FEATURES

LT1618

Constant-Current/

Constant-Voltage 1.4MHz

Step-Up DC/DC Converter

U

DESCRIPTIO

■

Accurate Input/Output Current Control: ±5% Over

Temperature

■

Accurate Output Voltage Control: ±1%

■

Wide VIN Range: 1.6V to 18V

■

1.4MHz Switching Frequency

■

High Output Voltage: Up to 35V

■

Low V

■

Available in (3mm × 3mm × 0.8mm) 10-Pin DFN and

Switch: 200mV at 1A

CESAT

10-Pin MSOP Packages

U

APPLICATIO S

■

LED Backlight Drivers

■

USB Powered Boost/SEPIC Converters

■

Input Current Limited Boost/SEPIC Converters

■

Battery Chargers

U

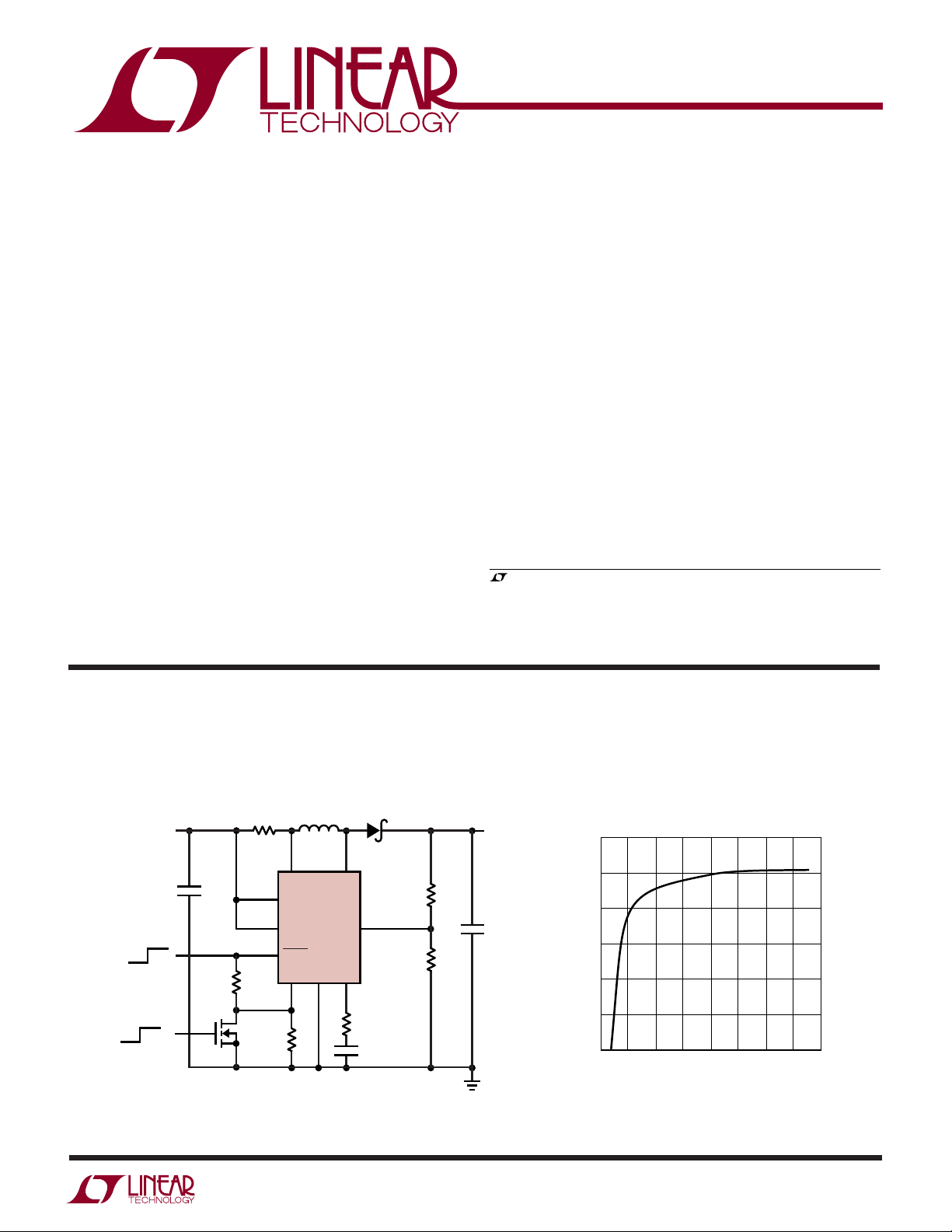

TYPICAL APPLICATIO

The LT®1618 step-up DC/DC converter combines a traditional voltage feedback loop and a unique current feedback

loop to operate as a constant-current, constant-voltage

source. This fixed frequency, current mode switcher operates from a wide input voltage range of 1.6V to 18V, and

the high switching frequency of 1.4MHz permits the use of

tiny, low profile inductors and capacitors. The current

sense voltage is set at 50mV and can be adjusted using the

I

pin.

ADJ

Available in the 10-Pin (3mm × 3mm) Exposed Pad DFN

and 10-pin MSOP packages, the LT1618 provides a complete solution for constant-current applications.

, LTC and LT are registered trademarks of Linear Technology Corporation.

(with Selectable 100mA/500mA Input Current Limit)

V

IN

5V

C1

4.7µF

3.3V

OFF

ON

0V

3.3V

100mA

500mA

0V

C1: TAIYO YUDEN JMK212BJ475

C2: TAIYO YUDEN EMK316BJ475

D1: ON SEMICONDUCTOR MBR0520

L1: SUMIDA CR43-100

USB to 12V Boost Converter

L1

3

8

9

13k

ISN

ISP

V

IN

SHDN

I

ADJ

10µH

2

LT1618

GND

SW

FB

V

C

5104

0.1Ω

20k

D1

7

R1

909k

1

R2

107k

2k

10nF

V

OUT

12V

C2

4.7µF

1618 TA01a

90

85

80

75

EFFICIENCY (%)

70

65

60

0

Efficiency Curve

20 60

40

LOAD CURRENT (mA)

100

120

160

1618 TA01b

sn1618 1618fas

80

140

1

LT1618

WW

W

ABSOLUTE AXI U RATI GS

U

(Note 1)

VIN, SHDN Voltage ................................................... 18V

SW Voltage .............................................................. 36V

ISP, ISN Voltage ...................................................... 36V

I

Voltage ............................................................... 6V

ADJ

FB Voltage .............................................................. 1.5V

Voltage .............................................................. 1.5V

V

C

UUW

PACKAGE/ORDER I FOR ATIO

TOP VIEW

10

FB

1

ISN

2

11

3

ISP

4

I

ADJ

5

GND

10-LEAD (3mm × 3mm) PLASTIC DFN

T

JMAX

DD PACKAGE

= 125°C, θJA = 43°C/W, θJC = 3°C/W

EXPOSED PAD (PIN 11) IS GND AND

MUST BE SOLDERED TO PCB

V

C

SHDN

9

V

8

IN

7

SW

6

SW

ORDER PART

NUMBER

LT1618EDD

DD PART

MARKING

LAFQ

Junction Temperature...........................................125°C

Operating Temperature Range (Note 2) .. – 40°C to 85°C

Storage Temperature Range

MSOP ............................................... – 65°C to 150°C

DFN ................................................. – 65°C to 125°C

Lead Temperature (Soldering, 10 sec) (MSOP) .... 300°C

ORDER PART

TOP VIEW

1

FB

2

ISN

3

ISP

4

I

ADJ

GND

5

MS PACKAGE

10-LEAD PLASTIC MSOP

T

= 125°C, θJA = 160°C/W

JMAX

10

V

C

9

SHDN

V

8

IN

SW

7

NC

6

NUMBER

LT1618EMS

MS PART

MARKING

LTNH

Consult LTC marketing for parts specified with wider operating temperature ranges.

