Page 1

e/eM Style Open

Technology Keypad

Installation/

Programming Manual

This manual applies to these models: SSWe and SSWeM.

This equipment is designed to be installed and serviced by security

and lock industry professionals.

Put Service Company Contact Information Here:

Company Name:

Service Number:

Contents

Section 1: Features and Product Description

Section 2: Specifications

Section 3: U.L. Requirements

Section 4: Mounting

Section 5: Wiring

Section 6: Testing the Keypad

Section 7: Programming

Section 8: Troubleshooting

Section 9: Wire Harness Loopback Connections

Section 10: Warranty

Manual Revision Date: 12/10/04 Firmware Version: 1.0b

Document # 6104400, Rev. 1.0, D1c 1

Page 2

e/eM Style Open Technology Keypad Installation/Programming

Manual

1. Features and Product

Description

1.1 Keypad Features

• Flush Mount, Single Gang

• Rugged Construction for Indoor and Outdoor Use

• DurableMetalBrailleKeys(ekeypadonly)

• Keypress feedback via Built-In Sounder

• Illuminated Backlit Keys (eM keypad only)

• Bi-Color Red/Green LED Indicators

• Yellow LED Indicates Program Mode

• Works with all IEI Secured Series Hub Control Products

• Works with all 26-Bit Wiegand Access Control Panels

• Wiegand Format and Site Code ID Programmable

• 10 to 30 Volt DC Operation

• 12 to 24 Volt AC Operation

1.2 Keypad Product Description

The keypad works as a front end for all IEI Secured Series access

systemsaswellasall26-BitWiegand Access Control products. For

quick installation, the keypad can be configured for either operation using a simple programming command or special loopback

configurations using the wire harness. The keypad can also be programmed to operate with seven other Wiegand formats and the

site code ID is programmable, along with other various keypad options.

2 Document # 6104400, Rev. 1.0, D1c

Page 3

e/eM Style Open Technology Keypad Installation/Programming Manual

All keypads are designed for both indoor and outdoor flush

mount applications. The electronics for each keypad are conformal

coated in the manufacturing process to provide this level of application flexibility. All keypads mount to any standard single-gang

electrical box or directly to any wall.

