Page 1

FEATURES

prop

LT3080

Adjustable1.1A Single

Resistor Low Dropout

Regulator

U

DESCRIPTIO

■

Outputs May be Paralleled for Higher Current and

Heat Spreading

■

Output Current: 1.1A

■

Single Resistor Programs Output Voltage

■

1% Initial Accuracy of SET Pin Current

■

Output Adjustable to 0V

■

Low Output Noise: 40μV

■

Wide Input Voltage Range: 1.2V to 36V

■

Low Dropout Voltage: 300mV

■

<1mV Load Regulation

■

<0.001%/V Line Regulation

■

Minimum Load Current: 0.5mA

■

Stable with 2.2μF Minimum Ceramic Output

(10Hz to 100kHz)

RMS

Capacitor

■

Current Limit with Foldback and Overtemperature

Protected

■

Available in 8-Lead MSOP, 3mm × 3mm DFN,

5-Lead TO-220 and 3-Lead SOT-223

U

APPLICATIO S

■

High Current All Surface Mount Supply

■

High Effi ciency Linear Regulator

■

Post Regulator for Switching Supplies

■

Low Parts Count Variable Voltage Supply

■

Low Output Voltage Power Supplies

The LT®3080 is a 1.1A low dropout linear regulator that can

be paralleled to increase output current or spread heat in

surface mounted boards. Architected as a precision current source and voltage follower allows this new regulator

to be used in many applications requiring high current,

adjustability to zero, and no heat sink. Also the device

brings out the collector of the pass transistor to allow low

dropout operation —down to 300 millivolts— when used

with multiple supplies.

A key feature of the LT3080 is the capability to supply a

wide output voltage range. By using a reference current

through a single resistor, the output voltage is programmed

to any level between zero and 36V. The LT3080 is stable

with 2.2μF of capacitance on the output, and the IC uses

small ceramic capacitors that do not require additional

ESR as is common with other regulators.

Internal protection circuitry includes current limiting and

thermal limiting. The LT3080 regulator is offered in the

8-lead MSOP (with an Exposed Pad for better thermal

characteristics), a 3mm × 3mm DFN, 5-lead TO-220 and

a simple-to-use 3-lead SOT-223 version.

, LT, LTC and LTM are registered trademarks of Linear Technology Corporation. All other

trademarks are the

erty of their respective owners.

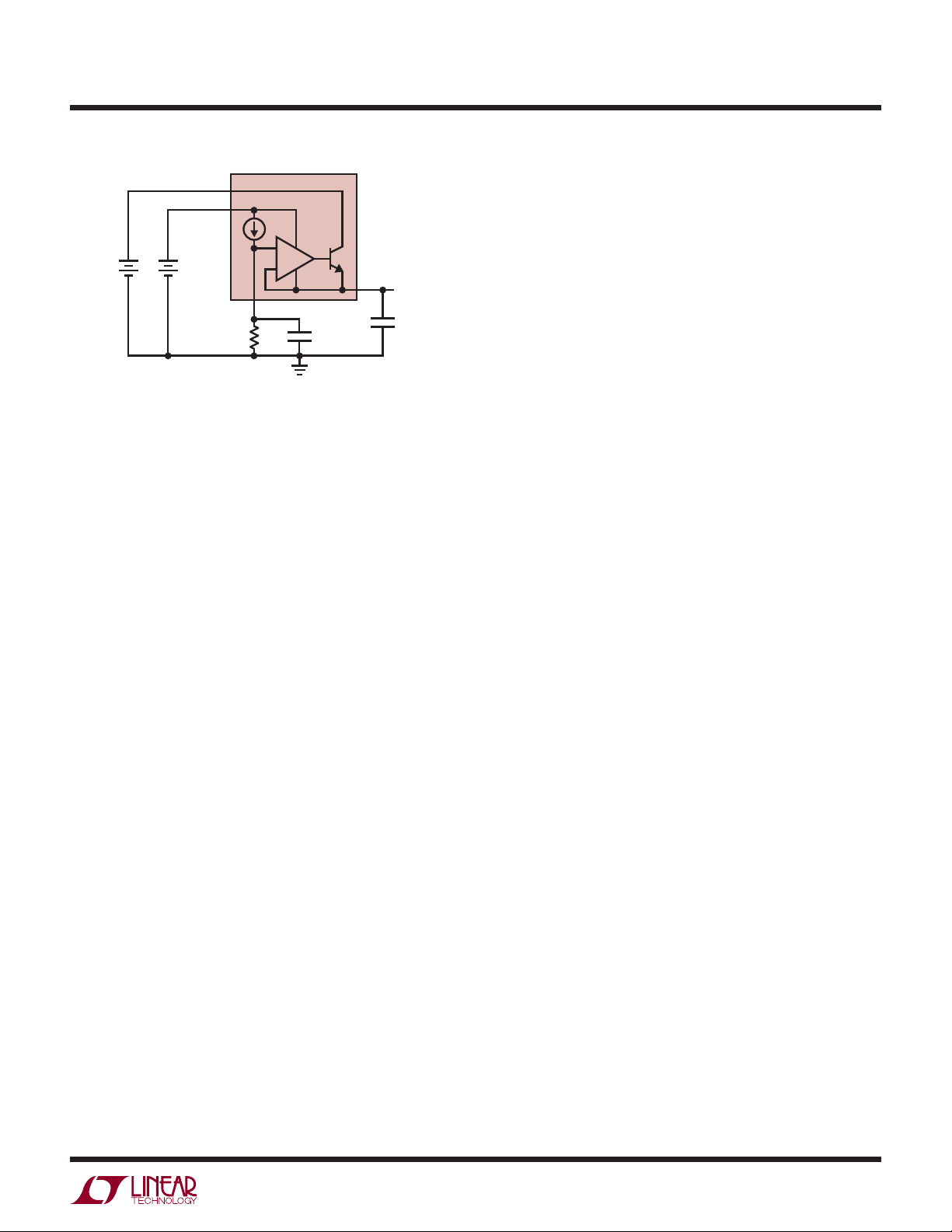

TYPICAL APPLICATIO

Variable Output Voltage 1.1A Supply

SET

LT3080

R

SET

V

OUT

+

–

V

1.2V TO 36V

V

CONTROL

1μF

IN

IN

= R

SET

U

• 10μA

OUT

3080 TA01a

V

OUT

2.2μF

Set Pin Current Distribution

N = 13792

9.80

9.90

SET PIN CURRENT DISTRIBUTION (μA)

10.00

10.10

3080 G02

10.20

3080f

1

Page 2

LT3080

(

WW

W

ABSOLUTE AXI U RATI GS

V

CONTROL

Pin Voltage ..................................... 40V, –0.3V

U

(Note 1)(All Voltages Relative to V

IN Pin Voltage ................................................ 40V, –0.3V

SET Pin Current (Note 7) .....................................±10mA

SET Pin Voltage (Relative to OUT) .........................±0.3V

Output Short-Circuit Duration .......................... Indefi nite

PIN CONFIGURATION

TOP VIEW

1OUT

OUT

2

OUT

3

SET

4

8-LEAD

T

= 125°C, θJA = 64°C/W, θJC = 3°C/W

JMAX

EXPOSED PAD (PIN 9) IS OUT, MUST BE SOLDERED TO PCB

9

DD PACKAGE

3mm × 3mm) PLASTIC DFN

8

7

6

5

IN

IN

NC

V

CONTROL

)

OUT

Operating Junction Temperature Range

(Notes 2, 10) .......................................... –40°C to 125°C

Storage Temperature Range: .................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)

MS8E, T and ST Packages Only ........................ 300°C

TOP VIEW

8

OUT

1

OUT

2

OUT

SET

T

EXPOSED PAD (PIN 9) IS OUT, MUST BE SOLDERED TO PCB

8-LEAD PLASTIC MSOP

= 125°C, θJA = 60°C/W, θJC = 10°C/W

JMAX

9

3

4

MS8E PACKAGE

IN

7

IN

6

NC

5

V

CONTROL

FRONT VIEW

3

IN*

TAB IS

OUT

ST PACKAGE

3-LEAD PLASTIC SOT-223

AND IN TIED TOGETHER

CONTROL

= 125°C, θJA = 55°C/W, θJC = 15°C/W

JMAX

2

OUT

1

SET

TAB IS

OUT

FRONT VIEW

5

4

3

2

1

T PACKAGE

5-LEAD PLASTIC TO-220

T

= 125°C, θJA = 40°C/W, θJC = 3°C/W

JMAX

IN

V

CONTROL

OUT

SET

NC

*IN IS V

T

ORDER INFORMATION

LEAD FREE FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3080EDD#PBF LT3080EDD#TRPBF LCBN 8-Lead (3mm × 3mm) Plastic DFN –40°C to 125°C

LT3080EMS8E#PBF LT3080EMS8E#TRPBF LTCBM 8-Lead Plastic MSOP –40°C to 125°C

LT3080ET#PBF LT3080ET#TRPBF LT3080ET 5-Lead Plastic TO-220 –40°C to 125°C

LT3080EST#PBF LT3080EST#TRPBF 3080 3-Lead Plastic SOT-223 –40°C to 125°C

LEAD BASED FINISH TAPE AND REEL PART MARKING PACKAGE DESCRIPTION TEMPERATURE RANGE

LT3080EDD LT3080EDD#TR LCBN 8-Lead (3mm × 3mm) Plastic DFN –40°C to 125°C

LT3080EMS8E LT3080EMS8E#TR LTCBM 8-Lead Plastic MSOP –40°C to 125°C

LT3080ET LT3080ET#TR LT3080ET 5-Lead Plastic TO-220 –40°C to 125°C

LT3080EST LT3080EST#TR 3080 3-Lead Plastic SOT-223 –40°C to 125°C

Consult LTC Marketing for parts specifi ed with wider operating temperature ranges.

For more information on lead free part marking, go to: http://www.linear.com/leadfree/

For more information on tape and reel specifi cations, go to: http://www.linear.com/tapeandreel/

3080f

2

Page 3

LT3080

The ● denotes the specifi cations which apply over the full operating

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifi cations are at T

PARAMETER CONDITIONS MIN TYP MAX UNITS

SET Pin Currrent I

Output Offset Voltage (V

V

= 1V, V

IN

CONTROL

= 2V, I

OUT

OUT

– V

= 1mA

SET

)

V

Load Regulation ΔI

ΔV

Line Regulation (Note 9)

DFN and MSOP Package

Line Regulation (Note 9)

SOT-223 and TO-220 Package

ΔI

ΔV

ΔI

ΔV

Minimum Load Current (Notes 3, 9) VIN = V

V

Dropout Voltage (Note 4) I

CONTROL

VIN Dropout Voltage (Note 4) I

CONTROL Pin Current I

Current Limit VIN = 5V, V

Error Amplifi er RMS Output Noise (Note 6) I

Reference Current RMS Output Noise (Note 6) 10Hz ≤ f ≤ 100kHz 1 nA

Ripple Rejection f = 120Hz, V

Thermal Regulation, I

SET

Note 1: Stresses beyond those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to any Absolute

Maximum Rating condition for extended periods may affect device

reliability and lifetime.

Note 2: Unless otherwise specifi ed, all voltages are with respect to V

The LT3080 is tested and specifi ed under pulse load conditions such that

T

≈ TA. The LT3080 is 100% tested at TA = 25°C. Performance at –40°C

J

and 125°C is assured by design, characterization and correlation with

statistical process controls.

