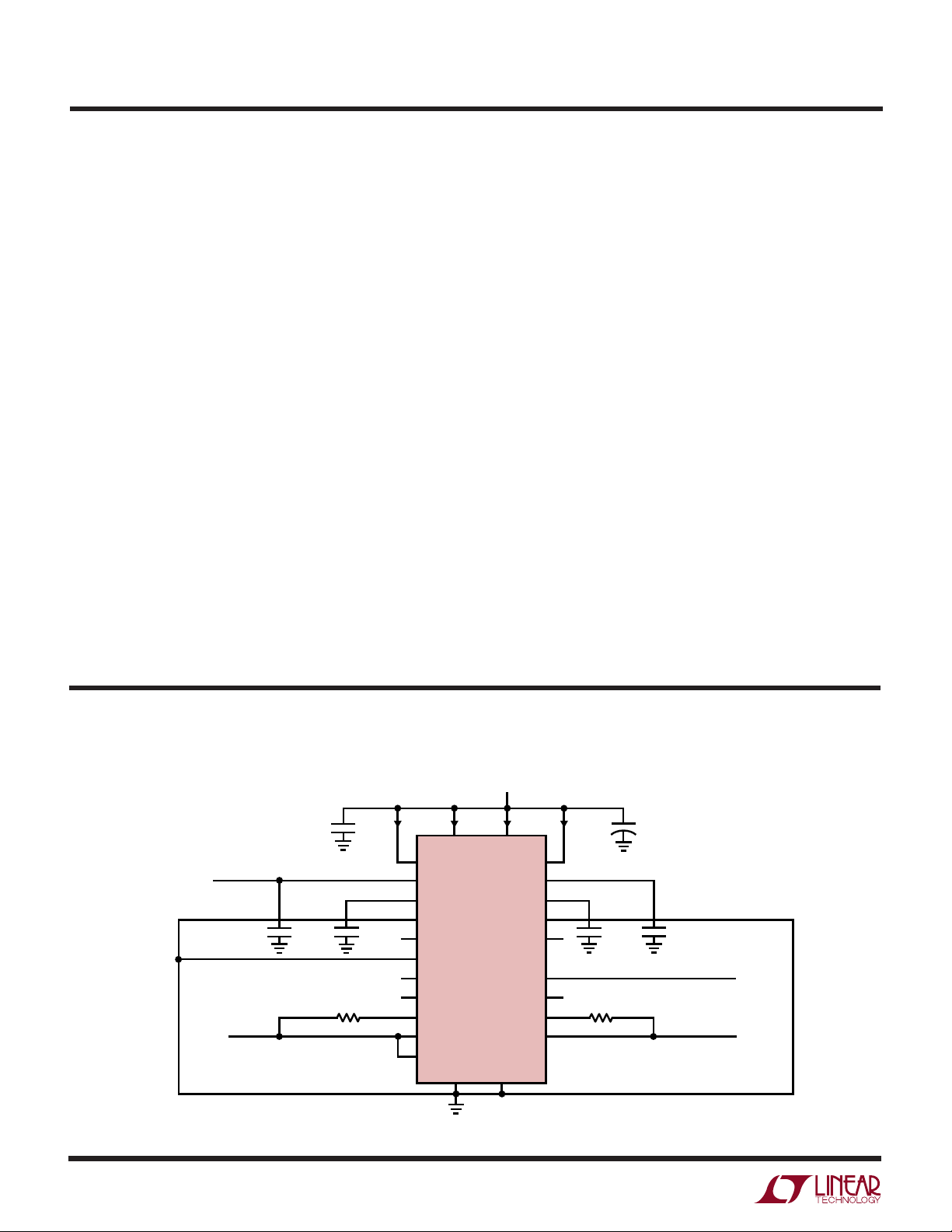

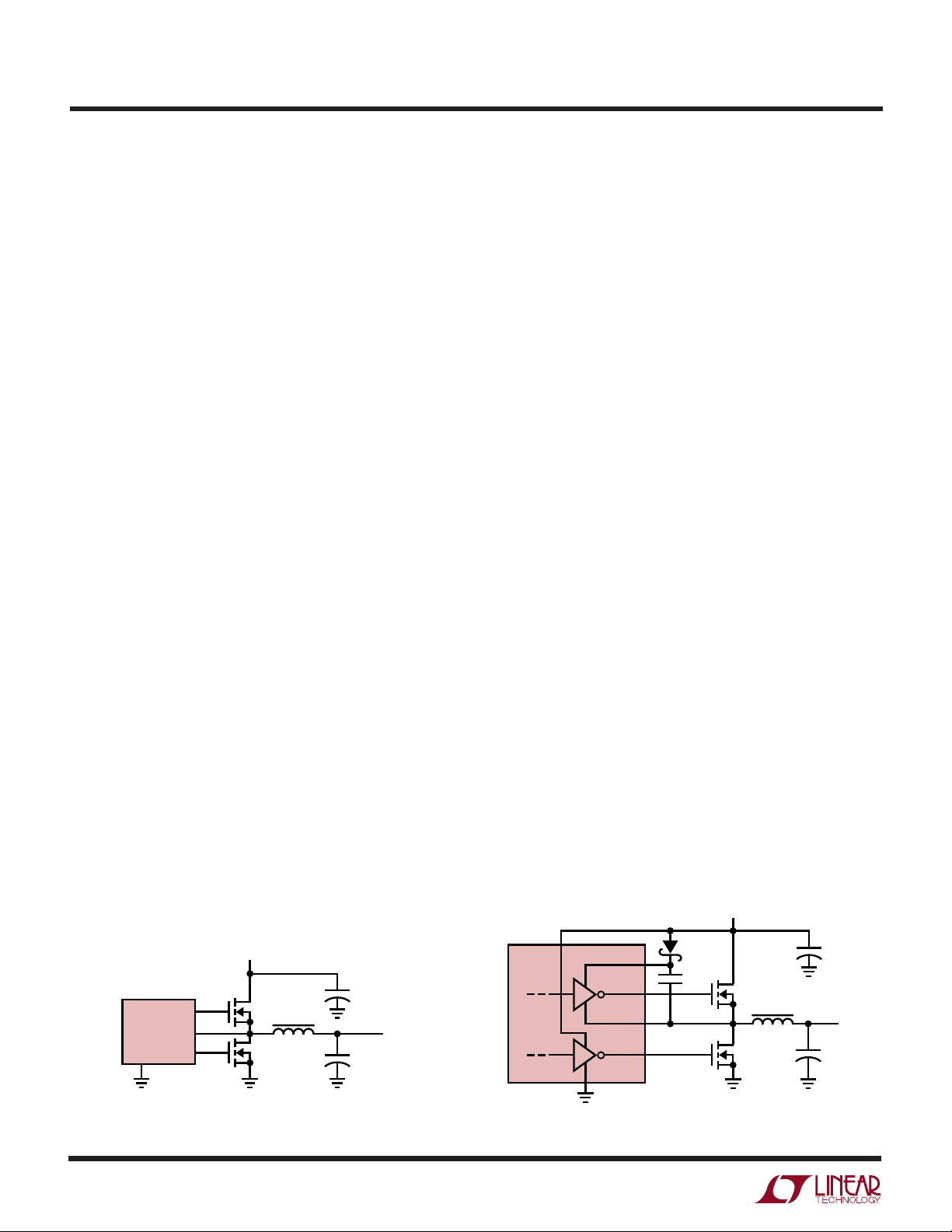

TYPICAL APPLICATIO

4.5V TO 5.5V

+

STBY/ON

10k

0.1%

1k

1k

QSS1

68k

4.75k

0.1%

330pF

56k

5-BIT VID

10µF

QSS2

220pF

U

Low Cost Desktop CPU Supply with RDRAM Keepalive

1µF

MBR0530T

1µF

IN OUT

LT1761

GND

ADJ

L2

L1

56pF

0.1µF

39pF

FB2

COMP2

RUN/SS2

RUN/SS1

SENSE

FB1

COMP1

FCB

VID4:0

10Ω

V

SGND PGND

CC

LTC1873

PV

BOOST2

I

FAULT

BOOST1

I

CC

TG2

SW2

BG2

MAX2

TG1

SW1

BG1

MAX1

+

C

IN

MBR0530T

1µF

QT2

QB2

47k

QT1B

QT1A

QB1A

33k

QB1B

16.2k

0.1%

16.9k

0.1%

1873 TA01

V

RDRAM

2.5V/7A

+

2.45V/100mA STANDBY

C

OUT2

V

CORE

1.3V TO 3.5V

+

20A

C

C

= SANYO 10MV1200GX (6 IN PARALLEL)

OUT1

IN

= SANYO 6MV1500GX (8 IN PARALLEL)

C

OUT1

= SANYO 6MV1500GX (3 IN PARALLEL)

C

OUT2

L1: 1µH SUMIDA CEP125-1R0MC-H

L2: 2.2µH COILTRONICS UP2B-2R2

QSS1, QSS2: MOTOROLA MMBT3904LT1

QT1A, QT1B, QB1A, QB1B: FAIRCHILD FDS6670A

QT2, QB2: 1/2 SILICONIX Si4966

1

LTC1873

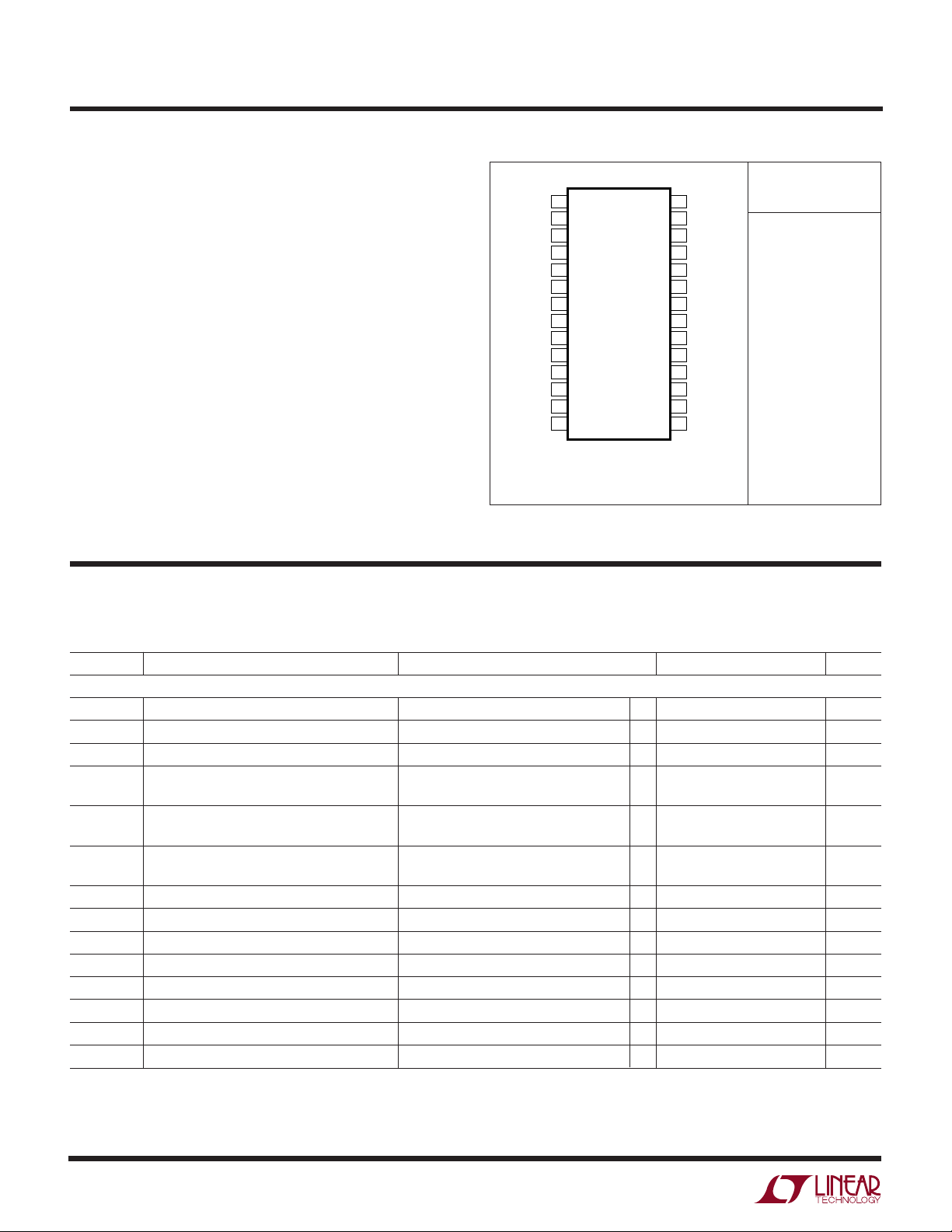

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Supply Voltage

V

...........................................................................................

CC

BOOST

n...............................................................

BOOSTn – SWn.................................................... 7V

Input Voltage

SWn.......................................................... –1V to 8V

VIDn....................................................... –0.3V to 7V

All Other Inputs ......................... – 0.3V to VCC + 0.3V

Peak Output Current < 10µs

TGn, BGn............................................................... 5A

Operating Temperature Range

(Note 2) ............................................. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

7V

15V

PV

BOOST1

BG1

TG1

SW1

I

MAX1

FCB

RUN/SS1

COMP1

SGND

FB1

SENSE

VID0

VID1

TOP VIEW

1

CC

2

3

4

5

6

7

8

9

10

11

12

13

14

G PACKAGE

28-LEAD PLASTIC SSOP

T

= 125°C, θJA = 55°C/W

JMAX

28

27

26

25

24

23

22

21

20

19

18

17

16

15

I

MAX2

BOOST2

BG2

TG2

SW2

PGND

FAULT

RUN/SS2

COMP2

FB2

V

CC

VID4

VID3

VID2

ORDER PART

LTC1873EG

Consult factory for Industrial and Military grade parts.