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at TA = 25°C. VIN = 1.6V, V

PARAMETER CONDITIONS MIN TYP MAX UNITS

Input Voltage 1.6 18 V

Quiescent Current V

Reference Voltage Measured at FB Pin 1.250 1.263 1.276 V

Reference Voltage Line Regulation 1.6V < VIN < 18V 0.01 0.03 %/V

FB Pin Bias Current VFB = 1.263V, VIN = 1.8V ● ±2 ±12 nA

Error Amplifier Voltage Gain 180 V/V

Error Amplifier Transconductance ∆IC = ± 5µA 160 µmho

Error Amplifier Sink Current VFB = 1.35V, VC = 1V 15 µA

Error Amplifier Source Current VFB = 1.10V, VC = 1V 30 µA

Current Sense Voltage (ISP, ISN) VFB = 0V, V

ISP, ISN Pin Bias Currents (Note 3) V

(ISP, ISN) Common Mode Minimum Voltage 1.8 V

Switching Frequency VFB = 1V 1.25 1.4 1.6 MHz

Maximum Switch Duty Cycle ● 88 92 %

Switch Current Limit (Note 4) 1.5 2.1 2.8 A

The ● denotes specifications which apply over the full operating

= 1.6V, unless otherwise noted.

SHDN

= 1.6V, Not Switching 1.8 2.7 mA

SHDN

= 0V 0.1 1 µA

V

SHDN

● 1.243 1.263 1.283 V

= 0V ● 47.5 50 52.5 mV

IADJ

= 1.85V, V

ISP

= 0V 550 kHz

V

FB

= 1.80V, V

ISN

= 0V 50 80 µA

IADJ

sn1618 1618fas

2

LT1618

TEMPERATURE (°C)

–50

PEAK CURRENT (A)

125

1618 G03

0

75

2.5

2.0

1.5

1.0

0.5

0

–25 25 50

100

ELECTRICAL CHARACTERISTICS

temperature range, otherwise specifications are at T

The ● denotes specifications which apply over the full operating

= 25°C. VIN = 1.6V, V

A

= 1.6V, unless otherwise noted.

SHDN

PARAMETER CONDITIONS MIN TYP MAX UNITS

Switch V

CESAT

ISW = 1A (Note 4) 200 260 mV

Switch Leakage Current Switch Off, VSW = 5V 0.01 5 µA

SHDN Pin Current V

= 1.6V 5 20 µA

SHDN

Shutdown Threshold (SHDN Pin) 0.3 V

Start-Up Threshold (SHDN Pin) 1V

Note 1: Absolute Maximum Ratings are those values beyond which the life

of a device may be impaired.

Note 2: The LT1618 is guaranteed to meet performance specifications

from 0°C to 70°C. Specifications over the –40°C to 85°C operating

temperature range are assured by design, characterization, and correlation

with statistical process controls.

Note 3: Bias currents flow into the ISP and ISN pins.

Note 4: Switch current limit and switch V

for the DD package is

CESAT

guaranteed by design and/or correlation to static test.

UW

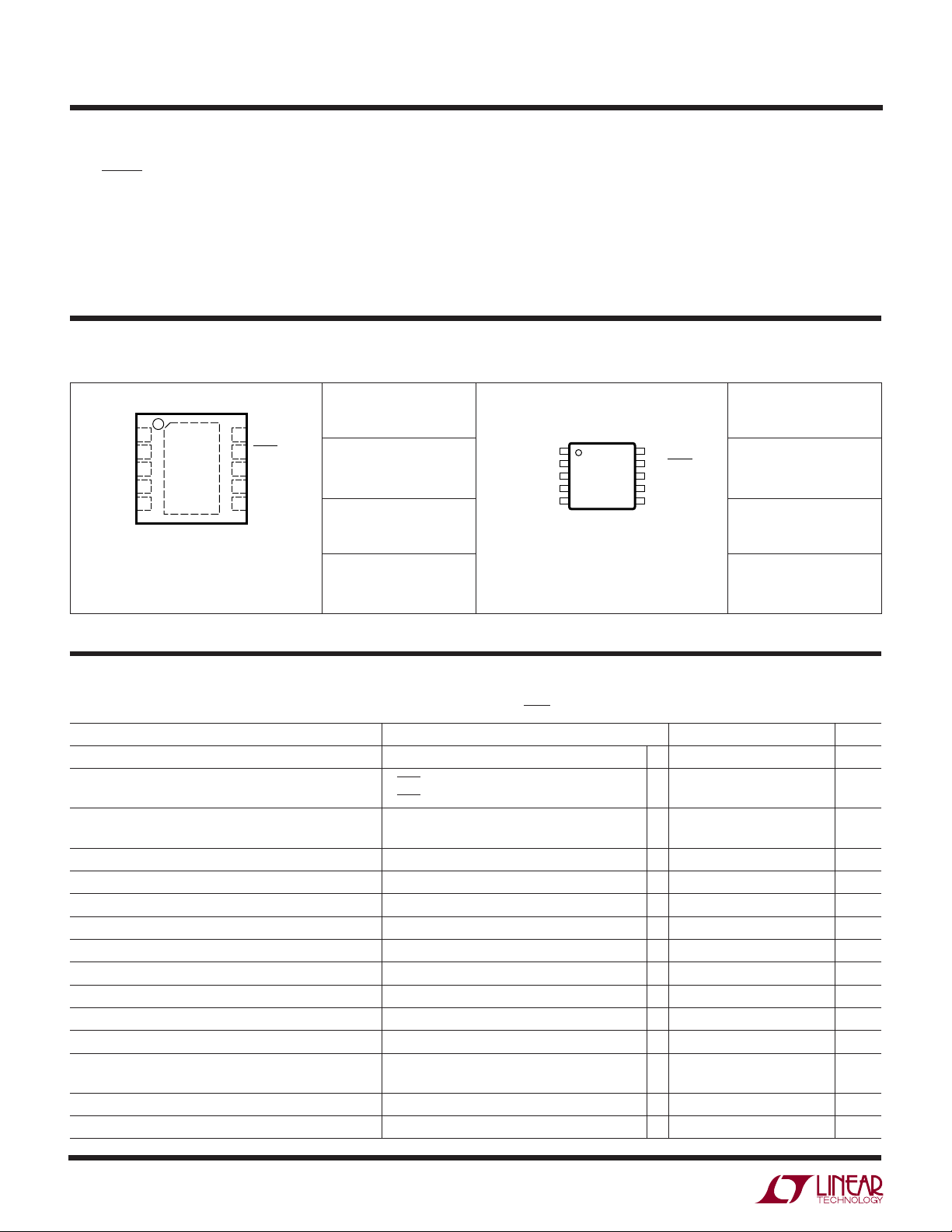

TYPICAL PERFOR A CE CHARACTERISTICS

Switch Saturation Voltage

(V

500

CE, SAT

)

