Linear Technology LTC1735 Datasheet

FEATURES

LTC1735

High Efficiency

Synchronous Step-Down

Switching Regulator

U

DESCRIPTIO

■

Dual N-Channel MOSFET Synchronous Drive

■

Synchronizable/Programmable Fixed Frequency

■

Wide VIN Range: 3.5V to 36V Operation

■

V

Range: 0.8V to 6V

OUT

■

OPTI-LOOPTM Compensation Minimizes C

■

±

1% Output Voltage Accuracy

■

Internal Current Foldback

■

Output Overvoltage Crowbar Protection

■

Latched Short-Circuit Shutdown Timer

OUT

with Defeat Option

■

Very Low Dropout Operation: 99% Duty Cycle

■

Forced Continuous Control Pin

■

Optional Programmable Soft-Start

■

Remote Output Voltage Sense

■

Logic Controlled Micropower Shutdown: IQ < 25µA

■

LTC1435 Pin Compatible with

Minor Component Changes

■

Available in 16-Lead Narrow SSOP and SO Packages

U

APPLICATIO S

■

Notebook and Palmtop Computers, PDAs

■

Cellular Telephones and Wireless Modems

■

DC Power Distribution Systems

The LTC®1735 is a synchronous step-down switching

regulator controller that drives external N-channel power

MOSFETs using a fixed frequency architecture. Burst

ModeTM operation provides high efficiency at low load

currents. The precision 0.8V reference is compatible with

future microprocessor generations. OPTI-LOOP compensation allows the transient response to be optimized over

a wide range of output capacitance and ESR values.

The operating frequency (synchronizable up to 500kHz) is

set by an external capacitor allowing maximum flexibility

in optimizing efficiency. A forced continuous control pin

reduces noise and RF interference and can assist secondary winding regulation by disabling Burst Mode operation

when the main output is lightly loaded.

Protection features include internal foldback current limiting, output overvoltage crowbar and optional shortcircuit shutdown. Soft-start is provided by an external

capacitor that can be used to properly sequence supplies.

The operating current level is user-programmable via an

external current sense resistor. Wide input supply range

allows operation from 3.5V to 30V (36V maximum).

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode and OPTI-LOOP are trademarks of Linear Technology Corporation.

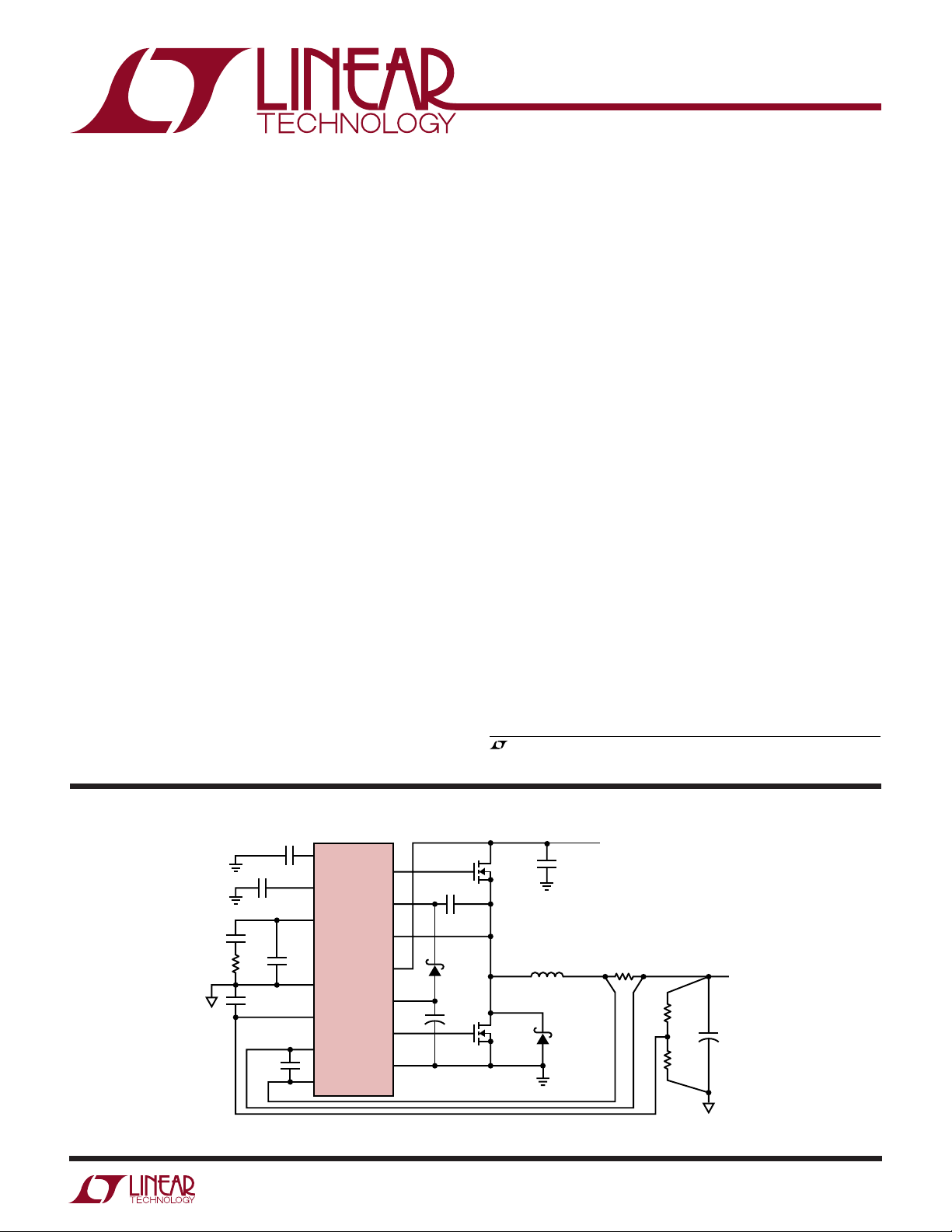

TYPICAL APPLICATIO

C

OSC

47pF

C

SS

0.1µF

C

C

330pF

C

100pF

1000pF

C

100pF

R

33k

U

C

OSC

RUN/SS

I

TH

C2

SGND

V

OSENSE

SENSE

SENSE

LTC1735

–

+

BOOST

INTV

PGND

TG

SW

V

IN

CC

BG

C

0.22µF

D

CMDSH-3

+

4.7µF

Figure 1. High Efficiency Step-Down Converter

M1

FDS6680A

B

B

M2

FDS6680A

L1

2µH

D1

MBRS340T3

V

IN

5V TO 24V

C

IN

22µF

50V

: PANASONIC EEFUEOG181R

C

OUT

: MARCON THCR70E1H226ZT

C

IN

L1: PANASONIC ETQP6FZR0HFA

R

SENSE

R

SENSE

0.005Ω

: IRC LRF2010-01-R005J

R1

20k

1%

R2

20k

1%

1735 F01

V

OUT

1.6V

9A

C

OUT

180µF

+

4V

×4

SP

1

LTC1735

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

Input Supply Voltage (VIN).........................36V to –0.3V

Topside Driver Supply Voltage (BOOST)....42V to –0.3V

Switch Voltage (SW) ....................................36V to – 5V

EXTVCC Voltage ...........................................7V to –0.3V

Boosted Driver Voltage (BOOST – SW) .......7V to –0.3V

SENSE+, SENSE– Voltages ..........1.1 (INTVCC) to –0.3V

FCB Voltage ............................(INTVCC + 0.3V) to –0.3V

ITH, V

OSENSE

RUN/SS Voltages.........................................7V to – 0.3V

Peak Driver Output Current <10µs (TG, BG) .............. 3A

INTVCC Output Current ......................................... 50mA

Operating Ambient Temperature Range

LTC1735C ............................................... 0°C to 85°C

LTC1735I............................................ –40°C to 85°C

Junction Temperature (Note 2).............................125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

