Page 1

Commercial Door Operators

External Entrapment Protection Devices

UL325 2010 requires the use of approved monitored

external entrapment protection devices or the operator

must be constant pressure to close. Linear offers a broad

range of approved devices:

Linear Photo Eyes:

Easy to adjust, 25’ range

OPTOEDGE by FRA BA:

Field configurable enclosed

optical edge

MillerEdge (ME and MT Families):

Many different edge styles with

monitoring

The v2010 Solid State Controller

It’s not just a board, it’s an entire system!

Linear commercial door operators feature a solid state

controller that reduces complexity of the operator and

simplifies installation. It makes the operator ready

right out of the box for most applications and reduces

the “learning curve” for new installers. Many options

are built-in so they don’t require special ordering from

the factory. (Controller board not applicable to Model

LCO75.)

FE ATU R E S

• Used in single and 3-phase operators

• UL325 Listed

• Rated for continuous duty

• Reduces operator complexity

• Simplifies installation

• Reduces the “learning curve” for new installers

• Diagnostic LED indicators

• Wire harness connections for ease of service,

no point-to-point wiring

• On-board OPEN/CLOSE/STOP buttons for service

and adjustments

• Terminals labeled and grouped by function

• Six selectable operating modes; B2, C2, E2, etc.

• Seven adjustable features

• Auto-detect monitored photo beam or optical sensing

edge for simplified installation

• Plug-in MVP receiver module compatible with Allstar

& MVP transmitters

• Field adjustable built-in functions; timer to close, mid-stop,

delay on reverse, maximum run time, etc.

• Single (five relay) replacement board services all Linear

solid state commercial door operators

• Logic functions controlled by microprocessor

• Permanent memory saves user settings even if power

is removed

• Finger-safe high voltage connection for power and motor

• Rated for horsepower and voltage

• Configured for motor type

• Can control contactor for high HP applications

• Only two limits required; open & close

• Close limit functions as reversing cutout and close limit

• Provision for interlock (disconnect, pass-door, etc.)

OPTOEYE by FRA BA:

NEMA4 photo eyes, uses common

emitter/detector with the OPTOEDGE

Page 2

Commercial Door Operators

CDO Series Selection Guide

Match the Duty to the Door

Selecting the correct commercial operator and accessories

for your specific application is a straight forward process:

Just follow these three easy steps:

1 From the chart, find the Series of the model which fits the general

specifications for your application. Then turn to the section in

this book which includes the models and specifications for that

series.

2 From the Models and Specifications Charts, choose the correct

operator for your specific application. Consult the features listed

as required. For unusual applications, call Linear for technical

assistance.

Light Duty

13 Cycles/Hour

50 Cycles/Day

Medium Duty

10 Cycles/Hour

75 Cycles/Day

Heavy Duty

Continuous Cycling

25 Cycles/Hour

100 Cycles/Day

3 Choose the options your specific application requires from the

Standard Lift Sectional

Doors

LCO - -

MD MJ MH

T

information listed in the Model and Specifications Charts. For

center mount and rolling steel doors, determine the door size,

shaft diameter, keyway, and number of door shaft turns to fully

open the door.

Vertical & High Lift

Sectional Doors

MGH

J

H

Rolling Steel

Curtain Doors

MGH

H

Extended Duty

Applications

35 Cycles/Hour

100+ Cycles/Day

Extra Heavy Duty

Applications

35 Cycles/Hour

150+ Cycles/Day

AUD AUJ AUH

GT MO MO

Page 3

Commercial Door Drawbar Operators

Product No. LC O75

DOOR TYPE

Fiberglass 250

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

MAXIMUM DOOR

AREA (SQ. FEET)

210

180

120

LCO75

Light Duty Drawbar Commercial Door Operator

3/4 HP Drawbar garage door operator for standard lift sectional

doors.

RATING S

• 115 VAC, Single phase, 3/4 HP only

• Maximum duty cycle: 13 cycles per hour, 50 cycles per day

• Maximum door height: 14 feet

• Shipping weight: 63 lbs.

FE ATU R E S

• Noise-reducing technology for quieter operation

• Quick release door arm for manual operation

• Automatic reconnect trolley

• Standard door speed is approximately 9 inches per second

• Standard rail and chain assemblies for 8, 10, 12, and 14 foot doors

• Motor thermal overload protection

• Torque sensing reversing

• Solid state control circuitry

• Deluxe lighted wall station

• 3-Button MegaCode transmitter

• Built-in MegaCode receiver

• Includes infrared photo eye safety beam

• Dual courtesy lights

RAIL OPTIONS

• 12-foot rail (includes HCI12 12’ chain I-rail)

• 14-foot rail (includes HCI12 12’ chain I-rail

and HCI+2 2’ chain I-rail extension)

• CHCR-10 bolt-on I-rail conversion kit for carriage house doors,

fits HCT10C 10-ft chain drive rail

WARRANTIES

• Lifetime — Motor

• 5 years — Chain

• 5 years — Mechanical parts

• 1 year — Electrical

Page 4

Product No. M D50 11S

DOOR TYPE

Fiberglass 310

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 100

MAXIMUM DOOR

AREA (SQ. FEET)

260

225

150

Commercial Door Drawbar Operators

MD Series

Medium Duty Drawbar Commercial Door Operator

1/2 HP Drawbar garage door operator for standard lift sectional

doors.

RATING S

• 115 VAC, Single phase, 1/2 HP only

• Maximum duty cycle: 10 cycles per hour, 75 cycles per day

• Maximum door height: 14 feet

• Shipping weight: 115 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All Steel Frame

• V-Belt drive from motor to clutch shaft

• Adjustable friction clutch

• Full #65 Roller Chain Drive

• Quick release door arm for manual door operation

• Standard door speed is approximately 11 inches per second

• Standard rail & chain assembly for door up to 12’ 6” high

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• 1/2 HP rigid base permanent split capacitor motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

RAIL OPTIONS

• Rail for up to 14’ 6” high doors

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• Solenoid brake: Add -BK to model number

