Page 1

VMC1

Video Security Intercom System for the Home

ALARM DOWN UP

BAND MEM

POWER

12

34

+

5

5

ME-UP

TUNER

AUX MUSIC

RADIO FILTER

GATE STATUS

AUX OUTPUT 1

AUX OUTPUT 2

Rough - In Instructions

-

1

AUX 1

5

VID 1

PRIV MON

CLEAR

VOLUME

2

AUX 2

INPUT FILTER

67

VID 3

VID 2

MUS

DOOR

HOUSE

+

4

3

LOCK

AUX

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

Page 2

IMPORTANT SAFETY INSTRUCTIONS

SHOCK HAZARD

This sign alerts user about un-insulated

“dangerous voltage” that poses risk of electric shock.

Read Instructions - All safety and

operating instructions should be read

before installing or operating the VMC1

Video Intercom system.

Retain Instructions - The safety and

operating instructions should be retained

for future reference.

Heed Warnings - All warnings on the

appliance and in the operating instructions

should be adhered to.

Follow Instructions - All operating and

use instructions should be followed.

Water and Moisture - The appliance

should not be used near water - for

example: near bathtub, washbowl, kitchen

sink, laundry tub, in a wet basement, or

near a swimming pool, and the like. Doing

so can create fire or shock hazards and

impair the warranty.

Attachments - Do not use attachments not

recommended by the product manufacturer

as they may cause hazards.

Ventilation - The appliance should be

situated so that its location or position does

not interfere with its proper ventilation.

For example, the appliance should not be

situated on a bed, sofa, rug, or similar surface

that may block the ventilation openings: or,

placed in a built in installation, such as a

bookcase or cabinet that may impede the

flow of air to the ventilation openings.

Heat - The appliance should be situated

away from heat sources such as radiators,

heat registers, stoves, or other appliances

(including amplifiers) that produce heat.

Power Sources - The appliance should be

connected to a power supply only of the

type described in the operating instructions

or as marked on the appliance.

Grounding or Polarization - Precautions

should be taken so that the grounding or

polarization means of an appliance is not

defeated.

operating, maintenance, and servicing instructions for

Power Lines - Locate outdoor antennas

away from power lines.

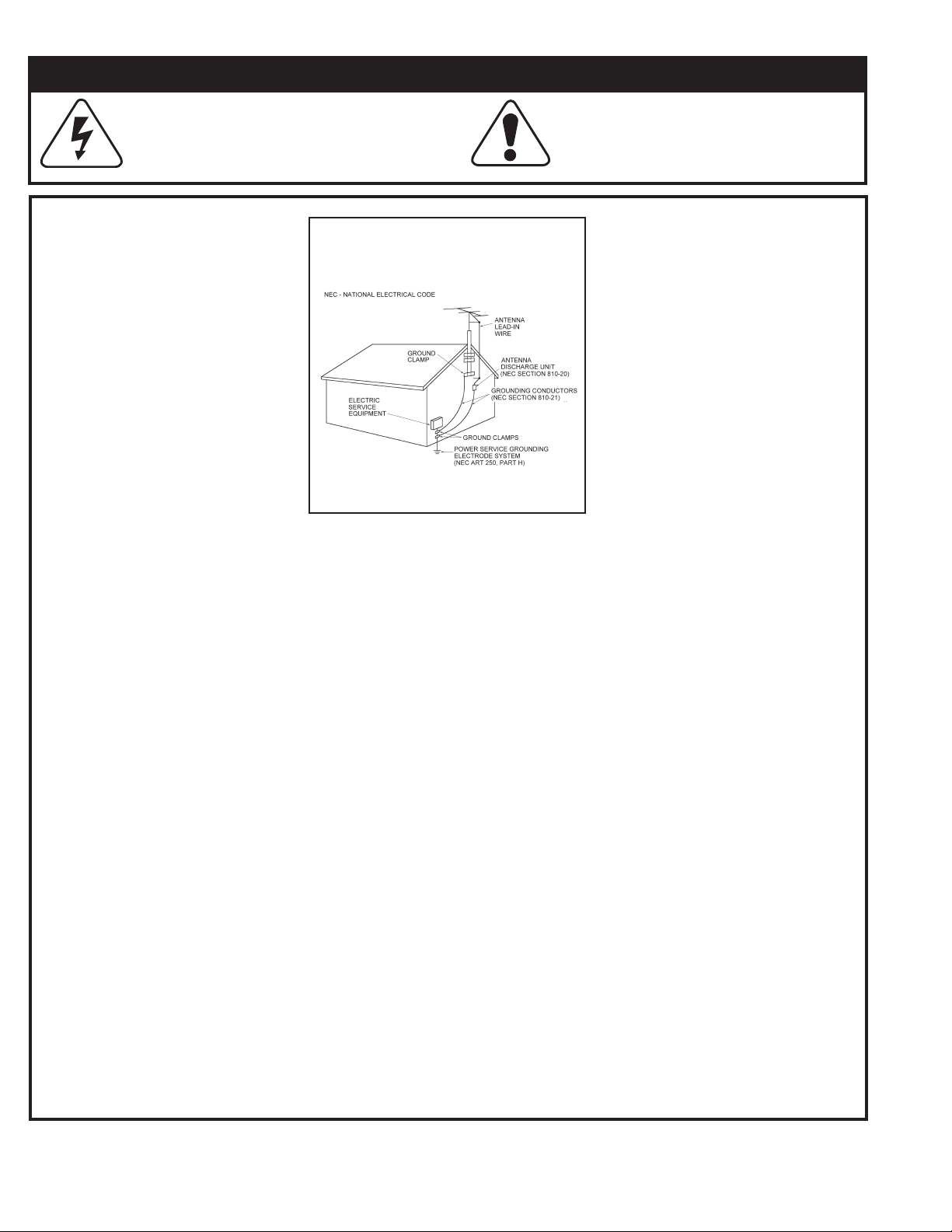

Outdoor Antenna Grounding - If an

outside antenna is connected to the

receiver, be sure the antenna system is

grounded so as to provide some protection

against voltage surges and built up static

charges. Section 810 of the National

Electrical Code, ANSI/NFPA No. 70 1984,

provides information with respect to proper

grounding of the mast and supporting

structure, grounding of the lead in wire

to an antenna discharge unit, size of

grounding conductors, location of antenna

discharge unit, connection to grounding

electrodes, and requirements for the

grounding electrode (see fi gure).

Object and Liquid Entry - Never push

objects of any kind into this product through

openings as they may touch dangerous

voltage points or short out parts that could

result in a fi re or electric shock. Never spill

liquid of any kind on the product.

CAUTION!

This sign warns user about important

this product.

Servicing - The user should not

attempt to service the appliance

beyond that described in the operating

instructions. All other servicing should be

referred to qualifi ed service personnel.

Damage Requiring Service - The

appliance should be serviced by qualifi ed

service personnel when:

• The power supply cord or the plug

has been damaged; or Objects have

fallen, or liquid has been spilled into

the appliance; or

• The appliance has been exposed to

rain; or

• The appliance does not appear to

operate normally or exhibits a marked

change in performance; or

• The appliance has been dropped, or

the enclosure damaged.

When the product exhibits a distinct

change in performance - this indicates a

need for service.

Replacement Parts - When replacement

parts are required, be sure the service

technician has used replacement parts

specifi ed by the manufacturer or have the

same characteristics as the original part.

Unauthorized substitutions may result in

fi re, electric shock, or other hazards.

Safety Check - Upon completion of any

service or repairs to this product, ask

the service technician to perform safety

checks to determine that the product is in

proper operating condition.

Wall or Ceiling Mounting - The product

should be mounted to a wall or ceiling only

as recommended by the manufacturer.

Keep this manual in a safe place for future reference.

To replace this manual, download available from Linear Web site:www.linearcorp.com

Page 3

IMPORTANT DO’S & DON’TS

✔ DO ensure that all instructions have been followed before

power is applied to system. The installation shall be carried

out in accordance with all applicable installation rules.

✔ DO use only Cat-5 & RG-6 and specifi ed wires called out in

these instructions. The cable is designed and constructed

with electrical specifi cations necessary for proper audio

performance.

✔ DO use only a damp cloth to clean the exterior plastics on

the VMC1 Master Station and Room Stations.

✔ DO NOT use liquid or aerosols.

✔ DO make gradual bends of the cable where necessary -- no

sharper than 1” radius.

✔ DO dress the cables neatly with cable ties or Velcro™

wraps. Use loose or moderate pressure.

✔ DO use cable-pulling lubricant only for cable runs that may

otherwise require great force to install. When cable lubricant

is used, read the instructions to be sure it is compatible with

the cable jacket material (PVC or FEP).

