Page 1

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

LT1317/LT1317B

Micropower, 600kHz

U

PWM DC/DC Converters

DESCRIPTIO

Demonstration Circuit DC194 is a micropower boost

regulator that converts an input as low as 1.5V to an output

of 3.3V or 5.0V. DC194 version A uses the LT®1317CMS8;

version B uses the LT1317BCMS8. This circuit provides

regulated power for battery-powered devices, such as

laptop and palmtop computers, cellular phones, pagers,

LCD panels and other portable devices. It is also useful for

local conversion of logic supplies, such as 3.3V to 5V

conversion in PC card devices.

The LT1317 and LT1317B are 600kHz PWM DC/DC converters. Their high operating frequency and small package

result in small, cost effective solutions. The micropower

LT1317 shifts automatically to low power Burst Mode

operation at light loads, whereas the LT1317B operates at

a fixed frequency at all loads. Both parts feature a lowbattery detector that remains active while the part is shut

down. The wide voltage ratings (12V input and 30V

switch) make the LT1317 and LT1317B versatile parts,

suitable for implementing boost, flyback and SEPIC

topologies.

, LTC and LT are registered trademarks of Linear Technology Corporation.

Burst Mode is a trademark of Linear Technology Corportion.

UWWW

PERFOR A CE SU ARY

PARAMETER CONDITIONS VALUE

Input Voltage (Note 1) V

Maximum Load Current, Min V

Shutdown Current, Typ VIN = 2.5V, SHDN = 0V 25µA

No Load Quiescent Current, Typ V

Note 1: This limit is based on the DC194 circuit. The LT1317 can operate

from high supply voltages.