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 5

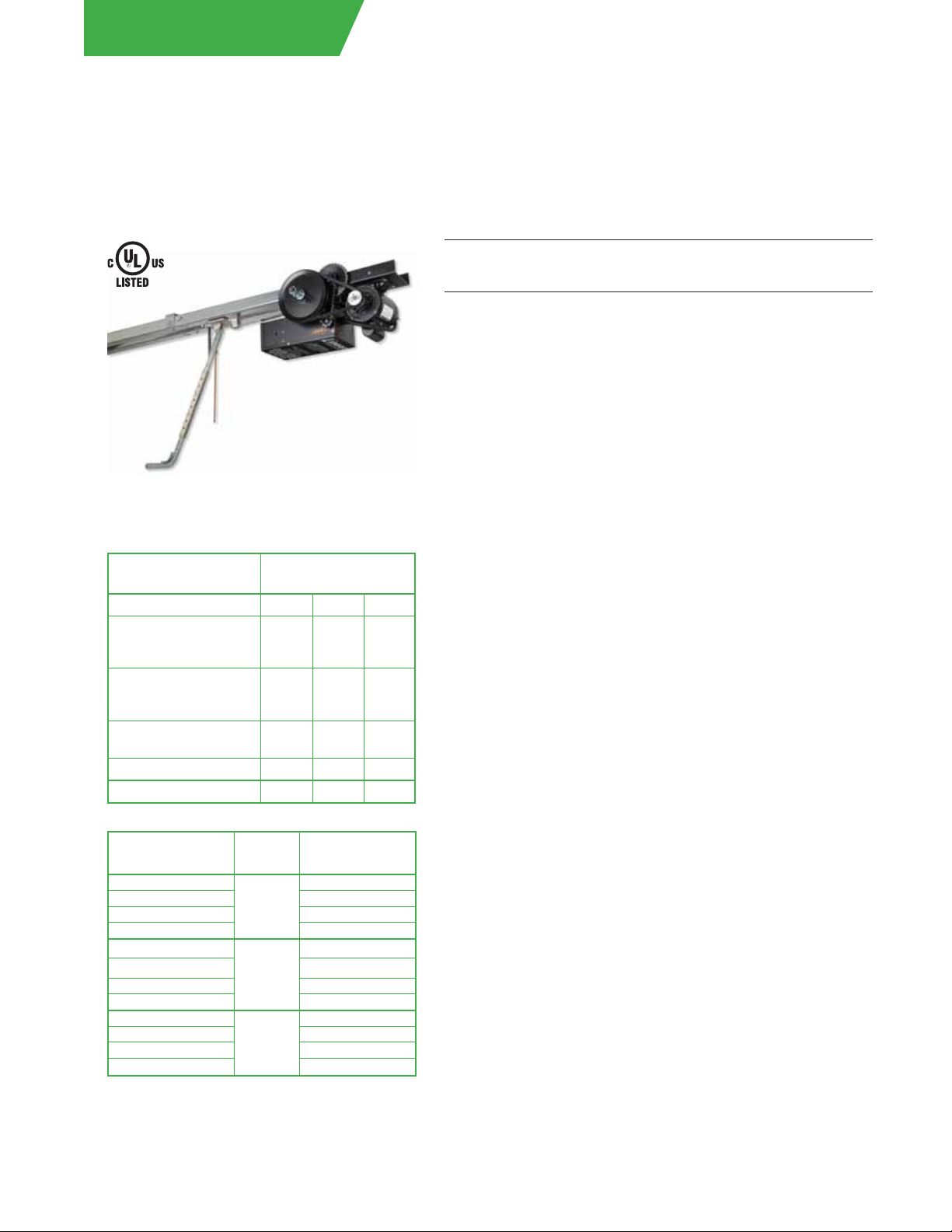

Commercial Door Drawbar Operators

Product No. See table below

DOOR TYPE

Fiberglass 310 420 570

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 125 200 280

Operator size to use 1/3 HP 1/2 HP 3/4 HP

MODEL HP

T3311S

T3321S 230V 1P

T3323S 230V 3P

T3343S 460V 3P

T5011S

T5021S 230V 1P

T5023S 230V 3P

T5043S 460V 3P

T7511S

T7521S 230V 1P

T7523S 230V 3P

T7543S 460V 3P

MAXIMUM DOOR

AREA (SQ. FEET)

285 350 520

260 320 480

175 250 380

VOLTAGE &

PHASE

115V 1P

1/3

115V 1P

1/2

115V 1P

3/4

T Series

Heavy-Duty Drawbar Commercial Door Operator

Heavy-duty drawbar garage door operator for standard lift

sectional doors.

RATING S

• Maximum duty cycle: 25 cycles per hour, 100 cycles per day

• Maximum door height: 22-1/2 feet

• Shipping weight: 135 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All welded steel frame

• 5L V-Belt drive from motor to clutch shaft

• #65 Roller chain on 1/3 and 1/2 HP

• #41 Roller chain on 3/4 HP

• Quick disconnect door arm for manual door operation

• Solenoid brake standard on 3/4 HP (optional on 1/3 & 1/2 HP)

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single-button (residential type) radio control

RAIL OPTIONS

• Rail for up to 14’ 6” high doors

• Rail for up to 16’ 6” high doors

• Rail for up to 18’ 6” high doors

• Rail for up to 20’ 6” high doors

• Rail for up to 22’ 6” high doors

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• Solenoid brake: Add -BK to model number

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 6

Product No. See table below

DOOR TYPE

Fiberglass 330 420 570

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 145 225 300

Operator size to use 1/3 HP 1/2 HP 3/4 HP

MODEL HP

AUD3311S

AUD3321S 230V 1P

AUD3323S 230V 3P

AUD3343S 460V 3P

AUD5011S

AUD5021S 230V 1P

AUD5023S 230V 3P

AUD5043S 460V 3P

AUD7511S

AUD7521S 230V 1P

AUD7523S 230V 3P

AUD7543S 460V 3P

MAXIMUM DOOR

AREA (SQ. FEET)

310 395 540

280 340 500

195 275 400

VOLTAGE &

PHASE

115V 1P

1/3

115V 1P

1/2

115V 1P

3/4

Commercial Door Drawbar Operators

AUD Series

Extended-Duty Drawbar Commercial Door Operator

Extended-duty drawbar garage door operator for standard lift

sectional doors.

RATING S

• Maximum duty cycle: 35 cycles per hour, 100+ cycles per day

• Maximum door height: 22-1/2 feet

• Shipping weight: 130 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All Steel frame

• Adjustable friction clutch

• 3/4” Shafting used throughout

• #65 Roller chain on 1/3 HP

• #41 Roller chain on 1/2, 3/4 HP

• Solenoid brake standard on 3/4 HP (optional on 1/3 & 1/2 HP)

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

RAIL OPTIONS

• Rail for up to 14’ 6” high doors

• Rail for up to 16’ 6” high doors

• Rail for up to 18’ 6” high doors

• Rail for up to 20’ 6” high doors

• Rail for up to 22’ 6” high doors

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• Solenoid brake: Add -BK to model number

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 7

Commercial Door Drawbar Operators

Product No. See table below

DOOR TYPE

Fiberglass 420 570 625

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 200 280 325

Operator size to use 1/2HP 3/4HP 1HP

MODEL HP

GT5011S

GT5021S 230V 1P

GT5023S 230V 3P

GT5043S 460V 3P

GT7511S

GT7521S 230V 1P

GT7523S 230V 3P

GT7543S 460V 3P

GT10011S

GT10021S 230V 1P

GT10023S 230V 3P

GT10043S 460V 3P

MAXIMUM DOOR

AREA (SQ. FEET)

350 520 575

320 480 525

250 380 425

VOLTAGE &

PHASE

115V 1P

1/2

115V 1P

3/4

115V 1P

1

GT Series

Extra Heavy-Duty Gear Reduced Drawbar Commercial

Door Operator

Extra heavy-duty gear reduced drawbar garage door operator

for standard lift sectional doors.