Note 3: Minimum load current is equivalent to the quiescent current of

the part. Since all quiescent and drive current is delivered to the output

of the part, the minimum load current is the minimum current required to

maintain regulation.

Note 4: For the LT3080, dropout is caused by either minimum control

voltage (V

) or minimum input voltage (VIN). Both parameters are

CONTROL

specifi ed with respect to the output voltage. The specifi cations represent the

minimum input-to-output differential voltage required to maintain regulation.

Note 5: The CONTROL pin current is the drive current required for the

output transistor. This current will track output current with roughly a 1:60

ratio. The minimum value is equal to the quiescent current of the device.

Note 6: Output noise is lowered by adding a small capacitor across the

voltage setting resistor. Adding this capacitor bypasses the voltage setting

VIN = 1V, V

SET

V

≥ 1V, V

IN

DFN and MSOP Package

OS

SOT-223 and T0-220 Package

ΔI

SET

SET

SET

OS

LOAD =

ΔI

OS

LOAD =

VIN = 1V to 25V, V

V

OS

IN

VIN = 1V to 26V, V

V

IN

V

IN

V

IN

LOAD

I

LOAD

LOAD

I

LOAD

LOAD

I

LOAD

LOAD

= 1V to 25V, V

= 1V to 26V, V

= V

= V

f = 10kHz

f = 1MHz

10ms Pulse 0.003 %/W

= 25°C. (Note 11)

A

CONTROL

CONTROL

= 2.0V, I

≥ 2.0V, 1mA ≤ I

= 1mA, TJ = 25°C

LOAD

1mA to 1.1A

1mA to 1.1A (Note 8)

=1V to 25V, I

CONTROL

=1V to 25V, I

CONTROL

=1V to 26V, I

CONTROL

=1V to 26V, I

CONTROL

= 10V

CONTROL

= 25V (DFN and MSOP Package)

CONTROL

= 26V (SOT-223 and TO-220 Package)

CONTROL

= 100mA

= 1.1A

= 100mA

= 1.1A

= 100mA

= 1.1A

CONTROL

= 5V, V

SET

= 0V, V

= 1.1A, 10Hz ≤ f ≤ 100kHz, C

RIPPLE

= 0.5V

P-P

, I

LOAD

= 0.2A, C

resistor shot noise and reference current noise; output noise is then equal

to error amplifi er noise (see Applications Information section).

Note 7: SET pin is clamped to the output with diodes. These diodes only

carry current under transient overloads.

.

OUT

Note 8: Load regulation is Kelvin sensed at the package.

Note 9: Current limit may decrease to zero at input-to-output differential

voltages (V

(SOT-223 and TO-220 package). Operation at voltages for both IN and

V

CONTROL

between input and output voltage is below the specifi ed differential (V

V

OUT

when the device is in current limit.

Note 10: This IC includes over-temperature protection that is intended

to protect the device during momentary overload conditions. Junction

temperature will exceed the maximum operating junction temperature

when over-temperature protection is active. Continuous operation above

the specifi ed maximum operating junction temperature may impair device

reliability.

Note 11: The SOT-223 package connects the IN and V

together internally. Therefore, test conditions for this pin follow the

V

CONTROL

≤ 1.1A (Note 9)

LOAD

●

●

●

9.90

9.801010

–2

–3.5

–5

–6

10.10

10.20

2

3.5

5

6

–0.1

LOAD

LOAD

LOAD

LOAD

=1mA

=1mA

=1mA

=1mA

●

●

●

●

●

●

0.6 1.3

0.1

0.003

0.1

0.003

300 500

0.5 nA/V

0.5 nA/V

1

1

1.2

OUT

= 10μF, C

OUT

= –0.1V

SET

= 0.1μF, C

SET

●

●

●

●

●

●

= 0.1μF 40 μV

= 2.2μF

OUT

1.35 1.6

100

350

17

200

500

4

6

30

1.1 1.4 A

75

55

20

) greater than 25V (DFN and MSOP package) or 26V

IN–VOUT

is allowed up to a maximum of 36V as long as the difference

) voltage. Line and load regulation specifi cations are not applicable

pins

CONTROL

conditions listed in the Electrical Characteristics Table.

μA

μA

mV

mV

mV

mV

nA

mV

mV/V

mV/V

μA

mA

mA

mV

mV

mA

mA

RMS

RMS

dB

dB

dB

–

IN

3080f

V

V

3

Page 4

LT3080

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Set Pin Current

10.20

10.15

10.10

10.05

10.00

9.95

SET PIN CURRENT (μA)

9.90

9.85

9.80

–50

–25

0

50

25

TEMPERATURE (°C)

75

100

125

150

3080 G01

Offset Voltage Distribution

N = 13250

–2

–1

VOS DISTRIBUTION (mV)

Load Regulation Minimum Load Current

0

ΔI

= 1mA TO 1.1A

LOAD

– V

V

–0.1

IN

OUT

–0.2

–0.3

–0.4

–0.5

–0.6

–0.7

CHANGE IN OFFSET VOLTAGE WITH LOAD (mV)

–0.8

CHANGE IN REFERENCE CURRENT

CHANGE IN OFFSET VOLTAGE

–50

–25

0

0

= 2V

(V

– V

OUT

25

TEMPERATURE (°C)

)

SET

50

75

100

125

3080 G04

3080 G07

2

CHANGE IN REFERENCE CURRENT WITH LOAD (nA)

20

10

0

–10

–20

–30

–40

–50

–60

150

1

Set Pin Current Distribution Offset Voltage (V

N = 13792

9.80

9.90

SET PIN CURRENT DISTRIBUTION (μA)

Offset Voltage Offset Voltage

1.00

I

= 1mA

LOAD

0.75

0.50

0.25

0

–0.25

OFFSET VOLTAGE (mV)

–0.50

–0.75

–1.00

0.8

0.7

0.6

0.5

0.4

0.3

0.2

MINIMUM LOAD CURRENT (mA)

0.1

612 24

0

INPUT-TO-OUTPUT VOLTAGE (V)

*SEE NOTE 9 IN ELECTRICAL

CHARACTERISTICS TABLE

V

IN, CONTROL

V

IN, CONTROL

0

–50

–25

0

25

TEMPERATURE (°C)

*SEE NOTE 9 IN ELECTRICAL

CHARACTERISTICS TABLE

– V

– V

10.00

18

OUT

OUT

50

= 36V*

= 1.5V

75

10.10

100

– V

2.0

OUT

IL = 1mA

1.5

1.0

0.5

0

–0.5

OFFSET VOLTAGE (mV)

–1.0

–1.5

36*

–2.0

–50

0.25

0

–0.25

–0.50

–0.75

–1.00

OFFSET VOLTAGE (mV)

–1.25

–1.50

–1.75

–25

0

TEMPERATURE (°C)

TJ = 125°C

0.2 0.4 0.8

0

LOAD CURRENT (A)

25

TJ = 25°C

50

0.6

10.20

3080 G02

30

3080 G05

)

SET

75

100

1.0

125

150

3080 G03

1.2

3080 G06

Dropout Voltage (Minimum IN

Voltage)

400

350

125

3080 G08

150

) (mV)

OUT

300

– V

250

IN

200

150

100

50

MINIMUM IN VOLTAGE (V

0

0.2 0.4 0.8

0

OUTPUT CURRENT (A)

TJ = 125°C

0.6

TJ = 25°C

1.0

1.2

3080 G09

4

3080f

Page 5

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT3080

Dropout Voltage (Minimum IN

Voltage)

400

350

) (mV)

OUT

300

– V

IN

250

I

200

150

100

50

MINIMUM IN VOLTAGE (V

0

–25

–50

0

TEMPERATURE (°C)

LOAD

I

LOAD

50

25

Current Limit

1.6

1.4

1.2

VIN = 7V

1.0

0.8

0.6

CURRENT LIMIT (A)

0.4

0.2

0

–50

V

–25

OUT

= 0V

0

50

25

TEMPERATURE (°C)

I

LOAD

= 500mA

= 100mA

75

75

= 1.1A

100

100

125

125

3080 G10

3080 G13

150

150

Dropout Voltage (Minimum

Pin Voltage)

TJ = –50°C

TJ = 25°C

0.2 0.4 0.8

0.6

OUTPUT CURRENT (A)

) (V)

1.6

OUT

1.4

– V

1.2

CONTROL

1.0

0.8

0.6

0.4

0.2

0

MINIMUM CONTROL VOLTAGE (V

V

CONTROL

0

Current Limit

1.6

1.4

1.2

1.0

0.8

0.6

CURRENT LIMIT (A)

MSOP

0.4

0.2

0

612 24

0

INPUT-TO-OUTPUT DIFFERENTIAL (V)

*SEE NOTE 9 IN ELECTRICAL

CHARACTERISTICS TABLE

SOT-223

AND

TO-220

AND

DFN

18

TJ = 125°C

TJ = 25°C

1.0

30

3080 G11

3080 G14

1.2

36*

Dropout Voltage (Minimum

) (V)

1.6

OUT

1.4

– V

1.2

CONTROL

1.0

0.8

0.6

0.4

0.2

0

MINIMUM CONTROL VOLTAGE (V

–50

V

CONTROL

–25

0

Pin Voltage)

I

= 1mA

LOAD

50

25

TEMPERATURE (°C)

Load Transient Response

75

50

25

0

–25

–50

OUTPUT VOLTAGE DEVIATION (mV)LOAD CURRENT (mA)

400

300

200

100

C

OUT

0

105

0

C

OUT

= 2.2μF CERAMIC

2015

25

TIME (μs)

I

= 1.1A

LOAD

75

100

V

= 1.5V

OUT

= 0.1μF

C

SET

= V

V

IN

CONTROL

= 10μF CERAMIC

30 35 45

40

125

150

3080 G12

= 3V

50

3080 G15

Load Transient Response Line Transient Response

150

100

50

0

–50

–100

OUTPUT VOLTAGE DEVIATION (mV)LOAD CURRENT (A)

1.2

0.9

0.6

0.3

0

105

0

VIN = V

V

C

C

2015

25

TIME (μs)

CONTROL

= 1.5V

OUT

= 10μF CERAMIC

OUT

= 0.1μF

SET

30 35 45

40

= 3V

50

3080 G16

75

50

25

0

–25

–50

6

5

4

3

2

2010

0

IN/CONTROL VOLTAGE (V) OUTPUT VOLTAGE DEVIATION (mV)

4030

50

TIME (μs)

V

= 1.5V

OUT

= 10mA

I

LOAD

= 2.2μF

C

OUT

CERAMIC

= 0.1μF

C

SET

CERAMIC

60 70 90

80

3080 G17

100

Turn-On Response

5

4

3

2

1

0

2.0

1.5

1.0

0.5

0

OUTPUT VOLTAGE (V) INPUT VOLTAGE (V)

21

0

C

= 2.2μF CERAMIC

OUT

43

5

TIME (μs)

R

= 100k

SET

= 0

C

SET

= 1Ω

R

LOAD

67 9

8

3080 G27

3080f

5

10

Page 6

LT3080

UW

TYPICAL PERFOR A CE CHARACTERISTICS

V

CONTROL

25

20

15

10

CONTROL PIN CURRENT (mA)

