FEATURES

LT1932

Constant-Current DC/DC

LED Driver in ThinSOT

U

DESCRIPTIO

■

Up to 80% Efficiency

■

Inherently Matched LED Current

■

Adjustable Control of LED Current

■

Drives Five White LEDs from 2V

■

Drives Six White LEDs from 2.7V

■

Drives Eight White LEDs from 3V

■

Disconnects LEDs In Shutdown

■

1.2MHz Fixed Frequency Switching

■

Uses Tiny Ceramic Capacitors

■

Uses Tiny 1mm-Tall Inductors

■

Regulates Current Even When VIN > V

■

Operates with VIN as Low as 1V

■

Low Profile (1mm) ThinSOTTM Package

U

APPLICATIO S

■

Cellular Telephones

■

Handheld Computers

■

Digital Cameras

■

Portable MP3 Players

■

Pagers

OUT

The LT®1932 is a fixed frequency step-up DC/DC converter

designed to operate as a constant-current source. Because it directly regulates output current, the LT1932 is

ideal for driving light emitting diodes (LEDs) whose light

intensity is proportional to the current passing through

them, not the voltage across their terminals.

With an input voltage range of 1V to 10V, the device works

from a variety of input sources. The LT1932 accurately

regulates LED current even when the input voltage is

higher than the LED voltage, greatly simplifying batterypowered designs. A single external resistor sets LED

current between 5mA and 40mA, which can then be easily

adjusted using either a DC voltage or a pulse width

modulated (PWM) signal. When the LT1932 is placed in

shutdown, the LEDs are disconnected from the output,

ensuring a quiescent current of under 1µA for the entire

circuit. The device’s 1.2MHz switching frequency permits

the use of tiny, low profile chip inductors and capacitors to

minimize footprint and cost in space-conscious portable

applications.

, LTC and LT are registered trademarks of Linear Technology Corporation.

ThinSOT is a trademark of Linear Technology Corporation.

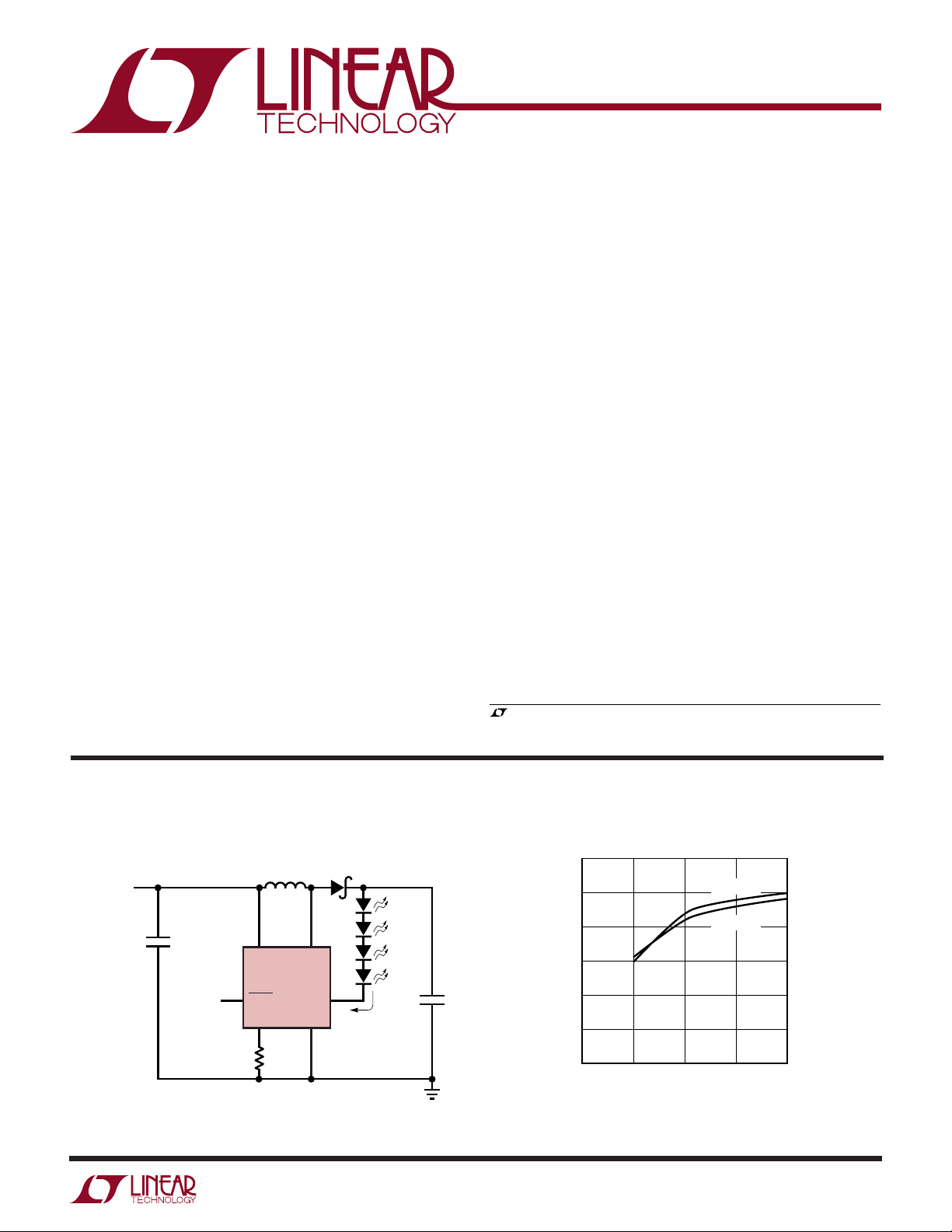

TYPICAL APPLICATIO

Li-Ion Driver for Four White LEDs Efficiency

L1

V

2.7V TO 4.2V

IN

C1

4.7µF

PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475

C2: TAIYO YUDEN EMK212BJ105

D1:ZETEX ZHCS400

L1: SUMIDA CLQ4D106R8 OR PANASONIC ELJEA6R8

6.8µH

61

V

IN

LT1932

SHDN

R

SET

4

R

SET

1.50k

SW

GND

LED

2

U

D1

35

15mA

C2

1µF

1932 TA01

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 4.2V

VIN = 2.7V

5101520

LED CURRENT (mA)

1932 TA02

1932f

1

LT1932

WWWU

ABSOLUTE AXI U RATI GS

PACKAGE/ORDER I FOR ATIO

UU

W

(Note 1)

VIN Voltage ............................................................. 10V

SHDN Voltage ......................................................... 10V

SW Voltage ............................................................. 36V

LED Voltage ............................................................. 36V

R

Voltage ............................................................. 1V

SET

Junction Temperature.......................................... 125°C

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range ................. –65°C to 150°C