NUMBER

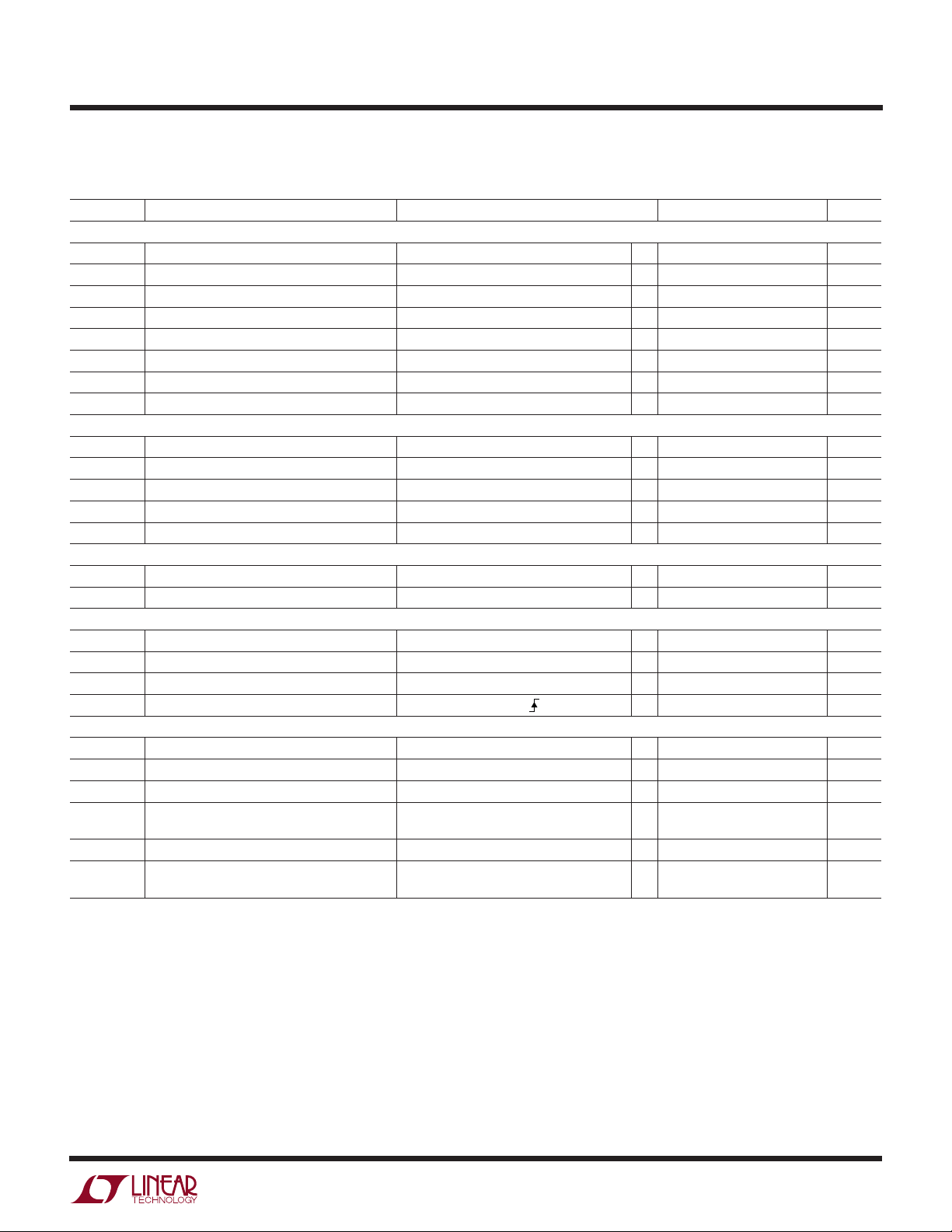

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V unless otherwise specified. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

V

CC

PV

CC

BV

CC

I

CC

IPV

I

BOOST

V

FB

∆V

FB

I

FB

V

FCB

∆V

FCB

I

FCB

V

RUN

I

SS

CC

VCC Supply Voltage ● 37V

PVCC Supply Voltage (Note 3) ● 37V

BOOST Pin Voltage V

– VSW (Note 3) ● 2.7 7 V

BOOST

VCC Supply Current Test Circuit 1 ● 2.2 8 mA

RUN/SS1 = RUN/SS2 = 0V (Note 6)

● 30 100 µA

PVCC Supply Current Test Circuit 1 (Note 5) ● 2.2 6 mA

RUN/SS1 = RUN/SS2 = 0V (Note 6)

● 6 100 µA

BOOST Pin Current Test Circuit 1 (Note 5) ● 1.3 3 mA

RUN/SS1 = RUN/SS2 = 0V

● 0.1 10 µA

Feedback Voltage Test Circuit 1 ● 0.790 0.800 0.810 V

Feedback Voltage Line Regulation VCC = 3V to 7V ● ±0.005 ±0.05 %/V

Feedback Current FB2 Only (Note 7) ● ±0.001 ±1 µA

FCB Threshold ● 0.75 0.8 0.85 V

FCB Feedback Hysteresis 20 mV

FCB Pin Current ● ±0.001 ±1 µA

RUN/SS Pin RUN Threshold ● 0.45 0.55 0.65 V

Soft Start Source Current RUN/SSn = 0V –1.5 –3.5 –5.5 µA

2

LTC1873

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are TA = 25°C.

VCC = 5V unless otherwise specified. (Note 4)

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Switching Characteristics

V

OSC

f

OSC

Φ

OSC2

DC

MIN1

DC

MIN2

DC

MAX

t

NOV

tr, t

f

Feedback Amplifier

A

VFB

GBW FB Gain Bandwidth 25 MHz

I

ERR

V

MIN

V

MAX

Current Limit Loop

A

VILIM

I

IMAX

Status Outputs

V

FAULT

V

OLF

I

FAULT

t

FAULT

VID Inputs

R1 Resistance Between SENSE and FB1 Side 1 Only 20 kΩ

V

Error % Output Voltage Accuracy Programmed from 1.3V to 3.5V ● –1.5 1.5 %

OUT

R

PULLUP

VID

T

I

VID-LEAK

V

PULLUP

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1873 is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: PV

the external MOSFETs used to ensure proper operation.

Note 4: All currents into device pins are positive; all currents out of device

pins are negative. All voltages are referenced to ground unless otherwise

specified.

Oscillator Amplitude 1V

P-P

Oscillator Frequency Test Circuit 1 ● 475 550 750 kHz

Controller 2 Oscillator Phase Relative to Controller 1 180 DEG

Minimum Duty Cycle VFB < V

Minimum Duty Cycle VFB > V

MAX

MAX

● 710 %

● 0%

Maximum Duty Cycle ● 87 90 93 %

Driver Nonoverlap Test Circuit 1 (Note 9) ● 40 100 ns

Driver Rise/Fall Time Test Circuit 1 (Note 9) ● 12 80 ns

FB DC Gain ● 74 85 dB

FB Sink/Source Current COMPN Output ● ±3 ±10 mA

MIN Comparator Threshold ● 760 785 mV

MAX Comparator Threshold ● 815 840 mV

I

Gain 40 dB

LIM

I

Source Current I

MAX

FAULT Trip Point VFB Relative to Regulated V

FAULT Output Low Voltage I

FAULT Output Current V

FAULT Delay Time VFB > V

VID Input Pull-Up Resistance V

= 0V ● –7 –10 –14 µA

MAX

OUT

= 1mA ● 0.03 0.1 V

FAULT

= 0V –10 µA

FAULT

to FAULT (Note 9) 25 µs

FAULT

= 0.6V (Note 8) 40 kΩ

DIODE

● +10 +15 +20 %

VID Input Voltage Threshold VIL (2.7V ≤ VCC ≤ 5.5V) 0.4 V

(2.7V ≤ VCC ≤ 5.5V) 1.6 V

V

IH

VID Input Leakage Current VCC < VID < 7V (Note 8) 0.01 ±1 µA

VID Pull-Up Voltage VCC = 3.3V 2.8 V

= 5V 4.5 V

V

CC

Note 5: Supply current in normal operation is dominated by the current

needed to charge and discharge the external MOSFET gates. This current

will vary with supply voltage and the external MOSFETs used.

