Linear T SERIES Owner's Manual

INSTALLATION AND

OWNER’S MANUAL

T OPERATORS

T-SERIES DRAWBAR COMMERCIAL

VEHICULAR DOOR OPERATORS

As of date of manufacture,

meets all ANSI/UL 325

Safety Requirements for

Vehicular door operators

Serial #:

Date Installed:

Your Dealer:

107349

READ THIS MANUAL

CAREFULLY BEFORE

INSTALLATION OR USE

SAVE THESE INSTRUCTIONS !

TABLE OF CONTENTS

Model T Drawbar Operator Features & Applications ..................................................3

Preparation.....................................................................................................................4

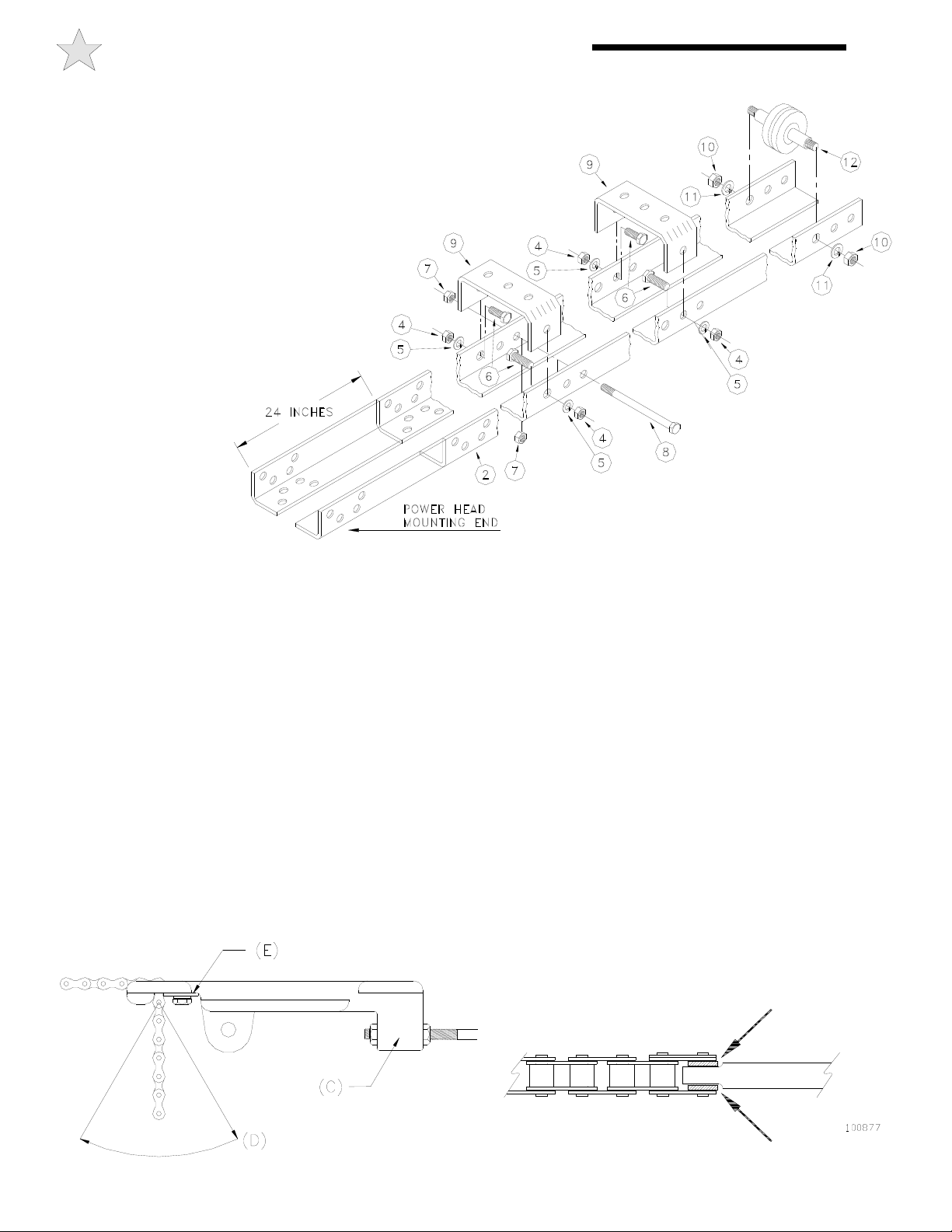

Figure 1 - Component Identification Pictorial..............................................................4

