Page 1

LT1946A

LOAD CURRENT (mA)

0

100 200 300 400 500

EFFICIENCY (%)

1946A TA01

90

85

80

75

70

65

60

55

50

2.7MHz Boost DC/DC

Converter with 1.5A Switch

and Soft-Start

FEATURES

■

1.5A, 36V Internal Switch

■

2.7MHz Switching Frequency

■

Integrated Soft-Start Function

■

Adjustable Output from VIN to 35V

■

Low V

■

12V at 430mA from a 5V Input

■

Small Thermally Enhanced 8-Lead MSOP Package

Switch: 300mV at 1.5A (Typical)

CESAT

U

APPLICATIO S

■

TFT-LCD Bias Supplies

■

GPS Receivers

■

DSL Modems

■

Local Power Supply

U

DESCRIPTIO

The LT®1946A is a fixed frequency step-up DC/DC converter containing an internal 1.5A, 36V switch. Capable of

generating 12V at 430mA from a 5V input, the LT1946A is

ideal for powering large TFT-LCD panels. The LT1946A

switches at 2.7MHz, allowing the use of tiny, low profile

inductors and low value ceramic capacitors. Loop compensation can be either internal or external, giving the user

flexibility in setting loop compensation and allowing optimized transient response with low ESR ceramic output

capacitors. Soft-start is controlled with an external capacitor which determines the input current ramp rate during

start up. The 8-lead MSOP package and high switching

frequency ensure a low profile overall solution less than

1.1mm high.

, LTC and LT are registered trademarks of Linear Technology Corporation.