FB Pin Voltage and Bias Current

1.270

Switch Current Limit

4

400

TJ = 125°C

300

200

SATURATION VOLTAGE (mV)

100

0

TJ = 25°C

TJ = –50°C

0

0.5

1.0

SWITCH CURRENT (A)

Current Sense Voltage

(I

Pin = 0V)

ADJ

52

51

50

49

CURRENT SENSE VOLTAGE (mV)

1.5

1618 G01

1.265

1.260

FEEDBACK VOLTAGE (V)

1.255

1.250

2.0

CURRENT SENSE VOLTAGE (mV)

VOLTAGE

–25 25 50

–50

0

TEMPERATURE (°C)

Current Sense Voltage

(V

60

50

40

30

20

10

ISP, ISN

)

CURRENT

75

100

FB PIN BIAS CURRENT (nA)

2

0

–2

–4

125

1618 G02

Quiescent Current

2.5

2.0

1.5

1.0

QUIESCENT CURRENT (mA)

0.5

VIN = 18V

VIN = 1.6V

48

–25 25 50

–50

0

TEMPERATURE (°C)

75

100

1618 G04

125

0

0.0 0.2 0.4 0.6 0.8 1.0 1.2 1.4 1.6

I

PIN VOLTAGE (V)

ADJ

1618 G05

0

–25 25 50

–50

0

TEMPERATURE (°C)

75

100

1618 G06

sn1618 1618fas

125

3

LT1618

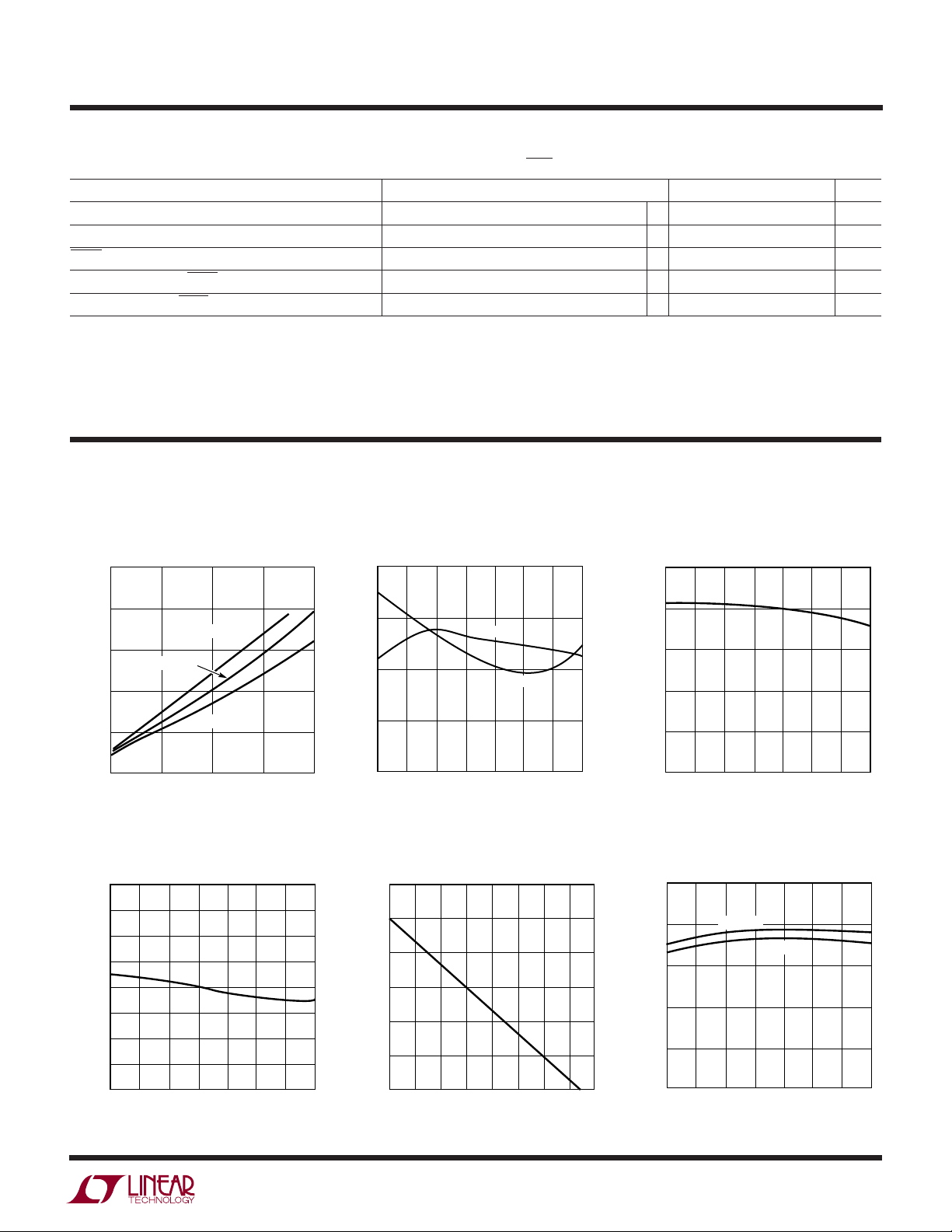

UW

TYPICAL PERFOR A CE CHARACTERISTICS

Switching Frequency Frequency Foldback SHDN Pin Current

1.8

1.7

1.6

1.5

1.4

1.3

1.2

SWITCHING FREQUENCY (MHz)

1.1

1.0

–25 25 50

–50

VIN = 18V

0

TEMPERATURE (°C)

VIN = 1.6V

75

100

125

1618 G07

1.6

TJ = 25°C

1.4

1.2

1.0

0.8

0.6

0.4

SWITCHING FREQUENCY (MHz)

0.2

0

0 0.2

0.4 0.6

FEEDBACK PIN VOLTAGE (V)

0.8

1.0

1618 G08

1.2

50

45

40

35

30

25

20

15

SHDN PIN CURRENT (µA)

10

5

0

0

UUU

PIN FUNCTIONS

(MS/DD)

TJ = –50°C

TJ = 25°C

TJ = 125°C

5

SHUTDOWN PIN VOLTAGE (V)

10

15

20

1618 G09

FB (Pin 1/Pin 1): Feedback Pin. Set the output voltage by

selecting values for R1 and R2 (see Figure 1):

RR

⎛

12

⎜

⎝

V

OUT

.

1 263

⎞

–

1=

⎟

V

⎠

ISN (Pin 2/Pin 2): Current Sense (–) Pin. The inverting

input to the current sense amplifier.

ISP (Pin 3/Pin 3): Current Sense (+) Pin. The noninverting

input to the current sense amplifier.

I

(Pin 4/Pin 4): Current Sense Adjust Pin. A DC voltage

ADJ

applied to this pin will reduce the current sense voltage. If

this adjustment is not needed, tie this pin to ground.

