Linear Technology LT1432 Datasheet

LT1432

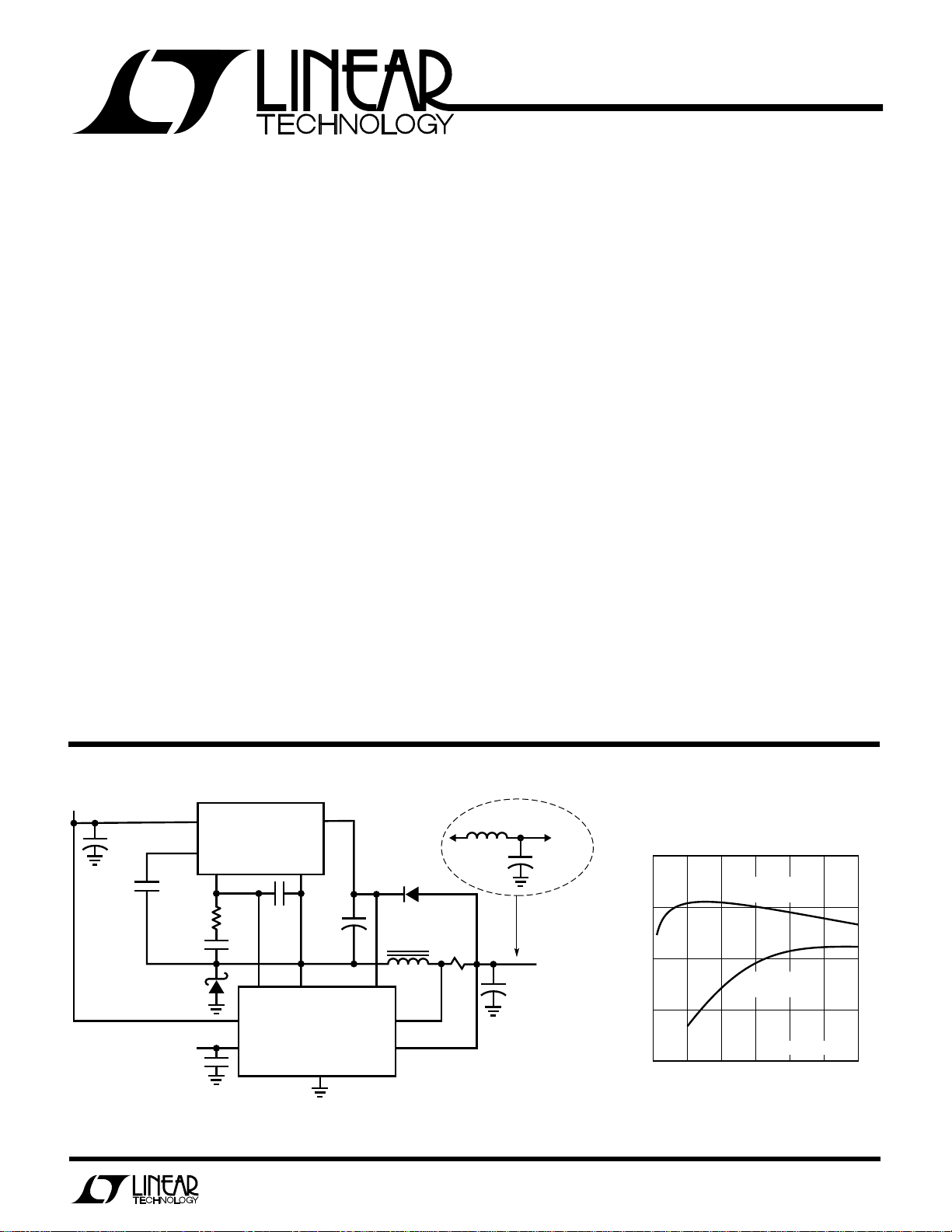

0

60

EFFICIENCY (%)

70

80

90

100

1A 2A

3A

20mA

LT1432 TA02

40mA

60mA

0

NORMAL MODE

(USE AMPS SCALE)

BURST MODE

(USE mA SCALE)

LT1271, L = 50µH

5V High Efficiency Step-Down

Switching Regulator Controller

EATU

F

■

Accurate Preset +5V Output

■

Up to 90% Efficiency

■

Optional Burst Mode for Light Loads

■

Can be Used with Many LTC Switching ICs

■

Accurate Ultra-Low-Loss Current Limit

■

Operates with Inputs from 6V to 30V

■

Shutdown Mode Draws Only 15µA

■

Uses Small 50µH Inductor

PPLICATI

A

■

Laptop and Palmtop Computers

■

Portable Data-Gathering Instruments

■

DC Bus Distribution Systems

■

Battery-Powered Digital Widgets

RE

S

O

U

S

DUESCRIPTIO

The LT1432 is a control chip designed to operate with the

LT1170/LT1270 family of switching regulators to make a

very high efficiency 5V step-down (buck) switching regulator. A minimum of external components is needed.

Included is an accurate current limit which uses only 60mV

sense voltage and uses “free” PC board trace material for

the sense resistor. Logic controlled electronic shutdown

mode draws only 15µA battery current. The switching

regulator operates down to 6V input.

The LT1432 has a logic controlled “burst” mode to achieve

high efficiency at very light load currents (0 to 100mA) such

as memory keep-alive. In normal switching mode, the

standby power loss is about 60mW, limiting efficiency at

light loads. In burst mode, standby loss is reduced to

approximately 15mW. Output current in this mode is

typically in the 5mA to 100mA range.

The LT1432 is available in 8-pin surface mount and DIP

packages. The LT1170/LT1270 family will also be available

in a surface mount version of the 5-pin TO-220 package.