5

0

0

*SEE NOTE 9 IN ELECTRICAL

CHARACTERISTICS TABLE

Pin Currrent

I

= 1.1A

LOAD

DEVICE IN

CURRENT LIMIT

I

= 1mA

LOAD

12 18 24

6

INPUT-TO-OUTPUT DIFFERENTIAL (V)

Ripple Rejection - Single Supply

100

VIN = V

90

80

70

60

50

40

30

RIPPLE REJECTION (dB)

20

10

= 2.2μF CERAMIC

C

OUT

0

CONTROL

I

= 1.1A

LOAD

FREQUENCY (Hz)

= V

OUT (NOMINAL)

RIPPLE = 50mV

10k 100k10010 1k 1M

I

LOAD

30 36*

+ 2V

= 100mA

3080 G18

P–P

3080 G21

V

CONTROL

30

V

V

25

20

15

10

CONTROL PIN CURRENT (mA)

5

0

0

Ripple Rejection - Dual Supply

- V

100

90

80

70

60

50

40

VIN = V

V

30

RIPPLE REJECTION (dB)

C

20

10

0

Pin Current

– V

CONTROL

– V

= 1V

IN

OUT

0.4 0.6 0.8

0.2

LOAD CURRENT (A)

Pin

CONTROL

I

LOAD

OUT (NOMINAL)

= V

CONTROL

= 2.2μF CERAMIC

OUT

RIPPLE = 50mV

= 2V

OUT

TJ = –50°C

= 125°C

T

J

= 1.1A

+ 1V

OUT (NOMINAL)

P–P

FREQUENCY (Hz)

+2V

10k 100k10010 1k 1M

I

LOAD

T

J

= 25°C

1.0 1.2

3080 G19

= 100mA

3080 G22

Residual Output Voltage with

Less Than Minimum Load

0.8

SET PIN = 0V

0.7

0.6

0.5

0.4

0.3

OUTPUT VOLTAGE (V)

0.2

0.1

0

V

IN

V

= 10V

IN

0

V

OUT

R

TEST

= 5V

V

IN

R

(Ω)

TEST

Ripple Rejection - Dual Supply

- IN Pin

100

90

80

70

60

50

VIN = V

40

30

RIPPLE REJECTION (dB)

20

10

V

CONTROL

RIPPLE = 50mV

C

= 2.2μF CERAMIC

OUT

= 1.1A

I

LOAD

0

OUT (NOMINAL)

= V

+ 1V

OUT (NOMINAL)

P–P

FREQUENCY (Hz)

+2V

10k 100k10010 1k 1M

VIN = 20V

2k1k

3080 G20

3080 G23

6

Ripple Rejection (120Hz)

80

79

78

77

76

75

74

73

RIPPLE REJECTION (dB)

72

71

70

–50

SINGLE SUPPLY OPERATION

= V

V

IN

RIPPLE = 500mV

= 1.1A

I

LOAD

= 0.1μF, C

C

SET

–25 25

0

TEMPERATURE (°C)

OUT(NOMINAL)

REFERENCE CURRENT NOISE SPECTRAL DENSITY (pA/ √Hz)

Noise Spectral Density

10k

1k

100

+ 2V

, f=120Hz

P-P

= 2.2μF

OUT

125

50

100

75

150

3080 G24

10

1

ERROR AMPLIFIER NOISE SPECTRAL DENSITY (nV/√Hz)

FREQUENCY (Hz)

10k 100k10010 1k

1k

100

10

1.0

0.1

3080 G25

3080f

Page 7

UW

TYPICAL PERFOR A CE CHARACTERISTICS

LT3080

Output Voltage Noise

V

OUT

100μV/DIV

3080 G26

V

OUT

R

SET

C

SET

C

OUT

I

LOAD

= 1V

TIME 1ms/DIV

= 100k

= O.1μF

= 10μF

= 1.1A

UUU

PI FU CTIO S

V

CONTROL

pin for the control circuitry of the device. The current fl ow

into this pin is about 1.7% of the output current. For the

device to regulate, this voltage must be more than 1.2V

to 1.35V greater than the output voltage (see Dropout

specifi cations).

IN (Pins 7, 8/Pins 7, 8/Pin 5/Pin 3): This is the collector

to the power device of the LT3080. The output load current

is supplied through this pin. For the device to regulate, the

voltage at this pin must be more than 0.1V to 0.5V greater

than the output voltage (see Dropout specifi cations).

(Pin 5/Pin 5/Pin 4/NA): This pin is the supply

(DD/MS8E/T/ST)

Error Amplifi er Gain and Phase

3080 G28

300

250

200

PHASE (DEGREES)

150

100

50

0

–50

–100

–150

–200

20

15

10

5

0

–5

GAIN (dB)

–10

–15

–20

–25

–30

FREQUENCY (Hz)

10k 100k10010 1k 1M

IL = 1.1A

= 100mA

I

L

IL = 1.1A

IL = 100mA

OUT (Pins 1-3/Pins 1-3/Pin 3/Pin 2): This is the power

output of the device. There must be a minimum load current of 1mA or the output may not regulate.

SET(Pin 4/Pin 4/Pin 2/Pin 1): This pin is the input to the

error amplifi er and the regulation set point for the device.

A fi xed current of 10μA fl ows out of this pin through a

single external resistor, which programs the output voltage

of the device. Output voltage range is zero to the absolute

maximum rated output voltage. Transient performance

can be improved by adding a small capacitor from the

SET pin to ground.

NC (Pin 6/Pin 6/Pin 1/NA): No Connection. No Connect

pins have no connection to internal circuitry and may be

tied to V

IN

, V

CONTROL

, V

, GND, or fl oated.

OUT

Exposed Pad (Pin 9/Pin 9/NA/NA): OUT on MS8E and

DFN packages.

TAB: OUT on TO-220 and SOT-223 packages.

3080f

7

Page 8

LT3080

BLOCK DIAGRA

W

V

CONTROL

IN

10μA

+

–

3080 BD

OUTSET

U

WUU

APPLICATIO S I FOR ATIO

The LT3080 regulator is easy to use and has all the protection features expected in high performance regulators.

Included are short-circuit protection and safe operating

area protection, as well as thermal shutdown.

The LT3080 is especially well suited to applications needing

multiple rails. The new architecture adjusts down to zero

with a single resistor handling modern low voltage digital

IC’s as well as allowing easy parallel operation and thermal

management without heat sinks. Adjusting to “zero” output

allows shutting off the powered circuitry and when the

input is pre-regulated – such as a 5V or 3.3V input supply

– external resistors can help spread the heat.

A precision “0” TC 10μA internal current source is connected to the non-inverting input of a power operational

amplifi er. The power operational amplifi er provides a low

impedance buffered output to the voltage on the non-inverting input. A single resistor from the non-inverting input to

ground sets the output voltage and if this resistor is set

to zero, zero output results. As can be seen, any output

voltage can be obtained from zero up to the maximum

defi ned by the input power supply.

What is not so obvious from this architecture are the benefi ts of using a true internal current source as the reference

as opposed to a bootstrapped reference in older regulators.

A true current source allows the regulator to have gain

and frequency response independent of the impedance on

the positive input. Older adjustable regulators, such as the

LT1086 have a change in loop gain with output voltage

as well as bandwidth changes when the adjustment pin

is bypassed to ground. For the LT3080, the loop gain is

unchanged by changing the output voltage or bypassing.

Output regulation is not fi xed at a percentage of the output

voltage but is a fi xed fraction of millivolts. Use of a true

current source allows all the gain in the buffer amplifi er

to provide regulation and none of that gain is needed to

amplify up the reference to a higher output voltage.

The LT3080 has the collector of the output transistor

connected to a separate pin from the control input. Since

the dropout on the collector (IN pin) is only 300mV, two

supplies can be used to power the LT3080 to reduce dissipation: a higher voltage supply for the control circuitry

and a lower voltage supply for the collector. This increases

effi ciency and reduces dissipation. To further spread the

heat, a resistor can be inserted in series with the collector

to move some of the heat out of the IC and spread it on

the PC board.

The LT3080 can be operated in two modes. Three terminal

mode has the control pin connected to the power input pin

which gives a limitation of 1.35V dropout. Alternatively,

the “control” pin can be tied to a higher voltage and the

power IN pin to a lower voltage giving 300mV dropout

on the IN pin and minimizing the power dissipation. This

allows for a 1.1A supply regulating from 2.5V

or 1.8V

to 1.2V

IN

with low dissipation.

OUT

IN

to 1.8V

OUT

3080f

8

Page 9

LT3080

U

WUU

APPLICATIO S I FOR ATIO

SET

R

LT3080

SET

+

–

C

SET

OUT

3080 F01

V

OUT

C

OUT

IN

V

CONTROL

+

+

V

V

CONTROL

IN

Figure 1. Basic Adjustable Regulator

Output Voltage

The LT3080 generates a 10μA reference current that fl ows

out of the SET pin. Connecting a resistor from SET to

ground generates a voltage that becomes the reference

point for the error amplifi er (see Figure 1). The reference

voltage is a straight

multiplication of the SET pin current

and the value of the resistor. Any voltage can be generated

and there is no minimum output voltage for the regulator.

A minimum load current of 1mA is required to maintain

regulation regardless of output voltage. For true zero

voltage output operation, this 1mA load current must be

returned to a negative supply voltage.

With the low level current used to generate the reference

voltage, leakage paths to or from the SET pin can create

errors in the reference and output voltages. High quality

insulation should be used (e.g., Tefl on, Kel-F); cleaning

of all insulating surfaces to remove fl uxes and other residues will probably be required. Surface coating may be

necessary to provide a moisture barrier in high humidity

environments.

Board leakage can be minimized by encircling the SET

pin and circuitry with a guard ring operated at a potential

close to itself; the guard ring should be tied to the OUT

pin. Guarding both sides of the circuit board is required.

Bulk leakage reduction depends on the guard ring width.

Ten nanoamperes of leakage into or out of the SET pin and

associated circuitry creates a 0.1% error in the reference

voltage. Leakages of this magnitude, coupled with other

sources of leakage, can cause signifi cant offset voltage

and reference drift, especially over the possible operating

temperature range.

If guardring techniques are used, this bootstraps any

stray capacitance at the SET pin. Since the SET pin is

a high impedance node, unwanted signals may couple

into the SET pin and cause erratic behavior. This will

be most noticeable when operating with minimum

output capacitors at full load current. The easiest way

to remedy this is to bypass the SET pin with a small

amount of capacitance from SET to ground, 10pF to

20pF is suffi cient.

Stability and Output Capacitance

The LT3080 requires an output capacitor for stability. It

is designed to be stable with most low ESR capacitors

(typically ceramic, tantalum or low ESR electrolytic).

A minimum output capacitor of 2.2μF with an ESR of 0.5Ω

or less is recommended to prevent oscillations.

values of output capacitance decrease peak

Larger

deviations

and provide improved transient response for larger load

current changes. Bypass capacitors, used to decouple

individual components powered by the LT3080, increase

the effective output capacitor value.

For improvement in transient performance, place a capacitor across the voltage setting resistor. Capacitors up to

1μF can be used. This bypass capacitor reduces system

noise as well, but start-up time is proportional to the time

constant of the voltage setting resistor (R

in Figure 1)

SET

and SET pin bypass capacitor.