RATING S

• Maximum duty cycle: 35 cycles per hour, 150+ cycles per day

• Maximum door height: 22-1/2 feet

• Shipping weight: 170 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All steel frame

• Oil bath gear reduction unit

• Quick disconnect door arm for manual door operation

• #41 roller chain drive

• Standard door speed approximately 11 inches per second

• Adjustable Torque Converter

• Solenoid brake standard

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• TEFC Motor standard on single phase 1 HP and over,

and all 3 phase operators

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

RAIL OPTIONS

• Rail for up to 14’ 6” high doors

• Rail for up to 16’ 6” high doors

• Rail for up to 18’ 6” high doors

• Rail for up to 20’ 6” high doors

• Rail for up to 22’ 6” high doors

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 8

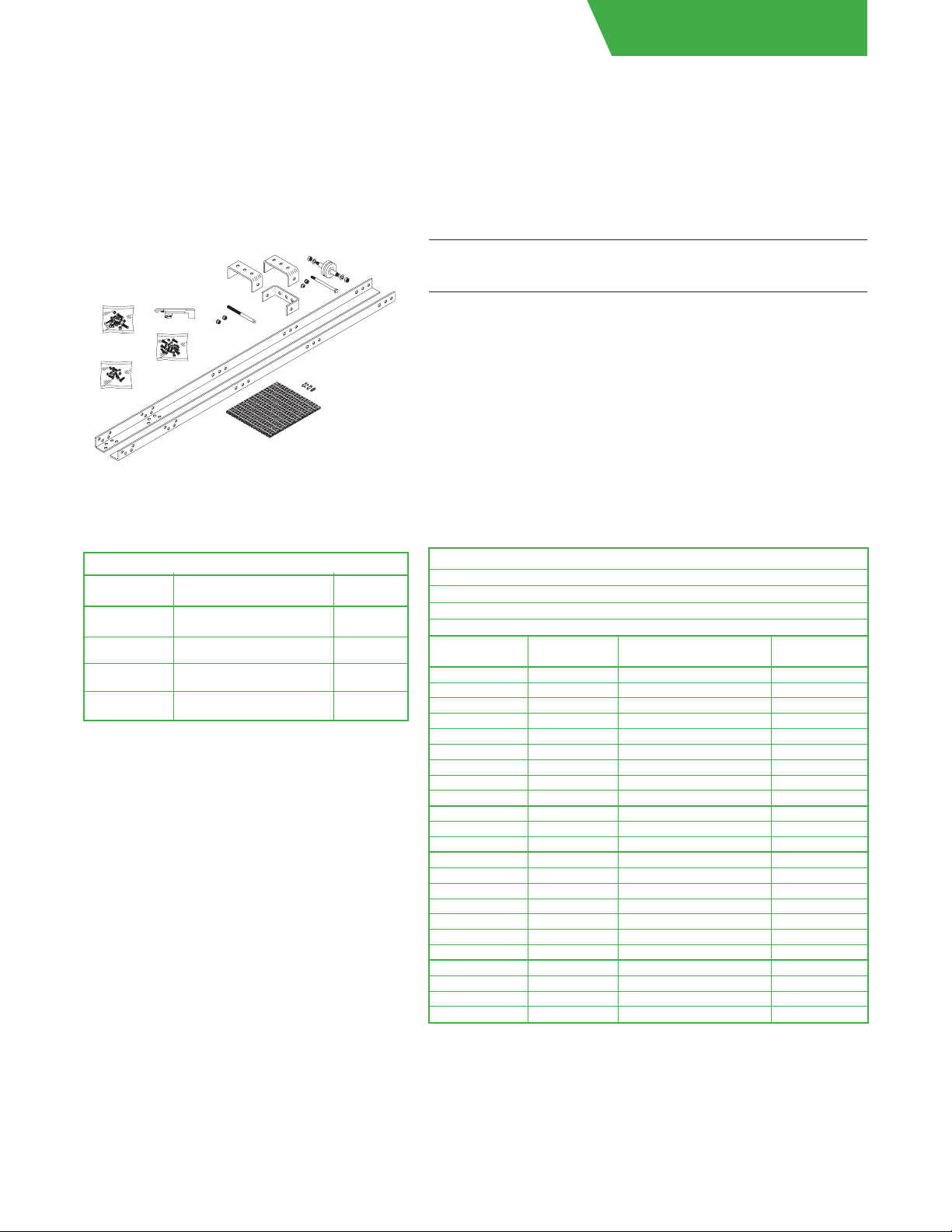

Commercial Door Drawbar Operators

Drawbar Rails & Chains

Rail and Chain/Hardware Kits for Drawbar Operators

Drawbar/trolley operators require: Separately ordered rails and

hardware kits. Longer rail and chain/hardware kits are available.

RAIL SELECTION

• From the first chart, choose a rail length that matches the door height.

Most models fit multiple size doors. They are pre-drilled and marked to

aid in cutting the rail to the desired length to fit the installation.

• Order two of the rail part numbers for each operator installation. One

part will become the left side, and the other part will become the right

side after the rail is assembled.

• From the second chart, choose a chain/hardware Kit that has the

correct size chain for the operator, and the correct length of chain for

the door height. Weather resistant nickel chain is also available in select

lengths for rough service applications. The chain/hardware Kits include

brackets, hardware, and chain.

OPERATOR RAILS (ORDER TWO PER OPERATOR)

PART

NUMBER

190-107358 10-FOOT 12-FOOT, OR 14-

190-106719 16-FOOT OR 18-FOOT 2” x 2” x

190-106721 20-FOOT OR 22-FOOT 2” x 2” x

190-106722 24 FOOT 2” x 2” x

FITS DOOR HEIGHT UNCUT

SIZE

FOOT

2” x 2” x

204”

252”

300”

324”

CHAIN / HARDWARE KITS (ORDER ONE PER OPERATOR)

Model MD: Uses #65 Chain

Model AUD: Uses #65 Chain on 1/3 HP, #41 Chain on higher HP

Model T: Uses #65 Chain on 1/3 & 1/2 HP, #41 Chain on higher HP

Model GT: Uses #41 Chain for all HP

PART

NUMBER

190-106936 #41 Standard 8-FOOT

190-106938 #41 Standard 10-FOOT

190-106940 #41 Standard 12-FOOT

190-106942 #41 Standard 14-FOOT

190-106944 #41 Standard 16-FOOT

190-106946 #41 Standard 18-FOOT

190-106948 #41 Standard 20-FOOT

190-106774 #41 Standard 22-FOOT

190-110082 #41 Standard 24-FOOT

190-108452 #41 Weather resistant nickel chain 12-FOOT

190-108454 #41 Weather resistant nickel chain 14-FOOT

190-108954 #41 Weather resistant nickel chain 16-FOOT

190-106935 #65 Standard 8-FOOT

190-106937 #65 Standard 10-FOOT

190-106939 #65 Standard 12-FOOT

190-106941 #65 Standard 14-FOOT

190-106943 #65 Standard 16-FOOT

190-106945 #65 Standard 18-FOOT

190-106947 #65 Standard 20-FOOT

190-107880 #65 Weather resistant nickel chain 10-FOOT

190-108451 #65 Weather resistant nickel chain 12-FOOT

190-108453 #65 Weather resistant nickel chain 14-FOOT

190-109009 #65 Weather resistant nickel chain 16-FOOT

CHAIN SIZE CHAIN TYPE DOOR

HEIGHT

Page 9

Commercial Door Jackshaft Operators

Equipped with

Product No. M J50 11S

DOOR TYPE

Fiberglass 320

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 120

Floor Level Disconnect

MAXIMUM DOOR

AREA

(SQ. FEET)

275

250

160

MJ Series

Medium Duty Jackshaft Commercial Door Operator

1/2 HP Jackshaft garage door operator for vertical and high lift

sectional doors.

