Page 1

LOAD CURRENT (A)

0.5

EFFICIENCY (%)

95

90

85

80

75

70

4.5

1950 TA01b

1.5

2.5

3.5

5.5

VIN = 48V

VIN = 36V

VIN = 72V

FEATURES

LT1950

Single Switch PWM

Controller with Auxiliary

Boost Converter

U

DESCRIPTIO

■

Wide Input Range: 3V to 25V

■

Programmable Volt-Second Clamp

■

Output Power Levels from 25W to 500W

■

Auxiliary Boost Converter Provides 10V Gate Drive

from VIN as Low as 3V

■

Programmable Operating Frequency (100kHz to

500kHz) with One External Resistor

■

Programmable Slope Compensation

■

Programmable Leading Edge Blanking

■

±2% Internal 1.23V Reference

■

Accurate Shutdown Pin Threshold with

Programmable Hysteresis

■

60ns Current Sense Delay

■

2.5V Auxiliary Reference Output

■

Synchronizable to an External Clock up to 1.5 • f

■

Current Mode Control

■

Small 16-Pin SSOP Package

U

APPLICATIO S

■

Telecom Power Supplies

■

Automotive Power Supplies

■

Portable Electronic Equipment

■

Isolated and Nonisolated DC/DC Converters

OSC

The LT®1950 is a wide input range, forward, boost, flyback

and SEPIC controller that drives an N-channel power

MOSFET with few external components required.

A resistor programmable duty cycle clamp can be used to

generate a volt-second clamp for forward converter applications. An internal boost switcher is available for creating

a separate supply for the output gate driver, allowing 10V

gate drive from input voltages as low as 3V. The LT1950’s

operating frequency can be set with an external resistor

over a 100kHz to 500kHz range and a SYNC pin allows the

part to be synchronized to an external clock. Additional

programmability exists for leading edge blanking and

slope compensation.

A fast current sense comparator achieves 60ns current

sense delay and the error amplifier is a true voltage mode

error amplifier, allowing a wide range of compensation

networks. An accurate shutdown pin with programmable

hysteresis is available for undervoltage lockout and shutdown. The LT1950 is available in a small 16-Pin SSOP

package.

, LTC and LT are registered trademarks of Linear Technology Corporation.

TYPICAL APPLICATIO

2.5V

0.1µF

249k

4.99k

U

36V to 72V DC to 26V/5A (Single Switch) Forward Converter

SLOPE

V

REF

BOOST

R

OSC

LT1950

BLANK

SYNC

GND

FB

V

V

SHDN

GATE

I

SENSE

PGND

COMP

V

IN2

SEC

10V

BIAS

IN

1µF

4.7k

0.022µF

470k

18k

100k

V

IN

MBRB20200

PA0581

Si7450

0.015Ω

47µH

47µF

1950 TA01a

V

26V

5A

Efficiency vs Load Current

OUT

1950fa

1

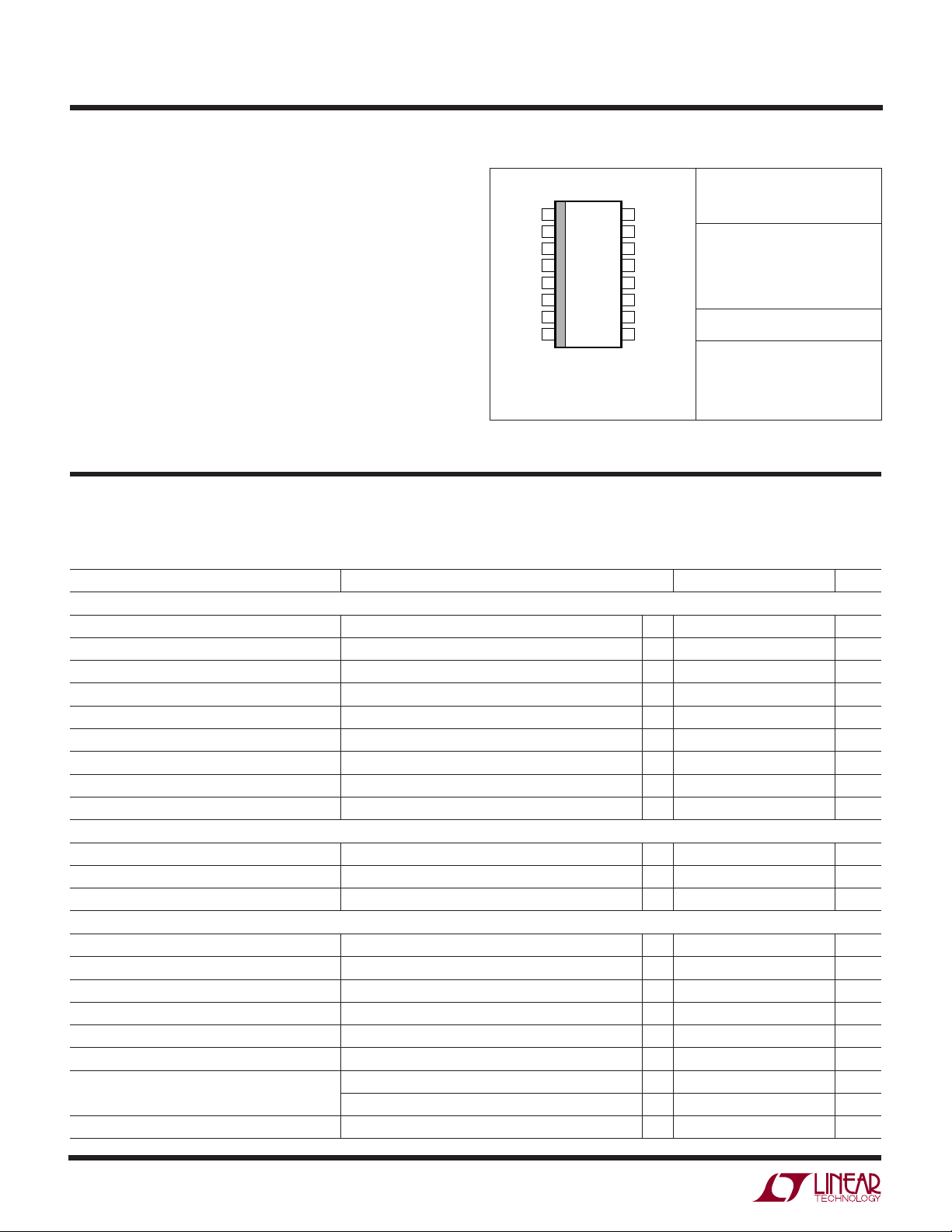

Page 2

LT1950

TOP VIEW

GN PACKAGE

16-LEAD NARROW PLASTIC SSOP

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

COMP

FB

R

OSC

SYNC

SLOPE

V

REF

SHDN

GND

V

SEC

V

IN

BOOST

PGND

GATE

V

IN2

I

SENSE

BLANK

ABSOLUTE AXI U RATI GS

(Note 1)

BOOST ....................................................... –0.3V to 35V

V

, V

IN

FB, SYNC, V

COMP, BLANK ..........................................–0.3V to 3.5V

SLOPE ...................................................... –0.3V to 2.5V

I

SENSE

R

OSC

V

REF

Operating Junction Temperature Range

LT1950EGN/LT1950IGN (Notes 2, 5) ... –40°C to 125°C

Storage Temperature Range ..................–65°C to 150°C

Lead Temperature (Soldering, 10 sec).................. 300°C

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. COMP = open, FB = 1.4V, R

= 0.1µF, SHDN = VIN, BLANK = 0V, I

specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

PWM Controller

Operating Input Voltage I

Minimum Start-Up Voltage I

VIN Quiescent Current I

V

Shutdown Current SHDN = 0V 5 20 µA

IN

Shutdown Threshold 3V < V

Shutdown Pin Current SHDN = 70mV Above Threshold –7 –10 –13 µA

Shutdown Pin Current Hysteresis SHDN = 100mV Below Threshold 4 7 10 µA

V

Quiescent Current I(V

IN2

V

Shutdown Current SHDN = 0V, V

IN2

V

(External Output)

REF

Output Voltage I

Line Regulation I

Load Regulation 0µA < I

Oscillator

Frequency: f

Minimum Programmable f

Maximum Programmable f

SYNC Input Resistance 20 kΩ

SYNC Switching Threshold 1.5 2.2 V

SYNC Frequency/f

f

OSC

V

ROSC

2

Line Reg 3V < VIN < 25V 0.05 0.15 %/V

WW

W

, SHDN ......................................... –0.3V to 25V

IN2

........................................... –0.3V to 6V

SEC

U

......................................................... –0.3V to 1V

.................................................................... –50µA

.................................................................... –10mA

The ● denotes the specifications which apply over the full operating

= 0V, V

SENSE

OSC

OSC

OSC

OSC

= 15V, GATE = 1nF, BOOST = open, VIN = 15V, V

IN2

= 0µA ● 3.0 25 V

VREF

= 0µA ● 2.6 3.0 V

VREF

= 0µA, FB = 1V, I

VREF

< 25V ● 1.261 1.32 1.379 V

IN

) = 0µA, FB = 1V, I

REF

= 2.7V (Boost Diode from VIN = 3V) 500 700 µA

IN2

= 0µA ● 2.425 2.500 2.575 V

VREF

= 0µA, 3V < VIN < 25V 1 5 mV

VREF

< 2.5mA 1 5 mV

VREF

R

= 249k, FB = 1V ● 170 200 230 kHz

OSC

R

= 499k 85 100 115 kHz

OSC

R

= 90.9k 440 500 560 kHz

OSC

(R

= 249k, f

OSC

9.5V < V

IN2

=200kHz), FB = 1V (Note 7) 1.25 1.5

OSC

< 25V 0.05 0.25 %/V

UUW

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

LT1950EGN

LT1950IGN

GN PART MARKING

1950E

T

= 125°C, θJA = 110°C/W,

JMAX

(PIN 8) = 30°C/W

θ

JC

Consult LTC Marketing for parts specified with wider operating temperature ranges.

