Page 1

DEMO MANUAL DC143

U

DESCRIPTIO

This demonstration circuit is a step-down (buck) regulator

using the LTC®1474/LTC1475. The exclusive use of surface

mount components and the LTC1474/LTC1475 in the tiny

MSOP package results in a highly efficient application in a

small board space. This demo board highlights the

capabilities of the LTC1474/LTC1475, which use a current

mode, constant off-time architecture to switch an internal

P-channel power MOSFET. This results in a power supply

that has low ripple and fast transient response. At low

output currents the LTC1474/LTC1475 automatically

switch to Burst ModeTM operation to maintain high operating

efficiencies and minimize supply current. At no load,only

DEMO MANUAL DC143

NO DESIGN SWITCHER

LTC1474/LTC1475

10µA I

, High Efficiency,

Q

Step-Down DC/DC

Converter

10µA (typical) is required to regulate the output. The parts

can be shut down to further reduce the supply current to

6µA (typical). In dropout, the internal P-channel MOSFET

is turned on continuously (100% duty cycle), providing

low dropout operation with V

battery detector allows the user to monitor the input

supply through an external resistive divider. This board is

intended for applications such as cellular phones, GSM

systems, 4mA to 20mA current-loop pirate supplies or any

portable battery-powered application. Gerber files for this

circuit board are available. Call the LTC factory.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corporation.