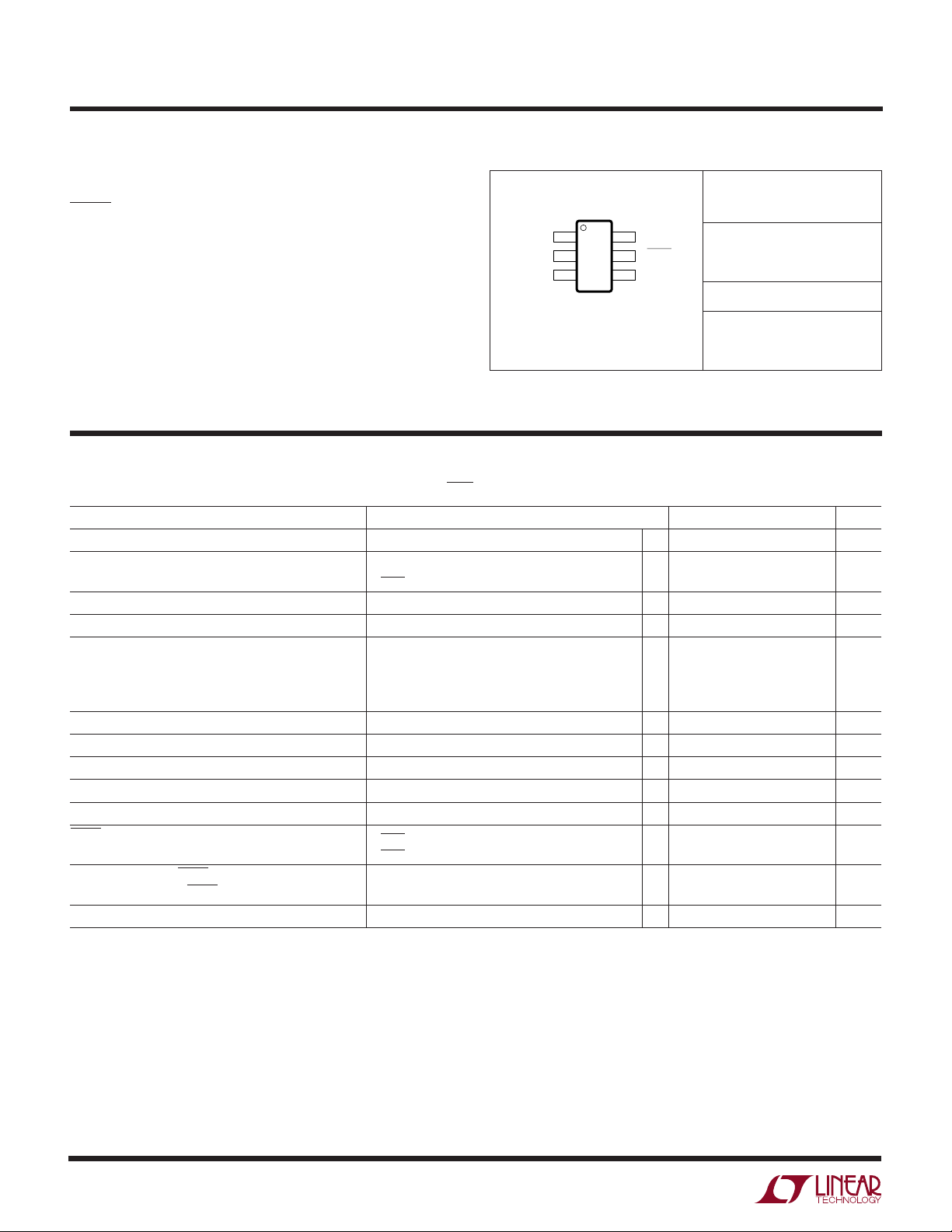

TOP VIEW

SW 1

GND 2

LED 3

S6 PACKAGE

6-LEAD PLASTIC SOT-23

T

= 125°C, θJA = 250°C/ W

JMAX

6 V

IN

5 SHDN

4 R

SET

ORDER PART

NUMBER

LT1932ES6

S6 PART MARKING

LTST

Lead Temperature (Soldering, 10 sec)..................300°C

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VIN = 1.2V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Minimum Input Voltage 1V

Quiescent Current V

V

R

Pin Voltage R

SET

LED Pin Voltage R

LED Pin Current R

R

R

R

LED Pin Current Temperature Coefficient I

Switching Frequency VIN = 1V 0.8 1.2 1.6 MHz

Maximum Switch Duty Cycle ● 90 95 %

Switch Current Limit 400 550 780 mA

Switch V

CESAT

SHDN Pin Current V

Start-Up Threshold (SHDN Pin) 0.85 V

Shutdown Threshold (SHDN Pin) 0.25 V

Switch Leakage Current Switch Off, VSW = 5V 0.01 5 µA

LED

ISW = 300mA 150 200 mV

V

The ● denotes specifications that apply over the full operating temperature

= 1.2V, unless otherwise noted.

SHDN

= 0.2V 1.2 1.6 mA

RSET

= 0V 0.1 1.0 µA

SHDN

= 1.50k 100 mV

SET

= 1.50k, VIN < V

SET

= 562Ω, VIN = 1.5V 33 38 45 mA

SET

= 750Ω, VIN = 1.2V 25 30 36 mA

SET

= 1.50k, VIN = 1.2V 12.5 15 17.5 mA

SET

= 4.53k, VIN = 1.2V 5 mA

SET

= 15mA –0.02 mA/°C

= 0V 0 0.1 µA

SHDN

= 2V 15 30 µA

SHDN

(Figure 1) 120 180 mV

OUT

Note 1: Absolute Maximum Ratings are those values beyond which the life of

a device may be impaired.

Note 2: The LT1932E is guaranteed to meet specifications from 0°C to 70°C.

Specifications over the –40°C to 85°C operating temperature range are

assured by design, characterization and correlation with statistical process

controls.

2

1932f

UW

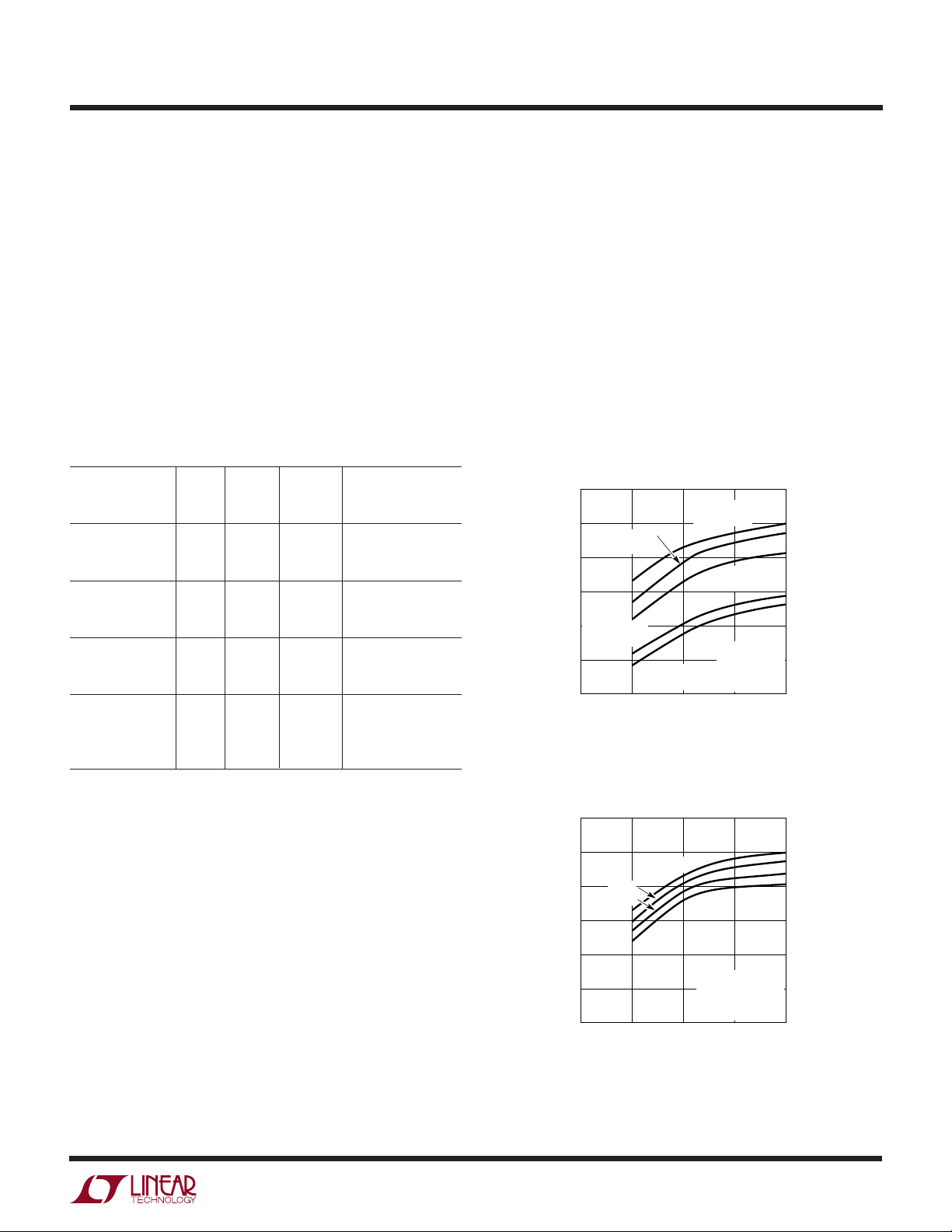

INPUT VOLTAGE (V)