Note 6: Supply current in shutdown is dominated by external MOSFET

leakage and may be significantly higher than the quiescent current drawn

by the LTC1873, especially at elevated temperature.

and BVCC (V

CC

– VSW) must be greater than V

BOOST

GS(ON)

of

Note 7: Feedback current at FB1 will be higher due to internal VID

resistors.

Note 8: Each built-in pull-up resistor attached to the VID inputs also has a

series diode connected to V

to allow input voltages higher than the V

CC

CC

supply without damage or clamping. (See Block Diagram.)

Note 9: Rise and fall times are measured at 20% to 80% levels. Delay and

nonoverlap times are measured using 50% levels.

3

LTC1873

TEMPERATURE (°C)

–50

0.4

R

ON

(Ω)

0.5

0.7

0.8

0.9

1.4

1.1

0

50

75

1873 G06

0.6

1.2

1.3

1.0

–25

25

100

125

V

PVCC

= 5V

V

BOOST

– VSW = 5V

GATE CAPACITANCE (pF)

0

25

30

35

6000 8000

1873 G03

20

15

2000 4000 10000

10

5

0

DRIVER SUPPLY CURRENT (mA)

TEST CIRCUIT 1

ONE DRIVER LOADED

MULTIPLY BY # OF ACTIVE

DRIVERS TO OBTAIN TOTAL

DRIVER SUPPLY CURRENT

TEMPERATURE (°C)

–50 –25

12

RISE/FALL TIME (ns)

12

15

0

50

75

1873 G09

11

14

13

25

100

125

TEST CIRCUIT 1

C

L

= 2000pF

UW

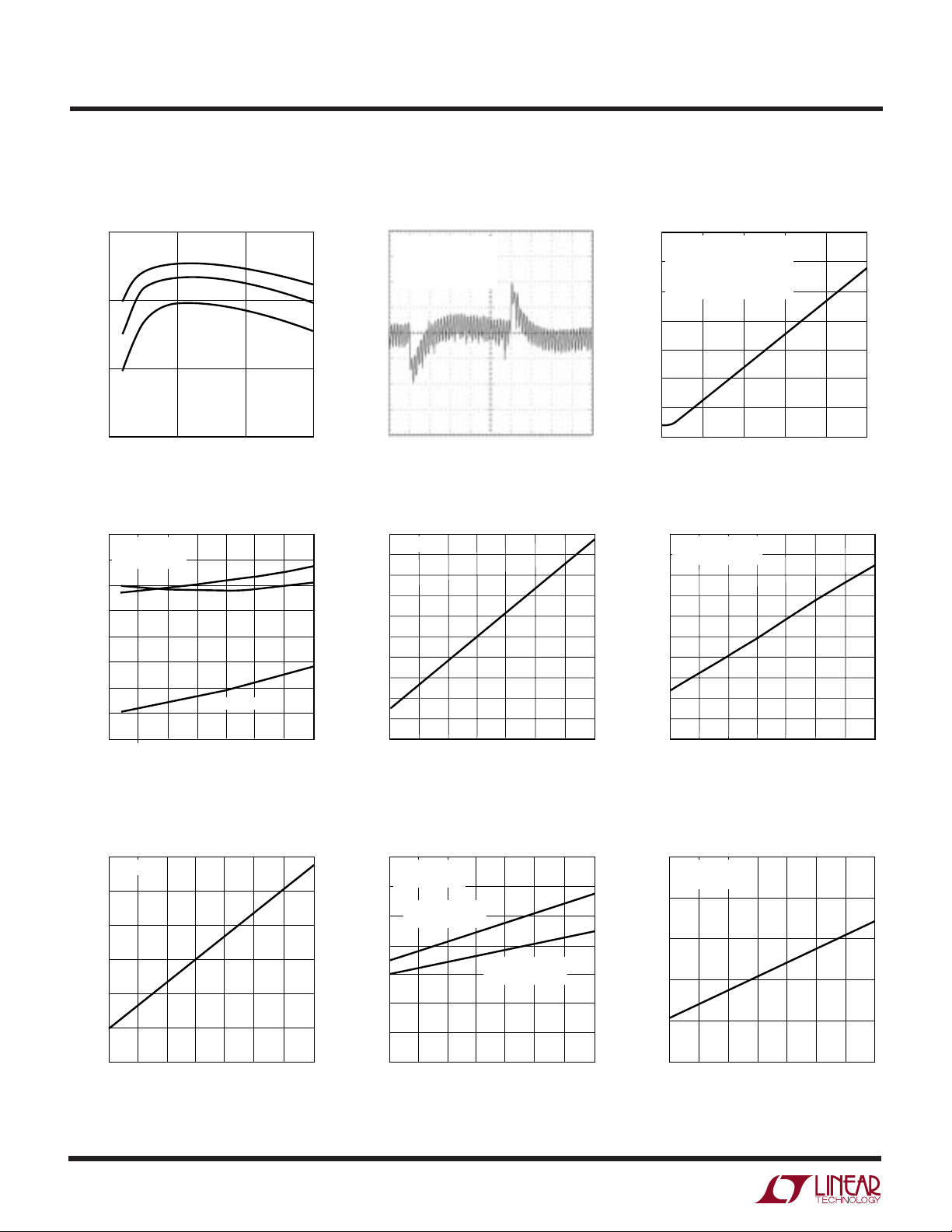

TYPICAL PERFOR A CE CHARACTERISTICS

Efficiency vs Load Current

100

= 5V

V

IN

90

EFFICIENCY (%)

80

V

OUT

V

OUT

V

OUT

= 3.3V

= 2.5V

= 1.6V

Transient Response

VIN = 5V

= 1.8V

V

OUT

I

= 0A-10A-0A

LOAD

±2.2% MAX DEVIATION

20mV/

DIV

MOSFET Driver Supply Current

vs Gate Capacitance

70

0

Supply Current vs Temperature

2.6

TEST CIRCUIT 1

= 0pF

C

2.4

L

2.2

2.0

1.8

1.6

SUPPLY CURRENT (mA)

1.4

1.2

1.0

–25 0 50

–50

RUN/SS Source Current

vs Temperature

5.0

VCC = 5V

4.5

4.0

3.5

3.0

SOURCE CURRENT (µA)

2.5

2.0

–50

–25 0

4

510

LOAD CURRENT (A)

PV

CC

V

CC

BOOST1, BOOST2

25

TEMPERATURE (°C)

