Linear Technology LTC1708-PG Datasheet

LTC1708-PG

Final Electrical Specifications

Dual Adjustable 5-Bit VID

High Efficiency, 2-Phase Current Mode

Synchronous Buck Regulator Controller

FEATURES

■

Out-of-Phase Controllers Reduce Input Capacitance

and Power Supply Induced Noise

■

OPTI-LOOPTM Compensation Minimizes C

■

Power Good Output Monitors Both Outputs

■

5-Bit Mobile VID Control, V

■

Dual N-Channel MOSFET Synchronous Drive

■

±1% Output Voltage Accuracy

■

DC Programmed Fixed Frequency 150kHz to 300kHz

■

Wide VIN Range: 3.5V to 36V Operation

■

Very Low Dropout Operation: 99% Duty Cycle

■

Adjustable Soft-Start Current Ramping

■

Foldback Output Current Limiting

■

Latched Short-Circuit Shutdown with Defeat Option

■

Output Overvoltage Protection

■

Remote Output Voltage Sense

■

Low Shutdown Current: 20µA

■

5V and 3.3V Standby Regulators

■

Selectable Constant Frequency, Burst ModeTM and

: 0.9V to 2.0V

OUT

OUT

Continuous Operation

U

APPLICATIO S

■

Notebook and Palmtop Computers, PDAs

■

Portable Instruments

U

February 2000

DESCRIPTIO

The LTC®1708 is a dual adjustable 5-bit VID programmable step-down switching regulator controller that drives

all N-Channel power MOSFET stages. A constant frequency current mode architecture allows adjustment of

the frequency up to 300kHz. Power loss and noise due to

the ESR of the input capacitance are minimized by operating the two main controller output stages out of phase.

OPTI-LOOP compensation allows the transient response

to be optimized over a wide range of output capacitance

and ESR values. The precision 0.8V reference is compatible with future microprocessor generations, and a wide

3.5V to 30V (36V maximum) input supply range that

encompasses all battery chemistries. A power good output indicates when the output voltages are within 7.5% of

their programmed value.

A RUN/SS pin for each controller provides both soft-start

and an optional timed, short-circuit shutdown. Other

protection features include: internal foldback current limiting and an output overvoltage crowbar. The force continuous control pin (FCB) can be used to inhibit Burst

Mode operation or to regulate a third, flyback output.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode and OPTI-LOOP are trademarks of Linear Technology Corporation.

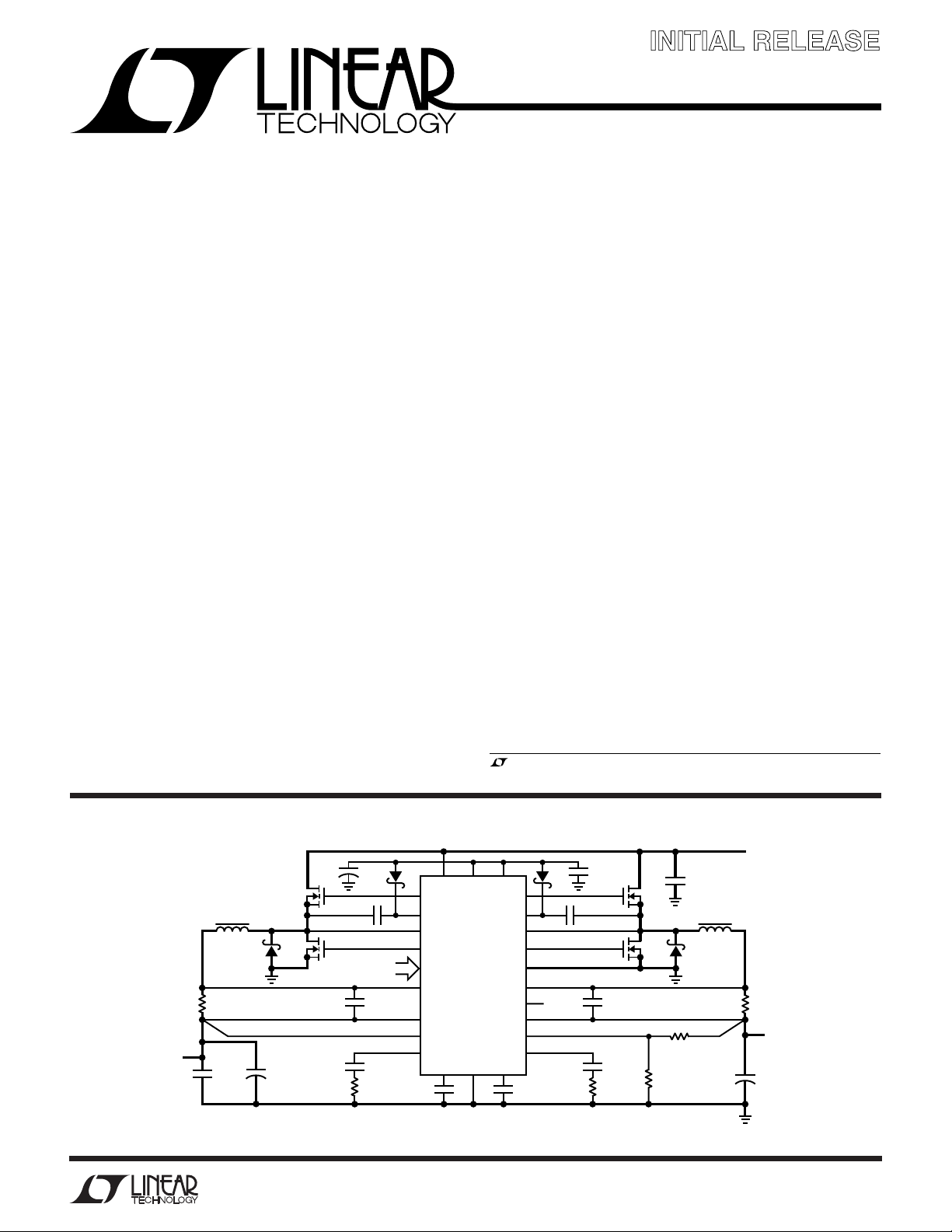

TYPICAL APPLICATIO

R

SENSE1

0.003Ω

V

OUT1

0.925V TO

2.00V

14.1A

C

10µF

6.3V

CERAMIC

U

+

4.7µF

D3

1µH

OUT1a

VINVIDVCCINTV

L1

M1

M2

D1

C

OUT1

+

270µF

2V

SP

×4

C

B1

0.47µF

5 VID BITS

1000pF

C

1500pF

R

C1

22k

C1

TG1 TG2

BOOST1 BOOST2

SW1 SW2

LTC1708-PG

BG1 BG2

VID0 TO VID4 PGND

+

SENSE1

–

SENSE1

ATTNIN V

I

TH1

RUN/SS1 RUN/SS2SGND

C

SS1

0.1µF

SENSE2

PGOOD

SENSE2

OSENSE2

CC

+

–

I

TH2

C

SS2

0.1µF

Figure 1. High Efficiency VID Controlled, 2-Output Step-Down Converter

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

D4

C

220pF

C2

R

15k

C

B2

C2

1µF

CERAMIC

0.1µF

1000pF

20k

1%

V

IN

L2

R

SENSE2

C

180µF

0.01Ω

OUT

4V

SP

4.75V TO 28V

V

OUT2

1.5V

4A

M1: IRF7811

+

M2: 1RF7809

M3a, M3b: FDS6982

L1: VISHAY 5050CE

ATTNOUT CONNECTED TO EAIN1

1628 F01

C

IN

10µF

50V

CERAMIC

M3a

×4

2.2µH

M3b

D2

R4

63.4k

1%

R3

1

LTC1708-PG

WW

W

U

ABSOLUTE AXI U RATI GS

(Note 1)