✔ DO avoid stressing cable conductors, limit pulling tension to

25 pounds or less as specifi ed by EIA/TIA-568A standard.

Pull cables gradually and with constant tension, taking care

not to crush or pinch bundles.

✔ DO use grommets to protect the cable where passing

through metal studs or anything that can possibly damage

them.

✔ DO test every installed cable run with a cable tester. “Toning”

alone is not acceptable.

✔ DO label every termination point. Use a unique identifi er

for each cable run. It will make moves, adds, changes, and

troubleshooting easier.

✔ DO support horizontal cable bundles using board supports,

J-hooks, or cable trays.

✔ DO have signal cables cross at right angles to power cables

to minimize induced interference.

✔ DO always obey all local and national fi re and building

codes. Be sure to “fi re-stop” all cables that penetrate a fi rewall. Use plenum-rated cable where mandated.

✔ DO have a licensed electrician to run a 120 VAC line from A

DEDICATED 15-AMP BREAKER to the VMC1 power supply.

✔ DO Use Cat-5 wire for all VMC1 wire runs.

✔ DO label all wire runs. Connecting the wires to the VMC1

master, room station, or door station incorrectly may result

in system damage.

✔ DO NOT STAPLE CABLES. Staples cause shorts.

✔ DO NOT SPLICE CABLES. Splices are unreliable and

defeat the signal isolation properties of the cable.

✔ DO keep cables at least 18 inches from fl uorescent light

fi xtures, Dimmer controls, and all other wiring. This includes

AC wiring, security cable, and other control wires. These can

cause a “hum” or “buzzing” sound.

✔ DO keep cables away from objects such as heating and air

conditioning ducts, metal construction plates, and anything

else with sharp edges that can damage the cables.

✔ DO follow the grounding and bonding requirements

established by Electrical Code TIA standard 607, and

equipment manufacturer’s specifi cations.

✔ DO NOT locate the VMC1 Master Station or Room Stations

on an exterior wall.

✔ DO NOT locate the VMC1 Master Station or Room Stations

in any wall cavity with any other electrical wiring in the

cavity.

✔ DO NOT attach non line-level audio devices or non M&S

authorized equipment to the system.

✔ DO NOT power up Master Station until all stations are

connected.

✔ DO NOT splice or repair cables damaged during wire

pulling, install a new cable.

✔ DO NOT coil or bundle the cables. This can cause electronic

feedback.

✔ DO NOT over-tighten the screws for the stations or the

intercom Master Station to prevent cracking.

✔ DO NOT install any station or speaker cables inside the 120

VAC transformer enclosure.

✔ DO NOT tie cables to electrical conduits or lay cables on

electrical fi xtures.

✔ DO NOT allow the cable to be sharply bent or kinked at any

time.

✔ DO NOT install cables “taut” anywhere. Good installation

should have cables loose, but never sagging.

✔ DO NOT run signal and power cables parallel without

adequate separation to minimize interference.

✔ DO NOT exert more than 25 pounds of tension on 4-pair

cables.

✔ DO NOT step on Cat-5 cable during installation.

✔ DO NOT overtighten the cable ties, apply cable ties loosely,

with random spacing.

✔ DO NOT untwist the wire pairs in Cat-5 cable more than 1/2”

to avoid crosstalk.

Keep this manual in a safe place for future reference.

To replace this manual, download available from Linear Web site:www.linearcorp.com

1

Page 4

Table of Contents

Block Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Rough-in Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Materials Required . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

The VMC1 System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Master Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Room Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Door Stations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Gates and Entrances . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Cameras. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

AM & FM Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Wiring Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cables and Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Maximum Length for Cable Runs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Cable Type and Confi guration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Master Station Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VMC1MB Master Station Mounting Bracket . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VMC1MB Installation - Unfi nished Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

VMC1MB Installation - Finished Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Room Station Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Room Station Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

Room Station Installation - Unfi nished Wall . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Room Station Installation - Finished Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Room Station Auxiliary Activation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Door Station Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

VMC1VDS Door Station Rough-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Door Station Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

VMC1VDS-S/BZ Door Station Rough-in . . . . . . . . . . . . . . . . . . . . . . . . . . .12

VMC1HR Rough-in Enclosure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .12

Power Supply Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

TE6D Power Supply . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Supply Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Power Supply Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Data Hub Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

H628 Data Hub . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Pull Wires . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

Antenna Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Radio Antennas . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

AM Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

FM Antenna . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Auxiliary Output Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Door Release Rough-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Chime Activated Control Output Rough-In . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Appendix A – Available Components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2 - Year Limited Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .22

2

Page 5

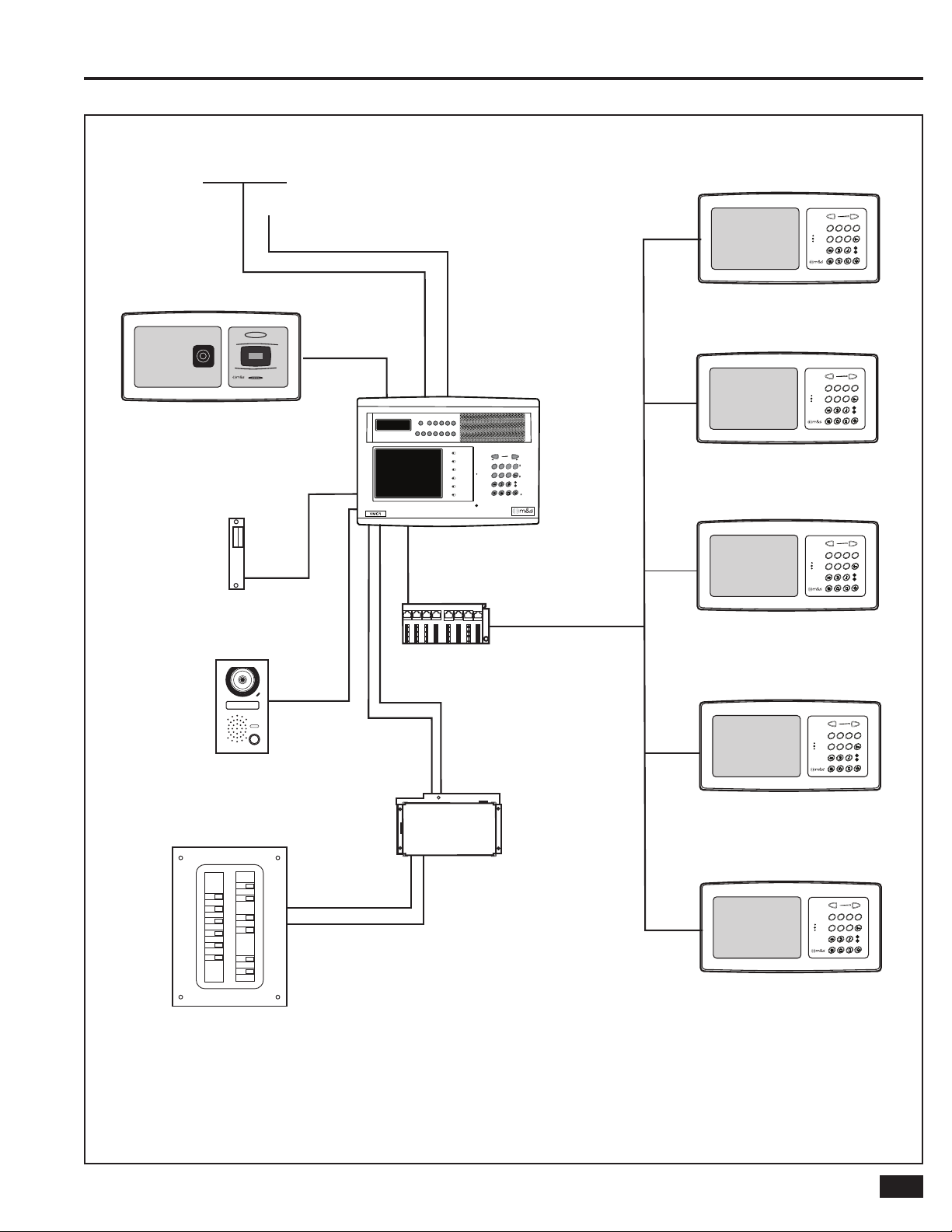

DOOR STATION

AM ANTENNA

FM ANTENNA

POWER BAND MEM

12

Block Diagram

ROOM STATION

+

-

VOLUME

4

23

1

6

7

5

MON

MUS

PRIV

AUX

DOOR

HOUSE

CLEAR

ROOM STATION

+

-

VOLUME

4

23

1

6

7

5

MON

MUS

PRIV

AUX

DOOR

HOUSE

ALARM DOWN UP

+

5

34

5

ME-UP

TUNER

AUX MUSIC

RADIO FILTER

GATE STATUS

AUX OUTPUT 1

AUX OUTPUT 2

+

-

VOLUME

4

3

2

1

AUX 2

INPUT FILTER

AUX 1

67

5

VID 3

VID 1

LOCK

VID 2

MUS

PRIV MON

AUX

DOOR

CLEAR

HOUSE

ROOM STATION

CLEAR

DOOR LOCK

VIDEO DOOR

STATION

MASTER STATION

H628 DATA HUB

TE6D

POWER SUPPLY

-

1

5

PRIV

CLEAR

ROOM STATION

-

1

5

PRIV

CLEAR

ROOM STATION

-

1

5

PRIV

CLEAR

VOLUME

23

6

MON

HOUSE

23

6

MON

HOUSE

23

6

MON

HOUSE

+

4

7

MUS

AUX

DOOR

+

VOLUME

4

7

MUS

AUX

DOOR

+

VOLUME

4

7

MUS

AUX

DOOR

DEDICATED POWER

3

Page 6

Introduction

The VMC1H installation rough-in prepares the home to

accommodate the video intercom system. A VMC1MB

mounting bracket is necessary for the Master Station. Room

stations and the Alloy Color Video Door Station (VMC1VDS)