Voltages ...............................2.7V to –0.3V

UUW

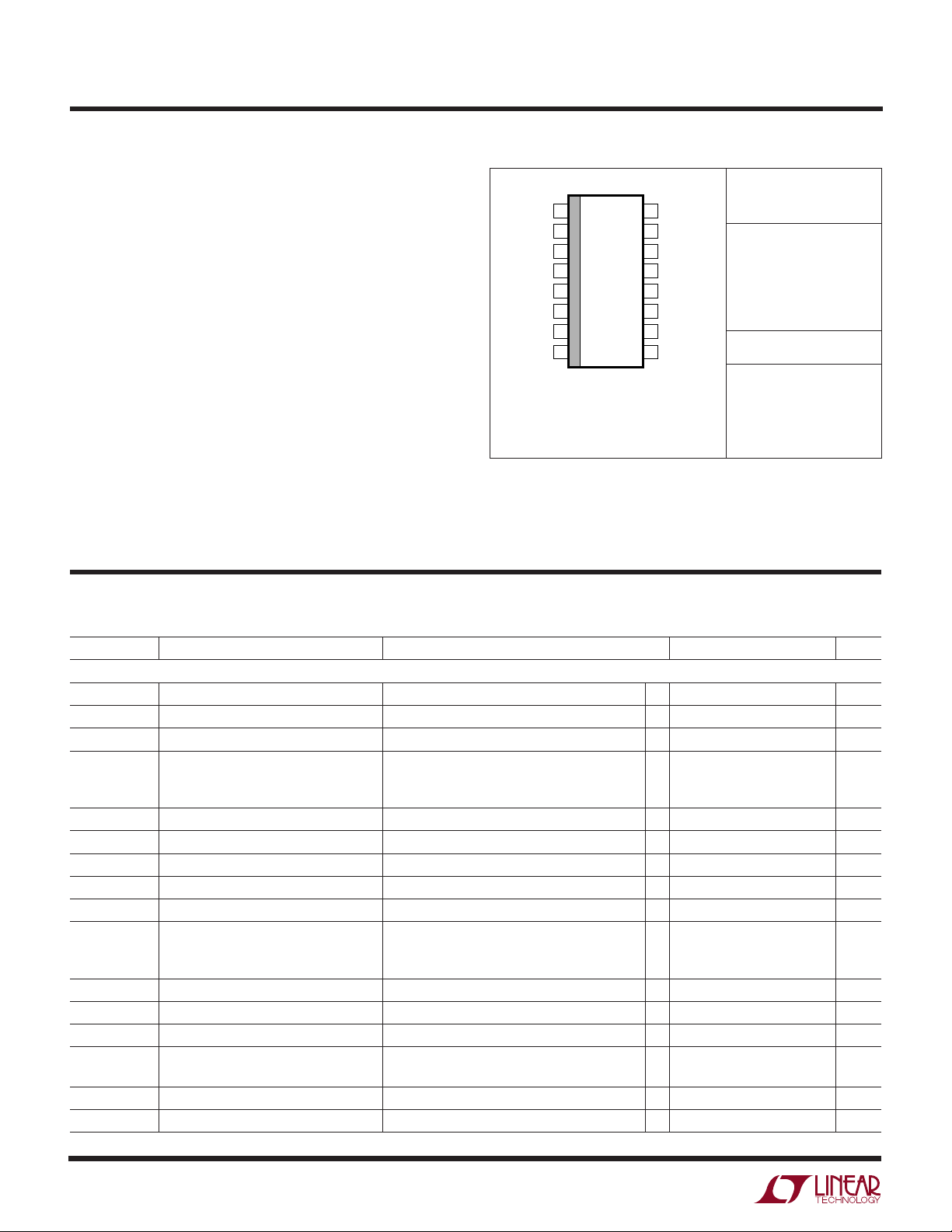

PACKAGE/ORDER I FOR ATIO

TOP VIEW

1

C

OSC

2

RUN/SS

3

I

TH

4

FCB

5

SGND

6

V

OSENSE

–

7

SENSE

+

8

SENSE

GN PACKAGE

16-LEAD NARROW

PLASTIC SSOP

T

= 125°C, θJA = 130°C/W (GN)

JMAX

= 125°C, θJA = 110°C/W (S)

T

JMAX

Consult factory for Military grade parts.

16

TG

15

BOOST

14

SW

13

V

IN

12

INTV

CC

11

BG

10

PGND

9

EXTV

CC

S PACKAGE

16-LEAD PLASTIC SO

ORDER PART

NUMBER

LTC1735CGN

LTC1735CS

LTC1735IGN

LTC1735IS

GN PART MARKING

1735

1735I

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 15V, V

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loop

I

VOSENSE

V

OSENSE

∆V

LINEREG

∆V

LOADREG

DF Max Maximum Duty Factor In Dropout 98 99.4 %

g

m

V

FCB

I

FCB

V

OVL

I

Q

V

RUN/SS

V

RUN/SS

I

RUN/SS

I

SCL

UVLO Undervoltage Lockout Measured at VIN Pin (VIN Ramping Down) ● 3.5 3.9 V

∆V

SENSE(MAX)

Feedback Current (Note 3) –4 –25 nA

Feedback Voltage (Note 3) ● 0.792 0.8 0.808 V

Reference Voltage Line Regulation VIN = 3.6V to 30V (Note 3) 0.001 0.02 %/V

Output Voltage Load Regulation (Note 3)

Transconductance Amplifier g

Forced Continuous Threshold ● 0.76 0.8 0.84 V

Forced Continuous Current V

Feedback Overvoltage Lockout ● 0.84 0.86 0.88 V

Input DC Supply Current (Note 4)

Normal Mode 450 µA

Shutdown V

Run Pin Start Threshold V

Run Pin Begin Latchoff Threshold V

Soft-Start Charge Current V

RUN/SS Discharge Current Soft Short Condition, V

Maximum Current Sense Threshold V

m

The ● denotes specifications which apply over the full operating

= 5V unless otherwise noted.

RUN/SS

Measured in Servo Loop; V

Measured in Servo Loop; V

= 0.85V – 0.17 –0.3 µA

FCB

= 0V 15 25 µA

RUN/SS

, Ramping Positive 1.0 1.5 1.9 V

RUN/SS

, Ramping Positive 4.1 4.5 V

RUN/SS

= 0V –0.7 – 1.2 µA

RUN/SS

= 4.5V

V

RUN/SS

= 0.7V ● 60 75 85 mV

OSENSE

= 0.7V ● 0.1 0.3 %

ITH

= 2V ● –0.1 –0.3 %

ITH

1.3 mmho

= 0.5V, 0.5 2 4 µA

OSENSE

2

LTC1735

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 15V, V

The ● denotes specifications which apply over the full operating

= 5V unless otherwise noted.

