Page 1

LINEAR LLC

USA & Canada (800) 835-5666 & (800) 421-1587

Toll Free FAX (800) 468-1340

(760) 438-7000

www.linearcorp.com

MODEL LSO50

BELT-DRIVE OR CHAIN-DRIVE

GARAGE DOOR OPERATOR

INSTALLATION INSTRUCTIONS

For Sectional and Jamb Type Doors

IMPORTANT SAFETY NOTES

Please read the instructions carefully! This garage door

operator is designed to provide safe and reliable service

if installed and tested as described in these instructions.

A garage door is the largest mechanical appliance in a

residence. Care must be taken to prevent injury or death

during installation and operation of the garage door and

garage door operator.

WARNING

This type of warning note is used to indicate

possible electrical shock hazards that may

cause serious injuries or death.

THE FOLLOWING FORMATS ARE USED FOR

SAFETY NOTES IN THESE INSTRUCTIONS.

WARNING

This type of warning note is used to indicate

possible mechanical hazards that may cause

serious injuries or death.

CAUTION

This type of warning note is used to indicate

the possibility of damage to the garage door or

garage door operator.

IMPORTANT INSTALLATION SAFETY INSTRUCTIONS

WARNING

TO REDUCE THE RISK OF SEVERE INJURY OR DEATH TO PERSONS, REVIEW

THESE INSTALLATION SAFETY STEPS BEFORE PROCEEDING

1 READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2 Install only on a properly balanced garage door. An improperly balanced door could result in severe

injury or death. Repairs to cables, spring assemblies, and other hardware must be made by a qualified

service person before installing the operator.

3 Disable all locks and remove all ropes connected to the garage door before installing the operator.

Ropes connected to a garage door can cause entanglement and death.

4 If possible, install door operator 7 feet or more above the floor with the manual release handle

mounted 6 feet above the floor.

5 Do not connect the operator to the power source until instructed to do so.

6 Locate the wall station within sight of the door at a minimum height of 5 feet so that small children

cannot reach it. Locate the wall station away from all moving parts of the door.

7 Install the User Safety Label on the wall adjacent to the wall station.

8 Upon completion of the installation, the door must reverse when it comes in contact with a 1-1/2” high

object (or a 2x4 laid flat at the center of the door) on the floor and when the infrared safety beam is

blocked.

9 Do not wear watches, rings or loose clothing while installing or servicing an operator. Jewelry or

loose clothing can be caught in the mechanism of the garage door or the operator.

10 DISCONNECT THE ELECTRIC POWER FROM THE GARAGE DOOR OPERATOR BEFORE MAKING

ANY REPAIRS OR REMOVING THE COVER.