= 249k, SYNC = 0V, SLOPE = open, V

OSC

= 0.2V 2.3 3.0 mA

SENSE

= 0.2V 1.7 2.5 mA

SENSE

= 0V, unless otherwise

SEC

1950I

1V

REF

1950fa

Page 3

LT1950

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. COMP = open, FB = 1.4V, R

= 0.1µF, SHDN = VIN, BLANK = 0V, I

SENSE

= 0V, V

IN2

The ● denotes the specifications which apply over the full operating

= 249k, SYNC = 0V, SLOPE = open, V

= 15V, GATE = 1nF, BOOST = open, VIN = 15V, V

OSC

= 0V, unless otherwise

SEC

REF

specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Error Amplifier

FB Reference Voltage 3V < VIN < 25V, V

FB Input Bias Current FB = FB Reference Voltage –75 –200 nA

Open Loop Voltage Gain VOL + 0.2V < COMP < VOH – 0.2 65 85 dB

Unity Gain Bandwidth (Note 6) 3 MHz

COMP Source Current FB = 1V, COMP = 1.6V ● –0.3 –1.1 –1.8 mA

COMP Sink Current FB = 1.4V, COMP = 1.6V 8 13 mA

COMP High Level: V

OH

FB = 1V, I

COMP

COMP Active Threshold Start of GATE Switching (Duty Cycle > 0%) 1.0 V

COMP Low Level: V

OL

FB = 1.4V, I

Current Sense

I

Maximum Threshold Duty Cycle < 10%, COMP = V

SENSE

I

Input Bias Current COMP = 2.5V, I

SENSE

Default Blanking Time FB = 1V, COMP = 2V, I

Adjustable Blanking Time FB = 1V, COMP = 2V, I

BLANK = 75k to Ground

Blanking Override Voltage– BLANK = Open, COMP = 2.5V (Note 4) 15 25 40 mV

Maximum Threshold

I

SENSE

Turn-Off Delay to Gate COMP = 2V 60 ns

Slope Compensation (Note 4) I

Max Threshold (DC < 10%) – (DC = 80%) (Note 4)

SENSE

Default, R

SLOPE

2x Default, R

3x Default, R

Internal Switcher

Boost Switch I

LIMIT

Boost Switch Off Time V

V

: Boost Disable 3V < VIN < 10V ● 9.5 11.0 11.75 V

IN2

V

: Boost Disable Hysteresis 3V < VIN < 10V –1.0 V

IN2

V

: Gate Enable 3V < VIN < 10V, FB = 1V (Note 4) ● 7.0 8.2 9.27 V

IN2

V

: Gate Enable Hysteresis 3V < VIN < 10V, FB = 1V (Note 4) –0.6 V

IN2

V

= 8V, 3V < VIN < 10V 70 125 180 mA

IN2

= 8V, 3V < VIN < 10V 250 500 1000 ns

IN2

GATE Driver Output

GATE Rise Time FB = 1V, V

GATE Fall Time FB = 1V, V

GATE Clamp Voltage I

GATE Low Level I

GATE High Level I

GATE

GATE

I

GATE

GATE

I

GATE

Maximum Duty Cycle FB = 1V, f

IN2

IN2

= 0µA, COMP = 2.5V, FB = 6V 11.5 13 14.5 V

= 20mA 0.25 0.4 V

= 200mA 1.2 1.75 V

= –20mA, V

= –200mA, V

OSC

+ 0.2V < COMP < VOH – 0.2 ● 1.205 1.230 1.254 V

OL

= – 250µA 2.5 V

= 250µA 0.15 V

COMP

90 100 110 mV

SENSE

OH

= I

Max Threshold –125 –170 –250 µA

SENSE

= 75mV 110 ns

SENSE

= 75mV 290 ns

SENSE

= ∞ 14 mV

= 8k 28 mV

SLOPE

= 3.3k 42 mV

SLOPE

= 12V, CL = 1nF (Notes 3, 6) 50 ns

= 12V, CL = 1nF (Notes 3, 6) 30 ns

= 12V, COMP = 2.5V, FB = 6V 10 V

IN2

= 12V, COMP = 2.5V, FB = 6V 9.75 V

IN2

= 200kHz 90 95 97 %

1950fa

3

Page 4

LT1950

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. COMP = open, FB = 1.4V, R

= 0.1µF, SHDN = VIN, BLANK = 0V, I

SENSE

= 0V, V

IN2

The ● denotes the specifications which apply over the full operating

= 249k, SYNC = 0V, SLOPE = open, V

= 15V, GATE = 1nF, BOOST = open, VIN = 15V, V

OSC

= 0V, unless otherwise

SEC

REF

specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Maximum Duty Cycle Clamp V

V

Input Bias Current 0V < V

SEC

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1950EGN is guaranteed to meet performance specifications

from 0°C to 125°C operating junction temperature. Specifications over the

–40°C to 125°C operating junction temperature range are assured by

design, characterization and correlation with statistical process controls.

The LT1950IGN is guaranteed over the full –40°C to 125°C operating

junction temperature range.

= 1.4V, FB = 1V, COMP = V

SEC

< 2.8V –0.3 –1.0 µA

SEC

OH

63 75 87 %

Note 4: Guaranteed by correlation to static test.

Note 5: This IC includes overtemperature protection that is intended to

protect the device during momentary overload conditions. Junction

temperature will exceed 125°C when overtemperature protection is active.

Continuous operation above the specified maximum operating junction

temperature may impair device reliability.

Note 6: Guaranteed but not tested.

Note 7: Maximum recommended SYNC frequency = 500kHz.

Note 3: Rise and Fall times are between 10% and 90% levels.

