FEATURES

LT1619

Low Voltage Current Mode

PWM Controller

U

DESCRIPTIO

■

Wide VIN Range: 1.9V to 18V

■

300kHz Fixed Frequency Current Mode Control

■

1A Rail-to-Rail N-Channel MOSFET Driver

■

Low 53mV Current Limit Threshold Voltage

Improves Efficiency

■

Implements Boost, SEPIC and Flyback Converters

Requiring Low Side Power Transistors

■

Internal Current Sense Amplifier

with Leading Edge Blanking

■

Up to 500kHz External Synchronization

■

Burst Mode® Operation for High Efficiency

at Light Load

■

140µA Quiescent Current

■

15µA Shutdown Current

■

8-Lead MSOP and SO Packages

U

APPLICATIO S

■

3.3V to 5V DC/DC Converters

■

Distributed Power Supplies

■

Isolated Power Supplies

The LT®1619 is a fixed frequency PWM controller for

implementing current mode DC/DC converters with minimum external parts. The LT1619 operates with input

voltages ranging from 1.9V to 18V and is suitable for a

variety of battery-powered and distributed DC/DC converters. The internal rail-to-rail N-channel MOSFET driver

operates either from the input in the nonbootstrapped

mode or from the output in bootstrapped operation. The

driver is designed to drive a low side power transistor in

boost, SEPIC, flyback and other topologies.

Converter efficiency is improved at heavy loads with a

53mV current sense voltage and at light load with Burst

Mode operation. The operating frequency is internally set

at 300kHz. The oscillator can also be synchronized externally up to 500kHz. No load quiescent current is 140µA and

shutdown current is 15µA.

The LT1619 is available in 8-lead MSOP and SO packages.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a registered trademark of Linear Technology Corporation.

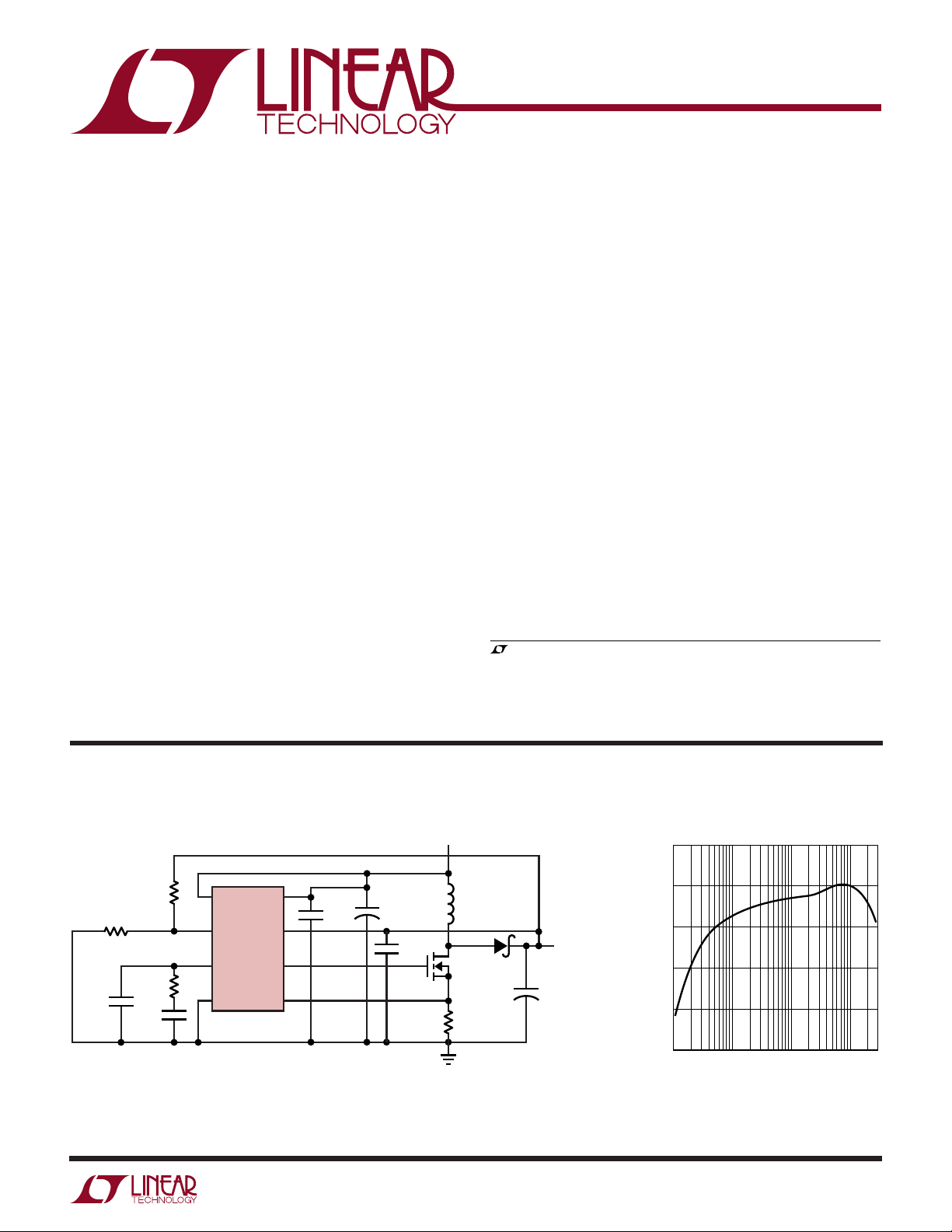

TYPICAL APPLICATIO

37.4k

12.4k

220pF

C1: PANASONIC EEFCDOK220R

: KEMET T495X227K010AS (×2)

C

OUT

D1: MBRD835L

L1: COILCRAFT DO5022P-562

75k

15nF

Figure 1. High Efficiency 3.3V to 5V DC/DC Converter

1

S/S

2

FB

LT1619

3

V

C

4

GND

V

DRV

GATE

SENSE

8

IN

7

6

5

U

0.1µF

V

IN

3.3V

+

C1

22µF

0.1µF

L1

5.6µH

5A

M1

Si9804

R

SENSE

0.01Ω

D1

1619 F01

V

OUT

5V

2.2A

+

C

OUT

440µF

95

90

85

80

EFFICIENCY (%)

75

70

1 100 1000

Efficiency

10

LOAD CURRENT (mA)

1619 F01a

1619fa

1

LT1619

1

2

3

4

8

7

6

5

TOP VIEW

V

IN

DRV

GATE

SENSE

S/S

FB

V

C

GND

S8 PACKAGE

8-LEAD PLASTIC SO

WWWU

ABSOLUTE AXI U RATI GS

(Note 1)

