Page 1

SSWFX Design Series XTreme Keypad Instructions_____________________________________________________

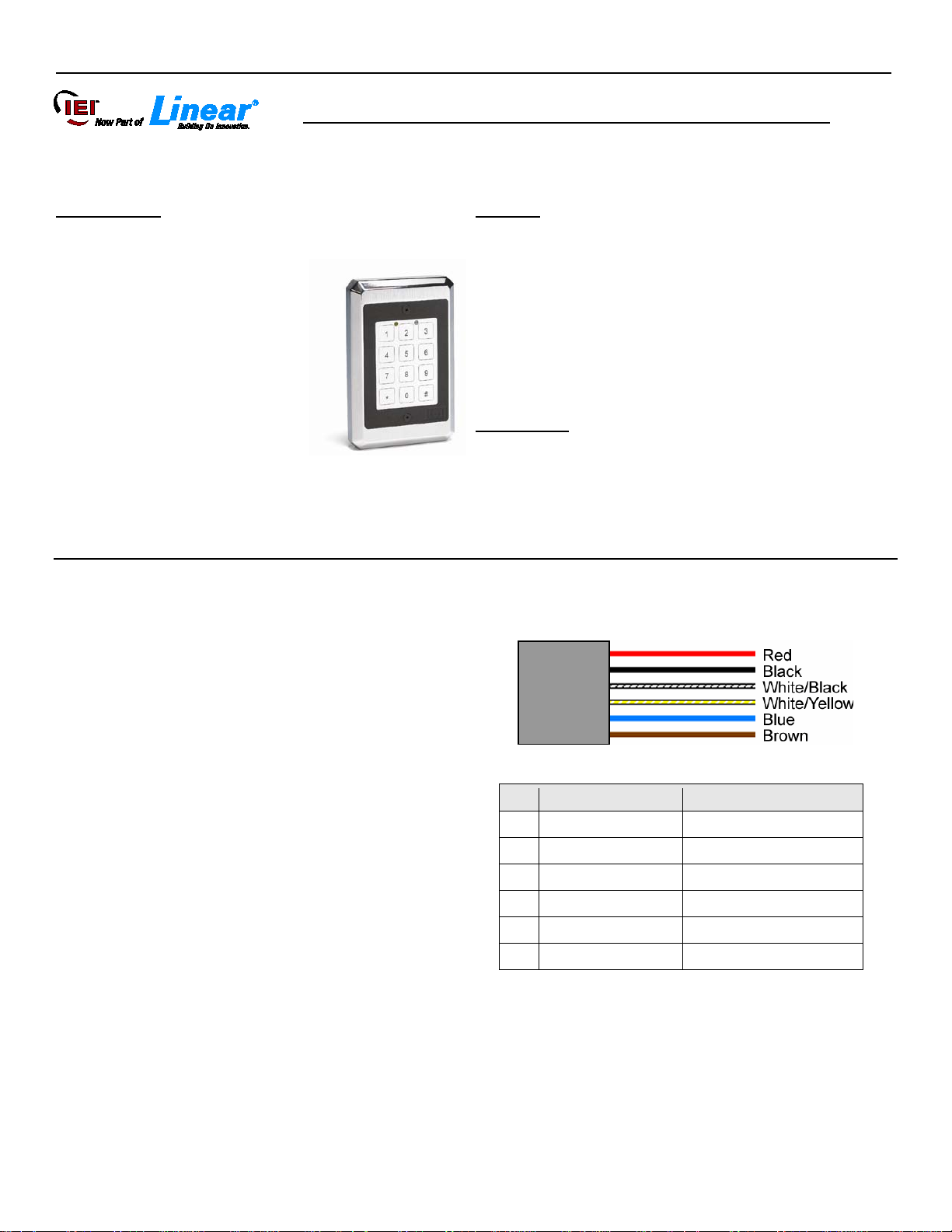

Pin

Wire Color

Signal Name

1

Red

Power (+)

2

Black

Power (-)

3

White/Black

Data 0

4

White/Yellow

Data 1

5

Blue

LED1

6

Brown

Not Used

SSWFX Design Series XTreme Keypad Instructions

Note: This product is designed to be installed and serviced by security and lock industry professionals.