UW

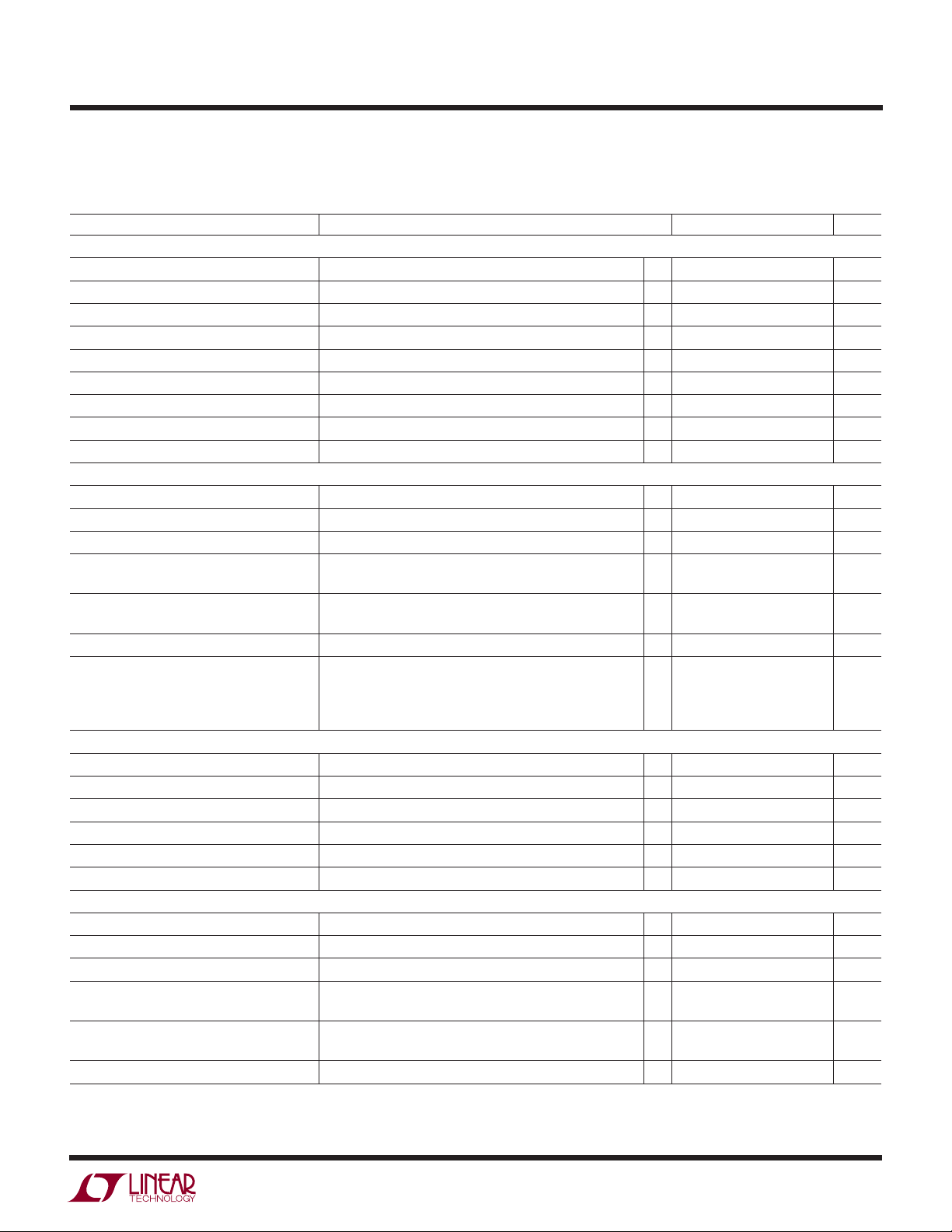

TYPICAL PERFOR A CE CHARACTERISTICS

Switching Frequency vs

FB Voltage vs Temperature

1.26

1.25

1.24

1.23

FB VOLTAGE (V)

1.22

1.21

1.20

–50

–25 0

25 75

TEMPERATURE (°C)

50 100 125

1950 G01

Temperature

240

230

220

210

200

190

FREQUENCY (kHz)

180

170

160

–25 25 75

–50

0

TEMPERATURE (°C)

50

100

1950 • G02

125

VIN Shutdown IQ vs Temperature

16

SHDN = 0V

14

12

(µA)

Q

10

8

6

SHUTDOWN I

IN

V

4

2

0

–25 25 75

–50

0

TEMPERATURE (°C)

50

100

125

1950 • G03

Shutdown Threshold vs

Temperature

1.45

1.40

1.35

1.30

SHUTDOWN THRESHOLD (V)

1.25

1.20

–25 25 75

–50

0

TEMPERATURE (°C)

4

I

Maximum I

Threshold vs

SENSE

Temperature

125

120

115

110

105

THRESHOLD (mV)

100

95

SENSE

90

85

MAXIMUM I

80

50

100

125

1950 • G04

75

–50

0

–25

TEMPERATURE (°C)

50

25

75

100

125

1950 G05

270

250

230

210

190

170

CURRENT (µA)

150

SENSE

I

130

110

90

Pin Current vs

SENSE

Temperature

–50 0

–25

50

25

TEMPERATURE (°C)

100

125

1950 G06

1950fa

75

Page 5

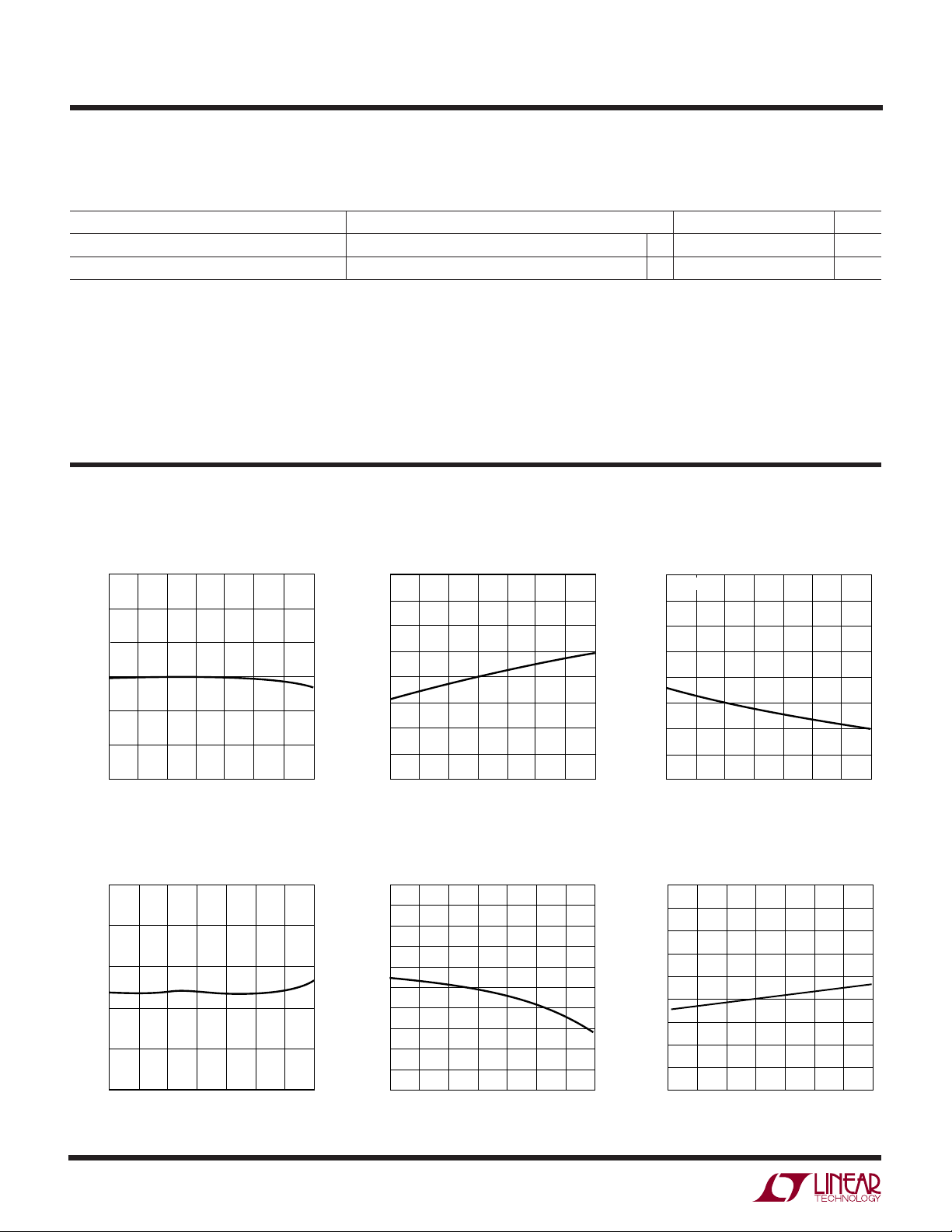

UW

TYPICAL PERFOR A CE CHARACTERISTICS

BLANK Override Threshold –

I

Maximum Threshold vs

SENSE

Temperature

40

35

30

25

20

MAXIMUM THRESHOLD (mV)

BLANK OVERRIDE THRESHOLD

15

SENSE

–I

10

–50

–25 0

25 75

TEMPERATURE (°C)

50 100 125

1950 G07

Minimum VIN Start-Up Voltage vs

Temperature (V

3.00

2.75

2.50

START-UP VOLTAGE (V)

IN

2.25

MINIMUM V

2.00

–25 25 75 125

–50

050

TEMPERATURE (°C)

Boosted)

IN2

100

1950 G08

3.1

2.9

2.7

2.5

(mA)

2.3

Q

I

IN

V

2.1

1.9

1.7

1.5

LT1950

V

vs Temperature

IN IQ

050

–25 25 75 125

–50

TEMPERATURE (°C)

100

1950 G09

SHDN Input Current *(–1) vs

Temperature

14

12

SHDN = SHDN THRESHOLD + 70mV

10

8

6

4

SHDN = SHDN THRESHOLD – 100mV

SHDN INPUT CURRENT*(–1) (µA)

2

0

–50 25 75

–25 0

TEMPERATURE (°C)

V

: GATE Enable

IN2

vs Temperature

9.2

8.7

GATE ENABLE

8.2

GATE ENABLE (V)

IN2

V

7.7

7.2

–50 25 75

–25 0

HYSTERESIS

GATE DISABLE

TEMPERATURE (°C)

50 100 125

1950 G10

50 100 125

1950 G13

SHDN Current Hysteresis vs

Temperature

11

10

9

8

7

6

5

SHDN CURRENT HYSTERESIS (µA)

4

3

–50

V

IN2

050

–25 25 75 125

TEMPERATURE (°C)

: BOOST Disable

vs Temperature

13.0

12.5

12.0

11.5

11.0

10.5

BOOST DISABLE (V)

IN2

V

10.0

9.5

9.0

–50

BOOST DISABLE

HYSTERESIS

BOOST RE-ENABLE

–25 25 75

0

TEMPERATURE (°C)

GATE Rise/Fall Time vs

GATE Capacitance

125

TA = 25°C

100

1950 G11

100

75

50

GATE RISE/FALL TIME (ns)

25

0

1000

0

BOOST Switch I

t

r

t

f

3000

2000

GATE CAPACITANCE (pF)

vs

LIMIT

4000

5000

1950 G12

Temperature

250

200

(mA)

LIMIT

150

100

BOOST SWITCH I

50

100

125

1950 G14

50

–50 25 75

–25 0

TEMPERATURE (°C)