can be mounted directly onto fi nished walls. All other door

stations require a rough-in enclosure (VMC1HR). The VMC1HR

is also recommended for installing room stations in new

construction or installations where the drywall has not yet

been installed.

Rough-in Kit

The VMC1H Rough-in Kit includes:

1 - (VMC1MB) Master Station mounting bracket

1 - (TE6D) Power Supply

1 - (101093) FM dipole antenna (#3)

1 - (226804) 300 ohm to 75 ohm F female Balum

1 - (250106-2) AM Antenna wire, Orange, 25 feet

1 - (233103) H628 Data Hub (#4)

VMC1MB

233103

TE6D

101093

226804250106-2

4

Page 7

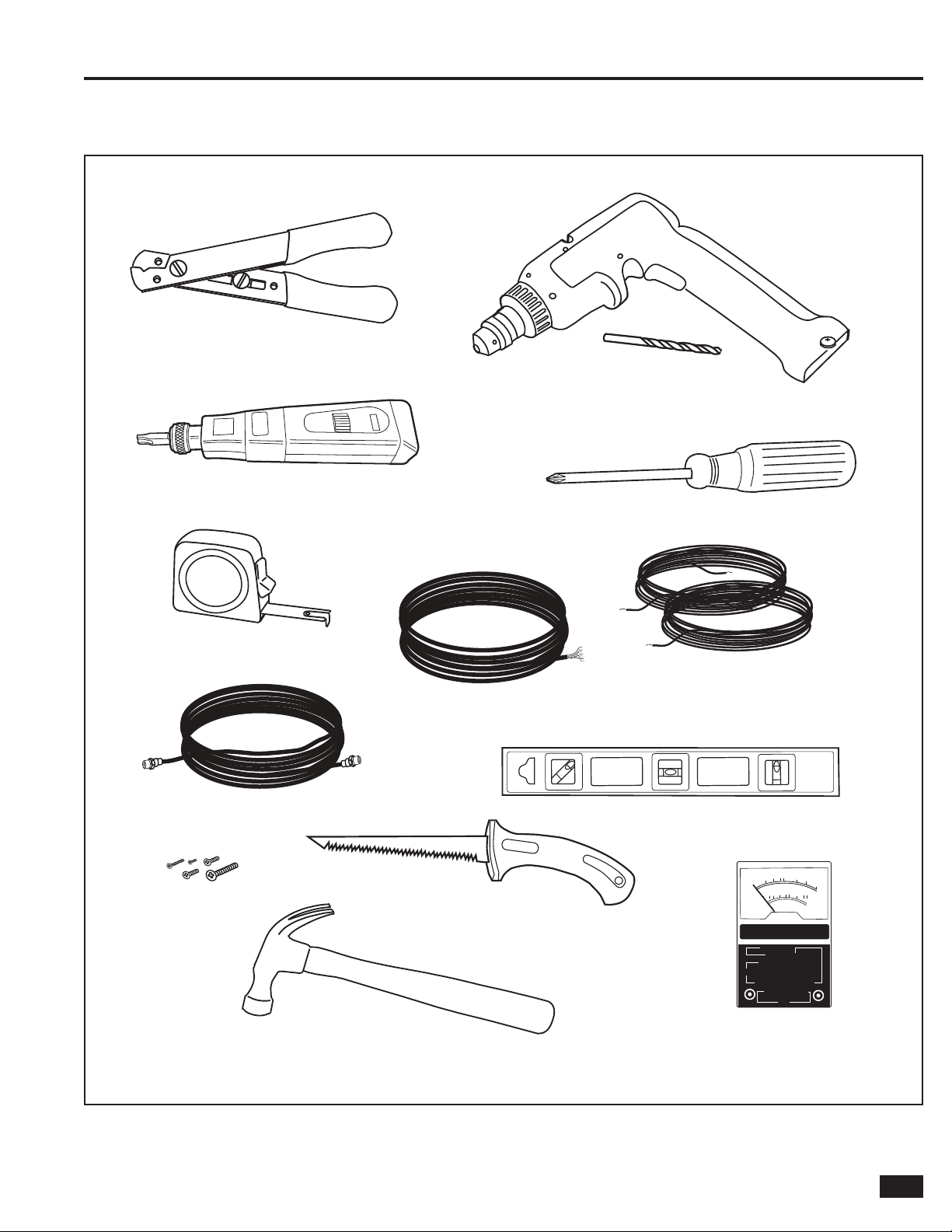

Tools

Most are required for purposes of this installation, but may

vary according to installer preferences.

WIRE STRIPPERS/CUTTER

110 PUNCH-DOWN TOOL

Materials Required

POWER DRILL WITH 1” AUGER

PHILLIPS SCREWDRIVER

TAPE MEASURE

COAX CABLE

MOUNTING SCREWS

(VARIOUS SIZES)

HAMMER

CAT-5 CABLE

DRYWALL SAW

14/18 GAUGE WIRE

LEVEL

0-M

10

0.5

50

50

250

200

500

+-

600

10

50

250

VOLTMETER

5

Page 8

Overview

The VMC1 System

Designed for installation in new homes, the VMC1 is a Whole

House Color Video Security Intercom system that provides

room to room communication, multiple camera support,

basic home automation controls, and video security for mid to

large residential applications. VMC1 provide years of service

and security for the homeowner as many people move into

‘smart home’ environment. New housing takes advantage of

state of the art electronics, internet, and security applications

such as video surveillance and monitoring. VMC1 provides up

to 20 remote intercom stations, three video camera stations,

and offers music and communication for the whole house.

With multiple 12 volt Control Outputs, VMC1 can trigger

lights, monitors, voice and text message alerts, and e-mail

door chime alerts delivered to a smart phone. VMC1 offers a

wide range of capacities with expanded options, accessories,

and recommended parts. (See Appendix A).

It is important that each step of the installation be

carefully completed by the installer. In the event you need

troubleshooting assistance, please call our technical support

staff at 1-800-421-1587.

General Information

The following general procedures must be observed in

relation to the location and installation of VMC1 components:

Where stations are to be installed outdoors, appropriate

measures to provide protection from the weather are to be

taken.

The power supply should be located in an area with suffi cient

space for heat dissipation.

Guidelines for maximum cable lengths as set out in this

manual are to be observed to avoid the possibility of operating

problems due to excessive cable voltage drop.

Interference

The circuitry of the intercom is designed to minimize the

effects of Radio Frequency Interference (RFI); and there will

be minimal and occasional radio frequency interference as

power outages, lightning storms, and any electrical apparatus

can affect the system. To reduce instances of interference,

reduce any unwanted audible buzz in audio appliances

such as microphone amplifi er, speaker amplifi er, car radio,

telephones etc, you add on-board EMI fi lters or special layout

techniques to help bypass EMI or improving RF immunity.

Most circuits have integrated RF fi lters or special design that

prevents demodulation of high-frequency carriers. The use of

microwaves, cell phones, cable television, bug zappers, even

heating pads in close proximity, can create interference.

Master Station

The Master Station should be positioned at a suggested

height of 4-1/2’ to 5-1/2’ from the fl oor to the center of the

unit. As all wiring from other stations is generally terminated

at the rear of the Master Station, the wall should be no less

than 3 inches in depth. Use the VMC1MB to provide adequate

support for the unit.