≅ VIN. An onboard low-

OUT

UW

WW

PERFORmANCE SU ARY

SYMBOL PARAMETER CONDITIONS BOARD SUFFIX VALUE

V

V

I

I

IN

OUT

OUT

Q

Input Voltage Range V

Output Voltage LTC1474/LTC1475 A, D 3.3V ± 0.10V

Maximum Output Current R

Typical Supply Current VIN = 10V, I

U

W

= 3.3V A, B, D, E 3.3V to 18V

OUT

= 5V C, F 5V to 18V

V

OUT

LTC1474-3.3/LTC1475-3.3 B, E 3.3V ± 0.10V

LTC1474-5/LTC1475-5 C, F 5V ± 0.15V

= 0Ω ALL 300mA

SENSE

= 0.25Ω ALL 150mA

R

SENSE

= 0 A, B, C 10µA

LOAD

V

IN

= 10V, I

= 0 D, E, F 15µA

LOAD

U

TYPICAL PERFOR A CE CHARACTERISTICS A D BOARD PHOTO

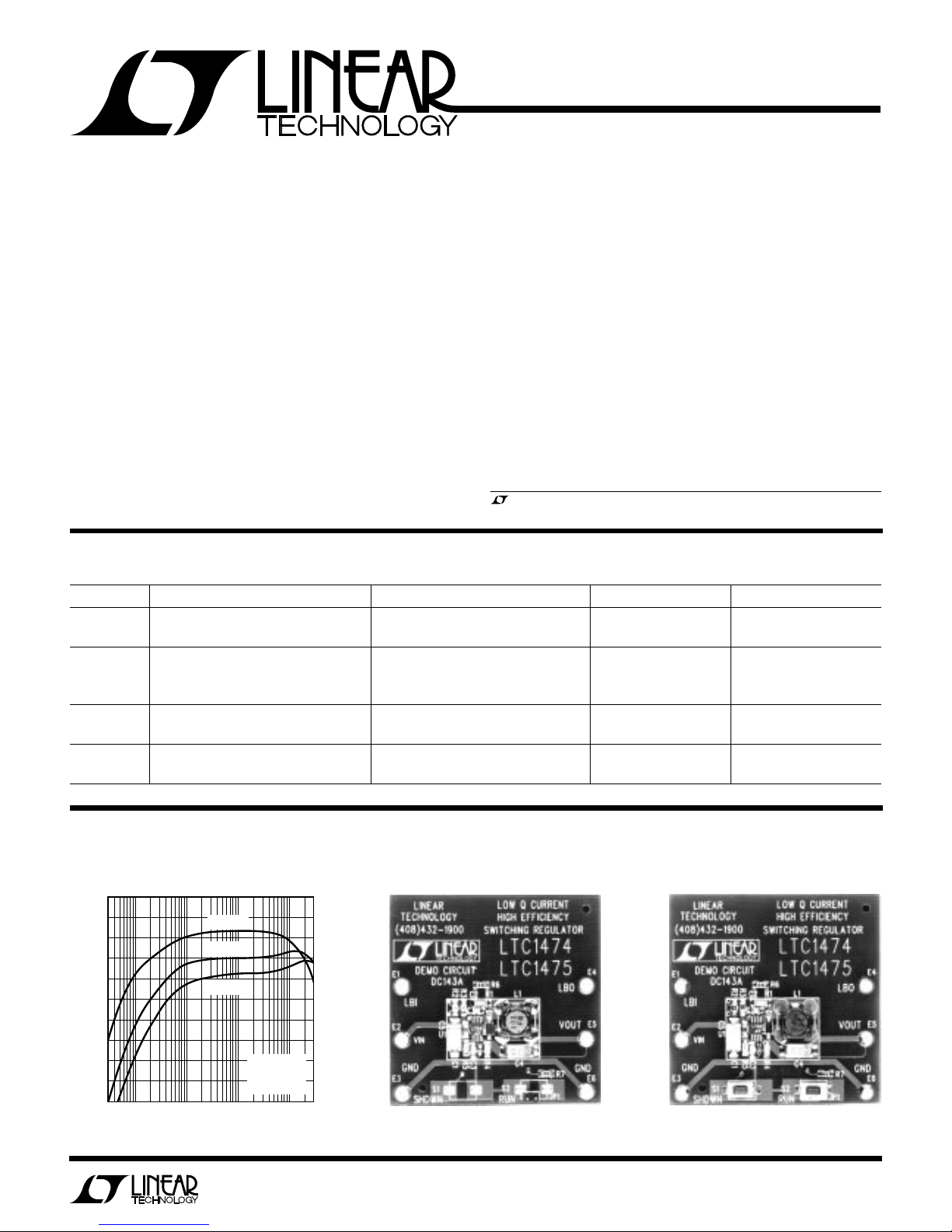

Board A, B, D, E Efficiency Demo Board A

100

VIN = 5V

90

80

VIN = 10V

VIN = 15V

Demo Board D

70

EFFICIENCY (%)

60

50

0.03 3 30 300

0.3

LOAD CURRENT (mA)

L = 100µH

= 3.3V

V

OUT

R

= 0Ω

SENSE

DM143 TPC

DM143 DB A

DM143 DB D

1

Page 2

DEMO MANUAL DC143

1

2

3

4

V

OUT

(VFB*)