50 100 125

1950 G15

1950fa

5

Page 6

LT1950

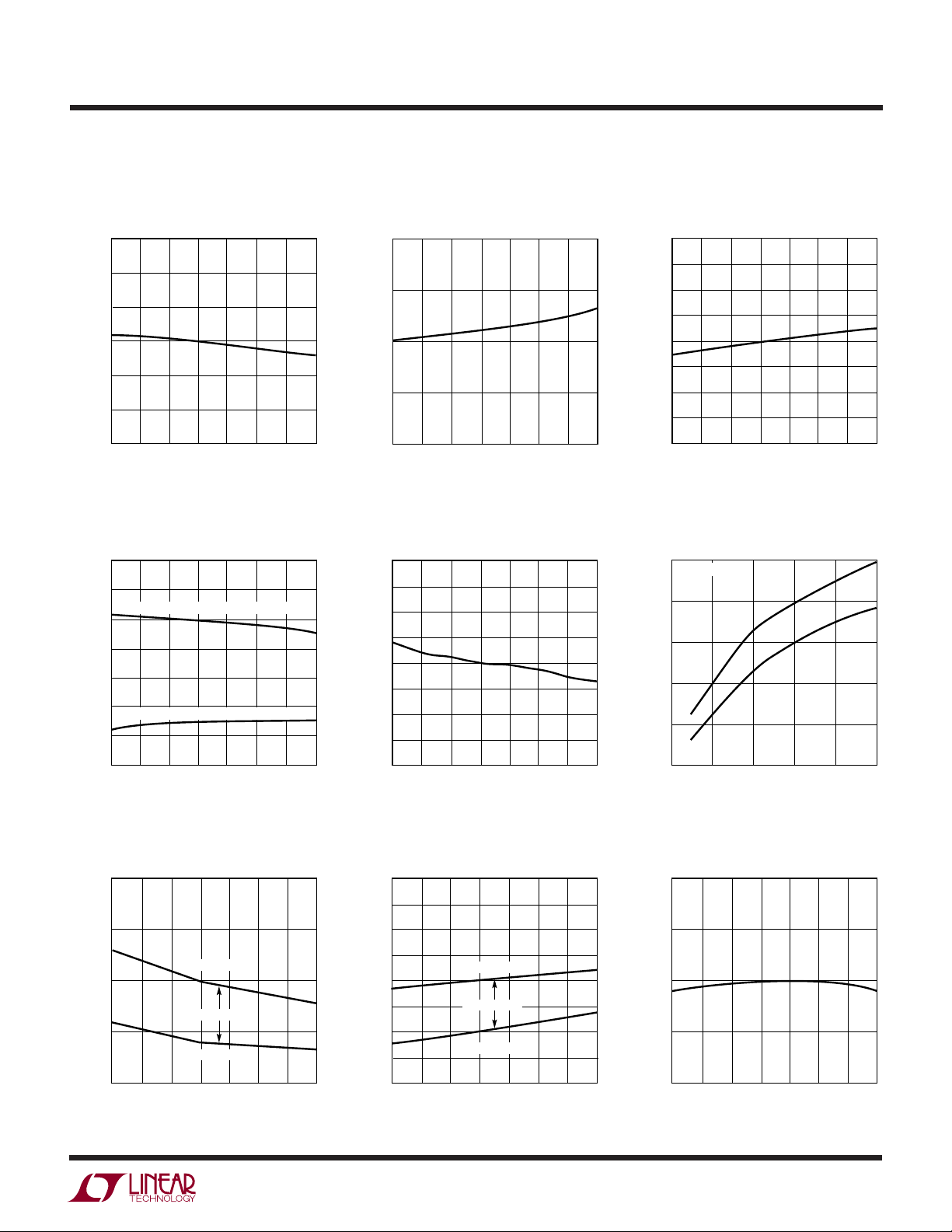

UW

TYPICAL PERFOR A CE CHARACTERISTICS

BOOST Switch Off Time vs

Temperature

700

600

500

400

BOOST SWITCH OFF TIME (ns)

300

–50 25 75

–25 0

TEMPERATURE (°C)

U

50 100 125

1950 G16

UU

Maximum Duty Cycle vs

Voltage

V

SEC

100

90

80

70

60

50

MAXIMUM DUTY CYCLE (%)

40

30

0.8

MAX DUTY CYCLE = (105/V

1.25V < V

= 25°C

T

A

1.6 2.0 2.4 2.8 3.2

1.2

V

SEC

PI FU CTIO S

COMP (Pin 1): The COMP pin is the output of the error

amplifier. The error amplifier is a true op amp which allows

the use of an RC network to be connected between the

Comp and FB pins to compensate the feedback loop for

optimum transient response. The peak switch current in

the external MOSFET will be proportional to the voltage on

the COMP pin. Typical operating voltage range for this pin

is 1V to 2.5V.

FB (Pin 2): The FB pin is the inverting input to the error

amplifier. The output voltage is set with a resistor divider.

The error amplifier adjusts the peak switch current to

maintain the FB pin voltage at the value of the internal

reference voltage of 1.23V.

R

(Pin 3): A resistor from the R

OSC

programs the operating frequency of the LT1950. Operating frequency range is 100kHz to 500kHz. Nominal voltage

on the R

pin is 1V.

OSC

pin to ground

OSC

GATE Clamp Voltage vs

Temperature

16

15

14

13

12

GATE CLAMP VOLTAGE (V)

11

10

–50

050

–25 25 75 125

TEMPERATURE (°C)

100

1950 G18

< 2.8V

SEC

VOLTAGE (V)

SEC

)%

1950 G17

SLOPE (Pin 5): The SLOPE pin is used to adjust the

amount of slope compensation. Leaving the pin open

circuit results in a default level of slope compensation. The

amount of slope compensation can be adjusted above this

default level by connecting a resistor from the SLOPE pin

to the V

V

REF

pin.

REF

(Pin 6): The V

pin is the output of an internal 2.5V

REF

reference. This pin is capable of sourcing up to 2.5mA for

external use. It is recommended that the V

REF

pin is

bypassed to ground with a 0.1µF ceramic capacitor.

SHDN (Pin 7): The SHDN pin is used to put the device into

a low power shutdown state. In shutdown the VIN supply

current drops to 5µA. The SHDN pin has an accurate

threshold of 1.32V which can be used to program an

undervoltage lockout threshold. Input current levels on

the SHDN pin can be used to program hysteresis into the

undervoltage lockout levels.

SYNC (Pin 4): The SYNC pin is used to synchronize the

internal oscillator to an external clock signal. The pin is

directly logic compatible and can be driven with any signal

with a duty cycle of 10% to 90%. If the SYNC function is

not used the pin can be left open circuit or connected to

ground.

6

GND (Pin 8): The GND pin is the analog ground for the

internal circuitry of the LT1950. Sensitive circuitry such as

the feedback divider, frequency setting resistor, reference

bypass capacitor should be tied directly to this pin. See the

Applications Information section for recommendations

on ground connections.

1950fa

Page 7

LT1950

U

UU

PI FU CTIO S

BLANK (Pin 9): The BLANK pin is used to adjust the

leading edge blanking period of the current sense amplifier

during FET turn-on. Shorting the BLANK pin to ground

provides a default blanking period of approximately 110ns.

A resistor from the BLANK pin to ground increases the

blanking period up to 290ns for R

I

(Pin 10): The I

SENSE

pin is the current sense input

SENSE

for the control loop. Connect this pin to the sense resistor

in the source of the external power MOSFET.

V

(Pin 11): The V

IN2

pin is the supply pin for the

IN2

MOSFET gate drive circuit. Power can be supplied to this

pin by an external supply such as VIN, and must exceed 8V

(the undervoltage lockout threshold for the gate driver

supply). For low VIN supply voltages an internal boost

regulator can be used to generate as much as 11V at the

V

pin. This allows the LT1950 to run with VIN supply

IN2

voltages down to 3V while still supplying enough gate

drive for standard level MOSFETs.

GATE (PIN 12): The GATE pin is the output of a high current

gate drive circuit used to drive an external MOSFET. The

output is actively clamped to a max voltage of 13V if V

is supplied by a high voltage.

PGND (Pin 13): This is the ground connection for the high

current gate driver stage. See the Applications Information section for recommendations on ground connections.

BLANK

= 75k.

IN2

BOOST (Pin 14): The BOOST pin is the NPN collector

output of the internal boost converter which can be used

to generate an 11V supply for the MOSFET gate driver

circuit. The boost converter runs with a fixed off-time of

0.5µs and a current limit of 125mA. The converter runs

until the V

the V

IN2

voltage exceeds 11V and then turns off until

IN2

voltage drops below 10V. If the V

voltage is

IN2

supplied externally, the BOOST pin should be shorted to

ground or left open.

VIN (Pin 15): The VIN pin is the main supply pin for the

LT1950. This pin must be closely bypassed to ground. If

V

is generated using the BOOST pin then the LT1950

IN2

will be fully functional, internal V

will be active and the

REF

gate output will be enabled with a VIN voltage as low as 3V.