0

LED CURRENT (mA)

35

6

1932 G06

20

10

24

5

0

40

45

50

30

25

15

810

R

SET

= 750Ω

R

SET

= 562Ω

R

SET

= 1.50k

R

SET

= 4.53k

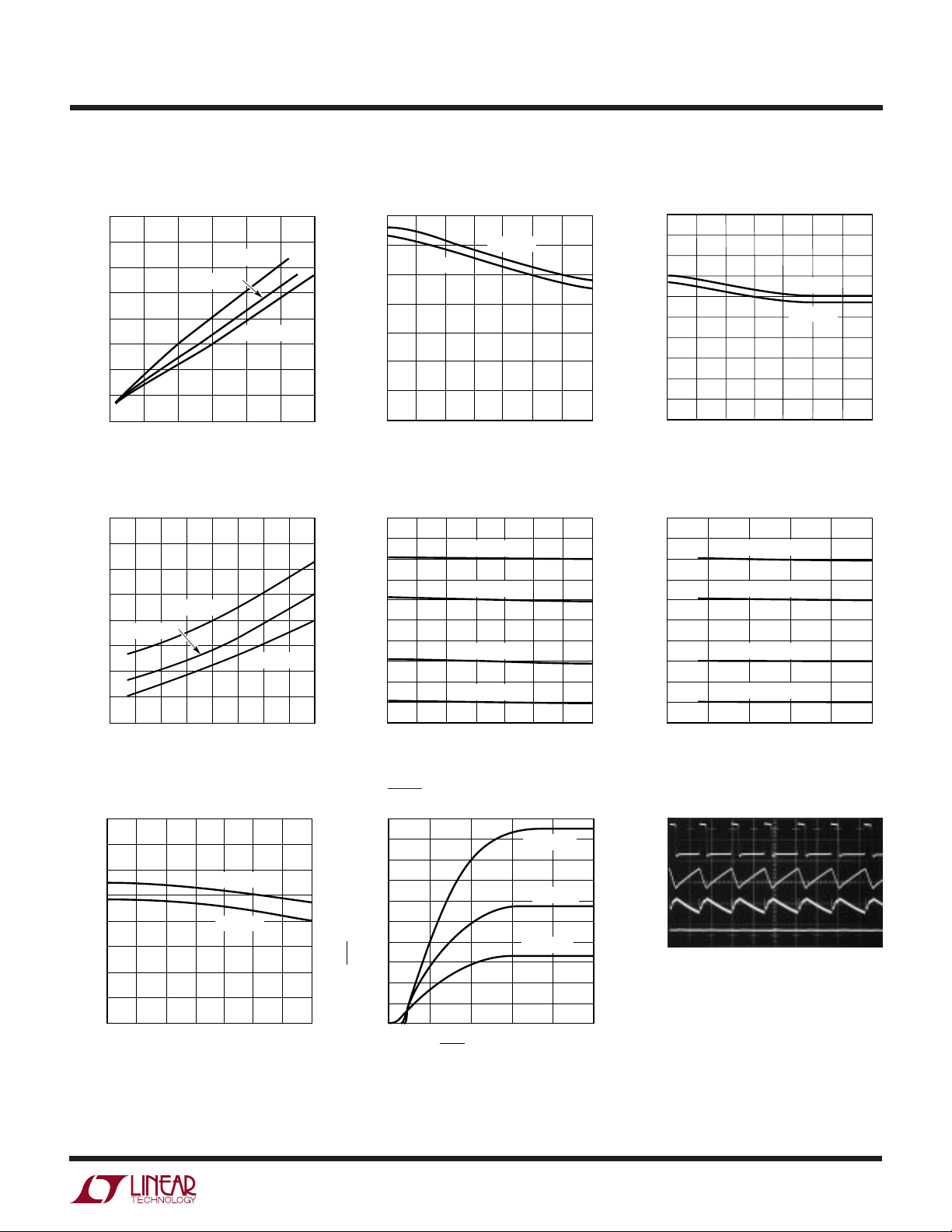

TYPICAL PERFOR A CE CHARACTERISTICS

LT1932

Switch Saturation Voltage (V

400

350

300

250

200

150

100

50

SWITCH SATURATION VOLTAGE (mV)

0

100 200 400

0

SWITCH CURRENT (mA)

TJ = 125°C

TJ = 25°C

300

TJ = –50°C

CESAT

500

1932 G01

600

)

Switch Current Limit Switching Frequency

700

600

500

400

300

PEAK CURRENT (mA)

200

100

0

–50

LED Pin Voltage LED Current

400

350

300

250

200

TJ = 25°C

150

LED PIN VOLTAGE (mV)

100

50

0

510 20

0

LED CURRENT (mA)

TJ = 125°C

15 25

T

= –50°C

J

4030 35

1932 G04

50

45

40

35

30

25

20

LED CURRENT (mA)

15

10

5

0

–50

VIN = 1.2V

VIN = 10V

50 100 125

–25 0

–25 0 50

25 75

TEMPERATURE (°C)

R

= 562Ω

SET

R

= 750Ω

SET

R

= 1.50k

SET

R

= 4.53k

SET

25

TEMPERATURE (°C)

1932 G02

75 100 125

1932 G05

2.0

1.8

1.6

1.4

1.2

1.0

0.8

0.6

0.4

SWITCHING FREQUENCY (MHz)

0.2

0

–50

–25

25

0

TEMPERATURE (°C)

LED Current

VIN = 10V

VIN = 1.2V

50

100

125

1932 G03

75

2.00

1.75

1.50

1.25

1.00

0.75

0.50

QUIESCENT CURRENT (mA)

0.25

Quiescent Current SHDN Pin Current

50

45

40

0

–25 0 50

–50

VIN = 10V

VIN = 1.2V

25

TEMPERATURE (°C)

75 100 125

1932 G07

35

30

25

20

SHDN PIN CURRENT

15

10

5

0

2

0

SHDN PIN VOLTAGE (V)

Switching Waveforms

V

= –50°C

T

J

TJ = 25°C

TJ = 125°C

6

8

4

10

1932 G08

SW

10V/DIV

I

200mA/DIV

V

OUT

20mV/DIV

AC COUPLED

I

LED

10mA/DIV

L1

VIN = 3V 0.5µs/DIV

4 WHITE LEDs

I

= 15mA

LED

CIRCUIT ON FIRST PAGE

OF THIS DATA SHEET

1093 G09

1932f

3

LT1932

U

UU

PI FU CTIO S

SW (Pin 1): Switch Pin. This is the collector of the internal

NPN power switch. Minimize the metal trace area connected to this pin to minimize EMI.

GND (Pin 2): Ground Pin. Tie this pin directly to local

ground plane.

LED (Pin 3): LED Pin. This is the collector of the internal

NPN LED switch. Connect the cathode of the bottom LED

to this pin.