RATING S

• 115 VAC, Single phase, 1/2 HP only

• Maximum duty cycle: 10 cycles per hour, 75 cycles per day

• Maximum door height: 14 feet

• Shipping weight: 60 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• Solenoid brake standard

• All steel frame

• V-belt drive from motor to clutch shaft

• Adjustable friction clutch

• Floor level disconnect for manual door operation

• Manual operation will not affect limit switch settings

• 41B30 door sprocket and #41 drive chain supplied

• Standard door speed is approximately 11 inches per second

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• 1/2 HP rigid base permanent split capacitor motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver installed

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 10

Product No. M H50 11S

Equipped with

Chain Hoist and

Floor Level Disconnect

MAXIMUM DOOR

DOOR TYPE

AREA

(SQ. FEET)

Fiberglass 320

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 120

275

250

160

Commercial Door Jackshaft Operators

MH Series

Medium Duty Jackshaft Commercial Door Operator

1/2 HP Jackshaft garage door operator for rolling steel curtain

doors.

RATING S

• 115 VAC, Single phase, 1/2 HP only

• Maximum duty cycle: 10 cycles per hour, 75 cycles per day

• Maximum door height: 14 feet

• Shipping weight: 80 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• Solenoid brake standard

• All steel frame

• V-belt drive from motor to clutch shaft

• Adjustable friction clutch

• Floor level disconnect for manual door operation

and chain hoist with interlock

• Manual operation will not affect limit switch settings

• 41B30 door sprocket and #41 drive chain supplied

• Standard door speed is approximately 11 inches per second

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• 1/2 HP rigid base permanent split capacitor motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type)

radio control

COMMON OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 11

Commercial Door Jackshaft Operators

Equipped with

Product No. See table below

DOOR TYPE

Fiberglass 330 420 570 700

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 145 225 300 310

Operator size to use 1/3 HP 1/2 HP 3/4 HP 1 HP

MODEL HP

J3311S

J3321S 230V 1P

J3323S 230V 3P

J3343S 460V 3P

J5011S

J5021S 230V 1P

J5023S 230V 3P

J5043S 460V 3P

J7511S

J7521S 230V 1P

J7523S 230V 3P

J7543S 460V 3P

J10023S

J10043S 460V 3P

Floor Level Disconnect

MAXIMUM DOOR AREA

(SQ. FEET)

310 375 540 625

280 340 500 560

195 275 400 420

VOLTAGE &

PHASE

115V 1P

1/3

115V 1P

1/2

115V 1P

3/4

1

230V 3P

J Series

Heavy-Duty Jackshaft Commercial Door Operator

Heavy-duty jackshaft garage door operator for vertical and

high lift sectional doors.

RATING S

• Maximum duty cycle: 25 cycles per hour,

100 cycles per day

• Maximum door height: 24 feet

• Shipping weight: 85 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All Steel Frame

• All gears and pulleys pinned or keyed

• Adjustable friction type clutch

• Floor level disconnect

• #50 Drive sprocket and chain

• Solenoid brake standard

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single-button (residential type)

radio control

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver installed

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 12

Equipped with

Chain Hoist and

Floor Level Disconnect

Product No. See table below

DOOR TYPE

Fiberglass 330 420 570 700

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 145 225 300 310

Operator size to use 1/3 HP 1/2 HP 3/4 HP 1 HP

MODEL HP

H3311S

H3321S 230V 1P

H3323S 230V 3P

H3343S 460V 3P

H5011S

H5021S 230V 1P

H5023S 230V 3P

H5043S 460V 3P

H7511S

H7521S 230V 1P

H7523S 230V 3P

H7543S 460V 3P

H10023S

H10043S 460V 3P

MAXIMUM DOOR AREA

(SQ. FEET)

310 375 540 625

280 340 500 560

195 275 400 420

VOLTAGE &

PHASE

115V 1P

1/3

115V 1P

1/2

115V 1P

3/4

1

230V 3P

Commercial Door Jackshaft Operators

H Series

Heavy-Duty Jackshaft Commercial Door Operator

Heavy-duty jackshaft garage door operator for vertical or high lift

sectional doors and rolling steel curtain doors.

RATING S

• Maximum duty cycle: 25 cycles per hour,

100 cycles per day

• Maximum door height: 24 feet

• Shipping weight: 105 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed (see Page 30)

• All Steel Frame

• All gears and pulleys pinned or keyed

• Adjustable friction type clutch

• Chain hoist with electrical interlock

• Floor level disconnect

• #50 Drive sprocket and chain

• Solenoid brake standard

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single-button (residential type) radio control

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver

installed: P/N 2650-159

WARRANTY

• 2 years

Page 13

Commercial Door Jackshaft Operators

Equipped with

Floor Level Disconnect

Product No. See table below

MAXIMUM

DOOR TYPE

Fiberglass 330 420

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 145 225

Operator size to use 1/3 HP 1/2 HP

MODEL HP

AUJ3311S

AUJ3321S 230V 1P

AUJ3323S 230V 3P

AUJ3343S 460V 3P

AUJ5011S

AUJ5021S 230V 1P

AUJ5023S 230V 3P

AUJ5043S 460V 3P

1/3

1/2

DOOR AREA

(SQ. FEET)

310 375

280 340

195 275

VOLTAGE &

PHASE

115V 1P

115V 1P

AUJ Series

Extended-Duty Jackshaft Commercial Door Operator

Extended-duty jackshaft garage door operator for vertical and

high lift sectional doors.

RATING S

• Maximum duty cycle: 35 cycles per hour, 100+ cycles per day

• Maximum door height: 24 feet

• Shipping weight: 90 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All Steel frame

• Adjustable friction clutch

• 3/4” Shafting and 1” Jackshaft

• Pillow block bearings on output shaft

• Floor level disconnect

• #41 Chain and Sprocket, 1/3 & 1/2 HP

• Solenoid brake standard

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-buttonstation

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver

installed: P/N 2650-159

WARRANTY

• 2 years

Page 14

Equipped with

Chain Hoist and

Floor Level Disconnect

Product No. See table below

DOOR TYPE

Fiberglass 330 420 570 700

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 145 225 300 310

Operator size to use 1/3 HP 1/2 HP 3/4 HP 1 HP

MODEL HP

AUH3311S

AUH3321S 230V 1P

AUH3323S 230V 3P

AUH3343S 460V 3P

AUH5011S

AUH5021S 230V 1P

AUH5023S 230V 3P

AUH5043S 460V 3P

AUH7511S

AUH7521S 230V 1P

AUH7523S 230V 3P

AUH7543S 460V 3P

AUH10023S

AUH10043S 460V 3P

MAXIMUM DOOR AREA

(SQ. FEET)

310 375 540 625

280 340 500 560

195 275 400 420

VOLTAGE &

PHASE

115V 1P

1/3

115V 1P

1/2

115V 1P

3/4

1

230V 3P

Commercial Door Jackshaft Operators

AUH Series

Extended-Duty Jackshaft Commercial Door Operator

Heavy-duty jackshaft garage door operator for rolling steel

curtain doors.

RATING S

• Maximum duty cycle: 35 cycles per hour, 100+ cycles per day

• Maximum door height: 24 feet

• Shipping weight: 110 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• All Steel frame

• Adjustable friction clutch

• 3/4” Shafting and 1” Jackshaft

• Pillow block bearings on output shaft

• Chain hoist with interlock and floor level disconnect

• #41 Chain and Sprocket, 1/3 & 1/2 HP

• #40 Chain and Sprocket, 3/4 & 1 HP

• Solenoid brake standard

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver

installed: P/N 2650-159

WARRANTY

• 2 years

Page 15

Commercial Door Jackshaft Operators

Equipped with

Chain Hoist and

Floor Level Disconnect

Product No. See table below

DOOR TYPE

Fiberglass 325 480 650

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga.

insulated

Steel-16 Ga.