An internal undervoltage lockout threshold exists at approximately 2.6V on the VIN pin. Undervoltage lockout

voltages greater than 3V can be programmed using a

voltage divider on the SHDN pin.

V

(Pin 16): The V

SEC

pin is used to program the

SEC

maximum duty cycle of the gate driver circuit. The maximum duty cycle will be equal to (105/V

)% for V

SEC

SEC

between 1.4V and 2.8V. This is a useful function to limit the

flyback voltage in a forward converter. If the maximum

duty cycle function is not used then the V

pin should be

SEC

tied to ground.

1950fa

7

Page 8

LT1950

BLOCK DIAGRA

W

SHDN

SYNC

R

OSC

SLOPE

V

IN

15 16 14

1.23V

–

+

1.32V

3µA

7

4

3

5

1.23V

+

(TYPICAL 200kHz)

OSC

ERROR AMPLIFIER

VOLTAGE GAIN = 85dB

V

REF

V

IN2

V

=

REF

INTERNAL +

EXTERNAL

SUPPLY

2.5V

(SOURCE 2.5mA

EXTERNALLY)

(V

) (2.6V)

IN

U/V LOCKOUT

(100-500)khz

6

(105/V

RAMP

–

V

SEC

SEC

)%

BOOST

SWITCHING PREREGULATOR

(125mA CURRENT LIMIT)

PGND

–

MAX DC

CLAMP

+

SLOPE COMP

CURRENT

SENSE

0mV – >100mV

FIXED OFF TIME

S

R

BLANKING

CMP

–

DISABLE

(V

) (8V)

IN2

U/V LOCKOUT

ENABLE

–

Q

+

+

±1A

DRIVER

+

–

+

–

13V

–

125mV

11V

8V

BLANKING

OVERRIDE

CMP

+

V

IN2

11

12

GATE

13

PGND

10

I

SENSE

FB COMP GND BLANK

81 92

Figure 1. LT1950 Block Diagram

U

OPERATIO

The LT1950 is a constant frequency, current mode controller for DC/DC forward, boost, flyback and SEPIC converter applications. The Block Diagram in Figure 1 shows

all of the key functions of the IC.

In normal operation, a VIN voltage as low as 3V allows an

internal switcher at the BOOST pin to generate a separate

8

1950 BD

11V supply at V

inductor, diode and capacitor. Since V

using a small surface mount external

IN2

supplies the

IN2

output driver of the IC, this architecture achieves high

GATE drive for an external N-channel power MOSFET even

though VIN voltage is very low. High GATE drive capability

reduces MOSFET R

for improved efficiency,

DS(ON)

1950fa

Page 9

OPERATIO

LT1950

U

increases the range of MOSFETs that can be selected and

allows applications requiring high gate drive with a large

swing in V

voltage. When V

IN

exceeds 8V, the GATE

IN2

output driver is enabled. The GATE switches between 0V

and V

R

OSC

at a constant frequency set by a resistor from the

IN2

pin to ground. When V

reaches 11V, the internal

IN2

switcher at the BOOST pin is disabled to save power and

only re-enabled when V

drops below 10V. The internal

IN2

boost switcher runs in burst mode operation, asynchronous to the main oscillator. If low VIN operation with high

GATE drive is not required, the BOOST pin is left open and

the V

pin shorted to VIN. With V

IN2

minimum operational V

8V (required at V

to enable the GATE output driver). For

IN2

voltage will increase from 3V to

IN

shorted to VIN the

IN2

GATE turn on, a PWM latch is set at the start of each main

oscillator cycle. For GATE turn off, the PWM latch is reset

when either the current sense comparator is tripped, the

maximum duty cycle is reached, or the BLANK override

threshold is exceeded.

A resistor divider from the application’s output voltage

generates a voltage at the FB pin that is compared to the

internal 1.23V reference by the error amplifier. The error

amplifier output (COMP) defines the input threshold

(I

voltage is clamped to 100mV. By connecting I

) of the current sense comparator. Maximum I

SENSE

SENSE

SENSE

to a

sense resistor in series with the source of the external

MOSFET, the peak switch current is controlled by COMP.

An increase in output load current causing the output

voltage to fall, will cause COMP to rise, increasing I

SENSE

threshold, increasing the current delivered to the output.

This current mode technique means that the error amplifier commands current to be delivered to the output rather

than voltage. This makes frequency compensation easier

and provides faster loop response to output load transients.

The current mode architecture requires slope compensation to be added to the current sensing loop to prevent

subharmonic oscillations which can occur for duty cycles

above 50%. Unlike most current mode converters which

have a slope compensation ramp that is fixed internally,

placing a constraint on inductor value and operating

frequency, the LT1950 has externally adjustable slope

compensation. A default level of slope compensation is

achieved with the SLOPE pin open. Increased slope compensation can be programmed by reducing the value of

resistance inserted between the SLOPE pin and V

REF

pin.

A SYNC pin allows the LT1950 main oscillator to be

synchronized to an external clock . To avoid loss of slope

compensation during synchronization, the free running

main oscillator frequency should be programmed to approximately 80% of the external clock frequency.

The LT1950 can be placed into shutdown mode when the

SHDN pin drops below an accurate 1.32V threshold. This

threshold can be used to program undervoltage lockout

(UVLO) at VIN for current limited or high source resistance

supplies. SHDN pin current hysteresis also exists to allow

external programming of UVLO voltage hysteresis. When

VIN and V

and 6.8V, the V

exceed internally set UVLO thresholds of 2.6V

IN2

output becomes active. The V

REF

REF

output

is a 2.5V reference supplying the majority of LT1950

control circuitry and capable of sourcing up to 2.5mA for

external use.

To prevent noise in the system causing premature turn off

of the external MOSFET the LT1950 has leading edge

blanking. This means the current sense comparator output is ignored during MOSFET turn on and for an extended

period after turn on. The extended blanking period is

adjusted by inserting a resistor from the BLANK pin to

ground. A short to ground defines a minimum default

blanking period. Increased resistance from the BLANK pin

to ground will increase blanking duration. Fault conditions

causing I

and reduce the I

to exceed 125mV will override blanking

SENSE

to GATE delay to 60ns.

SENSE

For applications requiring maximum duty cycle clamping,

the V

the pin. The V

pin reduces duty cycle for increased voltage on

SEC

pin provides a volt-second clamp critical

SEC

in forward converter applications.

Maximum duty cycle follows (105/V

ages between 1.4V to 2.8V. If unused, the V

)% for V

SEC

SEC

pin should

SEC

volt-

be shorted to ground, leaving the natural maximum duty

cycle of the part to be typically 95% for 200kHz operation.

1950fa

9

Page 10

LT1950

U

WUU

APPLICATIO S I FOR ATIO

LT1950 Input Supplies, V

is the main input supply for the LT1950. V

V

IN

input supply for the LT1950 output driver. V

provided by shorting the V

generating V

V

, V

IN2

REF

using the BOOST pin. Waveforms of VIN,

IN2

and GATE switching are shown in Figures 2 and

3. Figure 2 represents low VIN operation with V

ated using the B00ST pin. Figure 3 represents VIN = V

operation with the BOOST pin open circuit or shorted to

ground.

Low VIN Operation

The LT1950 can be configured to provide a minimum of

10V GATE drive for an external N-channel MOSFET from

VIN voltages as low as 3V, if the BOOST pin is used to

generate a second supply at the V

Applications Information “ Generating V

BOOST Pin”). The advantage of this configuration is that a

lower R

is achieved for the external N-channel

DS(ON)

MOSFET, improving efficiency, versus a controller running at 3V input without boosted gate drive. In addition,

typical controllers running at low input voltages have the

limitation of only being able to use logic level MOSFETs.

The LT1950 allows a greater range of usable MOSFETs.

This versatility allows optimization of the overall power

supply performance and allows applications which would

otherwise not be possible without a more complex topology. Figure 2 shows that for VIN above 2V, the internal

switcher at the BOOST pin is enabled. This switch generates the V

supply. As V

IN2

undervoltage lockout threshold of 6.8V the 2.5V reference

V

becomes active and powers up internal control

REF

circuitry. When V

driver is enabled. V

exceeds approximately 8V, the gate

IN2

is regulated between 10V and 11V,

IN2

providing a supply to the LT1950 output driver to ensure

a minimum of 10V drive at the GATE pin.

Output and GATE Enable

REF

IN2

IN2

pin to the VIN pin or by

IN2

IN2

pin (see Figure 2 and

IN2

Supply Using

IN2

ramps up above the

IN2

is the

can be

gener-

IN2

VIN = V

Operation

IN2

If low VIN operation is not required below approximately

8V on VIN the LT1950 can be configured to run without the

use of the BOOST pin by shorting the V

pin. Figure 3 shows that both VIN and V

exceed 6.8V to activate the 2.5V V

REF

pin to the V

IN2

IN2

must now

IN

output and must

exceed approximately 8V to enable the output driver

(GATE pin).