Input Supply Voltage (VIN).........................36V to –0.3V

Topside Driver Voltages

(BOOST1, BOOST2) ...................................42V to –0.3V

Switch Voltage (SW1, SW2) .........................36V to – 5V

INTV

(BOOST1-SW1), (BOOST2-SW2), ...............7V to –0.3V

SENSE1+, SENSE2+, SENSE1–,

SENSE2– Voltages....................... (1.1)INTVCC to –0.3V

FREQSET, STBYMD, FCB, VIDVCC, VID0-4,

PGOOD Voltages..........................................7V to –0.3V

I

TH1, ITH2

ATTNOUT Voltages ...................................2.7V to –0.3V

Peak Output Current <10µs (TG1, TG2, BG1, BG2) ... 3A

INTVCC Peak Output Current ................................ 50mA

Operating Ambient Temperature Range

(Note 2) ...................................................–40°C to 85°C

Junction Temperature (Note 3)............................. 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

EXTVCC, RUN/SS1, RUN/SS2,

CC,

, EAIN1, EAIN2, ATTNIN,

UUW

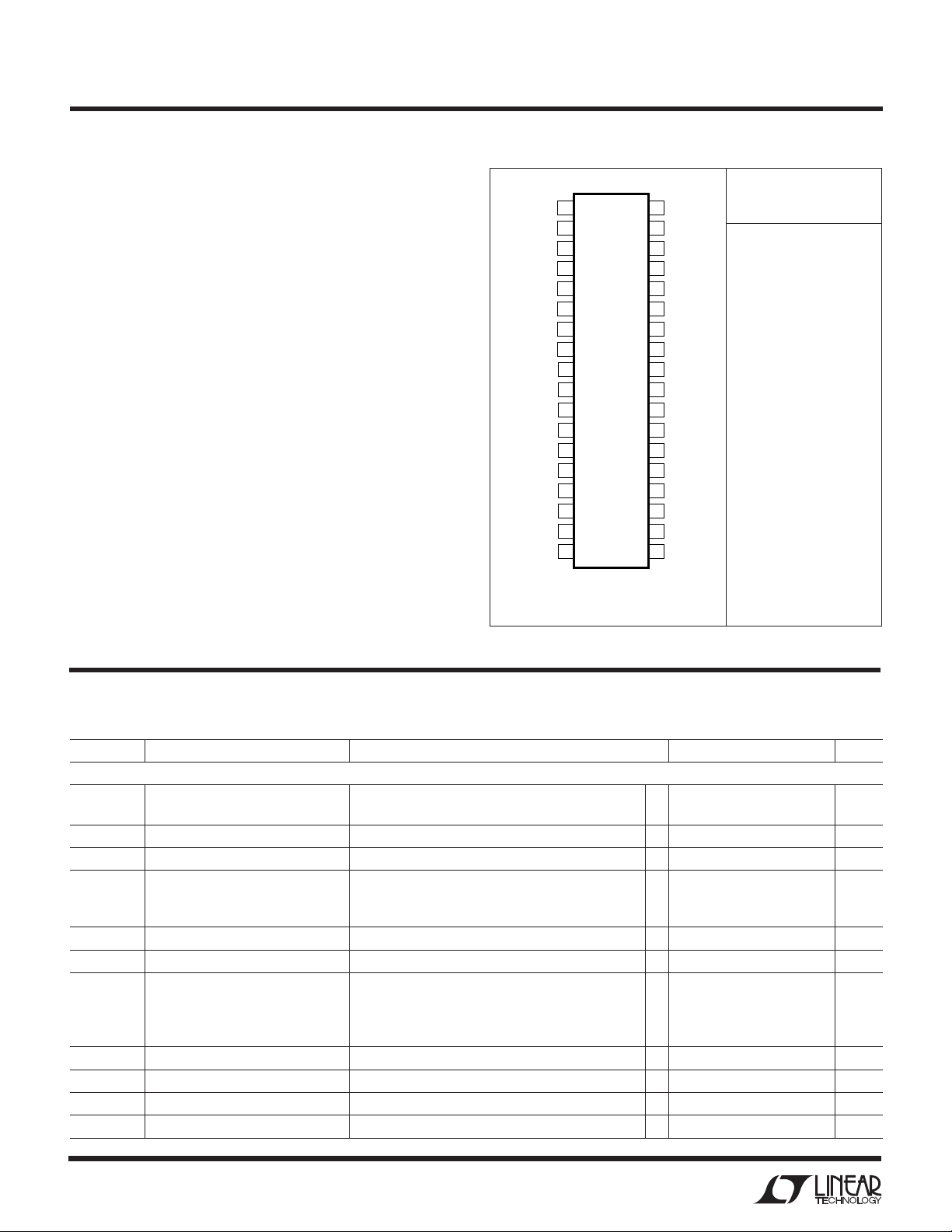

PACKAGE/ORDER I FOR ATIO

TOP VIEW

RUN/SS1

SENSE1

SENSE1

EAIN1

FREQSET

STBYMD

FCB

I

TH1

SGND

3.3V

OUT

I

TH2

EAIN2

SENSE2

SENSE2

ATTNOUT

ATTNIN

VID0

VID1

1

+

2

–

3

4

5

6

7

8

9

10

11

12

–

13

+

14

15

16

17

18

G PACKAGE

36-LEAD PLASTIC SSOP

T

= 125°C, θJA = 85°C/W

JMAX

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

19

PGOOD

TG1

SW1

BOOST1

V

IN

BG1

EXTV

CC

INTV

CC

PGND

BG2

BOOST2

SW2

TG2

RUN/SS2

VIDV

CC

VID4

VID3

VID2

Consult factory for Industrial and Military grade parts.