Room Stations

To avoid audio feedback, Room Stations should be kept at least

10 feet away from other stations. Never have more than one

station in any one room and avoid mounting stations in the

same wall cavity (i.e. directly below and above one another in

a two-story house). A suitable height is generally 4.5 feet from

the fl oor to the center of the unit. For Room Stations mounted

on wood frame walls, place near a stud to allow for adequate

support. For tiled surfaces, install a wall box before lining or

tiling the walls. Cut the tiles to the inside dimensions of the

wall box. Where Room Stations are mounted outside and are

exposed to the weather, the fi tting of weatherproof covers is

recommended (p/n DSWS). Stations must not be installed in

saunas.

Door Stations

Door Stations are best located adjacent to the front door

or at the front gate at a suggested height of 4’-6” and may

require a wall box depending upon the surface to which they

are to be affi xed. Door Stations are weather resistant, but

should not be exposed directly to rain or extreme weather.

Any station exposed to the weather requires a weather shield.

When equipped with the appropriate weather shield the Door

Station is designed to meet ANSI/IEC 60529 IP31 weather

proof standards.

Gates and Entrances

Where stations are to be installed in brick or concrete columns

at a front gate, the cable should be run in conduit from the

station to below ground level and back to the house.

Cameras

For Door Stations fi tted with cameras, consideration must be

given to the viewing area of the camera taking factors such as

lighting and sun exposure into account.

Power Supply

The Power Supply should be attached to the VMC1MB as

directed. Improper installation of the Power Supply can lead

to unit malfunction and void the warranty. The Power Supply

needs suffi cient space to dissipate heat effectively.

AM & FM Antennas

The antenna arrangement is critical to the installation for quality

radio reception. Place AM and FM antennas at the highest

point of the roof and at least 6 feet away from any electrical

or intercom wiring. Both AM and FM antennas are directional,

and correct positioning requires some experimentation to

achieve the best possible result. Antenna wires should also

be positioned at the highest and most accessible point in

the roof. Allow additional cable at the mounting bracket for

termination, at least 3 feet for the Master Station.

6

Page 9

Cables and Wiring

Excellent locations to run cables include:

• Roof space

• False ceilings/ bulkhead area

• Through and/or around external walls

• Under fl oors (subject to access being available)

• Underground in conduit

✓ NOTE: Keep Intercom cables far from any AC wiring. Avoid running

intercom cable in parallel to AC or any other type of wiring. Avoid placing

joins or splices in cables. Locate cables where there is access for future

servicing.

Maximum Length for Cable Runs

The system can be “home-run wired” from a central point or

“daisy chained” from station to station. However, the number

of stations on a daisy chain run governs the overall length

of the run. The tables below show the relationship between

the length on a cable run and the number of room stations

permitted and the maximum cable run to a Door Station.

✓ NOTE: The tables are based on the use of Cat-5 or Cat-6 cable. Where

required, the wire lengths maximum distances can be doubled by

running 12 AWG speaker wire in parallel with the POS & NEG wires. It

is important that the POS and NEG wires are balanced in terms of the

type of wire and the number of wires being used - i.e. if a Cat-5 wire and

12 AWG speaker wire are being used for the positive connection, a Cat-5

wire and a 12 AWG speaker wire should also be used for the negative

connection.

Wiring Information

Cable Type and Confi guration

The general intercom functions for VMC1 can be cabled using

Cat-5 or Cat-6 cables. If required, 6-conductor telephone

cables can be used provided the system is confi gured for

6-wire operation.

Be sure to clearly tag all cables to identify any damaged cables

or other system faults. See the table below for Cat-5 wire color

recommendations.

ROOM STATIONS SHOULD

BE AT LEAST TEN FEET

APART FROM ONE

ANOTHER

MAXIMUM CABLE LENGTH TO ROOM STATIONS NUMBER OF STATIONS ALLOWED

100 yards 1 Room Station

50 yards 2 Room Stations

33 yards 3 Room Stations

25 yards 4 Room Stations

MAXIMUM CABLE LENGTH TO DOOR STATIONS NUMBER OF STATIONS ALLOWED

80 yards 1 Door Station

MASTER STATION CONNECTION VIDEO DOOR STATION NON-VIDEO DOOR STATION ROOM STATION WIRING

POS

NEG Green Green Green

TC Orange White Orange White Orange White

VLC Orange

VLCx Orange Orange

COM1 Blue White Blue White Blue White

COM2 Blue Blue Blue

MUS1 Brown White

MUS2 Brown

VIDx Signal

GND Ground

AUX Yellow Optional

Green White Green White Green White

Cat-5/6

Optional Video Signal Brown White

Optional Video Ground Brown

Cat-5/6

7

Page 10

Master Station Rough-In

VMC1MB Master Station Mounting Bracket

The VMC1MB mounts fl ush with the wall stud and holds the

Master Station and Power Supply (See Figure 1). Position the

VMC1MB at a suggested height of 4-1/2 to 5-1/2 feet from the

fl oor to center of the unit. As all wiring from other stations

is generally terminated at the rear of the Master Station, the

wall should be no less than 3 inches deep. If required, install

additional wood shims or metal rough-in enclosures to allow

for adequate support of the Master Station.

✓ IMPORTANT: Install the Master Station in a cavity wall to allow for the

wiring behind it. Do not install in a brick wall. For wall tiling around the

Master Station, ensure that it is mounted either completely within or

clear of tile to avoid an uneven surface. Be sure to allow at least 10” of

space below Master Station Bracket and fi rebreaks for Power Supply.

This is also necessary for clearance when installing the Master Station

Mounting Bracket into pre-cut drywall opening.

The VMC1MB has a correct orientation, so review Figures 1

and 2 to be sure it is right side up.

WALL STUD

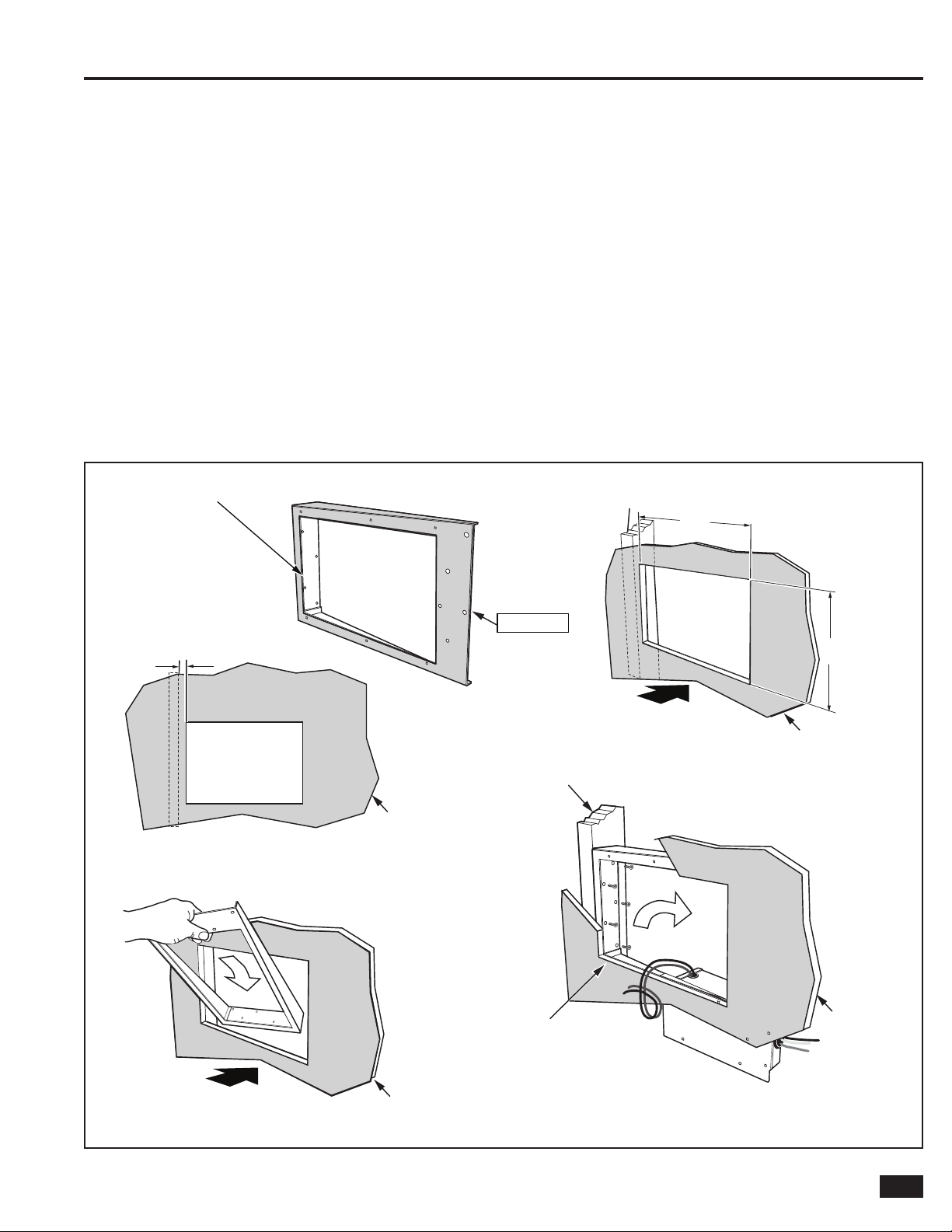

VMC1MB Installation - Unfi nished Wall

Install the VMC1MB fl ush with the front of the wall stud and

fasten in place with screws as shown. After drywall has been

installed, cut out an opening to the inside dimensions of the

VMC1MB (7-1/4” x 11.”).