LBO

LBI

GND

8

7

6

5

RUN

V

IN

SENSE

SW

TOP VIEW

MS8 PACKAGE

8-LEAD PLASTIC MSOP

*ADJUSTABLE OUTPUT VERSION

UW

WW

PERFORmANCE SU ARY

SYMBOL PARAMETER CONDITIONS BOARD SUFFIX VALUE

V

RIPPLE

∆V

V

LBI

OUT

Typical Output Ripple I

Typical Line Regulation 4V < VIN < 18V, R

Typical Load Regulation 0 < I

= 100mA All 50mV

OUT

< 18V, R

4V < V

IN

4V < VIN < 18V, R

4V < VIN < 18V, R

6V < VIN < 18V, R

< 18V, R

6V < V

IN

< 300mA, R

LOAD

0 < I

< 150mA, R

LOAD

SENSE

SENSE

SENSE

SENSE

SENSE

SENSE

= 0Ω, I

= 0.25Ω, I

= 0Ω, I

= 0.25Ω, I

= 0Ω, I

= 0.25Ω, I

SENSE

SENSE

= 100mA A, D 35mV

LOAD

= 100mA 25mV

LOAD

= 100mA B, E 20mV

LOAD

= 100mA 10mV

LOAD

= 100mA C, F 20mV

LOAD

= 100mA 10mV

LOAD

= 0Ω, VIN = 10V All 10mV

= 0.25Ω, VIN = 10V 10mV

Low-Battery Trip Threshold All 1.23V

W UW

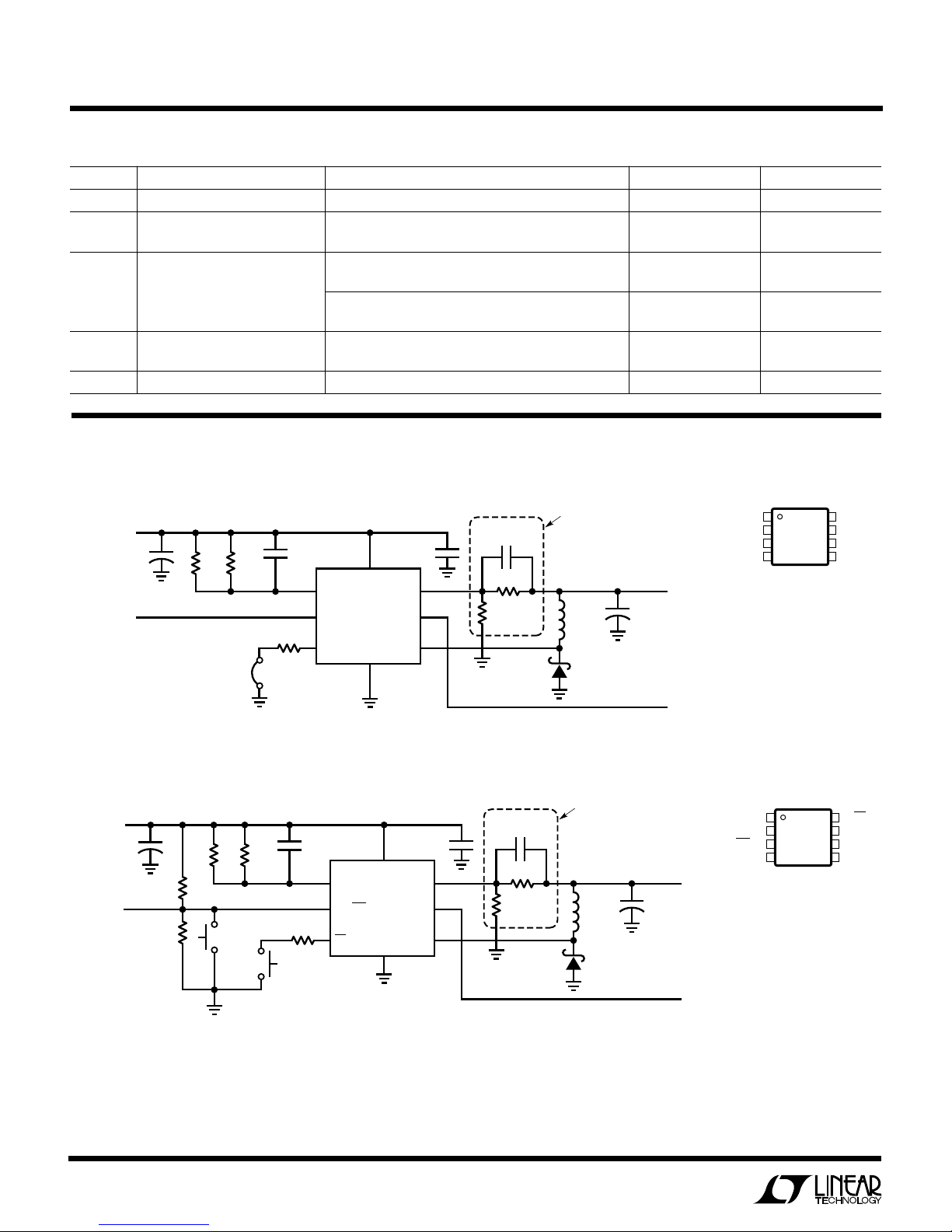

PACKAGE A D SCHE ATIC DIAGRA SM

VIN

4V* TO 18V

LBI

*3.3V AT NO LOAD

4.7µF

35V

C3

+

C1

R6

0Ω

JP1

RUN

R1

0.25Ω

R7

100k

C2

1000pF

6

3

8

SENSE

LBI

RUN

7

V

IN

LTC1474

GND

4

V

LBO

SW

0.1µF

FB

C5

1

2

5

10pF

R5

R4

THIS NETWORK

IS PRESENT IN

BOARD A ONLY

+

L1

100µH

D1

MBR0530

C4

100µF

6.3V

V

OUT

3.3V

300mA

LBO

DM143 F01

LTC1474CMS8

LTC1474CMS8-3.3

LTC1474CMS8-5

Figure 1. LTC1474 Demo Board Schematic

VIN

4V* TO 18V

4.7µF

LBI

*3.3V AT NO LOAD

35V

+

C1

3.01M

1M

R3

R2

R6

0Ω

SHDN

R1

0.25Ω

R7

100kRUN

C2

1000pF

Figure 2. LTC1475 Demo Board Schematic

2

6

3

8

SENSE

LBI/OFF

ON

7

V

IN

LTC1475

GND

4

V

LBO

SW

0.1µF

FB

C3

C5

1

2

5

10pF

R5

R4

THIS NETWORK

IS PRESENT IN

BOARD D ONLY

+

L1

100µH

D1

MBR0530

C4

100µF

6.3V

V

OUT (VFB

LBO

LBI/OFF

GND

V

OUT

3.3V

300mA

*ADJUSTABLE OUTPUT VERSION

TOP VIEW

1

*)