ORDER PART

NUMBER

LTC1708EG-PG

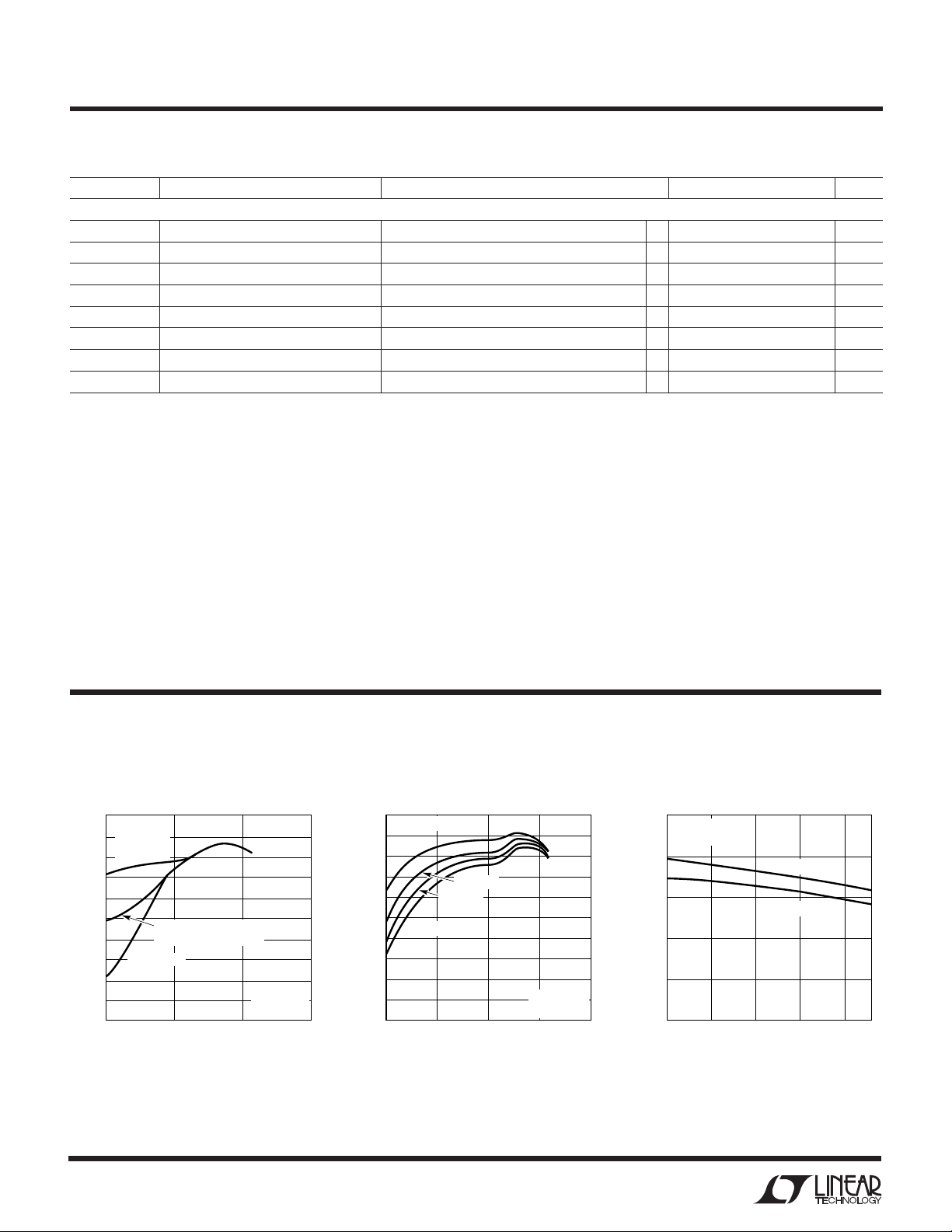

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 15V, V

The ● denotes the specifications which apply over the full operating

RUN/SS1, 2

= 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

Main Control Loops

V

EAIN1, 2

Regulated Feedback Voltage (Note 4); I

Voltage = 1.2V ● 0.792 0.800 0.808 V

TH1, 2

at EAIN Pin

I

EAIN1, 2

V

REFLNREG

V

LOADREG

g

m1, 2

g

mOL1, 2

I

Q

V

FCB

I

FCB

V

BINHIBIT

Feedback Current (Note 4) –5 – 50 nA

Reference Voltage Line Regulation VIN = 3.6V to 30V (Note 4) 0.002 0.02 %/V

Output Voltage Load Regulation (Note 4)

Transconductance Amplifier g

m

Transconductance Amplifier GBW I

Measured in Servo Loop; I

Measured in Servo Loop; I

I

= 1.2V; Sink/Source 5µA; (Note 4) 1.3 mmho

TH1, 2

= 1.2V; (gm • ZL, No Ext Load) (Note 4) 3 MHz

TH1, 2

Voltage = 1.2V to 0.7V ● 0.1 0.5 %

TH1, 2

Voltage = 1.2V to 2.0V ● –0.1 –0.5 %

TH1, 2

Input DC Supply Current (Note 5)

Normal Mode EXTV

Standby V

Shutdown V

Tied to GND; VID Inputs Open Circuit 850 µA

CC

RUN/SS1, 2

RUN/SS1, 2

= 0V, V

= 0V, V

> 2V 125 µA

STBYMD

= Open 20 35 µA

STBYMD

Forced Continuous Threshold ● 0.760 0.800 0.840 V

Forced Continuous Current V

= 0.85V –0.3 – 0.18 – 0.1 µA

FCB

Burst Inhibit Threshold Measured at FCB pin 4.3 4.8 V

UVLO Undervoltage Lockout VIN Ramping Down 3.5 4 V

2

LTC1708-PG

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 15V, V

The ● denotes the specifications which apply over the full operating

RUN/SS1, 2

= 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

OV

I

SENSE

V

STBYMD

V

STBYMD

DF

MAX

I

RUN/SS1, 2

V

RUN/SS1, 2

V

RUN/SS1, 2

I

SCL1, 2

I

SDLHO

V

SENSE(MAX)

Output Overvoltage Threshold Measured at EAIN1, 2 0.84 0.86 0.88 V

Sense Pins Total Source Current (Each Channel); V

MS Master Shutdown Threshold V

KA Keep-Alive Power On-Threshold V

SENSE1–, 2–

Ramping Down 0.4 0.6 V

STBYMD

Ramping Up, RUN

STBYMD

= V

SENSE1+, 2+

= 0V 1.5 2 V

SS1, 2

= 0V –85 –60 µA

Maximum Duty Factor In Dropout 98 99.4 %

Soft-Start Charge Current V

ON RUN/SS Pin ON Threshold V

LT RUN/SS Pin Latchoff Threshold V

RUN/SS1, 2

RUN/SS1, VRUN/SS2

RUN/SS1, VRUN/SS2

RUN/SS Discharge Current Soft Short Condition E

V

RUN/SS1, 2

= 1.9V 0.5 1.2 µA

Rising 1.0 1.5 1.9 V

Rising from 3V 4.1 4.5 V

= 0.5V; 0.5 2 4 µA

AIN1, 2

= 4.5V

Shutdown Latch Disable Current EAIN1, 2 = 0.5V 1.6 5 µA

Maximum Current Sense Threshold V

EAIN1, 2

V

EAIN1, 2

= 0.7V; V

= 0.7V; V

= 5V 65 75 85 mV

SENSE1, 2

= 5V ● 62 75 88 mV

SENSE1, 2

TG Transition Time:

TG1, 2 t

TG1, 2 t

r

f

Rise Time C

Fall Time C

= 3300pF (Note 10) 50 90 ns

LOAD

= 3300pF (Note 10) 50 90 ns

LOAD

BG Transition Time:

BG1, 2 t

BG1, 2 t

TG/BG t

r

f

1D

Rise Time C

Fall Time C

Top Gate Off to Bottom Gate On Delay C

= 3300pF (Note 10) 40 90 ns

LOAD

= 3300pF (Note 10) 40 80 ns

LOAD

= 3300pF Each Driver (Note 10) 90 ns

LOAD

Synchronous Switch-On Delay Time

BG/TG t

2D

Bottom Gate Off to Top Gate On Delay C

= 3300pF Each Driver (Note 10) 90 ns

LOAD

Top Switch-On Delay Time

t

ON(MIN)

Minimum On-Time Tested with a Square Wave (Notes 6, 10) 160 200 ns

INTVCC Linear Regulator

V

INTVCC

V

INT INTVCC Load Regulation ICC = 0 to 20mA, V

LDO

V

EXT EXTVCC Voltage Drop ICC = 20mA, V

LDO

V

EXTVCC

V

LDOHYS

Internal VCC Voltage 6V < VIN < 30V, V

EXTVCC

EXTVCC Switchover Voltage ICC = 20mA, EXTV

= 4V 4.8 5.0 5.2 V

EXTVCC

= 4V 0.2 1.0 %

EXTVCC

= 5V 120 240 mV

Ramping Positive ● 4.5 4.7 V

CC

EXTVCC Hysteresis 0.2 V

Oscillator

f

OSC

f

LOW

f

HIGH

I

FREQSET

Oscillator Frequency V

Lowest Frequency V

Highest Frequency V

FREQSET Input Current V

= Open (Note 7) 190 220 250 kHz

FREQSET

= 0V 120 140 170 kHz

FREQSET

= 2.4V 280 310 350 kHz

FREQSET

= 0V –2 – 1 µA

FREQSET

3.3V Linear Regulator

V

3.3OUT

V

3.3IL

V

3.3VL

3.3V Regulator Output Voltage No Load ● 3.25 3.35 3.45 V

3.3V Regulator Load Regulation I

3.3V Regulator Line Regulation 6V < V

= 0 to 10mA 0.5 2 %

3.3

< 30V 0.05 0.2 %

IN

PGOOD Output

V

PGL

I

PGOOD

V

PG

PGOOD Voltage Low I

PGOOD Leakage Current V

= 2mA 0.1 0.3 V

PGOOD

= 5V 1 µA

PGOOD

PGOOD Trip Level Relative to the 0.8V Regulated Feedback Voltage

EAIN1, 2 Ramping Negative from 0.8V – 10 –7.5 – 5 %

EAIN1, 2 Ramping Positive from 0.8V 5 7.5 10 %

3

LTC1708-PG

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 15V, V

The ● denotes the specifications which apply over the full operating

RUN/SS1, 2

= 5V unless otherwise noted.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

VID Parameters

VIDV

CC

I

VIDVCC

R

FBOUT1/SENSE1

R

RATIO

R

PULL-UP

V

IDT

I

VIDLEAK

V

PULL-UP

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LTC1708EG-PG is guaranteed to meet performance

specifications from 0°C to 70°C. Specifications over the –40°C to 85°C

operating temperature range are assured by design, characterization and

correlation with statistical process controls.