Specifications

Keypad Case Dimensions:

1

/8”L x 33/8”W x 5/8”D

5

Electrical:

Voltage: 5 – 12 VDC

Current (max): 15m A

Environmental:

Temperature: -20º F to 130° F

For Indoor or Outdoor Use

Description:

Combining elegant looks and flush mount design in a ruggedized

vandal resistant case, IEI's Design Series XTreme keypad can be

utilized for almost any application. Designed to perform in high

traffic and rough duty environments, IEI Design Series XTreme

keypad has solid state, touch sensitive piezo keys surrounded by

and aesthetically appealing protective metal case. Encapsulated

electronics make the Design Series XTreme keypad suitable for

indoor or outdoor installations.

Basic Operation:

Features

• Vandal Resistant Metal Case

• Sealed for Indoor or Outdoor A pplications

• No Moving Parts

• Touch Sensitive Piezo Keys

• LED's for Relay Status Indication

• Surface Mount

• Rated for Greater than One Million Key Cycles

Applications

• Heavy Traffic Areas

• Rough Service Environments

• Low Profile

Wire Harness Configuration:

To gain access through the door enter your code (1-6 digits)

followed by the * key on the ke y pad.

Packing List:

(1) SSWFX Keypad

(1) Six-Conductor Wire Harness

(2) 6-32 x 1

(2) # 6 1

11

(1)

(1) Anti-Oxidant Grease Pack

(1) SSWFX Installation/Programming Manual

Document # 6060763 Rev 1.1, D1a Page 1 of 8

1

/2 Machine Screws

1

/2 Sheet Metal Screws

/64” Allen Wrench

Page 2

_____________________________________________________SSWFX Design Series XTreme Keypad Instructions

SSWFX Keypad Installation Procedure:

Step 1: If you are mounting the keypad directly to a wall, drill a 3/4” hole into the mounting surface to allow the wire harness

connector and wires to fit through.

Step 2: On the keypad end, strip back the insulator from the wire and tape the drain wire (shield) to the jacket. Now connect

the four wires to the 6-conductor wire harness provided. The wire harness plugs into the 6-position connector on the

keypad. At the other end of your wire run, strip back the insulator from the wire but

be connected to ground at the controller end. When using IEI Secured Series product (such as a

jacket. The drain wire

Max or MiniMax), connect the drain wire to a fast-tab connector on the backplane. Refer to the IEI Secured Series Max or

MiniMax manual for details.

Step 3: Finally mount the SSWFX keypad onto the mount i ng surface using the provided #6 screws. Do no over-tighten the

screws, which may result in damage.