Extra consideration must be given to the use of ceramic

capacitors. Ceramic capacitors are manufactured with a

variety of dielectrics, each with different behavior across

temperature and applied voltage. The most common

dielectrics used are specifi ed with EIA temperature characteristic codes of Z5U, Y5V, X5R and X7R. The Z5U and

Y5V dielectrics are good for providing high capacitances

in a small package, but they tend to have strong voltage

and temperature coeffi cients as shown in Figures 2 and 3.

When used with a 5V regulator, a 16V 10μF Y5V capacitor

can exhibit an effective value as low as 1μF to 2μF for the

DC bias voltage applied and over the operating temperature range. The X5R and X7R dielectrics result in more

stable characteristics and are more suitable for use as the

output capacitor. The X7R type has better stability across

temperature, while the X5R is less expensive and is avail-

3080f

9

Page 10

LT3080

U

WUU

APPLICATIO S I FOR ATIO

20

0

–20

–40

–60

CHANGE IN VALUE (%)

–80

–100

0

Figure 2. Ceramic Capacitor DC Bias Characteristics

40

20

0

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10μF

X5R

Y5V

26

4

8

DC BIAS VOLTAGE (V)

14

12

10

X5R

16

3080 F02

ceramic capacitor the stress can be induced by vibrations

in the system or thermal transients.

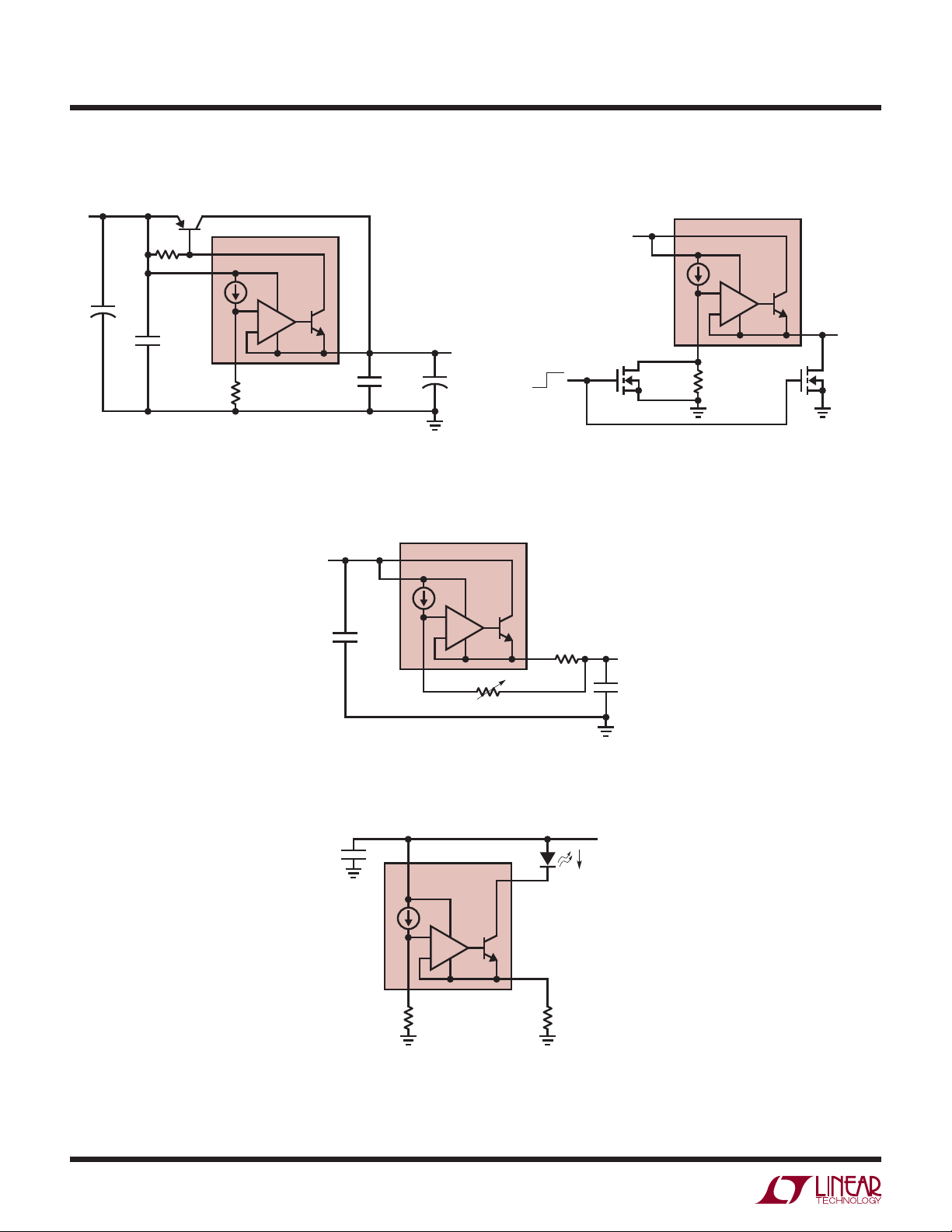

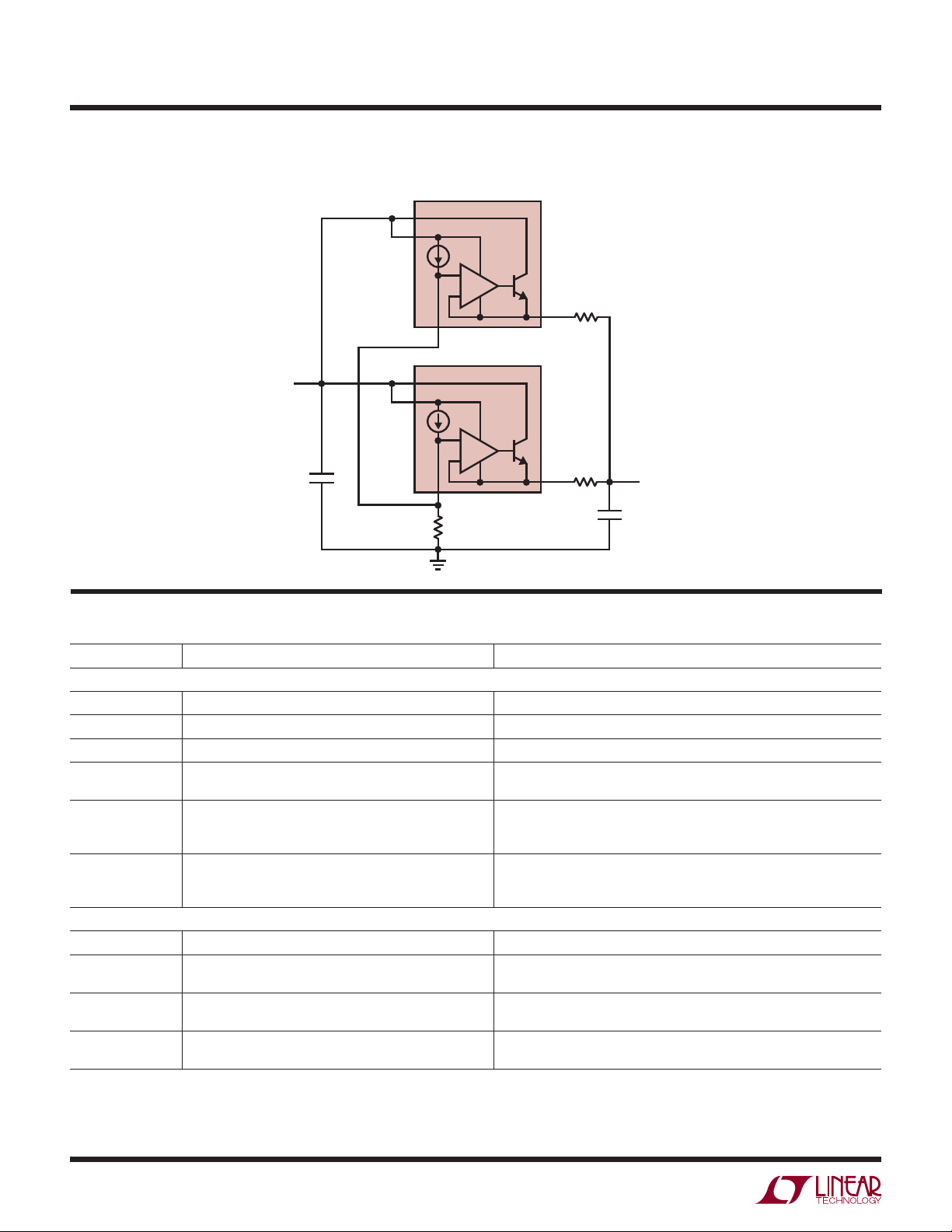

Paralleling Devices

LT3080’s may be paralleled to obtain higher output current.

The SET pins are tied together and the IN pins are tied

together. This is the same whether it’s in three terminal

mode or has separate input supplies. The outputs are

connected in common using a small piece of PC trace

as a ballast resistor to equalize the currents. PC trace

resistance in milliohms/inch is shown in Table 1. Only a

tiny area is needed for ballasting.

Table 1. PC Board Trace Resistance

WEIGHT (oz) 10 mil WIDTH 20 mil WIDTH

1 54.3 27.1

2 27.1 13.6

Trace resistance is measured in mOhms/in

–20

–40

–60

CHANGE IN VALUE (%)

–80

BOTH CAPACITORS ARE 16V,

1210 CASE SIZE, 10μF

–100

–50

–25 0

TEMPERATURE (°C)

Y5V

50 100 125

25 75

3080 F03

Figure 3. Ceramic Capacitor Temperature Characteristics

able in higher values. Care still must be exercised when

using X5R and X7R capacitors; the X5R and X7R codes

only specify operating temperature range and maximum

capacitance change over temperature. Capacitance change

due to DC bias with X5R and X7R capacitors is better than

Y5V and Z5U capacitors, but can still be signifi cant enough

to drop capacitor values below appropriate levels. Capacitor DC bias characteristics tend to improve as component

case size increases, but expected capacitance at operating

voltage should be verifi ed.

Voltage and temperature coeffi cients are not the only

sources of problems. Some ceramic capacitors have a

piezoelectric response. A piezoelectric device generates

voltage across its terminals due to mechanical stress,

similar to the way a piezoelectric microphone works. For a

The worse case offset between the set pin and the output

of only ± 2 millivolts allows very small ballast resistors

to be used. As shown in Figure 4, the two devices have

a small 10 milliohm ballast resistor, which at full output

current gives better than 80 percent equalized sharing of

the current. The external resistance of 10 milliohms (5

V

4.8V TO 28V

V

IN

V

CONTROL

V

V

CONTROL

IN

IN

1μF

Figure 4. Parallel Devices

SET

SET

165k

LT3080

+

–

LT3080

+

–

OUT

OUT

10mΩ

10mΩ

3080 F04

10μF

V

OUT

3.3V

2A

3080f

10

Page 11

LT3080

U

WUU

APPLICATIO S I FOR ATIO

milliohms for the two devices in parallel) only adds about

10 millivolts of output regulation drop at an output of 2A.

Even with an output voltage as low as 1V, this only adds

1% to the regulation. Of course, more than two LT3080’s

can be paralleled for even higher output current. They are

spread out on the PC board, spreading the heat. Input

resistors can further spread the heat if the input-to-output

difference is high.