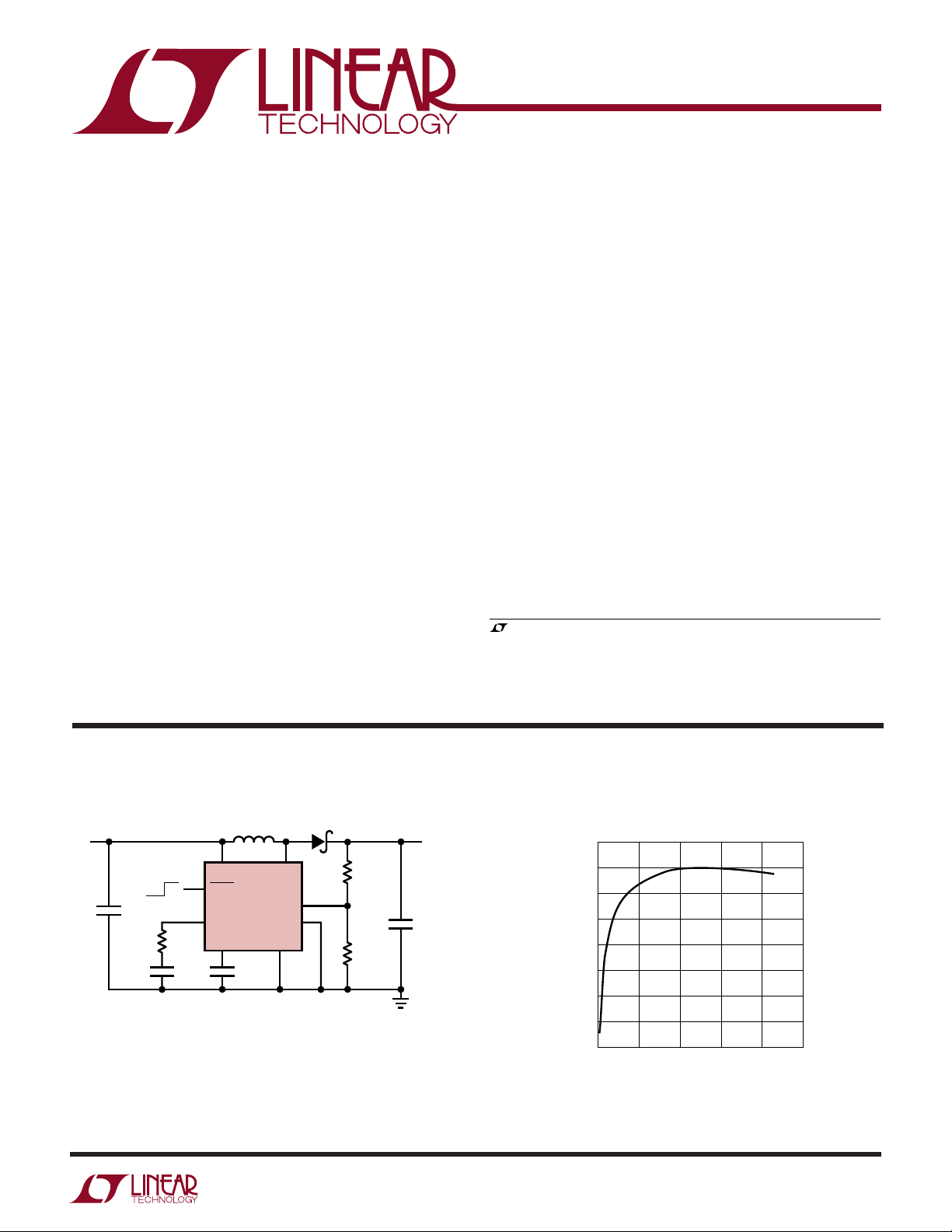

TYPICAL APPLICATIO

U

L1

V

IN

5V

OFF ON

C1

2.2µF

R

C

27.4k

C

C

270pF

C1: 2.2µF, X5R or X7R, 6.3V

C2: 2.2µF, X5R or X7R, 16V

D1: MICROSEMI UPS120 OR EQUIVALENT

L1: SUMIDA CR43-2R2

* EXPOSED PAD MUST ALSO BE GROUNDED

C

100nF

SS

2.2µH

65

V

IN

3

SHDN

LT1946A

1

V

C

GND*SS

Figure 1. 5V to 12V, 430mA Step-Up DC/DC Converter

SW

COMP

48

D1

R1

182k

2

FB

7

R2

21k

V

12V

430mA

C2

2.2µF

1946A TA01

OUT

Efficiency

sn1946a 1946afs

1

Page 2

LT1946A

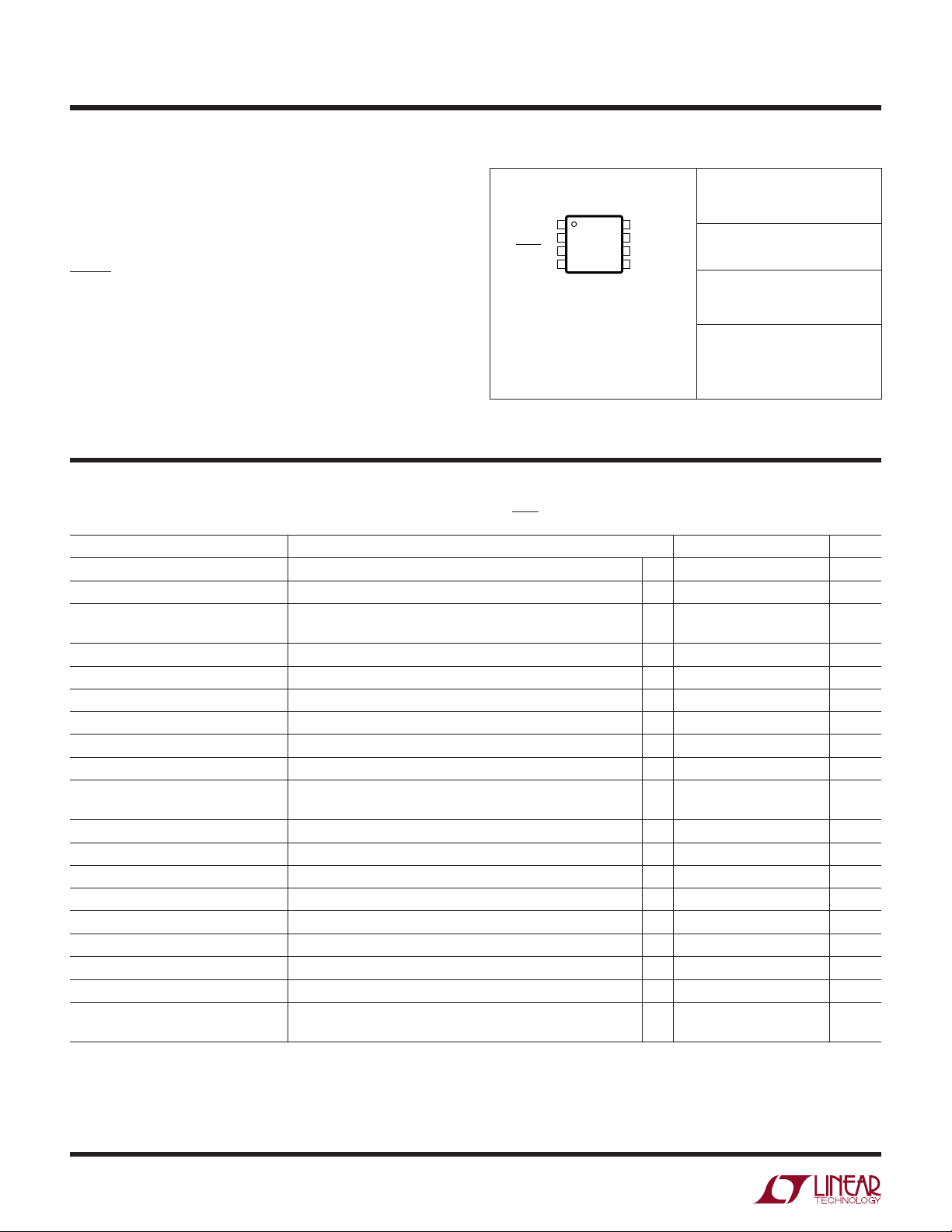

PACKAGE/ORDER I FOR ATIO

UU

W

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

VIN Voltage .............................................................. 16V

SW Voltage ................................................–0.4V to 36V

FB Voltage .............................................................. 2.5V

Current into FB Pin ............................................... ±1mA

SHDN Voltage .......................................................... 16V

Maximum Junction Temperature .......................... 125°C

Operating Temperature

Range (Note 2) ....................................... – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

ORDER PART

TOP VIEW

V

1

C

2

FB

3

SHDN

4

GND

MS8E PACKAGE

8-LEAD PLASTIC MSOP

EXPOSED PAD IS GROUND

(MUST BE SOLDERED TO PCB)

T

= 125°C, θJA = 40°C/W,

JMAX

= 10°C/W

θ

JC

Consult LTC Marketing for parts specified with wider operating temperature ranges.

