Linear Technology LT1721, LT1720 Datasheet

FEATURES

■

UltraFast: 4.5ns at 20mV Overdrive

7ns at 5mV Overdrive

■

Low Power: 4mA per Comparator

■

Optimized for 3V and 5V Operation

■

Pinout Optimized for High Speed Ease of Use

■

Input Voltage Range Extends 100mV

Below Negative Rail

■

TTL/CMOS Compatible Rail-to-Rail Outputs

■

Internal Hysteresis with Specified Limits

■

Low Dynamic Current Drain; 15µA/(V-MHz),

Dominated by Load In Most Circuits

U

APPLICATIO S

■

High Speed Differential Line Receiver

■

Crystal Oscillator Circuits

■

Window Comparators

■

Threshold Detectors/Discriminators

■

Pulse Stretchers

■

Zero-Crossing Detectors

■

High Speed Sampling Circuits

LT1720/LT1721

Dual/Quad,

4.5ns, Single Supply

3V/5V Comparators

with Rail-to-Rail Outputs

U

DESCRIPTIO

The LT®1720/LT1721 are UltraFastTM dual/quad comparators optimized for single supply operation, with a supply

voltage range of 2.7V to 6V. The input voltage range extends

from 100mV below ground to 1.2V below the supply voltage.

Internal hysteresis makes the LT1720/LT1721 easy to use

even with slow moving input signals. The rail-to-rail outputs

directly interface to TTL and CMOS. Alternatively, the symmetric output drive can be harnessed for analog applications

or for easy translation to other single supply logic levels.

The LT1720 is available in the 8-pin MSOP and SO packages;

three pins per comparator plus power and ground. The

LT1721 is available in the 16-pin SSOP and S packages.

The pinouts of the LT1720/LT1721 minimize parasitic effects

by placing the most sensitive inputs (inverting) away from the

outputs, shielded by the power rails. The LT1720/LT1721 are

ideal for systems where small size and low power are

paramount.

, LTC and LT are registered trademarks of Linear Technology Corporation.

UltraFast is a trademark of Linear Technology Corporation.

U

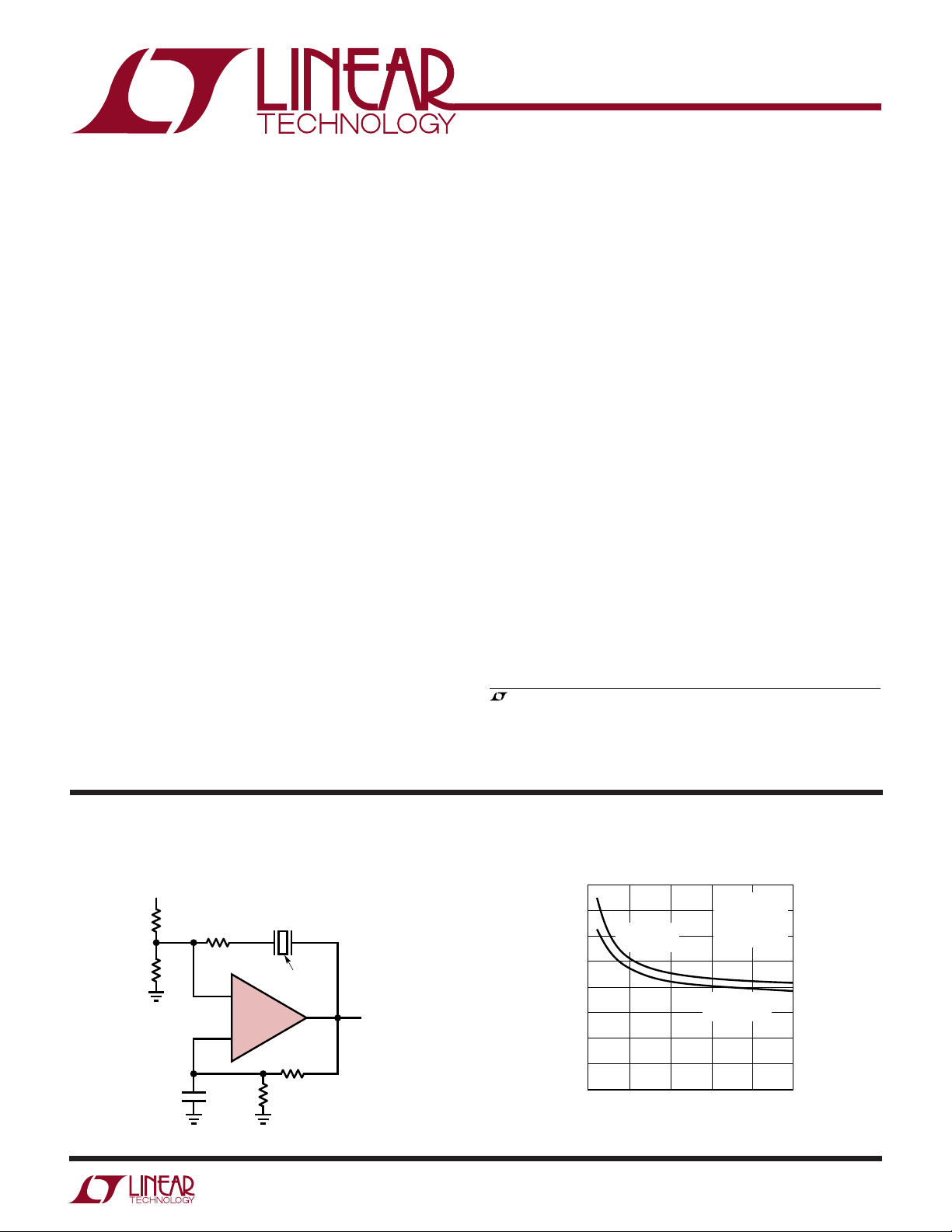

TYPICAL APPLICATIO

2.7V to 6V Crystal Oscillator with TTL/CMOS Output

2.7V TO 6V

2k

620Ω

1MHz TO 10MHz

CRYSTAL (AT-CUT)