Input Voltage (VIN) ................................... –0.3V to 20V

Gate Drive Supply Voltage (DRV) ............. –0.3V to 20V

Shutdown/Synch Voltage (S/S) ................ –0.3V to 20V

Feedback Voltage (FB) .............................................. V

IN

Compensation Voltage (VC) ...................................... 3V

Gate Drive Output Current (GATE) ........................ ±1.5A

UU

W

PACKAGE/ORDER I FOR ATIO

ORDER PART

NUMBER

TOP VIEW

S/S

1

FB

2

V

3

C

4

GND

MS8 PACKAGE

8-LEAD PLASTIC MSOP

T

= 125°C, θJA = 200°C/W

JMAX

8

7

6

5

V

IN

DRV

GATE

SENSE

LT1619EMS8

MS8 PART MARKING

LTHC

Current Sense Voltage (SENSE) .................– 0.5V to V

IN

Operating Temperature Range (Note 2) .. –40°C to 85°C

Junction Temperature (Note 3)............................. 125°C

Storage Temperature Range ................. –65°C to 150°C

Lead Temperature (Soldering, 10 sec)..................300°C

ORDER PART

NUMBER

LT1619ES8

S8 PART MARKING

1619

= 125°C, θJA = 120°C/W

T

JMAX

Consult LTC Marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= V

IN

PARAMETER CONDITIONS MIN TYP MAX UNITS

Reference Voltage Measured at the FB Pin ● 1.22 1.24 1.26 V

Reference Line Regulation 1.9V ≤ VIN ≤ 18V 0.004 0.05 %/V

FB Input Bias Current VFB = V

Error Amplifier Transconductance 80 170 260 µΩ

Error Amplifier Output Source Current VFB = 1V, V

Error Amplifier Output Sink Current VFB = 1.5V, V

Error Amplifier Clamp Voltage VFB = 1V 1.6 2.2 V

Undervoltage Lockout Threshold 1.65 1.85 V

Input Voltage Range ● 1.9 18 V

Switching Frequency 1.9V ≤ VIN ≤ 18V ● 220 300 360 kHz

Synchronization Frequency Range 370 500 kHz

Maximum Duty Cycle ● 88 92 %

Current Limit Threshold ● 40 53 66 mV

Burst Mode Operation Current Limit 10 mV

2

= 2.5V, V

DRV

= VIN, COMP open, V

S/S

= 0V unless otherwise noted.

SENSE

REF

= 1V 4 8.7 14 µA

COMP

= 1V 4 8.7 14 µA

COMP

10 25 nA

–1

1619fa

LT1619

ELECTRICAL CHARACTERISTICS

The ● denotes specifications which apply over the full operating temperature range, otherwise specifications are at TA = 25°C.

V

= V

IN

= 2.5V, V

DRV

PARAMETER CONDITIONS MIN TYP MAX UNITS

Current Sense Input Current V

Current Limit Delay 150 ns

Driver Output Rise Time CL = 3300pF 30 ns

Driver Output Fall Time CL = 3300pF 35 ns

Driver Output High Level I

Driver Output Low Level I

Shutdown Driver Output Level V

Idle Mode Driver Output Level V

S/S Pin Current V

Operating Supply Current VFB = 1V 9 mA

Quiescent Supply Current V

Shutdown Supply Current V

Shutdown Threshold 0.45 1.2 V

Shutdown Delay 12 17 33 µs

= VIN, COMP open, V

S/S

= 0V unless otherwise noted.

SENSE

= 0V ● –90 –120 –150 µA

SENSE

= –20mA V

OUT

I

= –200mA V

OUT

= 20mA 100 200 mV

OUT

= 200mA 0.5 0.7 V

I

OUT

= 0V, I

S/S

= VIN, VFB = 1.5V, I

S/S

= V

S/S

= 0V –2 µA

V

S/S

= VIN, VFB = 1.5V ● 140 220 µA

S/S

= 0V 15 19 µA

S/S

= 0V, VIN = 18V, TA = 85°C40µA

V

S/S

= 20mA 100 200 mV

OUT

= 20mA 100 200 mV

OUT

IN

– 0.6 V

DRV

– 1.6 V

DRV

– 0.35 V

DRV

– 1.2 V

DRV

4 µA

Note 1: Absolute Maximum Ratings are those values beyond which the life

of the device may be impaired.

Note 2: The LT1619E is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

Note 3: T

dissipation P

the formula:

is calculated from the ambient temperature TA, the power

J

T

= TA + PD • θ

J

temperature range are assured by design, characterization and correlation

with statistical process controls.

UW

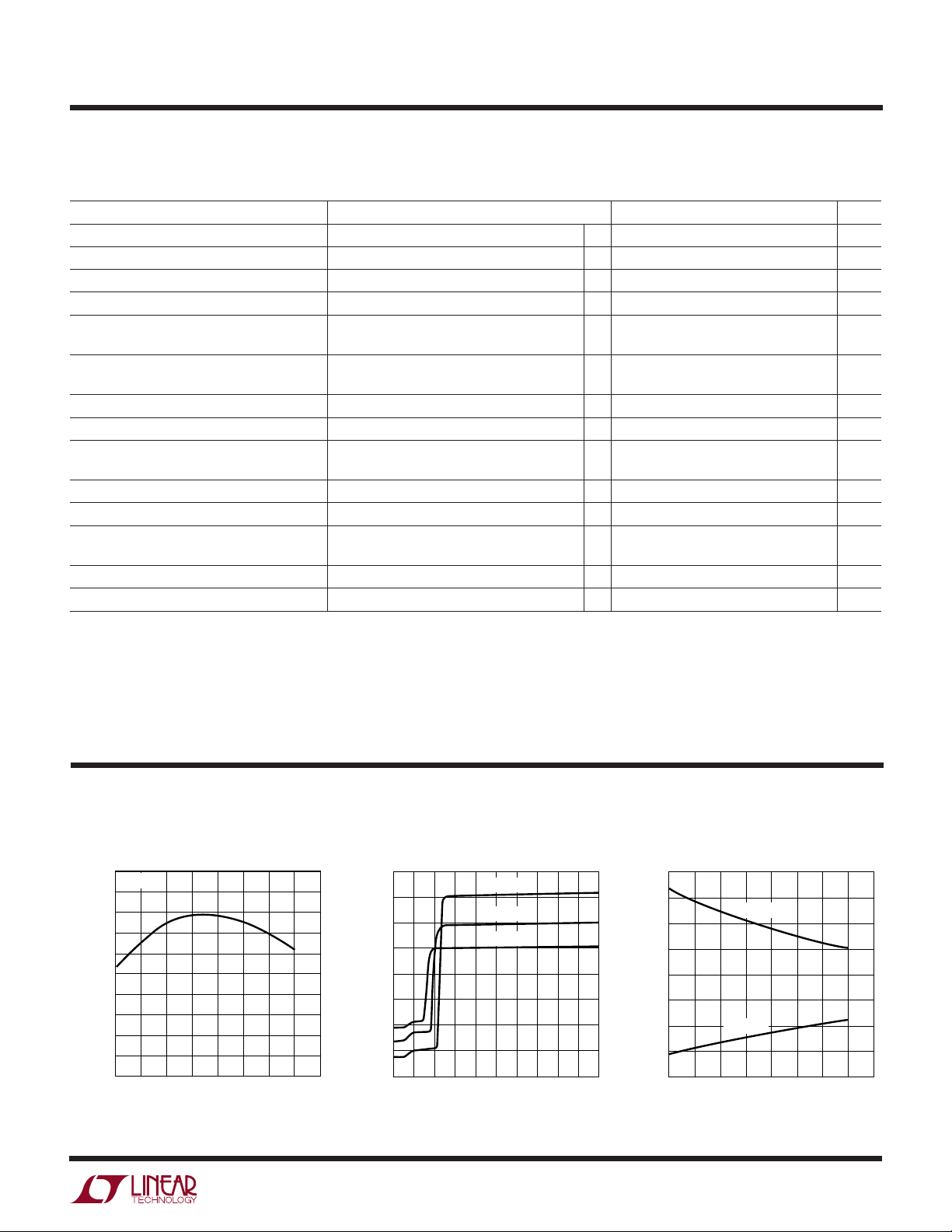

TYPICAL PERFOR A CE CHARACTERISTICS

Bandgap Voltage vs Temperature I

1.245

VIN = 2.5V

1.243

1.241

1.239

1.237

1.235

1.233

1.231

BANDGAP VOLTAGE (V)

