Linear Technology LTC1759 Datasheet

FEATURES

■

Single Chip Smart Battery Charger Controller

■

100% Compliant (Rev 1.0) SMBus Support

Allows for Operation with or without Host

■

SMBus Accelerator Improves SMBus Timing

■

Hardware Interrupt and SMBAlert Response

Eliminate Interrupt Polling

■

High Efficiency Synchronous Buck Charger

■

0.5V Dropout Voltage; Maximum Duty Cycle > 99.5%

■

AC Adapter Current Limit Maximizes Charge Rate*

■

1% Voltage Accuracy; 5% Current Accuracy

■

Up to 8A Charging Current Capability

■

Dual 10-Bit DACs for Charger Voltage and Current

Programming

■

User-Selectable Overvoltage and Overcurrent Limits

■

High Noise Immunity Thermistor Sensor

■

Small 36-Lead Narrow (0.209") SSOP Package

U

APPLICATIO S

■

Portable Computers

■

Portable Instruments

■

Docking Stations

*US Patent Number 5,723,970

LTC1759

Smart Battery Charger

U

DESCRIPTIO

The LTC®1759 Smart Battery Charger is a single chip

charging solution that dramatically simplifies construction of an SBS compliant system. The LTC1759 implements a Level 2 charger function whereby the charger can

be programmed by the battery or by the host. A thermistor

on the battery being charged is monitored for temperature, connectivity and battery type information. The SMBus

interface remains alive when the AC power adapter is

removed and responds to all SMBus activity directed to it,

including thermistor status (via the ChargerStatus command). The charger also provides an interrupt to the host

whenever a status change is detected (e.g., battery

removal,

Charging current and voltage are restricted to chemistry

specific limits for improved system safety and reliability.

Limits are programmable by two external resistors. Additionally, the maximum average current from the AC adapter

is programmable to avoid overloading the adapter when

simultaneously supplying load current and charging current. When supplying system load current, charging current is automatically reduced to prevent adapter overload.

AC adapter connection).

, LTC and LT are registered trademarks of Linear Technology Corporation.

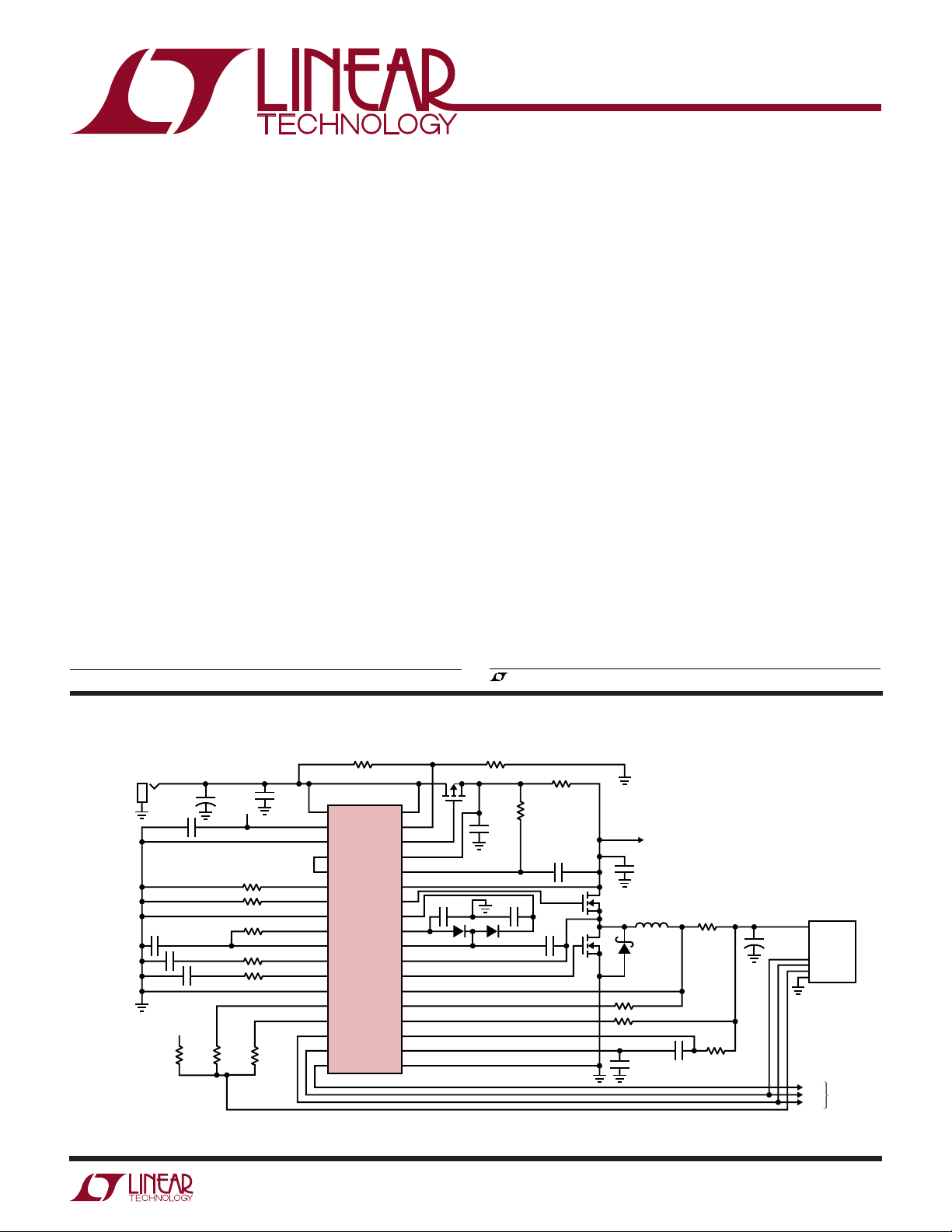

TYPICAL APPLICATIO

ADAPTER

INPUT

AC

0.1µF

1µF

0.33µF

V

DD

475k

+

0.68µF

10µF

35V

Al

10k

0.1µF

V

DD

33k

33k

3.83k

1.5k

1k

1k

U

15.8k

LTC1759

7

UV

16

V

DD

4

SYNC

5

SDB

12

CHGEN

25

V

LIMIT

24

I

LIMIT

18

DGND

17

I

SET

28

PROG

27

V

C

11

COMP1

6

AGND

20

RNR

19

THERM

14

SDA

15

SCL

13

INTB

DCIN

DCDIV

INFET

V

CLP

CLN

TGATE

BOOSTC

GBIAS

BOOST

BGATE

SPIN

SENSE

BAT1

BAT2

V

PGND

22

21

8

32

CC

9

10

2

2.2µF

33

34

1

3

SW

35

30

29

31

23

26

SET

36

Figure 1. 4A SMBus Smart Battery Charger

1k

499Ω

0.47µF

0.1µF

0.68µF

0.033Ω

1µF

SYSTEM

POWER

22µF

15µH

200Ω

200Ω

0.047µF

0.015µF

0.025Ω

68Ω

+

22µF

INTB

SCL

SDA

SMART

BATTERY

SMBus

TO

HOST

1759 F01

1

LTC1759

WW

W

U

ABSOLUTE MAXIMUM RATINGS

(Note 1)