8

7

6

5

SS

COMP

V

IN

SW

NUMBER

LT1946AEMS8E

MS8E PART

MARKING

LTYZ

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 3V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Operating Voltage 2.45 2.6 V

Maximum Operating Voltage 16 V

Feedback Voltage 1.23 1.25 1.27 V

FB Pin Bias Current VFB = 1.25V (Note 3) ● 20 120 nA

Error Amp Transconductance ∆I = 2µA40µmhos

Error Amp Voltage Gain 300 V/V

Quiescent Current V

Quiescent Current in Shutdown V

Reference Line Regulation 2.6V ≤ VIN ≤ 16V 0.01 0.05 %/V

Switching Frequency 2.4 2.7 3 MHz

Switching Frequency in Foldback VFB = 0V 0.85 MHz

Maximum Duty Cycle ● 73 80 %

Switch Current Limit (Note 4) ● 1.5 2.1 3.1 A

Switch V

CESAT

Switch Leakage Current VSW = 5V 0.01 1 µA

Soft-Start Charging Current VSS = 0.5V 2.5 4 6 µA

SHDN Input Voltage High 2.4 V

SHDN Input Voltage Low 0.5 V

SHDN Pin Bias Current V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1946AE is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

= 2.5V, Not Switching 3.6 5 mA

SHDN

= 0V, VIN = 3V 0 1 µA

SHDN

ISW = 1A 240 340 mV

= 3V 16 32 µA

SHDN

= 0V 0 0.1 µA

V

SHDN

The ● denotes the specifications which apply over the full operating

= VIN unless otherwise noted. (Note 2)

SHDN

● 1.22 1.27 V

● 2.3 3.1 MHz

temperature range are assured by design, characterization and correlation

with statistical process controls.

Note 3: Current flows out of the FB pin.

Note 4: Current limit guaranteed by design and/or correlation to static test.

Current limit is independent of duty cycle and is guaranteed by design.

sn1946a 1946afs

2

Page 3

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Feedback Pin Voltage Oscillator Frequency Current Limit

1.28

1.27

1.26

1.25

1.24

1.23

FEEDBACK VOLTAGE (V)

1.22

1.21

1.20

–50 –25 0 25 50 75 100 125

TEMPERATURE (°C)

1946A G01

Switch Saturation Voltage Quiescent Current

0.35

0.30

0.25

0.20

(V)

CESAT

0.15

V

0.10

0.05

0

0 0.2

0.4 0.6 0.8 1 1.2 1.4 1.6

SWITCH CURRENT (A)

1946A G04

3000

2700

2400

TA = –30°C TA = 100°C

2100

1800

1500

1200

900

600

OSCILLATOR FREQUENCY (kHz)

300

0

0 0.2

4.0

3.8

3.6

3.4

3.2

3.0

2.8

QUIESCENT CURRENT (mA)

2.6

2.4

2.2

–50 –25 0 25 50 75 100 125

0.4 0.6 0.8 1 1.2

FEEDBACK VOLTAGE (V)

TEMPERATURE (°C)

TA = 25°C

1946A G02

1946A G05

2.6

2.4

2.2

2.0

1.8

1.6

1.4

1.2

1.0

CURRENT LIMIT (A)

0.8

0.6

0.4

0.2

0

–50 –25

V

OUT

100mV/DIV

AC COUPLED

V

SW

10V/DIV

0V

0.5A/DIV

LT1946A

0 25 50 75 100 125

TEMPERATURE (°C)

Switching Waveforms for

Figure 1 Circuit

I

LI

100ns/DIV 1946A G06

1946A G03

V

100mV/DIV

AC COUPLED

0.5A/DIV

250mA

I

LOAD

150mA

Transient Response for

Figure 1 Circuit

OUT

I

LI

50µs/DIV 1946A G07

V

OUT

2V/DIV

200mA/DIV

V

SHDN

Start-Up Waveforms for

Figure 1 Circuit

I

IN

0A

5V

0V

R

= 250Ω 1ms/DIV 1946A G08

LOAD

sn1946a 1946afs

3

Page 4

LT1946A

U

UU

PI FU CTIO S

VC (Pin 1): Error Amplifier Output Pin. Tie external compensation network to this pin or use the internal compensation network by shorting the VC pin to the COMP pin.