2

3

4

MS8 PACKAGE

8-LEAD PLASTIC MSOP

LTC1475CMS8

LTC1475CMS8-3.3

8

7

6

5

ON

V

IN

SENSE

SW

LTC1475CMS8-5

LBO

DM143 F02

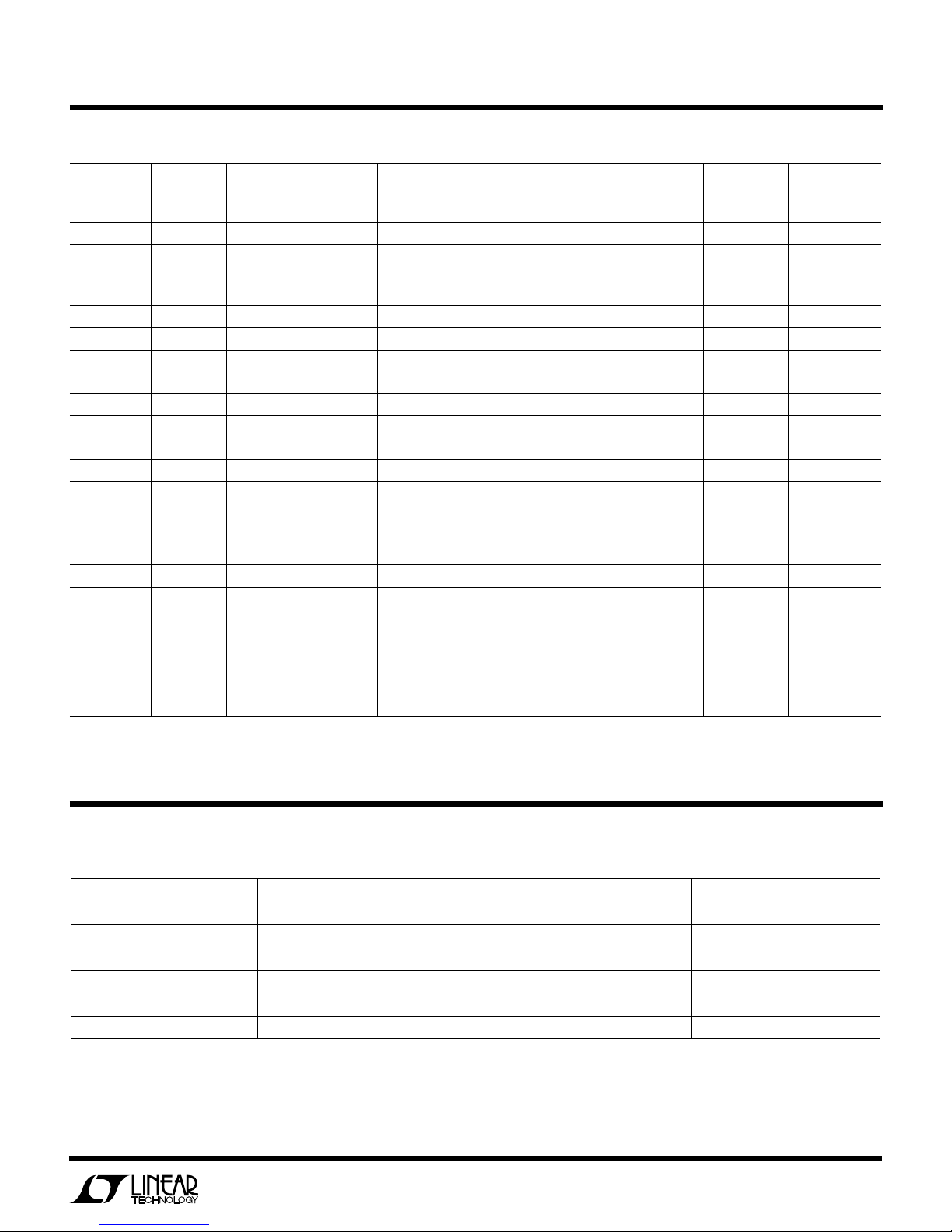

Page 3

DEMO MANUAL DC143

PARTS LIST

REFERENCE

DESIGNATOR QUANTITY PART NUMBER DESCRIPTION VENDOR TELEPHONE

C1 1 TPSC475M035 4.7µF 35V 20% Tantalum Capacitor AVX (207) 282-5111

C2 1 080553102KAT2A 1000pF 25V 10% X7R Capacitor AVX (803) 946-0362

C3 1 08055310KAT1A 10pF 25V 10% NPO Capacitor (Boards B, C, E, F Only) AVX (803) 946-0362

C4 1 TPSC107M006R0150 100µF 6.3V 20% Tantalum Capacitor (Boards A, B, D, E) AVX (207) 282-5111

TPSC336M010R0375 33µF 6.3V 20% Tantalum Capacitor (Boards C, F)

C5 1 08053E104ZAT1A 0.1µF 25V +80% to –20% Y5V Capacitor AVX (803) 946-0362

D1 1 MBR0530 0.5A 30V Schottky Diode Motorola (602) 244-3576

E1 to E6 6 2501-02 Terminal Turret Mill Max (516) 922-6000

JP1 1 2802S-02-G2 Connector Pin Header (Boards A, B, C) Comm Con (818) 301-4200

L1 1 CDRH73-101 100µH Inductor Sumida (847) 956-0666

R1 1 LR1206 01 R250 F0 0.25Ω 0.25W 1% Resistor IRC (512) 992-7900

R2 1 CR21-105J-T 1M 0.1W 5% Resistor (Boards D, E, F Only) AVX (803) 946-0524

R3 1 CR21-225J-T 2.2M 0.1W 5% Resistor (Boards D, E, F Only) AVX (803) 946-0524