= 3.3V 1.5V to 3.6V

OUT

V

= 5V 1.5V to 5.3V

OUT

= 3.3V, VIN = 1.6V 175mA

OUT

= 3.3V, VIN = 2.4V 320mA

V

OUT

= 5V, VIN = 2V 140mA

V

OUT

= 5V, VIN = 3.3V 290mA

V

OUT

= 3.3V, VIN = 2.4V, LT1317 125µA

OUT

= 3.3V, VIN = 2.4V, LT1317B 4.8mA

V

OUT

TM

U

W

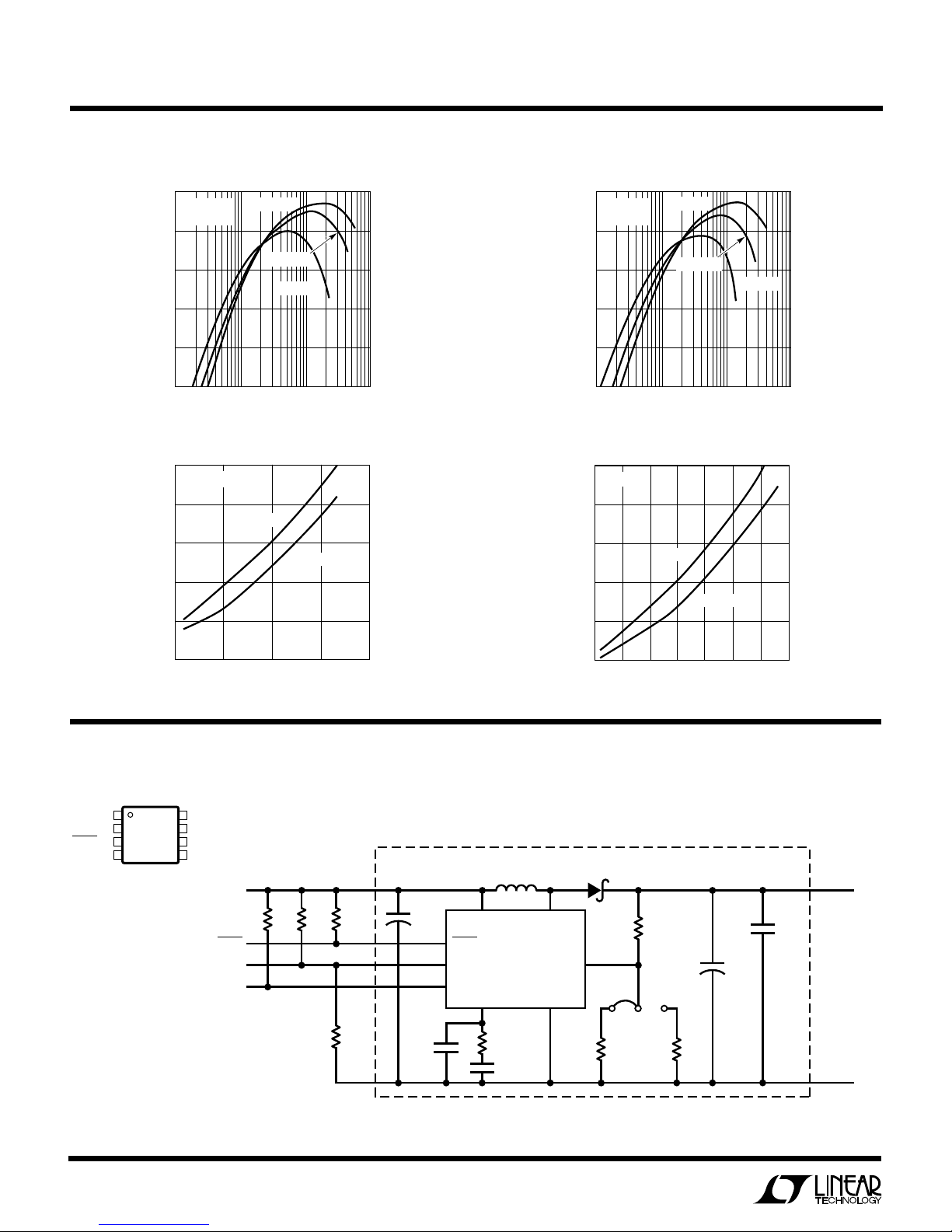

TYPICAL PERFOR A CE CHARACTERISTICS A D BOARD PHOTO

LT1317 Efficiency

90

VIN = 3V

80

LT1317

V

OUT

VIN = 1.6V

= 3.3V

1

LOAD CURRENT (mA)

70

60

EFFICIENCY (%)

50

40

0.3 10 100 1000

VIN = 2.4V

DC194 G04

LT1317 Efficiency

90

80

70

60

EFFICIENCY (%)

50

LT1317

= 5V

V

OUT

40

0.3 10 100 1000

1

VIN = 3.3V

VIN = 2.4V

VIN = 1.6V

LOAD CURRENT (mA)

U

Board Photo

DC194 BP

DC194 G03

1

Page 2

DEMO MANUAL DC194

LOAD CURRENT (mA)

1

EFFICIENCY (%)

90

80

70

60

50

40

10 100 1000

DC194 G05

LT1317B

V

OUT

= 5V

VIN = 3.3V

VIN = 1.6V

VIN = 2.4V

MICROPOWER BOOST REGULATOR

UW

TYPICAL PERFORMANCE CHARACTERISTICS

LT1317B Efficiency

90

LT1317B

V

OUT

80

70

60

EFFICIENCY (%)

50

40

1

= 3.3V

VIN = 3V

VIN = 2.4V

VIN = 1.6V

10 100 1000

LOAD CURRENT (mA)

Load Current vs Input Voltage

600

V

= 3.3V

OUT

500

400

300

OUTPUT CURRENT (mA)

200

TYPICAL

MINIMUM

DC194 G06

LT1317B Efficiency

Load Current vs Input Voltage

600

V

= 5V

OUT

500

400

300

OUTPUT CURRENT (mA)

200

TYPICAL

MINIMUM

100

1.5

2.0

2.5

INPUT VOLTAGE (V)