50 100 125

25 75

TEMPERATURE (°C)

15

1873 G01

75 100 125

1873 G04

1873 G07

10µs/DIV

Frequency Drift vs Temperature

2.5

VCC = 5V

2.0

1.5

1.0

0.5

0

–0.5

–1.0

FREQUENCY DRIFT (%)

–1.5

–2.0

–2.5

–50

–25

0

TEMPERATURE (°C)

50

25

1873 G02

Driver RON vs Temperature

100

125

1873 G05

75

Nonoverlap Time vs Temperature Driver Rise/Fall vs Temperature

70

TEST CIRCUIT 1

C

= 2000pF

L

60

TG FALLING EDGE

50

BG RISING EDGE

40

30

20

NONOVERLAP TIME (ns)

10

0

–50

–25 0

BG FALLING EDGE

TG RISING EDGE

50 100 125

25 75

TEMPERATURE (°C)

1873 G08

LTC1873

U

UU

PI FU CTIO S

PVCC (Pin 1): Driver Power Supply Input. PVCC provides

power to the two BGn output drivers. PVCC must be

connected to a voltage high enough to fully turn on the

external MOSFETs QB1 and QB2. PVCC should generally

be connected directly to VIN. PVCC requires at least a 1µF

bypass capacitor directly to PGND.

BOOST1 (Pin 2): Controller 1 Top Gate Driver Supply. The

BOOST1 pin supplies power to the floating TG1 driver.

BOOST1 should be bypassed to SW1 with a 1µF capacitor.

An additional Schottky diode from VIN to BOOST1 pin will

create a complete floating charge-pumped supply at

BOOST1. No other external supplies are required.

BG1 (Pin 3): Controller 1 Bottom Gate Drive. The BG1 pin

drives the gate of the bottom N-channel synchronous

switch MOSFET, QB1. BG1 is designed to drive up to

10,000pF of gate capacitance directly. If RUN/SS1 goes

low, BG1 will go low, turning off QB1. If FAULT mode is

tripped, BG1 will go high and stay high, keeping QB1 on

until the power is cycled.

TG1 (Pin 4): Controller 1 Top Gate Drive. The TG1 pin

drives the gate of the top N-channel MOSFET, QT1. The

TG1 driver draws power from the BOOST1 pin and returns

to the SW1 pin, providing true floating drive to QT1. TG1

is designed to drive up to 10,000pF of gate capacitance

directly. In shutdown or fault modes, TG1 will go low.

SW1 (Pin 5): Controller 1 Switching Node. SW1 should be

connected to the switching node of converter 1. The TG1

driver ground returns to SW1, providing floating gate

drive to the top N-channel MOSFET switch, QT1. The

voltage at SW1 is compared to I

comparator while the bottom MOSFET, QB1, is on.

I

(Pin 6): Controller 1 Current Limit Set. The I

MAX1

pin sets the current limit comparator threshold for

controller 1. If the voltage drop across the bottom MOSFET,

QB1, exceeds the magnitude of the voltage at I

controller 1 will go into current limit. The I

internal 10µA current source pull-up, allowing the current

threshold to be set with a single external resistor to PGND.

This current setting resistor should be Kelvin connected to

the source of QB1. See the Current Limit Programming

section for more information on choosing R

by the current limit

MAX1

MAX1

IMAX

MAX1

MAX1

pin has an

.

,

FCB (Pin 7): Force Continuous Bar. The FCB pin forces

both converters to maintain continuous synchronous

operation regardless of load when the voltage at FCB

drops below 0.8V. FCB is normally tied to VCC. To force

continuous operation, tie FCB to SGND. FCB can also be

connected to a feedback resistor divider from a secondary

winding on one converter’s inductor to generate a third

regulated output voltage. Do not leave FCB floating.

RUN/SS1 (Pin 8): Controller 1 Run/Soft-Start. Pulling

RUN/SS1 to SGND will disable controller 1 and turn off

both of its external MOSFET switches. Pulling both

RUN/SS pins down will shut down the entire LTC1873,

dropping the quiescent supply current below 50µA. A

capacitor from RUN/SS1 to SGND will control the turn-on

time and rate of rise of the controller 1 output voltage at

power-up. An internal 3.5µA current source pull-up at

RUN/SS1 pin sets the turn-on time at approximately

50ms/µF.

COMP1 (Pin 9): Controller 1 Loop Compensation. The

COMP1 pin is connected directly to the output of the first

controller’s error amplifier and the input to the PWM

comparator. An RC network is used at the COMP1 pin to

compensate the feedback loop for optimum transient

response.

SGND (Pin 10): Signal Ground. All internal low power

circuitry returns to the SGND pin. Connect to a low

impedance ground, separated from the PGND node. All

feedback, compensation and soft-start connections should

return to SGND. SGND and PGND should connect only at

a single point, near the PGND pin and the negative plate of

the CIN bypass capacitor.

FB1 (Pin 11): Controller 1 Feedback Input. The loop

compensation network for controller 1 should be connected to FB1. FB1 is connected internally to the VID

resistor network to set the output voltage at side 1.

SENSE (Pin 12): Output Sense. Connect to V

VID0 to VID4 (Pins 13 to 17): VID Programming Inputs.

These are logic inputs that set the output voltage at side 1

to a preprogrammed value (see Table 1). VID4 is the MSB,

VID0 is the LSB. The codes selected by the VIDn inputs

correspond to the Intel Desktop VID specification. Each

OUT1

.

5

LTC1873

U

UU

PI FU CTIO S

VIDn pin includes an on-chip 40kΩ pull-up resistor in

series with a diode (see Block Diagram).

VCC (Pin 18): Power Supply Input. All internal circuits

except the output drivers are powered from this pin. V

should be connected to a low noise power supply voltage

between 3V and 7V and should be bypassed to SGND with

at least a 1µF capacitor in close proximity to the LTC1873.

FB2 (Pin 19): Controller 2 Feedback Input. FB2 should be

connected through a resistor divider network to V

set the ouput voltage. The loop compensation network for

controller 2 also connects to FB2.

COMP2 (Pin 20): Controller 2 Loop Compensation. See

COMP1.

RUN/SS2 (Pin 21): Controller 2 Run/Soft-Start. See RUN/

SS1.

FAULT (Pin 22): Output Overvoltage Fault (Latched). The

FAULT pin is an open-drain output with an internal 10µA

pull-up. If either regulated output voltage rises more than

15% above its programmed value for more than 25µs, the

FAULT output will go high and the entire LTC1873 will be

OUT2

CC

to

disabled. When FAULT is high, both BG pins will go high,

turning on the bottom MOSFET switches and pulling down

the high output voltage. The LTC1873 will remain latched

in this state until the power is cycled. When FAULT mode

is active, the FAULT pin will be pulled up with an internal

10µA current source. Tying FAULT directly to SGND will

disable latched FAULT mode and will allow the LTC1873 to

resume normal operation when the overvoltage fault is

removed.

PGND (Pin 23): Power Ground. The BGn drivers return to

this pin. Connect PGND to a high current ground node in

close proximity to the sources of external MOSFETs, QB1

and QB2, and the VIN and V

bypass capacitors.