For 3.3V versions contact Linear Technology Corporation.

V

IN

+

C1

330µF

35V

C6

0.02µF

MBR330p

MODE LOGIC

<0.3V = NORMAL MODE

>2.5V = SHUTDOWN

OPEN = BURST MODE

U

O

A

PPLICATITYPICAL

0.1µF

220pF

V

SW

LT1170

LT1271

FB

V

C

R1

680Ω

C4

D1

V

V

IN

MODE

0.03µF

C

C5

V

GND

DIODE

LT1432

IN

4.7µF

TANT

GND

D2

1N4148

C3

+

L1

50µH

+

V

V

LIM

V

OUT

* R2 IS MADE FROM PC BOARD

COPPER TRACES.

** MAXIMUM CURRENT IS DETERMINED

BY THE CHOICE OF LT1070 FAMILY.

SEE APPLICATION SECTION.

Figure 1. High Efficiency 5V Buck Converter

R2*

0.013Ω

10µH

3A

100µF

16V

+

+

×

C2

390µF

16V

OPTIONAL

OUTPUT

FILTER

V

OUT

5V

3A**

LT1432 TA01

Efficiency

1

LT1432

WU

U

PACKAGE

/

O

RDER I FOR ATIO

W

O

A

LUTEXI T

S

VIN Pin .................................................................... 30V

V+ Pin ..................................................................... 40V

VC........................................................................... 35V

V

LIM

and V

Pins................................................... 7V

OUT

Diode Pin Voltage ................................................... 30V

Mode Pin Current (Note 2) ..................................... 1mA

Operating Temperature Range .................... 0°C to 70°C

Storage Temperature Range ................ –65°C to 150°C

Lead Temperature (Soldering, 10 sec.)................ 300°C

LECTRICAL C CHARA TERIST

E

VC = 6V, VIN = 12V, V+ = 10V, V

Device is in standard test loop unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNITS

Regulated Output Voltage VC Current = 220µA ● 4.9 5.0 5.1 V

Output Voltage Line Regulation VIN = 6V to 30V ● 520 mV

Input Supply Current (Note 1) VIN = 6V to 30V, V+ = VIN + 5V, VC = VIN + 1V ● 0.3 0.5 mA

Quiescent Output Load Current 0.9 1.2 mA

Mode Pin Current V

Mode Pin Threshold Voltage I

(Normal to Burst)

VC Pin Saturation Voltage V

VC Pin Maximum Sink Current V

VC Pin Source Current V

Current Limit Sense Voltage (Note 3) Device in Current Limit Loop 56 60 64 mV

Pin Current Device in Current Limit Loop ● 30 45 70 µA

V

LIM

Supply Current in Shutdown V

Burst Mode Output Ripple Device in Burst Test Circuit 100 mV

Burst Mode Average Output Voltage Device in Burst Test Circuit ● 4.8 5 5.2 V

Clamp Diode Forward Voltage IF = 1mA, All Other Pins Open ● 0.5 0.65 V

Startup Drive Current V

Restart Time Delay (Note 4) 1 1.8 10 ms

Transconductance, Output to VC Pin IC = 150µA to 250µA ● 1500 2000 2800 µmho

The ● denotes specifications which apply over the operating temperature

range.

Note 1: Does not include current drawn by the LT1070 IC. See operating

parameters in standard circuit.

Note 2: Breakdown voltage on the mode pin is 7V. External current must

be limited to value shown.

A

WUW

= Open, V

DIODE

U

ARB

G

I

S

1

V

LIM

2

V

OUT

3

V

IN

+

4

V

8-LEAD PLASTIC DIP

8-LEAD PLASTIC SO

TOP VIEW

N8 PACKAGE

S8 PACKAGE

ORDER PART

MODE

8

GND

7

V

6

C

DIODE

5

NUMBER

LT1432CN8

LT1432CS8

ICS

= V

, V

LIM

OUT

= 0V (current is out of pin) ● 30 50 µA

MODE

V

= 5V (shutdown) ● 15 30 µA

MODE

= 10µA (out of pin) ● 0.6 0.9 1.5 V

MODE

= 5.5V (forced) ● 0.25 0.45 V

OUT

= 5.5V (forced) ● 0.45 0.8 1.5 mA

OUT

= 4.5V (forced) ● 40 60 100 µA

OUT

(current is out of pin)

> 3V, VIN < 30V, VC and V+ = 0V ● 15 60 µA

MODE

= 2.5V (forced), V+ = 5V to 25V, ● 30 45 mA

OUT

VIN = 6V to 26V, V+ = VIN – 1V, VC = V

= 0V, TJ = 25°C

MODE

– 1.5V

IN

Note 3: Current limit sense voltage temperature coefficient is +0.33%/°C

to match TC of copper trace material.

Note 4: V

pin switched from 5.5Vto 4.5V.

OUT

p-p

2

LT1432

LECTRICAL C CHARA TERIST

E

Operating parameters in standard circuit configuration.

VIN = +12V, I

PARAMETER CONDITIONS MIN TYP MAX UNITS

Burst Mode Quiescent Input Supply Current 1.3 1.8 mA

Burst Mode Output Ripple Voltage I

Normal Mode Equivalent Input Supply Current Extrapolated from I

Normal Mode Minimum Operating Input Voltage 100mA < I

Burst Mode Minimum Operating Input Voltage 5mA < I

Efficiency Normal Mode I

Load Regulation Normal Mode 50mA < I

= 0, unless otherwise noted. These parameters guaranteed where indicated, but not tested.