3.0

3.5

DC194 G01

W UW

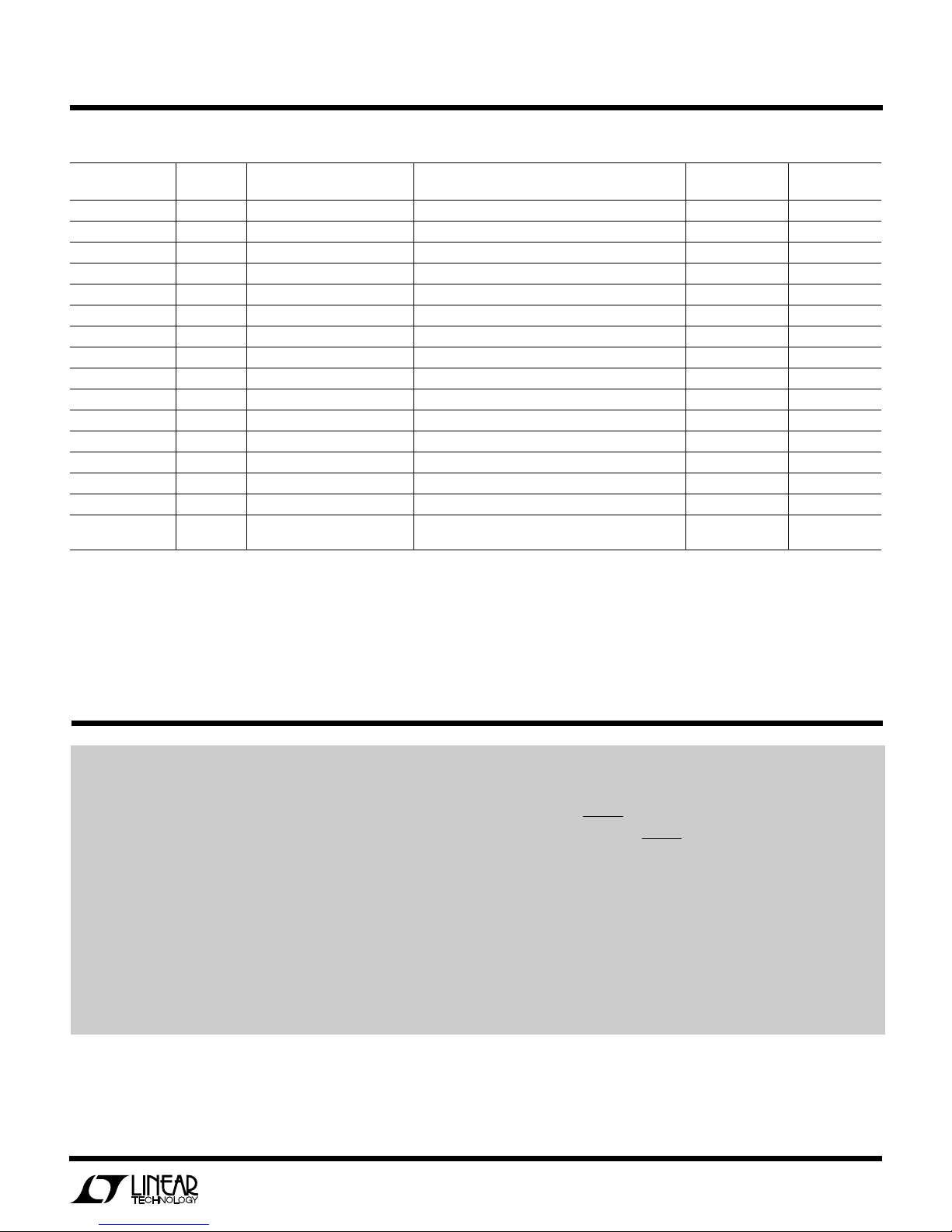

PACKAGE A D SCHE ATIC DIAGRA SM

TOP VIEW

V

1

C

2

FB

3

SHDN

4

GND

MS8 PACKAGE

8-LEAD PLASTIC MSOP

NOTES:

1. FOR VERSION A: USE LT1317CMS8 (LTHA)

2. FOR VERSION B; USE LT1317BCMS8 (LTHB)

3. FOR 3.3V OUTPUT, INSTALL SHUNT AT

JP1 PINS 1, 2

FOR 5V OUTPUT, INSTALL SHUNT AT

JP1 PINS 2, 3

8

LBO

7

LBI

6

V

IN

5

SW

SHDN

LBO

LT1317CMS8

LT1317BCMS8

V

IN

R7

OPT

LBI

R6

OPT

L1

10µH

R4

OPT

R5

OPT

+

C1

22µF

10V

3

7

8

C5

100pF

6

V

IN

LT1317CMS8(A)

SHDN

LBI

LT1317BCMS8(B)

LBO

V

C

1

R3

33k

C3

3300pF

LTHA

LTHB

Figure 1. Demo Board Schematic

U1

OR

SW

GND

5

4

100

1.5

MBR0520LT1

2

FB

3.0

R1B

332k

5V

3.5

4.0

C2

+

100µF

6.3V

2.5

2.0

INPUT VOLTAGE (V)