Thermal Performance

In this example, two LT3080 3mm × 3mm DFN devices

are mounted on a 1oz copper 4-layer PC board. They are

placed approximately 1.5 inches apart and the board is

mounted vertically for convection cooling. Two tests were

set up to measure the cooling performance and current

sharing of these devices.

The fi rst test was done with approximately 0.7V inputto-output and 1A per device. This gave a 700 milliwatt

dissipation in each device and a 2A output current. The

temperature rise above ambient is approximately 28°C

and both devices were within plus or minus 1°C. Both the

thermal and electrical sharing of these devices is excellent. The thermograph in Figure 5 shows the temperature

distribution between these devices and the PC board

reaches ambient temperature within about a half an inch

from the devices.

The power is then increased with 1.7V across each device.

This gives 1.7 watts dissipation in each device and a device

temperature of about 90°C, about 65°C above ambient

as shown in Figure 6. Again, the temperature matching

between the devices is within 2°C, showing excellent

tracking between the devices. The board temperature has

reached approximately 40°C within about 0.75 inches of

each device.

While 90°C is an acceptable operating temperature for these

devices, this is in 25°C ambient. For higher ambients, the

temperature must be controlled to prevent device temperature from exceeding 125°C. A 3-meter-per-second airfl ow

across the devices will decrease the device temperature

about 20°C providing a margin for higher operating ambient temperatures.

Both at low power and relatively high power levels devices can be paralleled for higher output current. Current

sharing and thermal sharing is excellent, showing that

acceptable operation can be had while keeping the peak

temperatures below excessive operating temperatures on

a board. This technique allows higher operating current

linear regulation to be used in systems where it could

never be used before.

Quieting the Noise

The LT3080 offers numerous advantages when it comes

to dealing with noise. There are several sources of noise

in a linear regulator. The most critical noise source for any

LDO is the reference; from there, the noise contribution

Figure 5. Temperature Rise at 700mW Dissipation

Figure 6. Temperature Rise at 1.7W Dissipation

3080f

11

Page 12

LT3080

U

WUU

APPLICATIO S I FOR ATIO

from the error amplifi er must be considered, and the gain

created by using a resistor divider cannot be forgotten.

Traditional low noise regulators bring the voltage reference out to an external pin (usually through a large value

resistor) to allow for bypassing and noise reduction of

reference noise. The LT3080 does not use a traditional

voltage reference like other linear regulators, but instead

uses a reference current. That current operates with typi-

⎯

cal noise current levels of 3.2pA/√

Hz (1nA

10Hz to 100kHz bandwidth). The voltage noise of this is

equal to the noise current multiplied by the resistor value.

The resistor generates spot noise equal to √⎯4⎯k⎯T⎯R (k =

Boltzmann’s constant, 1.38 • 10

-23

J/°K, and T is absolute

temperature) which is RMS summed with the reference

current noise. To lower reference noise, the voltage setting resistor may be bypassed with a capacitor, though

this causes start-up time to increase as a factor of the RC

time constant.

The LT3080 uses a unity-gain follower from the SET pin

to drive the output, and there is no requirement to use

a resistor to set the output voltage. Use a high accuracy

voltage reference placed at the SET pin to remove the errors in output voltage due to reference current tolerance

and resistor tolerance. Active driving of the SET pin is

acceptable; the limitations are the creativity and ingenuity

of the circuit designer.

over the

RMS

current limit as the input-to-output voltage increases and

keeps the power dissipation at safe levels for all values

of input-to-output voltage. The LT3080 provides some

output current at all values of input-to-output voltage up

to the device breakdown. See the Current Limit curve in

the Typical Performance Characteristics.

When power is fi rst turned on, the input voltage rises and

the output follows the input, allowing the regulator to start

into very heavy loads. During start-up, as the input voltage

is rising, the input-to-output voltage differential is small,

allowing the regulator to supply large output currents.

With a high input voltage, a problem can occur wherein

removal of an output short will not allow the output voltage to recover. Other regulators, such as the LT1085 and

LT1764A, also exhibit this phenomenon so it is not unique

to the LT3080.

The problem occurs with a heavy output load when the

input voltage is high and the output voltage is low. Common situations are immediately after the removal of a

short circuit. The load line for such a load may intersect

the output current curve at two points. If this happens,

there are two stable operating points for the regulator.

With this double intersection, the input power supply may

need to be cycled down to zero and brought up again to

make the output recover.

One problem that a normal linear regulator sees with reference voltage noise is that noise is gained up along with the

output when using a resistor divider to operate at levels

higher than the normal reference voltage. With the LT3080,

the unity-gain follower presents no gain whatsoever from

the SET pin to the output, so noise fi gures do not increase

accordingly. Error amplifi er noise is typically 125nV/√

(40μV

over the 10Hz to 100kHz bandwidth); this is

RMS

⎯

Hz

another factor that is RMS summed in to give a fi nal noise

fi gure for the regulator.

Curves in the Typical Performance Characteristics show

noise spectral density and peak-to-peak noise characteristics for both the reference current and error amplifi er

over the 10Hz to 100kHz bandwidth.

Overload Recovery

Like many IC power regulators, the LT3080 has safe operating area (SOA) protection. The SOA protection decreases

12

Load Regulation

Because the LT3080 is a fl oating device (there is no ground

pin on the part, all quiescent and drive current is delivered

to the load), it is not possible to provide true remote load

sensing. Load regulation will be limited by the resistance

SET

LT3080

+

–

R

SET

RESISTANCE

OUT

PARASITIC

R

P

R

P

R

P

LOAD

3080 F07

3080f

IN

V

CONTROL

Figure 7. Connections for Best Load Regulation

Page 13

LT3080

U

WUU

APPLICATIO S I FOR ATIO

of the connections between the regulator and the load.

The data sheet specifi cation for load regulation is Kelvin

sensed at the pins of the package. Negative side sensing

is a true Kelvin connection, with the bottom of the voltage

setting resistor returned to the negative side of the load

(see Figure 7). Connected as shown, system load regulation will be the sum of the LT3080 load regulation and the

parasitic line resistance multiplied by the output current.

It is important to keep the positive connection between

the regulator and load as short as possible and use large

wire or PC board traces.

Thermal Considerations

The LT3080 has internal power and thermal limiting circuitry designed to protect it under overload conditions.

For continuous normal load conditions, maximum junction temperature must not be exceeded. It is important

to give consideration to all sources of thermal resistance

from junction to ambient. This includes junction-to-case,

case-to-heat sink interface, heat sink resistance or circuit

board-to-ambient as the application dictates. Additional

heat sources nearby must also be considered.

For surface mount devices, heat sinking is accomplished

by using the heat spreading capabilities of the PC board

and its copper traces. Surface mount heat sinks and plated

through-holes can also be used to spread the heat generated by power devices.

Junction-to-case thermal resistance is specifi ed from the

IC junction to the bottom of the case directly below the

die. This is the lowest resistance path for heat fl ow. Proper

mounting is required to ensure the best possible thermal

fl ow from this area of the package to the heat sinking

material. For the TO-220 package, thermal compound is

strongly recommended for mechanical connections to a

heat sink. A thermally conductive spacer can be used for

electrical isolation as long as the added contribution to

thermal resistance is considered. Note that the Tab or

Exposed Pad (depending on package) is electrically

connected to the output.

The following tables list thermal resistance for several

different copper areas given a fi xed board size. All mea-

surements were taken in still air on two-sided 1/16” FR-4

board with one ounce copper.

Table 2. MSE Package, 8-Lead MSOP

COPPER AREA

TOPSIDE* BACKSIDE BOARD AREA

2500mm

1000mm

*Device is mounted on topside

Table 3. DD Package, 8-Lead DFN

TOPSIDE* BACKSIDE BOARD AREA

2500mm

1000mm

*Device is mounted on topside

Table 4. ST Package, 3-Lead SOT-223

TOPSIDE* BACKSIDE BOARD AREA

2500mm

1000mm

*Device is mounted on topside

2

2

2

225mm

2

100mm

COPPER AREA

2

2

2

225mm

2

100mm

COPPER AREA

2

2

2

225mm

2

100mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

2500mm22500mm

THERMAL RESISTANCE

(JUNCTION-TO-AMBIENT)

2

2

2

2

(JUNCTION-TO-AMBIENT)

2

2

2

2

(JUNCTION-TO-AMBIENT)

2

2

2

2

55°C/W

57°C/W

60°C/W

65°C/W

THERMAL RESISTANCE

60°C/W

62°C/W

65°C/W

68°C/W

THERMAL RESISTANCE

48°C/W

48°C/W

56°C/W

62°C/W

T Package, 5-Lead TO-220

Thermal Resistance (Junction-to-Case) = 3°C/W

Calculating Junction Temperature

Example: Given an output voltage of 0.9V, a V

CONTROL

voltage of 3.3V ±10%, an IN voltage of 1.5V ±5%, output

current range from 1mA to 1A and a maximum ambient

temperature of 50°C, what will the maximum junction

2

temperature be for the DFN package on a 2500mm

2

with topside copper area of 500mm

?

board

3080f

13

Page 14

LT3080

A

U

WUU

APPLICATIO S I FOR ATIO

The power in the drive circuit equals:

DRIVE

CONTROL

= (V

CONTROL

is equal to I

P

where I

of output current. A curve of I

in the Typical Performance Characteristics curves.

The power in the output transistor equals:

P

OUTPUT

= (VIN – V

The total power equals:

TOTAL

= P

DRIVE

P

The current delivered to the SET pin is negligible and can

be ignored.

V

CONTROL(MAX CONTINUOUS)

V

IN(MAX CONTINUOUS)

= 0.9V, I

V

OUT

OUT

Power dissipation under these conditions is equal to:

PDRIVE = (V

I

CONTROL

P

DRIVE

CONTROL

I

OUT

=

60

= (3.630V – 0.9V)(17mA) = 46mW

+ P

– V

OUT

OUTPUT

OUT

OUT

CONTROL

)(I

OUT

)(I

CONTROL

/60. I

)

CONTROL

= 3.630V (3.3V + 10%)

= 1.575V (1.5V + 5%)

= 1A, TA = 50°C

– V

1A

=

OUT

= 17mA

)(I

CONTROL

60

vs I

)

is a function

can be found

OUT

)

Junction Temperature will be equal to:

= TA + P

T

J

= 50°C + 721mW • 64°C/W = 96°C

T

J

• θJA (approximated using tables)

TOTAL

In this case, the junction temperature is below the maximum rating, ensuring reliable operation.

Reducing Power Dissipation

In some applications it may be necessary to reduce

the power dissipation in the LT3080 package without

sacrifi cing output current capability. Two techniques are

available. The fi rst technique, illustrated in Figure 8, employs a resistor in series with the regulator’s input. The

voltage drop across R

decreases the LT3080’s IN-to-OUT

S

differential voltage and correspondingly decreases the

LT3080’s power dissipation.

As an example, assume: VIN = V

and I

OUT(MAX)

= 1A. Use the formulas from the Calculating

CONTROL

= 5V, V

OUT

= 3.3V

Junction Temperature section previously discussed.