220Ω

+

C1

1/2 LT1720

–

0.01µF 1.8k

GROUND

CASE

2k

1720/21 TA01

OUTPUT

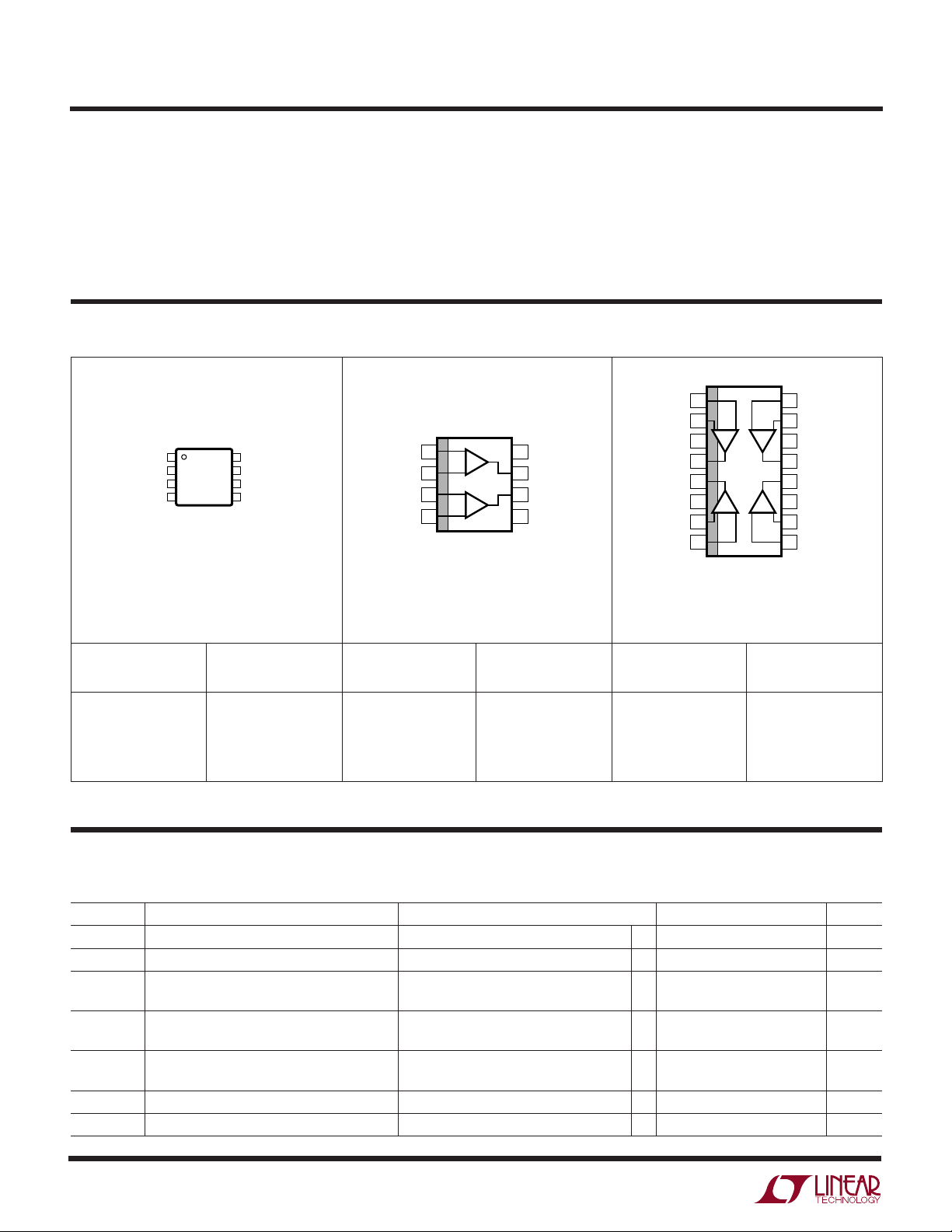

Propagation Delay vs Overdrive

8

7

RISING EDGE

6

5

4

DELAY (ns)

3

2

1

0

0

)

(t

PDLH

FALLING EDGE

10 20 40

OVERDRIVE (mV)

30

25°C

V

STEP

V

CC

C

LOAD

(t

= 100mV

= 5V

PDHL

= 10pF

)

50

1720/21 TA02

1

LT1720/LT1721

WW

W

ABSOLUTE MAXIMUM RATINGS

U

(Note 1)

Supply Voltage, VCC to GND ...................................... 7V

Input Current ...................................................... ±10mA

Output Current (Continuous) ............................. ±20mA

Junction Temperature........................................... 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