D1

R2

1.00M

3.3V

5V

231

JP1

R1A

604k

3.3V

4.5

DC194 G02

5.0

C4

0.1µF

DC194 F01

V

GND

OUT

2

Page 3

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

PARTS LIST

REFERENCE

DESIGNATOR QUANTITY PART NUMBER DESCRIPTION VENDOR TELEPHONE

C1 1 TPSB226M010R0700 22µF 10V 20% Tantalum Capacitor AVX (207) 282-5111

C2 1 TPSC107M006R0150 100µF 6.3V 20% Tantalum Capacitor AVX (207) 282-5111

C3 1 0805YG332KAT2 3300pF 16V Y5V 0805 Capacitor AVX (843) 946-0362

C4 1 08053G104KAT2 0.1µF 25V Y5V 0805 Capacitor AVX (843) 946-0362

C5 1 0805YG101KAT2 100pF 16V Y5V 0805 Capacitor AVX (843) 946-0362

D1 1 MBR0520LT1 20V 0.5A SOD123 Schottky Diode Motorola (800) 441-2447

L1 1 CD43-100MC 10µH CD43 Inductor Sumida (847) 956-0666

R1A 1 CR10-6043F-T 604k 1/10W 1% 0805 Resistor TAD (800) 508-1521

R1B 1 CR10-3323F-T 332k 1/10W 1% 0805 Resistor TAD (800) 508-1521

R2 1 CR10-1004F-T 1M 1/10W 1% 0805 Resistor TAD (800) 508-1521

R3 1 CR10-333J-T 33k 1/8W 5% 0805 Resistor TAD (800) 508-1521

R4 (Optional) 1 CR18-104J-T 100k 1/8W 5% 1206 Resistor TAD (714) 255-9123

R5 to R7 (Optional) 3 CR18-XXXJ-T XXX 1/8W 5% 1206 Resistor TAD (714) 255-9123

JP1 1 3801S-03-G1 3-Pin Header, 0.1" Center Comm (626) 301-4200

1 CCIJ230-G SHUNT FOR JP1 Comm (626) 301-4200

U1 1 LT1317CMS8, MSOP LTHA DC/DC Converter Version A LTC (408) 432-1900

LT1317BCMS8, MSOP LTHB DC/DC Converter Version B

QUICK START GUIDE

DC194 can regulate a 3.3V output from an input of 1.5V

to 3.6V; it can regulate a 5V output from an input of 1.5V

to 5.3V. Select the desired output voltage by moving

jumper JP1 to the appropriate position. Apply the DC

input voltage between the VIN and GND terminals of the

DC194. Do not apply more than 5.5V to the input of this

circuit.

With the input supply present, the LT1317/LT1317B will

regulate the output to 3.3V or 5V. Attach a suitable load

between V

and GND.

OUT

The LT1317/LT1317B can be placed in shutdown mode

by tying the SHDN terminal to the GND terminal. For

normal operation, the SHDN terminal can be left floating

or pulled high (above 1.4V and up to VIN).

Note that, as with any boost regulator, there is a direct DC

path between the input and output; a shorted output will

draw large currents, possibly damaging the DC194.

3

Page 4

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

U

OPERATIO

INTRODUCTION

The LT1317 and LT1317B are 600kHz PWM step-up

DC/DC converters. With a wide input voltage range (1.5V

to 12V) and high switch voltage (30V), these parts are

suitable for a wide variety of switching regulator circuits.

DC194 demonstrates their application in a simple boost

regulator with an output of either 3.3V or 5V.

DC194 is available in two versions. Version A uses the

LT1317CMS8. At light loads, this part switches automatically into power-saving Burst Mode operation, resulting in

high efficiency over a broad range of load currents. Version B uses the LT1317BCMS8, which operates at a fixed

frequency, regardless of load, eliminating low frequency

ripple on the output at the expense of light load efficiency.

You can confirm which version of the board you have by

checking the code on the IC; the LT1317 is marked with the

code LTHA, whereas the LT1317B is marked with LTHB. In

the comments below, “LT1317” will refer to both parts. In

cases where their characteristics result in different behavior, the LT1317B will be mentioned explicitly.

This manual describes the operation of this demonstration

circuit, its performance and variations on the basic circuit.

For a thorough discussion of the LT1317 and its application, please consult the part’s data sheet.

Hookup and Initial Tests

Select the desired output voltage by moving jumper JP1.

The input can safely accept a voltage up to 5.5V. A good

starting point is to apply 2.5V between the VIN and GND

terminals of the DC194, using a bench-top supply with a

1A current limit. Because the SHDN pin of the LT1317 has

been left floating, the LT1317 will begin operating as soon

as VIN is above 1.5V.

A load can be applied between the V

and GND termi-

OUT

nals, using either a fixed resistor, a decade resistor box

(provided that it is rated for the power) or an active load.

A simple initial load might be a 1/2W 100Ω resistor.

Warning: Because the basic boost circuit contains a DC

path between the input and output (through inductor L1

and diode D1), the circuit is not protected against a

shorted output. It is recommended that preliminary testing of the circuit be performed using a current-limited

supply on the input.

With power applied to the DC194, the LT1317 should be

switching and regulating the output. Figure 3 shows some

of the circuit’s operating waveforms. The scope photos

show the output voltage, the current through inductor L1

and the voltage on the SW pin of the LT1317. The LT1317

is in Burst Mode operation in the first photo. The second

photo shows operation at a higher load current, where the

LT1317 is operating at a fixed frequency. LT1317B circuits

will operate in this mode at all load currents.

DC194 is a fairly simple low power switching regulator.

However, some precautions are necessary in order to test

the circuit safely. Proper hookup and accurate measurements are necessary for meaningful evaluation of efficiency and line and load regulation. Refer to Figure 2 for

proper connections.

I

OUT

A

V

V

OUT

BENCH

SUPPLY

1.5V TO 5.5V

1A

Figure 2. Recommended Hookup for Proper Evaluation

of Efficiency and Regulation (See Text)

A

C

BULK

+

I

IN

V

V

IN

4

V

OUT

GND

V

IN

DC194

DC194 F02

PERFORMANCE

Input Range and Power Capability

The LT1317 will operate from inputs above 1.5V. The

maximum allowable input voltage to this circuit is 5.5V,

which is based on the voltage ratings of the input and

output capacitors C1 and C2. The boost circuit will allow

the LT1317 to regulate the output only when the input

voltage is less than the desired output voltage plus one

diode drop. This means that the practical input range is

1.5V to 3.6V for a 3.3V output and 1.5V to 5.3V for a 5V

output.