OUT

SW2 (Pin 24): Controller 2 Switching Node. See SW1.

TG2 (Pin 25): Controller 2 Top Gate Drive. See TG1.

BG2 (Pin 26): Controller 2 Bottom Gate Drive. See BG1.

BOOST2 (Pin 27): Controller 2 Top Gate Driver Supply.

See BOOST1.

I

(Pin 28): Controller 2 Current Limit Set. See I

MAX2

MAX1

.

TEST CIRCUIT

f

OSC

MEASURED

V

FB1

Test Circuit 1

5V

I

0.1µF

2k

BOOST1ICC

V

CC

BOOST1

TG1

BG1

2000pF2000pF 2000pF

SW1

I

MAX1

LTC1873

FCB

NC

VID0:4

RUN/SS1

NC NC

COMP1

FB1

SENSE

GND PGND

I

PVCC

PV

CC

BOOST2

SW2

I

MAX2

FAULT

RUN/SS2

COMP2

TG2

BG2

FB2

I

BOOST2

2000pF

2k

+

100µF

V

V

FAULT

FB2

1873 TC

6

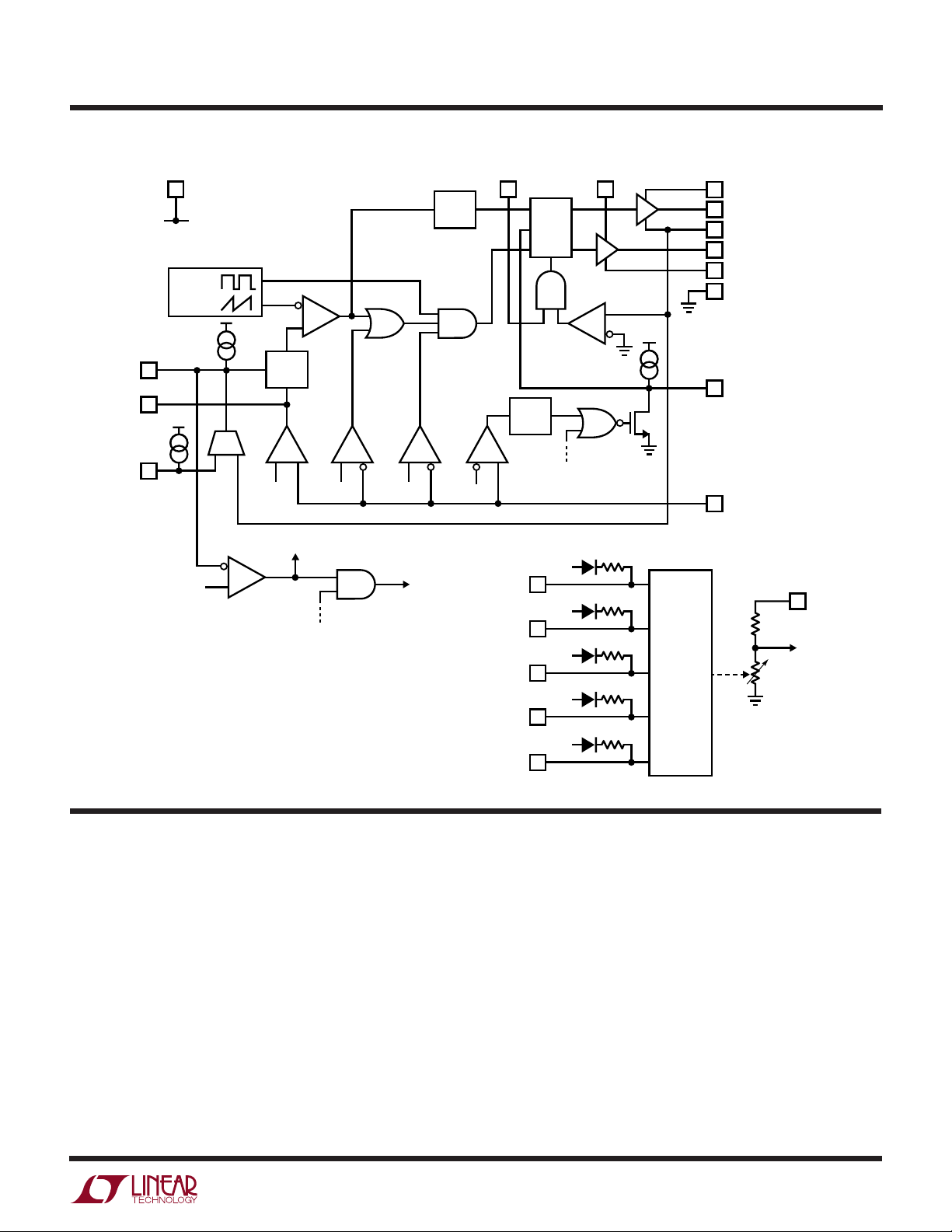

BLOCK DIAGRA

V

CC

OSC

550kHz

3.5µA

RUN/SS1,2

COMP1,2

I

LIM

800mV 760mV 840mV

SHUTDOWN TO

THIS CONTROLLER

I

MAX1,2

10µA

500mV

W

90% DUTY CYCLE

SOFT

START

FB

+

–

FROM

OTHER

CONTROLLER

MIN MAX

BURST

LOGIC

920mV

SHUTDOWN TO

ENTIRE CHIP

FLT

0V

FCB

VID0

VID1

VID2

VID3

VID4

DRIVE

LOGIC

25µs

DELAY

CONTROLLER

FROM

OTHER

V

CC

V

CC

V

CC

V

CC

V

CC

DIS

LTC1873

PV

40k

40k

40k

40k

40k

CC

10µA

SWITCH

CONTROL

LOGIC

BOOST1,2

TG1,2

SW1,2

BG1,2

PGND

SGND

FAULT

FB1,2

R11

20k

R

SENSE

TO FB1

B1

1873 BD

WUUU

APPLICATIO S I FOR ATIO

OVERVIEW

The LTC1873 is a dual, step-down (buck), voltage mode

feedback switching regulator controller. It is designed to

be used in a synchronous switching architecture with two

external N-channel MOSFETs per channel. It is intended to

operate from a low voltage input supply (7V maximum)

and provide a high power, high efficiency, precisely regulated output voltage. Several features make it particularly

suited for microprocessor supply regulation. Output regulation is extremely tight, with DC line and load regulation

and initial accuracy better than 1.5%, and total regulation

including transient response inside of 3.5% with a prop-

erly designed circuit. The 550kHz switching frequency

allows the use of physically small, low value external

components without compromising performance. An

onboard DAC sets the output voltage at channel 1, consistent with the Intel desktop VID specification (Table 1).