U

W

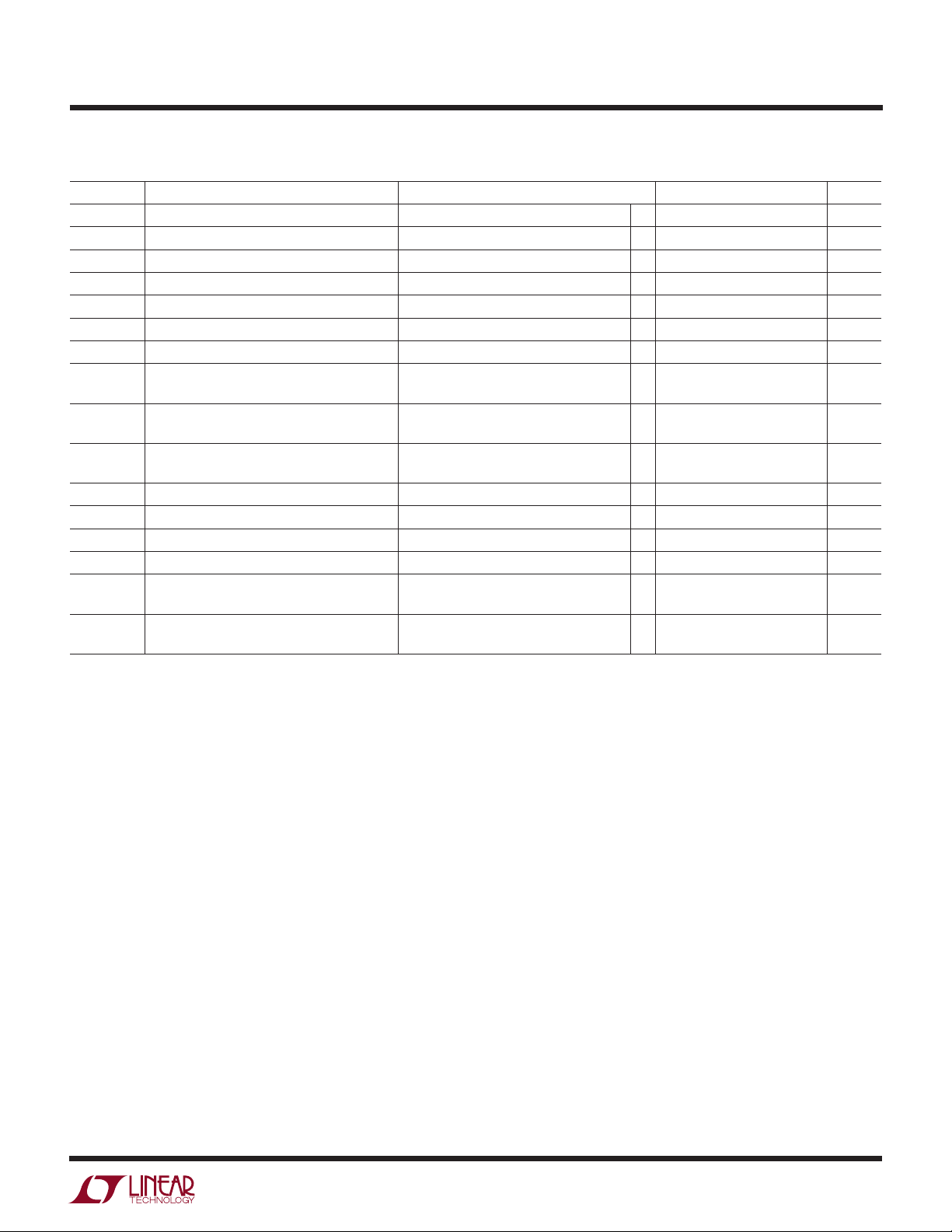

PACKAGE/ORDER INFORMATION

TOP VIEW

+IN A

1

–IN A

2

–IN B

3

+IN B

4

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 150°C, θJA = 230°C/W

JMAX

8

7

6

5

V

CC

OUT A

OUT B

GND

+IN A

1

–IN A

2

–IN B

3

+IN B

4

8-LEAD PLASTIC SO

T

= 150°C, θJA = 200°C/W

JMAX

S8 PACKAGE

Storage Temperature Range ................. –65°C to 150°C

Operating Temperature Range

C Grade .................................................. 0°C to 70°C

I Grade .............................................. – 40°C to 85°C

U

TOP VIEW

–IN A

TOP VIEW

1

+IN A

2

GND

8

V

CC

OUT A

7

OUT B

6

GND

5

3

OUT A

4

OUT B

5

GND

6

+IN B

7

–IN B

8

GN PACKAGE

16-LEAD NARROW

PLASTIC SSOP

T

= 150°C, θJA = 135°C/ W (GN)

JMAX

= 150°C, θJA = 115°C/ W (S)

T

JMAX

16

15

14

13

12

11

10

9

S PACKAGE

16-LEAD PLASTIC SO

–IN D

+IN D

V

CC

OUT D

OUT C

V

CC

+IN C

–IN C

ORDER PART

NUMBER

LT1720CMS8

MS8

PART MARKING

LTDS

ORDER PART

NUMBER

LT1720CS8

LT1720IS8

S8

PART MARKING

1720

1720I

ORDER PART

NUMBER

LT1721CGN

LT1721CS

GN

PART MARKING

1721

1721I

LT1721IGN

LT1721IS

Consult factory for Military grade parts.

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VCC = 5V, VCM = 1V, C

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

V

CC

V

CMR

+

V

TRIP

–

V

TRIP

V

OS

V

HYST

∆VOS/∆T Input Offset Voltage Drift ● 10 µV/°C

Supply Voltage ● 2.7 6 V

Common Mode Voltage Range (Note 2) ● –0.1 VCC – 1.2 V

Input Trip Points (Note 3) –2.0 5.5 mV

Input Trip Points (Note 3) –5.5 2.0 mV

Input Offset Voltage (Note 3) 1.0 3.0 mV

Input Hysteresis Voltage (Note 3) ● 2.0 3.5 5.0 mV

The ● denotes specifications that apply over the full operating temperature

= 10pF, V

OUT

OVERDRIVE

= 20mV, unless otherwise specified.

● –3.0 6.5 mV

● –6.5 3.0 mV

● 4.5 mV

2

LT1720/LT1721

ELECTRICAL CHARACTERISTICS

range, otherwise specifications are at TA = 25°C. VCC = 5V, VCM = 1V, C

The ● denotes specifications that apply over the full operating temperature

= 10pF, V

OUT

OVERDRIVE

= 20mV, unless otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN TYP MAX UNITS

I

B

I

OS

Input Bias Current ● –6 0 µA

Input Offset Current ● 0.6 µA

CMRR Common Mode Rejection Ratio (Note 4) ● 55 70 dB

PSRR Power Supply Rejection Ratio (Note 5) ● 65 80 dB

A

V

V

OH

V

OL

I

CC

t

PD20

t

PD5

∆t

PD

t

SKEW

t

r

t

f

t

JITTER

f

MAX

Voltage Gain (Note 6) ∞

Output High Voltage I

Output Low Voltage I

= 4mA, VIN = V

SOURCE

= 10mA, VIN = V

SINK

+

+ 10mV ● VCC – 0.4 V

TRIP

–

– 10mV ● 0.4 V

TRIP

Supply Current (Per Comparator) VCC = 5V ● 47 mA

= 3V ● 3.5 6 mA

V

CC

Propagation Delay V

Propagation Delay V

OVERDRIVE

OVERDRIVE

= 20mV (Note 7) 4.5 6.5 ns

● 8.0 ns

= 5mV (Notes 7, 8) 7 10 ns

● 13 ns

Differential Propagation Delay (Note 9) Between Channels 0.3 1.0 ns

+

Propagation Delay Skew (Note 10) Between t

PD

–

/t

PD

0.5 1.5 ns

Output Rise Time 10% to 90% 2.5 ns

Output Fall Time 90% to 10% 2.2 ns

Output Timing Jitter VIN = 1.2V

VCM = 2V, f = 20MHz t

Maximum Toggle Frequency V

OVERDRIVE

V

OVERDRIVE

(6dBm), ZIN = 50Ω t

P-P

= 50mV, VCC = 3V 70.0 MHz

= 50mV, VCC = 5V 62.5 MHz

PD

PD

+

–

15 ps

11 ps

RMS

RMS

Note 1: Absolute Maximum Ratings are those values beyond which the

life of a device may be impaired.

Note 2: If one input is within these common mode limits, the other

input can go outside the common mode limits and the output will be

valid.

Note 3: The LT1720/LT1721 comparators include internal hysteresis.

The trip points are the input voltage needed to change the output state

in each direction. The offset voltage is defined as the average of V

and V

–

, while the hysteresis voltage is the difference of these two.

TRIP

TRIP

Note 4: The common mode rejection ratio is measured with VCC = 5V

and is defined as the change in offset voltage measured from V

–0.1V to V

= 3.8V, divided by 3.9V.

CM

CM

=

Note 5: The power supply rejection ratio is measured with VCM = 1V

and is defined as the change in offset voltage measured from V

2.7V to V

= 6V, divided by 3.3V.