RUN/SS

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

SENSE

t

ON(MIN)

Sense Pins Total Source Current V

SENSE

–

= V

Minimum On-Time Tested with a Square Wave (Note 6) 160 200 ns

+

= 0V 60 80 µA

SENSE

TG Transition Time: (Note 7)

TG t

TG t

r

f

Rise Time C

Fall Time C

= 3300pF 50 90 ns

LOAD

= 3300pF 50 90 ns

LOAD

BG Transition Time: (Note 7)

BG t

r

BG t

f

TG/BG t

Rise Time C

Fall Time C

1D

Top Gate Off to Synchronous C

= 3300pF 50 90 ns

LOAD

= 3300pF 40 80 ns

LOAD

= 3300pF Each Driver 100 ns

LOAD

Gate On Delay Time

TG/BG t

2D

Synchronous Gate Off to Top C

= 3300pF Each Driver 70 ns

LOAD

Gate On Delay Time

Internal VCC Regulator

V

INTVCC

V

LDO(INT)

V

LDO(EXT)

V

EXTVCC

V

EXTVCC(HYS)

Internal VCC Voltage 6V < VIN < 30V, V

Internal V

EXTVCC Drop Voltage ICC = 20mA, V

Load Regulation ICC = 0 to 20mA, V

CC

EXTVCC

= 4V 5.0 5.2 5.4 V

EXTVCC

= 4V 0.2 1 %

EXTVCC

= 5V 130 200 mV

EXTVCC Switchover Voltage ICC = 20mA, EXTVCC Ramping Positive ● 4.5 4.7 V

EXTVCC Hysteresis 0.2 V

Oscillator

f

OSC

fH/f

OSC

f

FCB(SYNC)

Oscillator Frequency C

= 43pF (Note 5) 265 300 335 kHz

OSC

Maximum Sync Frequency Ratio 1.3

FCB Pin Threshold For Sync Ramping Negative 0.9 1.2 V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: T

dissipation P

LTC1735CS, LTC1735IS: T

is calculated from the ambient temperature TA and power

J

according to the following formulas:

D

= TA + (PD • 110 °C/W)

J

LTC1735CGN, LTC1735IGN: TJ = TA + (PD • 130°C/W)

Note 3: The LTC1735 is tested in a feedback loop that servos V

the balance point for the error amplifier (V

ITH

= 1.2V).

OSENSE

to

Note 4: Dynamic supply current is higher due to the gate charge being

delivered at the switching frequency. See Applications Information.

Note 5: Oscillator frequency is tested by measuring the C

current (I

) and applying the formula:

OSC

f

OSC

8 477 10

=

CpF I I

OSC CHG DIS

11

.( )

+

()

11

–

11

+

1

OSC

charge

Note 6: The minimum on-time condition corresponds to an inductor peakto-peak ripple current ≥40% of I

(see Minimum On-Time

MAX

Considerations in the Applications Information section).

Note 7: Rise and fall times are measured using 10% and 90% levels.

Delay times are measured using 50% levels.