OUT

ICS

= 0 100 mV

OUT

I

= 50mA 130 mV

OUT

= 20mA 6 mA

OUT

< 1.5A 6 V

OUT

< 50mA 6.2 V

OUT

= 0.5A 91 %

Burst Mode I

Burst Mode 0 < I

OUT

= 25mA 77 %

OUT

< 2A 10 25 mV

OUT

< 50mA 50 mV

OUT

p-p

p-p

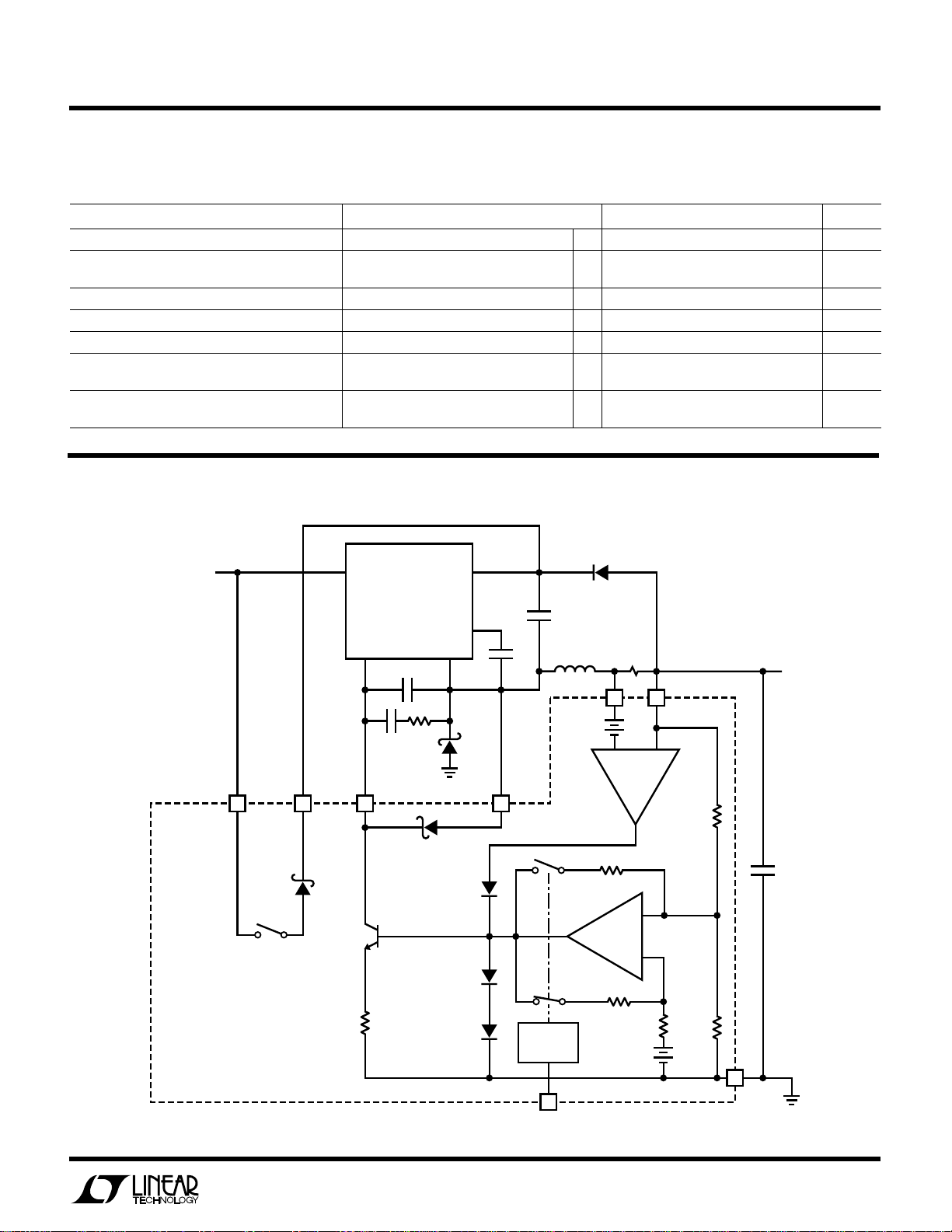

U

T

V

IN

E

S

CH

V

IN

34

S3*

W

A

V

CEQUIVALE

TI

V

SW

LT1271

V

C

+

V

C

65

GND

V

IN

FB

DIODE

S1**

V

60mV

LIM

+5V

V

1

+

OUT

2

–

+

* S3 IS CLOSED ONLY DURING STARTUP.

** S1 AND S2 ARE SHOWN IN NORMAL

MODE. REVERSE FOR BURST MODE.