Document # 6104400, Rev. 1.0, D1c 3

Page 4

e/eM Style Open Technology Keypad Installation/Programming

Manual

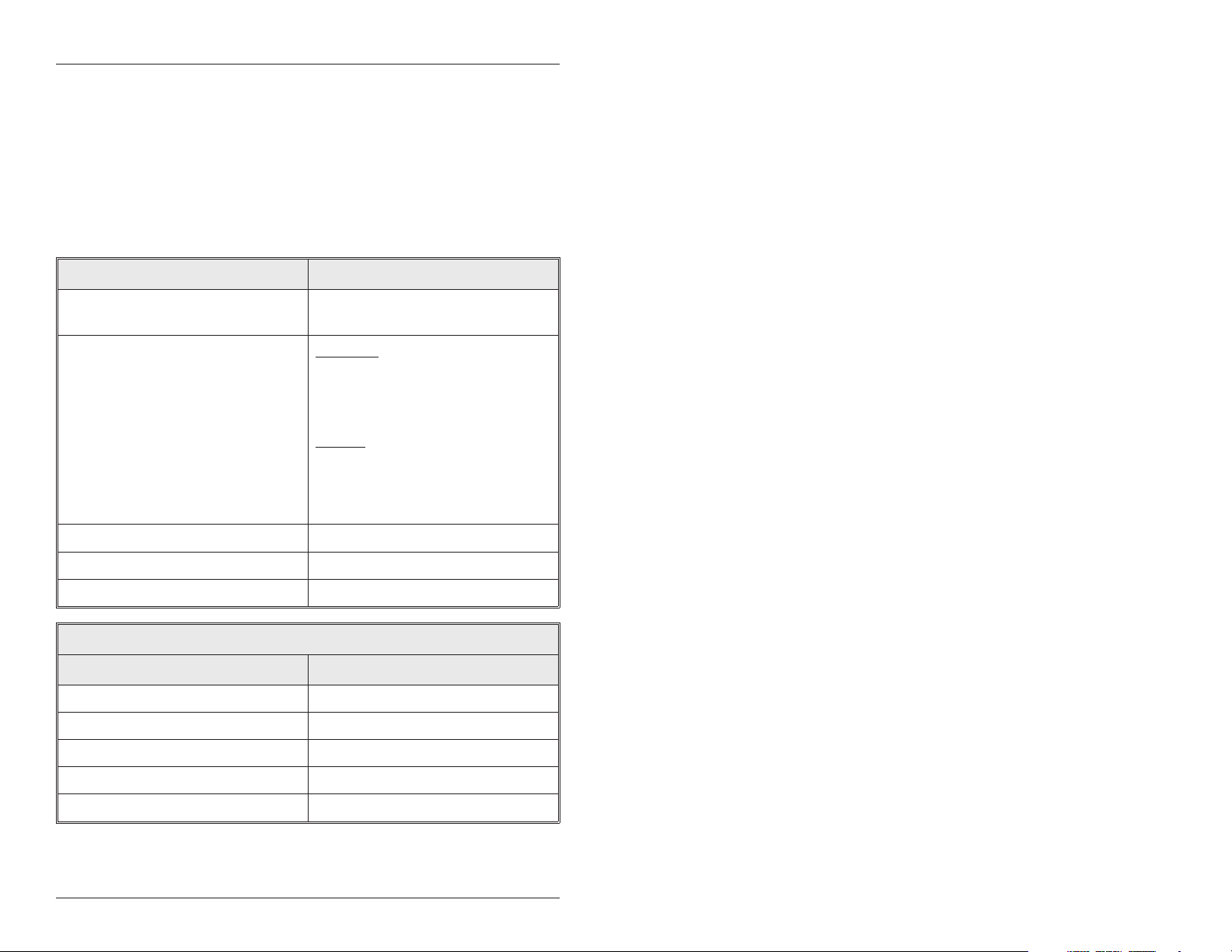

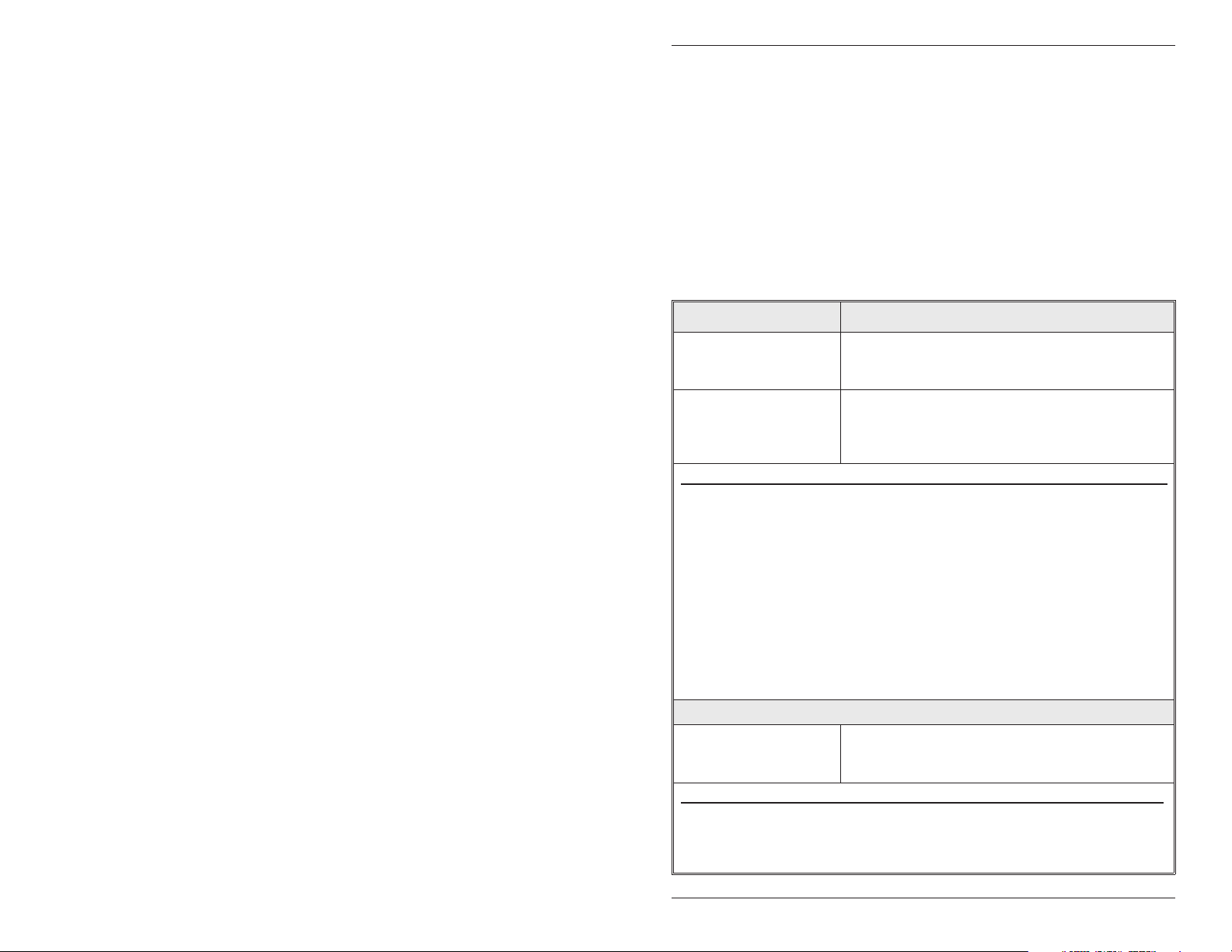

2. Specifications

Parameter Range/Description

Voltage

Current

Environment Indoor and Outdoor

Temperature Tolerance -20° F to 130° F (-28° C to 54° C)

Dimensions 4.5" H x 2.75" W x 0.60" D

Open Keypads Default Settings

Parameter Default Setting

Local Program Code 6789

Visual Keypress Feedback Enabled

Audio Keypress Feedback Enabled

10-30 VDC, 12-24 VAC

(auto-adjusting)

SSWeM:

12mA@10VDC,

22mA@30VDC,

25mA@12VAC,

40mA@24VAC

SSWe:

42mA@10VDC,

70mA@30VDC,

70mA@12VAC, and

114mA@24VDC

Front End Mode Hub Front End

Wiegand Format 26 Bit

4 Document # 6104400, Rev. 1.0, D1c

Page 5

e/eM Style Open Technology Keypad Installation/Programming Manual

3. U.L. Requirements

NOTE: ThissectionappliestotheSSWekeypadonly.TheSSWeM

keypad is not U.L. Listed.

TheSSWekeypadisaU.L.Listedaccesscontrolaccessorythat

complies with UL 294. This section contains information regarding

all the requirements necessary to meet U.L. requirements.

This system must be installed in accordance with the National Electrical code (NFPA70), local codes, and the authorities having jurisdiction. In addition, all wires and cables used must be stranded

andshieldedU.L.Listedand/orrecognizedwire.

This keypad must be connected to either a U.L. Listed IEI Door

Controller or a U.L. Listed Wiegand control panel.

A U.L. Listed access control power limited power supply must be

used to power the keypad.

NOTE: Therelayonthecircuitboardisnotusedinthisproduct

and was not evaluated by U.L.

Document # 6104400, Rev. 1.0, D1c 5

Page 6

e/eM Style Open Technology Keypad Installation/Programming

Manual

4. Mounting

Thekeypadisdesignedtobeflushmountedusingastandardsinglegang electrical box. In addition, it can be flush mounted directly to the

wallsurfacebycuttingaholeinthewall.Toproperlysizethemounting

and wire access hole, use the installation template on the last page in

this manual and on the unit’s container.