Without series resistor R

, power dissipation in the LT3080

S

equals:

1A

P

TOTAL

= 5V – 3.3V

()

•

60

+ 5V – 3.3V

()

•1

P

OUTPUT

P

OUTPUT

= (VIN – V

= (1.575V – 0.9V)(1A) = 675mW

OUT

)(I

OUT

)

Total Power Dissipation = 721mW

V

V

C1

Figure 8. Reducing Power Dissipation Using a Series Resistor

CONTROL

LT3080

SET

R

SET

IN

+

–

OUT

R

S

C2

3080 F08

VINʹ

V

IN

OUT

If the voltage differential (V

transistor is chosen as 0.5V, then R

RS=

= 1.73W

5V – 3.3V − 0.5V

1A

) across the NPN pass

DIFF

equals:

S

= 1.2Ω

Power dissipation in the LT3080 now equals:

1A

P

TOTAL

= 5V – 3.3V

()

•

+ 0.5V

()

60

•1A= 0.53W

The LT3080’s power dissipation is now only 30% compared

to no series resistor. R

dissipates 1.2W of power. Choose

S

appropriate wattage resistors to handle and dissipate the

power properly.

3080f

14

Page 15

LT3080

U

WUU

APPLICATIO S I FOR ATIO

The second technique for reducing power dissipation,

shown in Figure 9, uses a resistor in parallel with the

LT3080. This resistor provides a parallel path for current

fl ow, reducing the current fl owing through the LT3080.

This technique works well if input voltage is reasonably

constant and output load current changes are small. This

technique also increases the maximum available output

current at the expense of minimum load requirements.

As an example, assume: V

5.5V, V

I

OUT(MIN)

than 90% of I

Calculating R

RP=

= 3.3V, V

OUT

OUT(MIN)

= 0.7A. Also, assuming that RP carries no more

OUT(MIN)

yields:

P

5.5V – 3.2V

= 3.65Ω

0.63A

= V

IN

= 3.2V, I

= 630mA.

(5% Standard value = 3.6Ω)

CONTROL

= 5V, V

OUT(MAX)

IN(MAX)

=

= 1A and

The maximum total power dissipation is (5.5V – 3.2V) •

1A = 2.3W. However the LT3080 supplies only:

5.5V – 3.2V

1A –

3.6Ω

= 0.36A

Therefore, the LT3080’s power dissipation is only:

P

R

= (5.5V – 3.2V) • 0.36A = 0.83W

DIS

dissipates 1.47W of power. As with the fi rst technique,

P

choose appropriate wattage resistors to handle and dissipate the power properly. With this confi guration, the

LT3080 supplies only 0.36A. Therefore, load current can

increase by 0.64A to 1.64A while keeping the LT3080 in

its normal operating range.

V

V

C1

Figure 9. Reducing Power Dissipation Using a Parallel Resistor

CONTROL

SET

R

SET

LT3080

+

–

IN

OUT

IN

R

P

V

OUT

C2

3080 F09

3080f

15

Page 16

LT3080

TYPICAL APPLICATIO S

U

Higher Output Current

50Ω

V

MJ4502

CONTROL

IN

LT3080

V

IN

6V

+

SET

332k

+

–

OUT

4.7μF

V

OUT

3.3V

5A

+

100μF

3080 TA02

ON OFF

100μF

1μF

Adding Shutdown

V

IN

V

CONTROL

Q1

VN2222LL

SHUTDOWN

IN

LT3080

+

–

SET

R1

*

Q2 INSURES ZERO OUTPUT

IN THE ABSENCE OF ANY

OUTPUT LOAD.