Steel-20 Ga.

insulated

Steel-16 Ga.

insulated

Operator size to

use

MODEL HP

MO5011S

MO5021S 230V 1P

MO5023S 230V 3P

MO5043S 460V 3P

MO7511S

MO7521S 230V 1P

MO7523S 230V 3P

MO7543S 460V 3P

MO10011S

MO10021S 230V 1P

MO10023S 230V 3P

MO10043S 460V 3P

MO15011S

MO15021S 230V 1P

MO15023S 230V 3P

MO15043S 460V 3P

MO20023S

MO20043S 460V 3P

MAXIMUM DOOR AREA (SQ.

300 430 560

275 390 500 680

225 275 325 425 560

175 225 300 375 460

1/2 HP3/4

1-1/2

1/2

3/4

FEET)

1 HP

HP

1

2

1-1/2

2 HP

HP

VOLTAGE &

PHASE

115V 1P

115V 1P

115V 1P

115V 1P

230V 3P

MO Series

Extra Heavy-Duty Gearhead Jackshaft Commercial

Door Operator

Extra heavy-duty gearhead jackshaft garage door operator

for vertical or high lift sectional doors and rolling steel

curtain doors.

RATING S

• Maximum duty cycle: 35 cycles per hour, 150+ cycles per day

• Maximum door height: 24 feet

• Shipping weight: 135 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no

entrapment devices are installed

• Oil bath gear reduction unit

• Chain hoist with electrical interlock

• #50 Chain and sprocket, 1/2 - 1HP

• #60 Chain and sprocket, 1-1/2 - 2HP

• Solenoid brake standard

• TEFC Motor standard on single phase 1 HP

and over, and all 3 phase operators

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type)

radio control

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• Hood mounting bracket: P/N 190-107209

• Wall mounting bracket: P/N 190-107638

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 16

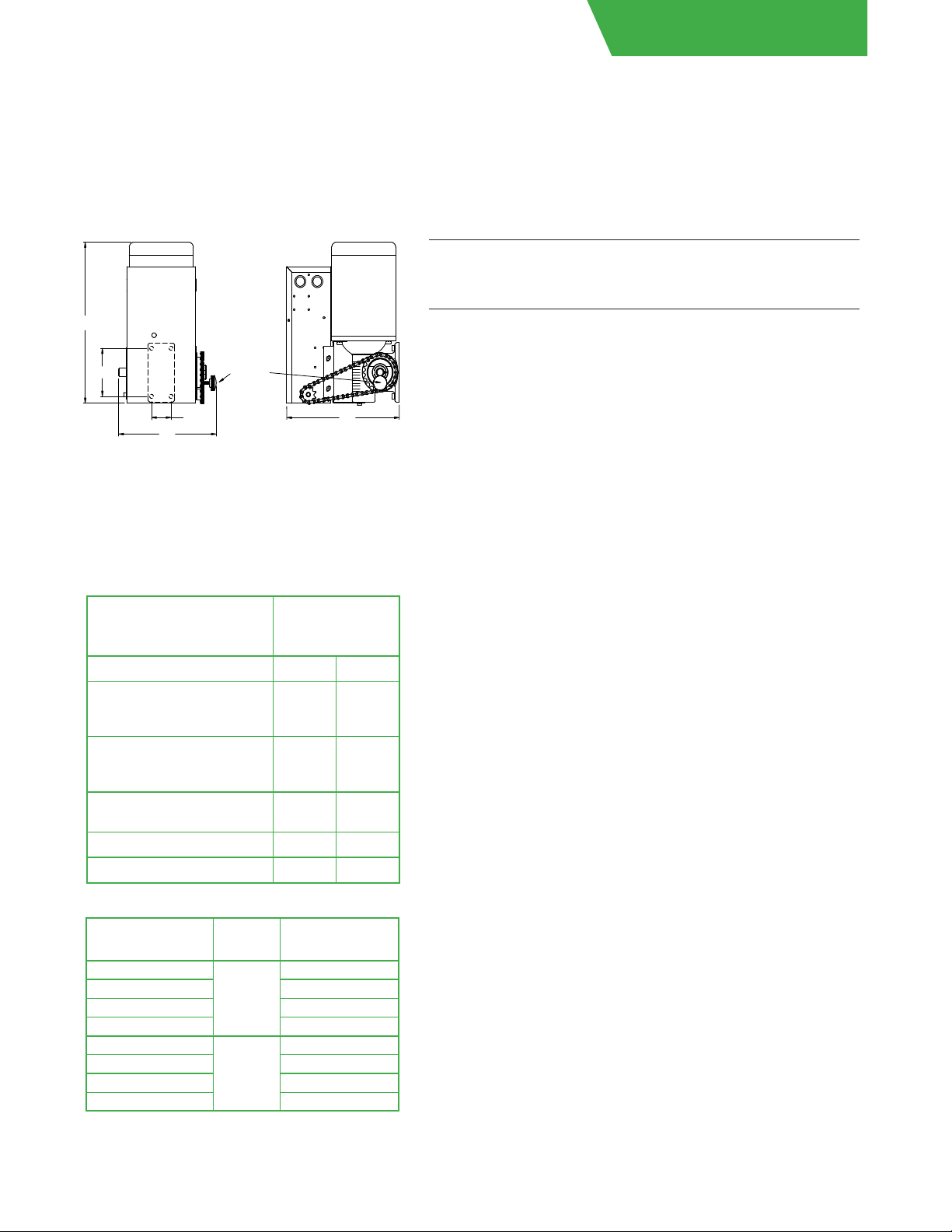

Commercial Door Jackshaft Operators

MGH Series

Special Service Gearhead Jackshaft Commercial

Door Operator

A = 15.5”

B = 4.5”

C = 2.0”

D = 10.25”

A

B

D

Product No. See table below

E = 11.63”

TORQUE

LIMITER

ADJUSTMENT

KNOB

C

E

MAXIMUM

DOOR TYPE

DOOR AREA

(SQ. FEET)

Fiberglass 280 420

Steel-24 Ga.

Steel-22 Ga.

Aluminum

Wood

Steel-20 Ga.

Steel-24 Ga. insulated

Steel-16 Ga.

Steel-20 Ga. insulated

Steel-16 Ga. insulated 120 160

Operator size to use 1/3 HP 1/2 HP

MODEL HP

MGH3311S

MGH3321S 230V 1P

MGH3323S 230V 3P

1/3

230 320

200 280

160 220

VOLTAGE &

PHASE

115V 1P

MGH3343S 460V 3P

MGH5011S

MGH5021S 230V 1P

MGH5023S 230V 3P

1/2

115V 1P

MGH5043S 460V 3P

Special service gearhead jackshaft garage door operator for

vertical or high lift sectional doors and rolling steel curtain

doors.

RATING S

• Maximum duty cycle: 25 cycles per hour, 100 cycles per day

• Maximum door height: 18 feet

• Shipping weight: 70 lbs.