GND (Pin 5/Pin 5): Ground Pin. Tie this pin directly to local

ground plane.

NC (Pin 6/NA): No Connection for MS Package.

SW (NA/Pin 6): Switch Pin for DD Package. Connect this

pin to Pin 7.

SW (Pin 7/Pin 7): Switch Pin. This is the collector of the

internal NPN power switch. Minimize the metal trace area

connected to this pin to minimize EMI.

VIN (Pin 8/Pin 8): Input Supply Pin. Bypass this pin with

a capacitor to ground as close to the device as possible.

SHDN (Pin 9/Pin 9): Shutdown Pin. Tie this pin higher

than 1V to turn on the LT1618; tie below 0.3V to turn it off.

VC (Pin 10/Pin 10): Compensation Pin for Error Amplifier.

Connect a series RC from this pin to ground. Typical values

are 2kΩ and 10nF.

Exposed Pad (NA/Pin 11): The Exposed Pad on the DD

package is GND and must be soldered to the PCB GND for

optimum thermal performance.

4

sn1618 1618fas

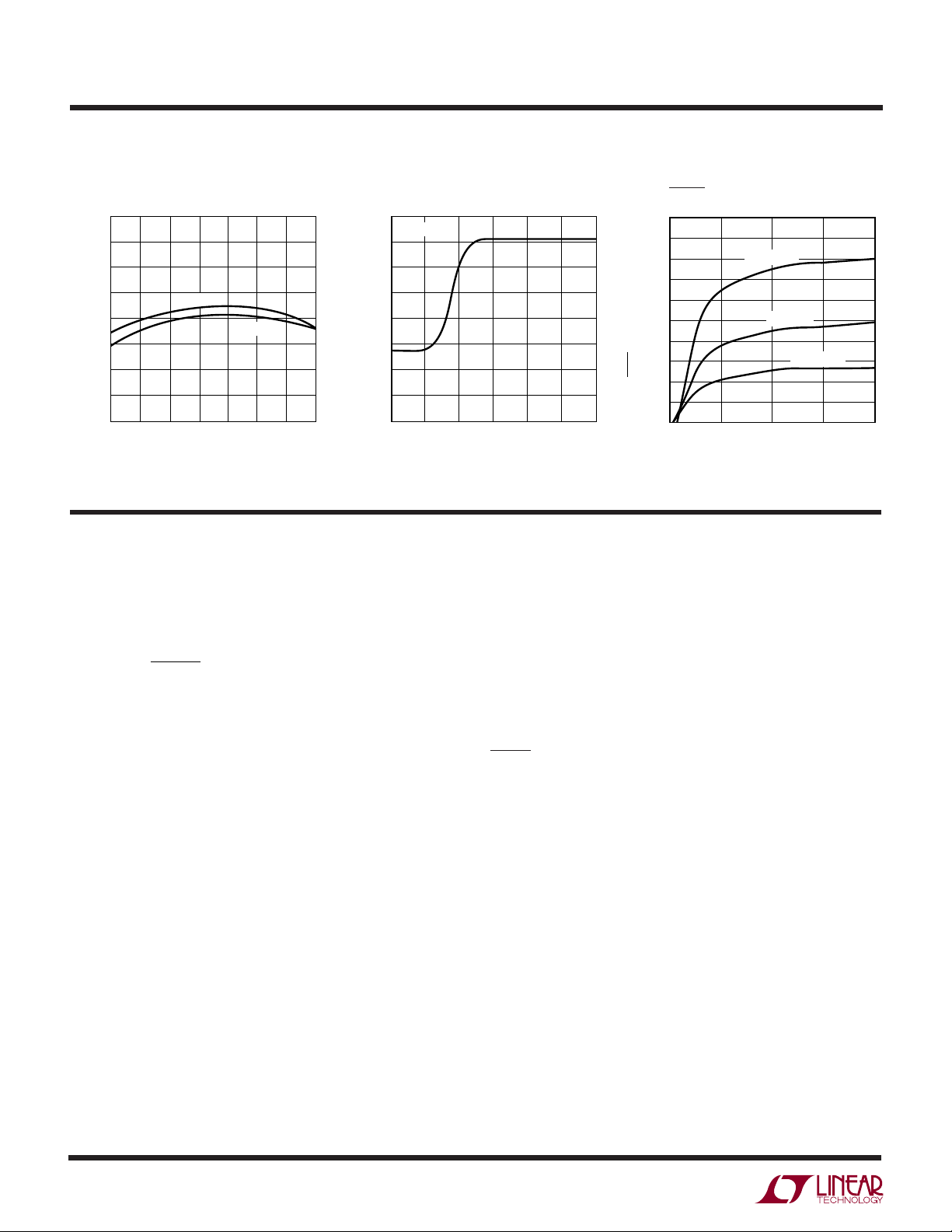

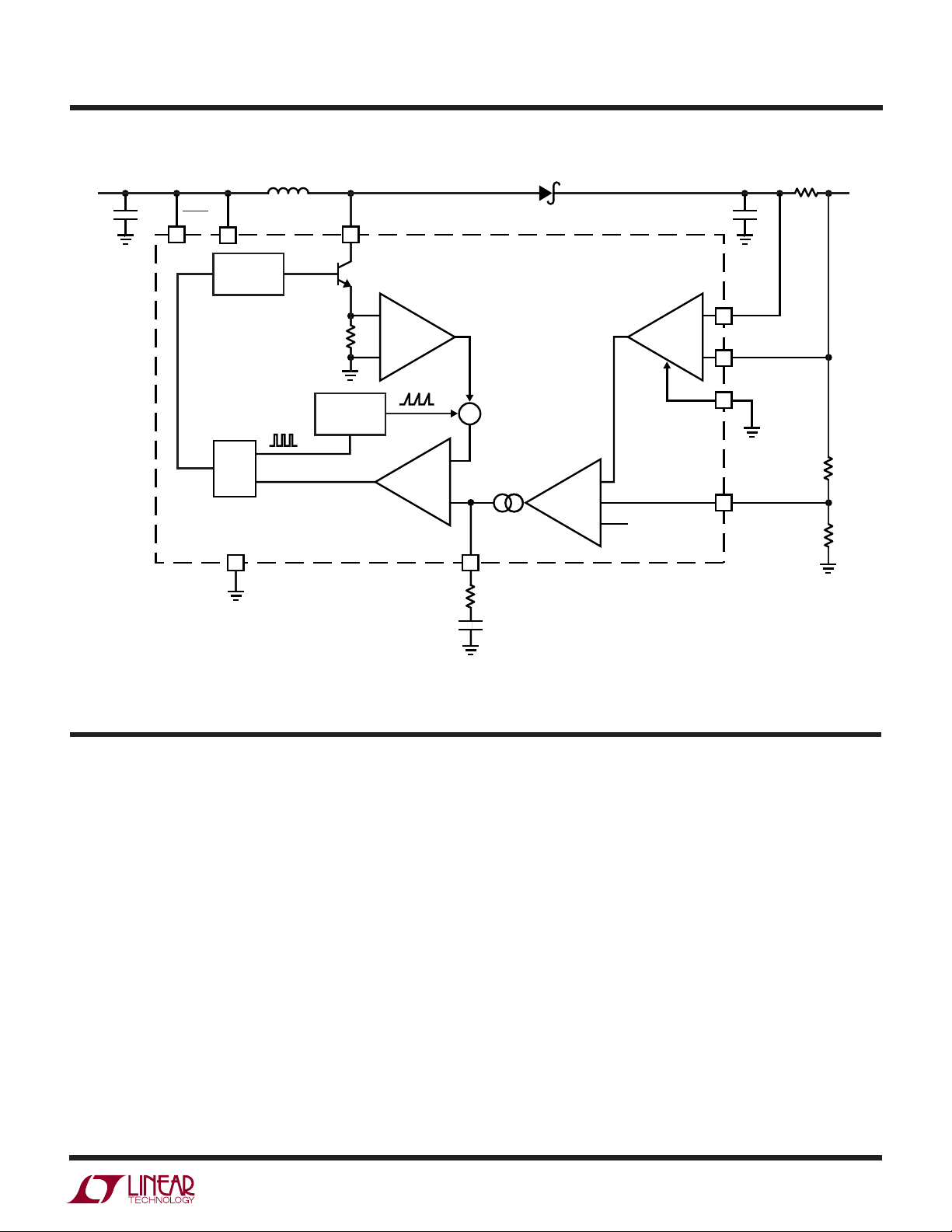

BLOCK DIAGRA

LT1618

W

V

IN

C1 C2

SHDN

V

8

DRIVER

L1

IN

SW

79

Q1

+

0.02Ω

×5

–

1.4MHz

OSCILLATOR

S

Q

R

A3

+

Σ

+

+

–

5 10

GND

V

C

R

C

C

D1

ISP

3

+

A1

×25

–

A2

–

1.263V

+

C

ISN

2

–

I

ADJ

4

FB

1

R

SENSE

V

OUT

R1

R2

Figure 1. LT1618 Block Diagram

U

OPERATIO

The LT1618 uses a constant frequency, current mode

control scheme to provide excellent line and load regulation. Operation can be best understood by referring to the

Block Diagram in Figure 1. At the start of each oscillator

cycle, the SR latch is set, turning on power switch Q1. The

signal at the noninverting input of PWM comparator A3 is

a scaled-down version of the switch current (summed

together with a portion of the oscillator ramp). When this

signal reaches the level set by the output of error amplifier

A2, comparator A3 resets the latch and turns off the power

switch. In this manner, A2 sets the correct peak current

level to keep the output in regulation. If the error amplifier’s

output increases, more current is delivered to the output;

if it decreases, less current is delivered. A2 has two

inverting inputs, one from the voltage feedback loop, and

one from the current feedback loop. Whichever inverting

input is higher takes precedence, forcing the converter

into either a constant-current or a constant-voltage mode.

The LT1618 is designed to transition cleanly between the

two modes of operation. Current sense amplifier A1 senses

the voltage between the ISP and ISN pins and provides a

25× level-shifted version to error amplifier A2. When the

voltage between ISP and ISN reaches 50mV, the output of

A1 provides 1.263V to one of the noninverting inputs of A2

and the converter is in constant-current mode. If the

current sense voltage exceeds 50mV, the output of A1 will

increase causing the output of A2 to decrease, thus

reducing the amount of current delivered to the output. In

this manner the current sense voltage is regulated to

50mV. Similarly, if the FB pin increases above 1.263V, the

output of A2 will decrease to reduce the peak current level

and regulate the output (constant-voltage mode).

sn1618 1618fas

5

LT1618

U

WUU

APPLICATIONS INFORMATION

Inductor Selection

Several inductors that work well with the LT1618 are listed

in Table 1, although there are many other manufacturers

and devices that can be used. Consult each manufacturer

for more detailed information and for their entire selection