Note 3: T

dissipation P

LTC1708EG-PG: T

Note 4: The LTC1708-PG is tested in a feedback loop that servos V

to a specified voltage and measures the resultant EAIN1, 2.

Note 5: The supply current is higher due to the gate charge being delivered

at the switching frequency. See Applications Information.

VID Operating Supply Voltage 2.7 5.5 V

VID Supply Current VIDVCC = 3.3V (Note 8) 0.01 5 µA

Resistance Between ATTNIN/ATTNOUT 10 5 kΩ

Resistor Ratio Accuracy Programmed from 0.925V to 2.00V 0.25 %

VID0 to VID4 Pull-Up Resistance (Note 9) V

= 0.7V 40 kΩ

DIODE

VID Voltage Threshold 0.4 1.0 1.6 V

VID Input Leakage Current (Note 9) VIDVCC < VIDVCC < 7V 0.1 1 µA

VID Pull-Up Voltage VIDVCC = 3V 2.5 2.8 3.1 V

Note 6: The minimum on-time condition corresponds to the on inductor

peak-to-peak ripple current ≥40% of I

(see minimum on-time

MAX

considerations in the Applications Information section).

Note 7: V

pin internally tied to 1.19V reference through a large

FREQSET

resistance.

Note 8: With all five VID inputs floating (or tied to VIDV

is calculated from the ambient temperature TA and power

J

according to the following formulas:

D

= TA + (PD • 85°C/W)

J

ITH1, 2

current is typically <1µA. However, the VIDVCC current will rise and be

approximately equal to the number of grounded VID input pins times

– 0.6V)/40k. (See the Applications Information section.)

(VIDV

CC

Note 9: Each built-in pull-up resistor attached to the VID inputs also has a

series diode to allow input voltages higher than the VIDV

damage or clamping. (See Applications Information section.)

Note 10: Rise and fall times are measured at 20% to 80% levels. Delay

) the VIDV

CC

supply without

CC

CC

and nonoverlap times are measured using 50% levels.