1.229

1.227

1.225

–20 0 20 40 60 120

–40

TEMPERATURE (°C)

80 100

1619 G01

(µA)

I

S/S

vs V

S/S

S/S

5

4

3

2

1

0

–1

–2

–3

1.0 2.0 3.0 5.03.50.5 1.5 2.5 4.5

0

TA = –40°C

TA = 25°C

TA = 85°C

V

(V)

S/S

4.0

and the thermal resistance θJA of the package according to

D

JA

S/S Pin Current vs Temperature

5

1619 G02

4

3

2

1

0

S/S PIN CURRENT (µA)

–1

–2

–3

–20

–40

V

= 2.5V

S/S

V

= 0V

S/S

0

40

20

TEMPERATURE (°C)

60

80

100

1619 G03

120

1619fa

3

LT1619

TEMPERATURE (°C)

–40

CURRENT LIMIT THRESHOLD (mV)

57

20

1619 G09

54

52

–20 0 40

51

50

58

56

55

53

60 80 100

VIN = 2.5V

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Shutdown Supply Current

vs Input Voltage

45

40

35

30

25

20

SUPPLY CURRENT (µA)

15

10

5

0

TA = –40°C

TA = 25°C

4 8 12 20142 6 10 18

INPUT VOLTAGE (V)

Maximum Duty Ratio

vs Temperature

95

VIN = 2.5V

94

93

92

DUTY RATIO (%)

91

TA = 85°C

Idle Mode Supply Current

vs Temperature

200

VIN = 2.5V

190

180

170

160

150

IDLE MODE SUPPLY CURRENT (µA)

140

–40

–20 20

16

1619 G04

040

TEMPERATURE (°C)

60

80

100

120

1619 G05

Deviation from Nominal

Frequency vs Input Voltage

8

TA = 25°C

NOMINAL FREQUENCY = 300kHZ

6

4

2

0

FREQUENCY DEVIATION (%)

–2

Frequency Deviation from

Nominal vs Temperature

10

VIN = 2.5V

8

NOMINAL FREQUENCY = 300kHz

6

4

2

0

–2

–4

–6

–8

DEVIATION FROM NOMINAL FREQUENCY (%)

–10

–20 0 40

–40

20

TEMPERATURE (°C)

60 80 100

Current Limit Threshold

vs Temperature

1619 G06

90

–40 –20

Burst Mode Operation Current

Limit Threshold vs Temperature

14

VIN = 2.5V

DUTY CYCLE = 0

12

10

8

6

4

2

CURRENT LIMIT THRESHOLD (mV)

0

–40

–20 0

4

40

20

0

TEMPERATURE (°C)

40 80 100

20 60

TEMPERATURE (°C)

80

100

1619 G07

1619 G10

60

–4

4

2

0

10

8

6

INPUT VOLTAGE (V)

SENSE Pin Input Bias Current

vs Temperature

–115

V

= 0V

SENSE

–117

–119

–121

–123

–125

–127

–129

SENSE PIN CURRENT (µA)

–131

–133

–135

–40

–20

0

20

TEMPERATURE (°C)

16

12

14

18

1619 G08

20

SENSE Pin Input Bias Current

vs Sense Voltage

–90

TA = 25°C

–95

–100

–105

–110

–115

–120

SENSE PIN CURRENT (µA)

–125

40

60

80

100

1619 G11

–130

–10

010

20 30

V

SENSE

(mV)

40 50

60

1619 G12

1619fa

LT1619

U

UU

PI FU CTIO S

S/S (Pin 1): Shutdown and Synchronization. Shutdown is

active low with a typical threshold voltage of 0.9V. For

normal operation, the S/S pin is tied to VIN. To externally

synchronize the controller, drive the S/S pin with pulses.

FB (Pin 2): The inverting Input of the Error Amplifier.

Connect the resistor divider tap here. Set V

to V

= 1.24(1 + R1/R2). See Figure 1.

OUT

according

OUT

VC (Pin 3): Compensation Pin for the Error Amplifier. VC is

the output of the transconductance amplifier. Overall loop

is compensated with an RC network from this pin to the

ground.

GND (Pin 4): Ground. Connect to local ground plane.

W

BLOCK DIAGRA

V

CVIN

1.24V

FB

3 8

ERROR

AMPLIFIER

1.8V

+

g

m

2

–

–

A2

UVLO

+

–

A1

V

+

B

–

SENSE (Pin 5): The Input of the Current Sense Amplifier.

The SENSE pin is connected to the source of the N-channel

MOSFET and to a sense resistor to the ground. The current

limit threshold is internally set at 53mV, giving a maximum

switch current of 53mV/R

SENSE

.

GATE (Pin 6): The Output of the MOSFET Driver.

DRV (Pin 7): The Pull-Up Supply of the MOSFET Driver. Tie

this pin to VIN (Pin 8) for nonbootstrapped operation or to

the converter output for bootstrapped operation.

VIN (Pin 8): Supply or Battery Input. Must be closely

bypassed to the ground plane.

IDLE

V

IN

DRV

7

S/S

C1

+

++

Σ

RAMP COMP

DELAY

300kHz

OSCILLATOR

REF/BIAS

1

SYNC

SHUTDOWN

CLK

COMPARATOR

CURRENT

LIMIT

S

Q

R

DRIVER

–

CURRENT

SENSE

+

AMP

+

I

–

LIM

280ns

LEADING

EDGE

BLANKING

6

5

4

GATE

SENSE

GND

1619 F02

R

LOAD

SENSE

Figure 2. LT1619 Block Diagram

1619fa

5

LT1619

OPERATIO

U

The LT1619 is a fixed frequency current mode switching

regulator PWM controller that can be used in boost, SEPIC

or flyback modes. The device operates from an input

supply range of 1.9V to 18V, and has a separate supply pin

(DRV) for the gate driver. The DRV pin can be bootstrapped

to V

for additional gate enhancement in low voltage

OUT

applications like 3.3V to 5V boost converters, or connected to the input supply for higher voltage inputs.

To best understand operation of the LT1619, please refer

to Figure 2, the Block Diagram. The gate drive circuit turns

on the external MOSFET at the trailing edge of oscillator

output signal CLK. MOSFET current is sensed with an

external resistor (R

of Figure 1). A leading edge

SENSE

blanking circuit disables the current sense amplifier for

280ns immediately following switch turn-on, preventing

gate charging current from prematurely tripping the PWM

comparator. A slope compensating ramp, derived from

the oscillator, is added to the current sense output. The

driver turns off the MOSFET when this sum exceeds the

error amplifier output VC. The switch current is limited

with a separate comparator. The compensating ramp is a

progressive nonlinear function of the operating duty ratio

whereas the current limit does not vary with the duty ratio.

Error amplifier output VC determines the peak switch current required to regulate the output voltage. VC can be

considered a measure of output current. At heavy loads,

VC is in its upper range. Average and peak inductor currents are high. In this range, the inductor tends to run in

continuous conduction mode (CCM), where current is always flowing in the inductor. As load current decreases,

average and peak inductor current decreases. When the

average inductor current falls below 1/2 of the peak-to-peak

inductor current ripple, the converter enters discontinuous conduction mode (DCM), where current in the inductor reaches zero sometime during the discharge phase.