of related parts. Many different sizes and shapes are

available. Ferrite core inductors should be used to obtain

the best efficiency, as core losses at 1.4MHz are much

lower for ferrite cores than for the cheaper powdered-iron

ones. Choose an inductor that can handle the necessary

peak current without saturating, and ensure that the

inductor has a low DCR (copper-wire resistance) to mini-

2

mize I

a good choice for many LT1618 designs.

Table 1. Recommended Inductors

PART (µH) (mΩ) (mm) VENDOR

CDRH5D18-4R1 4.1 57 2.0 Sumida

CDRH5D18-100 10 124 2.0 (847) 956-0666

CR43-2R2 2.2 71 3.5 www.sumida.com

CR43-4R7 4.7 109 3.5

CR43-100 10 182 3.5

CR54-100 10 100 4.8

LQH3C1R0M24 1.0 78 2.0 Murata

LQH3C2R2M24 2.2 126 2.0 (814) 237-1431

LQH3C4R7M24 4.7 260 2.0 www.murata.com

Capacitor Selection

Low ESR (equivalent series resistance) capacitors should

be used at the output to minimize the output ripple voltage.

Multilayer ceramic capacitors are an excellent choice.

They have an extremely low ESR and are available in very

small packages. X5R and X7R dielectrics are preferred, as

these materials retain their capacitance over wider voltage

and temperature ranges than other dielectrics. A 4.7µF to

10µF output capacitor is sufficient for high output current

designs. Converters with lower output currents may need

only a 1µF or 2.2µF output capacitor. Solid tantalum or

OSCON capacitors can be used, but they will occupy more

board area than a ceramic and will have a higher ESR for

R power losses. A 4.7µH or 10µH inductor will be

L MAX HEIGHT

the same footprint device. Always use a capacitor with a

sufficient voltage rating.

Ceramic capacitors also make a good choice for the input

decoupling capacitor, which should be placed as close as

possible to the VIN pin of the LT1618. A 1µF to 4.7µF input

capacitor is sufficient for most applications. Table 2 shows

a list of several ceramic capacitor manufacturers. Consult

the manufacturers for detailed information on their entire

selection of ceramic parts.

Table 2. Recommended Ceramic Capacitor Manufacturers

VENDOR PHONE URL

Taiyo Yuden (408) 573-4150 www.t-yuden.com

Murata (814) 237-1431 www.murata.com

Kemet (408) 986-0424 www.kemet.com

Diode Selection

Schottky diodes, with their low forward voltage drop and

fast switching speed, are the ideal choice for LT1618

applications. Table 3 shows several Schottky diodes that

work well with the LT1618. Many different manufacturers

make equivalent parts, but make sure that the component

chosen has a sufficient current rating and a voltage rating

greater than the output voltage. The diode conducts current only when the power switch is turned off (typically

less than half the time), so a 0.5A or 1A diode will be

sufficient for most designs. The companies below also

offer Schottky diodes with higher voltage and current

ratings.

Table 3. Recommended Schottky Diodes

1A PART 0.5A PART VENDOR PHONE/URL

UPS120 Microsemi (510) 353-0822

UPS130 www.microsemi.com

UPS140

MBRM120 MBR0520 ON Semiconductor (800) 282-9855

MBRM130 MBR0530 www.onsemi.com

MBRM140 MBR0540

B120 B0520 Diodes, Inc (805) 446-4800

B130 B0530 www.diodes.com

B140 B0540

6

sn1618 1618fas

LT1618

U

WUU

APPLICATIONS INFORMATION

Setting Output Voltage

To set the output voltage, select the values of R1 and R2

(see Figure 1) according to the following equation.