Voltage at VCC, UV, BAT1, CLP,CLN, SPIN,

SENSE with respect to AGND ....................–0.3V to 27V

Voltage at DCIN, BAT2 with Respect

to DGND ....................................................–0.3V to 27V

Voltage at INTB, SDA, SCL, DCDIV with Respect

to DGND ..................................................... – 0.3V to 7V

BOOST, BOOSTC Voltage with Respect to VCC........ 10V

Voltage at VDD with Respect to DGND ........ –0.3V to 7V

SW Voltage with Respect to AGND .............. –2V to V

GBIAS, SYNC ............................................ – 0.3V to 10V

VC, PROG, V

Voltage with Respect

SET

to AGND ......................................................– 0.3V to 7V

TGATE, BGATE Current Continuous .................. ±200mA

TGATE, BGATE Output Energy (per Cycle) ................ 2µJ

PGND, DGND with Respect to AGND .................... ±0.3V

Current into Any Pin ......................................... ±100mA

Operating Ambient Temperature Range...... 0°C to 70°C

Operating Junction

Temperature Range .............................. – 40°C to 125°C

Storage Temperature ........................... –65°C to 150°C

Lead Temperature (Soldering, 10 sec)................. 300°C

CC

U

W

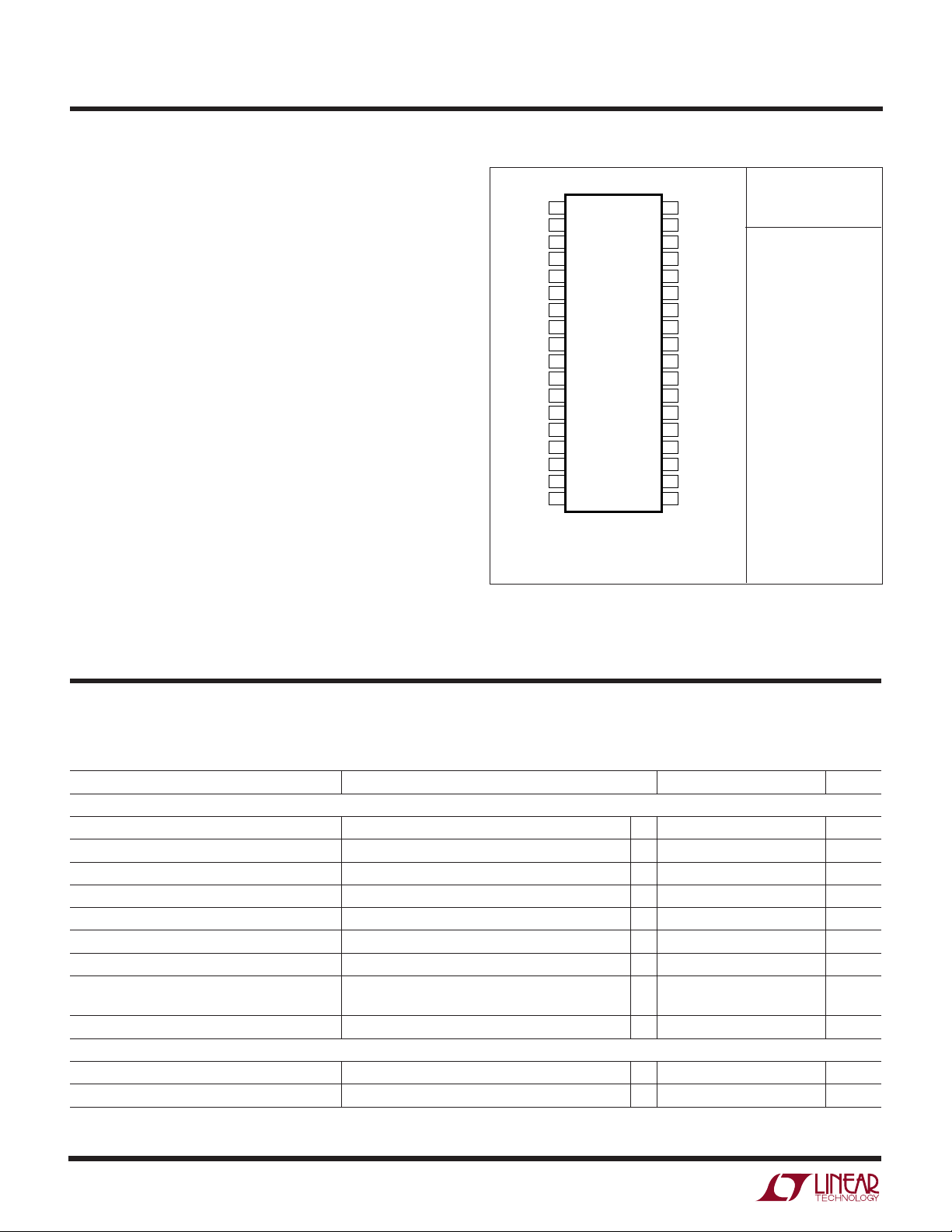

PACKAGE/ORDER INFORMATION

TOP VIEW

1

BOOST

2

TGATE

3

SW

4

SYNC

5

SDB

6

AGND

7

UV

8

INFET

9

CLP

10

CLN

11

COMP1

12

CHGEN

13

INTB

14

SDA

15

SCL

16

V

DD

17

I

SET

18

DGND

G PACKAGE

36-LEAD PLASTIC SSOP

T

= 125°C, θJA = 85°C/W

JMAX

Consult factory for Industrial and Military grade parts.