External compensation consists of placing a resistor and

capacitor in series from VC to GND. Typical capacitor

range is from 90pF to 270pF. Typical resistor range is from

25k to 120k.

FB (Pin 2): Feedback Pin. Reference voltage is 1.25V.

Connect resistive divider tap here. Minimize trace area at

FB. Set V

SHDN (Pin 3): Shutdown Pin. Tie to 2.4V or more to enable

device. Ground to shut down. Do not float this pin.

GND (Pin 4, Exposed Pad): Ground. Tie both Pin 4 and

the exposed pad directly to local ground plane. The

ground metal to the exposed pad should be wide for better

heat dissipation. Multiple vias (local ground plane ↔

ground backplane) placed close to the exposed pad can

further aid in reducing thermal resistance.

according to V

OUT

= 1.25 • (1+R1/R2).

OUT

SW (Pin 5): Switch Pin. This is the collector of the internal

NPN power switch. Minimize the metal trace area connected to this pin to minimize EMI.

VIN (Pin 6): Input Supply Pin. Must be locally bypassed.

COMP (Pin 7): Internal Compensation Pin. Provides an

internal compensation network. Tie directly to the VC pin

for internal compensation. Tie to GND if not used.

SS (Pin 8): Soft-Start Pin. Place a soft-start capacitor

here. Upon start-up, 4µA of current charges the capacitor

to 1.5V. Use a larger capacitor for slower start-up. Leave

floating if not in use.

4

sn1946a 1946afs

Page 5

BLOCK DIAGRA

LT1946A

W

V

OUT

R1 (EXTERNAL)

FB

R2 (EXTERNAL)

SHUTDOWN

V

SHDN

SS V

4µA

1.25V

6

IN

REFERENCE

+

A1

–

+

0.5V

A3

÷ 3

–

23

FB

COMP

C

1 78

RAMP

GENERATOR

2.7MHz

OSCILLATOR

120k

90pF

COMPARATOR

–

A2

RQ

S

+

DRIVER

+

Σ

5

SW

Q1

0.01Ω

–

4

GND

EXPOSED

PAD

1946A F02

Figure 2. Block Diagram

sn1946a 1946afs

5

Page 6

LT1946A

OPERATIO

U

The LT1946A uses a constant frequency, current mode

control scheme to provide excellent line and load regulation. Please refer to Figure 2 for the following description

of the part’s operation. At the start of the oscillator cycle,

the SR latch is set, turning on the power switch Q1. The

switch current flows through the internal current sense

resistor generating a voltage. This voltage is added to a

stabilizing ramp and the resulting sum is fed into the

positive terminal of the PWM comparator A2. When this

voltage exceeds the level at the negative input of A2, the SR

latch is reset, turning off the power switch. The level at the

negative input of A2 (VC pin) is set by the error amplifier

(A1) and is simply an amplified version of the difference

between the feedback voltage and the reference voltage of

1.250V. In this manner, the error amplifier sets the correct

peak current level to keep the output in regulation.

Two functions are provided to enable a very clean start-up

for the LT1946A. Frequency foldback is used to reduce the

oscillator frequency by one-third when the FB pin is below

WUUU

APPLICATIO S I FOR ATIO

Inductor Selection

Several inductors that work well with the LT1946A are

listed in Table 1. This table is not complete, and there are

many other manufacturers and devices that can be used.

Consult each manufacturer for more detailed information

and for their entire selection of related parts, as many

different sizes and shapes are available. Ferrite core inductors should be used to obtain the best efficiency, as core

losses at 2.7MHz are much lower for ferrite cores than for

the cheaper powdered-iron ones. Choose an inductor that

can handle at least 1.5A without saturating, and ensure

that the inductor has a low DCR (copper-wire resistance)

to minimize I2R power losses. A 1.5µH to 4.7µH inductor

will be the best choice for most LT1946A designs. Note

that in some applications, the current handling requirements of the inductor can be lower, such as in the SEPIC

topology where each inductor only carries one-half of the

total switch current.

The inductors shown in Table 1 were chosen for small size.

For better efficiency, use similar valued inductors with a

larger volume.

a nominal value of 0.5V. This is accomplished via comparator A3. This feature reduces the minimum duty cycle

that the part can achieve thus allowing better control of the

switch current during start-up. When the FB pin voltage

goes above 0.5V, the oscillator returns to the normal

frequency of 2.7MHz. A soft-start function is also provided

by the LT1946A. When the part is brought out of shutdown, 4µA of current is sourced out of the SS pin. By

connecting an external capacitor to the SS pin, the rate of

voltage rise on the pin can be set. Typical values for the

soft-start capacitor range from 10nF to 200nF. The SS pin

directly limits the rate of rise on the VC pin, which in turn

limits the peak switch current. Current limit is not shown

in Figure 2. The switch current is constantly monitored and

not allowed to exceed the nominal value of 2.1A. If the

switch current reaches 2.1A, the SR latch is reset regardless of the output of comparator A2. This current limit

protects the power switch as well as various external

components connected to the LT1946A.