Further reduction in output current moves VC towards its

lower operating range, decreasing inductor current. Hysteretic comparator A1 determines if VC is too low for the

LT1619 to operate efficiently. As VC falls below the trip

voltage VB, A1’s output goes high, turning off all blocks

except the error amplifier, A1 and A2. The LT1619 enters

the idle state and switching stops. The device draws just

140µA from the input in the idle state. Output load current

discharges the output capacitor, causing the output voltage to decrease. As V

decreases, VC increases. As V

OUT

C

increases above VB, switching action begins, delivering

power to the output. The switch current sense threshold is

about 10mV in this VC region. If the output load remains

light, the output voltage will rise and VC will fall, causing

the converter to idle again. This is known as Burst Mode

operation. The burst frequency depends on input voltage,

output voltage, inductance and output capacitance. Output voltage ripple during Burst Mode operation is usually

higher than when the converter is switching continuously.

Burst Mode operation increases light load efficiency because it delivers more energy per clock cycle than possible

with discontinuous mode operation and extremely low

peak switch current, allowing fewer switching cycles to

maintain a given output. IC supply current therefore becomes a small fraction of the total input current.

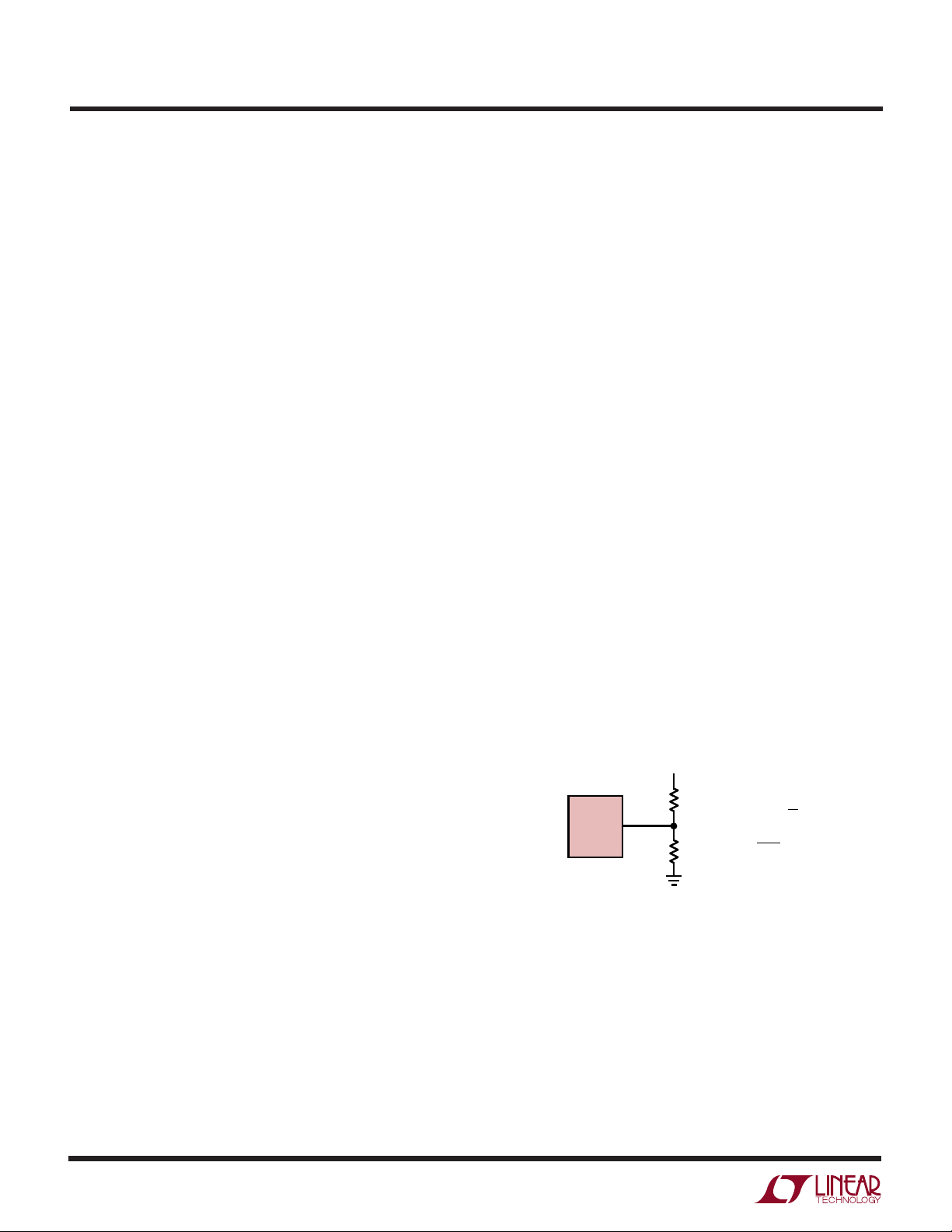

Setting Output Voltage

The output voltage of the LT1619 is set with resistive

divider R1 and R2 connected from the output to ground as

detailed in Figure 3. The divider tap is tied to the device FB

pin. Current through R2 should be significantly higher

than the FB pin bias current of 25nA. With R2 = 10k, the

input bias current of the error amplifier is 0.02% of the

current in R2.

V

O

R1

= 1.24V 1 +

LT1619

FB

Figure 3. Feedback Resistive Divider

V

O

R1 = R2

R2

R1

()

R2

V

O

– 1

()

1.24

1619 F03

Synchronization and Shutdown

The S/S pin (Pin 1) can be used to synchronize the

oscillator to an external source. The S/S pin is tied to the

input (VIN > 1.9V) for normal operation. The oscillator in

the LT1619 can be externally synchronized by driving the

S/S pin with a pulse train with an amplitude of at least 1V.

The maximum allowable rise time is a function of the

pulse amplitude, as shown in Table 1. Rise times equal to

6

1619fa

OPERATIO

LT1619

U

or less than the number specified in Table 1 are acceptable. The maximum duty cycle is essentially unaffected by

synchronization.

The device will go into shutdown mode if the S/S pin

voltage stays below the shutdown threshold of 0.45V for

Table 1. Maximum Allowable Rise Time of Synchronization

Pulse. Rise Time Can Be Slower if Clock Amplitude is Higher

SYNCHRONIZATION MAXIMUM ALLOWABLE

AMPLITUDE (V) RISE TIME (ns)

1.2 120

1.5 220

2.0 350

2.5 470

3.0 530

WUUU

APPLICATIO S I FOR ATIO

Inductor

The value of the inductor is usually selected so that the

peak-to-peak ripple current is less than 30% of the maximum inductor current. The inductor should be able to

handle the maximum inductor current at full load without

saturation. Powder iron cores are not suitable for high

frequency switch mode power supply applications because of their high core losses. Ferrite cores have very low

core losses and are the material of choice for high frequency DC/DC converters.

Power MOSFET Driver

The LT1619 is capable of driving a low side N-channel

power MOSFET with up to 60nC of total gate charge (Qg).

An external driver is recommended for MOSFETs with

greater than 80nC of total gate charge. The peak gate drive

current varies from 0.5A with V

V

= 10V. The MOSFET driver is capable of charging the

DRV

gate of the power MOSFET to within 350mV of the upper

gate drive supply rail (DRV). It can also pull the gate of the

MOSFET to within 100mV of ground during turnoff. The

upper supply rail of the gate drive is brought out as a device

= 2.5V to 1.2A with

DRV

more than 33µs. This shutdown delay is reset whenever

the S/S pin voltage rises above the shutdown threshold.