3080 TA04

OUT

Q2*

VN2222LL

V

OUT

Current Source

V

10V

V

CONTROL

IN

IN

LT3080

+

1μF

SET

–

100k

OUT

1Ω

I

OUT

0A TO 1A

4.7μF

3080 TA03

16

Low Dropout Voltage LED Driver

V

C1

CONTROL

LT3080

D1

IN

+

–

SET

R1

24.9k

OUT

R2

2.49Ω

3080 TA05

V

100mA

IN

3080f

Page 17

TYPICAL APPLICATIO S

LT3080

U

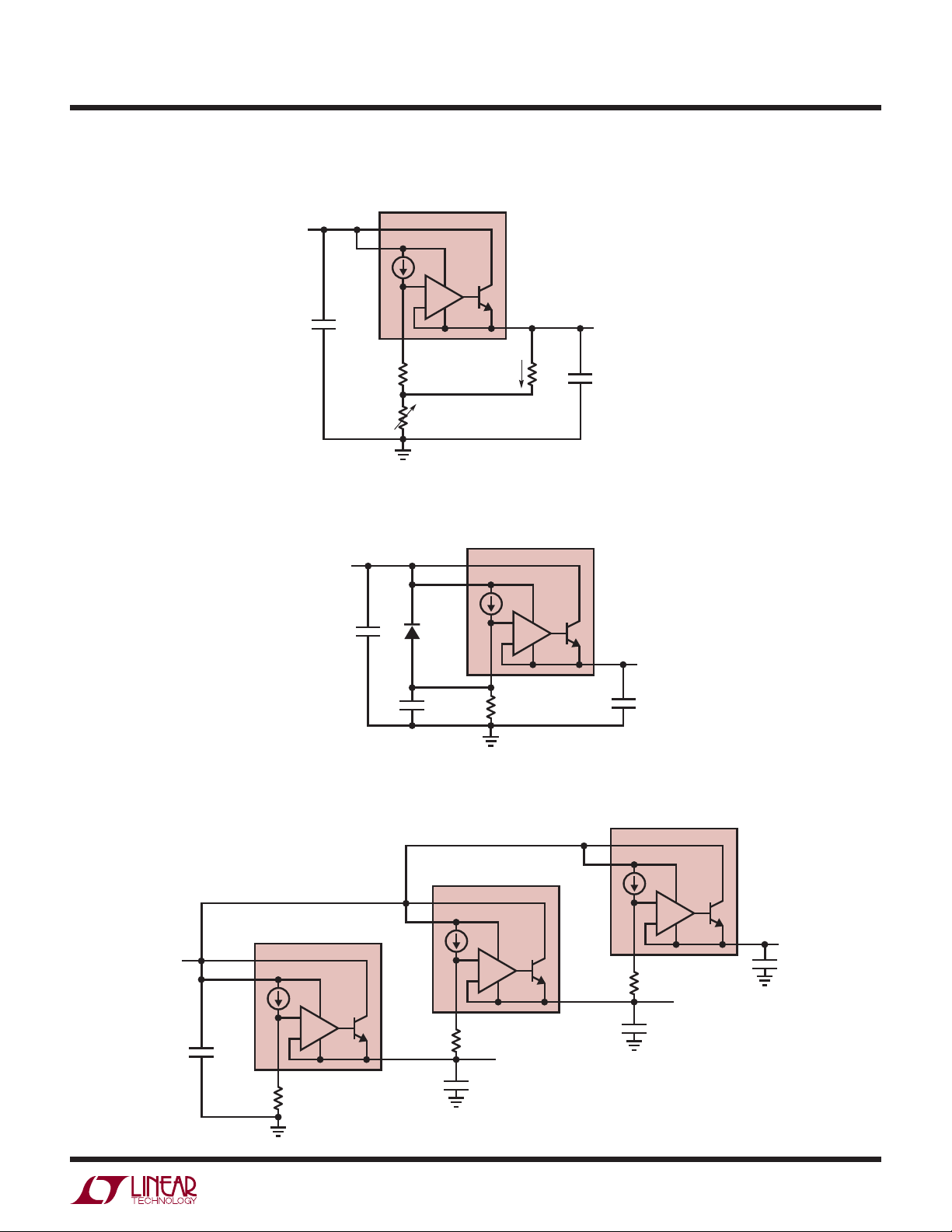

Using a Lower Value SET Resistor

V

IN

12V

4.8V to 28V

V

CONTROL

C1

1μF

V

IN

IN

LT3080

+

SET

R1

49.9k

1%

R

10k

–

SET

1mA

OUT

R2

499Ω

1%

3080 TA06

V

OUT

0.5V TO 10V

C

OUT

4.7μF

V

= 0.5V + 1mA • R

OUT

SET

Adding Soft-Start

SET

R1

332k

LT3080

+

–

OUT

3080 TA07

V

OUT

3.3V

1A

C

OUT

4.7μF

C1

1μF

V

CONTROL

D1

1N4148

C2

0.01μF

IN

V

7V TO 28V

Coincident Tracking

SET

169k

C3

4.7μF

LT3080

+

–

V

OUT2

3.3V

OUT

V

OUT3

5V

4.7μF

3080 TA08

3080f

IN

V

CONTROL

SET

R2

80.6k

C2

4.7μF

LT3080

+

–

V

OUT1

2.5V

1A

OUT

IN

V

CONTROL

LT3080

V

CONTROL

IN

IN

+

SET

R1

249k

–

OUT

C1

1.5μF

17

Page 18

LT3080

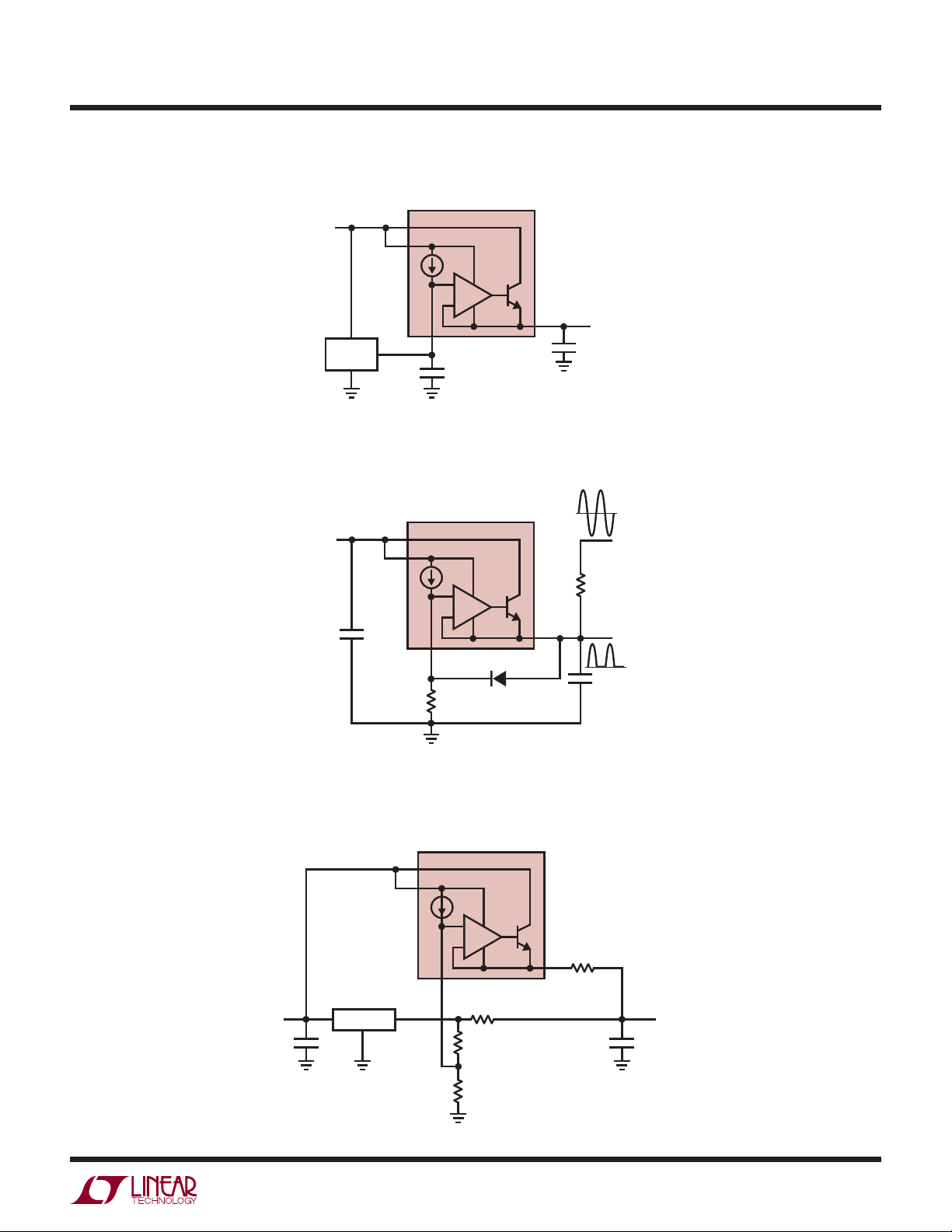

TYPICAL APPLICATIO S

U

Lab Supply

V

12V TO 18V

SETSET

LT3080

+

–

R4

1MEG

OUTOUT

4.7μF 100μF

+

V

OUT

0V TO 10V

3080 TA09

IN

V

CONTROL

+

15μF

LT3080

+

–

1Ω

+

100k

0A TO 1A

V

CONTROL

15μF

ININ

High Voltage Regulator

SET

R

SET

2MEG

6.1V

LT3080

+

–

4.7μF

OUT

V

OUT

1A

3080 TA10

V

OUT

V

OUT

= 20V

= 10μA • R

SET

V

50V

10k

IN

1N4148

IN

BUZ11

V

CONTROL

+

10μF

+

15μF

18

Ramp Generator

SET

LT3080

+

–

1μF

OUT

V

4.7μF

3080 TA12

OUT

3080f

V

IN

5V

1μF

IN

V

CONTROL

VN2222LL VN2222LL

Page 19

TYPICAL APPLICATIO S

LT3080

U

Reference Buffer

LT3080

V

CONTROL

IN

V

IN

+

LT1019

GND

INPUT

OUTPUT

–

SET

C1

1μF

OUT

*

V

OUT

C2

4.7μF

3080 TA11

*MIN LOAD 0.5mA

Ground Clamp

5k

LT3080

+

–

1N4148

OUT

20Ω

4.7μF

V

EXT

V

OUT

V

CONTROL

1μF

IN

V

IN

Boosting Fixed Output Regulators

5V

10μF

*4mV DROP ENSURES LT3080 IS

OFF WITH NO LOAD

MULTIPLE LT3080’S CAN BE USED

LT1963-3.3

SET

3080 TA13

LT3080

+

–

20mΩ

42Ω* 47μF

33k

OUT

20mΩ

3.3V

2.6A

3080 TA20

OUT

3080f

19

Page 20

LT3080

TYPICAL APPLICATIO S

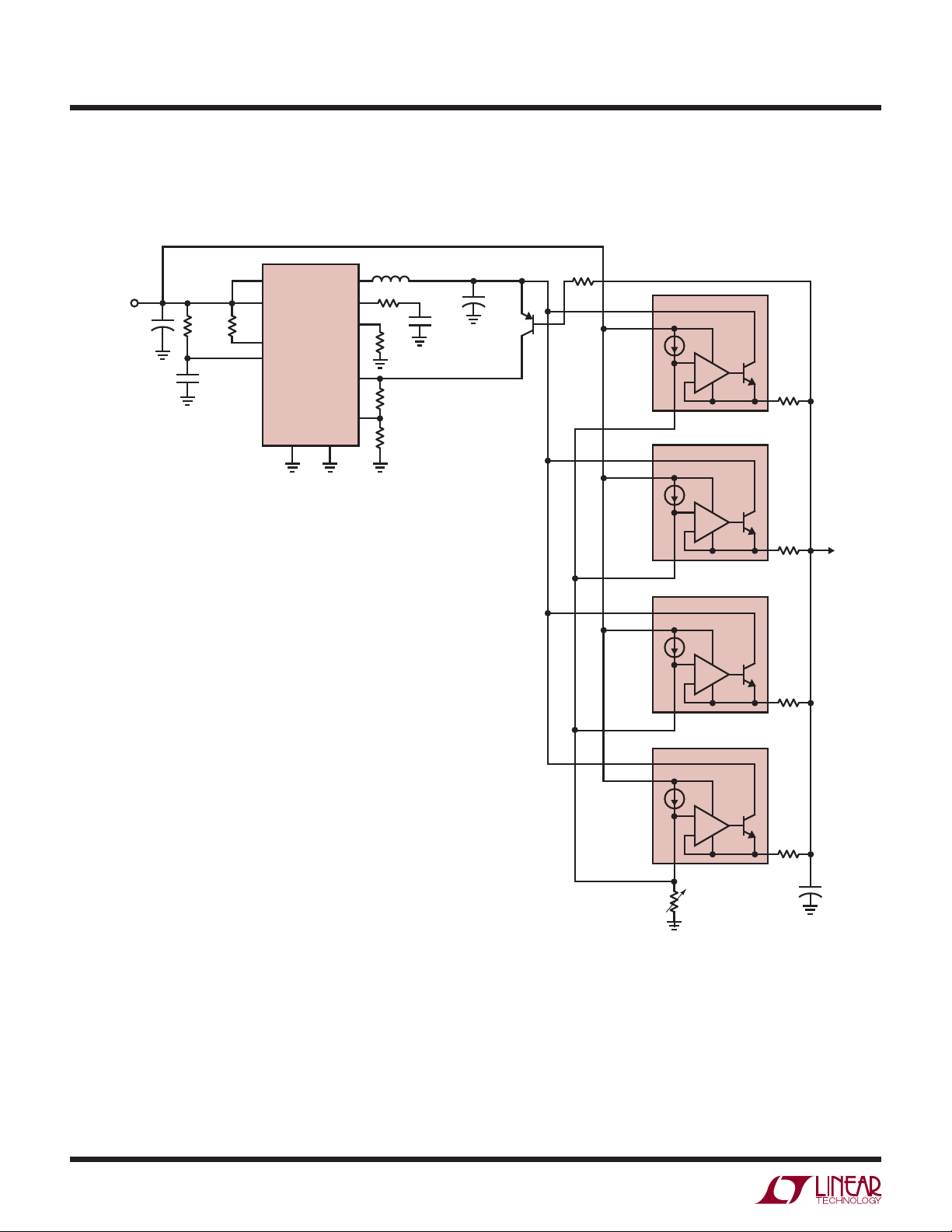

Low Voltage, High Current Adjustable High Effi ciency Regulator*

U

2.7V TO 5.5V

†

100μF

PV

IN

SV

+

2×

2.2MEG 100k

1000pF

IN

LTC3414

PGOOD

RUN/SS

SYNC/MODE

SGND PGND

*DIFFERENTIAL VOLTAGE ON LT3080

IS 0.6V SET BY THE V

†

MAXIMUM OUTPUT VOLTAGE IS 1.5V

BELOW INPUT VOLTAGE

0.47μH

SW

I

TH

12.1k

R

T

294k

V

FB

78.7k

124k

OF THE 2N3906 PNP.

BE

470pF

+

2×

100μF

2N3906

10k

V

CONTROL

V

CONTROL

V

CONTROL

IN

LT3080

+

–

SET

IN

LT3080

OUT

20mΩ

+

–

SET

IN

LT3080

OUT

20mΩ

0V TO 4V

4A

†

+

–

SET

OUT

20mΩ

20

V

CONTROL

IN

LT3080

+

–

SET

100k

3080 TA18

OUT

20mΩ

+

100μF

3080f

Page 21

TYPICAL APPLICATIO S

CMDSH-4E

LT3080

U

Adjustable High Effi ciency Regulator*

4.5V TO 25V

†

10μF

1μF

V

BOOST

IN

100k

0.1μF

*DIFFERENTIAL VOLTAGE ON LT3080

≈ 1.4V SET BY THE TPO610L P-CHANNEL THRESHOLD.

†

BELOW INPUT VOLTAGE

LT3493

GND

SW

FB

10k

IN

SHDN

MAXIMUM OUTPUT VOLTAGE IS 2V

0.1μF

10μH

MBRM140

68μF

TP0610L

2 Terminal Current Source

C

*

COMP

LT3080

V

CONTROL

10k

IN

LT3080

+

SET

1MEG

–

3080 TA19

OUT

4.7μF

0V TO 10V

1A

†

V

CONTROL

*C

COMP

R1 ≤ 10Ω 10μF

R1 ≥ 10Ω 2.2μF

SET

+

–

100k

R1

3080 TA21

I

OUT

1V

=

R1

3080f

21

Page 22

LT3080

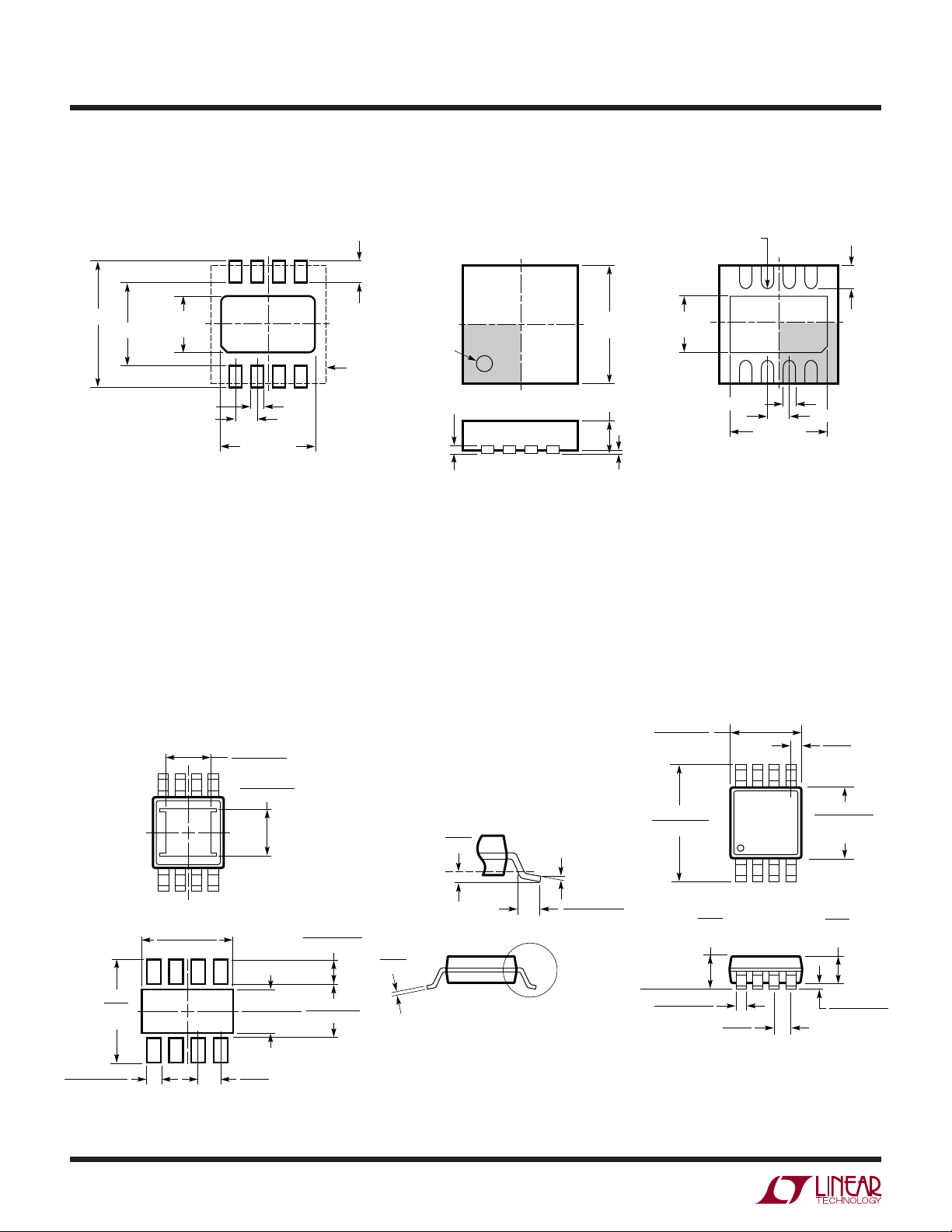

PACKAGE DESCRIPTIO

U

DD Package

8-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1698)