Table 1. Recommended Inductors - LT1946A

MAX Size

L DCR LxWxH

PART (µH) (mΩ) (mm) VENDOR

RLF5018-1R5M2R1 1.5 25 5.2x5.6x1.8 TDK

RLF5018-2R7M1R8 2.7 33 (847) 803-6100

RLF5018-4R7M1R4 4.7 45 www.tdk.com

RLF5018-100MR94 10.0 67

LPO1704-122MC 1.2 80 5.5x6.6x1.0 Coilcraft

LPO1704-222MC 2.2 120 (800) 322-2645

www.coilcraft.com

CR43-2R2 2.2 71 4.5x4.0x3.2 Sumida

CR43-3R3 3.3 86 (847) 956-0666

www.sumida.com

Capacitor Selection

Low ESR (equivalent series resistance) capacitors should

be used at the output to minimize the output ripple voltage.

Multilayer ceramic capacitors are an excellent choice, as

they have an extremely low ESR and are available in very

small packages. X5R dielectrics are preferred, followed by

X7R, as these materials retain the capacitance over wide

voltage and temperature ranges. A 2.2µF to 20µF output

sn1946a 1946afs

6

Page 7

WUUU

APPLICATIO S I FOR ATIO

capacitor is sufficient for most applications, but systems

with very low output currents may need only a 1µF or

smaller output capacitor. Solid tantalum or OSCON capacitors can be used, but they will occupy more board area

than a ceramic and will have a higher ESR. Always use a

capacitor with a sufficient voltage rating.

Ceramic capacitors also make a good choice for the input

decoupling capacitor, which should be placed as close as

possible to the LT1946A. A 2.2µF to 4.7µF input capacitor

is sufficient for most applications. Table 2 shows a list of

several ceramic capacitor manufacturers. Consult the

manufacturers for detailed information on their entire

selection of ceramic parts.

LT1946A

V

OUT

200mV/DIV

AC COUPLED

I

L1

0.5A/DIV

R

= 2.5k

C

Figure 3a. Transient Response Shows Excessive Ringing

50µs/DIV

1946A F03a

Table 2. Ceramic Capacitor Manufacturers

Taiyo Yuden (408) 573-4150 www.t-yuden.com

AVX (803) 448-9411 www.avxcorp.com

Murata (714) 852-2001 www.murata.com

Compensation

To compensate the feedback loop of the LT1946A, a series

resistor-capacitor network should be connected from the

COMP pin to GND. For most applications, a capacitor in the

range of 90pF to 470pF will suffice. A good starting value

for the compensation capacitor, CC, is 270pF. The compensation resistor, RC, is usually in the range of 20k to

100k. A good technique to compensate a new application

is to use a 100k potentiometer in place of RC, and use a

270pF capacitor for CC. By adjusting the potentiometer

while observing the transient response, the optimum

value for RC can be found. Figures 3a-3c illustrate this

process for the circuit of Figure 1. Figure 3a shows the

transient response with RC equal to 2.5k. The phase

margin is poor as evidenced by the excessive ringing in the

output voltage and inductor current. In Figure 3b the value

of RC is increased to 6.5k, which results in a more damped

response. Figure 3c shows the results when RC is increased further to 27.4k. The transient response is nicely

damped and the compensation procedure is complete.

The COMP pin provides access to an internal resistor

(120k) and capacitor (90pF). For some applications, these

values will suffice and no external RC and CC will be

needed.

V

OUT

200mV/DIV

AC COUPLED

I

L1

0.5A/DIV

R

= 6.5k

C

Figure 3b. Transient Response is Better

V

OUT

200mV/DIV

AC COUPLED

I

L1

0.5A/DIV

= 27.4k

R

C

Figure 3c. Transient Response is Well Damped

50µs/DIV

50µs/DIV

1946A F03b

1946A F03c

Compensation-Theory

Like all other current mode switching regulators, the

LT1946A needs to be compensated for stable and efficient

operation. Two feedback loops are used in the LT1946A:

a fast current loop which does not require compensation,

and a slower voltage loop which does. Standard bode plot

analysis can be used to understand and adjust the voltage

feedback loop.

sn1946a 1946afs

7

Page 8

LT1946A

Z

VR

VL

IN L

OUT

3

2

2

2

=

•

•• •π

WUUU

APPLICATIO S I FOR ATIO

As with any feedback loop, identifying the gain and phase

contribution of the various elements in the loop is critical.

Figure 4 shows the key equivalent elements of a boost

converter. Because of the fast current control loop, the

power stage of the IC, inductor, and diode have been

replaced by the equivalent transconductance amplifier

GMP. GMP acts as a current source where the output

current is proportional to the VC voltage. Note that the

maximum output current of GMP is finite due to the current

limit in the IC.

From Figure 4, the DC gain, poles and zeroes can be

calculated as follows:

Output Pole:

P

1

Error Amp Pole:

Error Amp Zero:

125.