Important Installation Warnings (Things To Do Before & During Installation) .........5

Table 1 - Component Identification Listing..................................................................5

Rail/Chain Assembly Instructions................................................................................6

Installation Instructions ...........................................................................................7-10

Setting The Limits........................................................................................................10

Electrical Wiring Instructions .....................................................................................11

Figure 16 - Pneumatic Door Edge Installation...........................................................12

Figure 17 - Field Wiring ...............................................................................................12

Operation and Adjustment Instructions................................................................13-17

Important Safety Instructions for Owner ...................................................................13

Wiring Terms................................................................................................................13

Wiring Types ................................................................................................................14

Clutch Adjustment.......................................................................................................15

Brake Adjustment........................................................................................................16

Testing..........................................................................................................................16

Maintenance ................................................................................................................17

Figure 20 - Operator Dimensions ...............................................................................17

Wiring Diagrams/Schematics (Single & Three Phase) .........................................18-19

Warranty.......................................................................................................................20

2

READ THESE STATEMENTS CAREFULLY AND FOLLOW THE

INSTRUCTIONS CLOSELY.

The Warning and Caution boxes throughout this manual are there to protect you and your

equipment. Pay close attention to these boxes as you follow the manual.

WARNING

Indicates a MECHANICAL

hazard of INJURY OR DEATH.

Gives instructions to avoid the

hazard.

CAUTION

Indicates a MECHANICAL

hazard of DAMAGE to your

operator or equipment. Gives

instructions to avoid the hazard.

WARNING

Indicates an ELECTRICAL

hazard of INJURY OR DEATH.

Gives instructions to avoid the

hazard.

CAUTION

Indicates an ELECTRICAL

hazard of DAMAGE to your

operator or equipment. Gives

instructions to avoid the hazard.

3

PRODUCT FEATURES

The purpose of this booklet is to provide assembly,

installation and operation information concerning Allstar TSeries Commercial Vehicular Garage Door Operators and

related Accessory Products.

NOTICE

IT IS IMPORTANT THAT THIS INSTRUCTION

MANUAL BE READ AND UNDERSTOOD

COMPLETELY BEFORE INSTALLATION OR

OPERATION IS ATTEMPTED. IT IS

INTENDED THAT THE INSTALLATION OF

THIS UNIT WILL BE DONE ONLY BY

PERSONS TRAINED AND QUALIFIED IN

THE INSTALLATION, ADJUSTMENT AND

SERVICE OF COMMERCIAL OVERHEAD

DOORS AND DOOR OPERATORS AND BY

QUALIFIED ELECTRICIANS.

NOTICE

THE IMPORTANT SAFEGUARDS AND

INSTRUCTIONS IN THIS MANUAL CANNOT

COVER ALL POSSIBLE CONDITIONS AND

SITUATIONS WHICH MAY OCCUR DURING

ITS USE. IT MUST BE UNDERSTOOD THAT

COMMON SENSE AND CAUTION MUST BE

EXERCISED BY THE PERSON(S) INSTAL-

LING, MAINTAINING AND OPERATING THE

EQUIPMENT DESCRIBED HEREIN. DO NOT

USE THIS EQUIPMENT FOR ANY OTHER

THAN ITS INTENDED

PURPOSE - OPERATING OVERHEAD

COMMERCIAL VEHICULAR GARAGE

DOORS.

T-SERIES OPERATOR APPLICATIONS:

Drawbar operators are for commercial and industrial use

on sectional overhead doors which use horizontal track

with normal radius. A draw bar operator is not suitable for

doors with high lift exceeding 24 inches or vertical lift

doors. The installation requires a minimum clearance of 5

inches above the high arc of the door (the highest point

reached by the door at any part of its travel). For backroom requirement refer to Figure 20, Page 17. When

properly installed a drawbar operator effectively locks the

door in the closed position.

The T-Series drawbar operators are used in the

following applications:

-Continuous Duty, Medium Cycle Commercial

installations only

-Indoor Use Only

-Up to 22 foot high doors with a maximum area of 480

square feet for 3/4 HP, 280 square feet for 1/2 HP and

200 square feet for 1/3 HP - maximum area slightly

higher for lighter doors - consult factory

-Use with foam or pneumatic reversing edge door

components - REQUIRED where the 3 button station is

out of sight of the door or any other automatic, remote

or manual control is used to activate the door.