Applying a logic low signal at the S/S pin causes the gate

drive output to go low. Although all circuits in the LT1619

are disabled, the pull-down circuit in the MOSFET buffer is

still biased on. It is capable of shunting any leakage or

transient current at the GATE pin to ground, eliminating

the need for an external bleed resistor. The LT1619 consumes 15µA in shutdown.

The LT1619 is guaranteed to start with a minimum VIN of

1.85V. Comparator A2 senses the input voltage and generates an undervoltage lockout (UVLO) signal if VIN falls

below this minimum. While in undervoltage lockout, VC is

pulled low and the LT1619 stops switching. The supply

current drawn by the device falls to 140µA.

pin (DRV) for design flexibility. In a boost converter

design, the DRV pin can be tied to the converter output if

the minimum input voltage is insufficient to fully enhance

the power MOSFET. During start-up, the MOSFET is driven

with a gate voltage starting from VIN – VD (VD is the

forward voltage of the rectifying diode). As the output

voltage rises, the gate drive also increases until steady

state is reached. If the steady-state converter output

voltage exceeds the maximum allowable gate source

voltage and the input voltage is sufficient to enhance the

MOSFET, the DRV pin is tied to the input supply. For a

SEPIC converter, the DRV pin can be tied to the input or

diode OR’ed from the input and the output (Figure 4).

V

•

V

IN

DRV

LT1619

GND

Figure 4. SEPIC Converter with Diode OR’ed Gate Drive Supply

+

•

R

S

OUT

+

1619 F03

1619fa

7

LT1619

WUUU

APPLICATIO S I FOR ATIO

Power MOSFET

MOSFET power dissipation can be separated into frequency independent and frequency dependent components. The R

mean square switch current and switch R

loss in the switch is the product of the

DS(ON)

DS(ON)

and it

does not vary with the operating frequency.

The frequency-dependent switching losses consist of 1)

switch transition loss due to finite rise and fall times of the

drain source voltage and the drain current 2) gate switching loss, i.e., a packet of charge Qg (the total gate charge)

which is moved from the gate drive power supply to

ground in every switch cycle, and 3) the drain switching

loss, charge stored on the parasitic drain capacitance,

C

is dumped to ground as the switch is turned on. The

OSS

transistor loss can be expressed as:

P

LOSS

+ 1/2C

= I

OSSVDS(OFF)

DRMS

2

R

DS(ON)

2

f

S

+ transition loss + QgVGf

S

where the transition loss can be estimated with:

2

()

TransitionLoss I

=

CV f

RSS DS OFF S

D

I

()

G AVG

Qg = The total gate charge

VG = Gate drive voltage ≈ V

I

= The average MOSFET buffer output current

G(AVG)

DRV

fS = Operating frequency

C

= The average CGD between VDS = 0V

RSS

and VDS = V

DS(OFF)

the output capacitor and the peak-to-peak capacitor

current. Depending on topology, current feeding the output capacitor can be continuous or discontinuous. The input

current can also be continuous or discontinuous even if the

inductor current itself is continuous. In boost topology, the

inductor is in series with the input source so the input

current is continuous and the output current is discontinuous. In buck-boost or flyback converters, the inductor is

not in series with the input source nor the output, so neither the input current nor output current is continuous.

Whenever a terminal current is discontinuous, the capacitor at that terminal should be chosen to handle the ripple

current. Capacitor reliability will be adversely affected if

the ripple current exceeds the maximum allowable ratings. This maximum rating is specified as the RMS ripple

current. Several capacitors may be mounted in parallel to

meet the size and ripple current requirements.

Besides the ripple voltage requirements, the output capacitor also needs to be sized for acceptable output

voltage variation under load transients.

Current Sensing Resistor R

SENSE

The LT1619 drives a low side N-channel MOSFET switch.

The switch current is sensed with an external resistor

R

connected between the source of the MOSFET and

SENSE

ground. The internal blanking circuit blocks the voltage

spike developed across R

for 280ns at switch turn-

SENSE

on. The switch is turned off when the instantaneous

voltage across R

V

. Allowing variations in V

SENSE

exceeds the current limit threshold,

SENSE

yields:

SENSE

At low V

(≤12V) and operating frequencies below

DS(OFF)

500kHz, the ohmic losses often dominate. For high voltage

converters, the transition loss and C

charge dumping

OSS

loss can dramatically impact the converter efficiency.

MOSFETs with lower parasitic capacitances but higher

R

may actually provide better efficiency in these

DS(ON)

situations.

Capacitors

In a switch mode DC/DC converter, output ripple voltage

is the product of the equivalent series resistance (ESR) of

8

V

SENSE MIN

R

SENSE

=

()

I

LMAX

()

The current limit threshold is constant and does not vary

with duty ratio.

Due to low signal level of the sense voltage, low inductance

sense resistors are required to reduce switching noise.

Low TC resistors maintain constant current limit over

temperature. Dale WSL and IRC series sense resistors

meet these criteria.

1619fa

WUUU

APPLICATIO S I FOR ATIO

LT1619

Diode

Schottky diodes are recommended for low output voltage

applications because of their low forward voltage. Since

Schottky diodes have negligible stored charge, charge

dumping loss is also reduced. The reverse breakdown

voltage of the diode should exceed the maximum reverse

voltage stress of the topology used. The diode should also

be able to carry the peak diode current with acceptable

foward voltage. For the boost converter in Figure 1, the

peak inductor current is approximately 5A. A Motorola

MBRD835 is used due to its low forward voltage.

Lowering Burst Mode Operation Current Limit

The LT1619 automatically enters Burst Mode operation as

VC voltage falls below VB. The corresponding switch

current is the Burst Mode operation switch current threshold, I

D(BURST)

.

The effective Burst Mode operation current threshold can

be lowered by adding an offset to the input of the current

sense amplifier so that the switch current appears higher

to the PWM comparator. This has the effect of shifting the

VC operating range above VB. Although Burst Mode operation is not entirely disabled, the peak switch current before

entering Burst Mode operation is greatly reduced due to

the offset of the current sense amplifier. The peak switch

current is also determined by the current sense amplifier

blanking.

tolerance of ±25% and is temperature stable, develops an

offset voltage at the sense input. The value of ROS required

for non-Burst Mode operation can be obtained with the

expression:

I

BIASROS

≥ V

SENSE(BURST)

where

V

SENSE(BURST)

For example, if I

R

≥

OS

120

Allowing for 25% and 30% variations in I

V

SENSE(BURST)

= (Burst Mode operation peak switch

10

mV

µ

BIAS

A

current, I

= 120µA and V

=Ω

83

D(BURST)

) • R

SENSE

SENSE(BURST)

respectively:

= 10mV:

and

BAIS

ROS = (1.25)(1.3)(83Ω)

Choose ROS = 137Ω to completely disable Burst Mode

operation. Lower values of ROS (for example, 50Ω to

100Ω) can be used to lower the effective Burst Mode

current limit.

The value of the sense resistor is then adjusted to compensate for the reduced full-scale sense voltage.