12

V

IN2

GATE

IN2

10µs/DIV

Figure 3. VIN = V

MIN

3V

V

IN

V

REF

50µs/DIV

Figure 2. Low VIN Operation

TYPICAL START-UP INPUT

Operation

IN2

IN2

IN2

V

V

>8.2V

IN2

IN2

L1

D1

C1

*

C1

V

IN

BOOST

BOOST

LT1950

V

V

V

IN

BOOST

BOOST

LT1950

*BOOST PIN CAN BE

LEFT OPEN OR

SHORTED TO GROUND

1950 F02

1950 F03

10.2

8.5

6.8

5.1

3.4

5.0

2.5

8

4

0

4

3

2

1

0

VIN = V

V

REF

0

10

GATE

5

0

10

1950fa

Page 11

LT1950

U

WUU

APPLICATIO S I FOR ATIO

Shutdown and Undervoltage Lockout

Figure 4 shows how to program undervoltage lockout

(UVLO) for the V

situations where the input supply is current limited, or has

a relatively high source resistance. A switching regulator

draws constant power from the source, hence source

current increases as source voltage drops. This looks like

a negative load resistance to the source and can cause the

source to current limit or latch low under low source

voltage conditions. An internally set undervoltage lockout

(UVLO) threshold prevents the regulator from operating at

source voltages where these problems might occur. An

internal comparator will force the part into shutdown

below the minimum VIN of 2.6V. This feature can be used

to prevent excessive discharge of battery-operated systems. Alternatively, UVLO threshold is adjustable. The

shutdown threshold voltage of the SHDN pin is 1.32V.

Forcing the SHDN pin below this 1.32V threshold causes

V

to be disabled and stops switching at the GATE pin.

REF

If the SHDN pin is left open circuit, a permanent 3µA flows

out of the pin to ensure that the pin defaults high to allow

normal operation. Voltages above the 1.32V threshold

cause an extra 7µA to be sourced out of the pin, providing

current hysteresis. This can be used to set voltage hysteresis of the UVLO threshold using the following equations:

supply. Typically, UVLO is used in

IN

Example: switching should not start until the input is

above 11V and is to stop if the input falls below 9V.

= 11V

V

H

V

= 9V

L

VV

11 9

R

1

R

2

–

=

7

=

11 1 32

(–.)

=

A

µ

132

.

VV

k

286

286

V

k

A

3

+µ

k

36

=

Keep the connections from the resistors to the SHDN pin

short and make sure that the interplane or surface capacitance to the switching nodes are minimized. If high resistance values are used, the SHDN pin should be bypassed

with a 1nF capacitor to prevent coupling problems from

the switch node.

LT1950

V

IN

R1

C1

R2

3µA

1.32V

7µA

GND

V

REF

+

VV

–

HL

R

1

=

A

7

µ

V

132

R

2

=

VV

(–. )

.

132

H

R

1

3

+µ

VH = Turn on threshold

VL = Turn off threshold

1950 F04

Figure 4. Undervoltage Lockout

Generating V

A

The LT1950’s BOOST pin is used to provide a “boosted”

11V supply at the V

Since V

IN2

the IC, it is advantageous to generate a boosted V

Supply Using BOOST Pin

IN2

pin for VIN voltages as low as 3V.

IN2

supplies the output driver for the GATE pin of

. This

IN2

architecture achieves high GATE drive for an external

1950fa

11

Page 12

LT1950

U

WUU

APPLICATIO S I FOR ATIO

N-channel power MOSFET even though VIN voltage is very

low. High GATE drive voltage reduces MOSFET R

improves efficiency and increases the range of MOSFETs

that can be selected. A small switching regulator at the

BOOST pin, with fixed current limit and fixed off time,

generates the V

connected between the BOOST pin and V

supply. With an external inductor

IN2

(see Figure 5),

IN

the BOOST pin will draw current until approximately

125mA is reached, turn off for 0.5µs and then turn back on.

The cycle is repeated for as long as the switcher is enabled.

By using a diode connected from BOOST to V

capacitor from V

inductor is transferred to the V

to ground, energy from the external

IN2

capacitor during the off-

IN2

IN2

time of the internal switcher. An auxiliary boost converter

is realized providing a supply to the V

inductor current, V

voltage and BOOST pin voltage

IN2

waveforms are shown in Figure 5. When V

the internal switcher is disabled. Since V

pin. The typical

IN2

reaches 11V,

IN2

supplies the

IN2

output driver of the LT1950, switching at the GATE pin will

eventually discharge the V

capacitor until V

IN2

reaches

IN2

a lower level of approximately 10V. At this level the internal

switcher is re-enabled and switches until V

12

(V)

(A)

(A)

(V)

10

0.25

0

0.25

0

15

0

Figure 5. V

5µs/DIV

Generation Using the BOOST Pin

IN2

V

IN2

I

I

BOOST

MIN

3V

D1

L1

V

IN

BOOST

BOOST

LT1950

IN2

V

returns to

V

IN2

IN2

DS(ON)

and a

L1

D1

C1

1950 F05

,

11V. This hysteretic (burst mode) operation for the internal switcher minimizes power dissipation from V

The V

output is a 2.5V reference supplying most of the

REF

IN

.

LT1950 control circuitry. It is available for external use

with maximum current capability of 2.5mA. The pin should

be bypassed to ground using a 0.1µF capacitor. Internal

undervoltage lockout thresholds for V

IN

and V

IN2

of approximately 2.6V and 6.8V respectively must be exceeded

before V

becomes active.

REF

Programming Oscillator Frequency

The oscillator frequency of the LT1950 is programmed

using an external resistor connected between the R

and ground. Figure 6 shows typical f

OSC

vs R

OSC

pin

OSC

resistor

values. The LT1950 is programmable for a free-running

oscillator frequency in the range of 100kHz to 500kHz.

Stray capacitance and potential noise pickup on the R

pin should be minimized by placing the R

close as possible to the R

the R

R

OSC

node as small as possible. The ground side of the

OSC

resistor should be returned directly to the GND

pin and keeping the area of

OSC

resistor as

OSC

OSC

(analog ground) pin.

500

450

400

350

300

250

FREQUENCY (kHz)

200

150

100

100 150 250200 300 350

50

R

(kΩ)

OSC

Figure 6. Oscillator Frequency (f

400 450 500

1950 F06

) vs R

OSC

OSC

12

1950fa

Page 13

LT1950

U

WUU

APPLICATIO S I FOR ATIO

Synchronizing

The SYNC pin is used to synchronize the LT1950 main

oscillator to an external clock. The SYNC pin can be driven

directly from a logic level output, requiring less

than 0.8V for a logic level low and greater than 2.2V for a

logic level high. Duty cycle must be between 10% and

90%. When synchronizing the part, slope compensation

will be reduced by approximately SYNC f/f

reduction of slope compensation affects performance,

R

can be reduced to increase slope compensation

SLOPE

and reestablish correct operation. If unused, the pin is left

open or shorted to ground. If left open, be aware that the

internal pin resistance is 20k and board layout should be

checked to avoid noise coupling to the pin.

SLOPE COMPENSATION

Programmability

The LT1950 allows its default level of slope compensation

to be easily increased by use of a single resistor connected

between the SLOPE pin and the V

pin. The ability to

REF

adjust slope compensation allows the designer to tailor his

application for a wider inductor value range as well as to

optimize the loop bandwidth. A resistor, R

nected between the SLOPE pin and V

increases the

REF

LT1950 slope compensation from its default level to as

high as 3X of default. The curves in Figure 7 show the

typical I

ous values of R

tion subtracts from the maximum I

maximum threshold vs duty cycle for vari-

SENSE

. It can be seen that slope compensa-

SLOPE

threshold as duty

SENSE

cycle increases from 0%. For example, with R

I

max threshold is 100mV at low duty cycle, but falls

SENSE

to approximately 86mV at 80% duty cycle. This must be

accounted for when designing a converter to operate up to

a maximum load current and over a given duty cycle range.

The application and inductor value will define the

minimum amount of slope compensation. Refer to the

OSC

SLOPE

SLOPE

. If the

, con-

open,

Electrical Characteristics for 1X, 2X and 3X default slope

compensation vs R

SLOPE

.

Requirement in Current Mode Converters/Advantage

of Adjustability

The LT1950 uses a current mode architecture to provide

fast response to load transients and to ease frequency

compensation requirements. Current mode switching regulators which operate with duty cycles above 50% and have

continuous inductor current, must add slope compensation to their current sensing loop to prevent subharmonic

oscillations. (For more information on slope compensation see Application Note 19). Typical current mode switching regulators have a fixed internal slope compensation.

This can place constraints on the value of the inductor. If

too large an inductor is used, the fixed internal slope

compensation will be greater than needed, causing operation to approach voltage mode. If too small an inductor is

used, the fixed internal slope compensation will be too

small, resulting in subharmonic oscillations. The LT1950

increases the range of usable inductor values by allowing

slope compensation to be adjusted externally.