3

LTC1735

UW

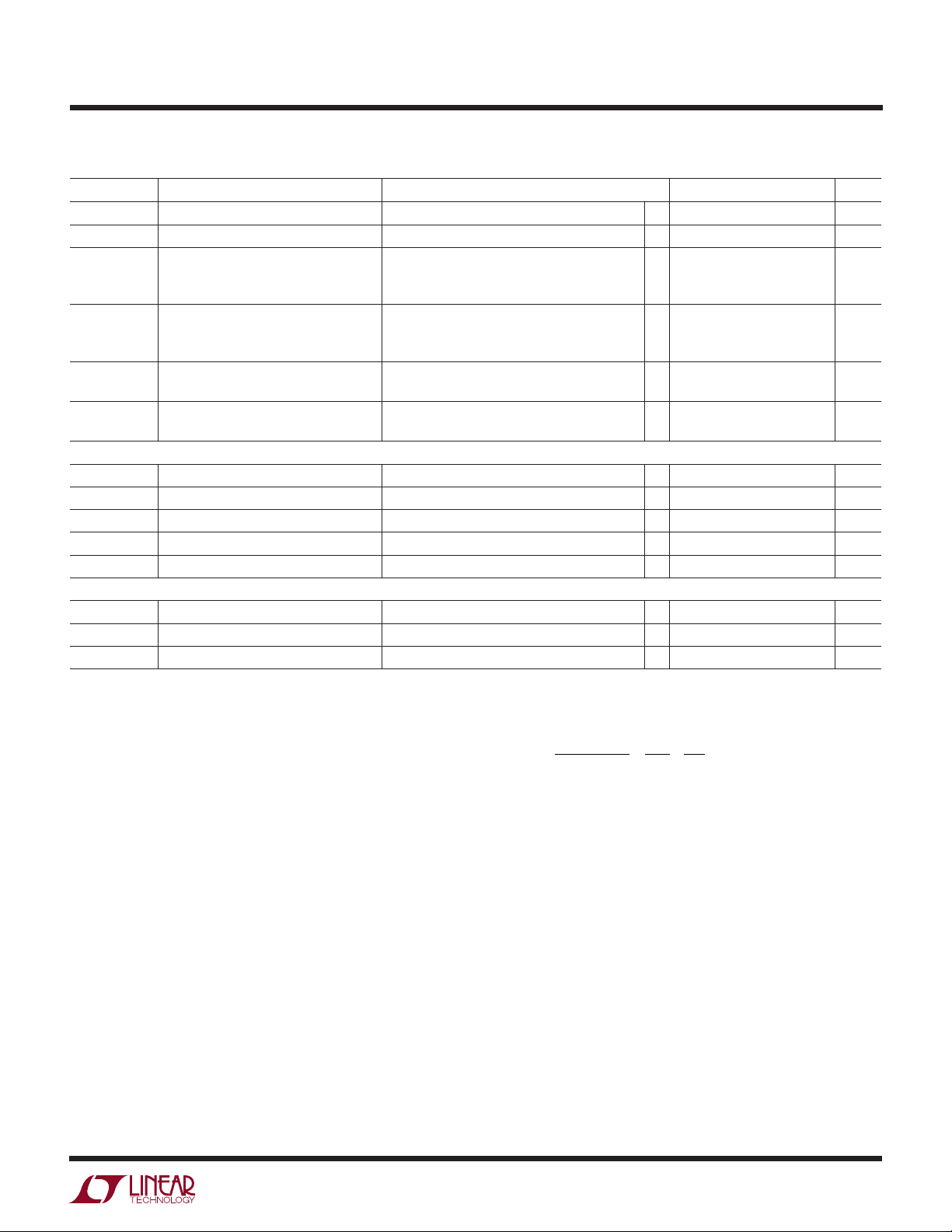

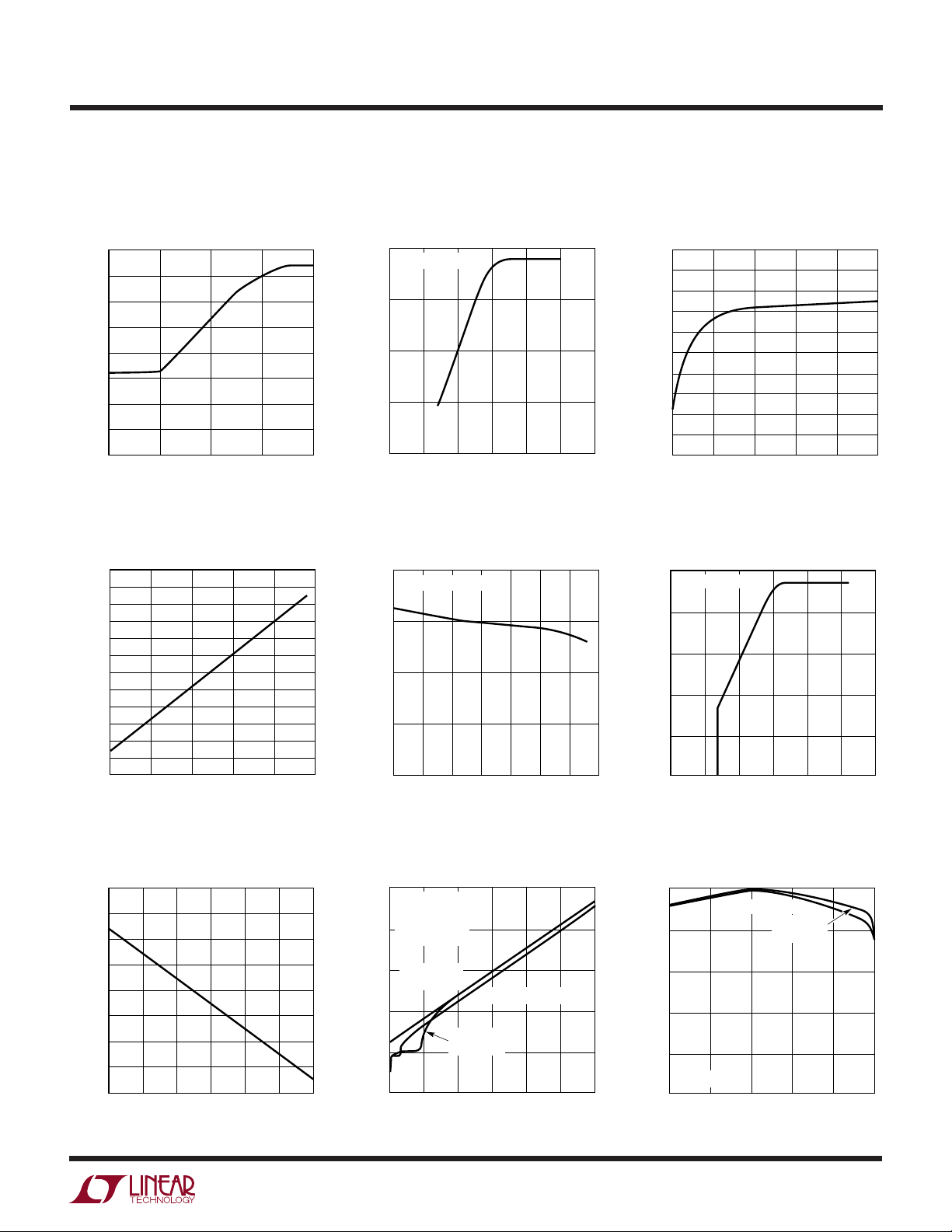

TYPICAL PERFOR A CE CHARACTERISTICS

Efficiency vs Load Current

(3 Operating Modes) Efficiency vs Load Current

100

EXTVCC OPEN

90

BURST

80

70

60

50

EFFICIENCY (%)

40

30

20

0.001

SYNC

0.01

0.1

LOAD CURRENT (A)

CONT

VIN = 10V

= 3.3V

V

OUT

R

= 0.01Ω

S

= 300kHz

f

O

1

10

1735 G01

100

EXTV

= 5V

CC

FIGURE 1

90

VIN = 5V

80

70

EFFICIENCY (%)

60

50

40

0.01 0.1 1 10

= 15V

V

IN

VIN = 24V

LOAD CURRENT (A)

1735 G02

Efficiency vs Input Voltage

100

EXTVCC = 5V

= 1.6V

V

OUT

95

FIGURE 1

90

85

I

EFFICIENCY (%)

80

75

70

0

5

OUT

10 15 20

INPUT VOLTAGE (V)

I

OUT

= 0.5A

= 5A

25 30

1735 G03

Efficiency vs Input Voltage

100

EXTVCC OPEN

= 1.6V

V

OUT

95

FIGURE 1

90

85

I

= 0.5A

EFFICIENCY (%)

80

75

70

OUT

0

10 15 20

5

INPUT VOLTAGE (V)

Input and Shutdown Currents

vs Input Voltage

500

EXTVCC OPEN

400

300

200

INPUT CURRENT (µA)

100

0

05

SHUTDOWN

EXTVCC = 5V

20

15

10

INPUT VOLTAGE (V)

I

OUT

= 5A

25

25 30

1735 G04

30

1735 G07

Load Regulation

0

–0.1

(%)

OUT

–0.2

NORMALIZED V

–0.3

–0.4

0

2

4

LOAD CURRENT (A)

VIN – V

vs Load Current

500

400

300

(mV)

OUT

– V

200

IN

V

100

R

SENSE

V

OUT

0

0

FCB = 0V

= 15V

V

IN

FIGURE 1

6

8

10

1735 G05

Dropout Voltage

OUT

= 0.005Ω

= 5V – 5% DROP

2468

LOAD CURRENT (A)

10

1735 G06

EXTVCC Switch Drop

INTVCC Line Regulation

100

SHUTDOWN CURRENT (µA)

80

60

40

20

0

35

6

1mA LOAD

5

4

3

VOLTAGE (V)

CC

2

INTV

1

0

0

510

INPUT VOLTAGE (V)

20 30 35

15 25

1735 G08

vs INTVCC Load Current

500

400

(mV)

300

CC

– INTV

200

CC

EXTV

100

0

10

0

INTVCC LOAD CURRENT (mA)