W

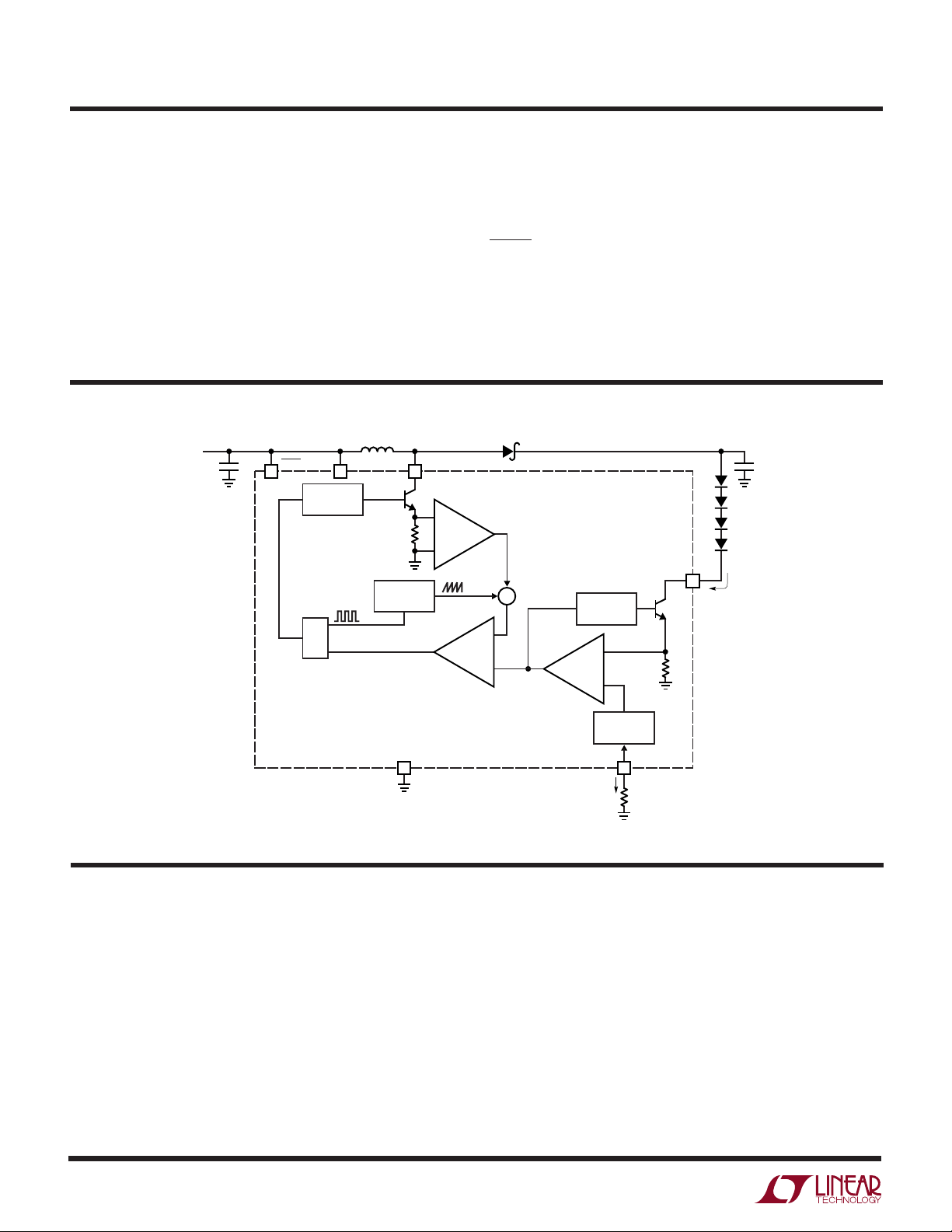

BLOCK DIAGRA

V

IN

SHDN

C1

5

DRIVER

S

Q

R

L1

V

IN

6

1

Q1

0.04Ω

1.2MHz

OSCILLATOR

SW

+

×5

–

R

(Pin 4): A resistor between this pin and ground

SET

programs the LED current (that flows into the LED pin).

This pin is also used to provide LED dimming.

SHDN (Pin 5): Shutdown Pin. Tie this pin higher than

0.85V to turn on the LT1932; tie below 0.25V to turn it off.

VIN (Pin 6): Input Supply Pin. Bypass this pin with a

capacitor to ground as close to the device as possible.

D1

+

Σ

+

+

A2

–

DRIVER

–

A1

+

V

OUT

C2

LED

3

I

Q2

LED

2

GND

Figure 1. LT1932 Block Diagram

U

OPERATIO

The LT1932 uses a constant frequency, current mode

control scheme to regulate the output current, I

Operation can be best understood by referring to the

block diagram in Figure 1. At the start of each oscillator

cycle, the SR latch is set, turning on power switch Q1. The

signal at the noninverting input of the PWM comparator

A2 is proportional to the switch current, summed together with a portion of the oscillator ramp. When this

signal reaches the level set by the output of error amplifier

A1, comparator A2 resets the latch and turns off the

LED

.

LED CURRENT

REFERENCE

4

R

SET

I

SET

R

SET

1932 F01

power switch. In this manner, A1 sets the correct peak

current level to keep the LED current in regulation. If A1’s

output increases, more current is delivered to the output;

if it decreases, less current is delivered. A1 senses the

LED current in switch Q2 and compares it to the current

reference, which is programmed using resistor R

R

pin is regulated to 100mV and the output current,

SET

I

, is regulated to 225 • I

LED

. Pulling the R

SET

SET

. The

SET

pin higher

than 100mV will pull down the output of A1, turning off

power switch Q1 and LED switch Q2.

1932f

4

WUUU

APPLICATIO S I FOR ATIO

LT1932

Inductor Selection

Several inductors that work well with the LT1932 are listed

in Table 1. Many different sizes and shapes are available.

Consult each manufacturer for more detailed information

and for their entire selection of related parts. As core

losses at 1.2MHz are much lower for ferrite cores that for

the cheaper powdered-iron ones, ferrite core inductors

should be used to obtain the best efficiency. Choose an

inductor that can handle at least 0.5A and ensure that the

inductor has a low DCR (copper wire resistance) to minimize I2R power losses. A 4.7µH or 6.8µH inductor will be

a good choice for most LT1932 designs.

Table 1. Recommended Inductors

MAX MAX

L DCR HEIGHT

PART (µH) (mΩ) (mm) VENDOR

ELJEA4R7 4.7 180 2.2 Panasonic

ELJEA6R8 6.8 250 2.2 (714) 373-7334

www.panasonic.com

LQH3C4R7M24 4.7 260 2.2 Murata

LQH3C100M24 10 300 2.2 (814) 237-1431

www.murata.com

LB2016B4R7 4.7 250 1.6 Taiyo Yuden

LB2016B100 6.8 350 1.6 (408) 573-4150

www.t-yuden.com

CMD4D06-4R7 4.7 216 0.8 Sumida

CMD4D06-6R8 6.8 296 0.8 (847) 956-0666

CLQ4D10-4R7 4.7 162 1.2 www.sumida.com

CLQ4D10-6R8 6.8 195 1.2

efficiency by up to 12% over the smaller, thinner ones.

Keep this in mind when choosing an inductor.

The value of inductance also plays an important role in the

overall system efficiency. While a 1µH inductor will have

a lower DCR and a higher current rating than the 6.8µH

version of the same part, lower inductance will result in

higher peak currents in the switch, inductor and diode.

Efficiency will suffer if inductance is too small. Figure 3

shows the efficiency of the Typical Application on the front

page of this data sheet, with several different values of the

same type of inductor (Panasonic ELJEA). The smaller

values give an efficiency 3% to 5% lower than the 6.8µH

value.