100

90

80

70

60

50

MAX THRESHOLD (mV)

40

SENSE

I

30

20

0

Figure 7. I

SENSE

40

20

DUTY CYCLE (%)

Maximum Threshold vs Duty Cycle

R

SLOPE

R

SLOPE

R

SLOPE

60 80

= OPEN

= 8k

= 3.3k

100

1950 F07

1950fa

13

Page 14

LT1950

U

WUU

APPLICATIO S I FOR ATIO

Programming Leading Edge Blank Time

For PWM controllers driving external MOSFETs, noise can

be generated during GATE rise time due to various parasitic effects. This noise can disturb the input to the current

sense comparator (I

of the external MOSFET. The LT1950 provides programmable leading edge blanking of the current sense comparator to avoid this effect.

Blanking is provided in 2 phases: The first phase is during

GATE rise time. GATE rise times vary depending on

MOSFET type. For this reason the LT1950 automatically

blanks the current comparator output until the “leading

edge” of the GATE is detected. This occurs when the GATE

voltage has risen within 0.5V of the output driver supply

(V

) or has reached its clamp level of 13V. The second

IN2

phase of blanking starts immediately after “leading edge”

has been detected. This phase is programmable using a

resistor (R

) from the BLANK pin to ground. Typical

BLANK

values for this portion of the blanking period are 110ns at

R

blanking vs R

= 0Ω up to 290ns at R

BLANK

BLANK

mated as:

BLANKING EXTENDED

() •=+

) and cause premature turn-off

SENSE

= 75k. Figure 8 shows

BLANK

. Blanking duration can be approxi-

⎛

110 60

⎜

⎝

R

BLANK

k

25

⎞

ns

⎟

⎠

Programming Volt-Second Clamp

The V

pin is used to provide an adaptive maximum duty

SEC

cycle clamp for sophisticated control of the simplest

forward converter topology (single primary-side switch).

This adaptive maximum duty cycle clamp allows the use of

the smallest transformers, MOSFETs and output rectifiers

by addressing the biggest concern in single switch forward converter topologies - transformer reset. The section “Application Circuits-Forward Converter Applications”

covers transformer reset requirements and highlights the

advantages of the LT1950 adaptive maximum duty cycle

clamp. The programmable maximum duty cycle clamp is

controlled by the voltage on the V

V

pin increases within a specified range, maximum

SEC

duty cycle decreases. By deriving V

pin. As voltage on the

SEC

pin voltage from

SEC

the system input supply, a volt-second clamp is realized.

Maximum GATE output duty cycle follows a 1/X relationship given by (105/V

V

Voltage graph in the Typical Performance Character-

SEC

)%. (see Maximum Duty Cycle vs

SEC

istics section). For example, if the minimum input supply

for a forward converter application is 36V, the V

SEC

pin can

be programmed with a maximum duty cycle of 75% at

1.4V. A movement of input voltage to 72V will lift the V

SEC

pin to 2.8V, resulting in a maximum duty cycle of 37.5%.

As the section on Forward Converter Applications will

show, transformer reset requirements are met with the

14

GATE

BLANKING

(AUTOMATIC)

LEADING

BLANKING

0 Xns

(DEFAULT)

EDGE

EXTENDED

BLANKING

R

= 0Ω 0Ω < R

BLANK

Figure 8. Blanking Timing Diagram

(X + 110)ns

(PROGRAMMABLE)

EXTENDED

BLANKING

BLANK

[X + 110 + (60 • R

CURRENT

SENSE

DELAY

< = 75k 60ns

BLANK

/25k)]ns

1950 F04

1950fa

Page 15

LT1950

U

WUU

APPLICATIO S I FOR ATIO

ability of the V

maximum switch duty cycle.

Forward Converter Applications

The LT1950 provides sophisticated control of the simplest

forward converter topology (single primary switch, see Q1

Figure 11). A significant problem in a single switch forward converter topology is transformer reset. Optimum

transformer utilization requires maximum duty cycles.

Unfortunately as duty cycles increase the transformer

reset time decreases and reset voltages increase. This

increases the voltage requirements and stress on both

transformer and switch. The LT1950 incorporates an

adaptive maximum duty cycle clamp which controls maximum switch duty cycle based on system input voltage.

The adaptive clamp allows the converter to operate at up

to 75% duty cycle, allowing 25% of the switching period

for resetting the transformer. This results in greater

utilization of MOSFET, transformer and output rectifier

components. The V

system input to adaptively control maximum duty cycle

(see Applications Information “Programming Volt-Second Clamp” and the Maximum Duty Cycle vs V

graph in the Typical Performance Characteristics section).

pin to follow input voltage and control

SEC

pin can be programmed from

SEC

Voltage

SEC

94% Efficient 3.3V, 20A Synchronous Forward

Converter

The synchronous forward converter in Figure 11 is based

on the LT1950 and uses MOSFETs as synchronous output

rectifiers to provide an efficient 3.3V, 20A isolated output

from 48V input. The output rectifiers are driven by the

LTC1698 which also serves as an error amplifier and

optocoupler driver. Efficiency and transient response

are shown in Figures 9 and 10. Peak efficiencies of 94%

and ultra-fast transient response are superior to presently

available power modules. In addition, the circuit in Figure 11

is an all-ceramic capacitor solution providing low output

ripple voltage and improved reliability. The LT1950-based

converter can be used to replace power module converters

at a much lower cost. The LT1950 solution benefits from

thermal conduction of the system board resulting in

higher efficiencies and lower rise in component temperatures. The 7mm height allows dense packaging and the

circuit can be easily adjusted to provide an output voltage

from 1.23V to 15V. In addition, higher currents are achievable by simple scaling of power components. The LT1950based solution in Figure 11 is a powerful topology for

replacement of a wide range of power modules.

100

95

90

85

EFFICIENCY (%)

80

75

70

0

Figure 9. LT1950-Based Synchronous Forward

Converter Efficiency vs Load Current

5101520

LOAD CURRENT (A)

VIN = 48V

= 3.3V

V

OUT

= 235kHz

f

OSC

1950 F09

LT1950

V

OUT

(100mV/DIV)

POWER

MODULE

V

OUT

(100mV/DIV)

500µs/DIV

Figure 10. Output Voltage Transient Response

to Load Steps (0A to 3.3A) LT1950 (Trace1)

vs Power Module (Trace 2)

1950 F10

1950fa

15

Page 16

LT1950

WUUU

APPLICATIO S I FOR ATIO

10V

R6

18k

C3

10nF

R3

4.7k

0.1µF

BIAS

C

1µF

U1

6

5

4

IN

R18

27k

D3

R1

4.7k

R17, 210k

C1

0.1µF

R4, 18k

R9

470k

10V

COMP

+V

1

2

3

4

5

6

7

8

IN

BIAS

100k

UV

COMP

FB

R

OSC

SYNC

SLOPE

V

REF

SHDN

GND

LT1950

BOOST

I

BLANK

Q4

BC847BF

4.7µF

V

SEC

V

PGND

GATE

V

IN2

SENSE

R2

4.7k

C6

IN

100k

470k

16

15

14

13

12

11

10

9

R5

UV

+V

C

S

BAT760

R7

255Ω

D1

BAS516

C4

1000pF

U4

HCPL-M453

36V

TO 72V

INPUT

10V

1

10V

3

BIAS

U2A

8

LTC1693-1

2

BAT760

BIAS

U2B

6

LTC1693-1

4

+V

–V

1

2

3

IN

IN

7

D2

5

220pF

2.2µF

100V

X5R

47Ω

T2

C

IN

T1

STG-0313W

1µF

X5R

C9, 33nF

+V

Q2

Si7380

2×

7V

BIAS

R13

270Ω

R14

1.2k

01

R15

4.7k

CG

1

2

3

4

5

6

7

8

R16

2.8k

CG

V

DD

CG

PGND

GND

OPTO

V

COMP

MARG

V

FB

LTC1698

=1.233V

Q1

FG

Si4490

R

S

0.015Ω

C

S

SYNC

560Ω

L1

C.PI-1365-1R2

Q3

Si7380

2×

16

FG

15

SYNC

14

V

AUX

13

I

COMP

12

+I

SNS

11

–I

SNS

10

PWTOK

9

OVP

FG

SYNC

+V

3.3V

20A

C

01

100µF

X5R

4×

0.1µF

01

COMP

Figure 11. 36V to 72V Input to 3.3V at 20A Synchronous Forward Converter

16

1950fa

Page 17

WUUU

APPLICATIO S I FOR ATIO

LT1950

High Efficiency, Isolated 26V 5A Output,

Nonsynchronous Forward Converter

Figure 13 illustrates a nonsynchronous forward converter

based on the LT1950 to provide a highly efficient, 26V 5A

isolated output from 48V input. The LT1950-based converter using a single switch topology and utilizing the

LT1950s adaptive maximum duty cycle clamp is a simple

and highly optimized solution. Peak efficiencies of 92.8%

(Figure 12) are achievable. Transformer and inductor are

standard components. The quarter brick sized DC/DC

converter (2.3" by 1.45") delivers over 125W and is only

0.4" high. The 26V converter can be used as a “front line”

(isolating) converter in telecom systems with multiple

outputs.