MOUNT

BRACKET

FLUSH WITH

FRONT OF

WALL STUD

BRACKET

FLANGE

FRONT VIEW

VMC1MB

MASTER STATION

BRACKET

POWER SUPPLY (TE6D)

MOUNTS TO FLANGE ON

MASTER STATION BRACKET

MOUNT BRACKET AT LEAST

10” FROM ANY FIREBREAK

TRACE THIS AREA

AS A TEMPLATE

FOR MASTER

STATION OPENING

ON DRYWALL

(7-1/4” x 11”)

WALL STUDS

VMC1MB

MASTER

STATION BRACKET

FIREBREAK

4’-5” to 5’-5”

MOUNTING HEIGHT

FROM FLOOR TO

CENTER LINE OF

BRACKET

Figure 1. Installing Bracket - Unfi nished Wall

8

Page 11

VMC1MB Installation - Finished Wall

Cut out an opening in the drywall (Height 7-1/4” x Width 11”)

but do not cut right up against the wall stud. Allow 5/8”

clearance between drywall opening and stud. This ensures that

drywall will overlap bracket (See Figure 2). Slide the VMC1MB

vertically, then turn clockwise 90˚. Mount in place onto stud

using fasteners as shown. Hang Power Supply on VMC1MB

in the lower right corner as shown. It may be necessary to

lightly tap Power Supply in place onto VMC1MB fl ange with

a hammer.

Master Station Rough-In

TRACE THIS AREA

AS A TEMPLATE

FOR MASTER

STATION OPENING

ON DRYWALL

(7-1/4” x 11”)

CUT OPENING

5/8” FROM STUD

DRYWALL OPENING

IS 5/8” FROM STUD

FRONT VIEW

DRYWALL

SLIDE VMC1MB BRACKET

VERTICALLY INTO DRYWALL

OPENING

VMC1MB

STUD

STUD BEHIND

DRYWALL

11”

CUT DRYWALL

OPENING

7-1/4”

FRONT VIEW

DRYWALL

THEN TURN BRACKET 90°

CLOCKWISE AND MOUNT

TO STUD

FRONT VIEW

DRYWALL

OVERLAPS

BRACKET

DRYWALL

HANG POWER

SUPPLY ON VMC1MB

BRACKET AS SHOWN.

USE HAMMER TO LIGHTLY

TAP INTO PLACE ON MASTER

STATION BRACKET FLANGE

Figure 2. Installing Bracket - Finished Wall

DRYWALL

9

Page 12

Room Station Rough-In

Room Station Mounting

The Room Stations are normally mounted at a height from the

fl oor of: 4-1/2’ to 5’. The Room Stations are not designed to be

installed outdoors.

Room Station Installation - Unfi nished Wall

For an unfi nished wall it is recommended that the VMC1HR

rough-in enclosure be used. Identify the location where the

Room Station is to be installed.

Attach the Rough-In Enclosure to the stud using the two inner

pre-punched holes (see Figure 3). The outside holes on the

wings of the box are to be used to mount the room station

and not to attach the Rough-in Enclosure to the stud.

Pull the Cat-5 wires through the hole in the back of the Roughin Enclosure and make a knot so they do not fall back into the

wall once the drywall is installed.

After drywall is installed, cut out an opening to the inside

dimensions of the VMC1HR utilizing the inside of the box as a

guide (see Figure 3 ).

Room Station Installation - Finished Wall

Identify the location where the Room Station is to be installed.

Cut a 3-1/2” x 7-3/4” rectangular hole in the drywall. When

possible, one short edge should be situated against a wall stud

to provide added support when installing the Room Station.

Pull the wire through the hole and attach to the drywall so it

will not fall back into the wall cavity.

Room Station Auxiliary Activation

When operating in single digit mode, each Room Station

can activate the Auxiliary Control Output (CO) triggers at the

Master Station.

Pull a yellow 18 gauge wire from the VMC1MB to the Room

Station location. Following this color convention will assist in

the fi nal installation of the VMC1 system.

Pull the yellow wire through the hole in the back of the

Rough-In Enclosure and loop it through so it does not fall back

into the wall once the drywall is installed.

USE INNER HOLES FOR

MOUNTING ROUGH-IN

ENCLOSURE TO STUD

VMC1RS-WH

ROOM STATION

MOUNTING PLATE

ELECTRONICS

PANEL

GRILLE

PRE-DRYWALL ROOM STATION

INSTALLATION

-

VOLUME

1

+

2

3

5

4

6

PRIV

MON

7

MUS

CLEAR

HOUSE

DOOR

AUX

BEZEL

VMC1RS-WH

ROOM STATION ROUGH-IN

ENCLOSURE (SEE DRAWING A)

7-3/4”

CAT5 CABLE LOOPED

WITH EXCESS AMOUNT

4’-6” to 5’-0”

MOUNTING HEIGHT

FROM FLOOR LINE

DRYWALL

ANCHORS

3-1/2”

VMC1HR

DRYWALL

DRAWING A

STUDS

ROOM STATION ROUGH-IN

ENCLOSURE

VMC1HR

10

-

VOLUME

1

+

2

3

5

4

6

PRIV

MON

7

MUS

CLEAR

HOUSE

DOOR

AUX

POST-DRYWALL ROOM STATION

INSTALLATION

Figure 3. Pre-Drywall and Post-Drywall Room Station Installation

Page 13

VMC1VDS Door Station Rough-in

The VMC1VDS is a metal door station with a 90 degree

horizontal viewing area. It is normally mounted at a height

from the fl oor of: 55” – 60”. When installing the VMC1VDS be

aware of the camera location and the direction of sunlight and

other ambient light. Direct sun or lighting into the lens of the

VMC1VDS camera may impact the video quality. Additionally,

exposure to extreme weather conditions is not recommended.

For added protection against weather, the VMC1VDS should

be equipped with a VDSWS-T weather shield. The installation

of the VDSWS-T is shown in Figure 4.

✓ NOTE: When removing allen screw from Video Door Station front bezel, a

small metal tab will drop out of the chassis. Be sure to re-install tab into

camera chassis slot before re-assembly.

Door Station Rough-In

1. Identify the location where the VMC1VDS is to be

installed.

2. Pull Cat-5 wire from the VMC1MB to this location.

3. Label and tie off the wires so they do not fall back into the

wall and are accessible when the VMC1VDS is installed.

4. If the door strike or Chime activated Control Output is

to be utilized, see “Door Release Rough-in” and “Chime

Activated CO Rough-in”.

CAMERA

CHASSIS

PLEXIGLASS

WEATHER

SHIELD (OPTIONAL)

VDSWS-T

BEZEL

VMC1VDS

ANCHORS

NOTE: METAL TAB

DROPS OUT WHEN

REMOVING ALLEN

SCREW HOLDING

FRONT BEZEL

TO CAMERA CHASSIS

DRYWALL

4-1/2’ to 5’-0”

MOUNTING

HEIGHT

FROM FLOOR

LINE

ALLEN

SCREW

Figure 4. VMC1VDS Door Station Rough-In

11

Page 14

Door Station Rough-In

VMC1VDS-S/BZ Door Station Rough-in

The VMC1VDS-S and VMC1VDS-BZ incorporate a wide angle

120 degree horizontal viewing camera into a Door Station. It

is normally mounted at a height from the fl oor of: 55” – 60”.

Installation of this unit on an exterior wall requires 4 screws

and anchors (See Figure 6). When installing these units, be

aware of the camera location and the direction of sunlight and

other ambient light. Direct sun or light pointed into the lens of

the VMC1VDS camera may impact video quality. Additionally,

exposure to extreme weather conditions is not recommended.

For added protection against weather, the VMC1VDS-S and

VMC1VDS-BZ should be equipped with a DSWS weather

shield. The installation of the DSWS is provided in the VMC1

Finish Out Guide.