UW

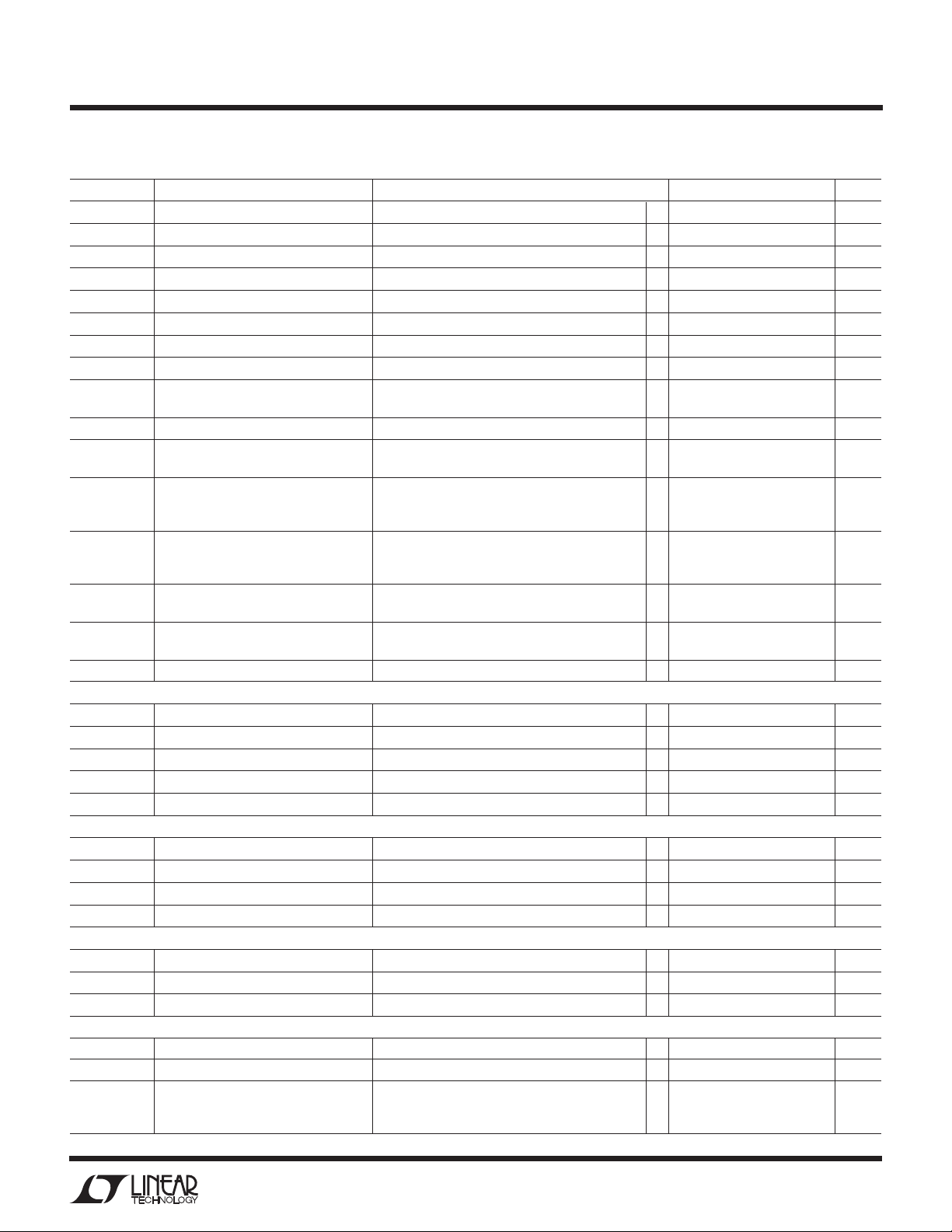

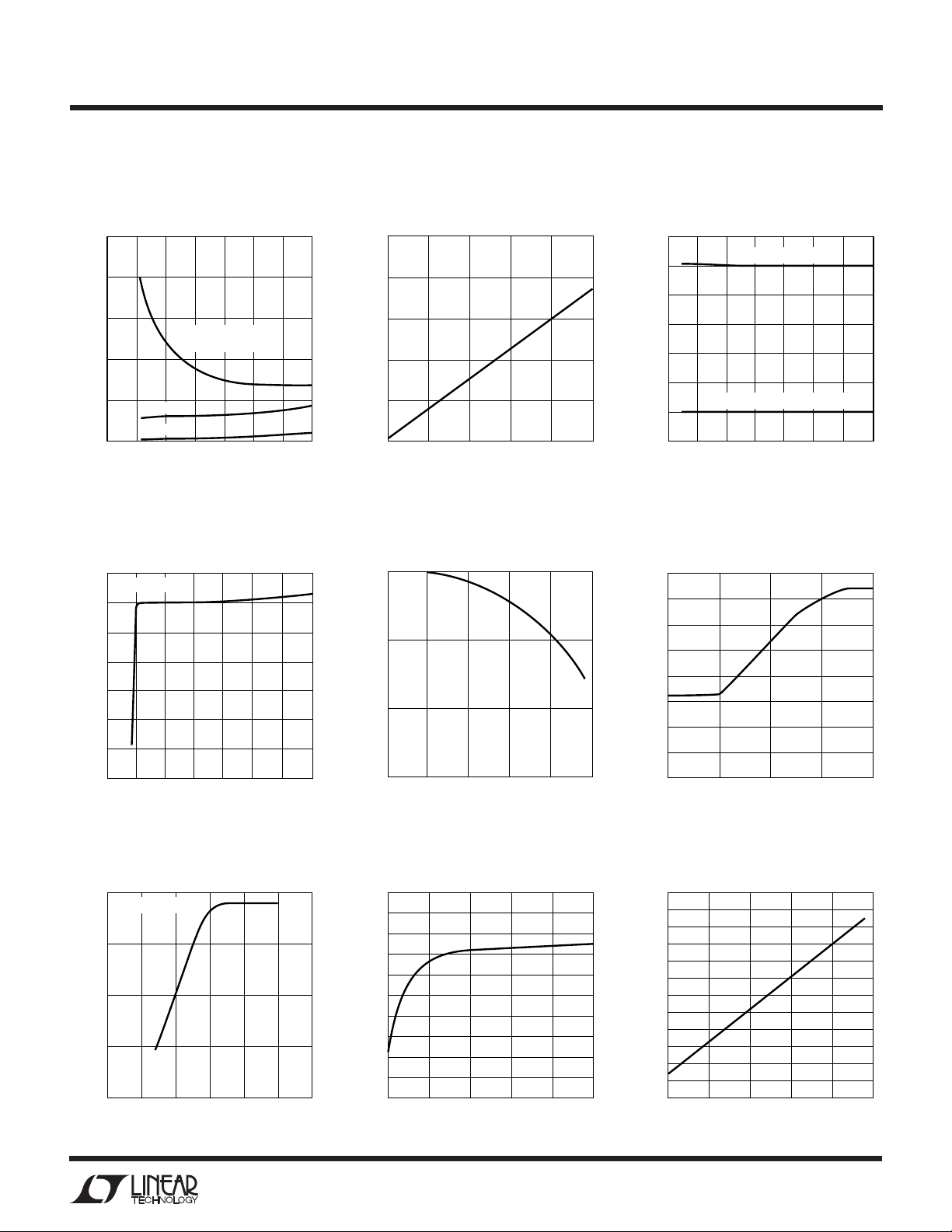

TYPICAL PERFOR A CE CHARACTERISTICS

Efficiency vs Output Current

and Mode (Figure 12)

100

90

Burst Mode

OPERATION

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.1

CONSTANT FREQUENCY

MODE

PWM MODE

1

OUTPUT CURRENT (A)

10

15A

VIN = 15V

= 1.6V

V

OUT

100

1708 G01

Efficiency vs Output Current

(Figure 12)

100

90

80

70

60

50

40

EFFICIENCY (%)

30

20

10

0

0.01

EXTV

V

IN

= 0V

CC

= 5V

VIN = 10V

V

= 15V

IN

VIN = 20V

0.1

OUTPUT CURRENT (A)

1

V

V

FCB

OUT

10

15A

= OPEN

= 1.6V

1708 G02

100

Efficiency vs Input Voltage

(Figure 12)

100

V

= 1.6V

OUT

= 0V

EXTV

CC

90

80

70

EFFICIENCY (%)

60

50

510

15 20

INPUT VOLTAGE (V)

I

I

OUT

OUT

= 7A

= 12A

25

1708 G03

28

4

UW

TEMPERATURE (°C)

–50

INTV

CC

AND EXTV

CC

SWITCH VOLTAGE (V)

4.95

5.00

5.05

25 75

1708 G06

4.90

4.85

–25 0

50 100 125

4.80

4.70

4.75

INTVCC VOLTAGE

EXTVCC SWITCHOVER THRESHOLD

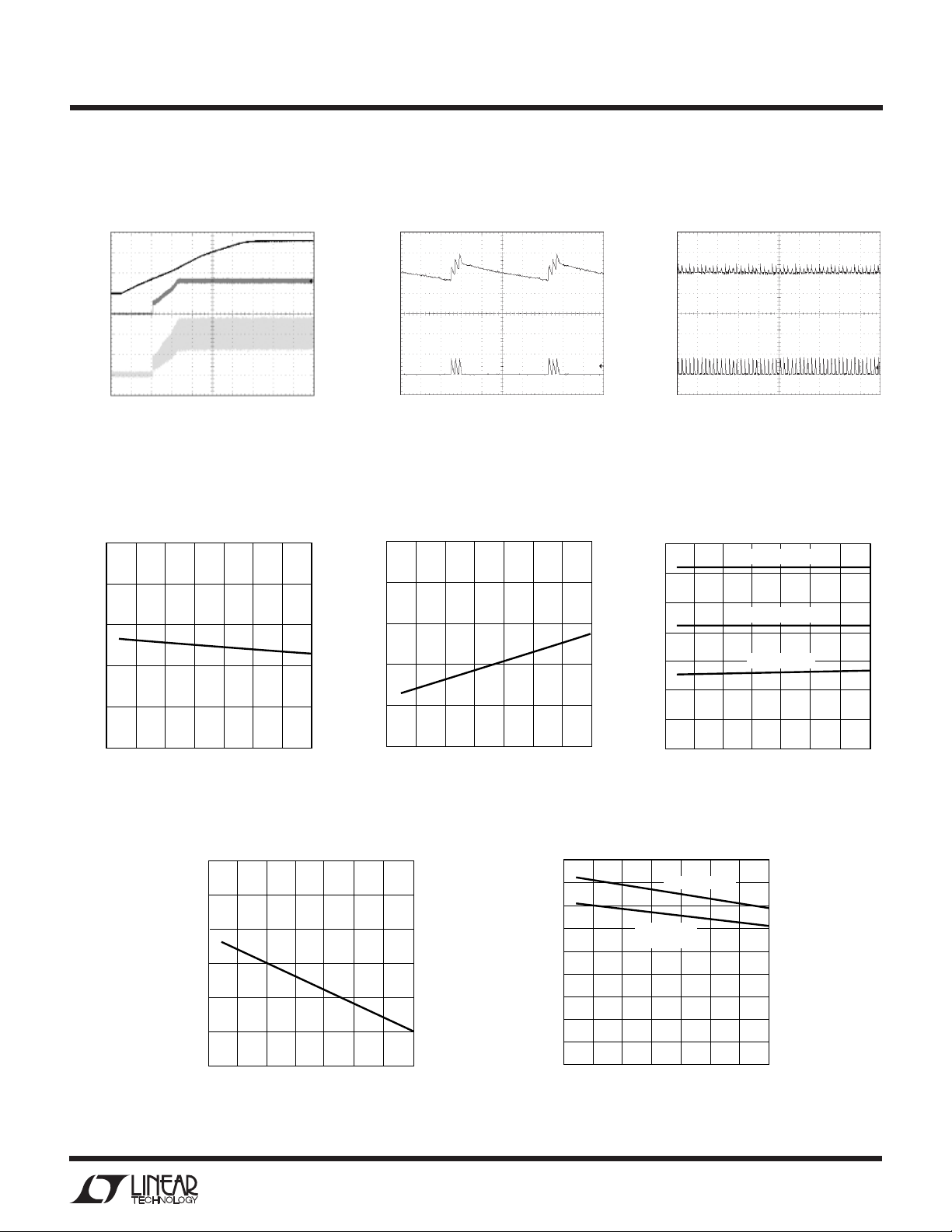

TYPICAL PERFOR A CE CHARACTERISTICS

LTC1708-PG

Supply Current vs Input Voltage

and Mode (Figure 12)

1000

800

600

400

SUPPLY CURRENT (µA)

200

0

05

BOTH

CONTROLLERS ON

STANDBY

SHUTDOWN

10

INPUT VOLTAGE (V)

20

15

Internal 5V LDO Line Reg

5.1

I

= 1mA

LOAD

5.0

4.9

4.8

VOLTAGE (V)

4.7

CC

INTV

4.6

4.5

4.4

0

510

INPUT VOLTAGE (V)

20 30 35

15 25

INTVCC and EXTVCC Switch

EXTVCC Voltage Drop

250

200

150

100

VOLTAGE DROP (mV)

CC

EXTV

50

30

35

1708 G04

25

0

10

0

CURRENT (mA)

30

40

20

50

1708 G05

Voltage vs Temperature

Maximum Current Sense Threshold

1708 G07

Maximum Current Sense Threshold

vs Duty Factor

75

50

(mV)

SENSE

V

25

0

0

20 40 60 80

DUTY FACTOR (%)