Figure 2

S2**

MODE

CONTROL

MODE

8

–

7

GND

LT1432 F02

3

LT1432

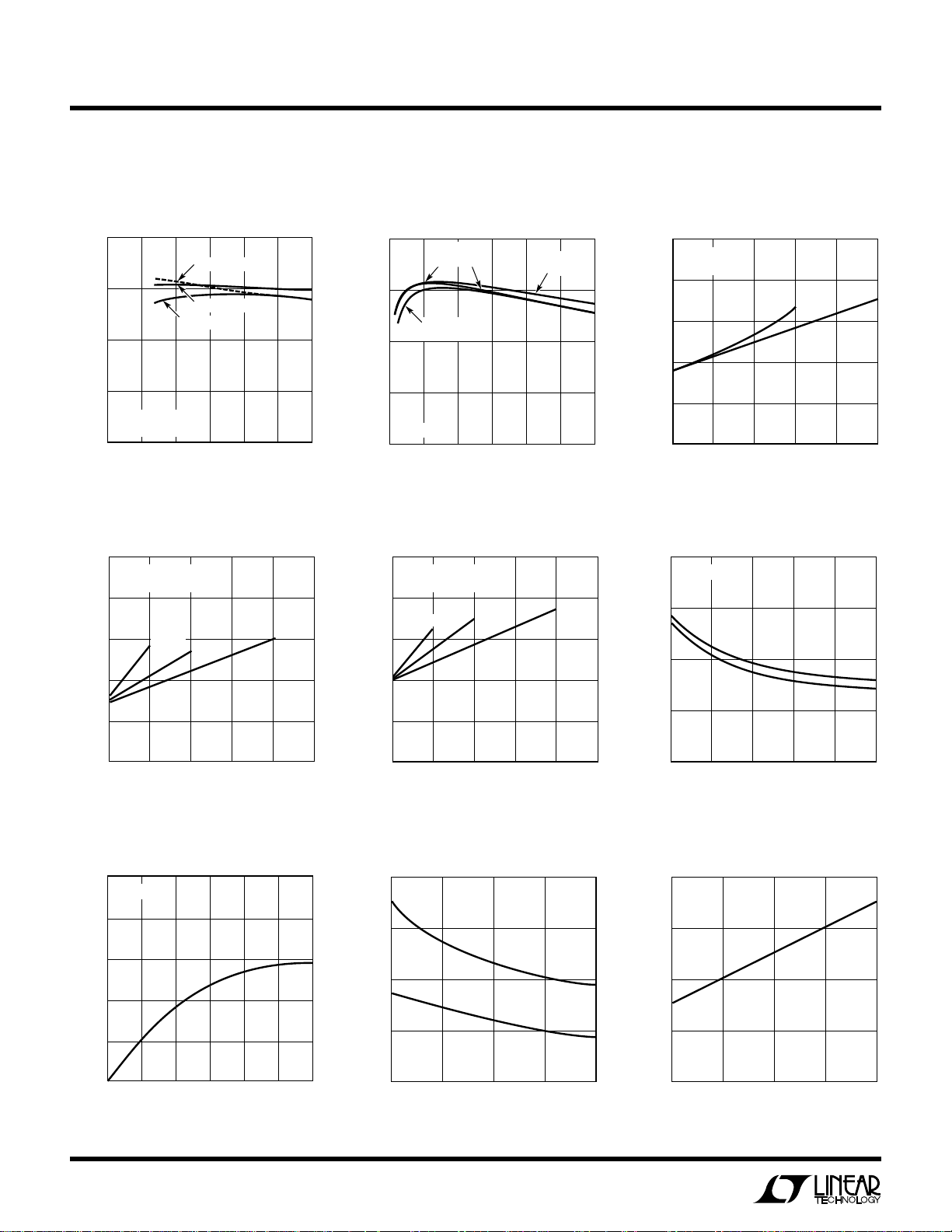

JUNCTION TEMPERATURE (°C)

0

SENSE VOLTAGE (mV)

60

70

100

LT1432 G11

50

40

25

50

75

80

* TEMPERATURE COEFFICIENT OF SENSE VOLTAGE IS

DESIGNED TO TRACK COPPER RESISTANCE.

OUTPUT CURRENT (A)

0

INPUT VOLTAGE (V)

6.5

7.0

7.5

4

LT1432 G03

6.0

5.5

5.0

1

2

3

5

LT1270

LT1271

LT1270/1271

T

J

= 25°C

LPER

Efficiency vs Input Voltage

100

90

I

80

LOAD

I

LOAD

I

LOAD

F

= 2A

O

= 0.5A

= 1A

R

ATYPICA

UW

CCHARA TERIST

E

C

Efficiency vs Load Current

100

L = 50µH

90

LT1170

80

L = 25µH

LT1271

ICS

LT1270

L = 50µH

Minimum Input Voltage – Normal

Mode (1270/1271)

EFFICIENCY (%)

70

TJ = 25°C

LT1271, L = 50µH

60

0

5101520

INPUT VOLTAGE (V)

Minimum Input Voltage – Normal

Mode (1070 Family)

7.5

LT1070 FAMILY(40kHz)

= 25°C

T

J

7.0

6.5

6.0

INPUT VOLTAGE (V)

5.5

5.0

0

LT1072

LT1071

1

2

OUTPUT CURRENT (A)

LT1070

3

25 30

LT1432 G01

4

LT1432 G04

EFFICIENCY (%)

70

TJ = 25°C

60

0

0.5 1.0 1.5 2.0

LOAD CURRENT (A)

Minimum Input Voltage – Normal

Mode (1170 Family)

7.5

LT1170 FAMILY(100kHz)

= 25°C

T

J

7.0

LT1172

6.5

6.0

INPUT VOLTAGE (V)

5.5

5

5.0

0

LT1171

1

2

OUTPUT CURRENT (A)

2.5 3.0

LT1432 G02

Burst Mode Minimum Input

Voltage

7.0

TJ = 25°C

LT1170

3

4

5

LT1432 G05

6.5

LT1170

6.0

INPUT VOLTAGE (V)

5.5

5.0

10

0

LT1070

30

20

LOAD CURRENT (mA)

40

50

LT1432 G06

Shutdown Current vs Input

Voltage

50

TJ = 25°C

40

30

20

CURRENT (µA)

10

0

0

5

4

10 15 20

INPUT VOLTAGE (V)

25 30

LT1432 G07

Battery Current in Shutdown*

40

30

20

CURRENT (µA)

10

0

0

*DOES NOT INCLUDE LT1271 SWITCH LEAKAGE.