CC

CC

=

Note 6: Because of internal hysteresis, there is no small-signal region

in which to measure gain. Proper operation of internal circuity is

ensured by measuring V

and VOL with only 10mV of overdrive.

OH

Note 7: Propagation delay measurements made with 100mV steps.

Overdrive is measured relative to V

TRIP

±

.

Note 8: tPD cannot be measured in automatic handling equipment with

low values of overdrive. The LT1720/LT1721 are 100% tested with a

100mV step and 20mV overdrive. Correlation tests have shown that

limits can be guaranteed with this test, if additional DC tests are

t

PD

performed to guarantee that all internal bias conditions are correct.

+

Note 9: Differential propagation delay is defined as the larger of the

two:

∆t

∆t

PDLH

PDHL

= t

PDLH(MAX)

= t

PDHL(MAX)

– t

PDLH(MIN)

– t

PDHL(MIN)

where (MAX) and (MIN) denote the maximum and minimum values of

a given measurement across the different comparator channels.

Note 10: Propagation Delay Skew is defined as:

t

= |t

– t

SKEW

PDLH

PDHL

|

3

LT1720/LT1721

TEMPERATURE (°C)

–50

3.6

3.8

4.2

25 75

1720/21 G03

0.2

0

–25 0

50 100 125

–0.2

–0.4

4.0

COMMON MODE INPUT VOLTAGE (V)

VCC = 5V

SUPPLY VOLTAGE (V)

0

0

SUPPLY CURRENT PER COMPARATOR (mA)

4

7

2

4

5

1720/21 G06

3

2

1

6

5

1

3

6

7

25°C

125°C

–55°C

SUPPLY VOLTAGE (V)

2.5

4.5

DELAY (ns)

5.0

4.0

4.0 5.0

1720/21 G09

3.0 3.5

4.5 5.5 6.0

RISING EDGE

(t

PDLH

)

FALLING EDGE

(t

PDHL

)