STANDARD FEATURES:

Limit Switches: Driven limit switches, easily adjusted over

a wide range. The motor may be removed without affecting

the limit switch adjustments

Manual Release: Permits manual operation of the door in

the event of a power failure.

Control Circuit: Standard three button open, close and stop.

24 Volts AC.

Connections For Auxiliary Entrapment Protection

Devices:

components or a photoelectric beam (across the opening)

devise.

Constant Contact To Close: Feature can be activated by

simply moving a wire on the terminal strip.

Momentary Contact To Open and Close: Standard

operation.

Use with foam or pneumatic reversing door edge

OPTIONAL FEATURES:

Digital Radio Controls: Open, Close and Stop operation.

Radio units are available to control up to 27 doors from one

transmitter

Digital Timer to Close: Adjustable from 0 to 17 minutes

in one second intervals.

Keyless Entry System: Connection terminals provided for

hard wired or wireless keyless entry system.

Brake: Optional on 1/3 & 1/2HP, Standard on 3/4HP.

Can be added in the field.

PREPARATION

WARNING

ELECTRIC DOOR OPENERS ARE DESIGNED

FOR DOORS IN GOOD WORKING CONDITION,

PROPERLY COUNTERBALANCED AND

PROPERLY ADJUSTED IN ACCORDANCE WITH

THE DOOR MANUFACTURER'S INSTALLATION

INSTRUCTIONS.

Before starting the installation of the operator, the door must be in

good working condition and properly counterbalanced. Inspect the

door and track for loose or missing hardware. Test the door

manually for balance and ease of operation. Lubricate door hinges

and rollers. If necessary, adjust the springs for proper

counterbalance of the door.

Before removing the operator powerhead from the shipping carton,

inspect the nameplate on the cover of the operator control box to

verify that it is the correct model for the intended application and

that the voltage and phase are in accordance with electrical power

provided at the job site.

4

The rails and drawbar chain/hardware package are shipped

separately from the powerhead. Warning: Rope off the area

to keep personnel and vehicles clear of the door and floor

space in the vicinity of the operator during the

installation.

WARNING

SPRINGS ARE SUBJECT TO VERY

HIGH FORCES AT ALL TIMES AND

ADJUSTMENTS MUST BE MADE ONLY

BY A QUALIFIED PROFESSIONAL

DOOR INSTALLER.

WARNING

REMOVE OR DISABLE ANY LOCKING

DEVICES FROM DOOR AND REMOVE

ALL ROPES

FIGURE 1 - COMPONENT IDENTIFICATION

107359

5

WARNING

IMPORTANT INSTALLATION NOTES

TO REDUCE THE RISK OF SEVERE INJURY

OR DEATH: READ AND FOLLOW ALL

INSTALLATION INSTRUCTIONS!

• Install only on a properly balanced garage

door. An improperly balanced door could cause

severe injury. Have a qualified service person

make repairs to cables, spring assemblys and

other hardware before installing the opener.

• Remove all ropes and remove or make

inoperative all locks (unless mechanically and/or

electrically interlocked to the power unit) that are

connected to the garage door before installing the

opener.

• Lightweight doors (fiberglass, aluminum etc.)

must be reinforced to avoid door damage. Check

the door manufacturer’s instruction manual for a

bracing procedure or the availability or a

Reinforcement Kit. See Page 9.

• T-Series Operators are Commercial Vehicular

Door Operators and as such ARE NOT

recommended for pedestrian traffic. In

installations where it is known that pedestrians

will be nearby ensure a pedestrian door is

available for entrance and exit to the building. In

addition YOU MUST install an auxiliary

entrapment protection device (reversing door edge

or photoelectric beam device).

across the door opening). A device of this type is

STRONGLY ADVISED FOR ALL commercial

operator installations. An auxiliary entrapment

protection device is REQUIRED when the three

button control station is out of sight of the door

or any other automatic or manual control is

used.

• Install the opener at least 8 feet or more

above the floor.

• Do not connect the opener to the source of

power until instructed to do so.

• Locate the control station:

a) within sight of the door and;

b) at a minimum height of five feet above

the floor and;

c) away from all moving parts of the door.

• Do not overtighten the clutch adjustment to

compensate for a poorly working door.

• Securely attach any WARNING signs or

placards to either the door or above the control

station as directed (see page 11).