100

1708 G08

vs Percent of Nominal Output

Voltage (Foldback)

80

70

60

50

(mV)

40

SENSE

V

30

20

10

0

0

25

PERCENT ON NOMINAL OUTPUT VOLTAGE (%)

50

75

100

1708 G09

80

60

(mV)

40

SENSE

V

20

0

Maximum Current Sense Threshold

vs V

V

SENSE(CM)

0

(Soft-Start)

RUN/SS

= 1.6V

1234

V

(V)

RUN/SS

56

1708 G10

Maximum Current Sense Threshold

vs Sense Common Mode Voltage

80

76

72

(mV)

SENSE

68

V

64

60

1

0

2

COMMON MODE VOLTAGE (V)

3

Current Sense Threshold

vs ITH Voltage

90

80

70

60

50

40

(mV)

30

20

SENSE

V

10

0

–10

–20

4

5

1708 G11

–30

0.5

0

1.5

2

1

V

(V)

ITH

2.5

1708 G12

5

LTC1708-PG

UW

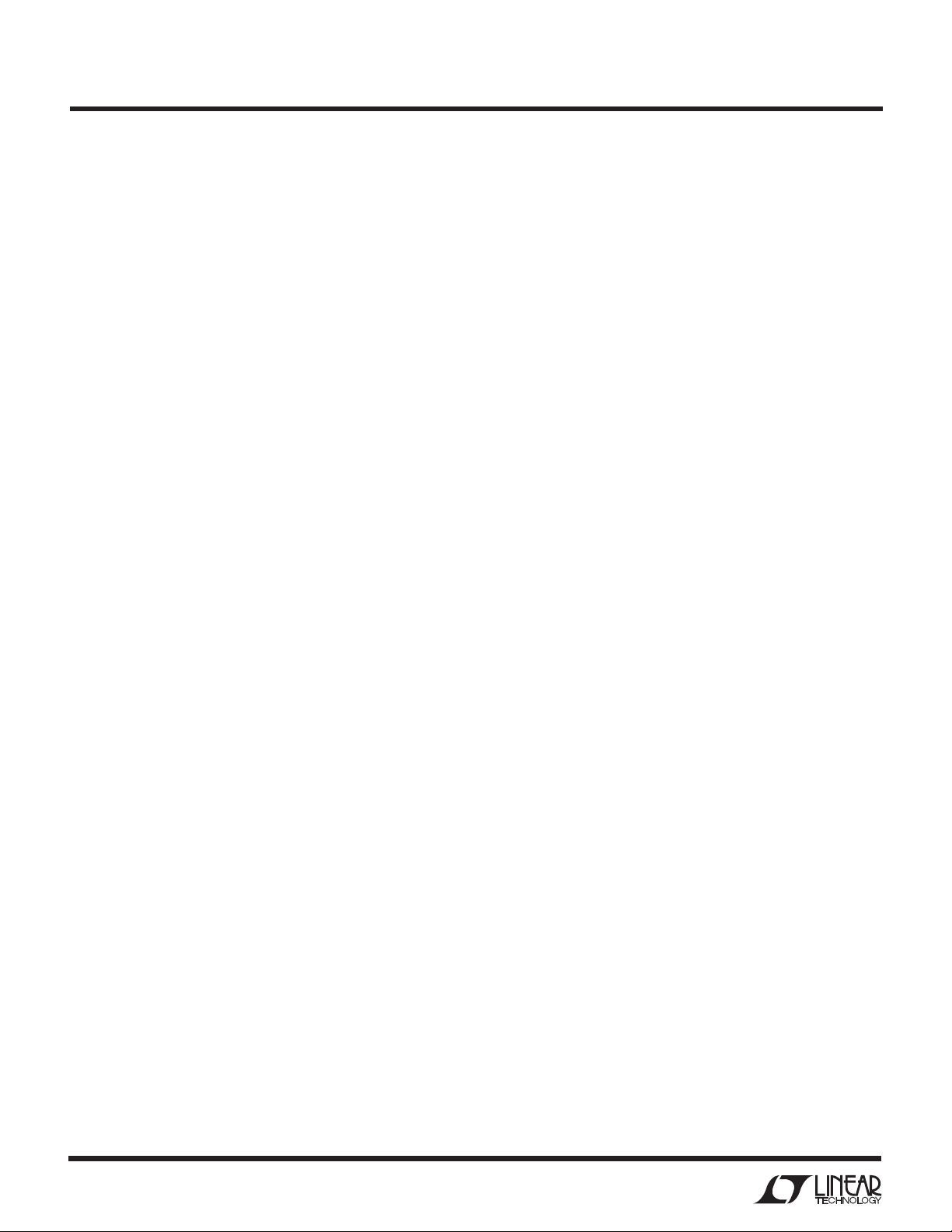

TYPICAL PERFOR A CE CHARACTERISTICS

Load Regulation

0.0

–0.1

(%)

OUT

–0.2

NORMALIZED V

–0.3

–0.4

0

1

2

LOAD CURRENT (A)

FCB = 0V

= 15V

V

IN

FIGURE 1

V

OUT2

3

4

5

1708 G13

(V)

ITH

V

2.5

2.0

1.5

1.0

0.5

V

vs V

ITH

RUN/SS

V

= 0.7V

EAIN

0

0

234

1

V

RUN/SS

(V)

Maximum Current Sense

Threshold vs Temperature Dropout Voltage vs Output Current

80

78

76

(mV)

SENSE

74

V

72

70

–50 –25

50

25

0

TEMPERATURE (°C)

100

125

1708 G17

75

4

V

= 5V

OUT

3

2

DROPOUT VOLTAGE (V)

1

0

0

0.5 1.0 1.5 2.0

OUTPUT CURRENT (A)

R

SENSE

R

= 0.015Ω

SENSE

= 0.010Ω

2.5 3.0 3.5 4.0

56

1708 G14

1708 G18

SENSE Pins Total Source Current

100

50

(µA)

0

SENSE

I

–50

–100

0

24

V

COMMON MODE VOLTAGE (V)

SENSE

RUN/SS Current vs Temperature

1.8

1.6

1.4

1.2

1.0

0.8

0.6

RUN/SS CURRENT (µA)

0.4

0.2

0

–50 –25

0 25 125

TEMPERATURE (°C)

6

1708 G15

75 10050

1708 G25

V

OUT

100mV/DIV

I

OUT

5A/DIV

6

Load Step (Figure 12)

= 15V 10µs/DIV 1708 G22

V

IN

V

= 1.6V

OUT2

LOAD STEP = 100mA – 15A

CONSTANT FREQUENCY MODE: V

ACTIVE VOLTAGE POSITIONING CIRCUIT

FCB

= V

INTVCC

V

OUT

100mV/DIV

I

OUT

5A/DIV

Load Step (Figure 12)

V

= 15V 10µs/DIV 1708 G20

IN

V

= 1.6V

OUT2

LOAD STEP = 100mA – 15A

Burst Mode OPERATION: V

ACTIVE VOLTAGE POSITIONING CIRCUIT

FCB

= OPEN

V

OUT

100mV/DIV

I

OUT

5A/DIV

Load Step (Figure 12)