R4 1 WCR0805-1474-F-P-LT 1.47M 0.1W 1% Resistor (Boards B, C, E, F Only) IRC (512) 992-7900

R5 1 CJ21-000J-T 0805 Shunt Resistor (Boards B, C, E, F) AVX (803) 946-0524

WCR0805-2494-F-P-LT 2.49M 0.1W 1% Resistor (Boards A, D) IRC (512) 992-7900

R6 1 CJ21-000J-T 0805 Shunt Resistor AVX (803) 946-0524

R7 1 CR21-104J-T 100k 0.1W 5% Resistor AVX (803) 946-0524

S1, S2 2 EVQ PJS05K Momentary Switch (Boards D, E, F) Panasonic (201) 392-4511

U1 1 LTC1474CMS8 8-Pin MSOP IC, LTC1474 (Board A) LTC (408) 432-1900

LTC1474CMS8-3.3 8-Pin MSOP IC, LTC1474-3.3 (Board B)

LTC1474CMS8-5 8-Pin MSOP IC, LTC1474-5 (Board C)

LTC1475CMS8 8-Pin MSOP IC, LTC1475 (Board D)

LTC1475CMS8-3.3 8-Pin MSOP IC, LTC1475-3.3 (Board E)

LTC1475CMS8-5 8-Pin MSOP IC, LTC1475-5 (Board F)

Table 1. Demo Board Version Cross Reference

BOARD SUFFIX PART NUMBER OUTPUT VOLTAGE ON/OFF CONTROL

A LTC1474 3.3V (Adjustable) Jumper

B LTC1474-3.3 3.3V Jumper

C LTC1474-5 5V Jumper

D LTC1475 3.3V (Adjustable) Pushbutton

E LTC1475-3.3 3.3V Pushbutton

F LTC1475-5 5V Pushbutton

3

Page 4

DEMO MANUAL DC143

QUICK START GUIDE

Demonstration Board DC143 is easy to set up for

evaluation of the LTC1474/LTC1475. Please follow the

procedure below for proper operation:

●

Connect the input power supply to the VIN and GND

terminals.