V

= 30V

IN

VIN = 6V

25

50

TEMPERATURE (°C)

75

Current Limit Sense Voltage*

100

LT1432 G08

LPER

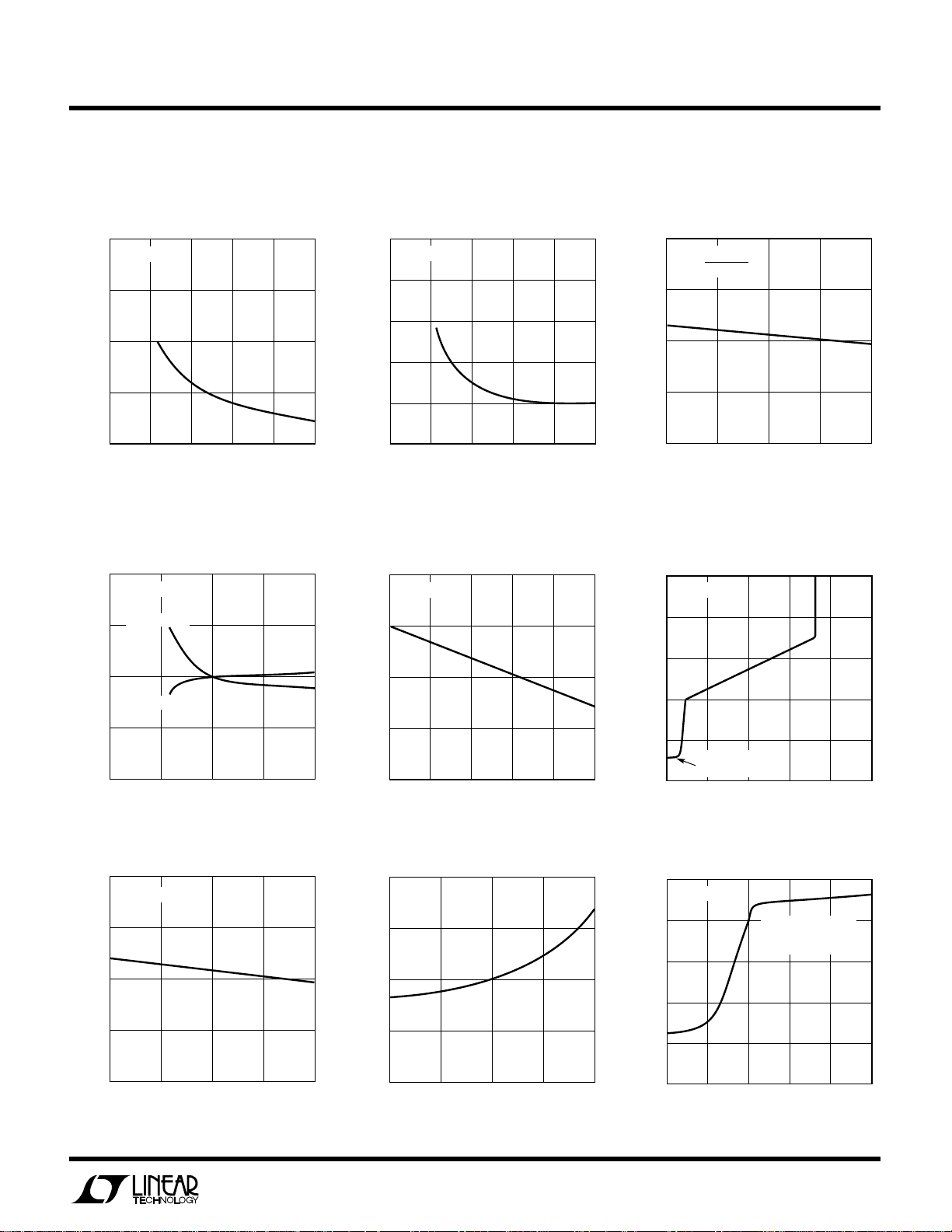

MODE PIN VOLTAGE (V)

0

CURRENT (µA)

20

40

60

8

LT1432 G15

0

–20

–40

2

4

6

10

MODE DRIVE MUST

SINK ≈ 30µA AT 0V

TJ = 25°C

V+ TO VIN VOLTAGE

–2

V+ PIN CURRENT (mA)

–20

0

5

20

LT1432 G18

–40

–60

–80

–1

0

10

30

TJ = 25°C

NOTE VERTICAL &

HORIZONTAL SCALE

CHANGES AT 0,0

F

O

R

ATYPICA

UW

CCHARA TERIST

E

C

LT1432

ICS

Incremental Battery Current * in

Burst Mode

2.0

TJ = 25°C

1.5

1.0

0.5

INCREMENTAL FACTOR (mA/mA)

0

* TO CALCULATE TOTAL BATTERY CURRENT IN BURST

MODE, MULTIPLY LOAD CURRENT BY INCREMENTAL

FACTOR AND ADD NO-LOAD CURRENT.

5

0

BATTERY VOLTAGE (V)

15

20

10

25

LT1432 G10

Line Regulation

40

TJ = 25°C

BURST MODE

20

No Load Battery Current in Burst

Mode

5

TJ = 25°C

4

3

2

BATTERY CURRENT (mA)

1

0

5

0

BATTERY VOLTAGE (V)

15

10

Burst Mode Load Regulation

25

TJ = 25°C

0

20

LT1432 G09

Transconductance – V

OUT

to V

C

Current

4000

3000

2000

1000

TRANSCONDUCTANCE (µmho)

25

40

∆I(V

PIN)

C

Gm =

∆V

OUT

0

25

JUNCTION TEMPERATURE (°C)

50

75

100

LT1432 G12

Mode Pin Current

0

OUTPUT CHANGE (mV)

–20

–40

40

30

20

CURRENT (mA)

10

0

NORMAL MODE

0

5

10

INPUT VOLTAGE (V)

Restart Load Current

V

= 4.5V

OUT

0

25

JUNCTION TEMPERATURE (°C)

50

–25

OUTPUT CHANGE (mV)

–50

15

75

20

LT1432 G13

100

LT1432 G16

–75

20

0

Restart Time Delay

4

3

2

TIME DELAY (ms)

1

0

0

25

JUNCTION TEMPERATURE (°C)

60

40

LOAD CURRENT (mA)

50

80

100

LT1432 G14

Startup Switch Characteristics

75

100

LT1432 G16

5

LT1432

U

O

PPLICATI

A

Basic Circuit Description

The LT1432 is a dedicated 5V buck converter driver chip

intended to be used with an IC switcher from the LT1070

family. This family of current mode switchers includes

current ratings from 1.25A to 10A, and switching frequencies from 40kHz to 100kHz as shown in the table below.