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PGND

BGATE

GBIAS

BOOSTC

V

CC

BAT1

SPIN

SENSE

PROG

V

C

V

SET

V

LIMIT

I

LIMIT

BAT2

DCIN

DCDIV

RNR

THERM

ORDER PART

NUMBER

LTC1759CG

U

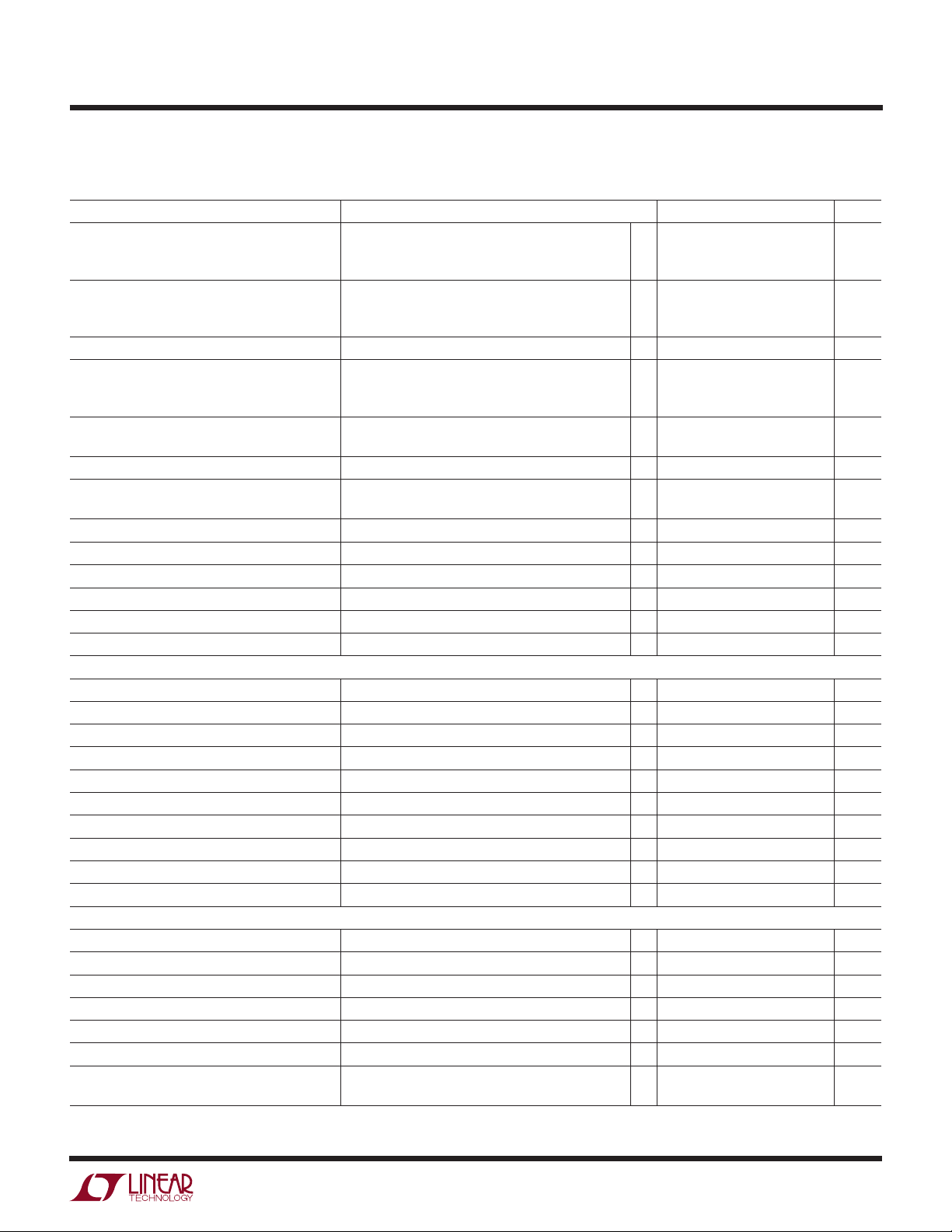

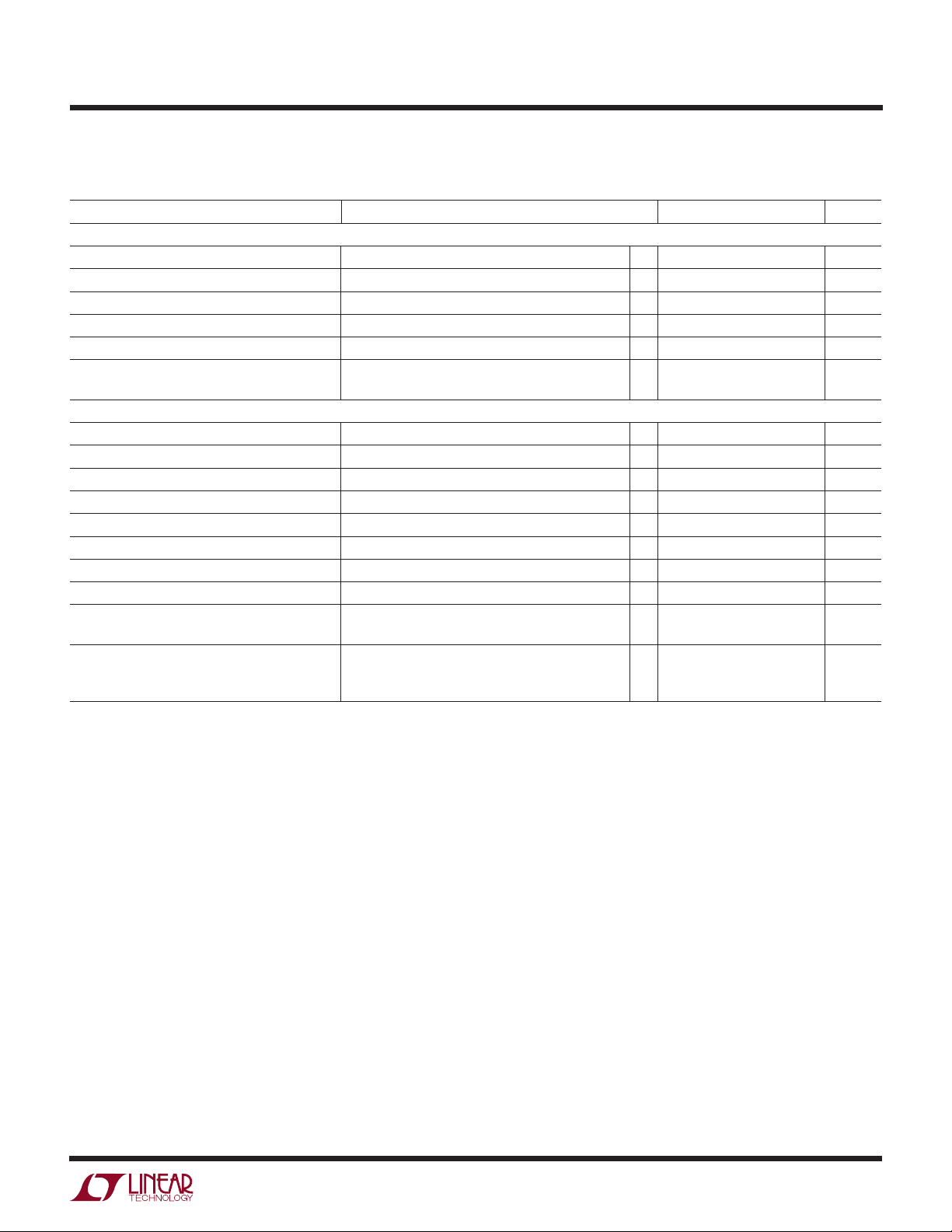

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range (TJ = 0°C to 100°C), otherwise specifications are

T

= 25°C. V

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Supply and Reference

DCIN, VCC Operating Voltage ● 11 24 V

VCC Operating Current VCC ≤ 24V ● 12 20 mA

DCIN Operating Current V

UV Lockout Threshold Voltage on UV Pin Rising ● 6.3 6.7 7.15 V

UV Pin Input Current 0V ≤ VUV ≤ 8V ● –1 5 µA

Battery Discharge Current VUV ≤ 0.4V, All Connected Pins 40 80 µA

VDD Operating Voltage ● 3.0 5.5 V

VDD Operating Current Charging, VDD = 5.5V, Shorted Thermistor 1.35 2 mA

VDD Undervoltage Lockout ● 1.6 2.2 2.9 V

Switching Regulator

Charging Voltage Accuracy (Notes 3, 5) 2.465V ≤ V

Charging Current Accuracy (Note 3) R

= DCIN = 18V, V

CC

= 12.6V, VDD = 3.3V unless otherwise specified.