• Connect an auxiliary entrapment protection

device (reversing edge or photoelectric device

TABLE 1 - COMPONENT IDENTIFICATION LISTING

ITEM # PART# DESCRIPTION QUAN.

1 Operator Power Head 1

2 Track Rails 2

7 F031 3/8-16 Keps Hex Nut 6

8 101315 3/8 - 16 X 6-1/2 Hex Head Blot 1

9 107049 Track Bracket AR

10 F034 1/2 - 15 Hex Nut 2

11 F049 1/2 Split Lockwasher 2

12 106265 Front Idler Assembly 1

13 Chain For Track Rail 1

14 3 Piece Chain Connecting Link 1

15 F084 Chain Tension Adjustment Bolt 1

16 F031 3/8 - 16 Keps Hex Nut 2

17 100512 Track Trolley 1

—— AR - As Required

• After installing the opener, all safety features

must be tested for proper operation (see page

16).

ITEM # PART# DESCRIPTION QUAN

18 E031 3 Button Station 1

19 100513 Release Door Arm 1

20 100236 Extension Door Arm 2

21 105162 Curved Door Arm 1

22 100108 Door Bracket 1

23 100469 Hardware Pkg Com. Door Arm 1

26 3/8 - 16 X 2-1/2 Carriage Bolt 2

16 3/8 - 16 X 1 Hex Head Bolt 1

27 3/8 Nylon Insert Locknut 1

28 5/16 - 18 X 1-1/4 Hex Head Bolt 4

29 5/16 - 18 Keps Hex Nuts 4

25 100468 Hardware Pkg Com. Track Assy 1

4 3/8 - 16 Hex Nut AR

5 3/8 Split Lockwasher AR

6 3/8 - 16 X 1-1/2 Hex Head Bolt AR

RAIL/CHAIN ASSEMBLY INSTRUCTIONS

6

RAIL/CHAIN ASSEMBLY

Refer to Figure 1 parts illustrations. The part names and item numbers are

referenced identically to the part names and numbers in the assembly

procedures that follow. Before starting assembly of the operator

track check for the proper length. The tracks supplied may

be longer than required for the door height. The tracks

should be three (3) feet longer than the door

height. If the tracks supplied with the operator

are longer than the door height plus three (3) feet

it will be necessary to trim the rails in two foot

increments from the power head mounting end

as shown in Figure 2.

CAUTION

TO CUT THE TRACK

ENSURE THE ENDS

ARE LINED UP

AS IN FIGURE 2.

1) Assemble the

operator track by

assembling the items as

shown in Figure 2.

2) After the track is assembled, position track assembly onto

the operator power head and attach with four 3/8”-16 x 1” bolts,

lock washers and nuts (supplied in a separate hardware package

#100470).

3) Referring to Figure 1 , 2 and 3 (below) , slide the trolley

onto the track with the chain take up bolt lug (C) toward the

power head. Thread one 3/8-16 keps nut (attached star washer)

onto the Chain take up bolt with the keps part (attached star

washer) away from the chain attachment end. Insert the chain

take up bolt threaded end through the lug hole on the trolley (C)

just far enough to start a second 3/8-16 keps nut. Attach one end

of the chain to the opposite end of the threaded stud using a 3piece chain link (provided). See Figure 3.

: WHEN NECESSARY

link. 1/3 and 1/2 horsepower operators use the narrower #65

chain and the use of the spacers is not required.

Install chain around drive sprocket at operator head then around

idler at front end of rail and thread through opening at front end

of carrier. If the rail is equipped with a chain guide-spacer near

its center (12 foot rail or longer only) pass the chain over it in one

direction and under it in the other direction to separate the two

lengths of chain. Apply initial tension by pushing forward on the

carrier while pulling chain tight through opening in the carrier in

the direction of D. When maximum tension has been applied by

this means, swing chain forward and insert retaining plate, E, in

place. Insert 1/4-20 x 5/8 hex head machine screw through

retaining plate, E, and tighten plate in place. Make final

adjustment of chain tension to remove excess sag by adjusting

nuts on threaded rod at chain lug, C.

107068

Figure 2

NOTE: To keep #41 chain (used on

3/4 H.P. operators) centered on the

threaded stud, place a .065" thick flat washer

(provided) on each side of the flat, as indicated by the

arrows in Figure 4, when installing the connecting

100461

Figure 3

Figure 4

Loading...

Loading...