The LTC1873’s internal feedback amplifier is a 25MHz

gain-bandwidth op amp, allowing the use of complex

multipole/zero compensation networks. This allows the

feedback loop to maintain acceptable phase margin at

higher frequencies than traditional switching regulator

controllers allow, improving stability and maximizing transient response. The 800mV internal reference at channel

2

7

LTC1873

WUUU

APPLICATIO S I FOR ATIO

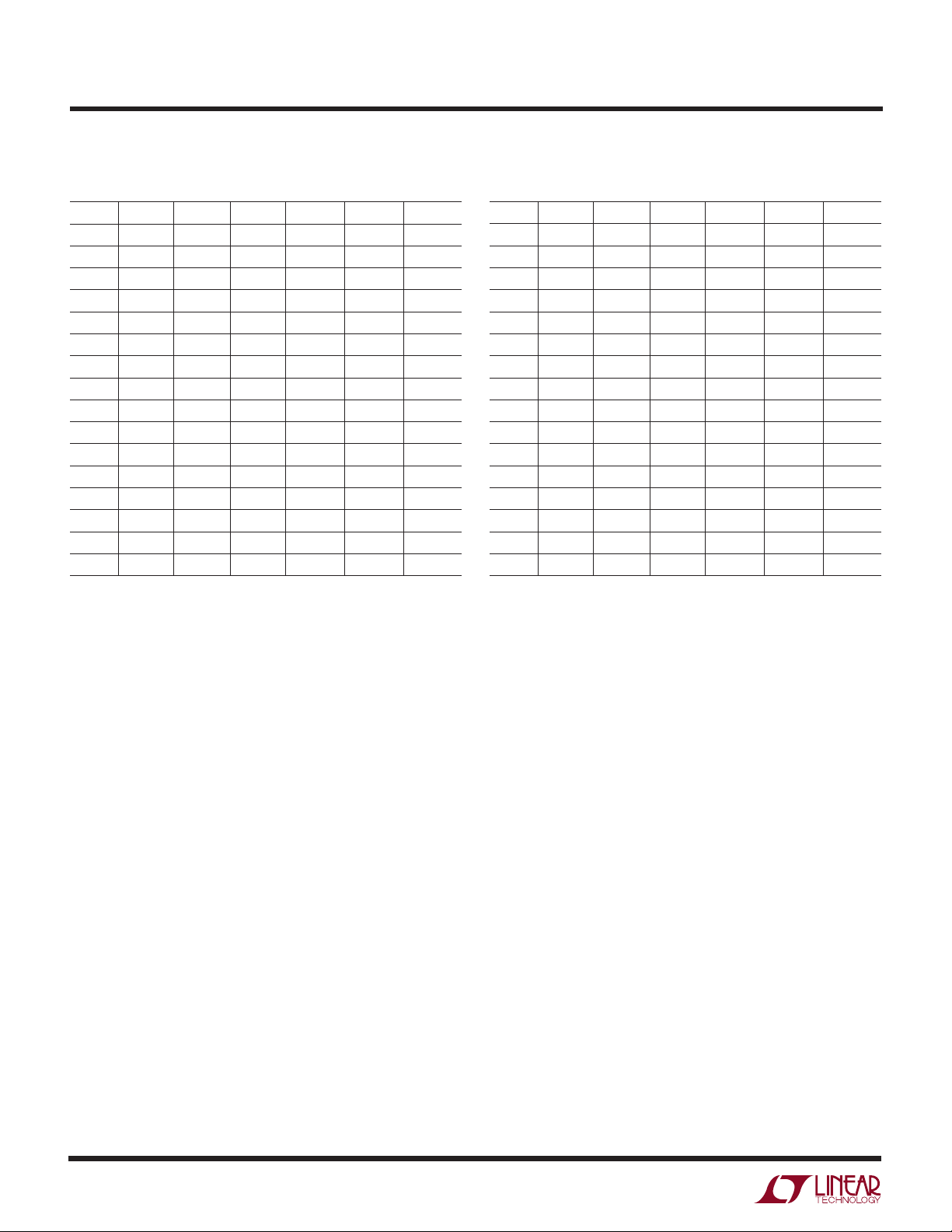

Table 1. VID Inputs and Corresponding Output Voltage for

Channel 1

CODE VID4 VID3 VID2 VID1 VID0 V

00000 GND GND GND GND GND 2.05V

00001 GND GND GND GND Float 2.00V

00010 GND GND GND Float GND 1.95V

00011 GND GND GND Float Float 1.90V

00100 GND GND Float GND GND 1.85V

00101 GND GND Float GND Float 1.80V

00110 GND GND Float Float GND 1.75V

00111 GND GND Float Float Float 1.70V

01000 GND Float GND GND GND 1.65V

01001 GND Float GND GND Float 1.60V

01010 GND Float GND Float GND 1.55V

01011 GND Float GND Float Float 1.50V

01100 GND Float Float GND GND 1.45V

01101 GND Float Float GND Float 1.40V

01110 GND Float Float Float GND 1.35V

01111 GND Float Float Float Float 1.30V

* 11111 is defined by Intel to signify “no CPU.” The LTC1873

will generate the output voltage shown when this codes is selected.

OUT1

CODE VID4 VID3 VID2 VID1 VID0 V

10000 Float GND GND GND GND 3.50V

10001 Float GND GND GND Float 3.40V

10010 Float GND GND Float GND 3.30V

10011 Float GND GND Float Float 3.20V

10100 Float GND Float GND GND 3.10V

10101 Float GND Float GND Float 3.00V

10110 Float GND Float Float GND 2.90V

10111 Float GND Float Float Float 2.80V

11000 Float Float GND GND GND 2.70V

11001 Float Float GND GND Float 2.60V

11010 Float Float GND Float GND 2.50V

11011 Float Float GND Float Float 2.40V

11100 Float Float Float GND GND 2.30V

11101 Float Float Float GND Float 2.20V

11110 Float Float Float Float GND 2.10V

11111* Float Float Float Float Float 2.00V

OUT1

allows regulated output voltages as low as 800mV without

external level shifting amplifiers.

The LTC1873’s synchronous switching logic transitions

automatically into Burst Mode operation, maximizing efficiency with light loads. An onboard overvoltage (OV) fault

flag indicates when an OV fault has occurred. The OV flag

can be set to latch the device off when an OV fault has

occurred, or to automatically resume operation when the

fault is removed.

2-Phase Operation

The LTC1873 dual switching regulator controller offers

considerable benefits using 2-phase operation. Circuit

benefits include lower input filtering requirements,

reduced electromagnetic interference (EMI) and increased

efficiency associated with 2-phase operation.

Why the need for 2-phase operation? Until recently, constant-frequency dual switching regulators operated both

channels in phase (i.e., single-phase operation). This

means that both topside MOSFETs turned on at the same

time, causing current pulses of up to twice the amplitude

of those for one regulator to be drawn from the input

capacitor. These large amplitude current pulses increased

the total RMS current flowing from the input capacitor,

requiring the use of more expensive input capacitors and

increasing both EMI and losses in the input capacitor and

input power supply.

With 2-phase operation, the two channels of the LTC1873

are operated 180 degrees out of phase. This effectively

interleaves the current pulses coming from the switches,

greatly reducing the overlap time where they add together.

The result is a significant reduction in total RMS input

current, which in turn allows less expensive input capacitors to be used, reduces shielding requirements for EMI

and improves real world operating efficiency.