VMC1HR Rough-in Enclosure

1. Attach the VMC1HR fl ush to the exterior wall using the

two inner pre-punched holes in the VMC1HR. The outside

holes on the wings of the box are to be used to mount the

VMC1VDS-S/BZ and not to be used to attach the VMC1HR

to the exterior wall.

2. Pull the Cat-5 wires through the hole in the back of the

VMC1HR and loop it through so they do not fall back into

the wall.

3. If the door strike or Chime activated Control Output is

to be utilized, see “Door Release Rough-in and “Chime

Activated CO Rough-in

PRE-DRYWALL COLOR VIDEO DOOR

STATION

USE INNER HOLES FOR

MOUNTING ROUGH-IN

ENCLOSURE TO STUD

VMC1VDS-BZ

VMC1VDS-S

BEZEL

ELECTRONICS

PANEL

VMC1VDS-BZ

VMC1VDS-S

7-3/4”

3-1/2”

CAT5 CABLE LOOPED

WITH EXCESS AMOUNT

COLOR VIDEO DOOR

STATION WALL

MOUNTING PLATE

VMC1HR

DRYWALL

ANCHORS

12

GRILLE

POST-DRYWALL COLOR

VIDEO DOOR

STATION

Figure 5. VMC1VDS-S/BZ Door Station Rough-In

Page 15

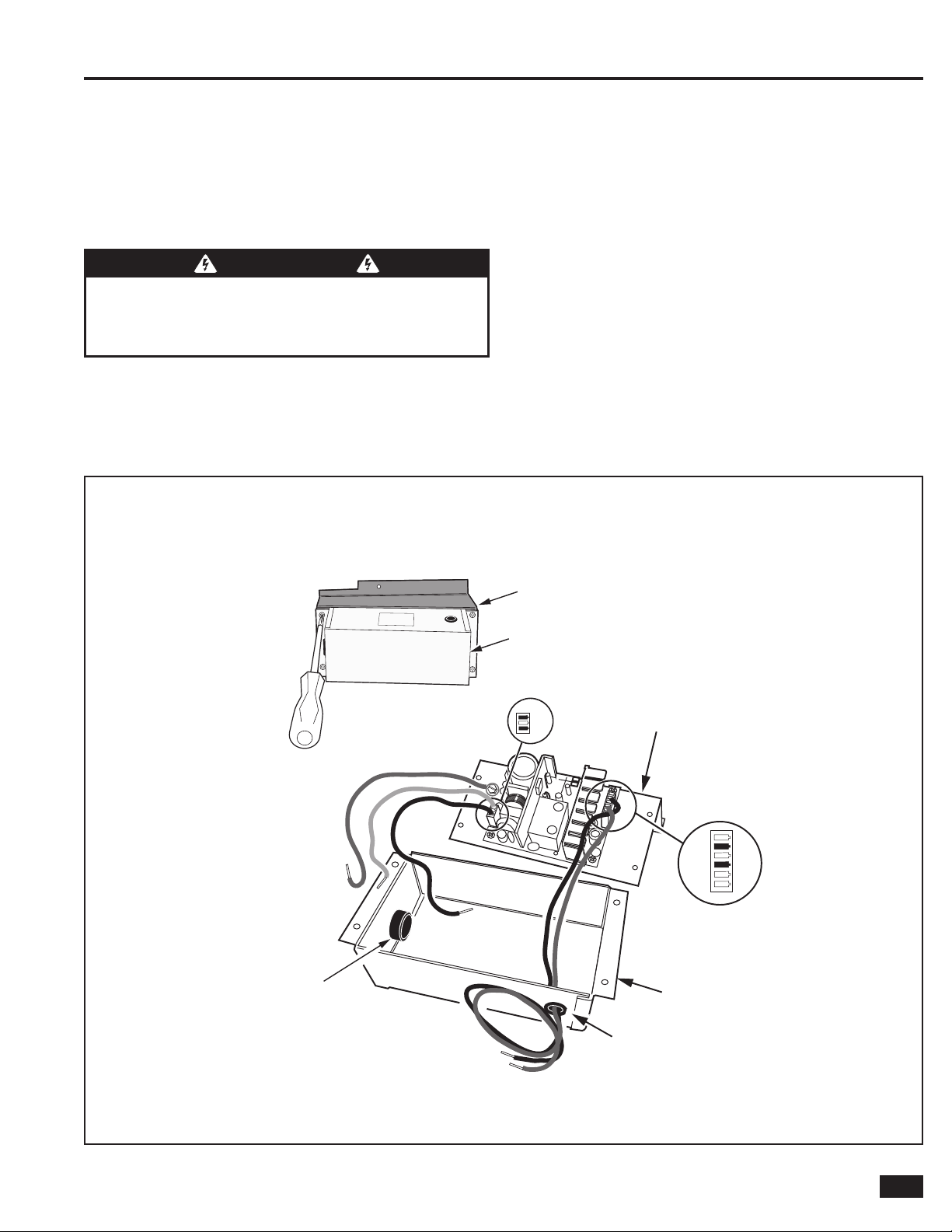

TE6D Power Supply

The Power Supply unit is pre-wired and self contained, and

the wires are tucked inside. To access connection wires, open

the Power Supply unit by removing four screws as shown

in Figure 6. In the unlikely case that the TE6D electrical

connectors become unplugged, the 3-pin and 6-pin connector

blocks can be re-installed in their respective locations on the

power supply board. Plug connectors in as shown.

WARNING

ALL AC ELECTRICAL CONNECTIONS TO THE POWER SOURCE TE6D

POWER SUPPLY MUST BE MADE BY A LICENSED ELECTRICIAN

AND MUST OBSERVE ALL NATIONAL AND LOCAL ELECTRICAL

CODES

Power Supply Rough-In

Power Supply Connections

The 6-pin connector is the low voltage (13.8 VDC, 3.8 amp)

output from the TE6D Power Supply unit:

• Position 3 is the Black Negative connection for the Master

Station

• Position 5 is the Red Positive connection for the Master

Station

The 3-pin connector is for the 110/120 High Voltage input:

• Black wire is position 1

• White wire is position 3

PRE-WIRED SELF CONTAINED TE6D POWER SUPPLY

REMOVE 4 SCREWS

TO ACCESS POWER

SUPPLY WIRES

STRAIN RELIEF

BOTTOM HOUSING

TOP HOUSING

3-PIN

3

WHT

2

CONNECTOR

BLK

1

BOTTOM HOUSING

6-PIN CONNECTOR

6

5

RED

4

BLACK

3

2

1

TOP HOUSING

STRAIN RELIEF

Figure 6. Opening TE6D Power Supply

13

Page 16

Power Supply Rough-In

Power Supply Wiring

1. Run a 14 AWG 120 VAC power cable (including ground)

from a dedicated 15-amp circuit breaker to the Master

Station Mounting Bracket location. The VMC1 requires a

dedicated power source so there’s no interference from

other equipment.

2. Route incoming power cable into the Power Supply

enclosure through the hole on the SIDE of the Power

Supply.

3. Use wire nuts to connect the incoming power cable

to the TE6D Power Supply BLACK (HOT) and WHITE

(NEUTRAL) input wires.

4. Connect the GREEN (GROUND) wire to the ground

conductor.

PRE-WIRED SELF CONTAINED TE6D POWER SUPPLY

HOT WIRE

GROUND WIRE

(GREEN)

(BLACK)

5. Secure all power cables entering the Power Supply

enclosure with cable strain reliefs.

6. Tuck cables into the Power Supply enclosure.

7. Pull the Red and Black low voltage wires out of the top

of the TE6D for later connection to the Master Station.

Re-assemble the TE6D housing with the provided screws

(See Figure 7).

8. Hook the power supply onto the fl ange of the VMC1MB

and attach the it with screw provided (See Figure 7).

✓ NOTE: Be sure all power cables entering the power supply enclosure are

secured with cable strain reliefs.

BOTTOM HOUSING

NEUTRAL WIRE

(WHITE)

WIRE NUTS

INSERT

WIRE FROM

BREAKER INTO

STRAIN RELIEF

STRAIN RELIEF

FEED WIRES THROUGH

STRAIN RELIEFS ON TOP

HOUSING AS SHOWN. CONNECT

WIRES USING WIRE NUTS, THEN

RE-INSTALL TOP HOUSING

WITH 4 SCREWS

PLUS 13V WIRE (RED)

NEGATIVE WIRE (BLACK)

TOP HOUSING

STRAIN RELIEF

POWER IDENTIFICATION

AT MASTER STATION

PLUS 13V

WIRE (RED)

NEGATIVE

WIRE (BLACK))

110/120V HIGH

VOLTAGE INPUT

(BLACK)

14

RE-ASSEMBLED TE6D POWER SUPPLY

WITH WIRES PROTRUDING

Figure 7 - TE6D Power Supply Wiring

SCREW

(PROVIDED)

NEUTRAL

(WHITE)

TE6D POWER SUPPLY

GROUND

(GREEN)

Page 17

H628 Data Hub

The H628 Data Hub is used to connect each station to the

Master Station.