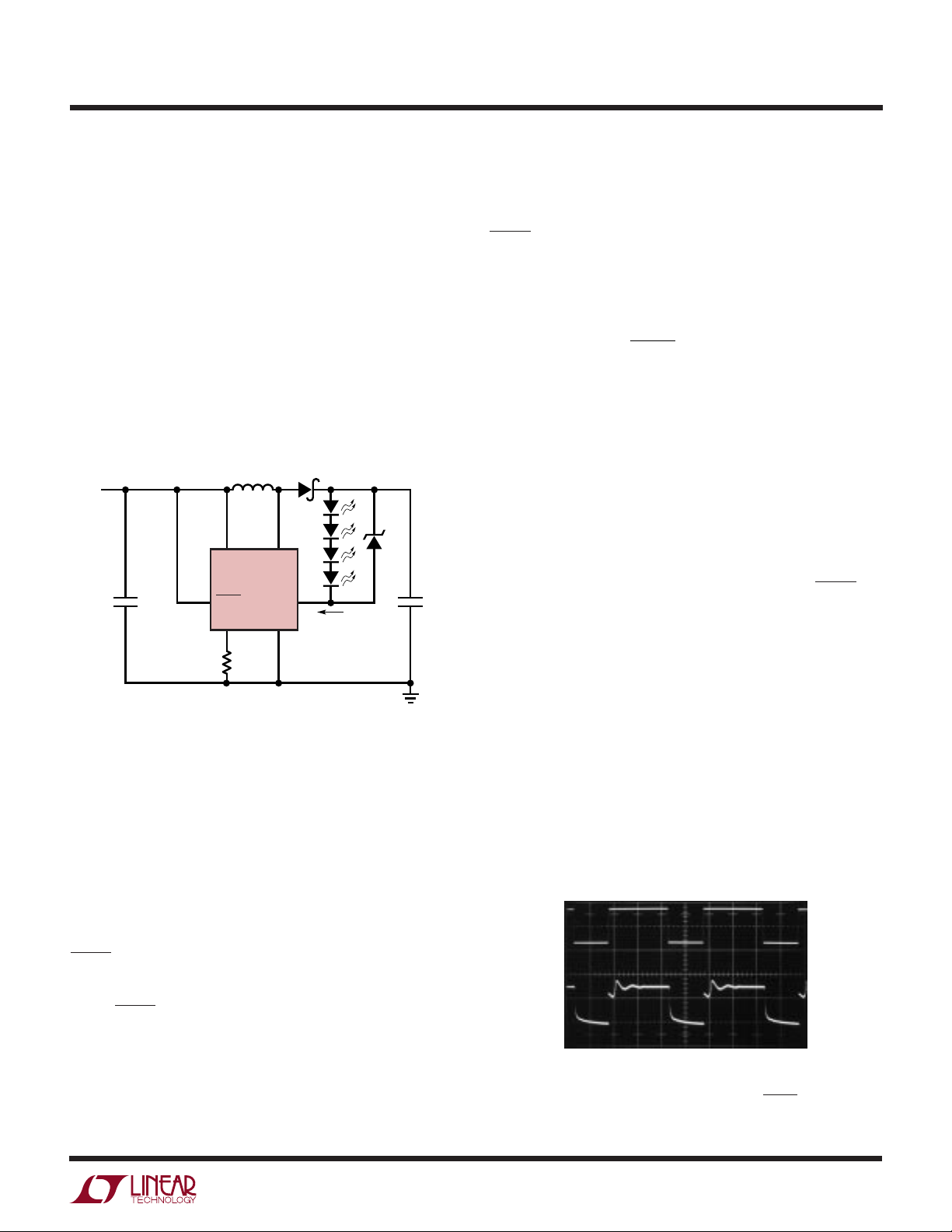

85

PANASONIC

80

75

70

EFFICIENCY (%)

65

60

55

SUMIDA

CLQ4D10-6R8

TAIYO YUDEN

LB2016B6R8

0

TAIYO YUDEN

LB2012B6R8

5101520

LED CURRENT (mA)

Figure 2. Efficiency for Several Different Inductor Types

ELJEA6R8

SUMIDA

CMD4D06-6R8

VIN = 3.6V

4 WHITE LEDs

ALL ARE 10µH

INDUCTORS

1932 F02

Inductor Efficiency Considerations

Many applications have thickness requirements that restrict component heights to 1mm or 2mm. There are 2mm

tall inductors currently available that provide a low DCR

and low core losses that help provide good overall efficiency. Inductors with a height of 1mm (and less) are

becoming more common, and a few companies have

introduced chip inductors that are not only thin, but have

a very small footprint as well. While these smaller inductors will be a necessity in some designs, their smaller size

gives higher DCR and core losses, resulting in lower

efficiencies. Figure 2 shows efficiency for the Typical

Application circuit on the front page of this data sheet, with

several different inductors. The larger devices improve

85

80

75

4.7µH

70

EFFICIENCY (%)

65

60

55

0

22µH

6.8µH

2.2µH

VIN = 3.6V

4 WHITE LEDs

PANASONIC ELJEA

INDUCTORS

5101520

LED CURRENT (mA)

1932 F03

Figure 3. Efficiency for Several Different Inductor Values

1932f

5

LT1932

WUUU

APPLICATIO S I FOR ATIO

Capacitor Selection

Low ESR (equivalent series resistance) capacitors should

be used at the output to minimize the output ripple

voltage. Because they have an extremely low ESR and are

available in very small packages, multilayer ceramic capacitors are an excellent choice. X5R and X7R type

capacitors are preferred because they retain their capacitance over wider voltage and temperature ranges than

other types such as Y5V or Z5U. A 1µF or 2.2µF output

capacitor is sufficient for most applications. Always use a

capacitor with a sufficient voltage rating. Ceramic capacitors do not need to be derated (do not buy a capacitor with

a rating twice what your application needs). A 16V ceramic capacitor is good to more than 16V, unlike a 16V

tantalum, which may be good to only 8V when used in

certain applications. Low profile ceramic capacitors with

a 1mm maximum thickness are available for designs

having strict height requirements.

Ceramic capacitors also make a good choice for the input

decoupling capacitor, which should be placed as close as

possible to the LT1932. A 2.2µF or 4.7µF input capacitor

is sufficient for most applications. Table 2 shows a list of

several ceramic capacitor manufacturers. Consult the

manufacturers for detailed information on their entire

selection of ceramic parts.

Table 2. Recommended Ceramic Capacitor Manufacturers

VENDOR PHONE URL

Taiyo Yuden (408) 573-4150 www.t-yuden.com

Murata (814) 237-1431 www.murata.com

Kemet (408) 986-0424 www.kemet.com

Diode Selection

turned off (typically less than one-third the time), so a 0.4A

or 0.5A diode will be sufficient for most designs.

Table 3. Recommended Schottky Diodes

PART VENDOR

MBR0520 ON Semiconductor

MBR0530 (800) 282-9855

MBR0540 www.onsemi.com

ZHCS400 Zetex

ZHCS500 (631) 543-7100

www.zetex.com

Programming LED Current

The LED current is programmed with a single resistor

connected to the R

pin (see Figure 1). The R

SET

SET

pin is

internally regulated to 100mV, which sets the current

flowing out of this pin, I

LT1932 regulates the current into the LED pin, I

times the value of I

SET

, equal to 100mV/R

SET

SET

LED

. The

, to 225

. For the best accuracy, a 1% (or

better) resistor value should be used. Table 4 shows

several typical 1% R

values, use the following equation to choose R

R

SET

Table 4. R

=

SET

22501•

Resistor Values

I

(mA) R

LED

40 562Ω

30 750Ω

20 1.13k

15 1.50k

10 2.26k

5 4.53k

values. For other LED current

SET

V

.

I

LED

VALUE

SET

SET

.

Schottky diodes, with their low forward voltage drop and

fast switching speed, are the ideal choice for LT1932

applications. Table 3 shows several different Schottky

diodes that work well with the LT1932. Make sure that the

diode has a voltage rating greater than the output voltage.

The diode conducts current only when the power switch is

6

Most white LEDs are driven at maximum currents of 15mA

to 20mA. Some higher power designs will use two parallel

strings of LEDs for greater light output, resulting in 30mA

to 40mA (two strings of 15mA to 20mA) flowing into the

LED pin.

1932f

WUUU

APPLICATIO S I FOR ATIO

LT1932

Open-Circuit Protection

For applications where the string of LEDs can be disconnected or could potentially become an open circuit, a zener

diode can be added across the LEDs to protect the LT1932

(see Figure 4). If the device is turned on without the LEDs

present, no current feedback signal is provided to the LED

pin. The LT1932 will then switch at its maximum duty

cycle, generating an output voltage 10 to 15 times greater

than the input voltage. Without the zener, the SW pin could

see more than 36V and exceed its maximum rating. The

zener voltage should be larger than the maximum forward

voltage of the LED string.