FE ATU R E S

• Solid state control circuit

• Constant pressure required to close if no entrapment

devices are installed

• Oil-bath worm gear reduction unit

• Self locking gearing

• Adjustable torque limiter

• Release for manual operation

• Motor overload protection

• Wired to accept reversing devices

• Internally adjustable limit switches

• High starting torque, continuous duty motor

• 24-Volt control circuit with OPEN, CLOSE

and STOP 3-button station

• OPEN button (and single button) will automatically override

down travel and reverse door to the full open position

• External terminals for single button (residential type) radio control

• TEFC Motor standard on all 3 phase operators

FACTORY OPTIONS

• Linear Photo Beam Kit: HAE00056

• MVP-MR 3-channel open-close-stop modular receiver installed:

P/ N 2 6 50 -159

WARRANTY

• 2 years

Page 17

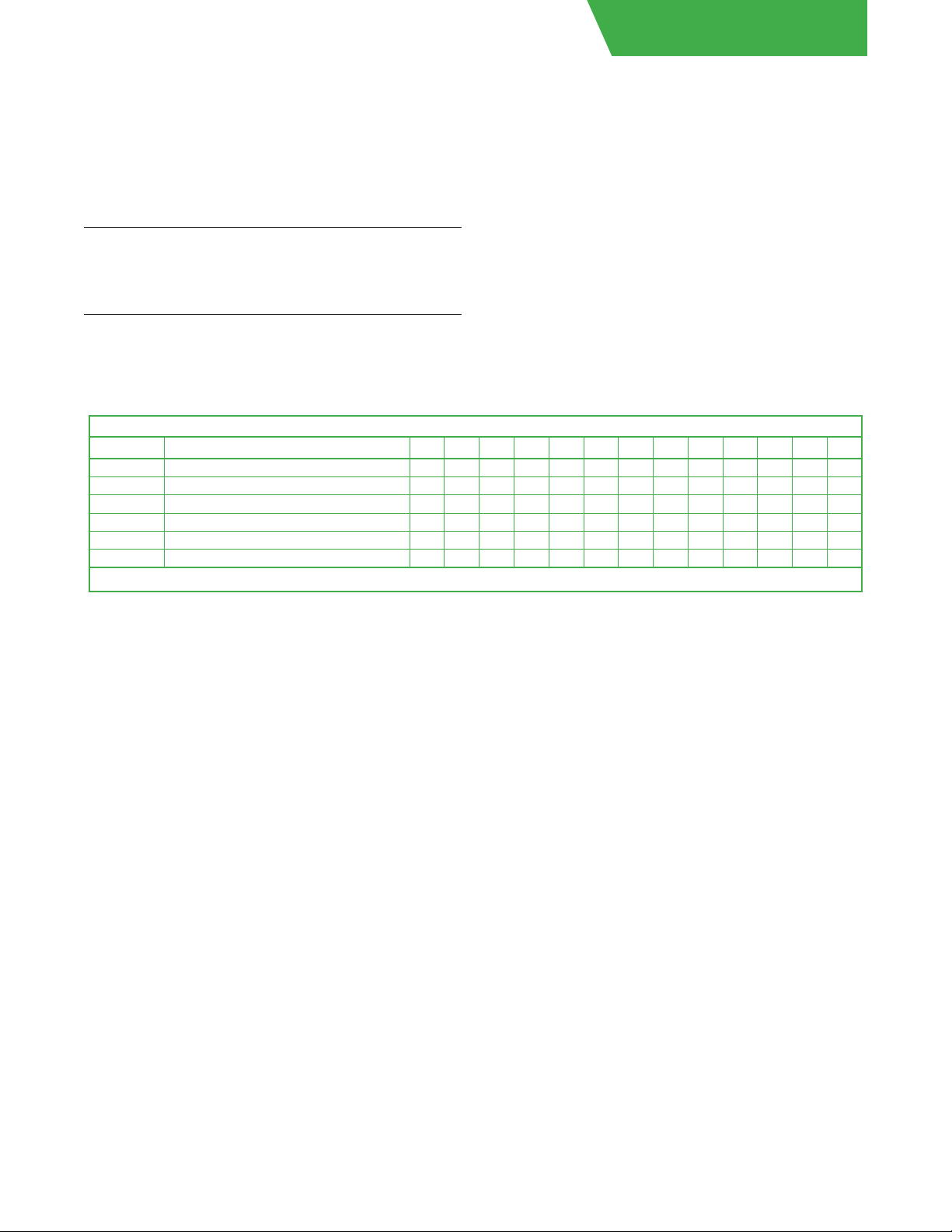

Commercial Door Operator Options

Factory Options

Drive Train Modification Selection Guide

When ordering a commercial door operator, there are

several options for specific applications that can be

selected. Most of these options are factor y installed

modifications, some may require assembly in the field.

will be required for the application. Each option is

explained in the chart.

2 Looking at the chart, verify that the modification

desired is available for the model of operator being

ordered. Some modifications are not compatible with

certain models.

3 Add the modification part number to your operator order.

Some modifications are ordered by simply adding the

part number to the end of the operator’s part number.

DRIVE TRAIN MODIFICATION SELECTION CHART

PART # DESCRIPTION LCO MD T AUD GT MJ MH J H AUJ AUH MO MGH M6H

1 From the chart below, choose the factory options that

-BK

-FC

-BB

-XBK

-DC

-CM

-50 #50 Drive Chain and Sprockets in lieu of #41

Solenoid Brake

Adds a solenoid activated brake to prevent door from

drifting down after stopping

Friction Clutch

Adjustable clutch to control door force

High Cycle Roller Bearing Modification

Operator bearings are for high cycle service

External Brake Shoe Modification

Provides a single external shoe brake on motor, 115 V

only, No charge on 3/4 HP or larger units

Direct Couple - Side Mount

Connects output shaft directly to door torsion bar

Center Mount Modification

Modifies operator for center mounting

◆ ✜◆

◆

◆ ◆ ◆ ◆ ◆ ◆

◆ ◆ ◆ ♣ ◆ ♣ ♣ ♣ ♣

S S S S S S S S S

✜

◆ ◆

◆ ◆

◆ ◆

◆

-60 #60 Drive Chain and Sprockets in lieu of #50

190-101524

190-106472

190-104034

190-109645

190-109646

190-109648

190 -109829

190-107016

190-109155

◆ = Available for the operator model

★ = Field assembly required † = Field assembly required, add to order one rail kit and two rails ‡ = Field assembly required, add to

order two rail kits and four rails ♣ = No charge on these operators, regardless of HP

Shaft Support Bracket Kit ★

Chain tension kit to reduce drive chain slack,

For 1” diameter shafts ONLY

Chain Hoist for Drawbar Operator ★

Hoist for drawbar operators with #41 chain

Auxiliary Hoist ★

Hoist for center mount jackshaft operators

Auxiliary Trolley Kit †

Single drawbar/trolley conversion kit for jackshaft

operators, #41 chain, (12’ 6” rail adder applies)

Dual Auxiliary Trolley Kit ‡

Dual drawbar/trolley conversion kit for jackshaft

operators, #41 chain, (12’ 6” rail adder applies)

Dual Trolley Drive Kit ‡

Adds second drawbar/trolley to drawbar operator, #41 or

#65 chain, (12’ 6” rail adder applies)

Minimum Depth Modification

Places head parallel to rail to reduce tail overhang, #41

chain

Slow Door Speed Modification

Modification to slow operator, #65 chain

Slow Door Speed Modification

Modification to slow operator, #41 chain

Rolling Steel Door Modification

Modifies operator for rolling steel door

S = Standard equipment for the operator model ✜ = Standard equipment for 3/4 & 1 HP models

◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆

◆ ◆ ◆

◆ ◆ ◆

◆

◆ ◆

◆ ◆

◆ ◆

◆ ◆

◆ ◆ ◆ ◆ ◆

◆ ◆ ◆ ◆ ◆

◆

Page 18

Factory Options

Environmental Modification Selection Guide

Commercial Door Operator Options

When ordering a commercial door operator, there are

several options for specific applications with special

environmental requirements that can be selected.