must

do not tape the drain wire to the

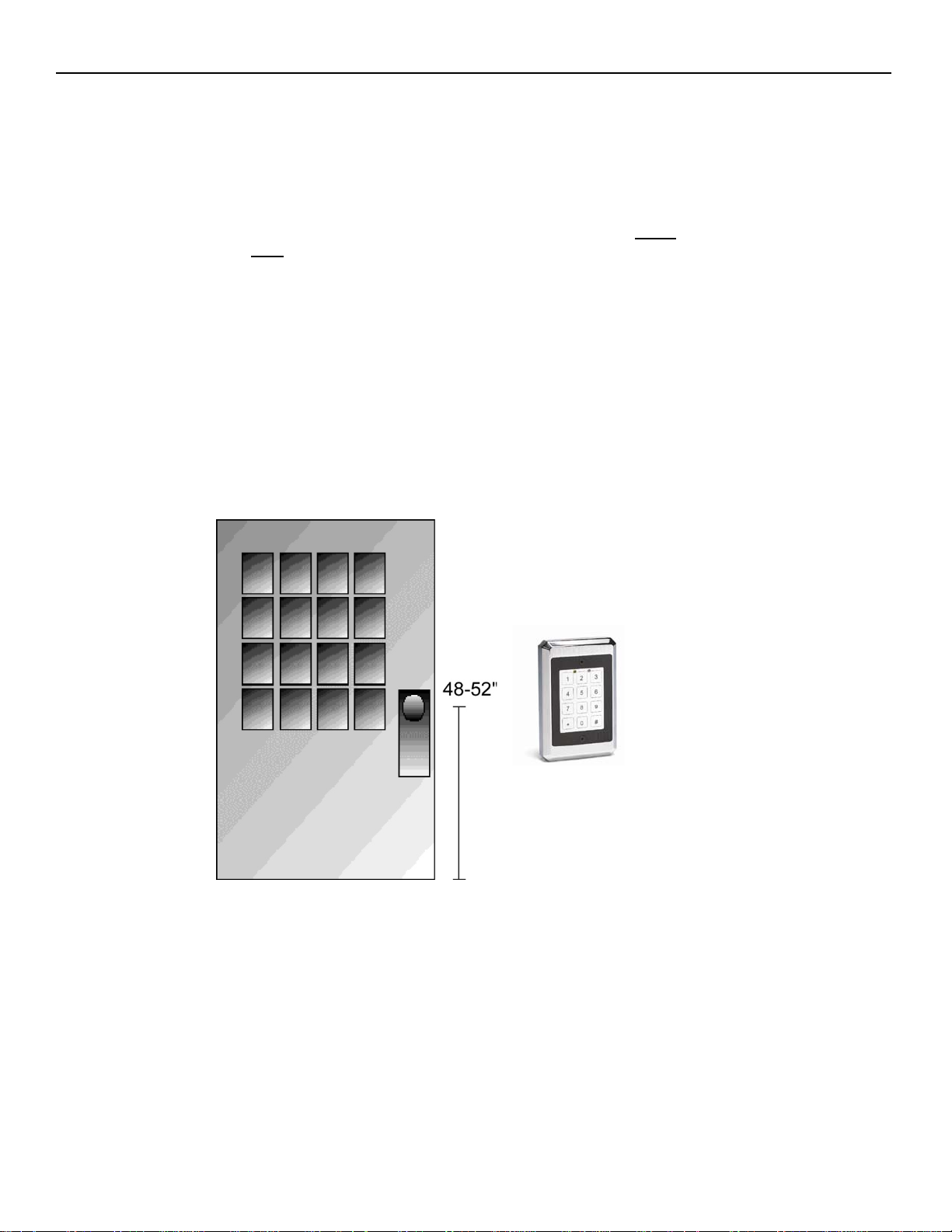

Keypad Mounting Height

Mounting height can vary depending on requirements. An appropriate range is typically between 48 and 52 inches on center off the

floor.

Page 2 of 8 Document # 6060763 Rev 1.1, D1a

Page 3

SSWFX Design Series XTreme Keypad Instructions_____________________________________________________