25°C

V

STEP

= 100mV

OVERDRIVE = 20mV

C

LOAD

= 10pF

W

U

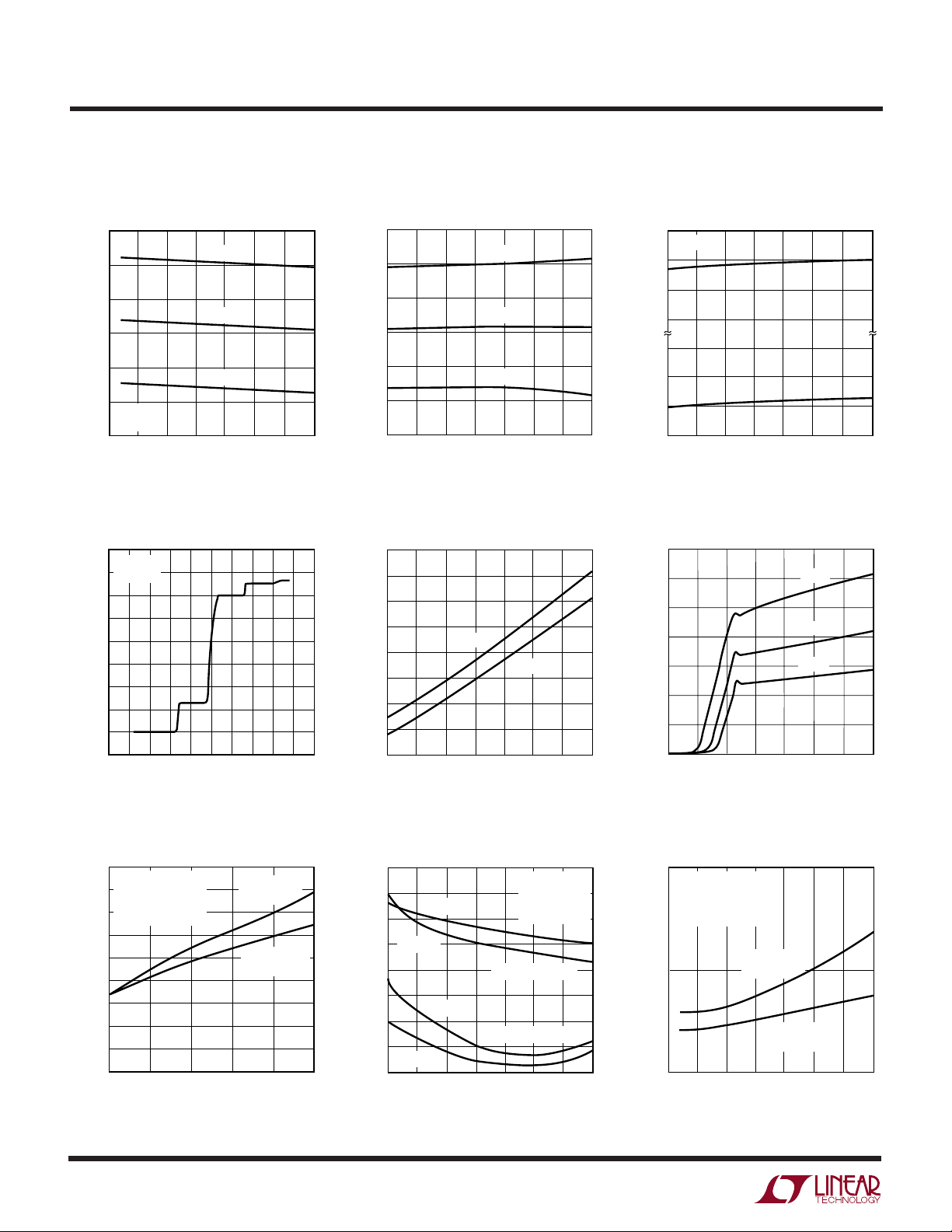

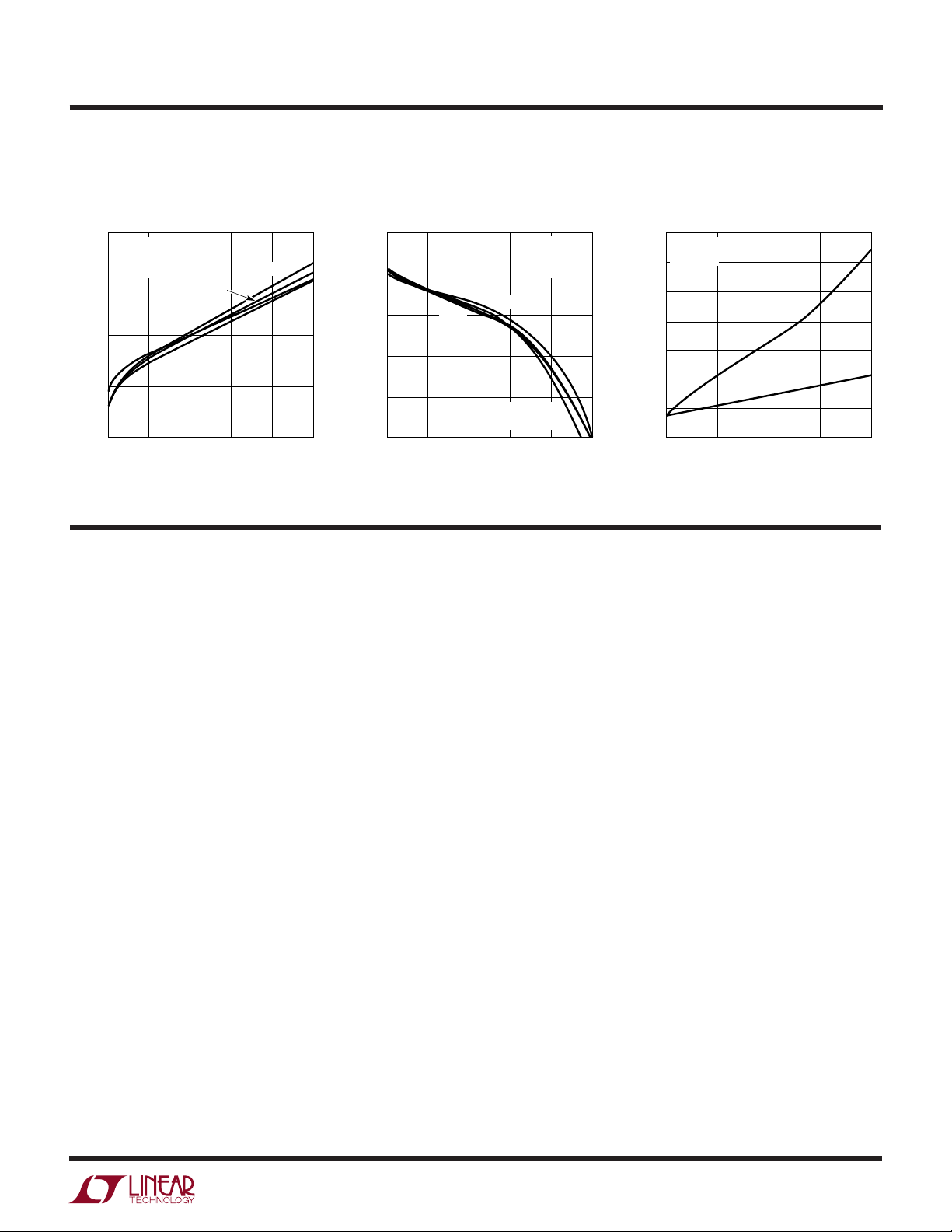

TYPICAL PERFORMANCE CHARACTERISTICS

Input Offset and Trip Voltages

vs Supply Voltage

3

V

2

1

0

–1

AND TRIP POINT VOLTAGE (mV)

–2

OS

V

25°C

V

= 1V

CM

–3

2.5

3.0 3.5

SUPPLY VOLTAGE (V)

TRIP

V

V

TRIP

4.5 5.5 6.0

4.0 5.0

Input Current

vs Differential Input Voltage

2

25°C

1

V

= 5V

CC

0

–1

–2

–3

–4

INPUT CURRENT (µA)

–5

–6

–7

–4 –3 –2 –1 0 5

–5

DIFFERENTIAL INPUT VOLTAGE (V)

+

OS

–

1720/21 G01

1234

1720/21 G04

Input Offset and Trip Voltages

vs Temperature

3

+

V

2

1

0

–1

AND TRIP POINT VOLTAGE (mV)

–2

OS

V

–3

–50 0 50 75 125

–25 25 100

TRIP

V

OS

–

V

TRIP

TEMPERATURE (°C)

1720/21 G02

Quiescent Supply Current

vs Temperature

6.0

5.5

5.0

4.5

4.0

3.5

3.0

2.5

2.0

–50

QUIESCENT SUPPLY CURRENT PER COMPARATOR (mA)

VCC = 5V

–25 0 50

25

TEMPERATURE (˚C)

= 3V

V

CC

75 100 125

1720/21 G05

Input Common Mode Limits

vs Temperature

Quiescent Supply Current

vs Supply Voltage

Propagation Delay

vs Load Capacitance

9

25°C

= 100mV

V

8

STEP

OVERDRIVE = 20mV

7

V

= 5V

CC

6

5

4

DELAY (ns)

3

2

1

0

0

4

10 20 40

OUTPUT LOAD CAPACITANCE (pF)

30

RISING EDGE

)

(t

PDLH

FALLING EDGE

)

(t

PDHL

1720/21 G07

Propagation Delay

vs Temperature

8.0

7.5

7.0

6.5

6.0

5.5

5.0

PROPAGATION DELAY (ns)

4.5

50

4.0

–50

VCC = 3V

VCC = 5V

VCC = 5V

VCC = 3V

–25 0 50

25

TEMPERATURE (°C)

t

PDLH

VCM = 1V

V

= 100mV

STEP

C

= 10pF

LOAD

OVERDRIVE = 5mV

OVERDRIVE = 20mV

75 100 125

1720/21 G08

Propagation Delay

vs Supply Voltage

W

FREQUENCY (MHz)

0

7

8

10

30

NO LOAD

1720/21 G12

6

5

10 20 40

4

3

9

SUPPLY CURRENT PER COMPARATOR (mA)

25°C

V

CC

= 5V

C

LOAD

= 20pF

U

TYPICAL PERFORMANCE CHARACTERISTICS

LT1720/LT1721

Output Low Voltage

vs Load Current

0.5

VCC = 5V

= 1V

V

CM

= –15mV

V

IN

0.4

0.3

–55°C

OUTPUT VOLTAGE (V)

0.2

0.1

4

0

OUTPUT SINK CURRENT (mA)

V

CC

8

125°C

= 2.7V

125°C

25°C

12

16

20

1720/21 G10

Output High Voltage

vs Load Current

0.0

(V)

125°C

CC

–0.2

–0.4

–0.6

–0.8

OUTPUT VOLTAGE RELATIVE TO V

–1.0

0

OUTPUT SOURCE CURRENT (mA)

UUU

PIN FUNCTIONS

LT1720

+IN A (Pin 1): Noninverting Input of Comparator A.

Supply Current vs Frequency

VCC = 5V

= 1V

V

CM

= 15mV

V

IN

–55°C

25°C

25°C

V

= 2.7V

CC

4

12

16

8

20

1720/21 G11

LT1721

–IN A (Pin 1): Inverting Input of Comparator A.