These options are all factory installed modifications

ENVIRONMENTAL MODIFICATION SELECTION CHART

PART # DESCRIPTION LCO MD AUD T GT MJ MH AUJ AUH J H MO MGH

-TEFC TEFC Motor (Totally Enclosed Fan Cooled)

-N12 Control Enclosure Modification

-N12P NEMA 12/13 Oil-tight/Dust-tight Package

-WASH NEMA 4 Water Resistant Modification

-N4X NEMA 4X Corrosion Resistant Modification

-N7P NEMA 7/9 for Hazardous Locations

◆ = Available for the operator model

Part # -TEFC

TEFC Motor (Totally Enclosed Fan Cooled)

Standard operators (unless otherwise specified) are supplied

with an ODP (Open Drip-proof) motor. The TEFC modification

replaces the ODP motor with a fully enclosed and fan cooled

motor. A fan (not enclosed) is attached to the end of the

motor for cooling purposes. Not available for 1/3 HP motors

Part # -N12

Control Enclosure Modification

This modification provides for all electrical control equipment

on the operator to be enclosed in a dust-tight/oil-tight NEMA

12 Control Enclosure. If the operator would normally be

supplied or is ordered with a solenoid brake, the solenoid

is not considered part of the electrical control equipment (it

has no electrical contact points) and is supplied in a general

purpose enclosure only. This modification is supplied with a

NEMA 1 motor.

Part # -N12P

NEMA 12/13 Oil-tight/Dust-tight Package

Provides more complete protection against water spray,

oil and other fluids than the Water Resistant Modification.

Includes a TEFC Washdown duty motor, a NEMA 12/13 oiltight/dust-tight control enclosure, oil-tight/dust-tight 3-button

control station, nickel plated chain, a delay on reverse circuit

and a dynamic brake replacing the solenoid brake. This

allows the brake to also be enclosed in a oil-tight/dust-tight

enclosure.

1 From the chart below, choose the factory environmental

options that will be required for the application. Each

option is explained in the chart.

2 Looking at the chart, verify that the modification

desired is available for the model of operator being

ordered. Some modifications are not compatible with

certain models.

3 Add the modification part number to the end of the

operator’s part number.

◆ ◆ ◆ ◆ ◆ ◆ ◆ ◆

◆ ◆ ◆ ◆ ◆ ◆

◆ ◆

◆ ◆ ◆ ◆

◆

◆ ◆

Part # -WASH

NEMA 4 Water Resistant Modification

Provides a water resistant motor, NEMA 4/12 water-tight/

oil-tight control enclosure, water-tight/oil-tight 3-button

control station and nickel-plated chain in place of all

standard roller chain on the operator. This operator uses

a water resistant washdown duty motor and should

not be compared to other manufacturer’s “carwash”

operators that have only a standard TEFC motor.

Part # -N4X

NEMA 4X Corrosion Resistant Modification

This modification (available only on the MO series; 230 or 460

VAC, three phase; 1-1/2 hp maximum), provides water-tight/

oil-tight and corrosion resistant components where possible,

and includes a corrosion resistant TENV motor, NEMA 4X

control circuit enclosure, NEMA 4X 3-button control station,

dynamic brake, delay on reverse circuit, nickel plated chain

and corrosion resistant coating on other components of the

operator where possible.

Part # -N7P

NEMA 7/9 for Hazardous Locations

This modification meets requirements as defined by National

Electrical Code for: Class I, Division I & II, Group D; Class II,

Division I & II, Groups F & G. Includes NEMA 7 & 9 3-button

control station. This modification may be provided as a

complete operator package from another manufacturer.

Consult factory for specifics prior to ordering.

Page 19

Commercial Door Operator Accessories

Monitored Entrapment Devices

Commercial Door Operator Photo Beams

HAE00056

Linear Photo Beam Kit

Photo Beams

HAE00056 Linear infrared photo beam kit, 30-foot range,

UL325 2010 Listed, includes adjustable

emitter and detector mounting brackets,

metal beam covers.

2510-476 Optoeye infrared photo beam kit, 45-foot

range, UL325 2010 Listed, NEMA 4 rated,

includes adjustable emitter and detector

mounting brackets, mounting hardware.

2510-47 6

Optoeye Photo Beam K it

Page 20

Monitored Entrapment Devices

Commercial Door Operator Door Edges

OSE Door Edges

2510-477 Optoedge photo edge kit, 30-foot range,

2500-2554 Edge profile “Astragal” door seal for sectional

2510-47 7

Optoedge Photo Edge Kit

2500-2555 Edge profile “Astragal” door seal for rolling

Commercial Door Operator Accessories

UL325 2010 Listed, includes infrared emitter/

detector set, two NEMA 4 weathertight

junction boxes, one 2-conductor 13-foot

extended 24 AWG coil-cord, two adjustable

height door bumpers, one stationary cord

bracket with strain relief, and two sensor

adapter sleeves.

doors, infrared beam passes through profile,

use with 2510-477 Optoedge entrapment

detector.

steel doors, infrared beam passes through

profile, use with 2510-477 Optoedge

entrapment detector.

2510-4 85 -10

Miller Edge with Monitoring Module

Electric Edges

2510-485-10 10-foot Miller edge ME123 with monitoring

module, C channel, mounting hardware, two

junction boxes, 15-foot coil cord.

2510-485-12 12-foot Miller edge ME123 with monitoring

module, C channel, mounting hardware, two

junction boxes, 15-foot coil cord.

2510-485-14 14-foot Miller edge ME123 with monitoring

module, C channel, mounting hardware, two

junction boxes, 15-foot coil cord.

2510-486-10 10-foot Miller edge MT22 with monitoring

module, two junction boxes, 15-foot coil cord.

2510-486-12 12-foot Miller edge MT22 with monitoring

module, two junction boxes, 15-foot coil cord.

2510-486-14 14-foot Miller edge MT22 with monitoring

module, two junction boxes, 15-foot coil cord.

2510-487-10 10-foot Miller edge MU22 with monitoring

module, two junction boxes, 15-foot coil cord.

2510-487-12 12-foot Miller edge MU22 with monitoring

module, two junction boxes, 15-foot coil cord.

2510-487-14 14-foot Miller edge MU22 with monitoring

module, two junction boxes, 15-foot coil cord.

Add-on Monitoring Systems for Electromechanical

Controllers

190-113428 Quik-protect Monitoring System - Monitors up

to two sets of Access Alliance photo beams,

Vitector Optical Sensing Edge (OSE) or Miller

two or four-wire resistive safety edge.

Page 21

Commercial Door Operator Accessories

Control Stations

Interior Controls & Weather-Tight Controls

Linear commercial door operators are designed

to be used with the following control stations to

function as a system. Consult factory for answers

to system design questions.