BAT1, 2

= 24V ● 85 150 µA

DCIN

Not Charging, V

Tolerance = 1% –5 5 %

SET

= 5.5V 80 150 µA

DD

≤ V

BAT2

MAX

● –1 1 %

2

LTC1759

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range (TJ = 0°C to 100°C), otherwise specifications are

T

= 25°C. V

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

BOOST Pin Current V

V

Threshold to Turn T

BOOST

(Note 6) Low to High

BOOSTC Pin Current V

Sense Amplifier CA1 Gain and Input Offset Voltage 11V ≤ VCC ≤ 24V, 0V ≤ V

(With R

(Measured Across R

CA1 Bias Current (SENSE, BAT1) V

CA1 Input Common Mode Range ● –0.25 VCC – 0.3 V

SPIN Input Current V

CL1 Turn-On Threshold 0.5mA Output Current 87 92 97 mV

CL1 Transconductance Output Current from 50µA to 500µA 0.5 1 3 mho

CLP Input Current 0.5mA Output Current 1 3 µA

CLN Input Current 0.5mA Output Current 0.8 2 mA

CA2 Transconductance VC = 1V, IVC = ±1µA 150 200 300 µmho

VA Transconductance (Note 5) Ouput Current from 50µA to 500µA 0.21 0.6 1 mho

Gate Drivers

V

GBIAS

V

High (V

TGATE

V

High I

BGATE

V

Low (V

TGATE

V

Low I

BGATE

INFET “ON” Clamping Voltage (VCC – V

INFET “ON” Drive Current V

INFET “OFF” Clamping Voltage VCC Not Connected, I

INFET “OFF” Drive Current VCC = 12.4V, (VCC – V

V

, V

TGATE

Trip Points

DCDIV Threshold V

DCDIV Hysteresis 25 mV

DCDIV Input Bias Current V

Power-Fail Indicator (V

Power-Fail Indicator Hysteresis (V

SYNC Pin Threshold 0.9 1.4 2.0 V

SYNC Pin Input Current V

= DCIN = 18V, V

CC

= 12.6V, VDD = 3.3V unless otherwise specified.

BAT1, 2

= VSW + 8V, 0V ≤ VSW ≤ 20V

BOOST

TGATE High 2 3 mA

TGATE Low 2 3 mA

Off Measured at (V

GATE

BOOST

– VSW)