VIN = 15V 10µs/DIV 1708 G21

V

= 1.6V

OUT2

LOAD STEP = 100mA – 15A

CONTINUOUS MODE: V

ACTIVE VOLTAGE POSITIONING CIRCUIT

FCB

= 0V

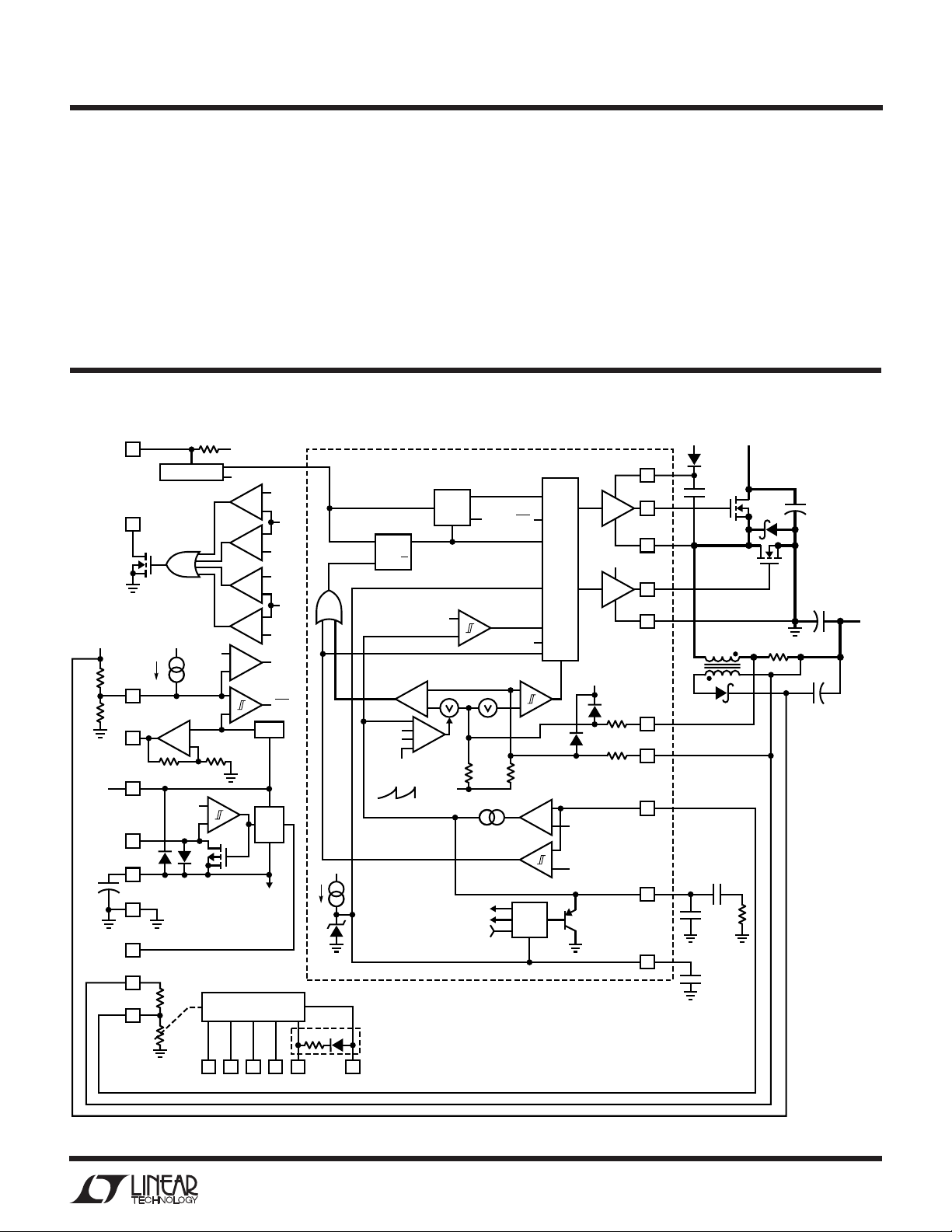

UW

TEMPERATURE (°C)

–50

200

250

350

25 75

1708 G28

150

100

–25 0

50 100 125

50

0

300

FREQUENCY (kHz)

V

FREQSET

= 5V

V

FREQSET

= OPEN

V

FREQSET

= 0V

TYPICAL PERFOR A CE CHARACTERISTICS

Soft-Start Up (Figure 12)

V

RUN/SS

2V/DIV

V

OUT

1V/DIV

I

OUT

5A/DIV

20mV/DIV

Burst Mode Operation (Figure 12)

V

OUT

I

OUT

5A/DIV

V

OUT

20mV/DIV

I

OUT

2A/DIV

LTC1708-PG

Constant Frequency (Burst Inhibit)

Operation (Figure 12)

CURRENT SENSE INPUT CURRENT (µA)

V

= 15V 100ms/DIV 1708 G19

IN

V

= 1.6V

OUT2

Current Sense Input Current

vs Temperature

35

33

31

29

27

25

–50 –25

0

TEMPERATURE (°C)

50

25

Undervoltage Lockout

vs Temperature

3.50

3.45

3.40

3.35

3.30

UNDERVOLTAGE LOCKOUT (V)

3.25

3.20

–50

–25 0

75

100

1708 G26

25 75

TEMPERATURE (°C)

10

8

6

4

SWITCH RESISTANCE (Ω)

CC

2

EXTV

125

50 100 125

0

V

= 15V 20µs/DIV 1708 G23

IN

V

= 1.6V

OUT2

= OPEN

V

FCB

I

= 250mA

OUT

EXTVCC Switch Resistance

vs Temperature

50

25

–50 –25

1708 G29

0

TEMPERATURE (°C)

75

V

IN

V

OUT2

V

FCB

I

OUT

Oscillator Frequency

vs Temperature

125

100

1708 G27

Shutdown Latch Thresholds

vs Temperature

4.5

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

SHUTDOWN LATCH THRESHOLDS (V)

0

–50 –25

LATCH ARMING

LATCHOFF

THRESHOLD

0 25 125

TEMPERATURE (°C)

= 15V 20µs/DIV 1708 G24

= 1.6V

= V

INTVCC

= 250mA

75 10050

1708 G30

7

LTC1708-PG

UUU

PI FU CTIO S

RUN/SS1, RUN/SS2 (Pins 1, 23): Combination of softstart, run control inputs and short-circuit detection timers.

A capacitor to ground at each of these pins sets the ramp

time to full output current. Forcing either of these pins

back below 1.0V causes the IC to shut down the circuitry

required for that particular controller. Latchoff overvoltage protection is also invoked via this pin as described in

the Applications Information section.

SENSE1+, SENSE2+ (Pins 2, 14): The (+) Input to the

Differential Current Comparators. The Ith pin voltage and

built-in offsets between the SENSE– and SENSE+ pins in

conjunction with R

SENSE1–, SENSE2– (Pins 3, 13): The (–) Input to the

Differential Current Comparators.

EAIN1, EAIN2 (Pins 4, 12): Receives the remotely sensed

feedback voltage for each controller from a resistive

divider across the output. The VID section may be used for

one resistive divider.

FREQSET (Pin 5): Frequency Control Input to the Oscillator. This pin can be left open, tied to ground, tied to INTV

or driven by an external voltage source. This pin can also

be used with an external phase detector to build a true

phase-locked loop.

STBYMD (Pin 6): Control pin that determines which circuitry remains active when the controllers are shut down

and/or provides a common control point to shut down

both controllers. See the Operation section for details.

FCB (Pin 7): Forced Continuous Control Input. This input

acts on both controllers and is normally used to regulate

a secondary winding using a resistive divider. An applied

input voltage below 0.8V will force continuous synchronous operation on both controllers. Do not leave this pin

floating.

I

TH1, ITH2

ing Regulator Compensation Point. Each associated channels’ current comparator trip point increases with this

control voltage.

SGND (Pin 9): Small-Signal Ground. Common to both

controllers, this pin must be routed separately from high

current grounds to the common (–) terminals of the

C

OUT

(Pins 8, 11): Error Amplifier Output and Switch-

capacitors.

sets the current trip threshold.

SENSE

CC

3.3V

supplying 10mA DC with peak currents as high as 50mA.

ATTNOUT (Pin 15): Divided down output voltage feeding

the EAIN pin of the regulator. The VID inputs program a

resistive divider between ATTNIN and SGND. ATTNOUT is

the tap point on the divider. The voltage on ATTNOUT is

0.8V when the output is in regulation. This pin can be

bypassed to SGND with 50pF.

ATTNIN (Pin 16): Receives the remotely sensed feedback

voltage from the output.

VID0 to VID4 (Pins 17 to 21): Digital inputs for controlling

the output voltage from 0.925V to 2.0V. Table 1 specifies

the output voltage for the 32 combinations of digital

inputs. The LSB (VID0) represents 50mV increments in

the upper voltage range (2.00V to 1.30V) and 25mV

increments in the lower voltage range (1.275V to 0.925V).