All accessories are covered by their respective

manufacturer’s warranty. (NOTE: Product may

vary from photo.)

2500-282 2500-288 2500-033

2510 -115

Interior Controls

2500-282 Interior single-button station, surface mount,

NEMA 1

2500-288 Interior 2-button station, surface mount,

OPEN-CLOSE, NEMA 1

2500-033 Interior 3-button station, surface mount,

OPEN-CLOSE-STOP, NEMA 1

2500-1773 Interior 2-button station, flush mount,

OPEN-CLOSE, NEMA 1

2500-691 Interior 3-button station, flush mount,

OPEN-CLOSE-STOP, NEMA 1

2510-115 Interior 3-button station, surface mount,

OPEN-CLOSE-STOP, with lockout toggle

switch, NEMA 1

Weather-Tight Controls

2520-047 Exterior mushroom head pushbutton

(momentary contact), surface mount, NEMA 4

2500-2089 Exterior single-button station, surface mount,

NEMA 4

2500-1486 Exterior 2-button station, surface mount,

OPEN-CLOSE, NEMA 4

2500-1773 2500-691

2500-2089 2500-1486 2500-1482

2500-834 2500-1322

2520-047

2500-824

2500-1482 Exterior 3-button station, surface mount,

OPEN-CLOSE-STOP, NEMA 4

2500-834 Exterior 2-button station with keyed lock,

surface mount, OPEN-CLOSE, NEMA 4

2500-824 Exterior 3-button station with keyed lock,

non-metallic, surface mount,

OPEN-CLOSE-STOP, NEMA 4

2500-1322 Exterior 3-button station with keyed lock,

surface mount, OPEN-CLOSE-STOP, NEMA 4

2500-514 Extra key for keyed stations

Page 22

Control Stations

Keyed, Pull Switch, and Explosion Proof Controls

Keyed Controls

2500-2486 Interior key station, flush mount,

2500-2487 Interior key station, flush mount, OPEN-CLOSE with

Commercial Door Operator Accessories

OPEN-CLOSE with center return, NEMA 1

with center return and STOP button, NEMA1

2500-2486 2500-2487

2500-2488 2500-2489

2500-289 2500-2483

2500-1129

2500-2488 Exterior key station, flush mount, OPEN-CLOSE

with center return

2500-2489 Exterior key station, flush mount, OPEN-CLOSE

with center return and STOP button

2500-289 Exterior key station, surface mount, OPEN-CLOSE

with center return, NEMA 4

2500-2483 Exterior key station, surface mount, OPEN-CLOSE

with center return and STOP button, NEMA4

2500-1129 Exterior lockout control, surface mount, ON-OFF,

key can be removed in either position, NEMA 4

2500-514 Extra key for keyed stations

Pull Switch Controls

2520-023 Ceiling pull switch, SPST, single function (OPEN

only or CLOSE only), NEMA 4

2500-038 Ceiling pull switch, DPST, dual function

OPEN-CLOSE, NEMA 4

Explosion Proof Controls

2520-213 Explosion proof 3-button wall station, surface

mount, OPEN-CLOSE-STOP, NEMA 7 & 9

2500-038 190-112410

2520-213

190-112410 Explosion proof ceiling pull switch, DPST, dual

function OPEN-CLOSE, NEMA 7 & 9

Page 23

Commercial Door Operator Accessories

Radio Controls

Commercial Door Operator Transmitters & Receivers

Linear commercial door operators are designed to be

used with the following radio controls. Consult factory

for answers to system design question (also see the

Radio Control section of this catalog).

190-1126 30

MVP-OC S

190-107483

831T

190-111662

QC-CLASSIC-OCS

19 0 -10 747 7

733T

190-1 093 72

8833T-OCS

19 0 -10 747 6

639T

190-109025

8833TC-OCS

19 0 -10 747 5

535T

Allstar Transmitters

190-112630 MVP-OCS 3-Button Open-Close-Stop MVP

Quik-Code Transmitter

190-111662 QC-CLASSIC-OCS 3-Button

Open-Close-Stop Allstar Quik-Code Classic

Transmit te r

190-109372 8833T-OCS 3-Button, 1-Door,

Open-Close-Stop, Transmitter

190-109025 8833TC-OCS 3-Button, 3-Door,

Open-Close-Stop, Transmitter

190-107483 831T 3-Button 1-Door, Open-Close-Stop,

Stationary Transmitter

190-107477 733T 3-Button 3-Door, Open-Close-Stop,

Stationary Transmitter

190-107476 639T 3-Button 9-Door, Open-Close-Stop,

Stationary Transmitter

190-107475 535T 3-Button 27-Door, Open-Close-Stop,

Stationary Transmitter

190-112052 CKT-240 240-Door, Commercial

Open-Close-Stop, Wireless Keypad

190-11315 7

MVP-MR

190-113317

MVP-R-24V-FC

190-107480

831R

190-1120 52

CKT-240

190-110554

MVP-RE-24V-8W-FC

19 0 -10 747 8

831R J

Allstar Receivers

190-113157 MVP-MR 3-Channel Open-Close-Stop

Modular Receiver

2650-159 MVP-MR 3-Channel Open-Close-Stop

Modular Receiver (installed in SS operator)

190-110554 MVP-RE-24V-8W-FC 1-Door

Open-Close-Stop Receiver

190-113317 MVP-R-24V-FC 1-Channel Receiver

190-107480 831R 1-Door, Open-Close-Stop, 24-Volt

Receiver

190-107481 831R-115V 1-Door, Open-Close-Stop, 115-

Volt Receiver

190-107478 831RJ 1-Door, Open-Close-Stop, 24-Volt,

Receiver in Oil Tight (JIC) Case

190-107479 831RJ-115V 1-Door, Open-Close-Stop,

115-Volt Receiver in Oil Tight (JIC) Case

Page 24

2500-2025

MT-1B

2500-2026

MT-2B

2500-2186

ACT-31B

2500-2187

AC T-3 4B

Commercial Door Operator Accessories

Radio Controls

Commercial Door Operator Transmitters & Receivers

MegaCode Transmitters

2500-2025 MT-1B 1-Channel factory block coded transmitter

2500-2026 MT-2B 2-Channel factory block coded transmitter

2500-2186 ACT-31B 1-Channel keychain block coded

transmitter

ACP00954 ACT-31D 1-Channel keychain block coded

transmitter with built-in proximity tag

2500-2187 ACT-34B 4-Channel keychain block coded

transmitter

ACP00955 ACT-34D 4-Channel keychain block coded

transmitter with built-in proximity tag

DOOR OPERATORS

ACP00954

ACT-31D

25 10 -374

SMDRG

ACP00955

AC T-3 4D

2500-2185

MDKP

2500-2325

MDR/U

2500-2185 MDKP Wireless keypad, transmits 1-6 digit codes

250’

MegaCode Receivers

2510-374 SMDRG* 1-Channel extended range receiver

(800’), with 15’ coax

2500-2325 MDR/U 1-Channel 110VAC plug-in universal,

receiver

2520-512 AP-5 Single door/gate controller (installed)

2510-409 MGR2* MegaCode 2-channel gate receiver

(installed)

2500-2028 EXA-2000 Remote directional antenna

*Includes 2510-009 coax kit

2520 -512

AP-5

2510-4 09

MGR -2

39

Loading...

Loading...