I

BIASROS

+ I

L(MAX)RSENSE

= 40mV

Filtering Current Sense Signal

To lower the Burst Mode operation current sense threshold, a resistor ROS is added between the SENSE pin and

the sense resistor R

current I

Figure 5. Lowering Burst Mode Operation Current Limit

of the current sense amplifier, which has a

BIAS

I

= 120µA

BIAS

(Figure 5). The input bias

SENSE

CURRENT

SENSE

AMPLIFIER

–

+

= 120µA

I

BIAS

5

R

SENSE

4

GND

OS

R

I

D

SENSE

1619 F05

I

n a current mode converter, the current sense circuit

senses the switch current and terminates the switch

conduction. In the LT1619, the current sense amplifier

has a full-scale input voltage range from the ground to the

current limit threshold (53mV). Due to high speed switching transients and parasitic trace inductances, the current

sense signal V

tends to be noisy. If the V

SENSE

SENSE

switching transient is excessive, the current sense amplifier will amplify the spurious transient instead, resulting in

jittery operation. In situations where the internal leading

edge blanking is inadequate, a lowpass filter (Figure 6)

with corner frequency about 5 times the switching

fre

quency can be used to further attenuate high speed

switching transients. In Figure 6 the lowpass filter ROS and

CS has a corner frequency of:

1619fa

9

LT1619

WUUU

APPLICATIO S I FOR ATIO

f

CORNER

=≈

(The input impedance of the sense amplifier at the SENSE

pin is 2500Ω and ROS is typically less than 137Ω.) Typical

values for ROS and CS are 100Ω and 1nF. The 100Ω value

for ROS reduces Burst Mode threshold; use 10Ω and 10nF

when this is not desireable.

PWM

COMPARATOR

25π

LT1619

1

RC

OS S

CURRENT

SENSE

AMPLIFIER

f

S

I

D

R

SENSE

5

+

GND

4

–

OS

C

R

S

SENSEVSENSE

+

–

1619 F06

V

IN

V

Z

R3

1

S/S

I

S/S

2

FB

LT1619

3

V

C

4

GND

V

DRV

GATE

SENSE

1619 F07

8

IN

I

S/S

7

()

UVLO THRESHOLD = V

6

THRESHOLD ≈ V

I

S/S

5

R3 < SHUTDOWN THRESHOLD

V

= 0

S/S

+ V

Z

BE

≈ –2µA

V

= 0

S/S

+ SHUTDOWN

Z

Figure 7. Implementing Undervoltage Lockout

I

ZENER

+

I

V

–

DIODE

AVALANCHE

DIODE

Figure 6. Current Sense Filter for Improving Jitter Performance

Use of Shutdown Function to

Modify Undervoltage Lockout

The LT1619 is designed to operate from an input supply

with voltage as low as 1.85V. Shutdown is activated when

the S/S pin is pulled below 0.45V. The shutdown threshold

is slightly greater than one junction diode forward voltage

and has the temperature characteristics of a junction

diode. The S/S pin is normally tied to the input when

operating from a low voltage input source.

Consider the 12V to –65V isolated flyback converter (see

Typical Applications). The converter draws 3A at low line

while delivering 0.4A to the output. If the S/S pin is tied to

the input, then the LT1619 will start switching as soon as

VIN exceeds the internal UVLO threshold. With full load,

the converter can draw much higher than the steady-state

3A from the input source during start-up. If the input

source is current limited, the input voltage will collapse

and latch low.

The start-up problem can be prevented by adding a zener

diode and a resistor to the S/S pin (Figure 7). This is

equivalent to increasing undervoltage lockout voltage of

the controller. Before VIN exceeds the zener voltage VZ, the

S/S pin current is shunted to the ground through the

V

0

BV < 5V

Figure 8. I-V Characteristics of Zener

and Avalanche Breakdown Diodes

V

IN

R4

1

S/S

2

FB

C1

R3

LT1619

3

V

C

4

GND

V

DRV

GATE

SENSE

1619 F09

8

IN

7

6

5

Figure 9. Filtering Input Voltage Ripple in UVLO Circuit

resistor R3. The voltage developed across R3 due to I

S/S

should be less than the shutdown threshold. The LT1619

remains off until VIN exceeds the sum of VZ and the

shutdown threshold. True zener diodes (BV < 5V) and

higher voltage avalanche diodes have different I-V characteristics (Figure 8). They need to be biased appropriately

(value of R3) in order to obtain correct UVLO threshold.

When implementing UVLO with converters with high input

ripple voltages (such as flyback and forward), the circuit

in Figure 7 is modified and shown in Figure 9.

1619fa

10

WUUU

APPLICATIO S I FOR ATIO

LT1619

Here the input voltage ripple is filtered with R3, R4 and C1

so as to prevent the input ripple from falsely tripping the

LT1619 synchronization circuit. It is recommended that:

1

RR

4

3

≈

5

and

2341

1

RRC

π

||

()

<<

f

OSC

Implementation of Hysteretic UVLO

with External Synchronization

The UVLO circuit shown in Figure 10 operates down to

0.9V supply voltage. Algebraically the UVLO trip points

are:

VVV

=+ +

INH Z BE

1

RR

5

R

67

||

and

RRR

579

V

=

INL Z BE

UVLOHysteresis V V

+

|| ||

()

R

5

==

+

VV

–

INH INL Z

V

BE

RR

RRR

579

RR R R

56 7 9

|| ||

++

RRR

579

|||| R R

R

R

5

67

||

5

–

+

()

()

R

5

79

+

()

R

6

+

V

+

The collector votage of Q2 is made about 1.4V at the V

IN

lower trip voltage. This is necessary to prevent the UVLO

circuit from interfering with the feedback amplifier in the

LT1619.

Trickle Current Start from High Voltage Supplies

The low shutdown and idle mode quiescent supply currents of the LT1619 can be utilized to implement trickle

current start from high voltage input sources (such as a

36V to 72V telecom bus). The trickle current start-up

circuit in Figure 11 is modified from the UVLO circuit of

Figure 10. R10 is a high value resistor that charges the

storage capacitor C2 during start-up. Before VCC reaches

the upper UVLO trip point, Q2 holds the S/S pin low. The

LT1619 draws shutdown mode current (≈15µA) from VCC.

Q2 collector can also be tied to the VC pin through a diode

as in Figure 10. The LT1619 will then draw idle mode

quiescent current (≈140µA) from VCC. R10 should be able

to charge C2 while supplying current to the UVLO circuit

and the LT1619. Maximizing R5 to R9 values reduces

power dissipation in R10.

When VCC crosses the upper UVLO threshold, the LT1619

starts switching and its current consumption increases.

Before the bootstrap takes over, the LT1619 draws its

current from C2. VCC ramps towards the lower UVLO

threshold. Increasing the value of C2 allows more time for

the bootstrap circuit to establish itself before the converter

enters undervoltage lockout.

V

IN

1

CLK

D1

V

V

S/S

2

FB

LT1619

3

V

C

4

GND

UPPER TRIP POINT = 10V

IN

LOWER TRIP POINT = 8.4V

IN

R7

51k

Q1

2N2222

R9

510k

BAT85

Q2

2N2222

R8

30k

+

8.2V

–

R5

51k

R6

51k

Figure 10. Addition of Hysteresis UVLO While Synchronizing the

LT1619. Component Values Shown are for the Upper and the

Lower VIN Trip Points of 10V and 8.4V. In UVLO, the Gate Drive

is Disabled by Pulling the VC Pin Low. Disabling the Clock Shuts

Down the LT1619. If Not Synchronized, the Collector of Q2 Can

Be Tied to the S/S Pin and the Diode D1 Can Be Eliminated

V

DRV

GATE

SENSE

1619 F10

8

IN

7

6

5

HV V

IN

R10

C2

Figure 11. Trickle Current Start-Up with Bootstrapped V

R8

R7

R5

Q1

R6

V

CC

1

R9

Q2

S/S

2

FB

LT1619

3

V

C

4

GND

V

DRV

GATE

SENSE

1619 F11

8

IN

7

6

5

BOOTSTRAP

WINDING

D2

T1

CC

1619fa

11

LT1619

WUUU

APPLICATIO S I FOR ATIO

Increasing Ramp Compensation While Synchronizing

The LT1619 is synchronized by forced discharge of the

internal timing ramp. The timing ramp amplitude decreases as the synchronization frequency increases. Since

the internal compensation ramp is derived from the timing

ramp, reduced timing ramp results in diminished compensating ramp. If the LT1619 is synchronized at frequencies 20% to 30% higher than the free-running frequency,

external ramp compensation will be required. Figures 12

and 13 show two such schemes.