⎛

V

RR

12

OUT

⎜

.

1 263

⎝

For current source applications, use the FB pin for overvoltage protection. Pick R1 and R2 so that the output

voltage will not go too high if the load is disconnected or

if the load current drops below the preset value. Typically

choose R1 and R2 so that the overvoltage value will be

about 20% to 30% higher than the normal output voltage

(when in constant-current mode). This prevents the voltage loop from interfering with the current loop in current

source applications. For battery charger applications, pick

the values of R1 and R2 to give the desired end of charge

voltage.

⎞

–

1=

⎟

⎠

the output of the error amplifier (the VC pin) will be pulled

down and the LT1618 will stop switching.

A pulse width modulated (PWM) signal can also be used

to adjust the current sense voltage; simply add an RC

filterto convert the PWM signal into a DC voltage for the

I

pin. If the I

ADJ

pin is not used, it should be tied to

ADJ

ground. Do not leave the pin floating.

For applications needing only a simple one-step current

sense adjustment, the circuit in Figure 2 works well. If a

large value resistor (≥2MΩ) is placed between the I

ADJ

pin

and ground, the current sense voltage will reduce to about

25mV, providing a 50% reduction in current. Do not leave

the I

pin open. This method gives a well-regulated

ADJ

current value in both states, and is controlled by a logic

signal without the need for a variable PWM or DC control

signal. When the NMOS transistor is on, the current sense

voltage will be 50mV, when it is off, the current sense

voltage will be reduced to 25mV.

Selecting R

/Current Sense Adjustment

SENSE

Use the following formula to choose the correct current

sense resistor value (for constant current operation).

R

For designs needing an adjustable current level, the I

pin is provided. With the I

SENSE

= 50mV/I

MAX

pin tied to ground, the

ADJ

ADJ

nominal current sense voltage is 50mV (appearing between the ISP and ISN pins). Applying a positive DC

voltage to the I

pin will decrease the current sense

ADJ

voltage according to the following formula:

VV

1 263 0 8

V

ISENSE

.–(.)

=

25

For example, if 1V is applied to the I

IADJ

pin, the current

ADJ

sense voltage will be reduced to about 18mV. This

adjustability allows the regulated current to be reduced

without changing the current sense resistor (e.g. to adjust

brightness in an LED driver or to reduce the charge current

in a battery charger). If the I

pin is taken above 1.6V,

ADJ

LT1618

I

ADJ

FULL

CURRENT

2M

1618 F02

Figure 2

Considerations When Sensing Input Current

In addition to regulating the DC output current for currentsource applications, the constant-current loop of the

LT1618 can also be used to provide an accurate input

current limit. Boost converters cannot provide output

short-circuit protection, but the surge turn-on current can

be drastically reduced using the LT1618’s current sense

at the input. SEPICs, however, have an output that is DCisolated from the input, so an input current limit not only

helps soft-start the output but also provides excellent

short-circuit protection.

sn1618 1618fas

7

LT1618

U

WUU

APPLICATIONS INFORMATION

When sensing input current, the sense resistor should be

placed in front of the inductor (between the decoupling

capacitor and the inductor) as shown in the circuits in the

Typical Applications section. This will regulate the average

inductor current and maintain a consistent inductor ripple

current, which will, in turn, maintain a well regulated input

current. Do not place the sense resistor between the input

source and the input decoupling capacitor, as this may

allow the inductor ripple current to vary widely (even

though the average input current and the average inductor

current will still be regulated). Since the inductor current

is a triangular waveform (not a DC waveform like the

output current) some tweaking of the compensation

values (RC and CC on the VC pin) may be required to ensure

a clean inductor ripple current while the constant-current

loop is in effect. For these applications, the constantcurrent loop response can usually be improved by reducing the RC value, or by adding a capacitor (with a value of

approximately CC/10) in parallel with the RC and C

compensation network.

Frequency Compensation

The LT1618 has an external compensation pin (VC), which

allows the loop response to be optimized for each application. An external resistor and capacitor (or sometimes just

a capacitor) are placed at the VC pin to provide a pole and

a zero (or just a pole) to ensure proper loop compensation.

Numerous other poles and zeroes are present in the closed

C

loop transfer function of a switching regulator, so the V

C

pin pole and zero are positioned to provide the best loop

response. A thorough analysis of the switching regulator

control loop is not within the scope of this data sheet, and

will not be presented here, but values of 2kΩ and 10nF will

be a good choice for many designs. For those wishing to

optimize the compensation, use the 2kΩ and 10nF as a

starting point. For LED backlight applications where a

pulse-width modulation (PWM) signal is used to drive

the I

pin, the resistor is usually not included in the

ADJ

compensation network. This helps to provide additional

filtering of the PWM signal at the output of the error

amplifier (the VC pin).

Switch Node Considerations

To maximize efficiency, switch rise and fall times are made

as short as possible. To prevent radiation and high frequency resonance problems, proper layout of the high

frequency switching path is essential. Keep the output

switch (SW pin), diode and output capacitor as close

together as possible. Minimize the length and area of all

traces connected to the switch pin, and always use a

ground plane under the switching regulator to minimize

interplane coupling. The high speed switching current

path is shown in Figure 3. The signal path including the

switch, output diode and output capacitor contains nanosecond rise and fall times and should be kept as short as

possible.

8

SWITCH

L1

NODE

V

IN

HIGH

FREQUENCY

CIRCULATING

PATH

Figure 3

LOAD

V

1618 • F03

OUT

sn1618 1618fas

U

TYPICAL APPLICATIO S

4.5W Direct Broadcast Satellite (DBS) Power Supply with Short-Circuit Protection

LT1618

L1

V

IN

12V

4.7µF

C1

0.068Ω

C1: TAIYO YUDEN EMK316BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

C3, C4: TAIYO YUDEN TMK325BJ335 (408) 573-4150

D1: ON SEMICONDUCTOR MBRM140 (800) 282-9855

L1, L2: SUMIDA CR54-330 (847) 956-0666

L3: SUMIDA CR43-2R2 (847) 956-0666

33µH

2

ISN

3

ISP

LT1618

8

V

IN

9

SHDN

I

ADJ

GND

7

SW

FB

V

C

5104

R

C

2k

C

33nF

C2

1µF

1

C

80

D1

L2

33µH

RHCP

0V

ADD 5V

3.3V

LHCP

R5

24.9k

Efficiency

R1

100k

R2

10k

2.2µH

C3

3.3µF

L3

C4

3.3µF

MMBT3904

R3

10k

Q1

FMMT717

ZETEX

R4

1k

22kHz

NETWORK

TUNING

Q1

D2

MURS110

13.5V/18.5V

1618 TA02a

75

70

EFFICIENCY (%)

65

60

0

50 100 150 200

LOAD CURRENT (mA)