A

DC Gain:

R

C

C

C

=

V

OUT

–

G

MP

+

V

C

R

O

P

G

2=•• •π

2

Z

1

MA

2

RC

L OUT

1

2=•• •π

RC

OC

1

RC

2=•• •π

GRGR

••••

MA O MP L

+

–

CC

1.250V

REFERENCE

ESR

C

OUT

R

1

R

2

V

OUT

R

L

ESR Zero:

Z

2

2=•• •π

1

ESR C

OUT

RHP Zero:

F

S

>

High Frequency Pole:

P

3

3

Using the circuit of Figure 1 as an example, Table 3 shows

the parameters used to generate the bode plot shown in

Figure 5.

Table 3. Bode Plot Parameters

Parameter Value Units Comment

R

L

C

OUT

R

O

C

C

R

C

V

OUT

V

IN

G

MA

G

MP

L 2.2 µH Application Specific

F

S

ESR 10 mΩ Not Adjustable

28 Ω Application Specific

2.2 µF Application Specific

10 MΩ Not Adjustable

270 pF Adjustable

27.4 kΩ Adjustable

12 V Application Specific

5 V Application Specific

40 µmho Not Adjustable

5 mho Not Adjustable

2.7 MHz Not Adjustable

From Figure 5, the phase when the gain reaches 0dB is

122° giving a phase margin of 58°. This is more than

adequate. The cross-over frequency is 90kHz, which is

about 30 times lower than the frequency of the right half

plane zero Z2. It is important that the cross-over frequency

be at least 3 times lower than the frequency of the RHP zero

to achieve adequate phase margin.

GMA: TRANSCONDUCTANCE AMPLIFIER INSIDE IC

: POWER STAGE TRANSCONDUCTANCE AMPLIFIER

G

MP

: OUTPUT CAPACITOR

C

OUT

: OUTPUT RESISTANCE DEFINED AS V

R

L

R1, R2: FEEDBACK RESISTOR DIVIDER NETWORK

: OUTPUT RESISTANCE OF G

R

O

RC: COMPENSATION RESISTOR

: COMPENSATION CAPACITOR

C

C

MA

Figure 4. Boost Converter Equivalent Model

8

DIVIDED BY I

OUT

LOAD

(MAX)

sn1946a 1946afs

Page 9

WUUU

APPLICATIO S I FOR ATIO

LT1946A

100

50

GAIN (f)

0

–50

100 10k 100k 1M

0

–100

PHASE (f)

–180

–200

100 10k 100k 1M

1k

FREQUENCY (Hz)

1946A FO5a

58°

1k

FREQUENCY (Hz)

1946A FO5b

Figure 5. Gain and Phase Plots of Figure 1 Circuit

Setting Output Voltage

To set the output voltage, select the values of R1 and R2

(see Figure 1) according to the following equation:

RR

12

V

OUT

.

125

–

1=

V

A good range for R2 is from 5k to 30k.

Layout Hints

The high speed operation of the LT1946A demands careful

attention to board layout. You will not get advertised

performance with careless layouts. Figure 6 shows the

recommended component placement for a boost converter.

GROUND PLANE

R1

SHUTDOWN

C

C

R

C

R2

1

2

3

4

CSS

LT1946A

C1

+

8

7

6

5

V

IN

L1

Diode Selection

A Schottky diode is recommended for use with the LT1946A.

The Microsemi UPS120 is a very good choice. Where the

input to output voltage differential exceeds 20V, use the

UPS140 (a 40V diode). These diodes are rated to handle an

average forward current of 1A. For applications where the

average forward current of the diode is less than 0.5A, an

ON Semiconductor MBR0520 diode can be used.

MULTIPLE

VIAs

GND

NOTE: DIRECT HIGH CURRENT PATHS USING WIDE PC TRACES. MINIMIZE TRACE AREA AT

PIN 1(V

) AND PIN 2(FB). USE MULTIPLE VIAS TO TIE PIN 4 COPPER TO GROUND PLANE. USE

C

VIAS AT ONE LOCATION ONLY TO AVOID INTRODUCING SWITCHING CURRENTS INTO THE

GROUND PLANE.

C2

V

OUT

19949 F04

Figure 6. Recommended Component

Placement for Boost Converter

sn1946a 1946afs

9

Page 10

LT1946A

A

VDD

LOAD CURRENT (mA)

EFFICIENCY (%)