Logic Low = GND, Logic High = VIDVCC or Float.

VIDVCC (Pin 22): VID Input Supply Voltage. Range from

2.7V to 5.5V. Typically this pin is tied to INTVCC.

PGND (Pin 28): Driver Power Ground. Connects to the

sources of bottom (synchronous) N-channel MOSFETs, anode of the Schottky rectifier and the (–) terminal(s) of CIN.

INTVCC (Pin 29): Output of the Internal 5V Linear Low

Dropout Regulator and the EXTVCC Switch. The driver and

control circuits are powered from this voltage source. Must

be decoupled to power ground with a minimum of 4.7µF

tantalum or other low ESR capacitor. The INTVCC regulator

standby function is determined by the STBYMD pin.

EXTVCC (Pin 30): External Power Input to an Internal

Switch Connected to INTVCC. This switch closes and

supplies VCC power, bypassing the internal low dropout

regulator, whenever EXTVCC is higher than 4.7V. See

EXTVCC connection in Applications Information section.

Do not exceed 7V on this pin.

BG1, BG2 (Pins 31, 27): High Current Gate Drives for

Bottom (Synchronous) N-Channel MOSFETs. Voltage

swing at these pins is from ground to INTVCC.

VIN (Pin 32): Main Supply Pin. A bypass capacitor should

be tied between this pin and the signal ground pin.

(Pin 10): Output of a linear regulator capable of

OUT

8

UUU

PI FU CTIO S

LTC1708-PG

BOOST1, BOOST2 (Pins 33, 26): Bootstrapped Supplies

to the Topside Floating Drivers. Capacitors are connected

between the boost and switch pins and Schottky diodes

are tied between the boost and INTV

at the boost pins is from INTV

CC

pins. Voltage swing

CC

to (VIN + INTVCC).

SW1, SW2 (Pins 34, 25): Switch Node Connections to

Inductors. Voltage swing at these pins is from a Schottky

diode (external) voltage drop below ground to VIN.

UU

W

FU CTIO AL DIAGRA

V

V

SEC

IN

+

FREQSET

PGOOD

3.3V

EXTV

INTV

5V

STBYMD

ATTNIN

ATTNOUT

VARIABLE

FCB

V

SGND

0.17µA

OUT

IN

CC

CC

R1

1M

OSCILLATOR

4.5V

0.8V

+

–

4.8V

R2

10k

1.19V

CLK1

CLK2

–

+

–

+

–

+

–

+

–

+

+

–

V

REF

+

–

5-BIT VID DECODER

5V

LDO

REG

INTERNAL

SUPPLY

0.86V

V

0.74V

0.86V

V

0.74V

BINH

FCB

DUPLICATE FOR SECOND

CONTROLLER CHANNEL

DROP

OUT

FB1

SRQ

FB2

0.86V

4(VFB)

SLOPE

COMP

1.2µA

6V

40k

EACH VID

INPUT

DET

Q

+

0.6V

–

I

1

+

+– –+

–

45k

2.4V

4(VFB)

TG1, TG2 (Pins 35, 24): High Current Gate Drives for Top

N-Channel MOSFETs. These are the outputs of floating

drivers with a voltage swing equal to INTV

CC

– 0.5V

superimposed on the switch node voltage SW.

PGOOD (Pin 36): Open-Drain Logic Output. PGOOD is

pulled to ground when the voltage at either EAIN pin is not

within 7.5% of the setpoint.

V

CC

IN

D

B

C

B

D

SEC

C

C

R

C

C

C2

C

SS

D

R

1

SENSE

+

C

IN

C

OUT

+

+

C

SEC

SHDN

RST

BOT

3mV

TOP ON

FCB

SHDN

–

+

45k

OV

RUN

SOFTSTART

I

2

EA

SWITCH

LOGIC

–

+

+

–

V

FB

0.800V

0.860V

TOP

BOT

INTV

INTV

CC

30k

30k

CC

BOOST

TG

SW

BG

PGND

SENSE

SENSE

EAIN

I

TH

RUN/SS

INTV

+

–

V

OUT

VID0

VID1 VID2 VID3 VID4

VIDV

CC

1708 F02

Figure 2

9

LTC1708-PG

U

OPERATIO

(Refer to Functional Diagram)

Main Control Loop

The LTC1708 uses a constant frequency, current mode

step-down architecture with the two controller channels

operating 180 degrees out of phase. During normal operation, each top MOSFET is turned on when the clock for that

channel sets the RS latch, and turned off when the main

current comparator, I1, resets the RS latch. The peak

inductor current at which I1 resets the RS latch is controlled by the voltage on the I

each error amplifier EA. The EAIN pin receives the voltage

feedback signal, which is compared to the internal reference voltage by the EA. When the load current increases,

it causes a slight decrease in EAIN relative to the 0.8V

reference, which in turn causes the ITH voltage to increase

until the average inductor current matches the new load

current. After the top MOSFET has turned off, the bottom

MOSFET is turned on until either the inductor current

starts to reverse, as indicated by current comparator I2, or

the beginning of the next cycle.

The top MOSFET drivers are biased from floating bootstrap capacitor CB, which normally is recharged during

each off cycle through an external diode when the top

MOSFET turns off. As VIN decreases to a voltage close to

V

, the loop may enter dropout and attempt to turn on

OUT

the top MOSFET continuously. The dropout detector detects this and forces the top MOSFET off for about 500ns

every tenth cycle to allow CB to recharge.

The main control loop is shut down by pulling the RUN/SS

pin low. Releasing RUN/SS allows an internal 1.2µA

current source to charge soft-start capacitor CSS. When

CSS reaches 1.5V, the main control loop is enabled with the

ITH voltage clamped at approximately 30% of its maximum

value. As CSS continues to charge, the I

gradually released allowing normal, full-current operation. When both RUN/SS1 and RUN/SS2 are low, all

LTC1708 controller functions are shut down, and the

STBYMD pin determines if the standby 5V and 3.3V

regulators are kept alive.

Low Current Operation

The FCB pin is a multifunction pin providing two functions: 1) to provide regulation for a secondary winding by

temporarily forcing continuous PWM operation on

pin, which is the output of

TH

pin voltage is

TH

controller 1 and 2) select between

current operation. When the FCB pin voltage is below

0.8V, the controller forces continuous PWM current

mode operation. In this mode, the top and bottom

MOSFETs are alternately turned on to maintain the output

voltage independent of direction of inductor current.

When the FCB pin is below V

0.8V, the controller enters Burst Mode operation. Burst

Mode operation sets a minimum output current level

before inhibiting the top switch and turns off the synchronous MOSFET(s) when the inductor current goes negative. This combination of requirements will, at low currents, force the ITH pin below a voltage threshold that will

temporarily inhibit turn-on of both output MOSFETs until

the output voltage drops. There is 60mV of hysteresis in

the burst comparator B tied to the ITH pin. This hysteresis

produces output signals to the MOSFETs that turn them

on for several cycles, followed by a variable “sleep”

interval depending upon the load current. The resultant

output voltage ripple is held to a very small value by

having the hysteretic comparator after the error amplifier

gain block.

Constant Frequency Operation

When the FCB pin is tied to INTVCC, Burst Mode operation

is disabled and the forced minimum output current requirement is removed. This provides constant frequency,

discontinuous (preventing reverse inductor current) current operation over the widest possible output current

range. This constant frequency operation is not as efficient

as Burst Mode operation, but does provide a lower noise,

constant frequency operating mode down to approximately 1% of designed maximum output current.

Continuous Current (PWM) Operation

Tying the FCB pin to ground will force continuous current

operation. This is the least efficient operating mode, but

may be desirable in certain applications. The output can

source or sink current in this mode. When sinking current

while in forced continuous operation, current will be

forced back into the main power supply potentially boosting the input supply to dangerous voltage levels—

BEWARE!

INTVCC

two

modes of low

␣ –␣ 2V but greater than

10

Loading...

Loading...