●

The LBO pin is a current sinking pin. When the LBI pin

goes below 1.23V, the LBO pin will sink 0.7mA of

current.

●

The LBI pin is the low-battery detector input pin.

Normally, its input comes from the input voltage

U

OPERATIO

The circuits shown in Figures 1 and 2 operate from input

voltages of 3.3V to 18V. The six different versions of the

demo board provide 3.3V or 5V, as specified in Table 1. For

output voltages other than 3.3V or 5V, use Board A or D

and change the resistive divider R4/R5 to the appropriate

ratio. For output voltages lower than 3V, input voltages as

low as 3V can be used. The demo boards provide two

on/off options— by opening or shorting jumper JP1

(Boards A, B and C) or push-button (Boards D, E and F).

Operation

The LTC1474/LTC1475 use a current mode, constant offtime architecture shown in Figure 3. Current mode operation provides the well known advantages of clean start-up

and excellent line and load regulation. Constant off-time

adds to this list simplicity (neither an oscillator nor ramp

compensation is required) and inherent 100% duty cycle

in dropout.

The LTC1474/LTC1475 use Burst Mode operation to keep

the output capacitor charged to the proper output voltage

while minimizing quiescent current. Burst Mode operation

works by using short burst cycles to keep the output

capacitor charged, followed by a “sleep” mode where the

load current is supplied by the output capacitor and the

LTC1474/LTC1475 draw only 9µA of supply current.

Because of Burst Mode operation and the constant

off-time, the frequency changes with input voltage and

through a resistor network (the resistor divider is

present only on boards D, E and F).

●

Connect the load between the V

Refer to Figure 6 for proper measurement equipment

setup.

●

For board A, B or C, open jumper JP1 to turn on or short

the jumper to shut down. For Board C, D or E,

momentarily depress the RUN push-button to turn on

or momentarily depress the SHDN push-button to shut

down.

load. During sleep mode, the low quiescent current is

achieved by turning on only the voltage comparator and

voltage reference, which are needed to monitor the output

voltage, and the low-battery comparator. The low quiescent current and variable frequency minimize losses that

would normally dominate at light loads (DC supply current

losses and switching losses due to the MOSFET switch

gate charge). This results in the high efficiencies down to

extremely light loads and the ultralow supply current

required to maintain the output voltage at no load.

The LTC1474/LTC1475 also provide user-programmable

peak inductor current: the user can set the peak current to

any value between 10mA and 400mA with the appropriate

sense resistor. At the beginning of the burst cycle, the

internal P-channel MOSFET switch is turned on, causing

the inductor current to begin to increase. This current

flows through both an internal and an optional external

sense resistor. The internal current comparator monitors

the voltage drop across the sense resistors and, when the

voltage reaches 100mV, the current comparator trips and

turns the switch off, causing the inductor current to

decrease. At the end of the 4.75µs off-time, the switch

either turns back on or stays off (sleep mode), depending

on the status of the voltage comparator. Without an

external sense resistor (Pins 6 and 7 shorted), the peak

current defaults to the 400mA max due to the internal

sense resistor.

and GND terminals.

OUT

4

Page 5

OPERATIO

1µA

LTC1474: RUN

LTC1475: ON

8

2

LBO

CONNECTION NOT PRESENT IN LTC1474 SERIES

×

CONNECTION PRESENT IN LTC1474 SERIES ONLY

U

LBI/OFF

1-SHOT

TRIGGER OUT

V

ON

FB

LB

×

4.75µs

+

–

3

READY

LTC1474: LBI

LTC1475: LBI/OFF

ON

ON

C

–

+

–

V

+

1.23V

REFERENCE

100mV

1.23V

DEMO MANUAL DC143

V

IN

7

R

SENSE

(OPTIONAL)

V

CC

5Ω

1×

GND

4

25×

SENSE

6

SW

5

V

FB

1

V

IN

+

V

OUT

+

DM143 F03

Figure 3. LTC1474/LTC1475 Block Diagram

The demo board includes two sense resistors; 0.25Ω R1

is shorted out with a 0Ω resistor (R6) to easily demonstrate

peak current programming. With the short in place (R

SENSE

= 0Ω), the peak current is the maximum 400mA providing

a maximum load of 300mA. With the short removed

(R

= 0.25Ω), the peak current is reduced to 200mA

SENSE

and the maximum load is 150mA.