Pull Wires

Pull all the Door and Room Station cables to the location of

the Master Station Mounting Bracket (VMC1MB).

If the installation consists of more than 5 room stations, Linear

recommends using the optional Linear DMD-16 (16 stations)

Data Distribution module and the Model H275 Universal

Bracket (Optional, see Appendix A).

1. Determine a mounting location for the H628 Data Hub. It

is recommended to use a Model H275 Universal Bracket

(Optional, see Appendix A).

2. Terminate Cat-5 cables from stations with RJ-45 modular

plugs wired to TIA-568A wiring standard (See Table at

right).

3. Cut a length of Cat-5 cable to run from the H628 Data Hub

to the Master Station location.

4. Strip back about 8” of cable insulation and use a 110

Punch-down tool to bridge all of the punch-down

connectors with the Cat-5 cable as shown in Figure 8.

5. Plug all of the station’s modular plugs into the RJ-45

sockets on the H628 Data Hub.

6. Route the bridged Cat-5 cable to the Master Station

location and secure it so it won’t fall back into the wall.

TIA-568A WIRING STANDARD

DATA HUB RJ-45

MODULAR PLUG

Pin 1 White/Green

Pin 2 Green

Pin 3 White/Orange

Pin 4 Blue

Pin 5 White/Blue

Pin 6 Orange

Pin 7 White/Brown

Pin 8 Brown

Data Hub Wiring

Cat-5 WIRE COLOR

CAREFULLY PUNCH

WIRES INTO TERMINAL

BLOCK USING A

110 PUNCH-DOWN TOOL

110 PUNCH-DOWN TOOL

CAT-5 CABLE

TO MASTER STATION

Figure 8. H628 Data Hub Wiring

FROM

DOOR

STATION

FROM

ROOM

STATION

STATION

110 PUNCHDOWN CONNECTORS

8” OF CAT-5 CABLE INSULATION STRIPPED

FROM

ROOM

FROM

ROOM

STATION

FROM

NIGHTSTAND

STATION

RJ-45 PLUG SOCKETS

1 BROWN

2 WHITE/BROWN

3 GREEN

4 WHITE/GREEN

5 ORANGE

6 WHITE/ORANGE

7 BLUE

8 WHITE/BLUE

15

Page 18

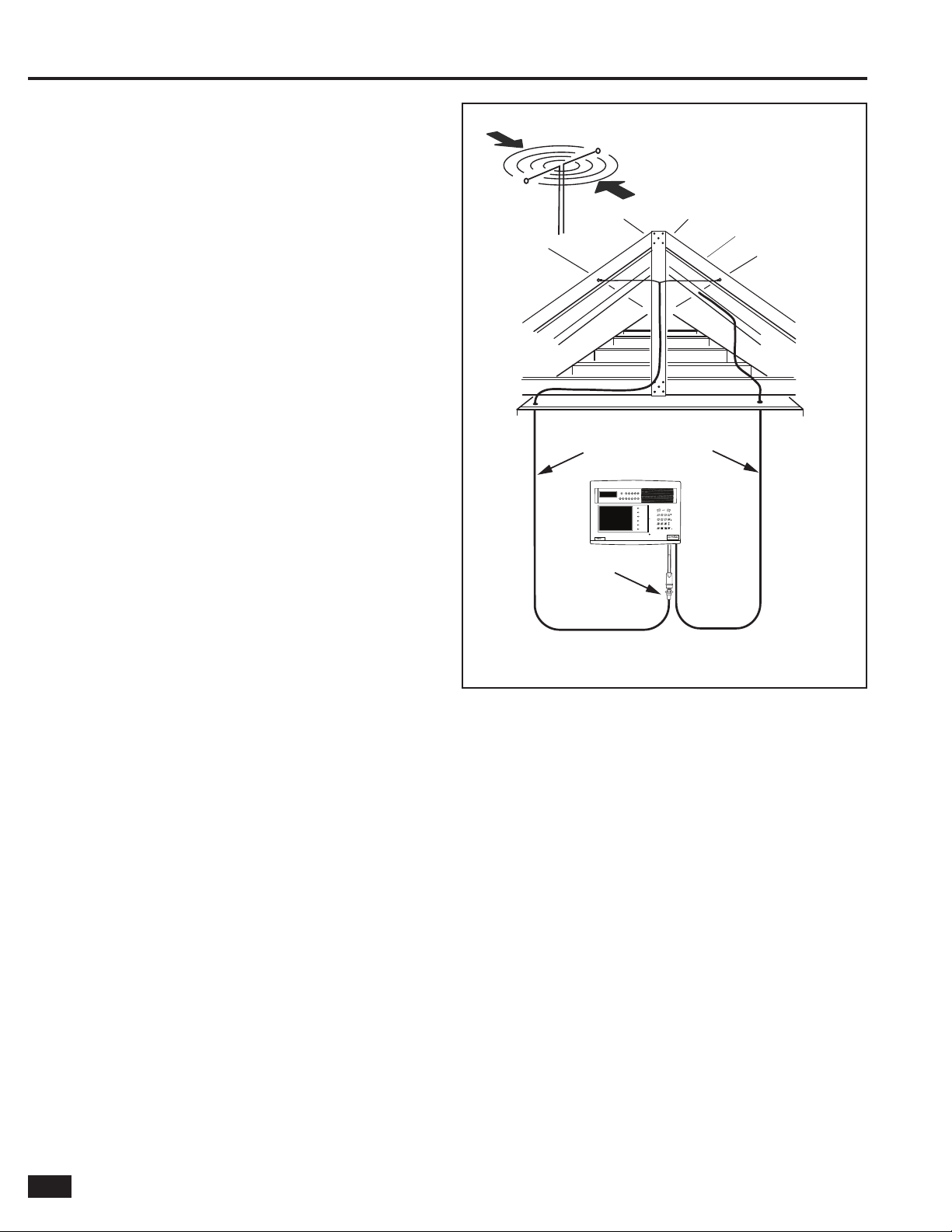

Antenna Installation

Radio Antennas

VMC1 requires two antennas, one for AM and one for FM

reception. The AM antenna is a 25-foot wire the FM antenna is

a 25-foot length of coax with a “T” shaped wire dipole at one

end that attaches between rafters in the attic.

Antenna arrangement is crucial to quality radio reception. AM

and FM antennas should be placed at the highest point of the

roof and at least six feet away from any electrical or intercom

wiring.

✓ IMPORTANT! Isolate the antenna leads from the intercom station cables

by running them through a separate hole in the ceiling plate. If grouped

together, the intercom station cables can shield the antenna leads

resulting in poor radio reception. Also keep the antenna leads away

from metal duct work and aluminum backed insulation, which reduces

reception.

AM Antenna

1. Unroll the 25-foot AM antenna wire.

2. Route the antenna wire to the best location, ideally in an

attic.

3. Route the antenna wire down through the hole in the

ceiling plate, down the stud bay to where the VMC1MB

was installed (see Figure 9).

✓ NOTE: the overall length of the antenna wire may be extended by splicing

on to the ‘open’ end of antenna with insulated wire. The gauge end of the

wire should be strong enough to support it without breaking.

✓ NOTE: Some customers may want to use an external tuned loop antenna

or vertical amplifi ed broadband antenna. Refer to those manufacturer’s

installation instructions for further information.

ORIENTATE FM ANTENNA

FOR STRONGEST RECEPTION

FM ANTENNA

WIRING

MASTER STATION

ALARMDOWN UP

POWER BANDMEM

+

5

34

5ME-UP

12

TUNER

AUX MUSIC

RADIO FILTER

GATE STATUS

AUX OUTPUT 1

AUX OUTPUT 2

75 OHM TO 300 OHM

ADAPTER

AM ANTENNA

WIRING

+

-

VOLUME

4

3

2

1

AUX 2

INPUT FILTER

AUX 1

6 7

5

VID 3

VID 1

LOCK

VID 2

MUS

PRIV MON

AUX

DOOR

CLEAR

HOUSE

ATTIC

FM Antenna

1. Unroll and examine the FM antenna. The antenna is

formed by spreading the red and black wires at the end

of the COAX. The terminal lug at the end of each wire is

for screw mounting the wires outstretched. The antenna

is provided with an F type connector allowing for easy

connection of additional cable.

2. Use screws to attach the red and black antenna leads to

the structure outstretched (See Figure 9).