The power capability of the DC194 is determined primarily

by the input voltage and the current limit of the LT1317’s

internal power switch and, to a lesser extent, by the value

of inductor L1. Therefore, the maximum load current that

this circuit can supply depends on the input voltage. A

Page 5

OPERATIO

V

OUT

AC COUPLED

100mV/DIV

I

L1

200mA/DIV

V

SW

5V/DIV

V

OUT

AC COUPLED

100mV/DIV

I

L1

200mA/DIV

V

SW

5V/DIV

U

5µs/DIV

DC194 F03a

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

LT1317 will run in this condition. The LT1317 will also

operate if this pin is pulled above 1.4V by an external

signal. The SHDN pin can be pulled as high as VIN + 0.3V.

The LT1317 is placed in shutdown mode by pulling this pin

below 0.4V; you can do this by tying the SHDN terminal of

the DC194 to the GND terminal. The current consumption

of the LT1317 in shutdown mode is typically 25µ A. However, the load can draw additional current through the

inductor and catch diode, raising the power consumption

in shutdown. The LT1317’s low-battery detector remains

active in shutdown. Applications of the low-battery detector are discussed below.

Efficiency

The efficiency of the DC194 is plotted in the Typical

Performance section of this manual. Efficiency measurements should be made with care, as there is plenty of

opportunity for errors to creep in.

1µs/DIV

DC194 F03b

Figure 3. DC194’s Operating Waveforms. In the Upper Photo,

the LT1317 Is in Burst Mode, Delivering 50mA to the Load. In

the Lower Photo, the Load Curent Is 160mA and the LT1317 Is

Switching at 600kHz. VIN = 2.5V, V

OUT

= 3.3V

graph of maximum load appears in the Typical Performance section of this manual. The lower curve shows the

guaranteed load capability based on the minimum current

limit specification in the LT1317 data sheet. The upper

curve shows the load capability of a typical DC194. As load

current is increased beyond this level, the output voltage

will sag as the LT1317 reaches its current limit. Again, be

aware that L1 and D1 provide a direct path between the

input and output and that this circuit does not limit the

output current. As an increasing load drags the output

voltage below the input, a larger current will flow, limited

only by the impedance of the power source, inductor L1

and diode D1.

Shutdown Mode

The SHDN pin of the LT1317 is tied directly to the SHDN

terminal of the DC194 and has been left floating. An

internal current source will pull up on this pin and the

The efficiency is defined as the power delivered to the load

divided by the power drawn from the input supply. Normally, the average input voltage, input current, output

voltage and output current are measured under steadystate conditions and the efficiency is calculated from these

values. Each should be measured with the highest accuracy and precision possible.

Figure 2 shows connections for the proper measurement

of efficiency and output regulation. The input and output

voltages are measured at the DC194 in order to avoid

including voltage drops across ammeters and terminal

connections. It is best to take all of these measurements

at one time. Be aware that most digital multimeters drop

significant voltage when they are used as ammeters, so

you must measure the input voltage while the ammeter is

in the circuit—the input voltage will be lower than the

voltage at the output of your bench-top supply. Another

difficulty occurs at low power when the LT1317 is in Burst

Mode operation. Here, the part will be drawing a few

hundred milliamperes while switching, but only a few

hundred microamperes average. An ammeter set to a

sensitive scale will have too much resistance to allow

these pulses of current to pass without large voltage

drops. The result is that the power delivered to the LT1317

is not equal to the average current times the average

5

Page 6

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

U

OPERATIO

voltage. Normally, the high resistance of the ammeter will

not be present, so its negative effect on efficiency measurements is misleading. This measurement problem can

be avoided by adding a large (1000µ F to 10,000µ F) bypass

capacitor across VIN between the ammeter and the DC194.

Comments on Layout

The layout used for this demonstration circuit may be

transferred to your circuit board (Gerber files are available). Also, the data sheet includes layout guidelines.

A boost regulator contains a high frequency current loop

that includes the power switch (between the SW and GND

pins of the LT1317), the diode (D1) and the output

capacitor (C2). This loop should be kept small and an

unbroken ground plane should be placed below it. Connect this local ground plane to the LT1317 near its ground

pin and to the system ground at just one point. The

feedback resistors and the components on the VC pin

should be as close as possible to the LT1317 and should

be returned to the LT1317’s ground pin.

Testing in Your System

You may want to paste this circuit into your system to test

compatibility. This should be done with care, since long

hookup wires and ground loops can introduce noise

sources and regulation problems that would not be present

if the LT1317 DC/DC converter was properly designed into

your PCB.

Treat the DC194 as a 3-terminal device with VIN, V

GND terminals. Wire the DC194 to your circuit board with

wires as short as practical, to points on the circuit board

that are close to each other. Also, add high frequency

bypass capacitors (0.1µ F ceramics) from VIN and V

ground on your circuit board.

If you are bringing power directly to the DC194, use two

wires from the input source to the VIN and GND terminals

of the DC194. The output power should be applied to your

system as described above, and either the input supply or

your circuit should be floating in order to avoid ground

loops.