30

40

20

50

1735 G09

4

UW

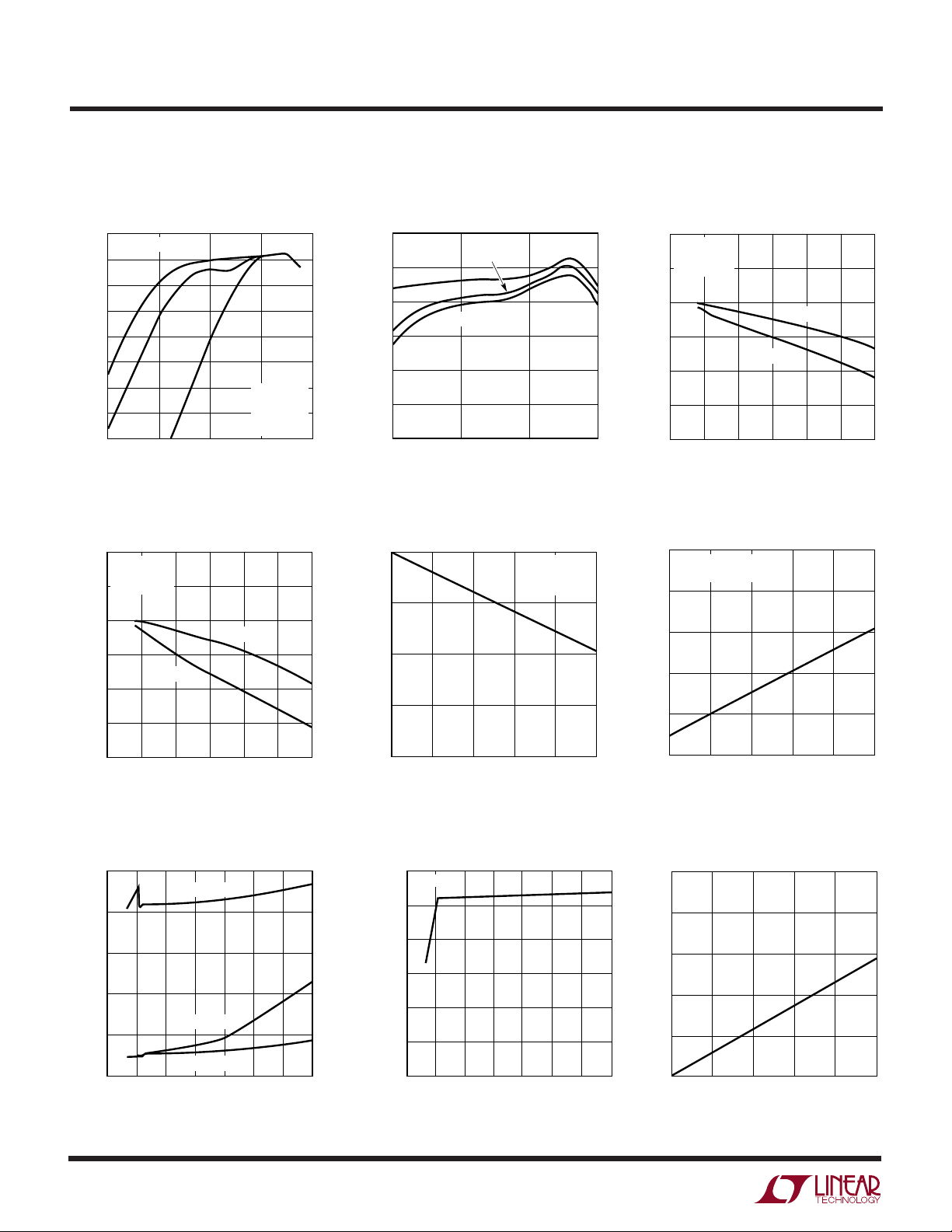

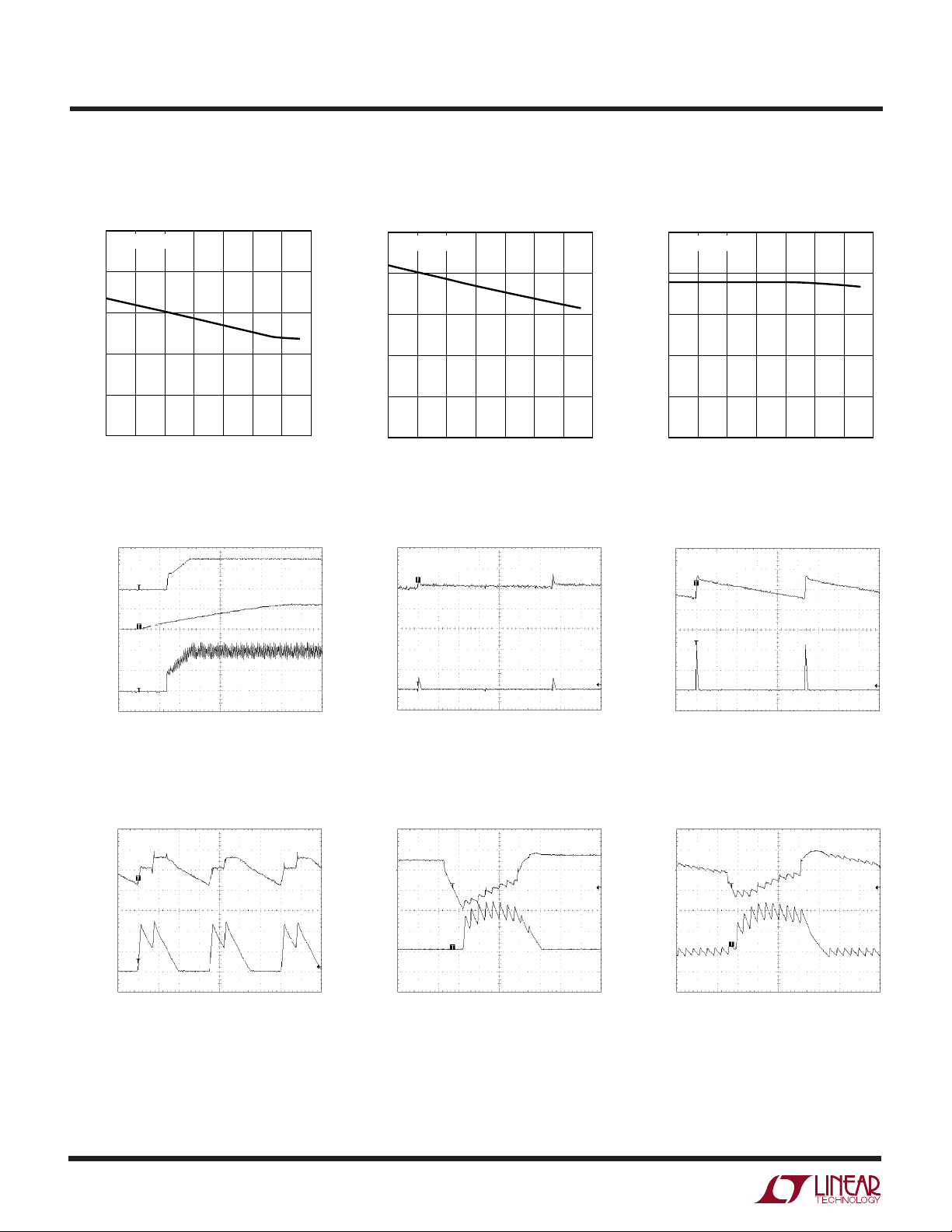

TYPICAL PERFOR A CE CHARACTERISTICS

Maximum Current Sense Threshold

vs Normalized Output Voltage

(Foldback)

80

70

60

50

40

30

20

10

MAXIMUM CURRENT SENSE THRESHOLD (mV)

0

0

25

NORMALIZED OUTPUT VOLTAGE (%)

50

75

100

1735 G10

Maximum Current Sense Threshold

vs V

RUN/SS

80

V

60

40

20

MAXIMUM CURRENT SENSE THRESHOLD (mV)

0

0

= 1.6V

SENSE(CM)

1234

V

(V)

RUN/SS

56

1735 G11

LTC1735

Maximum Current Sense Threshold

vs Sense Common Mode Voltage

80

76

72

68

64

MAXIMUM CURRENT SENSE THRESHOLD (mV)

60

1

0

COMMON MODE VOLTAGE (V)

3

2

4

5

1735 G12

Maximum Current Sense Threshold

vs ITH Voltage

90

80

70

60

50

40

30

20

10

0

–10

–20

MAXIMUM CURRENT SENSE THRESHOLD (mV)

–30

0.5

0

1.5

1

V

(V)

ITH

SENSE Pins Total Source Current

100

50

(µA)

0

SENSE

I

–50

–100

0

24

V

COMMON MODE VOLTAGE (V)

SENSE

Maximum Current Sense Threshold

V

vs Temperature

80

V

75

70

65

MAXIMUM CURRENT SENSE THRESHOLD (mV)

2

2.5

1735 G13

60

–40

= 1.6V

SENSE(CM)

–15 10 35 60

TEMPERATURE (°C)

85 110 135

1735 G18

(V)

ITH

V

ITH Voltage vs Load Current

1735 G16

2.5

VIN = 10V

= 3.3V

V

OUT

= 0.01Ω

R

SENSE

2.0

= 300kHz

f

O

CONTINUOUS

1.5

VOLTAGE (V)

1.0

TH

I

0.5

6

0

MODE

SYNCHRONIZED f = f

Burst Mode

OPERATION

0

234

1

LOAD CURRENT (A)

O

56

1735 G17

100

(%)

MAX

/I

OUT

AVERAGE OUTPUT CURRENT I

vs V

ITH

RUN/SS

2.5

V

= 0.7V

OSENSE

2.0

1.5

1.0

0.5

0

0

234

1

V

RUN/SS

(V)