+V

IN

C

36V

TO 72V

INPUT

–V

IN

2.2µF

100V

X5R

IN

T1

PA0581

MBR20200CT

94

93

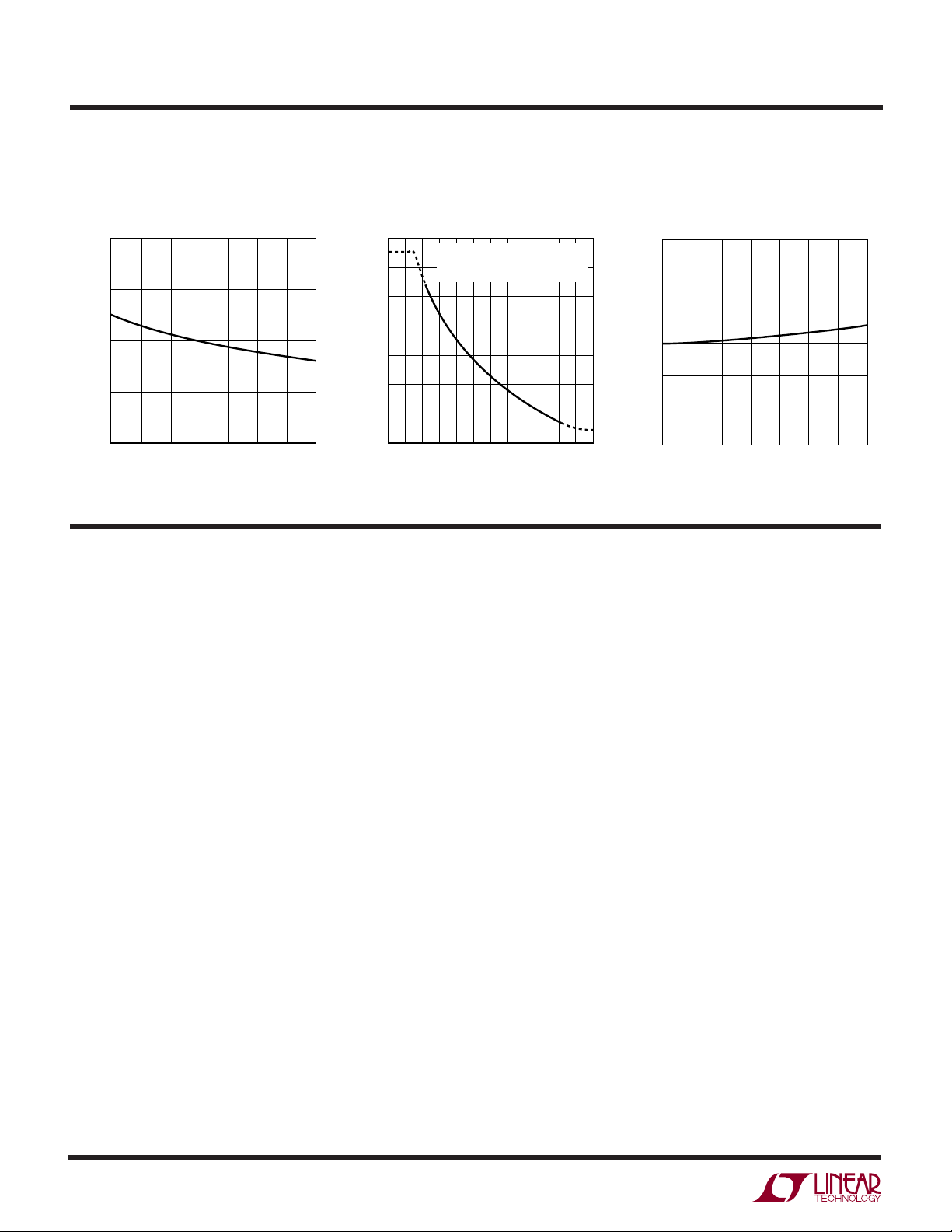

92

91

90

89

88

EFFICIENCY (%)

87

86

85

84

1

2

LOAD CURRENT (A)

VIN = 48V

V

OUT

f

OSC

3

4

Figure 12. LT1950-Based Nonsynchronous

Forward Converter Efficiency vs Load

Current (Figure 13 Circuit)

+V

47µH

OUT

= 26V

= 235kHz

5

1950 F12

232k

24.9k

18k

–

4

5

1

U3

LT1797

47k

3

+

2

1µF

U2

LT1009

FMMT625

1µF

6.8k

0.1µF

210k

27k

5

6

3

9

4

2

1

SLOPE

V

REF

R

OSC

BLANK

SYNC

FB

COMP

LT1950

V

SHDN

GATE

I

SENSE

PGND

V

SEC

GND

10V

+V

BIAS

IN

15

V

IN

11

IN2

470k

16

7

18k

12

10

8

13

Si7450

0.015

47µF

470pF

330R

OC1

Figure 13. 36V to 72V Input to 26V at 5A Nonsynchronous Forward Converter

22k

8.2V

1950 F13

1950fa

17

Page 18

LT1950

WUUU

APPLICATIO S I FOR ATIO

10.5k

1.21k

BOOST

PGND

I

SENSE

BLANK

V

IN

V

SEC

V

GATE

V

IN

IN2

3.3V BIAS

16

15

14

13

12

11

10

9

47k

C3

4.7µF

16V

L1

4.7µH

D2

BAS516

R9, 47Ω

C6

0.01µF

R8

*L2, L3 (COUPLED INDUCTORS)

VP5-0155

+V

OUT

C1

R3

2200pF

R1

R2

R4

133k

35.7k

18k

R5

16.2k

C2

0.1µF

R6

1

2

3

4

5

6

7

8

COMP

FB

R

OSC

SYNC

SLOPE

V

REF

SHDN

GND

R7

71.5k

LT1950

Figure 14. 4V to 36V Input, 12V/1.5A Automotive SEPIC Converter

C

IN

10µF

50V

TDK

L2*

C4

4.7µF

16V

V

4V TO 36V

C5

10µF

50V

Q1

Si7456

R10

0.010Ω

IN

MBRD660CT

L3*

D1

+V

OUT

12V, 1.5A

C

OUT

47µF, 16V

X5R, TDK

×4

18

1950fa

Page 19

PACKAGE DESCRIPTIO

LT1950

U

GN Package

16-Lead Plastic SSOP (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1641)

.045 ±.005

.254 MIN

RECOMMENDED SOLDER PAD LAYOUT

.007 – .0098

(0.178 – 0.249)

.016 – .050

NOTE:

1. CONTROLLING DIMENSION: INCHES

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

*DIMENSION DOES NOT INCLUDE MOLD FLASH. MOLD FLASH

SHALL NOT EXCEED 0.006" (0.152mm) PER SIDE

**DIMENSION DOES NOT INCLUDE INTERLEAD FLASH. INTERLEAD

FLASH SHALL NOT EXCEED 0.010" (0.254mm) PER SIDE

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.150 – .165

.0250 TYP.0165 ± .0015

.015 ± .004

(0.38 ± 0.10)

0° – 8° TYP

× 45°

.229 – .244

(5.817 – 6.198)

.053 – .068

(1.351 – 1.727)

.008 – .012

(0.203 – 0.305)

16

15

12

.189 – .196*

(4.801 – 4.978)

14

12 11 10

13

5

4

3

678

.0250

(0.635)

BSC

.009

(0.229)

9

.004 – .0098

(0.102 – 0.249)

REF

.150 – .157**

(3.810 – 3.988)

GN16 (SSOP) 0502

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1950fa

19

Page 20

LT1950

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1534 Ultralow Noise 2A Switching Regulator Reduces Conducted and Radiated EMI, Low Switching Harmonics,

20kHz to 250kHz Switching Frequency

LT1619 Low Voltage Current Mode Controller 1.9V ≤ VIN ≤ 18V, 300kHz Operation, Boost, Flyback, SEPIC

LT1681/LT3781 Dual Transistor Synchronous Forward Controller Operation Up to 72V Maximum

LTC1693 High Speed MOSFET Driver 1.5A Peak Output Current, 16ns Rise/Fall Time at VCC = 12V, CL = 1nF

LTC1698 Secondary Synchronous Rectifier Controller Use with the LT1950 or LT1681, Isolated Power Supplies,

Contains Voltage Margining, Optocoupler Driver, Synchronization

Circuit with the Primary Side

LT1725 General Purpose Isolated Flyback Controller No Optoisolator Required, Accurate Regulation Without User Trims,

50kHz to 250kHz Switching Frequency, SSOP-16 Package

LTC1871 Wide Input Range, No R

LT1910 Protected High Side MOSFET Driver 8V to 48V Supply Range, Protected –15V to 60V Supply Transient

LTC3440 Micropower Buck-Boost DC/DC Converter Synchronous, Single Inductor, No Schottky Diode Required

LTC3704 Positive-to-Negative DC/DC Controller 2.5V ≤ VIN ≤ 36V, No R

No R

is a trademark of Linear Technology Corporation.

SENSE

TM

Controller Operation as Low as 2.5V Input, Boost, Flyback, SEPIC

SENSE

Current Mode Operation,

Excellent Transient Response

SENSE

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

1950fa

LT/TP 0504 1K REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2003

Loading...

Loading...