SWITCH OUTPUT CURRENT IN

DEVICE CURRENT FREQUENCY BUCK CONVERTER

LT1270A 10A 60kHz 7.5A

LT1270 8A 60kHz 6A

LT1170 5A 100kHz 3.75A

LT1070 5A 40kHz 3.75A

LT1271 4A 60kHz 3A

LT1171 2.5A 100kHz 1.8A

LT1071 2.5A 40kHz 1.8A

LT1172 1.25A 100kHz 0.9A

LT1072 1.25A 40kHz 0.9A

The maximum load current which can be delivered by

these chips in a buck converter is approximately 75% of

their switch current rating. This is partly due to the fact that

buck converters must operate at very high duty cycles

when input voltage is low. The “current mode” nature of

the LT1070 family requires an internal reduction of peak

current limit at high duty cycles, so these devices are rated

at only 80% of their full current rating when duty cycle is

80%. A second factor is inductor ripple current, half of

which subtracts from maximum available load current.

See Inductor Selection for details. The LT1070 family was

originally intended for topologies which have the negative

side of the switch grounded, such as boost converters. It

has an extremely efficient quasi-saturating NPN switch

which mimics the linear resistive nature of a MOSFET but

consumes much less die area. Driver losses are kept to a

minimum with a patented adaptive antisat drive that maintains a forced beta of 40 over a wide range of switch

currents. This family is attractive for high efficiency buck

converters because of the low switch loss, but to operate

as a positive buck converter, the ground pin of the IC must

be floated to act as the switch output node. This requires

a floating power supply for the chip and some means for

level shifting the feedback signal. The LT1432 performs

these functions as well as adding current limiting, micropower shutdown, and dual mode operation for high

conversion efficiency with both heavy and very light loads.

S

I FOR ATIO

WU

U

The circuit in Figure 1 is a basic 5V positive buck converter

which can operate with input voltage from 6V to 30V. The

power switch is located between the VSW pin and GND pin

on the LT1271. Its current and duty cycle are controlled by

the voltage on the VC pin with respect to the GND pin. This

voltage ranges from 1V to 2V as switch current increases

from zero to full scale. Correct output voltage is maintained by the LT1432 which has an internal reference and

error amplifier (see Equivalent Schematic in Figure 2). The

amplifier output is level shifted with an internal open

collector NPN to drive the VC pin of the switcher. The

normal resistor divider feedback to the switcher feedback

pin cannot be used because the feedback pin is referenced

to the GND pin, which is switching up and down. The

feedback pin (FB) is simply bypassed with a capacitor.

This forces the switcher VC pin to swing high with about

200µA sourcing capability. The LT1432 VC pin then sinks

this current to control the loop. Transconductance from

the regulator output to the VC pin current is controlled to

approximately 2000µmhos by local feedback around the

LT1432 error amplifier (S2 closed in Figure 2). This is done

to simplify frequency compensation of the overall loop. A

word of caution about the FB pin bypass capacitor (C6):

this capacitor value is very non-critical, but the capacitor

must be connected directly to the GND pin or tab of the

switcher to avoid differential spikes created by fast switch

currents flowing in the external PCB traces. This is also

true for the frequency compensation capacitors C4 and

C5. C4 forms the dominant loop pole with a loop zero

added by R1. C5 forms a higher frequency loop pole to

control switching ripple at the VC pin.

A floating 5V power supply for the switcher is generated by

D2 and C3 which peak detect the output voltage during

switch “off” time. The diode used for D2 is a low capacitance type to avoid spikes at the output. Do not substitute

a Schottky diode for D2 (they are high capacitance). This

is a very efficient way of powering the switcher because

power drain does not increase with regulator input voltage. However, the circuit is not self-starting, so some

means must be used to start the regulator. This is performed by the internal current path of the LT1432 which

allows current to flow from the input supply to the V+ pin

during startup.

6

LT1432

P

VV V I

V

FIN–OUT OUT

IN

=

()()

U

O

PPLICATI

A

D1, L1 and C2 act as the conventional catch diode and

output filter of the buck converter. These components

should be selected carefully to maintain high efficiency

and acceptable output ripple. See other sections of this

data sheet for detailed discussions of these parts.

Current limiting is performed by R2. Sense voltage is only

60mV to maintain high efficiency. This also reduces the

value of the sense resistor enough to utilize a printed

circuit board trace as the sense resistor. The sense voltage

has a positive temperature coefficient of 0.33%/°C to

match the temperature coefficient of copper. See Current

Limiting section for details.

The basic regulator has three different operating modes,

defined by the mode pin drive. Normal operation occurs

when the mode pin is grounded. A low quiescent current

“burst” mode can be initiated by floating the mode pin.

Input supply current is typically 1.3mA in this mode, and

output ripple voltage is 100mV

above 2.5V forces the entire regulator into micropower

shutdown where it typically draws less than 20µA. See

Mode Pin Drive for details.