Figure 7 shows example waveforms for a single switching

regulator channel versus a 2-phase LTC1873 system with

both sides switching. A single-phase dual regulator with

both sides operating would exhibit double the single side

numbers. In this example, 2-phase operation reduced the

RMS input current from 9.3A

4.8A

. While this is an impressive reduction in itself,

RMS

remember that the power losses are proportional to I

(2 × 4.66A

RMS

RMS

) to

RMS

2

,

meaning that the actual power wasted is reduced by a

8

WUUU

APPLICATIO S I FOR ATIO

LTC1873

factor of 3.75. The reduced input ripple voltage also means

less power is lost in the input power path, which could

include batteries, switches, trace/connector resistances

and protection circuitry. Improvements in both conducted

and radiated EMI also directly accrue as a result of the

reduced RMS input current and voltage.

Small Footprint

The LTC1873 operates at a 550kHz switching frequency,

allowing it to use low value inductors without generating

excessive ripple currents. Because the inductor stores

less energy per cycle, the physical size of the inductor can

be reduced without risking core saturation, saving PCB

board space. The high operating frequency also means

less energy is stored in the output capacitors between

cycles, minimizing their required value and size. The

remaining components, including the SSOP-28 LTC1873,

are tiny, allowing an entire dual-output LTC1873 circuit to

be constructed in 1.5in2 of PCB space. Further, this space

is generally located right next to the microprocessor or in

some similarly congested area, where PCB real estate is at

a premium.

Fast Transient Response

The voltage mode feedback loop and MOSFET VDS current

limit sensing remove the need for an external current

sense resistor, eliminating an external component and a

source of power loss in the high current path. Properly

designed circuits using low gate charge MOSFETs are

capable of efficiencies exceeding 90% over a wide range

of output voltages.

VID Programming

The LTC1873 includes an onboard feedback network that

programs the output voltage at side 1 in accordance with

the Intel Desktop VID specification (Table 1). The network

includes a 20k resistor (R1) connected from SENSE to

FB1, and a variable value resistor (RB) from FB1 to SGND,

with the value set by the digital code present at the VID0:4

pins. SENSE should be connected to V

network to monitor the output voltage. No additional

feedback components are required to set the output voltage at controller 1, although loop compensation components are still required. Each VIDn pin includes an internal

40k pull-up resistor, allowing it to float high if left unconnected. The pull-up resistors are connected to VCC through

diodes (see Block Diagram), allowing the VIDn pins to be

pulled above VCC without damage.

to allow the

OUT1

The LTC1873 uses a fast 25MHz GBW op amp as an error

amplifier. This allows the compensation network to be

designed with several poles and zeros in a more flexible

configuration than with a typical gm feedback amplifier.

The high bandwidth of the amplifier, coupled with the high

switching frequency and the low values of the external

inductor and output capacitor, allow very high loop crossover frequencies. The low inductor value is the other half

of the equation—with a typical value on the order of 1µH,

the inductor allows very fast di/dt slew rates. The result is

superior transient response compared with conventional

solutions.

High Efficiency

The LTC1873 uses a synchronous step-down (buck)

architecture, with two external N-channel MOSFETs per

output. A floating topside driver and a simple external

charge pump provide full gate drive to the upper MOSFET.

Note that code 11111, defined by Intel to indicate “no CPU

present,” does generate an output voltage at V

Note also that controller 2 on the LTC1873 is not connected to the VID circuitry, and works independently from

controller 1.

ARCHITECTURE DETAILS

The LTC1873 dual switching regulator controller includes

two independent regulator channels. The two sides of the

chip and their corresponding external components act

independently of each other with the exception of the

common input bypass capacitor, the VID circuitry at side

1, and the FCB and FAULT pins, which affect both channels. In the following discussions, when a pin is referred

to without mentioning which side is involved, that discussion applies equally to both sides.

OUT1

(2.00V).

9

LTC1873

+

TG

BOOST

SW

BG

PGND

PV

CC

D

CP

C

IN

+

C

OUT

1873 F02

V

OUT

L

EXT

V

IN

QT

QB

C

CP

1µF

LTC1873

WUUU

APPLICATIO S I FOR ATIO

Switching Architecture

Each half of the LTC1873 is designed to operate as a

synchronous buck converter (Figure 1). Each channel

includes two high power MOSFET gate drivers to control

external N-channel MOSFETs QT and QB. These drivers

have 0.5Ω output impedances and can carry well over an

amp of continuous current with peak currents up to 5A to

slew large MOSFET gates quickly. The external MOSFETs

are connected with the drain of QT attached to the input

supply and the source of QT at the switching node SW. QB

is the synchronous rectifier with its drain at SW and its

source at PGND. SW is connected to one end of the

inductor, with the other end connected to V

capacitor is connected from V

to PGND.

OUT

. The output

OUT

When a switching cycle begins, QB is turned off and QT is

turned on. SW rises almost immediately to VIN and the

inductor current begins to increase. When the PWM pulse

finishes, QT turns off and one nonoverlap interval later, QB

turns on. Now SW drops to PGND and the inductor current

decreases. The cycle repeats with the next tick of the

master clock. The percentage of time spent in each mode

is controlled by the duty cycle of the PWM signal, which in

turn is controlled by the feedback amplifier. The master

clock runs at a 550kHz rate and turns QT once every 1.8µs.

In a typical application with a 5V input and a 1.5V output,

the duty cycle will be set at 1.5/5 × 100% or 30% by the

feedback loop. This will give roughly a 540ns on-time for

QT and a 1.26µs on-time for QB.

This constant frequency operation brings with it a couple

of benefits. Inductor and capacitor values can be chosen

with a precise operating frequency in mind and the feedback loop components can be similarly tightly specified.

Noise generated by the circuit will always be in a known

frequency band with the 550kHz frequency designed to

leave the 455kHz IF band free of interference. Subharmonic

oscillation and slope compensation, common headaches

with constant frequency current mode switchers, are

absent in voltage mode designs like the LTC1873.

During the time that QT is on, its source (the SW pin) is at

VIN. VIN is also the power supply for the LTC1873. However, QT requires VIN + V

at its gate to achieve

GS(ON)

minimum RON. This presents a problem for the LTC1873—

it needs to generate a gate drive signal at TG higher than

its highest supply voltage. To accomplish this, the TG

driver runs from floating supplies, with its negative supply

attached to SW and its power supply at BOOST. This

allows

it to slew up and down with the source of QT. In combination

with a simple external charge pump (Figure 2),

this allows

the LTC1873 to completely enhance the gate of QT without

requiring an additional, higher supply voltage.

The two channels of the LTC1873 run from a common

clock, with the phasing chosen to be 180° from side 1 to

side 2. This has the effect of doubling the frequency of the

switching pulses seen by the input bypass capacitor,

significantly lowering the RMS current seen by the capacitor and reducing the value required (see the 2-Phase

section).

Feedback Amplifier

Each side of the LTC1873 senses the output voltage at

V

with an internal feedback op amp (see Block Dia-

OUT

gram). This is a real op amp with a low impedance output,

85dB open-loop gain and 25MHz gain-bandwidth product.

The positive input is connected internally to an 800mV

reference, while the negative input is connected to the FB

10

V

IN

TG

1/2

SW

LTC1873

PGND

BG

Figure 1. Synchronous Buck Architecture

QT

L

EXT

QB

+

C

IN

V

+

OUT

C

OUT

1873 F01

Figure 2. Floating TG Driver Supply

Loading...

Loading...