Output Current vs Duty Cycle

I

(SYNC)

OUT/IMAX

80

60

40

20

f

= f

SYNC

0

O

0

20

DUTY CYCLE (%)

I

OUT/IMAX

(FREE RUN)

40 60 80

56

1735 G15

100

1735 G14

5

LTC1735

UW

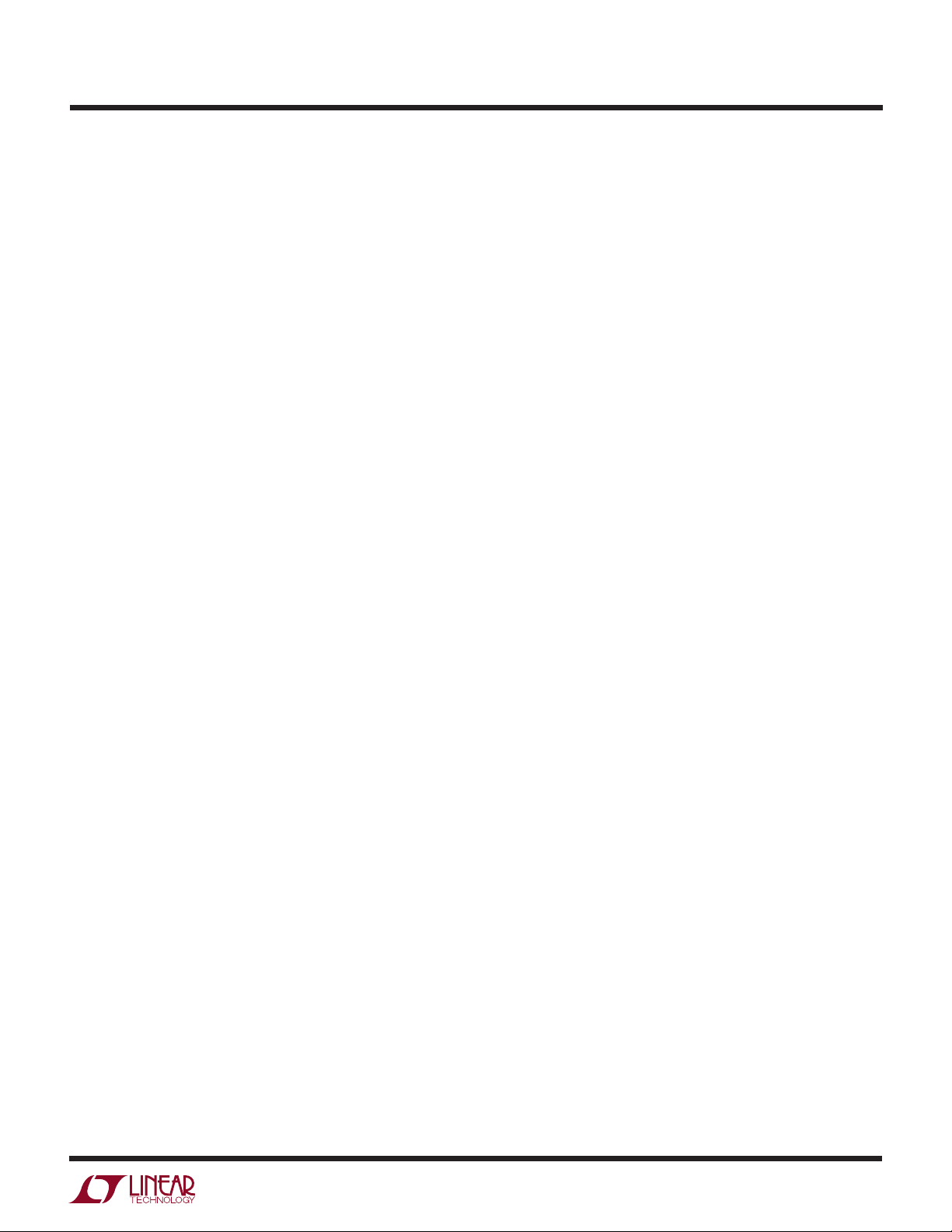

TYPICAL PERFOR A CE CHARACTERISTICS

Oscillator Frequency

vs Temperature

300

C

= 47pF

OSC

290

280

270

FREQUENCY (kHz)

260

250

–40 –15

10

TEMPERATURE (°C)

Start-Up

V

OUT

1V/DIV

V

RUN/SS

5V/DIV

RUN/SS Pin Current

vs Temperature

0

V

= 0V

RUN/SS

–1

–2

–3

RUN/SS CURRENT (µA)

–4

60

35

85

110

135

1735 G19

–5

V

OUT

10mV/DIV

–40 –15

V

OUT(RIPPLE)

I

LOAD

60

35

10

TEMPERATURE (°C)

85

110

135

1735 G20

(Synchronized)

= 10mA I

FIGURE 1 FIGURE 1

FCB Pin Current vs Temperature

0

V

= 0.85V

FCB

–0.2

–0.4

–0.6

FCB CURRENT (µA)

–0.8

–1.0

–40 –15

V

OUT(RIPPLE)

35

10

TEMPERATURE (°C)

(Burst Mode Operation)

= 50mA

LOAD

V

OUT

20mV/DIV

60

85

110

135

1735 G21

5A/DIV

V

OUT

20mV/DIV

5A/DIV

I

L

= 15V 5ms/DIV

V

IN

V

= 1.6V

OUT

= 0.16Ω

R

LOAD

V

OUT(RIPPLE)

(Burst Mode Operation)

I

= 1.5A

LOAD

I

L

FCB = 5V 5µs/DIV

V

= 15V

IN

= 1.6V

V

OUT

I

L

I

L

5A/DIV

1735 G22 1735 G23 1735 G24

EXT SYNC f = f

V

= 15V

IN

= 1.6V

V

OUT

O

10µs/DIV

5A/DIV

FCB = 5V 50µs/DIV

= 15V

V

IN

V

= 1.6V

OUT

Load Step (Burst Mode Operation) Load Step (Continuous Mode)

FIGURE 1 FIGURE 1 FIGURE 1

V

OUT

V

OUT

50mV/DIV

I

L

5A/DIV

1735 G27 1735 G26 1735 G25

10mA TO 10µs/DIV

9A LOAD STEP

FCB = 5V

= 15V

V

IN

= 1.6V

V

OUT

50mV/DIV

5A/DIV

I

L

0A TO 10µs/DIV

9A LOAD STEP

FCB = 0V

= 15V

V

IN

= 1.6V

V

OUT

6

UUU

PI FU CTIO S

C

(Pin 1): External capacitor C

OSC

ground sets the operating frequency.

RUN/SS (Pin 2): Combination of Soft-Start and Run

Control Inputs. A capacitor to ground at this pin sets the

ramp time to full output current. The time is approximately

1.25s/µF. Forcing this pin below 1.5V causes the device to

be shutdown. In shutdown all functions are disabled.

Latchoff overcurrent protection is also invoked via this pin

as described in the Applications Information section.

ITH (Pin 3): Error Amplifier Compensation Point. The

current comparator threshold increases with this control

voltage. Nominal voltage range for this pin is 0V to 2.4V.

FCB (Pin 4): Forced Continuous/Synchronization Input.

Tie this pin to ground for continuous synchronous operation, to a resistive divider from the secondary output when

using a secondary winding or to INTVCC to enable Burst

Mode operation at low load currents. Clocking this pin with

a signal above 1.5V

allows cycle-skipping at low load currents and synchronizes the internal oscillator with the external clock.