Hysteresis 0.25 V

= VCC + 8V 1 mA

BOOSTC

= RS3 = 200Ω)R

S2

TGAGE

TGATE

at Shutdown V

BGATE

) (Note 4) R

S1

– VSW)I

– VSW)I

) ● 6.5 7.8 9 V

INFET

≥ V

BAT2

) (Note 7) AC_PRESENT = 1, V

DCIN

≥ V

BAT2

) AC_PRESENT = 1, V

DCIN

= 4.93k ● 92 100 108 mV

SET

= 49.3k 7 10 13 mV

SET

= High ● –50 –120 µA

SDB

= Low (Shutdown) –10 µA

V

SDB

= High, V

SDB

= Low 10 µA

V

SDB

VCC ≥ 11V, I

TGATE

BGATE

TGATE

BGATE

INFET

= Low, I

SDB

DCDIV

DCDIV

SYNC

V

SYNC

SPIN

GBIAS

≤ 20mA ● 5.6 6.6 V

≤ 20mA ● 6.2 7.2 V

≤ 50mA ● 0.8 V

≤ 50mA ● 0.8 V

= VCC – 6V ● 820 mA

TGATE

Rising from 0.8V to 1.2V ● 0.9 1.0 1.1 V

= 1V ● 100 nA

= 0V –500 µA

= 2V –30 µA

BAT

= 12.6V ● 2mA

≤ 15mA, V

< –2µA 1.4 V

INFET

INFET

= I

BGATE

= 6V ● 0.84 0.89 0.94 V/V

DCIN

= 6V 0.02 V/V

DCIN

● 6.8 7.1 7.3 V

≤ 20V

= High ● 8.4 8.9 9.3 V

SDB

) ≥ 2V –2.5 mA

= 10µA ● 1V

3

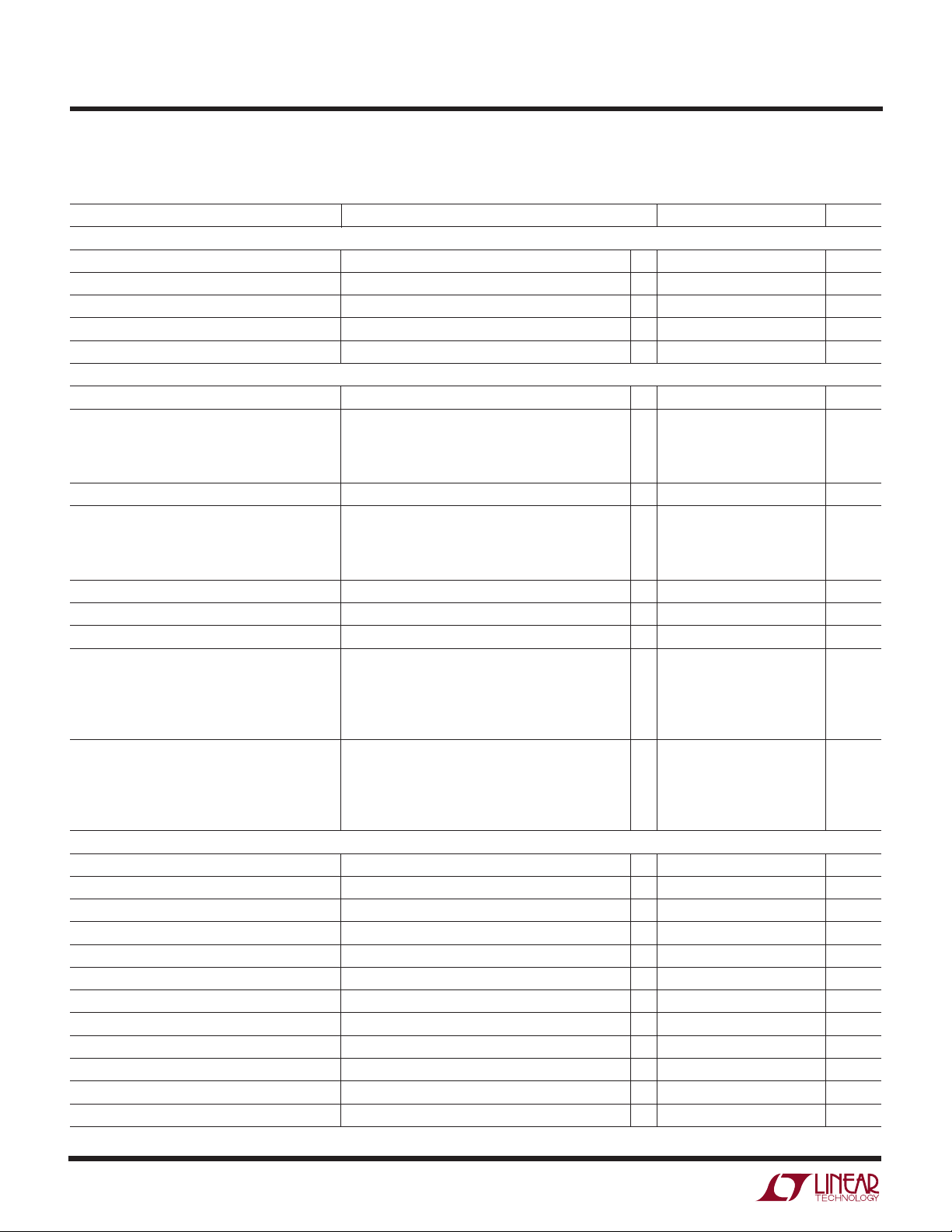

LTC1759

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range (TJ = 0°C to 100°C), otherwise specifications are

T

= 25°C. V

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Thermistor Decoder (Note 11)

Combined Input Leakage on RNR and THERM 200 nA

Thermistor Trip (COLD/OR) R

Thermistor Trip (IDEAL/COLD) RNR = 10k ±1% ● 26.4 30 33.6 kΩ

Thermistor Trip (HOT/IDEAL) RNR = 10k ±1% ● 2.64 3 3.36 kΩ

Thermistor Trip (UR/HOT) RUR = 1k ±1% ● 440 500 560 Ω

DACs

Charging Current Resolution Guaranteed Monotonic Above I

Charging Current Granularity R

Wake-Up Charging Current (I

Charging Current Limit (I

I

SET RDS(ON)

I

SET IOFF

Charging Voltage Resolution Guaranteed Monotonic (2.5V ≤ V

Charging Voltage Granularity R

Charging Voltage Limit R

Logic Levels (Note 12)

SCL/SDA Input Low Voltage (VIL) ● 0.6 V

SCL/SDA Input High Voltage (VIH) ● 1.4 V

SDA Output Low Voltage (VOL)I

SCL/SDA Input Current (IIL)V

SCL/SDA Input Current (IIH)V

INTB Output Low Voltage (VOL)I

INTB Output Pull-Up Current V

CHGEN Output Low Voltage (VOL)I

CHGEN Output High Voltage (VOH)I

SDB Shutdown Threshold ● 12V

SDB Pin Current 0V ≤ V

Power-On Reset Duration VDD Ramp from 0V to > 3V in < 5µs 100 µs

= DCIN = 18V, V

CC

WAKE-UP

)R

MAX

= 12.6V, VDD = 3.3V unless otherwise specified.

BAT1, 2

= 475k ±1% ● 80 100 120 kΩ

WEAK

/16 10 bits

MAX

= 0 1 mA

ILIMIT

= 10k ±1% 2 mA

R

ILIMIT

R

= 33k ±1% 4 mA

ILIMIT

= Open (or Short to VDD)8mA

R

ILIMIT

) (Note 8) 80 mA

= 0 1023 mA

ILIMIT

= 10k ±1 % 2046 mA

R

ILIMIT

= 33k ±1 % 4092 mA

R

ILIMIT

R

= Open (or Short to VDD) 8184 mA

ILIMIT

25 Ω

V

= 2.7V ● 1 µA

ISET

≤ 21V) 10 bits

BAT

= 0 16 mV

VLIMIT

R

= 10k ±1% 16 mV

VLIMIT

= 33k ±1% 32 mV

R

VLIMIT

= 100k ±1% 32 mV

R

VLIMIT

R

= Open (or Short to VDD)32mV

VLIMIT

= 0 ● 8.33 8.432 8.485 V

VLIMIT

= 10k ±1% ● 12.50 12.64 12.72 V

R

VLIMIT

= 33k ±1% ● 16.67 16.864 16.97 V

R

VLIMIT

R

= 100k ±1% ● 20.82 21.056 21.18 V

VLIMIT

= Open (or Short to VDD) (Note 2) 32.736 V

R

VLIMIT

= 350µA ● 0.4 V

PULLUP

, V

SDA

SDA

PULLUP

INTB

OL

OH

= V

SCL

IL

, V

= V

SCL

IH

= 500µA ● 0.4 V

= V

OL

= 200µA ● 0.4 V

= –200µA ● VDD – 0.4 V

≤ 3V 8 µA

SDB

● 1 µA

● 1 µA

● 3.5 10 17.5 µA

4

LTC1759

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range (TJ = 0°C to 100°C), otherwise specifications are

T

= 25°C. V

A

PARAMETER CONDITIONS MIN TYP MAX UNITS

Charger Timing

V

, V

TGATE

TGATE, BGATE Peak Drive Current 10nF Load 1 A

Regulator Switching Frequency ● 170 200 230 kHz

Synchronization Frequency ● 240 280 kHz

Maximum Duty Cycle in Start-Up Mode (Note 9) ● 85 90 %

t

TIMEOUT

Cold or Underrange Battery

SMBus Timing (refer to System Management Bus Specification, Revision 1.0, section 2.1 for timing diagrams) (Note 12)

SCL Serial Clock High Period (t

SCL Serial Clock Low Period (t

SDA/SCL Rise Time (tr)C

SDA/SCL Fall Time (tf) ● 30 300 ns

SMBus Accelerator Boosted Pull-Up Current VDD = 3V ● 1 2.5 mA

Start Condition Setup Time (t

Start Condition Hold Time (t

SDA to SCL Rising-Edge Setup Time (t

SDA to SCL Falling-Edge Hold Time, ● 300 ns

Slave Clocking in Data (t

t

TIMEOUT

ChargingCurrent() and ChargingVoltage()

Commands (Note 10)

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: This limit is greater than the absolute maximum for the charger.

Therefore, there is no effective limitation on voltage when this option is

selected. If the charger is requested to charge with a higher voltage than

the nominal limit, the VOLTAGE_OR bit will be set.

Note 3: Total system accuracy from SMBus request to output voltage or

output current.

Note 4: Test Circuit #1.