L1

V

IN

C1

4.7µF

Figure 4. LED Driver with Open-Circuit Protection

6.8µH

61

V

IN

LT1932

SHDN

R

SET

4

R

SET

1.50k

SW

LED

GND

D1

24V

35

15mA

2

C2

1µF

1932 F04

Dimming Using a PWM Signal

PWM brightness control provides the widest dimming

range (greater than 20:1) by pulsing the LEDs on and off

using the control signal. The LEDs operate at either zero or

full current, but their average current changes with the

PWM signal duty cycle. Typically, a 5kHz to 40kHz PWM

signal is used. PWM dimming with the LT1932 can be

accomplished two different ways (see Figure 6). The

SHDN pin can be driven directly or a resistor can be added

to drive the R

SET

pin.

If the SHDN pin is used, increasing the duty cycle will

increase the LED brightness. Using this method, the LEDs

can be dimmed and turned off completely using the same

control signal. A 0% duty cycle signal will turn off the

LT1932, reducing the total quiescent current to zero.

If the R

pin is used, increasing the duty cycle will

SET

decrease the brightness. Using this method, the LEDs are

dimmed using R

SHDN. If the R

the approximate value of R

and turned off completely using

SET

pin is used to provide PWM dimming,

SET

should be (where V

PWM

MAX

is

the “high” value of the PWM signal):

V

RR

=

PWM SET

•

MAX

.–015

1

V

In addition to providing the widest dimming range, PWM

brightness control also ensures the “purest” white LED

color over the entire dimming range. The true color of a

white LED changes with operating current, and is the

“purest” white at a specific forward current, usually 15mA

or 20mA. If the LED current is less than or more than this

value, the emitted light becomes more blue. For color

LCDs, this often results in a noticeable and undesirable

blue tint to the display.

When a PWM control signal is used to drive the SHDN pin

of the LT1932 (see Figure 6), the LEDs are turned off and

on at the PWM frequency. The current through them

alternates between full current and zero current, so the

average current changes with duty cycle. This ensures

that when the LEDs are on, they can be driven at the

appropriate current to give the purest white light. Figure

5 shows the LED current when a 5kHz PWM dimming

control signal is used with the LT1932. The LED current

waveform cleanly tracks the PWM control signal with no

delays, so the LED brightness varies linearly with the

PWM duty cycle.

V

PWM

2V/DIV

I

LED

10mA/DIV

50µs/DIV 1932 F05

Figure 5. PWM Dimming Using the SHDN Pin

1932f

7

LT1932

WUUU

APPLICATIO S I FOR ATIO

Dimming Using a Filtered PWM Signal

While the direct PWM method provides the widest dimming range and the purest white light output, it causes the

LT1932 to enter into Burst Mode® operation. This operation may be undesirable for some systems, as it may

reflect some noise to the input source at the PWM frequency. The solution is to filter the control signal by adding

a 10k resistor and a 0.1µF capacitor as shown in Figure 6,

converting the PWM to a DC level before it reaches the

R

pin. The 10k resistor minimizes the capacitance seen

SET

by the R

SET

pin.

Dimming Using a Logic Signal

For applications that need to adjust the LED brightness in

discrete steps, a logic signal can be used as shown in

Figure 6. R

sets the minimum LED current value (when

MIN

the NMOS is off):

R

=

22501•

MIN

R

sets how much the LED current is increased when

INCR

I

LED MIN

V

.

()

the NMOS is turned on:

R

INCR

=

22501•

.

I

()

LED INCREASE

V

Dimming Using a DC Voltage

For some applications, the preferred method of brightness

control uses a variable DC voltage to adjust the LED

current. As the DC voltage is increased, current flows

through R

ADJ

into R

, reducing the current flowing out

SET

of the R

R

ADJ

DC control voltage, I

by R

the DC control voltage is at V

R

Regulating LED Current when VIN > V

pin, thus reducing the LED current. Choose the

SET

value as shown below where V

is the current programmed

).

MAX

–.

MAX

–

SET

ADJ

, and I

=

22501•

LED(MAX)

LED(MIN)

is the minimum value of I

VV

II

() ()

LED MAX LED MIN

is the maximum

MAX

OUT

LED

(when

The LT1932 contains special circuitry that enables it to

regulate the LED current even when the input voltage is

higher than the output voltage. When VIN is less than V

OUT

,

the internal NPN LED switch (transistor Q2 in Figure 1) is

saturated to provide a lower power loss. When VIN is

greater than V

, the NPN LED switch comes out of

OUT

saturation to keep the LED current in regulation.

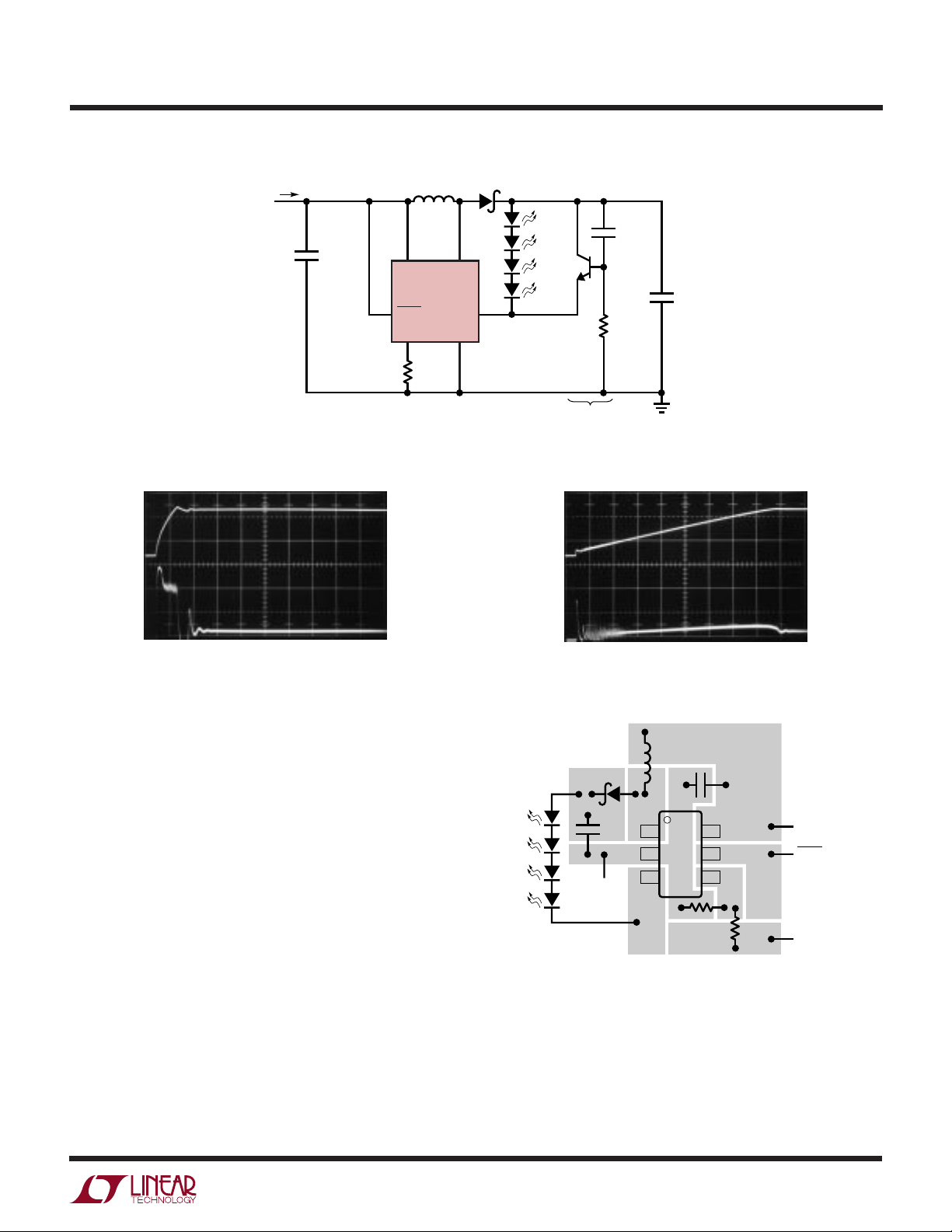

Soft-Start/Controlling Inrush Current

For many applications, it is necessary to minimize the

inrush current at start-up. When first turned on and the

LED current is zero, the LT1932 will initially command the

maximum switch current of 500mA to 600mA, which may

give an inrush current too high for some applications. A

soft-start circuit (Figure 7) can be added to significantly

reduce the start-up current spike. Figure 8 shows that

without soft-start the input current reaches almost 600mA.