In both figures the compensating ramps are kept linear by

making R11-C1 and R14-C2 products substantially higher

than the synchronizing period. The compensation ramps,

1

CLK

S/S

2

FB

LT1619

3

V

C

4

GND

Figure 12. Increasing Ramp Compensation. Q1 Buffers the C1

Ramp. D2 Discharges C1. Values Shown are for 10V Gate Drive

and 15mV Ramp Across R13 at 90% Duty Cycle and 500kHz

V

DRV

GATE

SENSE

8

IN

7

6

5

R11

100k

D2

1N4148

C1

220pF

Q1

2N2222

R12

2200Ω

R13

51Ω

MAIN POWER

TRANSISTOR

R

SENSE

1619 F12

whose peak amplitudes are made between 1/4 to 1/3 of the

current limit threshold, are developed across R13. As a

result, the effective current limit threshold is reduced by

the sum of the compensating ramp and the offset voltage

developed across R13 due to the SENSE pin input bias

current (see Figure 5). Moreover, the current limit threshold becomes duty cycle dependent.

PC Board Layout and Other Practical Considerations

The following is recommended for PC board layout:

1. Trace lengths of the branches carrying switched cur-

rent should be kept short. For example, in the boost

converter of Figure 1, the circuit loop formed by M1,

R

of this loop must be minimized. R

SENSE

, D1 and C

carries switched current. The size

OUT

and C

SENSE

OUT

should be grounded to a single point on a large ground

plane. This reduces switching noise and overall con-

verter jitter. It is also preferable to ground the input

capacitor C1 close to the common point between C

and R

although this is less important.

SENSE

OUT

2. Keep the trace between the sense resistor and the

SENSE pin short. When sensing high switch current,

Kelvin connection to R

is necessary.

SENSE

3. Bypass both the VIN and DRV pins with ceramic capaci-

tors next to the IC and the ground plane.

CLK

1

S/S

2

FB

LT1619

3

V

C

4

GND

V

DRV

GATE

SENSE

8

IN

7

1N4148

6

5

2.2nF

R14

8200Ω

D2

C2

D3

1N4148

R15

2400Ω

R13

51Ω

R

SENSE

1619 F13

Figure 13. Externally Increasing Ramp Compensation. Similar

to Figure 12 Except That C2 is Not Buffered with Transistor

12

4. Keep high voltage switching nodes, such as the drain

and gate of the MOSFET, away from the FB and VC pins.

5. Use inductor so that its ripple current is between 1/4

and 1/3 of its peak current. Steeper inductor current

ramp results in sharper PWM comparator switching,

hence less jitter.

6. In most cases, filtering the current sense signal is not

necessary for jitter-free operation.

Figure 14 is the PC board layout for the 5V/8A and 12V/5A

boost converters shown in Figures 15a and 16a.

1619fa

WUUU

APPLICATIO S I FOR ATIO

R1

R

C

R2

C

Z

C

P

GND

C

IN1

LT1619

C

DRV

C

IN2

1

2

LT1619

3

4

R

SENSE

C

OUT1, 2

8

7

G

6

5

S

M1

DD

S

G

M1

V

OUT

V

IN

D1

L1

1619 F14

Figure 14. Recommended Component Placement for the Boost Converters in Figures 15a and 16a

1619fa

13

LT1619

WUUU

APPLICATIO S I FOR ATIO

1

S/S

2

FB

3

V

R

C

150pF

: SANYO POSCAP 6TPB150M ×2

C

IN1

C

OUT1

D1: MOTOROLA MBRB1545CT

L1: SUMIDA CEPH149-1R0

R

SENSE

C

75k

P

C

15nF

: SANYO POSCAP 10TPB220M ×4

: PANASONIC 0.002Ω 1W

C

4

GND

Z

LT1619

V

DRV

GATE

SENSE

8

IN

7

6

5

C

IN2

1µF

CERAMIC

C

DRV

0.1µF

CERAMIC

V

IN

3.3V

L1

1µH

+

C

IN1

300µF

M1

FDS6680A

×2

R

SENSE

D1

C

OUT1

220µF

C

OUT2

+

×4

10µF

CERAMIC

R1

37400Ω

R2

12400Ω

1619 F15a

5V

8A

Figure 15a. 3.3V to 5V/8A Boost Converter

89

VIN = 3.3V

88

87

86

EFFICIENCY (%)

85

84

83

0.01

0.1 1 10

LOAD CURRENT (A)

1619 F15b

Figure 15b. Efficiency of the 5V/8A Boost Converter

14

1619fa

WUUU

APPLICATIO S I FOR ATIO

1

2

3

R

C

C

Z

2200pF

4

C

68.1k

P

47pF

: SANYO OS-CON 10SA100M

C

IN1

: SANYO OS-CON 16SA150M ×4

C

OUT1

D1: MOTOROLA MBRB1545CT

L1: SUMIDA CDEP149-1R8

: PANASONIC 0.002Ω 1W

R

SENSE

S/S

FB

V

C

GND

LT1619

V

DRV

GATE

SENSE

8

IN

7

6

5

C

IN2

1µF

CERAMIC

C

DRV

0.1µF

CERAMIC

LT1619

V

IN

5V

L1

1.8µH

+

C

IN1

100µF

M1

FDS6690A

×2

R

SENSE

D1

C

OUT1

600µF

C

OUT2

+

10µF

CERAMIC

R1

107k

R2

12400Ω

1619 F15a

12V

5A

Figure 16a. 5V to 12V/5A Boost Converter

95

VIN = 5V

94

93

92

91

90

89

EFFICIENCY (%)

88

87

86

85

0.01

0.1 1 10

LOAD CURRENT (A)

1619 F16b

Figure 16b. Efficiency of the 12V/5A Boost Converter

1619fa

15

LT1619

TYPICAL APPLICATIO S

V

IN

4.75V TO

5.25V

U

T1

•

–48V/0.5A

1µF

+

1500µF

6.3V

SANYO MV-GX

2.2nF

T1: COILTRONICS CTX02-14261, EFD20-3F3, 6 WINDINGS EACH, 12µH

1.1k

36k

22nF

1N749

4.3V

1

S/S

2

FB

3

V

4

GND

C

LT1619

SENSE

V

DRV

GATE

15Ω

8

IN

7

10µF

6

5

•

•

•

•

•

4.7µF

FILM

SUD45N05-20L

50V, 0.018Ω

43nC

0.007Ω

MBRS340T3

4.7µF

FILM

MBRS340T3

30Ω

220pF

470µF

35V

+

SANYO MV-GX

470µF

35V

+

SANYO MV-GX

2N5210

2N5210

1619 F17a

12k1M

10.5k

1%

432k

1%

Figure 17a. 5V to –48V Cuk Converter

90

89

88

87

86

85

84

83

EFFICIENCY (%)