SGND (Pin 5): Small-Signal Ground. All small-signal

components such as C

the loop compensation resistors and capacitor(s) should

single-point tie to this pin. This pin should, in turn, connect

to PGND.

V

OSENSE

external resistive divider across the output.

SENSE– (Pin 7): The (–) Input to the Current Comparator.

SENSE+ (Pin 8): The (+) Input to the Current Comparator.

Built-in offsets between SENSE– and SENSE+ pins in

conjunction with R

(Pin 6): Receives the feedback voltage from an

disables Burst Mode operation but

P–P

, CSS, the feedback divider plus

OSC

set the current trip threshold.

SENSE

from this pin to

OSC

LTC1735

EXTVCC (Pin 9): Input to the Internal Switch Connected to

INTVCC. This switch closes and supplies VCC power whenever EXTVCC is higher than 4.7V. See EXTVCC connection

in the Applications Information section. Do not exceed 7V

on this pin and ensure EXTVCC ≤ VIN.

PGND (Pin 10): Driver Power Ground. Connects to the

source of bottom N-channel MOSFET, the anode of the

Schottky diode, and the (–) terminal of CIN.

BG (Pin 11): High Current Gate Drive for Bottom

N-Channel MOSFET. Voltage swing at this pin is from

ground to INTVCC.

INTVCC (Pin 12): Output of the Internal 5.2V Regulator and

EXTVCC Switch. The driver and control circuits are powered from this voltage. Decouple to power ground with a

1µF ceramic capacitor placed directly adjacent to the IC

together with a minimum of 4.7µF tantalum or other low

ESR capacitor.

VIN (Pin 13): Main Supply Pin. Must be closely decoupled

to power ground.

SW (Pin 14): Switch Node Connection to Inductor and

Bootstrap Capacitor. Voltage swing at this pin is from a

Schottky diode (external) voltage drop below ground to

VIN.

BOOST (Pin 15): Supply to Topside Floating Driver. The

bootstrap capacitor is returned to this pin. Voltage swing

at this pin is from a diode drop below INTVCC to (VIN +

INTVCC).

TG (Pin 16): High Current Gate Drive for Top N-Channel

MOSFET. This is the output of a floating driver with a

voltage swing equal to INTVCC superimposed on the

switch node voltage SW.

7

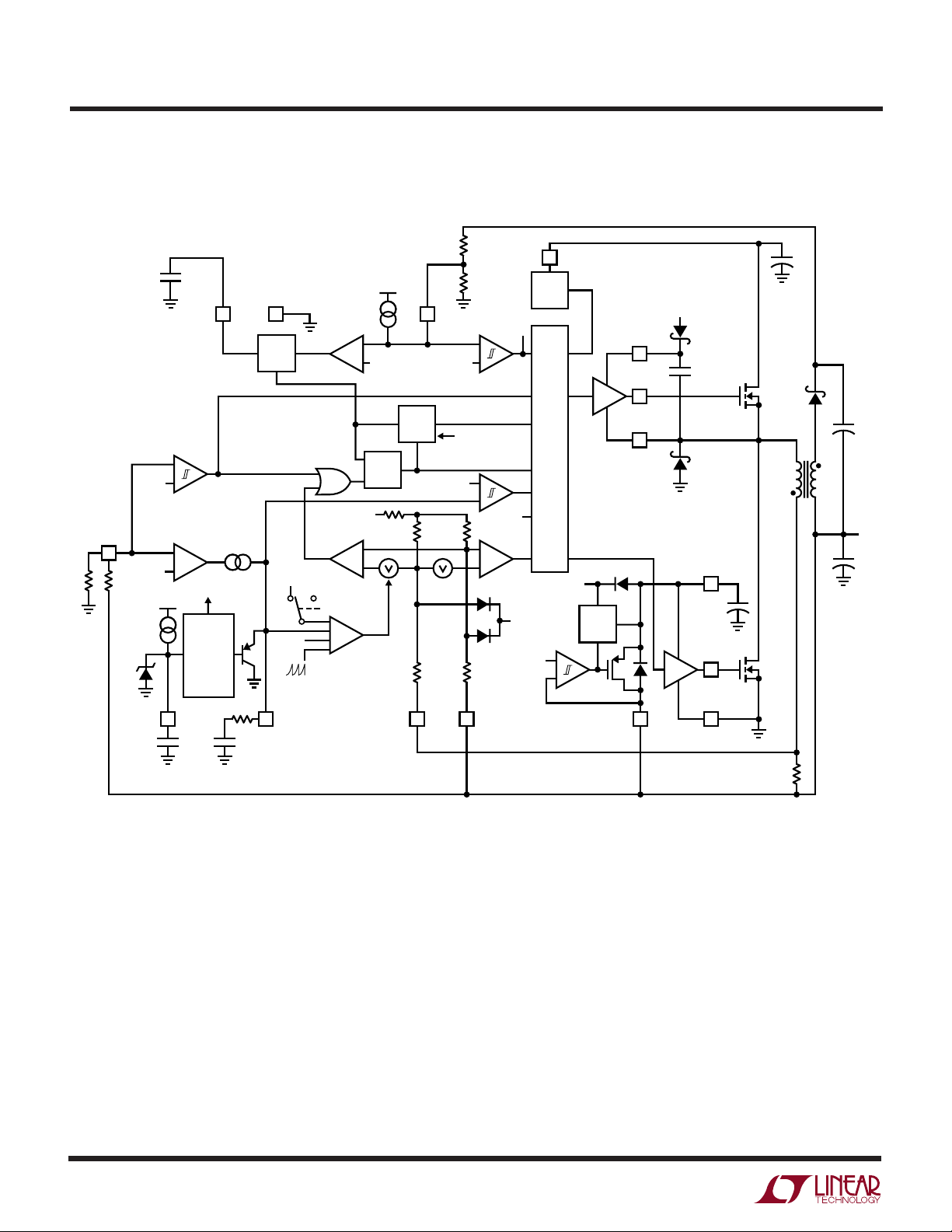

LTC1735

UU

W

FU CTIO AL DIAGRA

C

OSC

1 5 4

OSC

SYNC

OSC

OV

+

–

0.86V

V

OSENSE

V

FB

6

0.8V

R2

R1

1.2µA

6V

RUN/SS

C

SS

2

gm =1.3m

–

EA

+

CURRENT

LATCHOFF

SD

RUN

SOFT-

START

+

OVER-

C

C

Ω

R

C

0.86V

4(V

)

FB

SLOPE COMP

I

TH

ICMP

BURST

DISABLE

FC

0.17µA

C

–

+

1.2V 0.8V

FORCE BOT

S

R

2.4V

–

I

1

+

A

BUFFERED

I

TH

SENSE

Q

2k

+– –+

+

FCBSGNDC

DROP

OUT

DET

TOP ON

45k

3mV

30k 30k

0.55V

BOT

–

+

+

–

45k

–

+

SENSE

V

IN

V

13

IN

UVL

0.8V

REF

FC

F

TOP

SWITCH

LOGIC

B

SD

IREV

I

2

INTV

4.7V

–

BOT

V

IN

CC

5.2V

LDO

REG

+

–

EXTV

CC

BOOST

15

TG

16

SW

14

9783

INTV

CC

D

B

C

B

D

1

INTV

C

INTVCC

PGND

CC

12

BG

11

10

+

C

IN

V

SEC

+

C

SEC

V

OUT

+

C

OUT

+

8

R

SENSE

1735 FD

OPERATIO

LTC1735

U

(Refer to Functional Diagram)

Main Control Loop

The LTC1735 uses a constant frequency, current mode

step-down architecture. During normal operation, the top

MOSFET is turned on each cycle when the oscillator sets

the RS latch and turned off when the main current comparator I1 resets the RS latch. The peak inductor current at

which I1 resets the RS latch is controlled by the voltage on

Pin 3 (ITH), which is the output of error amplifier EA. Pin␣ 6

(V

OSENSE

receive an output feedback voltage VFB from an external

resistive divider. When the load current increases, it

causes a slight decrease in VFB relative to the 0.8V reference, which in turn causes the ITH voltage to increase until

the average inductor current matches the new load current. While the top MOSFET is off, the bottom MOSFET is

turned on until either the inductor current starts to reverse,

as indicated by current comparator I2, or the beginning of

the next cycle.