–IN A (Pin 2): Inverting Input of Comparator A.

–IN B (Pin 3): Inverting Input of Comparator B.

+IN B (Pin 4): Noninverting Input of Comparator B.

GND (Pin 5): Ground.

OUT B (Pin 6): Output of Comparator B.

OUT A (Pin 7): Output of Comparator A.

VCC (Pin 8): Positive Supply Voltage.

+IN A (Pin 2): Noninverting Input of Comparator A.

GND (Pins 3, 6): Ground.

OUT A (Pin 4): Output of Comparator A.

OUT B (Pin 5): Output of Comparator B.

+IN B (Pin 7): Noninverting Input of Comparator B.

–IN B (Pin 8): Inverting Input of Comparator B.

–IN C (Pin 9): Inverting Input of Comparator C.

+IN C (Pin 10): Noninverting Input of Comparator C.

VCC (Pins 11, 14): Positive Supply Voltage.

OUT C (Pin 12): Output of Comparator C.

OUT D (Pin 13): Output of Comparator D.

+IN D (Pin 15): Noninverting Input of Comparator D.

–IN D (Pin 16): Inverting Input of Comparator D.

5

LT1720/LT1721

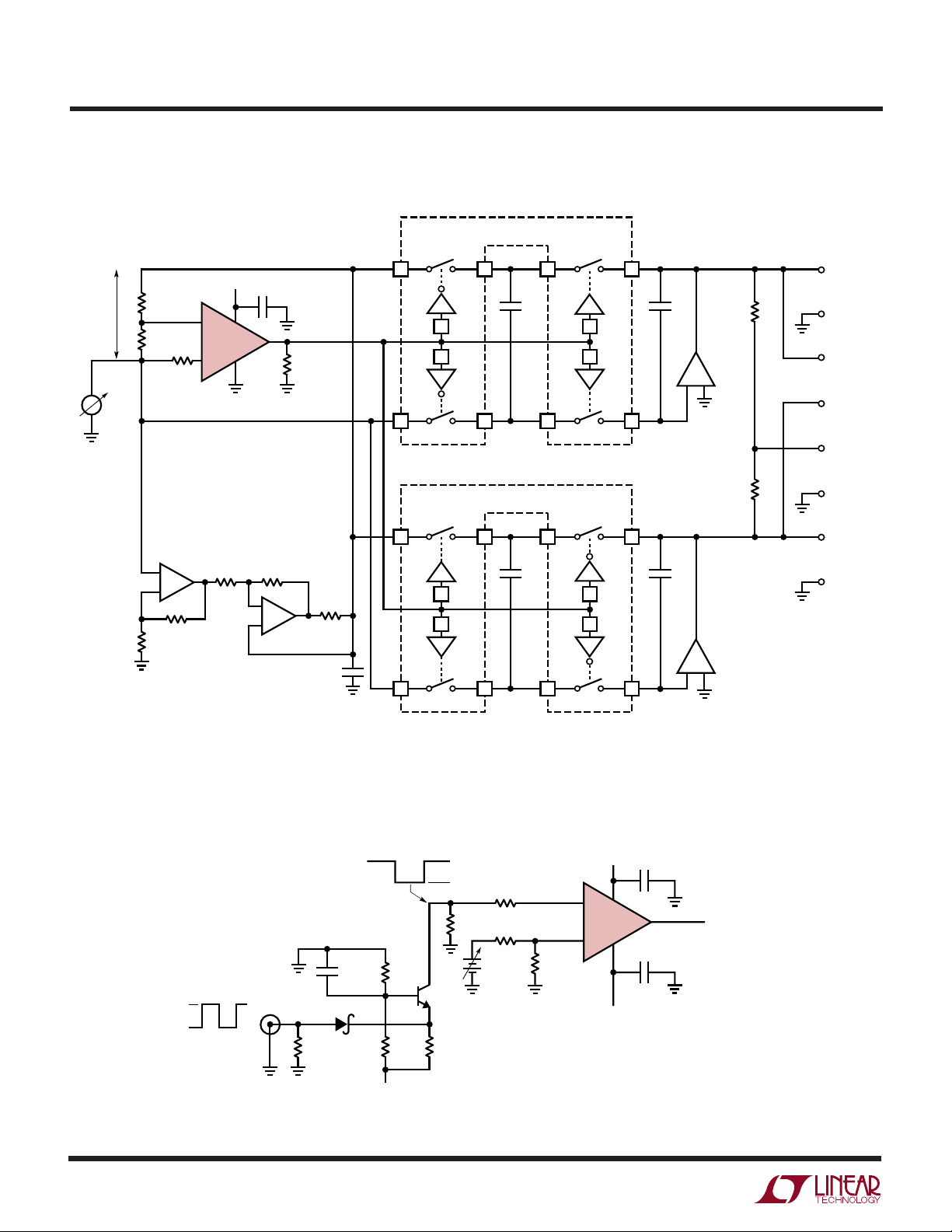

TEST CIRCUITS

15V

P-P

BANDWIDTH-LIMITED

TRIANGLE WAVE

~

1kHz

V

CC

50k

50Ω

50Ω

DUT

V

1/2 LT1720 OR

CM

NOTES: LT1638, LT1112, LTC203s ARE POWERED FROM ±15V.

1/4 LT1721

1/2 LT1638

+

–

100k

100k

200kΩ PULL-DOWN PROTECTS LTC203 LOGIC INPUTS

WHEN DUT IS NOT POWERED

0.1µF

+

–

100k

100k

+

–

1/2 LT1638

200k

2.4k

0.15µF

±V

LTC203

LTC203

Test Circuit

TRIP

16

9

1

8

15 3 214

1000 × V

TRIP

HYST

OS

TRIP

+

–

1000 × V

10k

1000 × V

10k

1000 × V

1720/21 TC01

1µF

1µF

–

–

1/2 LT1112

+

1/2 LT1112

+

10nF

1

8

10 6 711

2 14 153

10nF

16

9

7 11 106

6

–3V

Response Time Test Circuit

– V

+V

CC

+

–

TRIP

–V

CM

0.01µF

10 × SCOPE PROBE

(C

≈ 10pF)

IN

0.01µF

CM

+

)

1720/21 TC02

0V

–100mV

25Ω

0.1µF

0V

PULSE

IN

1N5711

50Ω

–5V

130Ω

400Ω

2N3866

750Ω

V1*

*V1 = –1000 • (OVERDRIVE + V

NOTE: RISING EDGE TEST SHOWN.