82

81

80

79

10

100 1000

LOAD CURRENT (mA)

VIN = 5V

= 4.75V

V

IN

VIN = 5.25V

1619 F17b

Figure 17b. Efficiency of the 5V to –48V Cuk

1619fa

16

TYPICAL APPLICATIO S

LT1619

U

V

IN

10.5V TO

13.7V

0.1µF

150µF

20V

SANYO

20SV150M

(OS-CON)

10k

20k

82k

8.1V

100Ω

1µF

0.22µF

50V

1

2

3

4

S/S

FB

V

C

GND

LT1619

SENSE

1k

1W

MBRS1100T3

8

V

IN

7

DRV

6

GATE

5

10µF

43Ω

330pF

50V

•

W1

•

W4

T1

W3

•

W2

•

IRLR024N

55V, 0.065Ω

= 15nC

Q

G

0.008Ω

330pF

43Ω

100V

1/4W

MBRS1100T3

1µF

50V

MBRS1100T3

10k

2.2µF

40V

–32.5V

2.2µF

40V

W4 6T TRIFILAR 28AWG

W3 24T 28AWG

W2 24T 28AWG

W1 6T TRIFILAR 28AWG

100Ω

62k

470pF

2.49k

–65V

PHILIPS EFD20-3F3-A100-S

CORE SET (0.013" GAP, AI = 100nH/T

CNY17-3

6.2V

220pF

121Ω

T1

LT1431

1

COLL

2

NC

3

V+

4

NC

2mil

POLYESTER

FILM

2

REF

FGND

SGND

NC

470Ω

8

7

6

5

1619 F18a

Figure 18a. Isolated Local SLIC Power Supply (Flyback) 20W Total Output Power (65V/0.3A or 32.5V/0.6A)

90

85

80

75

70

65

EFFICIENCY (%)

60

55

50

10

100 1000

LOAD CURRENT (mA)

VIN = 13.7V

= 12V

V

IN

= 10.5V

V

IN

1619 F18b

Figure 18b. Efficiency of the Isolated Local SLIC (Flyback)

1619fa

17

LT1619

PACKAGE DESCRIPTION

U

MS8 Package

8-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1660)

0.889 ± 0.127

(.035 ± .005)

5.23

(.206)

MIN

0.42 ± 0.04

(.0165 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.077)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

DETAIL “A”

(.126 – .136)

(.0256)

° – 6° TYP

0

DETAIL “A”

3.2 – 3.45

0.65

BSC

0.53 ± 0.015

(.021 ± .006)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.90

± 0.15

(1.93 ± .006)

0.22 – 0.38

(.009 – .015)

TYP

1.10

(.043)

MAX

8

12

0.65

(.0256)

BSC

7

0.52

5

4

(.206)

REF

3.00 ± 0.102

(.118 ± .004)

NOTE 4

0.86

(.034)

REF

0.13 ± 0.076

(.005 ± .003)

MSOP (MS8) 0802

6

3

18

1619fa

PACKAGE DESCRIPTION

.050 BSC

N

U

S8 Package

8-Lead Plastic Small Outline (Narrow .150 Inch)

(Reference LTC DWG # 05-08-1610)

.189 – .197

.045 ±.005

(4.801 – 5.004)

8

NOTE 3

7

6

LT1619

5

.245

MIN

1 2 3 N/2

.030 ±.005

TYP

RECOMMENDED SOLDER PAD LAYOUT

.010 – .020

(0.254 – 0.508)

.008 – .010

(0.203 – 0.254)

NOTE:

1. DIMENSIONS IN

2. DRAWING NOT TO SCALE

3. THESE DIMENSIONS DO NOT INCLUDE MOLD FLASH OR PROTRUSIONS.

MOLD FLASH OR PROTRUSIONS SHALL NOT EXCEED .006" (0.15mm)

× 45°

.016 – .050

(0.406 – 1.270)

INCHES

(MILLIMETERS)

.160

±.005

0°– 8° TYP

.228 – .244

(5.791 – 6.197)

.053 – .069

(1.346 – 1.752)

.014 – .019

(0.355 – 0.483)

TYP

N

.150 – .157

(3.810 – 3.988)

4

.050

(1.270)

BSC

NOTE 3

.004 – .010

(0.101 – 0.254)

SO8 0502

N/2

1

3

2

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

1619fa

19

LT1619

TYPICAL APPLICATIO

V

IN

4V TO 28V

U

T1

7

9

C4

1.5µF

100V

1N4687

LOW LEVEL

= 50µA)

(I

ZT

C4, C5: VITRAMON VJ1825Y155MXB (1825/X7R)

C6: TAIYO YUDEN LMK325BJ106MN (1210/X7R)

C8: TAIYO YUDEN EMK316BJ105ML (1206/X7R)

T1: COILTRONICS VP1-0190 (ER11/5, 6 WINDINGS EACH 12.2µH)

D4

4.3V

R3

5.6k

Q1

FMMT3904

VINDRV

S/S

C8

1µF

16V

D3

MBRS0530T1

876

GATE

SENSE

LT1619

FB

GND V

C

14

3

R9

2.2k

C9

2.2nF

5

2

R7

30Ω

C7

220pF

••

10

2

••

5

3

••

6

C5

1.5µF

100V

Q3

MMFT3055VL

3.74k

1%

R8

0.015Ω

12

1

4

8

11

D2

MBRS340T3

R10

1.24k

1%

R5

100Ω

C1

0.022µF

1619 TA01

R6

C6

10µF

10V

V

OUT

5V

0.5A

Figure 19. 2.5W, 4VIN-28VIN to 5V/0.5A Nonisolated Supply

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1370 500kHz, 6A Switching Regulator Boost, Buck, Flyback, Forward, Inverting; 42V Switch Voltage

LT1372 500kHz, 1.5A Switching Regulator SO-8, 2.7V ≤ VIN ≤ 30V, 42V Switch Voltage

LT1613 1.4MHz, SOT-23 DC/DC Converter Fixed Frequency, 0.9V ≤ VIN ≤ 10V, 36V Switch Voltage

LTC1624 Switching Regulator Controller SO-8, Drives N-Ch MOSFET, 3.5V ≤ VIN ≤ 36V

LT1680 Synchronous Boost Controller Synchronous Operation for High Current/High Efficiency

LT1698 Isolated or Nonisolated 10W to 100W 50% Lower Cost than Quarter Brick and Half Brick Modules

Power Supply Solution with Multiple Outputs Fits the Foot Print

LTC1871 No R

LTC1872 SOT-23 Boost Controller 550kHz Fixed Frequency, Current Mode

LT1946 1.2MHz, 65A DC/DC Converter MSOP-8, 5V to 12V/400mA

LT3710/LT3781 Isolated or Nonisolated 10W to 100W 50% Lower Cost than Quarter Brick and Half Brick Modules

Power Supply Solution with Multiple Outputs Fits the Foot Print

Boost, Flyback, SEPIC Controller 2.5V ≤ V

SENSE

≤ 36V, Current Mode Control, 50kHz to 1MHz

IN

Adjustabe Frequency, MSOP-10

20

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear.com

1619fa

LT/TP 1002 1K REV A • PRINTED IN USA

LINEAR TECHNOLOGY CORP ORATION 2000

Loading...

Loading...