OUT

OUT

and

to

DESIGN ALTERNATIVES

Component Selection

The components used for the DC194 represent a compromise in cost, performance and size. They are well matched

for the power capabilities of the LT1317 but there are many

options for the designer to optimize the circuit for his or

her application.

Diode D1 (Motorola MBR0520LT1) is a 0.5A, 20V Schottky diode. It is a good choice for nearly any LT1317

application, unless the output voltage or the circuit topology requires a diode rated for higher reverse voltages.

Motorola also offers 30V and 40V versions. Most 0.5A and

1A Schottky diodes are suitable and they are available

from many manufacturers. If you use a silicon diode, it

must be an ultrafast recovery type. Efficiency will be lower

due to the silicon diode’s higher forward voltage drop.

L1 is a 10µ H inductor rated for 1A of operating current. The

value of the inductor should be matched to the power

requirements and operating voltages of your application.

In most cases a value of 10µH is suitable. The inductor

should be rated for ~0.75A peak without excessive saturation—the current limit of the LT1317 internal power

switch allows the part to tolerate moderate inductance

loss. The Sumida CD43-100 used on the DC194 has a

relatively small footprint with low losses. The DO1608

series from Coilcraft offers a similar inductor. A smaller,

less expensive choice is the Murata LQH3C100K24, which

fits in a tiny 1210 footprint. Efficiency will be slightly lower

at higher operating currents. Finally, Coiltronics’ CTX10-1

is a surface mount toroidal inductor with good performance; it will generate lower stray magnetic fields than the

drum-type inductors listed above.

Lower Ripple

The quality of the output capacitor is the greatest determinant of the boost converter’s output voltage ripple. The

output capacitor performs two major functions. It must

have enough capacitance to satisfy the load under transient conditions, and it must shunt the AC component of

the current coming through the diode from the inductor.

The ripple on the output results when this AC current

6

Page 7

U

OPERATIO

passes through the finite impedance of the output capacitor. The capacitor should have low impedance at the

600kHz switching frequency of the LT1317. The impedance at this frequency is usually dominated by the

capacitor’s equivalent series resistance (ESR). Choosing

a capacitor with lower ESR will result in lower output

ripple. Note also that the AC current contains fast edges,

so that you need low impedance at the switching regulator’s

harmonics. This can be obtained by adding a small ceramic

capacitor in parallel with the main output capacitor.

The DC194 uses a surface mount tantalum capacitor from

AVX. Other companies, including Kemet and Sprague,

make similar products. Some tantalum capacitor manufactures recommend doubling the voltage rating for power

supply applications; for highest reliability in 5V applications, the output capacitor of the DC194 should be

replaced with a 10V version. The ESR of tantalum capacitors designed for DC/DC converters is specified by the

manufacturers and you have some choice in trading ripple

performance for cost and size.

Newer technologies also offer low ESR capacitors.

Panasonic’s SP series and Sanyo’s POSCAP series of

surface mount capacitors use an organic electrolyte to

achieve a lower ESR than tantalum capacitors of the same

size.

Loop Compensation Components

The components connected to the VC pin of the LT1317

(C3, R3 and C5) compensate the control loop of the

DC194. The values chosen here are conservative and

provide stable operation for a wide range of input voltage,

output voltage and output capacitor types. However, the

loop response can be optimized further once the power

components have been chosen. Figure 4 shows the transient response of the DC194; the upper trace in each photo

is the output voltage and the lower trace is the load current.

The lower photo shows the improvement in dynamic

response after changing the compensation components.

All Ceramic, Low Profile Design

Large value ceramic capacitors are now available that are

suitable for use as the main output capacitor of an LT1317

boost regulator. These capacitors have very low ESR and

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

V

OUT

AC COUPLED

50mV/DIV

I

LOAD

100mA/DIV

200µs/DIV

DC194 F04a

V

OUT

AC COUPLED

50mV/DIV

I

LOAD

100mA/DIV

200µs/DIV

DC194 F04b

Figure 4. The Dynamic Response of the Circuit Can Be

Improved by Optimizing the Compensation Network. The

Upper Photo Shows the Response to a Load Current Step from

20mA to 120mA. With R3 = 68k and C3 = 1.5nF, the Circuit

Responds Faster to Changing Loads (Lower Photo). When the

Load Current Is High, the 25mV

V

Trace Appear as Two Traces.

OUT

VIN = 2.5V, V

= 3.3V, LT1317B

OUT

therefore offer very low output ripple in a small package.

However you should approach their use with some

caution.

Ceramic capacitors are manufactured using a number of

dielectrics, each with different behavior across temperature and applied voltage. Y5V is a common dielectric used

for high value capacitors, but you can lose more than 80%

of the original capacitance with applied voltage and

extreme temperatures. The transient behavior and loop

stability of the switching regulator depend on the value of

the output capacitor, so you may not be able to afford this

loss. Other dielectrics (X7R and X5R) result in more stable

characteristics and are suitable for use as the output

Output Ripple Makes the

P-P

7

Page 8

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

U

OPERATIO

capacitor. The X7R type has better stability across temperature, while the X5R is less expensive and is available

in higher values.