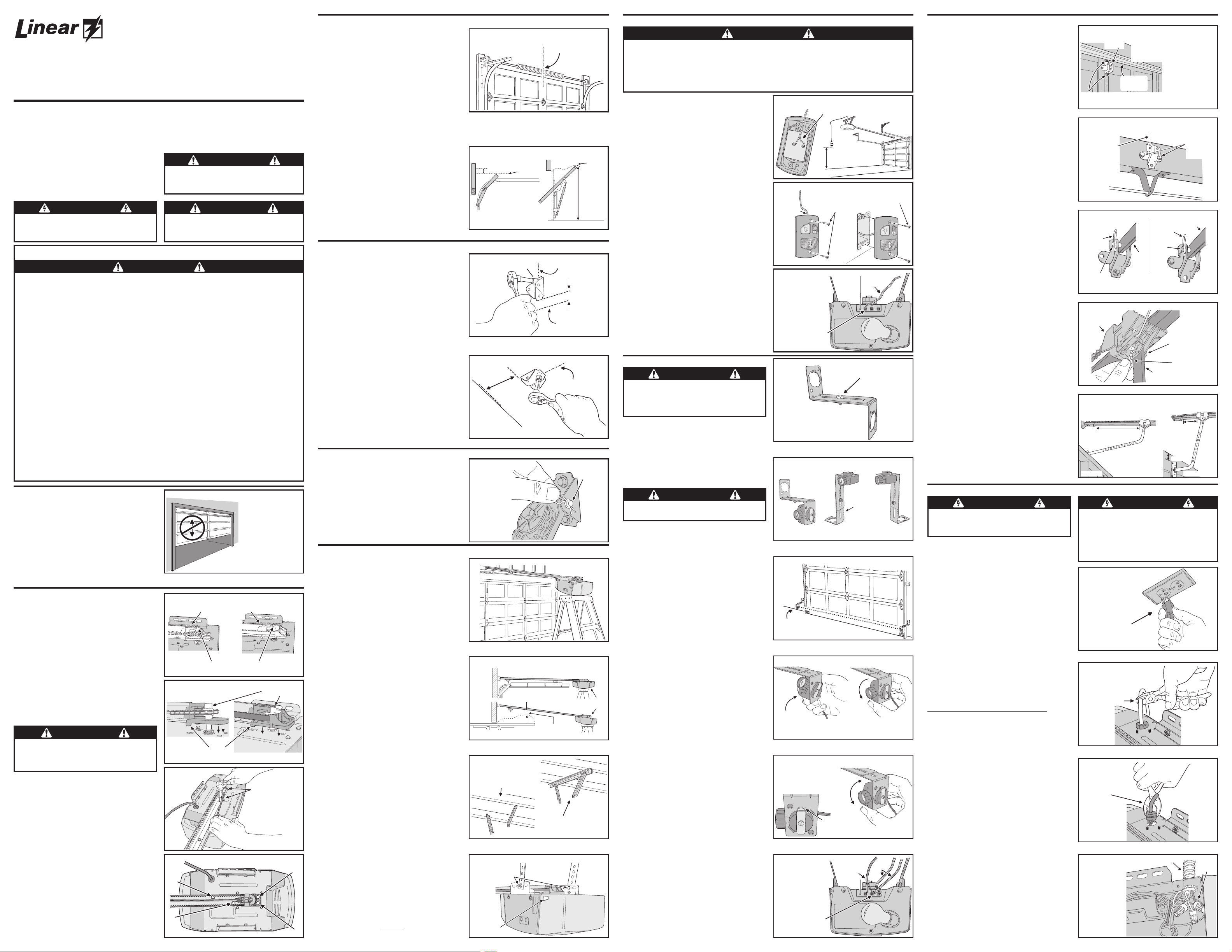

1 Check the Door Balance

1 From outside the garage, slowly open the door all the

way, and then close it all the way. Notice if there is

any binding, sticking or rubbing. The door should move

smoothly in both directions.

2 Raise the garage door about halfway up. Carefully

release the door and see if the door balances. It should

stay in place. Close the door.

� IMPORTANT: If the garage door is unbalanced or

the door travel isn’t smooth, have a qualified garage

door professional adjust or repair the door.

2 Attach the Rail to the Operator

1 Place the operator head on the garage floor with

cardboard underneath it to protect the finish.

� NOTE: To prevent upsetting the pre-adjusted door

limits in the operator, keep the trolley at the same place

on the rail until the sprocket is on the drive shaft.

2 Align the rail over the center of the operator head.

3 Be sure the flat on the sprocket lines up with the flat on

the drive shaft.

4 Slide the sprocket onto the shaft.

5 Attach the rail to the operator head by installing four

¼-20 x ¾” bolts.

6 Tighten the four bolts in the order shown with a 7/16”

socket.

CAUTION

- BELT RAILS HBT7 ONLY! -

TURN THE OPERATOR’S OPEN LIMIT 4 TURNS IN

THE DOWN DIRECTION BEFORE OPERATING UNIT.