250 300

1618 TA02b

sn1618 1618fas

9

LT1618

TYPICAL APPLICATIONS

U

2-Cell White LED Driver

L1

V

IN

1.6V TO 3V

C1

4.7µF

10kHz TO 50kHz

PWM

BRIGHTNESS

ADJUST

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK316BJ105 (408) 573-4150

D1: ON SEMICONDUCTOR MBR0520 (800) 282-9855

L1: SUMIDA CLQ4D10-4R7 (847) 956-0666

R3

5.1k

0.1µF

C3

4.7µH

87

V

IN

9

SHDN

LT1618

4

I

ADJ

GND

510

C

C

0.1µF

2-Cell Luxeon LED Driver

L1

V

1.8V TO 3V

IN

C1

1µF

10µH

87

V

IN

9

SHDN

LT1618

4

I

ADJ

GND

510

100nF

SW

ISP

ISN

V

SW

ISP

ISN

V

D1

2.49Ω

3

2

1

FB

C

C2

1µF

D1

0.15Ω

3

2

1

FB

C

C2

1µF

20mA

R1

2M

R2

160k

350mA

332k

124k

1618 • TA03

D2

10

C1, C2: TAIYO YUDEN JMK107BJ105KA

D1: ON SEMICONDUCTOR MBR0520

D2: LUMILEDS LXHL-BW02

L1: SUMIDA CR43-100

1618 • TA12

sn1618 1618fas

U

TYPICAL APPLICATIONS

LT1618

Li Ion White LED Driver

2.7V TO 5V

10kHz TO 50kHz

BRIGHTNESS

V

IN

2.7V TO 5V

C1

4.7µF

10kHz TO 50kHz

PWM

BRIGHTNESS

ADJUST

L1

V

IN

C1

4.7µF

PWM

ADJUST

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

D1: ON SEMICONDUCTOR MBR0530 (800) 282-9855

L1: SUMIDA CLQ4D10-100 (847) 956-0666

R3

5.1k

C3

0.1µF

10µH

87

V

IN

9

SHDN

LT1618

4

I

ADJ

GND

510

0.1µF

D1

SW

3

ISP

2

ISN

1

FB

V

C

C

C

White LED Driver for 20 LEDs

L1

D1

0.619Ω

SW

3

ISP

2

ISN

1

FB

V

C

C2

1µF

C

C

R3

5.1k

0.1µF

10µH

87

V

IN

9

SHDN

LT1618

4

I

ADJ

GND

C3

510

0.1µF

2.49Ω

C2

1µF

80mA

R1

2M

R2

121k

20mA

R1

2M

R2

100k

1618 • TA04

51Ω 51Ω 51Ω 51Ω

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN TMK316BJ105 (408) 573-4150

D1: ON SEMICONDUCTOR MBR0530 (800) 282-9855

L1: SUMIDA CR43-100 (847) 956-0666

1618 • TA05

sn1618 1618fas

11

LT1618

TYPICAL APPLICATIONS

USB to 5V SEPIC Converter

3

ISN

ISP

V

IN

SHDN

I

ADJ

10µH

2

LT1618

GND

5104

L1

SW

FB

V

C

I

IN

V

IN

5V

C1

4.7µF

3.3V

OFF

ON

0V

3.3V

100mA

500mA

0V

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN JMK316BJ106 (408) 573-4150

C3: TAIYO YUDEN EMK212BJ474 (408) 573-4150

D1: ON SEMICONDUCTOR MBR0520 (800) 282-9855

L1: SUMIDA CR43-100 (847) 956-0666

0.1Ω

8

9

20k

13k

U

7

2k

C3

0.47µF

1

10nF

D1

L2

10µH

R1

316k

R2

107k

V

OUT

5V

C2

10µF

1618 • TA09a

80

75

70

EFFICIENCY (%)

65

60

50 150 200

0

Efficiency

100

LOAD CURRENT (mA)

250

300

350

1618 F09b

V

OUT

2V/DIV

50mA/DIV

USB SEPIC During Start-Up

I

IN

1ms/DIV

1618 TA10

50mA/DIV

USB SEPIC Start-Up with Output Shorted

V

OUT

2V/DIV

1ms/DIV

1618 TA11

12

sn1618 1618fas

TYPICAL APPLICATIO S

12V Boost Converter with 500mA Input Current Limit

ISN

ISP

V

IN

SHDN

I

ADJ

4

L1

10µH

2

LT1618

GND

510

I

L1

V

IN

1.8V TO 5V

C1

4.7µF

C1: TAIYO YUDEN JMK212BJ475 (408) 573-4150

C2: TAIYO YUDEN EMK316BJ475 (408) 573-4150

D1: ON SEMICONDUCTOR MBR0520 (800) 282-9855

L1: SUMIDA CR43-100 (847) 956-0666

0.1Ω

3

8

9

U

SW

V

LT1618

D1

7

R1

909k

1

FB

R2

C

2k

10nF

107k

V

OUT

12V

C2

4.7µF

1618 • TA06a

90

85

80

75

EFFICIENCY (%)

70

65

60

20 60 100 160

0

Efficiency

VIN = 5V

VIN = 3.3V

40 80

L0AD CURRENT (mA)

120 140

1618 TA06b

12V Boost Converter Start-Up with Input Current Limit

V

OUT

5V/DIV

200mA/DIV

(VIN = 1.8V, I

I

LI

LOAD

50µs/DIV

= 40mA)

1618 TA07

12V Boost Converter Start-Up without Input Current Limit

V

OUT

5V/DIV

200mA/DIV

(VIN = 1.8V, I

I

LI

50µs/DIV

LOAD

= 40mA)

1618 TA08

sn1618 1618fas

13

LT1618

PACKAGE DESCRIPTIO

U

DD Package

10-Lead Plastic DFN (3mm × 3mm)

(Reference LTC DWG # 05-08-1698)

0.675 ±0.05

3.50 ±0.05

1.65 ±0.05

(2 SIDES)2.15 ±0.05

PACKAGE

OUTLINE

0.25 ± 0.05

RECOMMENDED SOLDER PAD PITCH AND DIMENSIONS

PIN 1

TOP MARK

(SEE NOTE 6)

0.200 REF

NOTE:

1. DRAWING TO BE MADE A JEDEC PACKAGE OUTLINE M0-229 VARIATION OF (WEED-2).

CHECK THE LTC WEBSITE DATA SHEET FOR CURRENT STATUS OF VARIATION ASSIGNMENT

2. DRAWING NOT TO SCALE

3. ALL DIMENSIONS ARE IN MILLIMETERS

4. DIMENSIONS OF EXPOSED PAD ON BOTTOM OF PACKAGE DO NOT INCLUDE

MOLD FLASH. MOLD FLASH, IF PRESENT, SHALL NOT EXCEED 0.15mm ON ANY SIDE

5. EXPOSED PAD SHALL BE SOLDER PLATED

6. SHADED AREA IS ONLY A REFERENCE FOR PIN 1 LOCATION ON THE

TOP AND BOTTOM OF PACKAGE

2.38 ±0.05

(2 SIDES)

0.50

BSC

3.00 ±0.10

(4 SIDES)

0.75 ±0.05

0.00 – 0.05

1.65 ± 0.10

(2 SIDES)

R = 0.115

TYP

2.38 ±0.10

(2 SIDES)