Note 5: Voltage accuracy is calculated using measured reference voltage,

obtained from V

ratio.

Note 6: When supply and battery voltage differential is low, high oscillator

duty cycle is required. The LTC1759 has a unique design to achieve duty

cycle greater than 99% by skipping cycles. Only when V

the comparator threshold, will TGATE be turned off. See Applications

Information section.

= DCIN = 18V, V

CC

Rise/Fall Time 1nF Load 25 ns

BGATE

for Wake-Up Charging a ● 140 175 210 sec

HIGH

LOW

SU:STA

HD:STA

)

HD:DAT

Between Receiving Valid ● 140 175 210 sec

pin using Test Circuit #2, and VDAC resistor divider

SET

= 12.6V, VDD = 3.3V unless otherwise specified.

BAT1, 2

)I

)I

) ● 4.7 µs

) ● 4.0 µs

) ● 250 ns

SU:DAT

= 350µA, C

PULLUP

= 350µA, C

PULLUP

= 150pF ● 1000 ns

LOAD

drops below

BOOST

= 150pF ● 4 µs

LOAD

= 150pF ● 4.7 µs

LOAD

Note 7: Power failure bit is set when the battery voltage is above 89% of

the power adapter voltage (V

Note 8: The charger provides wake-up current when a battery is inserted

into the connector, prior to the battery requesting charging current and

voltage. See Smart Battery Charger Specification (Revision 1.0), section

6.1.3 and 6.1.8.

Note 9: In system start-up, C6 (boost capacitor) has no charge stored in it.

The LTC1759 will keep TGATE off, and turn BGATE on for 0.2µs, thus

charging C6. A comparator senses V

PWM mode when V

Note 10: Refer to Smart Battery Charge Specification (Revision 1.0),

section 6.1.2.

Note 11: Maximum total external capacitance on RNR and THERM pins

is 75pF.

Note 12: SMBus operation guaranteed by design from –40°C to 85°C.

BOOST

).

DCIN

and switches to the normal

is above its threshold.

BOOST

5

LTC1759

TEMPERATURE (°C)

0

DCDIV (V)

1.10

1.05

1.00

0.95

0.90

1759 G03

10 20 30 40 50 60 70 80

VDD = 5.5V

VDD = 3V

CHARGING CURRENT (mA)

256

1256 2256 3256 4256

OUTPUT CURRENT ERROR (mA)

1759 G06

0

–10

–20

–30

–40

–50

–60

R

ILIMIT

= 33k

V

IN

= 15V

V

OUT

= 12V

T

A

= 25°C

VDD = 5.5V

VDD = 3V

UW

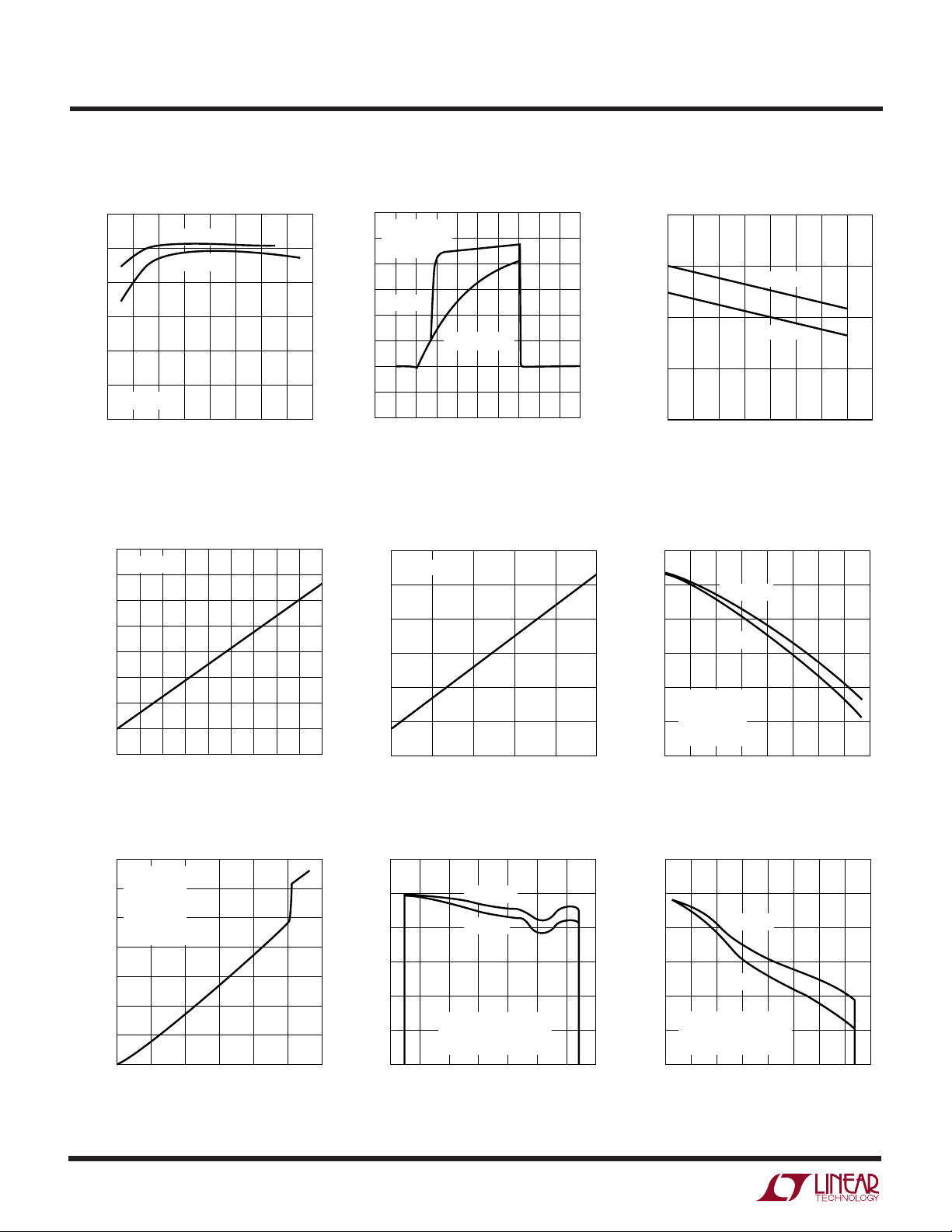

TYPICAL PERFOR A CE CHARACTERISTICS

Charger Efficiency

100

95

90

85

EFFICIENCY (%)

80

75

VIN = 20V

70

0.5

16.8V

12.6V

1.5 2.5 3.5

CHARGING CURRENT (A)

Current from Battery vs Battery

Voltage (Does Not Include V

Current)

90

TA = 25°C

80

70

60

(µA)

50

BAT

I

40

30

20

10

6 8 10 12 14 16 18 20 22 24

V

(V)