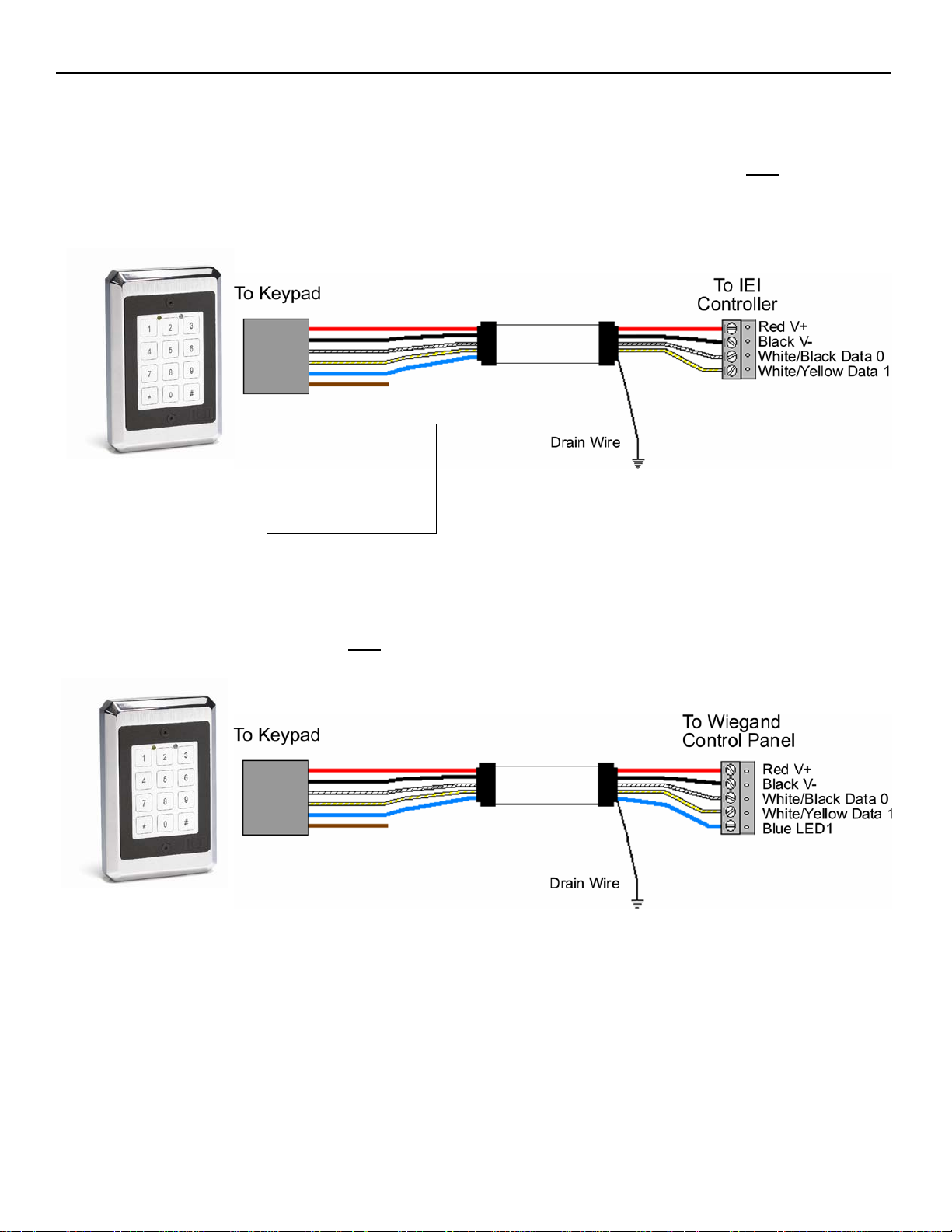

Wiring Requirements:

Wiring the SSWFX to the IEI Secured Series Door Control Module (DCM)

The connection between the SSWFX keypad and an IEI Secured Series Door Control Module requires a 4-conductor, stranded wire

with overall foil shield. The 6-conductor wire harness from the keypad connects to terminal strip TS5 on the Door Control Module.

Connect the red, black, white/black and white/yellow wires to matching terminal on the Door Control Module (the terminals are

must

labeled with the wire color). Refer to the wire lengths below. As mentioned in step 2 on page 2, the drain wire

fast-tab on the Max or MiniMax backplane.

be attached to a

18 AWG – 1000 Ft.

20 AWG – 500 Ft.

22 AWG – 250 Ft.

Wiring the SSWFX to the a third party Wiegand Access Control Panel

The connection between the SSWFX keypad and a Wiegand Access Control Panel requires a 6-conductor, stranded wire with overall

foil shield. Connect the red wire to V+, the black wire to V-, white/black wire to Data 0, white/yellow wire to Data 1 and the blue wire

be connected to ground at the controller end.

to the LED control connection. The drain wire

must

Document # 6060763 Rev 1.1, D1a Page 3 of 8

Page 4

_____________________________________________________SSWFX Design Series XTreme Keypad Instructions

Command/Action

Keys to Enter/Details

Command 90

Change Local Program Code

Command 91

below, defa ults in bold)

Option

Clear

Set

0 – Visual Keypress Feedback

0 = Disabled

1 = Enabled

1 – Audio Keypress Feedback

0 = Disabled

1 = Enabled

3 – Front End Output Selection

0 = Secured Series Mode

1 = Wiegand Mode

4 – Secured Series IN/OUT Event

Recording

5 – Wiegand Red LED Enable

0 = Disabled

1 = Enabled

6 – Wiegand Red LED Active State

0 = Active Low

1 = Active High

7 – Wiegand Green LED Enable

0 = Disabled

1 = Enabled

8 – Wiegand Green LED Active State

0 = Active Low

1 = Active High

Note: Auto-Entry is not available in this model.

Programming the SSWFX Keypad

The SSWFW keypad has it's own local programming options. All user codes and other access control features are programmed into

the control system, either the IEI Secured Series products or a third party Wiegand Access Control System. Refer the those product's

documentation for programming instructions. The programming options chart below shows all the programming commands available

in the SSWFX.

To program the SSWFX you first must enter program mode.

To enter program mode ent er the following on the key pad: 099 # program code * (default program code is 6789).