BOTTOM VIEW—EXPOSED PAD

106

15

0.25 ± 0.05

0.50 BSC

0.38 ± 0.10

(DD10) DFN 1103

14

sn1618 1618fas

PACKAGE DESCRIPTIO

U

MS Package

10-Lead Plastic MSOP

(Reference LTC DWG # 05-08-1661)

0.889 ± 0.127

(.035 ± .005)

LT1618

5.23

(.206)

MIN

0.305 ± 0.038

(.0120 ± .0015)

TYP

RECOMMENDED SOLDER PAD LAYOUT

0.254

(.010)

GAUGE PLANE

0.18

(.007)

NOTE:

1. DIMENSIONS IN MILLIMETER/(INCH)

2. DRAWING NOT TO SCALE

3. DIMENSION DOES NOT INCLUDE MOLD FLASH, PROTRUSIONS OR GATE BURRS.

MOLD FLASH, PROTRUSIONS OR GATE BURRS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

4. DIMENSION DOES NOT INCLUDE INTERLEAD FLASH OR PROTRUSIONS.

INTERLEAD FLASH OR PROTRUSIONS SHALL NOT EXCEED 0.152mm (.006") PER SIDE

5. LEAD COPLANARITY (BOTTOM OF LEADS AFTER FORMING) SHALL BE 0.102mm (.004") MAX

3.20 – 3.45

(.126 – .136)

DETAIL “A”

DETAIL “A”

0.50

(.0197)

BSC

° – 6° TYP

0

0.53 ± 0.152

(.021 ± .006)

SEATING

PLANE

3.00 ± 0.102

(.118 ± .004)

(NOTE 3)

4.90 ± 0.152

(.193 ± .006)

(.043)

0.17 – 0.27

(.007 – .011)

TYP

1.10

MAX

12

0.50

(.0197)

BSC

8910

3

7

6

45

0.497 ± 0.076

(.0196 ± .003)

REF

3.00 ± 0.102

(.118 ± .004)

(NOTE 4)

0.86

(.034)

REF

0.127 ± 0.076

(.005 ± .003)

MSOP (MS) 0603

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

sn1618 1618fas

15

LT1618

SHDN

I

ADJ

V

C

V

IN

SW

ISN

ISP

FB

LT1618

V

IN

16V

C1

4.7µF

2.2nF

220pF

1618 TA14

D1

D2

700mA

L1

47µH

3

2

1

9

8

7

GND

5104

C1: TAIYO YUDEN TMK325BJ475MN

D1: PHILIPS PMEG2010

D2: LUMILEDS DS45

L1: TOKO D104C

10k

0.07Ω

TYPICAL APPLICATIONS

U

RELATED PARTS

PART NUMBER DESCRIPTION COMMENTS

LT1613 550mA (ISW), 1.4MHz, High Efficiency Step-Up DC/DC Converter VIN: 0.9V to 10V, V

LT1615/LT1615-1 300mA/80mA (ISW), Constant Off-Time, High Efficiency Step-Up VIN: 1.2V to 15V, V

LT1930/LT1930A 1A (ISW), 1.2MHz/2.2MHz, High Efficiency Step-Up VIN: 2.6V to 16V, V

LT1932 Constant Current, 1.2MHz, High Efficiency White LED VIN: 1V to 10V, V

LT1944/LT1944-1 Dual Output 350mA/100mA (ISW), Constant Off-Time, VIN: 1.2V to 15V, V

(Dual) High Efficiency Step-Up DC/DC Converter MS Package

LT1945 (Dual) Dual Output, Pos/Neg, 350mA (ISW), Constant Off-Time, VIN: 1.2V to 15V, V

LT1961 1.5A (ISW), 1.25MHz, High Efficiency Step-Up DC/DC Converter VIN: 3V to 25V, V

LTC3401/LTC3402 1A/2A (ISW), 3MHz, Synchronous Step-Up DC/DC Converter VIN: 0.5V to 5V, V

LT3461/LT3461A 0.3A (ISW), 1.3MHz/3MHz, High Efficiency Step-Up DC/DC VIN: 2.5V to 16V, V

LT3463/LT3463A 250mA (ISW), Boost/Inverter Dual, Micropower DC/DC Converter VIN: 2.4V to 15V, V

LT3464 0.08A (ISW), High Efficiency Step-Up DC/DC Converter with VIN: 2.3V to 10V, V

LT3465/LT3465A Constant Current, 1.2MHz/2.7MHz, High Efficiency White LED VIN: 2.7V to 16V, V

LT3467/LT3467A 1.1A (ISW), 1.3MHz/2.1MHz, High Efficiency Step-Up DC/DC VIN: 2.4V to 16V, V

ThinSOT is a trademark of Linear Technology Corporation.

16

Li-Ion Buck-Boost Mode Luxeon LED Driver

D2

350mA

D1

7

100k

1

C

10k

10nF

3.2V TO 5V

0.15Ω

V

IN

2

8

9

C1

4.7µF

C1: TAIYO YUDEN JMK212BJ475KG

C2: TAIYO YUDEN EMK316BJ475ML

D1: ON SEMICONDUCTOR MBRM120

D2: LUMILEDS DS25

L1: NEC PLC-07453R3

ISP

ISN

V

IN

SHDN

I

ADJ

3.3µH

3

LT1618

GND

L1

SW

FB

V

5104

C2

4.7µF

1618 TA13

Buck Mode Luxeon LED Driver

ThinSOT

TM

OUT(MAX)

Package

OUT(MAX)

= 34V, IQ = 3mA, ISD < 1µA,

= 34V, IQ = 20µA, ISD < 1µA,

DC/DC Converter ThinSOT Package

= 34V, IQ = 4.2mA/5.5mA,

DC/DC Converter I

< 1µA, ThinSOT Package

SD

OUT(MAX)

OUT(MAX)

= 34V, IQ = 1.2mA, ISD < 1µA,

Boost Regulator ThinSOT Package

= 34V, IQ = 20µA, ISD < 1µA,

OUT(MAX)

= ±34V, IQ = 20µA, ISD < 1µA,

OUT(MAX)

High Efficiency Step-Up DC/DC Converter MS Package

OUT(MAX)

= 35V, IQ = 0.9mA, ISD < 6µA,

MS8E Package

= 6V, IQ = 38µA, ISD < 1µA,

Linear Technology Corporation

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

Converter with Integrated Schottky SC70 and ThinSOT Packages

with Integrated Schottky Diodes DFN Package

Integrated Schottky, Output Disconnect ThinSOT Package

Boost Regulator with Integrated Schottky Diode ThinSOT Package

Converter with Integrated Soft-Start ThinSOT Package

●

www.linear.com

MS Package

OUT(MAX)

= 38V, IQ = 2.8mA, ISD < 1µA,

OUT(MAX)

= ±40V, IQ = 40µA, ISD < 1µA,

OUT(MAX)

= 34V, IQ = 25µA, ISD < 1µA,

OUT(MAX)

= 34V, IQ = 1.9mA, ISD < 1µA,

OUT(MAX)

= 40V, IQ = 1.2mA, ISD < 1µA,

OUT(MAX)

LT/TP 0504 1K REV A • PRINTED IN USA

© LINEAR TECHNOLOGY CORPORATION 2001

sn1618 1618fas

Loading...

Loading...