3. Route the connector end of the antenna COAX down

through the hole in the ceiling plate, down the stud bay,

and on the right side of where the VMC1 Master Unit will

be installed.

4. Connect the included 75 Ohm to 300 Ohm adapter to the

end of the cable.

Figure 9. Antenna Location

16

Page 19

Door Release Rough-in

The Door Release Trigger can be activated from the VMC1

Master or any remote room station by pressing the Lock

button. The Trigger will deactivate after 4 seconds and can be

activated multiple times while the intercom is active.

To connect the optional Linear Model DRW Door Release

Mechanism, refer to Figure 10 For controlling other door

release devices, refer to the hook-up instructions supplied

with the device.

1. Route a blue and a white 18 gauge wire from the Door

Station location or VMC1MB to the optional 12V Model

284 relay. (See Appendix A). Following this color

convention will assist in the fi nal installation of the Door

Station.

2. Connect the blue wire to the red coil wire on the 284

relay.

3. Connect the white wire to the white coil wire on the 284

relay.

4. Connect a red 18 gauge wire to the green Normally Open

wire on the 284 relay.

5. Connect a red 18 gauge wire to the blue Common wire

on the 284 relay.

6. Connect the other end of the red wire from the relay to

the Yellow wire on the RT35 or either of the wires on the

RT11.

7. Connect the other end of the red wire from the relay to

one of the wires from the DRW.

8. Connect the remaining wire on the DRW to the Yellow/

Red wire on the RT35 or the remaining wire on the RT11.

9. Install the optional DRW into the door frame following

the included instructions.

Auxiliary Output Rough-In

Chime Activated Control Output Rough-In

The Chime Activated Control Output allows for any number of

security related automation functions including 10 available

door chimes. To connect an auxiliary Chime refer to Figure 10.

Refer to the hook-up instructions supplied with the chime.

1. Route a blue and a black 18 gauge wire from the Door

Station location or VMC1VDS to the optional 12V

Model 284 relay. (See Appendix). Following this color

convention will assist in the fi nal installation of the Door

Station.

2. Connect the blue wire to the red coil wire on the 284

relay.

3. Connect the black wire to the white coil wire on the 284

relay.

4. Connect a red 18 gauge wire to the green Normally Open

wire on the 284 relay.

5. Connect a red 18 gauge wire to the blue Common wire

on the 284 relay.

6. Connect the other end of the red wire from the relay to

the Yellow wire on the RT35 or either of the wires on the

RT11.

7. Connect the other end of the red wire from the relay to

one of the wires from the Chime.

8. Connect the remaining wire on the Chime to the Yellow/

Red wire on the RT35 or the remaining wire on the RT11.

9. Install the optional Auxiliary Chime following its

instructions.

VMC1VDS

DOOR

STATION

BLUE

WHITE

BLACK

USE WHITE WIRE FOR DOOR RELEASE

USE BLACK WIRE FOR AUXILIARY CONTROL OUTPUT

RED

WHITE

MODEL 284

12V 5 AMP RELAY

Figure 10. Electric Door Strike Wiring

GRAY

N/C NORMALLY CLOSED

COMMON

GREEN

NORMALLY OPEN

110VAC

24VAC

MODEL RT11 OR RT35

PLUG-IN TRANSFORMER

DRW

MODEL DRW

ELECTRONIC DOOR STRIKE

OR CHIME

BLUE

17

Page 20

Appendix A – Available Components

Point-to-Point, Point-to-Group and All Call

with 10 different door chimes, 90º horizontal

and 50º degree vertical viewing angle. Standard

System Master Station

with 5.6” TFT LED color screen

supporting up to 20 remote stations.

intercom with hands free response.

UL 60950 certifi ed

VMC1 (White pictured)

VMC1-BK (Black)

VMC1-BZ (Bronze)

Color Video Door Station

weather resistance (IP30) Metal Alloy

(VMC1VDS)

Color video door station with 10 door chimes, a

120º horizontal and 80º vertical viewing angle.

Standard weather resistance IP30

Bronze (pictured)(VMC1VDS-BZ)

Silver (VMC1VDS-S)

5 pack of alternative color room station

faceplates

VMC1RST-WH-5 White

VMC1RST-AL-5 Almond (pictured)

VMC1RST-BK-5 Black

VMC1RST-BZ-5 Bronze

Room station for all non-video intercom, home

security and automation functions

White (pictured)

(VMC1RS-WH)

18

Page 21

Appendix A – Available Components

Starter Kit for VMC1 Security Intercom System

one (1) Master, one (1) Alloy Door Station and

four (4) room stations

White(VMC1PACK)

Non-video door station. Basic doorbell intercom

station where video is not required. Standard

weather resistance IP30

(VMC1DS-BZ Bronze)

(VMC1DS-S Silver) pictured

Nightstand station.

Provides all of the function of the intercom for

use on a nightstand or desk

Black (VMC1TTS)

Plexiglas weather shield increases the weather

resistance of VMC1VDS to IP31 Smoke Color

(VDSWS-T)

Plexiglas weather shield increases the weather

resistance of VMC1VDS-BZ/S to IP31

Clear (DSWS)

19

Page 22

Appendix A – Available Components

Mounting bracket for VMC1 Master

Steel (VMC1MB)

Rough in kit for the VMC1 Master.

Includes mounting frame,

TE6D power supply,

FM Dipole antenna,

AM antenna wire and

installation hardware

(VMC1H)

Metal mounting box for room and video stations

except VMC1VDS

(VMC1HR Steel)

Model H275 Universal Bracket for

Data Hub Installation

20

Indoor Box Color Camera

(left) & Color Video Cameras w/nite vision (right)

(MLTL2DN49IR)

Page 23

Appendix A – Available Components

Electronic Door Release

w/power supplies

Remote Door Lock

(DRW)

12V Control Output switched 110V outlets for

lights and other “notifi cation” devices

Remote Turn On for Lights

AC1 (1 outlet) AC3 (2 outlets)

MFG: Xantec/Niles

2-Channel Receiver (DXR-702)

Miniature door / window transmitter

(DXS-32)

Wire Relay

The 284 Leaded Accessory Relay is a 5 amp

Form C relay with wire leads pre-attached.

(0-200284)

Video Modulator and distribution hub to transmit

door camera image to TV or get Video on TV

Single channel video modulator

(5415)

For more parts and accessories, please go to

www.linearcorp.com

21

Page 24

2 - Year Limited Warranty

Linear LLC warrants these products to be free of defects for

2 years. The warranty period begins on either (a) the date of

purchase or installation date of this product or (b) the date

of closing on a new residence in which this product was

originally installed. The warranty extends to the original user

of the product and to each subsequent owner of the product

during the term of the warranty. Linear LLC will repair or

replace, at its option, parts and materials at no charge. Parts

supplied under this warranty may be new or rebuilt at the

option of Linear LLC.

If during the warranty period the product appears to have a

defect, please call our toll free service number (800-421-1587)

prior to dismantling. Dismantling the product prior to

calling our service number may void the warranty. Before

returning any product to Linear LLC, contact your local dealer

or distributor. Linear LLC will return the repaired product

freight prepaid within the continental United States. There

are no obligations or liabilities on the part of Linear LLC for

consequential damages arising out of or in connection with

use or performance of this product or other indirect damages

with respect to loss of property, revenue, or profi t, or cost of

removal, installation, or reinstallation.

ANY PRODUCT RETURNED TO LINEAR LLC WITHOUT A

RPA NUMBER WILL BE REFUSED. This limited warranty is in

lieu of any other warranties, express or implied, including

any implied warranty of merchantability or fi tness for a

particular purpose or otherwise, and of any other obligations

or liability on the seller’s part. This limited warranty does

not cover damage caused by improper installation, acts

of God, criminal acts, the violation of applicable building

or electrical codes or the use of non-recommended

wire, cable (excluding Cat-5 and RG-6) or wall housings.

Under no circumstances shall Linear LLC be liable for

consequential, incidental or special damages arising in

connection with use, or inability to use this product. In no

event shall Linear LLC liability hereunder exceed the cost of the

product covered hereby. No person is authorized to assume

for us or obligate us for any other liability in connection

with the sale of this product. Some states do not allow the

exclusion or limitation of consequential, incidental or special

damages, so the above limitation or exclusion may not apply

to you. This limited warranty gives you specifi c legal rights,

and you may also have other rights, which vary from state to

state. This Linear LLC Warranty is in lieu of all other warranties

express or implied.

USA & Canada (800) 421-1587 & (800) 392-0123

(760) 438-7000 - Toll Free FAX (800) 468-1340

www.linearcorp.com

Copyright © 2012 Linear LLC 233254 AX3

Loading...

Loading...