0.675 ±0.05

R = 0.115

TYP

0.38 ± 0.10

85

3.5 ±0.05

5.23

(.206)

MIN

0.42 ± 0.038

(.0165 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

1.65 ±0.05

(2 SIDES)2.15 ±0.05

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-1)

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION

ON TOP AND BOTTOM OF PACKAGE

BOTTOM VIEW OF

EXPOSED PAD OPTION

1

8

2.794 ± 0.102

(.110 ± .004)

2.38 ±0.05

(2 SIDES)

2.06 ± 0.102

(.081 ± .004)

1.83 ± 0.102

(.072 ± .004)

2.083 ± 0.102

(.082 ± .004)

0.65

(.0256)

BSC

0.50

BSC

0.889 ± 0.127

(.035 ± .005)

(.126 – .136)

3.20 – 3.45

1.65 ± 0.10

0.00 – 0.05

(2 SIDES)

0.25 ± 0.05

BOTTOM VIEW—EXPOSED PAD

PACKAGE

OUTLINE

PIN 1

TOP MARK

(NOTE 6)

0.200 REF

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

MS8E Package

8-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1662)

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

PLANE

4.90 ± 0.152

(.193 ± .006)

0.22 – 0.38

(.009 – .015)

TYP

1.10

(.043)

MAX

0.65

(.0256)

BSC

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

DETAIL “A”

0° – 6° TYP

0.53 ± 0.152

(.021 ± .006)

DETAIL “A”

SEATING

2.38 ±0.10

(2 SIDES)

8

7

12

6

3

5

4

(DD8) DFN 1203

14

0.50 BSC

0.52

(.0205)

REF

3.00 ± 0.102

(.118 ± .004)

(NOTE 4)

0.86

(.034)

REF

0.127 ± 0.076

(.005 ± .003)

MSOP (MS8E) 0603

22

3080f

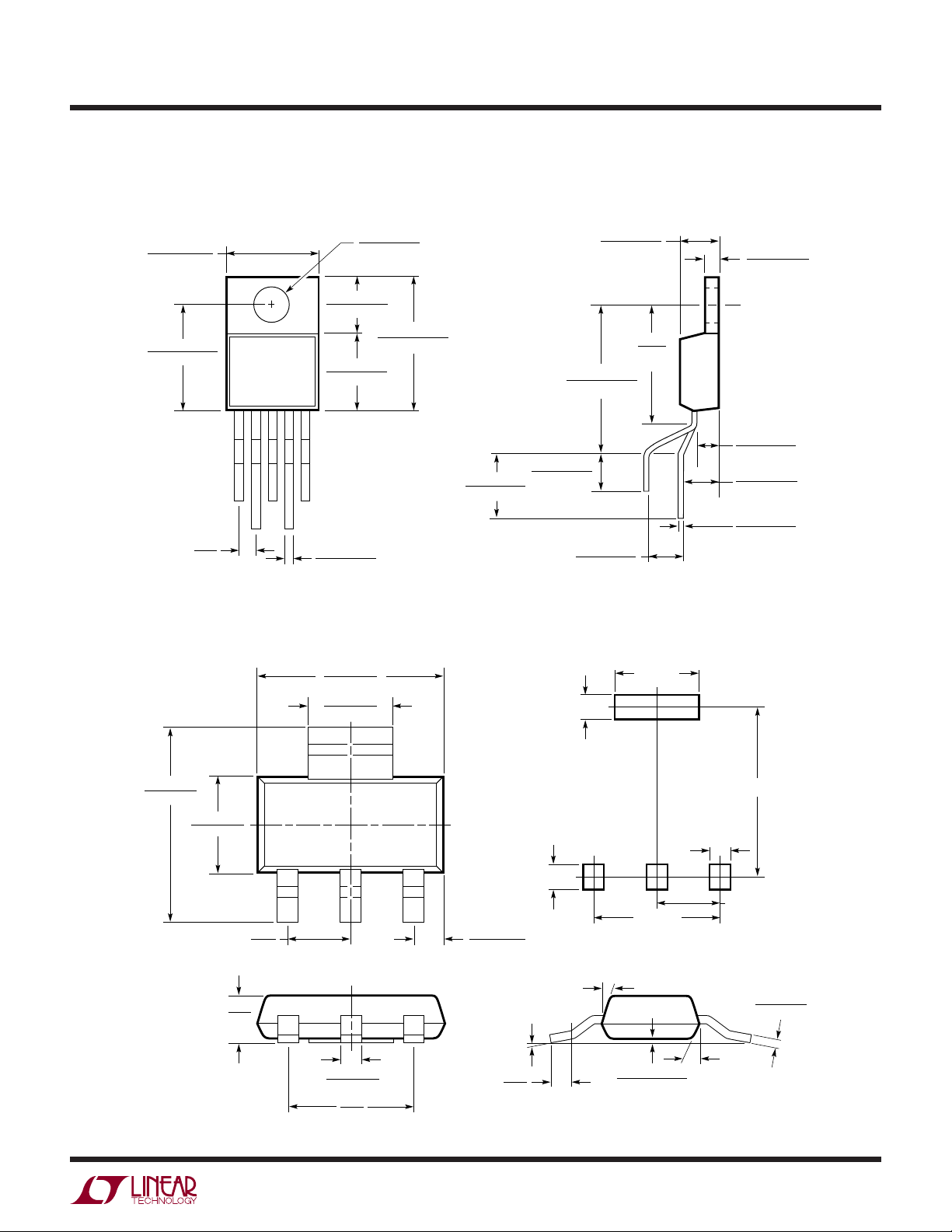

Page 23

PACKAGE DESCRIPTIO

.390 – .415

(9.906 – 10.541)

.460 – .500

(11.684 – 12.700)

U

.147 – .155

(3.734 – 3.937)

.230 – .270

(5.842 – 6.858)

(14.478 – 15.748)

.330 – .370

(8.382 – 9.398)

T Package

5-Lead Plastic TO-220 (Standard)

(Reference LTC DWG # 05-08-1421)

DIA

.570 – .620

.700 – .728

(17.78 – 18.491)

.165 – .180

(4.191 – 4.572)

.620

(15.75)

TYP

LT3080

.045 – .055

(1.143 – 1.397)

BSC

.264 – .287

(6.70 – 7.30)

.067

(1.70)

.130 – .146

(3.30 – 3.71)

.0905

(2.30)

BSC

.028 – .038

(0.711 – 0.965)

.248 – .264

(6.30 – 6.71)

.114 – .124

(2.90 – 3.15)

SEATING PLANE

.152 – .202

.260 – .320

(6.60 – 8.13)

(3.861 – 5.131)

ST Package

3-Lead Plastic SOT-223

(Reference LTC DWG # 05-08-1630)

.059 MAX

.033 – .041

(0.84 – 1.04)

.135 – .165

(3.429 – 4.191)

.129 MAX

.059 MAX

.181 MAX

RECOMMENDED SOLDER PAD LAYOUT

* MEASURED AT THE SEAT

.039 MAX

.095 – .115

(2.413 – 2.921)

.155 – .195*

(3.937 – 4.953)

.013 – .023

(0.330 – 0.584)

.248 BSC

.090

BSC

.071

(1.80)

MAX

10° – 16°

10°

MAX

.024 – .033

(0.60 – 0.84)

.181

(4.60)

BSC

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

.012

(0.31)

MIN

.0008 – .0040

(0.0203 – 0.1016)

.010 – .014

(0.25 – 0.36)

10° – 16°

ST3 (SOT-233) 0502

3080f

23

Page 24

LT3080

TYPICAL APPLICATIO

U

Paralleling Regulators

LT3080

V

CONTROL

IN

+

V

4.8V TO 28V

–

SET

LT3080

V

CONTROL

IN

IN

OUT

20mΩ

+

–

1μF

SET

165k

OUT

20mΩ

10μF

3080 TA14

V

OUT

3.3V

2A

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LDOs

LT1086 1.5A Low Dropout Regulator Fixed 2.85V, 3.3V, 3.6V, 5V and 12V Output

LT1117 800mA Low Dropout Regulator 1V Dropout, Adjustable or Fixed Output, DD-Pak, SOT-223 Packages

LT1118 800mA Low Dropout Regulator OK for Sinking and Sourcing, S0-8 and SOT-223 Packages

LT1963A 1.5A Low Noise, Fast Transient Response LDO 340mV Dropout Voltage, Low Noise: 40μV

TO-220, DD, SOT-223 and SO-8 Packages

LT1965 1.1A Low Noise LDO 290mV Dropout Voltage, Low Noise 40μV

V

= 1.2V to 19.5V, Stable with Ceramic Caps TO-220, DDPak, MSOP

OUT

and 3mm × 3mm DFN packages.

LT C®3026 1.5A Low Input Voltage VLDOTM Regulator VIN: 1.14V to 3.5V (Boost Enabled), 1.14V to 5.5V (with External 5V),

V

= 0.1V, IQ = 950μA, Stable with 10μF Ceramic Capacitors, 10-Lead

DO

MSOP and DFN Packages

Switching Regulators

LT1976 High Voltage, 1.5A Step-Down Switching Regulator f = 200kHz, I

LTC3414 4A (I

), 4MHz Synchronous Step-Down DC/DC

OUT

95% Effi ciency, VIN: 2.25V to 5.5V, V

= 100μA, TSSOP-16E Package

Q

OUT(MIN)

Converter

LTC3406/LTC3406B 600mA (I

Converter

LTC3411 1.25A (I

Converter

), 1.5MHz Synchronous Step-Down DC/DC

OUT

), 4MHz Synchronous Step-Down DC/DC

OUT

95% Effi ciency, VIN: 2.5V to 5.5V, V

I

< 1μA, ThinSOTTM Package

SD

95% Effi ciency, VIN: 2.5V to 5.5V, V

I

< 1μA, 10-Lead MS or DFN Packages

SD

OUT(MIN)

OUT(MIN)

VLDO and ThinSOT are trademarks of Linear Technology Corporation.

, VIN = 2.5V to 20V,

RMS

, VIN = 1.8V to 20V,

RMS

= 0.8V, TSSOP Package

= 0.6V, IQ = 20μA,

= 0.8V, IQ = 60μA,

24

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

3080f

LT 1107 • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2007

Loading...

Loading...