The second concern in using ceramic capacitors is that

many switching regulators benefit from the ESR of the

output capacitor because it introduces a zero in the

regulator’s loop gain. This zero may not be effective

because the ceramic capacitor’s ESR is very low. Most

current mode switching regulators (including the LT1317)

can be easily compensated without this zero. Any design

should be tested for stability at the extreme operating

temperatures; this is particularly true of circuits that use

ceramic output capacitors.

Figure 5 shows a design that uses ceramic capacitors at

both input and output. It is intended to convert 3.3V to 5V

at 250mA and is a good circuit for use in PCMCIA cards.

The ceramic capacitors result in both low output ripple and

low height. The inductors listed result in a circuit height

under 1.8mm. The Sumida inductor requires a hole in the

circuit board for mounting; however, it requires less board

area than the Coiltronics part. Figure 6 shows the ripple

and transient response. Note that transient response

generally suffers with reduced output capacitance. This is

especially true with the LT1317 in Burst Mode operation,

when the load changes from a very low current (<100µ A)

to a higher current.

V

IN

1.5V

TO 5V

C1

2.2µF

6.3V

15k

C1: TAIYO-YUDEN JMK316BJ106ML

C2: TAIYO-YUDEN LMK212BJ225MG

D1: MOTOROLA MBR0520

SHDN

V

6.8nF

V

C

IN

LT1317/

LT1317B

L1

GND

D1

SW

FB

1.00M

332k

L1: SUMIDA CLQ61B-8R2 OR

COILTRONICS TP1-100

V

5V

(250mA

AT 3.3V

C2

10µF

6.3V

OUT

DC194 F05

)

IN

Figure 5. Ceramic Capacitors Result in Low Output Ripple

and Minimum Circuit Size in This Low Profile Design

V

OUT

AC COUPLED

100mV/DIV

I

LOAD

100mA/DIV

200µs/DIV

DC194 F06

Low-Battery Detector

The LT1317’s low-battery detector is a comparator whose

open collector output appears at the LBO pin of the

LT1317. The inverting input is internally tied to a 200mV

reference and the noninverting input appears at the LBI

pin. The LBI and LBO pins appear at the edge of the DC194.

There are also pads to add a resistor divider (R5 and R6)

from VIN to the LBI pin and a pull-up resistor (R4) from the

LBO to VIN. Figure 7 shows two applications of the lowbattery detector. The first shows its intended use, as an

input voltage monitor; the second shows how to use it as

an undervoltage lockout.

8

Figure 6. Above Is the Transient Response of the All-Ceramic

Design to a 50mA Load Step. The Low Impedance of the

Ceramic Output Capacitor Results in Low Output Ripple.