Programming Options Chart

90 # 0 # 0 # new code * new code * (default = 6789)

Set/Clear Keypad Options (options

91 # option # set/clear # **

0 = Record IN Event

1 = Records OUT Event

Page 4 of 8 Document # 6060763 Rev 1.1, D1a

Page 5

SSWFX Design Series XTreme Keypad Instructions_____________________________________________________

Command/Action

Keys to Enter/Details

Program Keypad Parameters

Parameter

Value

1 – Wiegand Format

1-8 (default = 1, 26 bit – see Wiegand format chart below)

2 – Interpulse Spacing

1-255 (default = 32, 640μS; 20μS increments)

3 – Pulse Width

1-255 (default = 8, 160μS; 20μS Increments)

Command 93

Program Wiegand Site and Group ID

ID Type

ID Value

0 – Site ID

See Wiegand format chart below (default = 0)

1 – Group ID

See Wiegand format chart below (default = 0)

Secured Series Front End Mode

96 # 0 # 0 # **

26-Bit Wiegand Front End Mode

96 # 1 # 1 # **

Exit Program Mode

Press the * Key

Format Value

Wiegand Format

Largent PIN Value

Largest Site Value

Largest Group Val ue

1

26 bit

65535

255

N/A 2 28 bit

32767

255

N/A

3

29 bit

524287

255

N/A

4

30 bit

65535

255

15 5 31 bit

65535

255

31

6

32 bit

8191

2047

63

7

36 bit

1048575

255

N/A 8 29 bit

524287

255

N/A

LED State

Description

Red Solid

Door Locked

Green Solid

Door Unlocked

Yellow Solid

Programming Error

Yellow Flashing Slowly (single f l ash)

Controller Program Mode

Yellow Flashing Slowly (double f l ash)

Front End Program Mode

Yellow Momentary Flash (key press)

Visual Keypress Feedback

Programming Options Chart - Continued

Command 92

Command 96

Reset Keypad to Default Settings

Wiegand Format Chart

92 # parameter # value #

93 # ID Type # ID Value # **

LED Indications

Document # 6060763 Rev 1.1, D1a Page 5 of 8

Page 6

_____________________________________________________SSWFX Design Series XTreme Keypad Instructions

Testing the Keypad

After installing the keypad, IEI recommends that you perform the keypad self-test once a year, to ensure that the keypad is working

properly.

To perform the self-test, with the unit powered up, press the following keys on the keypad: 7890#123456*

If all 12 key presses are accepted, the keypad enters self-test mode.

The LEDs alternate three times followed by the sounder beeping three times.

When finished the yellow LED starts flickering rapidly.

Press * to clear.

Program Mode Loopback Connection

If you've forgotten the local program code, use the following loopback connection to enter program mode. Power down the unit, short

the wires in the configuration illustrated, then power the unit back up. The yellow LED should be flashing. Now change your local

program code or reset the unit. Power the keypad down and reconnected the wire harness in the original configuration.

Secured Series Front End Default Loopback Connection

The following loopback connection allows you to default the keypad in Secured Series front end mode. Power down the unit, short the

wires in the configuration illustrated, then power the unit back up. After you hear the three beeps, remove power and reconnect the

wires in the proper configuration.

Wiegand Front End Default Loopback Connection

The following loopback connection allows you to default the keypad in Wiegand front end mode. Power down the unit, short the wires

in the configuration illustrated, then power the unit back up. After you hear the three beeps, remove power and reconnect the wires in

the proper configuration.

Page 6 of 8 Document # 6060763 Rev 1.1, D1a

Page 7

SSWFX Design Series XTreme Keypad Instructions_____________________________________________________

Linear Limited Warranty

This Linear product is warranted against defects in material and workmanship for twenty four (24) months. This warranty extends

only to wholesale customers who buy direct from Linear or through Linear’s normal distribution channels. Linear does not warrant

this product to consumers. Consumers should inquire from their selling dealer as to the nature of the dealer’s warranty, if any. There

are no obligations or liabilities on the part of Linear LLC for consequential damages arising out of or in connection with use

or performance of this product or other indirect damages with respect to loss of property, revenue, or profit, or cost of

removal, installation, or reinstallation. All implied warranties, including implied warranties for merchantability and implied

warranties for fitness, are valid only until the warranty expires. This Linear LLC Warranty is in lieu of all other warranties

express or implied.

All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear Technical Services

at 1-800-421-1587 for an RPA# and other important details.

Document # 6060763 Rev 1.1, D1a Page 7 of 8

Page 8

_____________________________________________________SSWFX Design Series XTreme Keypad Instructions

Page 8 of 8 Document # 6060763 Rev 1.1, D1a

Loading...

Loading...