Efficiency

Efficiency in normal mode is maximum at about 500mA

load current, where it exceeds 90%. At lower currents, the

operating supply current of the switching IC dominates

losses. The power loss due to this term is approximately

8mA × 5V, or 40mW. This is 4% of output power at a load

current of 200mA. At higher load currents, losses in the

switch, diode, and inductor series resistance begin to

increase as the square of current and quickly become the

dominant loss terms.

Loss in inductor series resistance;

P = RS (I

Loss in switch on resistance;

VRI

P

=

Loss in switch driver current;

)

OUT

()

OUT SW

S

I FOR ATIO

2

2

()

OUT

V

IN

p-p

WU

. Pulling the mode pin

U

IV

()

OUT OUT

P

=

40V

Diode loss;

(Use

VF vs I

I

)

OUT

RS = Inductor series resistance

RSW = Switch resistance of LT1271, etc.

IF = Diode current

VF = Diode forward voltage at IF = I

Inductor core loss depends on peak-to-peak ripple current

in the inductor, which is independent of load current for

any load current large enough to establish continuous

current in the inductor. Believe it or not, core loss is also

independent of the physical size of the core. It depends

only on core material, inductance value, and switching

frequency for fixed regulator operating conditions. Increasing inductance or switching frequency will reduce

core loss, because of the resultant decrease in ripple

current. For high efficiency, low loss cores such as ferrites

or Magnetics Inc. molypermalloy or KoolMµ are recommended. The lower cost Type 52 powdered iron from

Phillips is acceptable only if larger inductance is used and

the increased size and slight loss in efficiency is acceptable. In a typical buck converter using the LT1271 (60kHz)

with a 12V input, and a 50µH inductor, core loss with a

Type 52 powdered iron core is 203mW. A molypermalloy

core reduces this figure to 28mW. With a 1A output, this

translates to 4% and 0.56% core loss respectively – a big

difference in a high efficiency converter. For details on

inductor design and losses, see Application Note 44.

What are the benefits of using an active (synchronous)

switch to replace the catch diode? This is the trendy thing

to do, but calculations and actual breadboards show that

the improvement in efficiency is only a few percent at best.

This can be shown with the following simplified formulas:

Diode Loss

F

2

IN

graph on diode data sheet, assuming IF =

OUT

VV V I

()()

FIN–OUT OUT

=

V

IN

7

LT1432

U

O

PPLICATI

A

FET Switch Loss

(Ignoring gate drive power)

The change in efficiency is:

Diode Loss – FET Loss Efficiency

()()

This is equal to:

V–V V–R I E

()

IN OUT F FET OUT

If VF (diode forward voltage) = 0.45V, VIN = 10V, V

R

= 0.1Ω, I

FET

ment in efficiency is only:

10V – 5V 0.45V – 0.1 1A 0.9

()

This does not take FET gate drive losses into account,

which can easily reduce this figure to less than 2%. The

added cost, size, and complexity of a synchronous switch

configuration would be warranted only in the most extreme circumstances.

Burst mode efficiency is limited by quiescent current drain

in the LT1432 and the switching IC. The typical burst mode

zero-load input power is 27mW. This gives about one

month battery life for a 12V, 1.2AHr battery pack. Increasing load power reduces discharge time proportionately.

Full shutdown current is only about 15µA, which is considerably less than the self-discharge rate of typical batteries.

Burst Mode Operation

Burst mode is initiated by allowing the mode pin to float,

where it will assume a DC voltage of approximately 1V. If

AC pickup from surrounding logic lines is likely, the mode

pin should be bypassed with a 200pF capacitor. Burst

mode is used to reduce quiescent operating current when

the regulator output current is very low, as in “sleep” mode

OUT

()()

S

I FOR ATIO

VV R I

()()()

IN–OUT SW OUT

=

VV

()( )

IN OUT

×

()()

VV

()( )

IN OUT

= 1A, and efficiency = 90%, the improve-

10V 5V

()()

×

Ω

WU

V

IN

2

2

OUT

2

2.8%

=

U

2

= 5V,

in a lap-top computer. In this mode, hysteresis is added to

the error amplifier to make it switch on and off, rather than

maintain a constant amplifier output. This forces the

switching IC to either provide a rapidly increasing current

or to go into full micropower shutdown. Current is delivered to the output capacitor in pulses of higher amplitude

and low duty cycle rather than a continuous stream of low

amplitude pulses. This maximizes efficiency at light load

by eliminating quiescent current in the switching IC during

the period between bursts.

The result of pulsating currents into the output capacitor

is that output ripple amplitude increases, and ripple frequency becomes a function of load current. The typical

output ripple in burst mode is 150mVp-p, and ripple

frequency can vary from 50Hz to 2kHz. This is not normally

a problem for the logic circuits which are kept “alive”

during sleep mode.

Some thought must be given to proper sequencing between normal mode and burst mode. A heavy (>100mA)

load in burst mode can cause excessive output ripple, and

an abnormally light load (10mA to 30mA, see curves) in

normal mode can cause the regulator to revert to a quasiburst mode that also has higher output ripple. The worst

condition is a sudden, large increase in load current

(>100mA) during this quasi-burst mode or just after a

switch from burst mode to normal mode. This can cause

the output to sag badly while the regulator is establishing

normal mode operation (≈100µs). To avoid problems, it is

suggested that the power-down sequence consist of reducing load current to below 100mA, but greater than the

minimum for normal mode, then switching to burst mode,

followed by a reduction of load current to the final sleep

value. Power-up would consist of increasing the load

current to the minimum for normal mode, then switching

to normal mode, pausing for 1ms, followed by return to

full load.

If this sequence is not possible, an alternative is to

minimize normal mode settling time by adding a 47kΩ

resistor between V+ and VC pins. The output capacitor

should be increased to >680µF and the compensation

capacitors should also be as small as possible, consistent

with adequate phase margin. These modifications will

8

LT1432

PPLICATI

A

U

O

S

I FOR ATIO

WU

U

often allow the power-down sequence to consist of simultaneous turn-off of load current and switch to burst mode.