1946A TA04

90

85

80

75

70

65

60

55

50

0 100 200 300 400 500

VON LOAD = 5mA

V

OFF

LOAD = 10mA

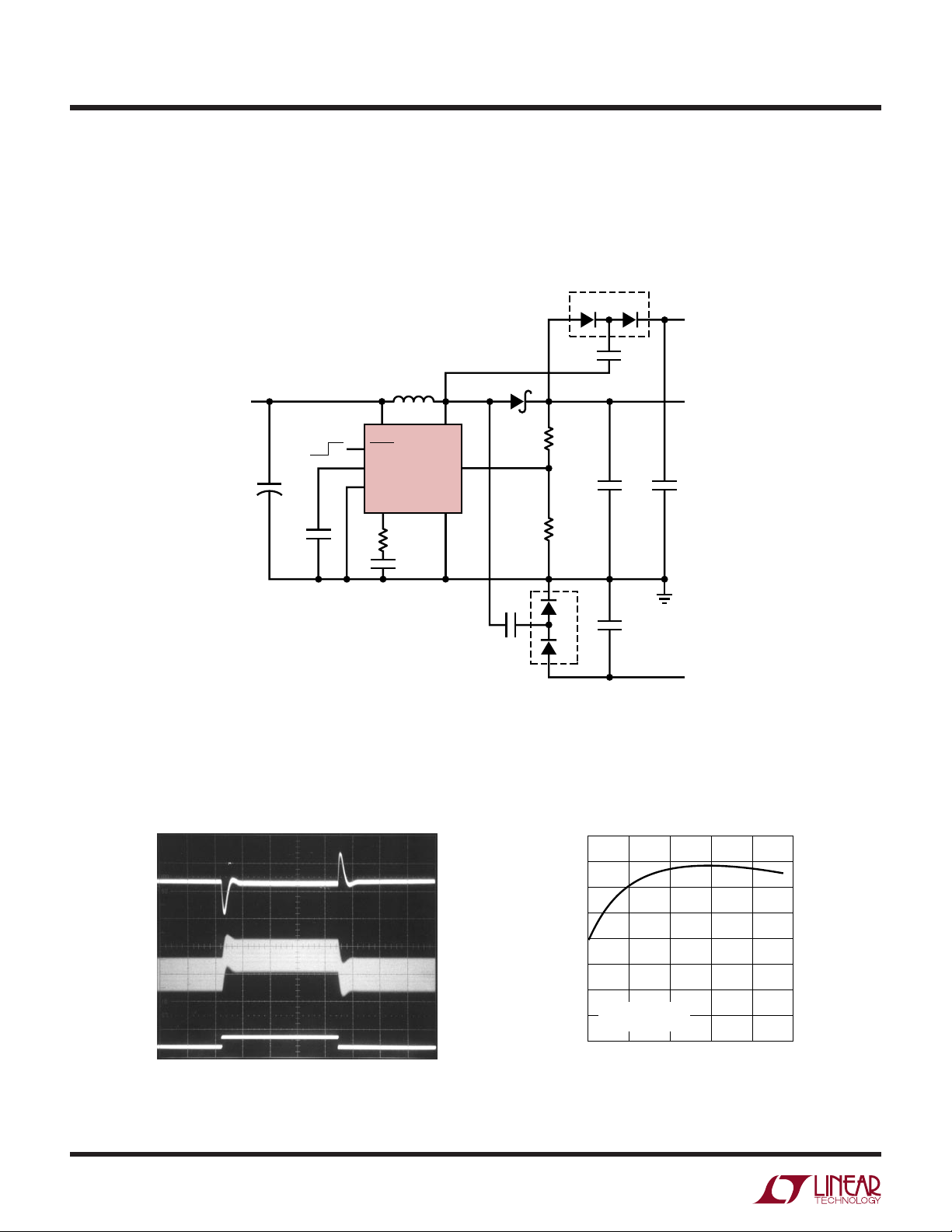

TYPICAL APPLICATIO S

Low Profile (<1.1mm Tall) Triple Output TFT Supply (10V, –10V, 20V)

U

V

IN

5V

V

IN

OFF ON

+

C1

4.7µF

C

SS

100nF

C1–C6: X5R or X7R

C1: 4.7µF, 6.3V

C2: 2× 10µF, 10V

C3: 1µF, 25V

C4: 2.2µF, 10V

C5–C6: 0.1µF, 10V

D1: MICROSEMI UPS120 OR EQUIVALENT

D2–D5: ZETEX BAT54S OR EQUIVALENT

L1: COILCRAFT LP01704-152MC

* EXPOSED PAD MUST ALSO BE GROUNDED

3

8

7

SHDN

SS

COMP

V

L1

1.5µH

65

SW

GND*

2

FB

4

LT1946A

C

1

R

C

59k

C

150pF

C

C6

0.1µF

D2 D3

C5

0.1µF

D1

R1

75k

C2

20µF

R2

10.5k

D4

D5

C4

2.2µF

V

20V

5mA

A

10V

475mA

C3

1µF

V

–10V

10mA

1946A TA02

ON

VDD

OFF

A

VDD

50mV/DIV

AC COUPLED

I

LI

0.5A/DIV

LOAD

A

VDD

10

350mA

200mA

Transient Response

100µs/DIV 1946A TA03

Efficiency

sn1946a 1946afs

Page 11

U

TYPICAL APPLICATIO S

Triple Output TFT Supply Uses SEPIC Topology for Output Disconnect

LT1946A

V

12V ± 10%

IN

+

C1

2.2µF

100nF

C1–C5: X5R or X7R

C1: 2.2µF, 6.3V

C2: 2× 10µF, 16V

C3: 1µF, 25V

C4: 0.22µF, 25V

C5: 0.22µF, 16V

D2

C4

D3

L1

10µH

65

V

IN

OFF ON

C

SS

3

SHDN

8

LT1946A

SS

1

V

C

COMP

GND*

7

D1: MICROSEMI UPS120 OR EQUIVALENT

D2–D3: CENTRAL SEMI CMDSH-3

L1–L2: TDK RLF5018-100MR94

* EXPOSED PAD MUST ALSO BE GROUNDED

SW

C3

1µF

2

FB

L2

10µH

4

0.22µF

C5

0.22µF

D1

R1

84.5k

R2

9.76k

V

23V

10mA

V

–12V

10mA

A

12V

250mA

C2

20µF

1946A TA09

ON

OFF

VDD

MS8E Package

8-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1662)