BAT

1759 G09

DD

1759 G04

SMBus Accelerator Operation DCDIV Trip Point vs Temperature

VCC = 5V

5V

= 200pF

C

LD

= 25°C

T

A

LTC1759

R

= 15k

PULLUP

0V

1µs/DIV

1759 G02

IDD vs VDD (Not Charging) Programmed Current Accuracy

120

TA = 25°C

110

100

90

(µA)

DD

I

80

70

60

3.0 3.5 4.0 4.5 5.0 5.5

VDD (V)

1759 G05

Low Current Mode

350

R

ILIMIT

= 15V

V

IN

300

V

OUT

= 25°C

T

A

250

C

PROG

R

SET

200

150

100

OUTPUT CURRENT (mA)

50

0

0

6

= 33k

= 12V

= 1nF

= 3.83k

50 100 150 200 250 300

CHARGING CURRENT (mA)

1759 G01

0

–5

–10

–15

–20

OUTPUT VOLTAGE ERROR (mV)

–25

–30

2000 3000 4000 5000 6000 7000 8000 9000

VDD = 5.5V

VDD = 3V

R

= 0

VLIMIT

LOAD CURRENT = 15mA

T

= 25°C

A

CHARGING VOLTAGE (mV)

1759 G07

Charging Voltage ErrorCharging Voltage Error

0

–5

–10

–15

–20

OUTPUT VOLTAGE ERROR (mV)

–25

–30

2000

VDD = 5.5V

VDD = 3V

R

= 33k

VLIMIT

LOAD CURRENT = 15mA

T

= 25°C

A

6000 10000 14000 18000

CHARGING VOLTAGE (mV)

1759 G08

UUU

PIN FUNCTIONS

LTC1759

Input Power-Related Pins

UV (Pin 7): Charger Section Undervoltage Lockout Pin.

The rising threshold is 6.7V with a hysteresis of 0.5V.

Switching stops in undervoltage lockout. Connect this

input to the input voltage source with no resistor divider.

UV must be pulled below 0.7V when there is no input

voltage source (5k resistor from adapter output to ground

is required) to obtain the lowest quiescent battery current.

INFET (Pin 8): Gate Drive to Input P-channel FET. For very

low dropout applications, use an external P-channel FET to

connect the adapter output and VCC. INFET is clamped to

7.8V below VCC.

CLP (Pin 9): Positive Input to the Input Current Limit

Amplifier CL1. When used to limit supply current, a filter

(R3 and C1 of Figure 10) is needed to filter out the

switching noise. The threshold is set at 92mV.

CLN (Pin 10): Negative Input to the Input Current Limit

Amplifier CL1. It should be connected to VCC (to the V

bypass capacitor C2 for less noise).

COMP1 (Pin 11): Compensation Node for the Input Current Limit Amplifier CL1. At input adapter current limit, this

node rises to 1V. By forcing COMP1 low with an external

transistor, amplifier CL1 will be defeated (no adapter

current limit). COMP1 can source 200µA. Ground (to

AGND) this pin if the adapter current limiting function is

not used.

CC

Battery Charging-Related Pins

BOOST (Pin 1): This pin is used to bootstrap and supply

power for the topside power switch gate drive and control

circuity. In normal operation, V

internally generated 8.6V regulator V

+ 8.9V when TGATE is high. Do not force an external

voltage on BOOST pin.

TGATE (Pin 2): This pin provides gate drive to the topside

power FET. When TGATE is driven on, the gate voltage will

be approximately equal to VSW + 6.6V. A series resistor of

5Ω to 10Ω should be used from this pin to the gate of the

topside FET.

is powered from an

BOOST

, V

GBIAS

BOOST

≈ V

CC

SW (Pin 3): This pin is the reference point for the floating

topside gate drive circuitry. It is the common connection

for the top and bottom side switches and the output

inductor. This pin switches between ground and VCC with

very high dv/dt rates. Care needs to be taken in the PC

layout to keep this node from coupling to other sensitive

nodes. A 1A Schottky clamping diode should be placed

very close to the chip from the ground pin to this pin to

prevent the chip substrate diode from turning on. See

Applications Information for more details.

SYNC (Pin 4): External Clock Synchronization Input. Pulse

width range: 10% to 90%.

SDB (Shutdown Bar) (Pin 5): Active Low Digital Input. The

charger is disabled when asserted. This pin is connected

to the CHGEN pin to enable charger control through the

SMBus interface.

CHGEN (Pin 12): Digital Output to Enable Charger Function. Connect CHGEN to SDB.

I

(Pin 17): Open-Drain CMOS Switch to DGND. An

SET

external resistor, R

current programming input, the PROG pin of the battery

charger section, which sets the range of the charging

current.

I

(Pin 24): An external resistor is connected between

LIMIT

this pin and DGND. The value of the external resistor

programs the range and resolution of the programmed

charger current. See Electrical Characteristics table for

more information.

V

(Pin 25): An external resistor is connected between

LIMIT

this pin and DGND. The value of the external resistor

programs the range and resolution of the V

Electrical Characteristics table for more information.

V

(Pin 26): This is the tap point of the programmable

SET

resistor divider, which provides battery voltage feedback

to the charger.

, is connected from I

SET

SET

divider. See

SET

to the

7

LTC1759

UUU

PIN FUNCTIONS

VC (Pin 27): This is the control signal of the inner loop of

the current mode PWM. Switching starts at 0.9V. Higher

VC corresponds to higher charging current in normal

operation. A capacitor of at least 0.33µF to AGND filters out

noise and controls the rate of soft start.

PROG (Pin 28): This pin is for programming the charging

current and for system loop compensation. During normal

operation, the pin voltage is approximately 2.465V.

SENSE (Pin 29): Current Amplifier CA1 Input. Sensing

must be at the positive terminal of the battery.

SPIN (Pin 30): This pin is for the internal amplifier

CA1 bias. It must be connected to R

Figure 1.

BAT1 (Pin 31): Current Amplifier CA1 Input.

BOOSTC (Pin 33): This pin is used to bootstrap and supply

the current sense amplifier CA1 for very low dropout

conditions. VCC can be as low as only 0.4V above the

battery voltage. A diode and a capacitor are needed to get

the voltage from V

VCC is always 3V or greater than V

floating or tied to VCC. Do not force this pin to a voltage

lower than VCC.

BGATE (Pin 35): Drives the gate of the bottom external

N-channel FET of the charger buck converter.

. If low dropout is not needed and

BOOST

BAT

as shown in

SENSE

, this pin can be left

Internal Power Supply Pins

AGND (Pin 6): DC Accurate Ground for Analog Circuitry.

VDD (Pin 16): Low Voltage Power Supply Input. Bypass

this pin with 0.1µF.

DGND (Pin 18): Ground for Digital Circuitry and DACs.

Should be connected to AGND at the negative terminal

of the charger output filter capacitor.

VCC (Pin 32): Power Input for Battery Charger Section.

Bypass this pin with 0.47µF.