Power-up is accomplished by switching to normal mode

and simultaneously increasing load current to the lowest

possible value (30mA to 500mA), followed by a short

pause and return to full load current.

Full Shutdown

When the mode pin is driven high, full shutdown of the

regulator occurs. Regulator input current will then consist

of the LT1432 shutdown current (≈15µA) plus the switch

leakage of the switching IC (≈1µA to 25µA). Mode input

current (≈15µA at 5V) must also be considered. Startup

from shutdown can be in either normal or burst mode, but

one should always check startup overshoot, especially if

the output capacitor or frequency compensation components have been changed.

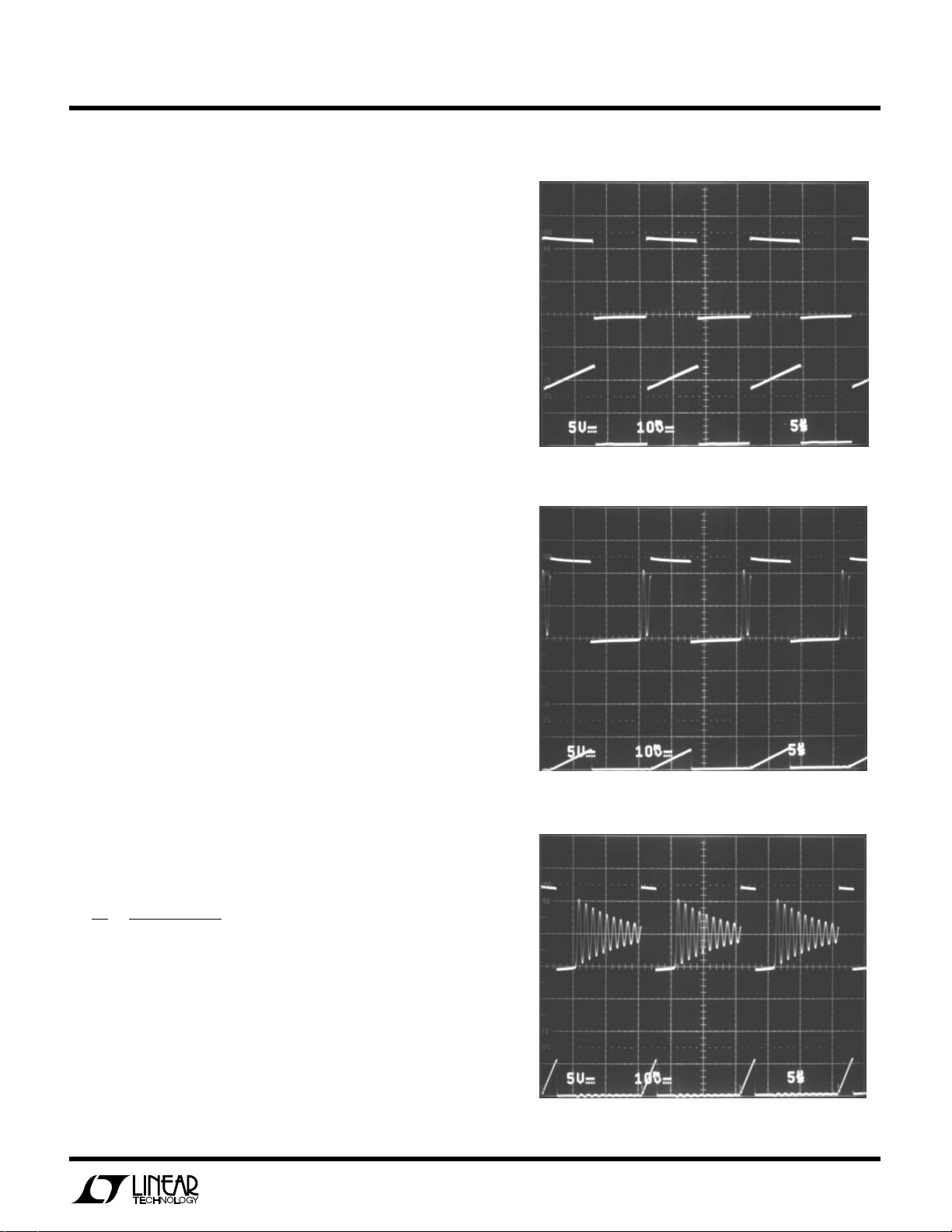

5V/DIV

0

1A/DIV

0

5µs/DIV

Figure 3

Switching Waveforms in Normal Mode

The waveforms in Figures 3 through 10 were taken with

an input voltage of 12V. Figure 3 shows the classic buck

converter waveforms of switch output voltage (5V/DIV) at

the top and switch current (1A/DIV) underneath, at an

output current of 2A. The regulator is operating in “continuous” mode as evidenced by the fact that switch

current does not start at zero at switch turn-on. Instead,

it jumps to an initial value, then continues to slope upward

during the duration of switch on time. The slope of the

current waveform is determined by the difference between input and output voltage, and the value of inductor

used.

V–V

()

dl

dt

=

IN OUT

L

According to theory, the average switch current during

switch on time should be equal to the 2A output current

and this is confirmed in the photograph. The peak switch

current, however, is about 2.4A.This peak current must

be considered when calculating maximum available load

current because both the LT1432 and the LT1070 family

current limit on instantaneous switch current.

5V/DIV

1A/DIV

5V/DIV

0.5A/DIV

0

0

0

0

5µs/DIV

Figure 4

5µs/DIV

Figure 5

9

Loading...

Loading...