Figure 9 shows that when the soft-start circuit is added,

the input current has only a brief 300mA spike, and on

average does not exceed 100mA.

8

LT1932

R

SET

PWM

Figure 6. Five Methods of LED Dimming

LT1932

R

SET

4

R

ADJ

V

DC

R

SET

1932 F06

1932f

WUUU

APPLICATIO S I FOR ATIO

LT1932

V

OUT

5V/DIV

I

200mA/DIV

I

IN

V

IN

C1

4.7µF

L1

6.8µH

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

2

D1

Q1

2N3904

35

SOFT-START

CIRCUIT

C3

0.047µF

R1

1.5k

V

OUT

C2

1µF

1932 F07

Figure 7. Soft-Start Circuit for the LT1932

V

OUT

5V/DIV

IN

I

200mA/DIV

IN

100µs/DIV 1932 F08

Figure 8. Input Current at Start-Up Without Soft-Start

Board Layout Considerations

As with all switching regulators, careful attention must be

paid to the PCB board layout and component placement.

To maximize efficiency, switch rise and fall times are made

as short as possible. To prevent radiation and high frequency resonance problems, proper layout of the high

frequency switching path is essential. Minimize the length

and area of all traces connected to the SW pin and always

use a ground plane under the switching regulator to

minimize interplane coupling. The signal path including

the switch, output diode D1 and output capacitor C2,

contains nanosecond rise and fall times and should be

kept as short as possible. In addition, the ground connection for the R

resistor should be tied directly to the GND

SET

pin and not be shared with any other component, ensuring

a clean, noise-free connection. Recommended component placement is shown in Figure 10.

100µs/DIV 1932 F09

Figure 9. Input Current at Start-Up with Soft-Start

L1

C1

V

6

5

4

R

SET

IN

SHDN

DIMMING

CONTROL

1932 F10

C2

GND

D1

1

2

3

Figure 10. Recommended Component Placement

1932f

9

LT1932

TYPICAL APPLICATIO S

U

V

1V TO 1.5V

V

1V TO 1.5V

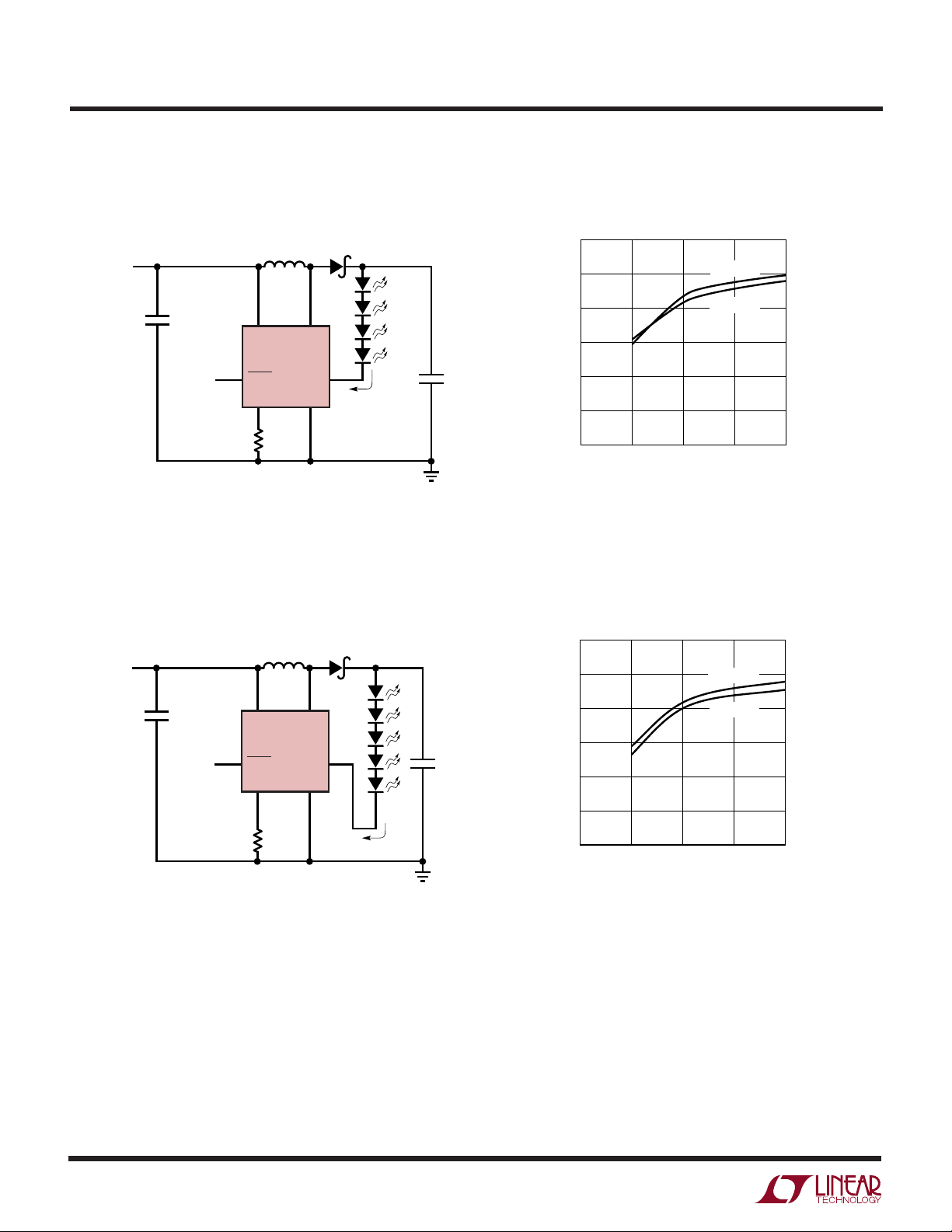

Single Cell Driver for One White LED

L1

IN

C1

4.7µF

2.5V PWM

DIMMING

CONTROL

C1, C2: TAIYO YUDEN JMK212BJ475 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

24.9k

4.7µH

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

Single Cell Driver for Two White LEDs

L1

IN

C1

4.7µF

2.5V PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN LMK212BJ225 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

24.9k

4.7µH

61

V

SHDN

R

SET

IN

4

R

1.50k

SW

LT1932

LED

GND

SET

Efficiency

D1

35

15mA

2

C2

4.7µF

1932 TA03a

80

75

70

65

EFFICIENCY (%)

60

55

50

0

VIN = 1.5V

VIN = 1.1V

510152.5 7.5 12.5

LED CURRENT (mA)

1932 TA03b

Efficiency

D1

35

15mA

2

C2

2.2µF

1932 TA04a

80

75

70

65

EFFICIENCY (%)

60

55

50

0

VIN = 1.5V

VIN = 1.1V

510152.5 7.5 12.5

LED CURRENT (mA)

1932 TA04b

10

1932f

TYPICAL APPLICATIO S

LT1932

U

1.8V TO 3V

V

1.8V TO 3V

2-Cell Driver for Two White LEDs

L1

V

IN

C1

4.7µF

2.5V DC

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN LMK212BJ225 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

60.4k

4.7µH

61

V

IN

LT1932

SHDN

R

SET

4

R

1.50k

GND

SET

2-Cell Driver for Three White LEDs Efficiency

L1

IN

C1

4.7µF

2.5V DC

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK316BJ225 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

60.4k

4.7µH

61

V

SHDN

R

SET

IN

4

R

1.50k

SW

LT1932

GND

SET

SW

LED

LED

2

Efficiency

D1

35

15mA

2

D1

35

15mA

C2

2.2µF

1932 TA15a

C2

2.2µF

1932 TA06a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 3V

VIN = 1.8V

10 20515

LED CURRENT (mA)