Low-Battery Detector

The low-battery indicator senses the input voltage through

an external resistive divider. This divided voltage connects

to the (–) input of a voltage comparator (Pin 3), which is

compared with a 1.23V reference voltage. Because the

current going into Pin 3 is negligible, the following

expression is used for setting the trip point:

V

= 1.23(1 + R3/R2)

LBTRIP

(Ω)

SENSE

R

5

4

3

2

1

0

0

100 150 200

50

MAXIMUM OUTPUT CURRENT (mA)

Figure 4. R

SENSE

250 300

DM143 F04

Selection

5

Page 6

DEMO MANUAL DC143

U

OPERATIO

V

IN

R3

LBI

R2

Figure 5. Low-Battery Comparator

LTC1474/LTC1475

–

+

1.23V

REFERENCE

DM143 F05

LBO

LBI

A

+

Figure 6. Correct Measurement Setup

V

IN

V

GND

LBO

V

OUT

GND

A

V

LOAD

DM143 F06

HOW TO MEASURE VOLTAGE REGULATION

When trying to measure voltage regulation, remember

that all measurements must be taken at the point of

regulation. This point is where the LTC1474/LTC1475’s

control loop looks for the information to keep the output

voltage constant. This information occurs between Pins 1

and 4 of the LTC1474/LTC1475. These points correspond

to the output terminals of the demonstration board. Test

leads should be attached to these terminals. Measurements should not be taken at the end of test leads at the

load. Refer to Figure 6 for proper monitoring equipment

configuration. This applies to line regulation (input-tooutput voltage regulation) as well as load regulation tests.

In doing line regulation tests, always look at the input

voltage across the input terminals.

For the purposes of these tests, the demonstration circuit

should be fed from a regulated DC bench supply so

additional variation on the DC input does not add an error

to the regulation measurements.

For measurement of no-load supply current and measurement of efficiency at loads below 1mA,

the input impedance of the voltmeters may have a significant effect on

measurements

. For example, in the case of voltmeters

with 10MΩ impedance, the no-load supply current at

VIN = 15V will increase from 10.5µA with no meters

connected to 12µA with meters connected to both the

input and output. Likewise, with VIN = 15V and I

LOAD

=

100µA, the efficiency decreases from 59% to 56.8% when

the voltmeters are connected. Therefore, for the most

accurate measurements at light loads, first record the

voltmeter readings, then disconnect the voltmeters before

making the input supply current measurement.

COMPONENTS

Component selection can be very critical in switching

power supply applications. This section discusses some

of the guidlines for selecting the different components.

The LTC1474/LTC1475 data sheet details more specific

selection criteria for most of the external components

surrounding the IC. Be sure to refer to the data sheet if

changes to this demo circuit are anticipated.

Capacitors

The most common component uncertainty with switching

power supplies involves capacitors. In this circuit (refer to

Figure 1) C1 and C4 are low ESR, high ripple current

tantalum capacitors specifically designed and developed

for use in switching power supplies. ESR (equivalent

series resistance) is the parasitic series resistance in the

capacitor. Often, this resistance is the limiting element in

reducing ripple at the output or input of the supply.

Other choices are organic semiconductor type capacitors

(OS-CON) that are specifically made for power supply

applications. For lower current applications (<50mA)

ceramic capacitors, available as large as 10µ F, provide the

smallest size and lowest ESR.

Normal tantalums are not recommended for use in these

applications (especially the low cost ones), as they do not

have the ability to take the large peak currents that are

required for the application. Standard wet electrolytics

also may not meet requirements, due to their high ESR,

limited operating life and larger size.

6

Page 7

OPERATIO

DEMO MANUAL DC143

U

Inductor

Many off-the-shelf surface mount inductors are available

that work well in LTC1474/LTC1475 applications. The

inductor used in this demo board is from Sumida, but

there is a wide variety of inductors available from other

manufacturers, such as the Dale LPT4545 series, Coilcraft

DO1608 and DO3316 series and Coiltronics CTX series.