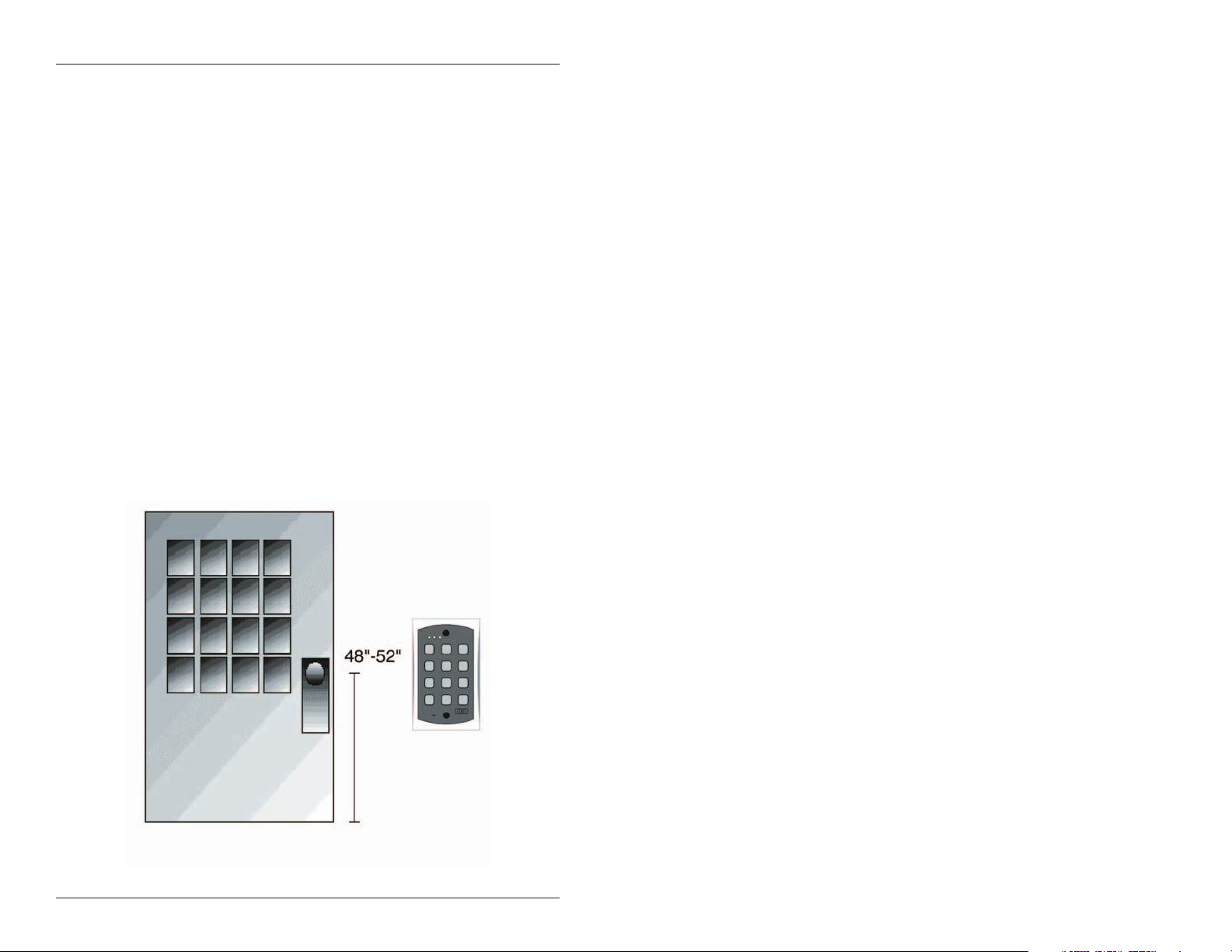

Mounting height can vary depending on requirements. An appropriate range is typically between 48 and 52 inches on center off the

floor.

For outdoorinstallations, use aweatherproof backbox and seal the wire

entry locations with silicone and provide a drain hole. In addition, use

the anti-oxidant grease pack for the wire harness connectors.

Figure 1 Keypad Mounting Height

6 Document # 6104400, Rev. 1.0, D1c

Page 7

e/eM Style Open Technology Keypad Installation/Programming Manual

5. Wiring

Figure 2 Connector Harness

Pin Wire Color Signal Name

1Red

2Black

3White/Black Data0

4 White/Yellow Data 1

5Brown LED1

6 White/Orange Not Used

7White NotUsed

8Green NotUsed

9Blue NotUsed

10 Gray Not Used

Document # 6104400, Rev. 1.0, D1c 7

V+ (Keypad

Power)

V- (Keypad

Power)

Page 8

e/eM Style Open Technology Keypad Installation/Programming

Manual

5.1 Wire Specifications

Connecting the keypad to an IEI controller or Wiegand panel requires a stranded wire cable with overall foil shield and drain

wire. Connect the drain wire at the controller end to your ground

wire.Atthekeypad,youmust cut back the drain wire and foil

shield and tape with electrical tape. The maximum wire distance is

shown in the table below.

Wire Gauge Wire Distance

18 AWG 1000 Feet

20 AWG 500 Feet

22 AWG 250 Feet

5.2 Connecting the Keypad to an IEI Hub Door

Controller

Only four wires are required to connect the keypad to an IEI Hub

DoorController.Connectthered(V+),black(V-),white/black

(Data 0) and white/yellow (Data 1) wires to the corresponding

wires on the IEI controller as shown in Figure 3.