GBIAS (Pin 34): 8.6V Regulator Output for Bootstrapping

V

needed. Switching will stop if V

PGND (Pin 36): High Current Ground Return for Charger

Gate Drivers.

SBS Interface Pins

INTB (Interrupt Bar) (Pin 13): Active Low Interrupt Output

to Host. Signals host that there has been a change of status

in the charger registers and that the host should read the

LTC1759 status registers to determine if any action on its

part is required. This signal can be connected to the

optional SMBALERT# line of the SMBus. Open drain with

weak current source pull-up to VDD (with Schottky to allow

it to be pulled to 5V externally, see Figure 2).

BOOST

and V

BOOSTC

. A bypass capacitor of at least 2µF is

drops below 7.1V.

BOOST

Monitor/Fault Diagnostic Pins

DCDIV (Pin 21): Supply Divider Input. This is a high

impedance comparator input with a 1V threshold (rising

edge) and hysteresis.

DCIN (Pin 22): Input connected to the DC input source to

monitor the DC input for power-fail condition.

BAT2 (Pin 23): Sensing Point for Voltage Control Loop.

Connect this to the positive terminal of the battery.

8

SDA (Pin 14): SMBus Data Signal from Main (Hostcontrolled) SMBus.

SCL (Pin 15): SMBus Clock Signal from Main (HostControlled) SMBus. External pull-up resistor is required.

THERM (Pin 19): Thermistor Force/Sense Pin to Smart

Battery. See Electrical Characteristics table for more

detail. Maximum allowed combined capacitance on THERM

and RNR is 75pF.

RNR (Pin 20): Thermistor Force/Sense Pin to Smart

Battery. See Electrical Characteristics table for more

detail. Maximum allowed combined capacitance on THERM

and RNR is 75pF.

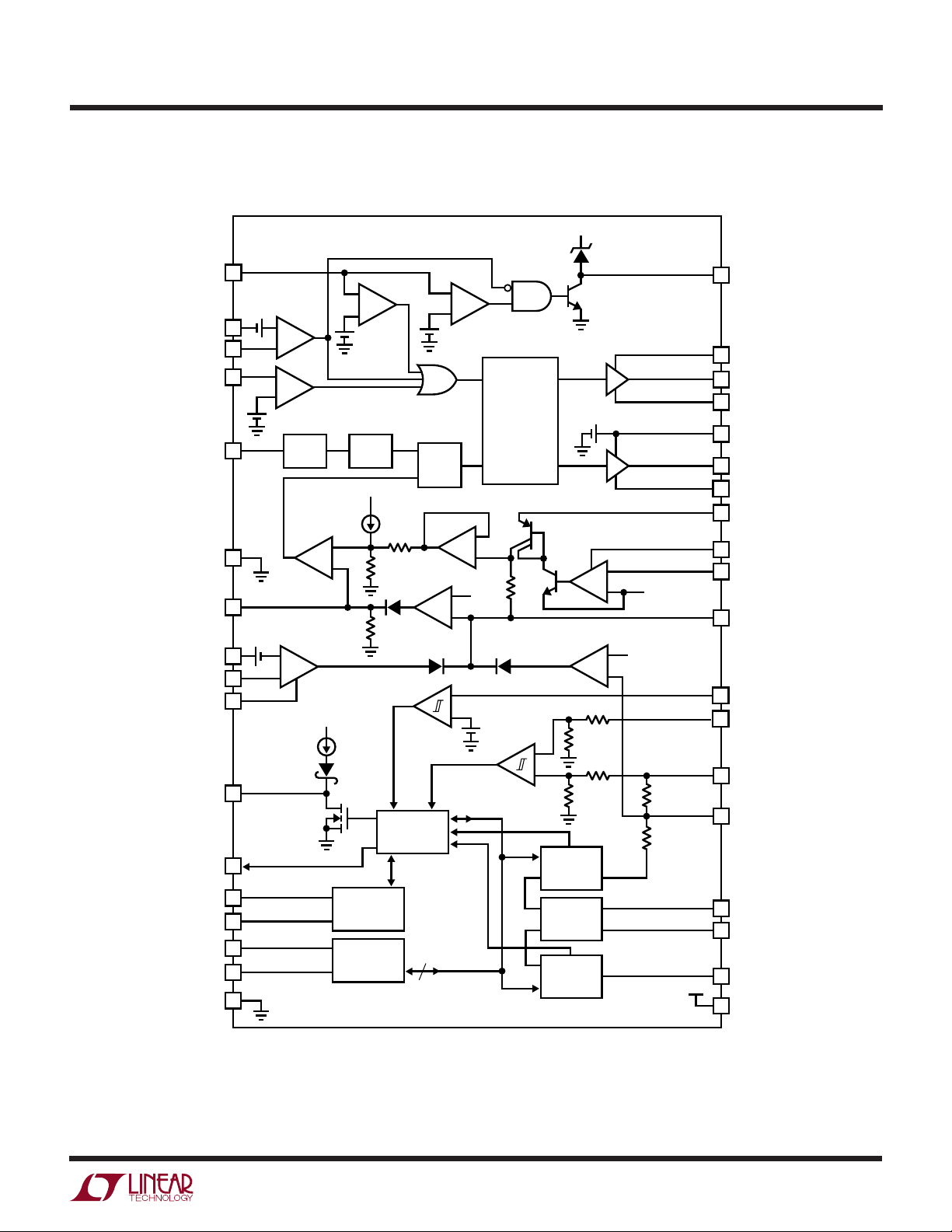

BLOCK DIAGRA

7

UV

0.2V

31

BAT1

32

V

CC

5

SDB

4

SYNC

6

AGND

V

27

C

92mV

+

CLP

9

CLN

10

COMP1

11

INTB

13

CHGEN

12

THERM

19

20

RNR

SCL

15

SDA

14

DGND

18

W

1.3V

LTC1759

V

CC

8V

8

INFET

1

BOOST

TGATE

2

3

SW

GBIAS

34

35 BGATE

36

PGND

33

BOOSTC

30

SPIN

29

SENSE

28

PROG

21

DCDIV

22

DCIN

23

BAT2

V

26

SET

I

24

LIMIT

25

V

LIMIT

17

I

SET

V

16

DD

1759 F02

S

R

CA2

13

+

–

6.7V

Q

–

B1

+

–

+

–

PWR_FAIL

+

V

SHDN

REF

1V

PWM

LOGIC

1k

–

+

20k

65k

10-BIT

VOLTAGE

DAC

LIMIT

DECODER

10-BIT

CURRENT

DAC

8.9V

CA1

VA

290k

812.5k

+

–

–

BAT1

V

REF

+

612k

72k

+

SLOPE COMP

+

–

V

DD

10µA

THERMISTOR

DECODER

CONTROLLER

–

6.7V

200kHz

OSC

75k

AC_PRESENT

CHARGER

CONTROLLER

SMBus

+

–

–

+

ONE

SHOT

C1

+

CL1

–

Figure 2

9

Loading...

Loading...