FOR FALLING EDGE, REVERSE LT1720 INPUTS

1/2 LT1720 OR

25Ω

50k

50Ω

DUT

1/4 LT1721

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

Input Voltage Considerations

The LT1720/LT1721 are specified for a common mode

range of –100mV to 3.8V when used with a single 5V

supply. In general the common mode range is 100mV

below ground to 1.2V below VCC. The criterion for this

common mode limit is that the output still responds

correctly to a small differential input signal. Also, if one

input is within the common mode limit, the other input

signal can go outside the common mode limits, up to the

absolute maximum limits (a diode drop past either rail at

10mA input current) and the output will retain the correct

polarity.

When either input signal falls below the negative common

mode limit, the internal PN diode formed with the substrate can turn on, resulting in significant current flow

through the die. An external Schottky clamp diode

between the input and the negative rail can speed up

recovery from negative overdrive by preventing the substrate diode from turning on.

When both input signals are below the negative common

mode limit, phase reversal protection circuitry prevents

false output inversion to at least –400mV common mode.

However, the offset and hysteresis in this mode will

increase dramatically, to as much as 15mV each. The input

bias currents will also increase.

When both input signals are above the positive common

mode limit, the input stage will become debiased and the

output polarity will be random. However, the internal

hysteresis will hold the output to a valid logic level, and

because the biasing of each comparator is completely

independent, there will be no impact on any other comparator. When at least one of the inputs returns to within

the common mode limits, recovery from this state will take

as long as 1µs.

The propagation delay does not increase significantly

when driven with large differential voltages. However, with

low levels of overdrive, an apparent increase may be seen

with large source resistances due to an RC delay caused

by the 2pF typical input capacitance.

Input Protection

The input stage is protected against damage from large

differential signals, up to and beyond a differential voltage

equal to the supply voltage, limited only by the absolute

maximum currents noted. External input protection circuitry is only needed if currents would otherwise exceed

these absolute maximums. The internal catch diodes can

conduct current up to these rated maximums without

latchup, even when the supply voltage is at the absolute

maximum rating.

The LT1720/LT1721 input stage has general purpose

internal ESD protection for the human body model. For use

as a line receiver, additional external protection may be

required. As with most integrated circuits, the level of

immunity to ESD is much greater when residing on a

printed circuit board where the power supply decoupling

capacitance will limit the voltage rise caused by an ESD

pulse.

Input Bias Current

Input bias current is measured with both inputs held at 1V.

As with any PNP differential input stage, the LT1720/

LT1721 bias current flows out of the device. With a

differential input voltage of even just 100mV or so, there

will be zero bias current into the higher of the two inputs,

while the current flowing out of the lower input will be

twice the measured bias current. With more than two

diode drops of differential input voltage, the LT1720/

LT1721’s input protection circuitry activates, and current

out of the lower input will increase an additional 30% and

there will be a small bias current into the higher of the two

input pins, of 4µA or less. See the Typical Performance

curve “Input Current vs Differential Input Voltage.”

High Speed Design Considerations

Application of high speed comparators is often plagued

by oscillations. The LT1720/LT1721 have 4mV of internal

hysteresis, which will prevent oscillations as long as

parasitic output to input feedback is kept below 4mV.

7

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

However, with the 2V/ns slew rate of the LT1720/LT1721

outputs, a 4mV step can be created at a 100Ω input

source with only 0.02pF of output to input coupling. The

pinouts of the LT1720/LT1721 have been arranged to

minimize problems by placing the most sensitive inputs

(inverting) away from the outputs, shielded by the power

rails. The input and output traces of the circuit board

should also be separated, and the requisite level of

isolation is readily achieved if a topside ground plane runs

between the outputs and the inputs. For multilayer boards

where the ground plane is internal, a topside ground or

supply trace should be run between the inputs and

outputs, as illustrated in Figure 1.

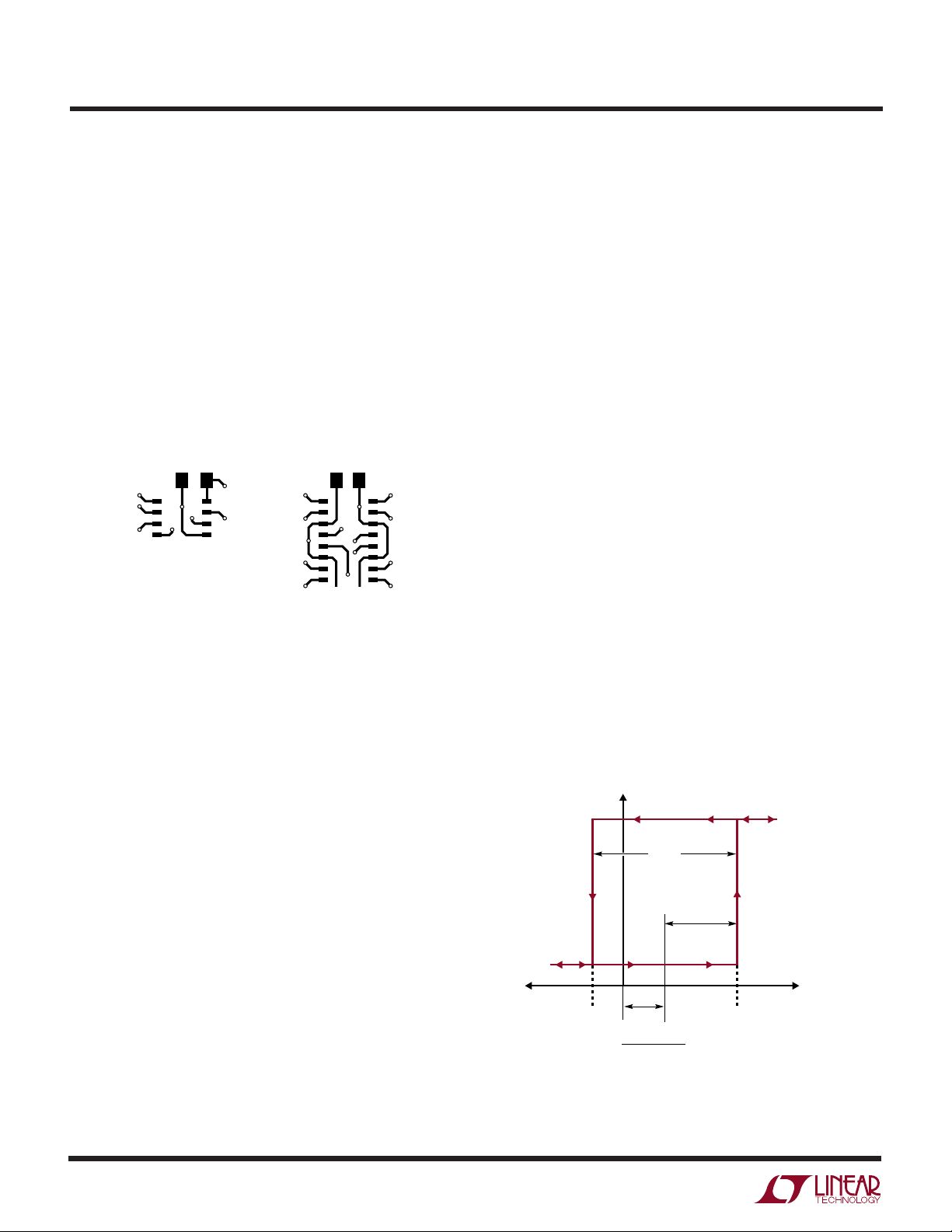

(b)(a)