Figure 3 Connecting the Keypad to Hub Door Controller

8 Document # 6104400, Rev. 1.0, D1c

Page 9

e/eM Style Open Technology Keypad Installation/Programming Manual

5.3 Connecting the Keypad to a Wiegand Panel

Only five wires are required to connect the keypad to a Wiegand

panel. Connect the red (V+), black (V-), white/black (Data 0),

white/yellow (Data 1) and brown (LED 1) wires to the corresponding wires on the Wiegand panel as shown in Figure 4.

Figure 4 Connecting the Keypad to a Wiegand Panel

Document # 6104400, Rev. 1.0, D1c 9

Page 10

e/eM Style Open Technology Keypad Installation/Programming

Manual

6. Testing the Keypad

After installing the keypad, IEI recommends that you perform the

keypad self-test once a year, to ensure that the keypad works properly.

• To perform the self-test, with the unit powered up, press

the following keys on the keypad:

7890#123456*

• If all 12 keypresses are accepted, the keypad enters self-test

mode.

• The LEDs alternate three times followed by the sounder

beeping three times.

• When finished (in Hub Front End mode only), the yellow

LED starts flickering rapidly.

• Press * to clear.

10 Document # 6104400, Rev. 1.0, D1c

Page 11

e/eM Style Open Technology Keypad Installation/Programming Manual

7. Programming

To enter program mode, enter your local Program Code by pressing

099 # Program Code * .

7.1 Programming Options Chart

Command/Action Keys to Enter/Details

Command 90.

Change Local Program

Code

Command 91.

Set/Clear Keypad

Options (options

below, defaults in bold)

Option Clear Set

0-visual keypress feedback 0=disabled 1=ENABLED

1-audio keypress feedback 0=disabled 1=ENABLED

3-front end select 0=HFE 1=wfe

4-HFE location 0=OUTSIDE 1=inside

5-WFE red led enabled 0=disabled 1=ENABLED

6-WFE red led active state 0=LOW 1=high

7-WFE green led enable 0=disabled 1=ENABLED

8-WFE green led active state 0=low 1=HIGH

10-PIN size test 0=DISABLED 1=enabled

11-keypad illumination 0=disabled 1=ENABLED

12-keypad dimming 0=disabled 1=ENABLED

HFE=Hub Front End WFE=Wiegand Front End

NOTE: Options 11 and 12 available only in e keypads.

90#0#0#code*code*(default=6789)

91#option#set/clear#**

Command 92.

Set Wiegand

Parameters

Parameter Value

1-Wiegand format 1-8 (defaults to 1=26 bit) (see Wiegand

2-Interpulse spacing 1-255 (defaults to 32= 64- microseconds)

3-Pulse width 1-255 (defaults to 8= 160 microseconds)

92 # parameter # value # **

Format chart)

Document # 6104400, Rev. 1.0, D1c 11

Page 12

e/eM Style Open Technology Keypad Installation/Programming

Manual

Command/Action Keys to Enter/Details

Command 93.

Set Wiegand ID’s

ID Type ID Value

0-site id See Wiegand Format chart (default=0)

1-group id See Wiegand Format chart (default=0)

Command 96.

Reset keypad

Settings to Default

93#IDType#IDValue#**

96#0#0#** Reset keypad to Hub

Front End

96#1#N#** Reset keypad to

Wiegand Front End

using wiegand format N.

7.2 Wiegand Format Chart

Format

Value

1 26 bit 65535 255 N/A

2 28 bit 32767 255 N/A

3 29 bit 524287 255 N/A

Wiegand

Format

Largest

PIN Value

Largest

Site Value

Largest

Group

Value

4 30 bit 65535 255 15

5 31 bit 65535 255 31

6 32 bit 8191 2047 63

7 36 bit 1048575 255 N/A

8 29 bit 524287 255 N/A

12 Document # 6104400, Rev. 1.0, D1c

Page 13

e/eM Style Open Technology Keypad Installation/Programming Manual

8. Troubleshooting

Refer tothis section if the keypadis not operatingcorrectly asdescribed

in this manual.

Problem Solution

The local program

code is not allowing

access to local

program mode.

No LED’s are lit on

the keypad.

The code works on

the controller but

does not work on

the keypad.