VIN = 3.3V, V

OUT

= 5V

Page 9

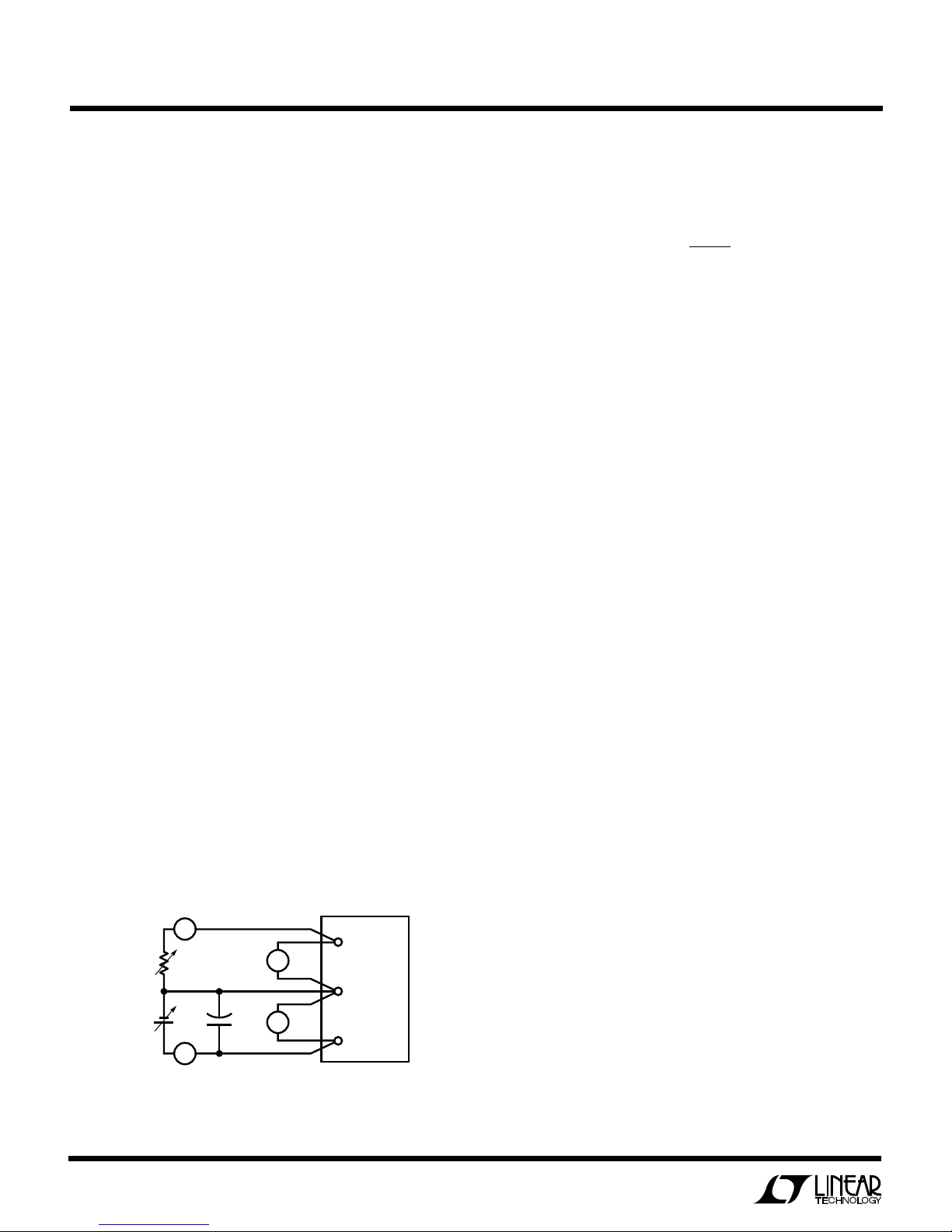

OPERATIO

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

U

BATTLOW

1.00M

118k

10M

1M

0.01µF

LBO

LBI

V

IN

GND

(a)

V

IN

1.00M

86.6k

10M

(b)

1M

SHDN

LBO

LBI

V

GND

IN

DC194 F07

Figure 7. Here Are Two Applications of the Low-Battery Detector.

In (a) It Is Used to Sense the Battery Voltage and Trips when V

IN

Falls Below 1.75V. In (b) It Is Used as an Undervoltage Lockout;

It Won’t Allow the LT1317 to Begin Switching until VIN Is Above

2.5V. In Both Cases the 10M Resistor Provides Hysteresis

9

Page 10

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

UW

PCB LAYOUT A D FIL

Silkscreen Top

DC194 TSLK

DC194 TSP

Solder Paste Top

Solder Mask Top

10

DC194 TSM

DC194 BSM

Solder Mask Bottom

Page 11

UW

PCB LAYOUT A D FIL

DEMO MANUAL DC194

MICROPOWER BOOST REGULATOR

Top Layer

DC194 TL

Information furnished by Linear Technology Corporation is believed to be accurate and reliable.

However, no responsibility is assumed for its use. Linear Technology Corporation makes no represen-

tation that the interconnection of its circuits as described herein will not infringe on existing patent rights.

DC194 BL

Bottom Layer

11

Page 12

DEMO MANUAL DC194

2.000

2.000

A

B

CCC

D

D

D

D

D

D

B

A

A

A

A

A

DC194 FAB

MICROPOWER BOOST REGULATOR

U

PC FAB DRAWI G

NUMBER

SYMBOL

DIAMETER

A

0.094

B

C

0.035

D

NOTES: UNLESS OTHERWISE SPECIFIED

1.MATERIAL: FR4 OR EQUIVALENT EPOXY, 2 OZ COPPER CLAD

THICKNESS 0.062 ± 0.006 TOTAL OF 2 LAYERS

2.FINISH: ALL PLATED HOLES 0.001 MIN/0.0015 MAX

COPPER PLATE ELECTRODEPOSITED TIN-LEAD

COMPOSTION BEFORE REFLOW, SOLDER

MASK OVER BARE COPPER (SMOBC)

3.SOLDER MASK: BOTH SIDES USING LPI OR EQUIVALENT

4.SILKSCREEN: USING WHITE NONCONDUCTIVE EPOXY INK

5.UNUSED SMD COMPONENTS SHOULD BE FREE OF SOLDER

6.FILL UP ALL VIAS WITH SOLDER

7.ALL DIMENSIONS ARE IN INCHES

OF HOLES

0.07

0.02

PLATED

YES

6

2

3

7

NO

YES

YES

Linear Technology Corporation

12

1630 McCarthy Blvd., Milpitas, CA 95035-7417

(408) 432-1900 ● FAX: (408) 434-0507

●

www.linear-tech.com

dc194 LT/TP 0299 500 • PRINTED IN USA

LINEAR TECHNOLOGY CORPORATION 1999

Loading...

Loading...