1720/21 F01

Figure 1. Typical Topside Metal for Multilayer PCB Layouts

Figure 1a shows a typical topside layout of the LT1720 on

such a multilayer board. Shown is the topside metal etch

including traces, pin escape vias, and the land pads for an

SO-8 LT1720 and its adjacent X7R 10nF bypass capacitor

in a 1206 case.

The ground trace from Pin 5 runs under the device up to

the bypass capacitor, shielding the inputs from the

outputs. Note the use of a common via for the LT1720 and

the bypass capacitor, which minimizes interference from

high frequency energy running around the ground plane or

power distribution traces.

The supply bypass should include an adjacent

10nF ceramic capacitor and a 2.2µF tantalum capacitor no

farther than 5cm away; use more capacitance if driving

more than 4mA loads. To prevent oscillations, it is helpful

to balance the impedance at the inverting and noninverting

inputs; source impedances should be kept low, preferably

1kΩ or less.

The outputs of the LT1720/LT1721 are capable of very

high slew rates. To prevent overshoot, ringing and other

problems with transmission line effects, keep the output

traces shorter than 10cm, or be sure to terminate the lines

to maintain signal integrity. The LT1720/LT1721 can drive

DC terminations of 250Ω or more, but lower characteristic

impedance traces can be driven with series termination or

AC termination topologies.

Hysteresis

The LT1720/LT1721 include internal hysteresis, which

makes them easier to use than many other comparable

speed comparators.

The input-output transfer characteristic is illustrated in

Figure 2 showing the definitions of VOS and V

HYST

based

upon the two measurable trip points. The hysteresis band

makes the LT1720/LT1721 well behaved, even with slowly

moving inputs.

OUT

V

V

HYST

+

–

– V

(= V

TRIP

TRIP

V

HYST

)

/2

V

OH

Figure 1b shows a typical topside layout of the LT1721 on

a multilayer board. In this case, the power and ground

traces have been extended to the bottom of the device

solely to act as high frequency shields between input and

output traces.

Although both VCC pins are electrically shorted internal to

the LT1721, they must be shorted together externally as

well in order for both to function as shields. The same is

true for the two GND pins.

8

V

OL

0

–

V

TRIP

V

Figure 2. Hysteresis I/O Characteristics

+

V

+ V

TRIP

=

OS

TRIP

2

V

TRIP

–

+

∆VIN = V

1720/21 F02

+

–

– V

IN

IN

LT1720/LT1721

U

WUU

APPLICATIONS INFORMATION

The exact amount of hysteresis will vary from part to part

as indicated in the specifications table. The hysteresis level

will also vary slightly with changes in supply voltage and

common mode voltage. A key advantage of the LT1720/

LT1721 is the significant reduction in these effects, which

is important whenever an LT1720/LT1721 is used to detect a threshold crossing in one direction only. In such a

case, the relevant trip point will be all that matters, and a

stable offset voltage with an unpredictable level of hysteresis, as seen in competing comparators, is of little value.

The LT1720/LT1721 are many times better than prior comparators in these regards. In fact, the CMRR and PSRR

tests are performed by checking for changes in either trip

point to the limits indicated in the specifications table.

Because the offset voltage is the average of the trip points,

the CMRR and PSRR of the offset voltage is therefore

guaranteed to be at least as good as those limits. This

more stringent test also puts a limit on the common mode

and power supply dependence of the hysteresis voltage.

Additional hysteresis may be added externally. The rail-torail outputs of the LT1720/LT1721 make this more predictable than with TTL output comparators due to the

LT1720/LT1721’s small variability of VOH (output high

voltage).

To add additional hysteresis, set up positive feedback by

adding additional external resistor R3 as shown in Figure

3. Resistor R3 adds a portion of the output to the threshold

set by the resistor string. The LT1720/LT1721 pulls the

outputs to the supply rail and ground to within 200mV of

the rails with light loads, and to within 400mV with heavy

loads. For the load of most circuits, a good model for the

voltage on the right side of R3 is 300mV or VCC – 300mV,

for a total voltage swing of (VCC – 300mV) – 300mV =

VCC – 600mV.

With this in mind, calculation of the resistor values needed

is a two-step process. First, calculate the value of R3 based

on the additional hysteresis desired, the output voltage

swing, and the impedance of the primary bias string:

R3 = (R1R2)(VCC – 0.6V)/(additional hysteresis)

Additional hysteresis is the desired overall hysteresis less

the internal 3.5mV hysteresis.

The second step is to recalculate R2 to set the same

average threshold as before. The average threshold before

was set at VTH = (V

)(R1)/(R1 + R2). The new R2 is

REF

calculated based on the average output voltage (VCC/2)

and the simplified circuit model in Figure 4. To assure that

the comparator’s noninverting input is, on average, the

same VTH as before:

R2′ = (V

– VTH)/(VTH/R1 + (VTH – VCC/2)/R3)

REF

For additional hysteresis of 10mV or less, it is not uncommon for R2′ to be the same as R2 within 1% resistor

tolerances.

This method will work for additional hysteresis of up to a

few hundred millivolts. Beyond that, the impedance of R3

is low enough to effect the bias string, and adjustment of

R1 may also be required. Note that the currents through

the R1/R2 bias string should be many times the input

currents of the LT1720/LT1721. For 5% accuracy, the

current must be at least 120µA(6µA IB ÷ 0.05); more for

higher accuracy.

V

REF

R2

R1

INPUT

Figure 3. Additional External Hysteresis

R3

+

1/2 LT1720

–

1720/21 F03

V

REF

R2′

V

TH

R1

Figure 4. Model for Additional Hysteresis Calculations

R3

+

1/2 LT1720

–

V

AVERAGE

V

=

1720/21 F04

CC

2

9

Loading...

Loading...