After performing the

keypad self-test, the

yellow LED is on

solid (not flickering

rapidly, HFE mode

only).

DEALERS/INSTALLERS ONLY! End users must contact dealer/installer

for support. If the keypad still does not work after troubleshooting,

please call IEI’s technical support department at 1-800-343-9502 (outside

MA) or 1-800-733-9502 (inside MA). Operating hours are Monday

through Friday from 8:00 A.M. to 7:00 P.M. Eastern Standard Time.

Perform the program mode loopback shown

in the next section (Figure 7) and reset the

local program code using command

90#0#0#code*code*

Power may not be reaching the keypad.

Using a voltmeter, verify that voltage is

reaching the keypad on the Red and Black

wires. If there is no voltage, verify the

voltage at the controller and power supply

and verify that there is no break in the

wires, then check continuity through the

whole length of the wire run. Also, when

using the keypad as a Wiegand front end,

verify that the LED wire is connected.

The data lines may not be connected. Verify

that both data lines are connected to the

keypad and controller and make sure there

is continuity through the whole length of the

wire run.

The data lines may not be connected. Verify

that both data lines are connected to the

keypad and controller and make sure there

is continuity through the whole length of the

wire run.

Document # 6104400, Rev. 1.0, D1c 13

Page 14

e/eM Style Open Technology Keypad Installation/Programming

Manual

9. Wire Harness Loopback

Connections

Ifthefourdatawiresareshortedinoneofthetwoconfigurations

shown below on power up, the option is set. To connect, remove

power after you hear the three beeps and then reconnect the data

lines to their proper working configuration.

9.1 Defaulting Door-Gard/Setting in Hub Front

End Mode

First, disconnect power from the system, then connect the

White/Black Wire (Data 0) to the White Wire and connect the

White/Yellow Wire (Data 1) to the Brown Wire (LED 1), as shown

in Figure 5, and power up the keypad.

Figure 5 Hub Front End Loopback

14 Document # 6104400, Rev. 1.0, D1c

Page 15

e/eM Style Open Technology Keypad Installation/Programming Manual

9.2 Defaulting Door-Gard/Setting in 26-bit

WiegandFrontEndMode

First, disconnect power from the system, then connect the White/Black

Wire (Data 0) tothe Brown Wire (LED 1) and connect the White/Yellow

Wire (Data 1) to the White Wire, as shown in Figure 6, and power up

the keypad.

Figure 6 Wiegand Front End Loopback

9.3EnteringProgramModeUsingtheWire

Harness

If the local program code is either not working or forgotten, power

down the system, connect the wire harness as shown below, and then

power the system up again. Next, change your local program code and

power down the system and restore the wire harness to its original

configuration and turn the power on again.

First, disconnect power from the system, then connect the

White/Yellow Wire (Data 1) to the Brown (LED 1) and White Wire,

asshowninFigure7,andpowerupthekeypad.

Figure 7 Program Mode Loopback

Document # 6104400, Rev. 1.0, D1c 15

Page 16

e/eM Style Open Technology Keypad Installation/Programming

Manual

10. Warranty

International Electronics Inc. (IEI) warrants its products to be free

from defects in material and workmanship when they have been

installed in accordance with the manufacturer’s instructions and

have not been modified or tampered with. IEI does not assume

any responsibility for damage or injury to person or property due

to improper care, storage, handling, abuse, misuse, normal wear

and tear, or an act of God.

IEI’s sole responsibility is limited to the repair (at IEI’s option) or

the replacement of the defective product or part when sent to IEI’s

facility (freight and insurance charges prepaid) after obtaining

IEI’s Return Material Authorization. IEI will not be liable to the

purchaser or any one else for incidental or consequential damages

arising from any defect in, or malfunction of, its products.

Except as stated above, IEI makes no warranties, either expressed

or implied, as to any matter whatsoever, including, and without

limitation to, the condition of its products, their merchantability, or

fitness for any particular purpose.

Warranty Periods Are:

1Year PowerKey

2 Years Door Gard & Secured Series

Products

2 Years LS Series

2 Years Glass Break

5 Years ‘e’ and ‘eM’ Style Keypads

Allproductshavedatecodelabelingtodeterminethewarrantyperiod.A

90-day grace period is added to all products to account for shelf life.

16 Document # 6104400, Rev. 1.0, D1c

Page 17

Page 18

Page 19

Page 20

Loading...

Loading...