2.794 ± 0.102

(.110 ± .004)

5.23

(.206)

MIN

0.42 ± 0.04

(.0165 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

2.083

(.082 ± .004)

0.65

(.0256)

BSC

0.889 ± 0.127

(.035 ± .005)

3.2 – 3.45

± 0.102

(.126 – .136)

GAUGE PLANE

0.18

(.077)

0.254

(.010)

DETAIL “A”

DETAIL “A”

° – 6° TYP

0

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

0.53 ± 0.015

(.021 ± .006)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.88

± 0.1

(.192 ± .004)

0.22 – 0.38

(.009 – .015)

1.10

(.043)

MAX

8

12

0.65

(.0256)

BCS

BOTTOM VIEW OF

NOTE 4

0.86

REF

0.13 ± 0.05

(.005 ± .002)

MSOP (MS8E) 1001

EXPOSED PAD OPTION

1

8

sn1946a 1946afs

2.06 ± 0.102

(.080 ± .004)

1.83 ± 0.102

(.072 ± .004)

0.52

7

(.206)

6

5

REF

3.00 ± 0.102

(.118 ± .004)

4

3

(.34)

11

Page 12

LT1946A

TYPICAL APPLICATIO S

Low Profile (<1.1mm Tall) Triple Output TFT Supply (8V, –8V, 24V)

U

V

IN

3.3V

3

OFF ON

+

C1

4.7µF

C

SS

100nF

C1–C8: X5R or X7R

C1: 4.7µF, 6.3V

C2: 2× 10µF, 10V

C3: 2.2µF, 10V

C4: 1µF, 25V

C5, C6, C8: 0.1µF, 10V

C7: 0.1µF, 16V

D1: MICROSEMI UPS120 OR EQUIVALENT

D2–D7: ZETEX BAT54S OR EQUIVALENT

L1: COILCRAFT LP01704-122MC

* EXPOSED PAD MUST ALSO BE GROUNDED

8

7

SHDN

SS

COMP

D2 D3

L1

1.2µH

56

LT1946A

SW

GND*

2

FB

4

V

IN

V

C

1

Transient Response

C5

0.1µF

C8

0.1µF

D4 D5

C6

0.1µF

C7

0.1µF

V

ON

23V

5mA

Efficiency

D1

R2

28.7k

C2

20µF

R3

5.23k

D7

D6

C3

2.2µF

AV

8V

375mA

C4

1µF

V

OFF

–8V

10mA

1946A TA05

DD

90

85

80

75

70

65

EFFICIENCY (%)

60

VON LOAD = 5mA

55

50

LOAD = 10mA

V

OFF

0 100 200 300 400

A

LOAD CURRENT (mA)

VDD

1946A TA06

Start-Up Waveforms

A

VDD

50mV/DIV

AC COUPLED

I

0.5A/DIV

350mA

I

LOAD

200mA

LI

50µs/DIV

1946A TA07 1946A TA08

A

VDD

5V/DIV

V

10V/DIV

V

OFF

5V/DIV

0.5A/DIV

ON

I

IN

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1613 550mA (ISW), 1.4MHz, Step-Up DC/DC Converter VIN = 0.9V to 10V, V

LT1615/LT1615-1 300mA/0.75mA (ISW), Constant Off-Time Step-Up VIN = 1V to 15V, V

DC/DC Converter

LT1930/LT1930A 1A (ISW), 1.2MHz/2.2MHz, Step-Up DC/DC Converter VIN = 2.6V to 16V, V

LT1946 1.5A (ISW), 1.2MHz, Step-Up DC/DC Converter VIN = 2.45V to 16V, V

LT1961 1.5A (ISW), 1.25MHz, Step-Up DC/DC Converter VIN = 3V to 25V, V

ThinSOT is a trademark of Linear Technology Corporation.

Linear Technology Corporation

12

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507 ● www.linear.com

OUT

OUT

1ms/DIV

to 34V, IQ = 3mA, ISD < 1µA, ThinSOT

OUT

TM

to 34V, IQ = 20µA, ISD < 1µA, ThinSOT

to 34V, IQ = 4.2mA/5.5mA, ISD < 1µA, ThinSOT

OUT

to 34V, IQ = 3.2mA, ISD < 1µA, MS8

OUT

to 35V, IQ = 0.9mA, ISD < 6µA, MS8E

sn1946a 1946afs

LT/TP 1102 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2001

Loading...

Loading...