The inductors vary in size, shape, cost, current rating and

loss characteristics. The only fixed requirement of the

inductor is that it must be able to support the output DC

current and still maintain its inductance value. The other

variables need to be traded off against the requirements

for area, efficiency and cost in choosing the optimal

inductor.

Sense Resistor

The demo board is provided with a 0.25Ω current sense

resistor—a special, low valued, current shunt resistor

made by IRC. However, in most cases the least expensive

solution is obtained by paralleling standard resistors (available in values ≥ 1Ω) instead of using this special low

valued resistor. Although a single resistor could be used

with the desired value, these low valued resistor types are

much more expensive and are currently not available in

case sizes smaller than 1206. Three or four 0603 size

standard resistors require about the same area as one

1206 size low valued resistor and are available at a fraction

of the cost.

Schottky Diode

The catch diode carries load current during the off-time.

The average diode current is therefore dependent on the

P-channel switch duty cycle. At high input voltages the

diode conducts most of the time. As VIN approaches V

OUT

the diode conducts only a small fraction of the time. The

most stressful condition for the diode is when the output

is short-circuited. Under this condition, the diode must

safely handle I

at close to 100% duty cycle.

PEAK

To maximize both low and high current efficiency, a fast

switching diode with low forward drop and low reverse

leakage should be used.

Low reverse leakage current is

critical to maximize low current efficiency, since the leakage can potentially approach the magnitude of the LTC1474/

LTC1475 supply current.

Low forward drop is critical for

high current efficiency, since loss is proportional to forward drop. These are conflicting parameters, but a good

compromise is the MBR0530 0.5A Schottky diode specified in the schematic. Using a diode with slightly lower

forward drop, for example the MBRS130, increases the

efficiency by 1.3%, but also increases the no-load suppy

current from 10µA to 16µA.

Component Manufacturers

Beside the components that are used on the demonstration board, other components may also be used. Below is

a partial list of the manufacturers whose components you

can use for the switching regulator. Using components

other than the ones on the demonstration board requires

recharacterizing the circuit for efficiency.

MANUFACTURER COMPONENT PART NUMBERS TELEPHONE FAX

Coilcraft Inductors DO1608, DO3316 Series (847) 639-6400 (847) 639-1469

Coiltronics International Inductors Econo-Pac, Octa-Pac (561) 241-7876 (561) 241-9339

Dale Electronics Inductors LPT4545 (605) 665-9301 (605) 665-1627

Sumida Electric Co. Ltd Inductors CD54, CDRH74B Series (847) 956-0666 (847) 956-0702

AVX Corporation Capacitors TPS/TAJ Series, AA Series (803) 448-9411 (803) 448-1943

Sanyo Video Components Capacitors OS-CON Series (619) 661-6835 (619) 661-1055

Sprague Capacitors 593D Series (207) 324-4140 (207) 324-7223

Marcon Capacitors THC Series (847) 696-2000 (847) 518-9985

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no representation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

7

Page 8

DEMO MANUAL DC143

UW

PCB LAYOUT A D FIL

Component Side Silkscreen Component Side

Solder Side

U

PC FAB DRAWI G

2.000

B

C

C

C

B

AA

C

2.000

C

C

Component Side Solder Mask

Solder Side Solder Mask

DIAMETER NUMBER OF

SYMBOL (INCH) HOLES PLATED

UNMARKED 0.015 11 YES

A 0.030 2 YES

B 0.070 2 NO

C 0.094 6 YES

TOTAL HOLES 21

NOTES:

1. MATERIAL IS FR4, 0.062” THICK WITH 2 OZ COPPER

2. PCB WILL BE DOUBLE-SIDED WITH PLATED THROUGH HOLES

3. PLATED THROUGH HOLE — WALL THICKNESS MIN 0.0014” (1 oz)

4. SOLDER MASK BOTH SIDES

5. SILKSCREEEN COMPONENT SIDE

6. ALL HOLE SIZES AFTER PLATING +0.003/–0

Linear Technology Corporation

8

1630 McCarthy Blvd., Milpitas, CA 95035-7417 ● (408) 432-1900

FAX: (408) 434-0507

●

TELEX: 499-3977 ● www.linear-tech.com

dc143 LT/TP 0697 500 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1997

Loading...

Loading...