1932 TA15b

VIN = 3V

VIN = 1.8V

5101520

LED CURRENT (mA)

1932 TA06b

1932f

11

LT1932

TYPICAL APPLICATIO S

2-Cell Driver for Four White LEDs Efficiency

U

1.8V TO 3V

V

IN

2V TO 3V

L1

V

IN

C1

4.7µF

PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK212BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

4.7µH

61

V

IN

LT1932

SHDN

R

SET

4

R

1.50k

GND

SET

2-Cell Driver for Five White LEDs

L1

4.7µH

SW

LED

D1

35

15mA

2

C2

1µF

1932 TA07a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 3V

VIN = 1.8V

5101520

LED CURRENT (mA)

1932 TA07b

Efficiency

D1

85

80

C1

4.7µF

PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

61

V

SHDN

R

IN

SET

LT1932

4

R

SET

1.50k

SW

LED

GND

2

35

15mA

C2

1µF

1932 TA05a

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 3V

VIN = 2V

5101520

LED CURRENT (mA)

1932 TA05b

1932f

12

TYPICAL APPLICATIO S

Li-Ion Driver for Two White LEDs Efficiency

L1

V

2.7V TO 4.2V

IN

C1

4.7µF

3.3V PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN LMK212BJ225 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: PANASONIC ELJEA6R8 (714) 373-7334

31.6k

6.8µH

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

2

U

LT1932

D1

35

15mA

C2

2.2µF

1932 TA08a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 4.2V

VIN = 2.7V

5101520

LED CURRENT (mA)

1932 TA08b

V

2.7V TO 4.2V

Li-Ion Driver for Three White LEDs Efficiency

L1

IN

C1

4.7µF

3.3V PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK316BJ225 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: PANASONIC ELJEA6R8 (714) 373-7334

31.6k

6.8µH

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

D1

35

15mA

2

C2

2.2µF

1932 TA09a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 4.2V

VIN = 2.7V

5101520

LED CURRENT (mA)

1932 TA09b

1932f

13

LT1932

TYPICAL APPLICATIO S

Li-Ion Driver for Four White LEDs Efficiency

L1

V

2.7V TO 4.2V

IN

6.8µH

U

D1

85

80

VIN = 4.2V

V

2.7V TO 4.2V

C1

4.7µF

PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK212BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: PANASONIC ELJEA6R8 (714) 373-7334

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

Li-Ion Driver for Five White LEDs Efficiency

L1

IN

C1

4.7µF

PWM

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

4.7µH

61

V

SHDN

R

SET

IN

4

LT1932

R

SET

1.50k

SW

LED

GND

75

70

35

15mA

2

D1

35

2

15mA

C2

1µF

1932 TA10a

C2

1µF

1932 TA11a

EFFICIENCY (%)

65

60

55

0

85

80

75

70

EFFICIENCY (%)

65

60

55

0

5101520

LED CURRENT (mA)

5101520

LED CURRENT (mA)

VIN = 2.7V

1932 TA10b

VIN = 4.2V

VIN = 2.7V

1932 TA11b

14

1932f

TYPICAL APPLICATIO S

Li-Ion Driver for Eight White LEDs Efficiency

LT1932

U

L1

V

3V TO 4.2V

IN

C1

4.7µF

3.3V DC

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN GMK316BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

80.6k

4.7µH

61

V

SHDN

R

IN

SET

LT1932

4

R

1.50k

SW

LED

GND

2

SET

PACKAGE DESCRIPTIO

D1

35

15mA

C2

1µF

1932 TA13a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 4.2V

VIN = 3V

5101520

LED CURRENT (mA)

1932 TA13b

U

S6 Package

6-Lead Plastic SOT-23

(LTC DWG # 05-08-1634)

(LTC DWG # 05-08-1636)

.20

(.008)

DATUM ‘A’

L

NOTE:

1. CONTROLLING DIMENSION: MILLIMETERS

2. DIMENSIONS ARE IN

3. DRAWING NOT TO SCALE

4. DIMENSIONS ARE INCLUSIVE OF PLATING

5. DIMENSIONS ARE EXCLUSIVE OF MOLD FLASH AND METAL BURR

6. MOLD FLASH SHALL NOT EXCEED .254mm

7. PACKAGE EIAJ REFERENCE IS:

SC-74A (EIAJ) FOR ORIGINAL

JEDEL MO-193 FOR THIN

MILLIMETERS

(INCHES)

.09 – .20

(.004 – .008)

(NOTE 2)

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

2.80 – 3.10

(.110 – .118)

(NOTE 3)

A2

A

1.90

(.074)

REF

A

A1

A2

L

SOT-23

(Original)

.90 – 1.45

(.035 – .057)

.00 – 0.15

(.00 – .006)

.90 – 1.30

(.035 – .051)

.35 – .55

(.014 – .021)

SOT-23

(ThinSOT)

1.00 MAX

(.039 MAX)

.01 – .10

(.0004 – .004)

.80 – .90

(.031 – .035)

.30 – .50 REF

(.012 – .019 REF)

A1

2.60 – 3.00

(.102 – .118)

1.50 – 1.75

(.059 – .069)

(NOTE 3)

.95

(.037)

REF

PIN ONE ID

.25 – .50

(.010 – .020)

(6PLCS, NOTE 2)

S6 SOT-23 0401

1932f

15

LT1932

TYPICAL APPLICATIO

Li-Ion Driver for Ten White LEDs Efficiency

U

V

2.7V TO 4.2V

V

2.7V TO 4.2V

L1

IN

C1

4.7µF

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK325BJ475 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C100M24 (814) 237-1431

IN

C1

4.7µF

3.3V DC

DIMMING

CONTROL

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

D1: ZETEX ZHCS400 (631) 543-7100

L1: MURATA LQH3C4R7M24 (814) 237-1431

80.6k

10µH

61

V

IN

LT1932

5

SHDN

R

SET

4

R

SET

750Ω

L1

4.7µH

61

V

IN

LT1932

SHDN

R

SET

4

R

SET

1.50k

SW

LED

GND

SW

LED

GND

D1

3

2

100Ω

30mA

100Ω

C2

4.7µF

1932 TA16a

80

75

70

65

EFFICIENCY (%)

60

55

50

0

VIN = 4.2V

VIN = 2.7V

10 20 3051525

TOTAL LED CURRENT (mA)

1932 TA16b

EfficiencyLi-Ion Driver for Six White LEDs

D1

35

2

15mA

C2

1µF

1932 TA12a

85

80

75

70

EFFICIENCY (%)

65

60

55

0

VIN = 4.2V

VIN = 2.7V

5101520

LED CURRENT (mA)

1932 TA12b

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1615 Micropower DC/DC Converter in 5-Lead ThinSOT 20V at 12mA from 2.5V Input, ThinSOT Package

LT1617 Micropower Inverting DC/DC Converter in 5-Lead ThinSOT –15V at 12mA from 2.5V Input, ThinSOT Package

LT1618 Constant-Current/Constant-Voltage DC/DC Converter Drives 20 White LEDs from Li-Ion, MS10 Package

LTC1682 Doubler Charge Pump with Low Noise Linear Regulator 3.3V and 5V Outputs with 60µV

LT1930 1.4MHz Switching Regulator in 5-Lead ThinSOT 5V at 480mA from 3.3V Input, ThinSOT Package

LT1931 Inverting 1.2MHz Switching Regulator in 5-Lead ThinSOT –5V at 350mA from 5V Input, ThinSOT Package

LTC3200 Low Noise Regulated Charge Pump 5V Output with Up to 100mA Output

LTC3201 Ultralow Noise, Charge Pump 100mA, Integrated LP Filter, MSOP8

LTC3202 High Efficiency, Fractional Charge Pump 125mA, Integrated 2-Bit DAC

Linear Technology Corporation

16

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

Noise, Up to 80mA Output

RMS

LT/TP 1201 2K • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 2001

1932f

Loading...

Loading...