The top MOSFET driver is powered from a floating bootstrap capacitor CB. This capacitor is normally recharged

from INTVCC through an external diode when the top

MOSFET is turned off. As VIN decreases towards V

converter will attempt to turn on the top MOSFET continuously (“dropout’’). A dropout counter detects this condition and forces the top MOSFET to turn off for about 500ns

every tenth cycle to recharge the bootstrap capacitor.

), described in the pin functions, allows EA to

, the

OUT

conditions that may overvoltage the output. In this case,

the top MOSFET is turned off and the bottom MOSFET is

turned on until the overvoltage condition is cleared.

Foldback current limiting for an output shorted to ground

is provided by amplifier A. As V

the buffered ITH input to the current comparator is gradually pulled down to a 0.86V clamp. This reduces peak

inductor current to about 1/4 of its maximum value.

Low Current Operation

The LTC1735 has three low current modes controlled by

the FCB pin. Burst Mode operation is selected when the

FCB pin is above 0.8V (typically tied to INTVCC). In Burst

Mode operation, if the error amplifier drives the ITH voltage

below 0.86V, the buffered ITH input to the current comparator will be clamped at 0.86V. The inductor current

peak is then held at approximately 20mV/R

1/4 of maximum output current). If ITH then drops below

0.5V, the Burst Mode comparator B will turn off both

MOSFETs to maximize efficiency. The load current will be

supplied solely by the output capacitor until ITH rises

above the 60mV hysteresis of the comparator and switching is resumed. Burst Mode operation is disabled by

comparator F when the FCB pin is brought below 0.8V.

This forces continuous operation and can assist secondary winding regulation.

OSENSE

drops below 0.6V,

(about

SENSE

The main control loop is shut down by pulling Pin 2

(RUN/SS) low. Releasing RUN/SS allows an internal 1.2µA

current source to charge soft-start capacitor CSS. When

CSS reaches 1.5V, the main control loop is enabled with the

ITH voltage clamped at approximately 30% of its maximum

value. As CSS continues to charge, ITH is gradually released allowing normal operation to resume. If V

not reached 70% of its final value when CSS has charged

to 4.1V, latchoff can be invoked as described in the

Applications Information section.

The internal oscillator can be synchronized to an external

clock applied to the FCB pin and can lock to a frequency

between 90% and 130% of its nominal rate set by capacitor C

An overvoltage comparator, OV, guards against transient

overshoots (>7.5%) as well as other more serious

OSC

.

OUT

has

When the FCB pin is driven by an external oscillator, a low

noise cycle-skipping mode is invoked and the internal

oscillator is synchronized to the external clock by comparator C. In this mode the 25% minimum inductor

current clamp is removed, providing constant frequency

discontinuous operation over the widest possible output

current range. This constant frequency operation is not

quite as efficient as Burst Mode operation, but provides a

lower noise, constant frequency spectrum.

The FCB pin is tied to ground when forced continuous

operation is desired. This is the least efficient mode, but is

desirable in certain applications. The output can source or

sink current in this mode. When sinking current while in

forced continuous operation, current will be forced back

into the main power supply potentially boosting the input

supply to dangerous voltage levels—BEWARE.

9

LTC1735

OPERATIO

U

(Refer to Functional Diagram)

Foldback Current, Short-Circuit Detection and

Short-Circuit Latchoff

The RUN/SS capacitor, CSS, is used initially to limit the

inrush current of the switching regulator. After the controller has been started and been given adequate time to

charge up the output capacitors and provide full load current, CSS is used as a short-circuit time-out circuit. If the

output voltage falls to less than 70% of its nominal output

voltage, CSS begins discharging on the assumption that

the output is in an overcurrent and/or short-circuit condition. If the condition lasts for a long enough period as

determined by the size of CSS, the controller will be shut

down until the RUN/SS pin voltage is recycled. This builtin latchoff can be overridden by providing a current >5µA

at a compliance of 5V to the RUN/SS pin. This current

shortens the soft-start period but also prevents net discharge of C

condition. Foldback current limiting is activated when the

during an overcurrent and/or short-circuit

SS

U

WUU

APPLICATIO S I FOR ATIO

output voltage falls below 70% of its nominal level whether

or not the short-circuit latchoff circuit is enabled.

INTVCC/EXTVCC POWER

Power for the top and bottom MOSFET drivers and most

of the internal circuitry of the LTC1735 is derived from the

INTVCC pin. When the EXTVCC pin is left open, an internal

5.2V low dropout regulator supplies the INTVCC power

from VIN. If EXTVCC is raised above 4.7V, the internal

regulator is turned off and an internal switch connects

EXTVCC to INTVCC. This allows a high efficiency source,

such as the primary or a secondary output of the converter

itself, to provide the INTVCC power. Voltages up to 7V can

be applied to EXTVCC for additional gate drive capability.

To provide clean start-up and to protect the MOSFETs,

undervoltage lockout is used to keep both MOSFETs off

until the input voltage is above 3.5V.

The basic LTC1735 application circuit is shown in Figure␣ 1

on the first page. External component selection is driven

by the load requirement and begins with the selection of

R

Next, the power MOSFETs and D1 are selected. The

operating frequency and the inductor are chosen based

largely on the desired amount of ripple current. Finally, C

is selected for its ability to handle the large RMS current

into the converter and C

ESR to meet the output voltage ripple and transient specifications. The circuit shown in Figure 1 can be configured

for operation up to an input voltage of 28V (limited by the

external MOSFETs).

R

R

The LTC1735 current comparator has a maximum threshold of 75mV/R

SGND to 1.1(INTVCC). The current comparator threshold

sets the peak of the inductor current, yielding a maximum

average output current I

half the peak-to-peak ripple current, ∆IL.

. Once R

SENSE

Selection for Output Current

SENSE

is chosen based on the required output current.

SENSE

is known, C

SENSE

is chosen with low enough

OUT

and an input common mode range of

SENSE

equal to the peak value less

MAX

and L can be chosen.

OSC

IN

Allowing a margin for variations in the LTC1735 and

external component values yields:

mV

R

SENSE

C

Selection for Operating Frequency and

OSC

Synchronization

The choice of operating frequency and inductor value is a

trade-off between efficiency and component size. Low

frequency operation improves efficiency by reducing

MOSFET switching losses, both gate charge loss and

transition loss. However, lower frequency operation requires more inductance for a given amount of ripple

current.

The LTC1735 uses a constant frequency architecture with

the frequency determined by an external oscillator capacitor C

OSC

voltage on C

C

is charged by a fixed current. When the voltage on the

OSC

50

=

I

MAX

. Each time the topside MOSFET turns on, the

is reset to ground. During the on-time,

OSC

10

Loading...

Loading...