CHECKING THE DOOR BALANCE

THE DOOR SHOULD

BALANCE WITHOUT

GOING UP OR DOWN

ALIGNING THE RAIL

CHAIN DRIVE

MATING THE SPROCKET AND SHAFT

CHAIN DRIVE

ATTACHING THE RAIL

TIGHTEN THE RAIL-TO-HEAD BOLTS IN THIS ORDER

1

2

LINE UP THE RAIL OVER THE DRIVE SHAFT

ON TOP OF THE OPERATOR HEAD

BE SURE THE FLAT ON THE SPROCKET

LINES UP WITH THE FLAT ON THE DRIVE SHAFT

TABS FIT INTO SLOTS

INSTALL FOUR 1/4-20 x 3/4"

RAIL-TO-HEAD BOLTS

USING A 7/16" SOCKET

(SEE TORQUE ORDER BELOW)

PULL THE BELT OR CHAIN

AWAY FROM THE RAIL TO FIT

THE SOCKET ON THE

FRONT BOLTS

BELT DRIVE

SLIDE THE SPROCKET

INTO THE SHAFT

BELT DRIVE

3 Locate the Header Bracket Position

1 Check whether door is a sectional or one-piece jamb type.

Note the differences in mounting header bracket,

door arm assembly and hanging the operator.

2 Close the door.

3 From inside the garage, use a pencil to mark the

vertical centerline of the door on the header wall and

on the top panel of a sectional door or on the top edge

of a jamb door.

4 Examine the area above the center of the door on the

door header wall for a header bracket mounting location.

5 Open the door to the high-rise point (the point where

the top edge of the door is highest above the floor) and

measure the distance to the floor.

6 Close the door and use a pencil to mark the header

wall 1” above (sectional) or 7” above (jamb) the

measured high-rise point.

� NOTE: In some installations, the header bracket

location will be higher than the door header. This will

require adding a 2x4 (or larger) cross piece to the wall

studs to provide a mounting location for the header

bracket. Use lag screws (not supplied) to attach the

2x4 to the studs.

7 On sectional doors with low headroom, the header

bracket can be attached to the ceiling up to 6” back

from the header wall (see next step).

MARKING THE CENTERLINE

MARKING ABOVE THE HIGH-RISE POINT

MARK HEADER

1" ABOVE

SECTIONAL DOOR JAMB DOOR

HIGH-RISE

POINT

MARK THE CENTERLINE

OF THE DOOR ON THE

HEADER AND THE TOP

DOOR PANEL

IF JAMB DOOR

MARK THE TOP

EDGE OF THE DOOR

HIGH-RISE

POINT

MEASURE

DISTANCE

TO FLOOR

CLOSE DOOR

AND MARK

HEADER 7"

ABOVE

4 Install the Header Bracket

Attaching the Header Bracket to the Wall

1 Hold the header bracket on the center line drawn

above the door with the bottom edge of the bracket on

the line marked above the high-rise point.

2 Use a pencil to mark the two bracket holes.

3 Drill two 3/16” pilot holes about 2” deep.

4 Use a ½” socket to fasten the bracket with two 5/16” x 2”

lag screws.

Attaching the Header Bracket to the Ceiling

� NOTE: On a finished ceiling, be sure there is a joist

to fasten to under the sheetrock where the header

bracket will be located (use a stud finder). If there is

none, install a 2x4 cross piece between the two closest

joists to fasten the header bracket onto.

1 Extend the center line drawn on the header wall along

the ceiling.

2 Hold the bracket on the center line with the edge of the

bracket no further than 6” from the header wall.

3 Use a pencil to mark the two bracket holes.

4 Drill two 3/16” pilot holes about 2” deep.

5 Use a ½” socket to fasten the bracket with two

5/16” x 2” lag screws.

ATTACHING THE HEADER BRACKET

1/2" SOCKET

ATTACH HEADER

BRACKET WITH

TWO 5/16" x 2"

LAG SCREWS

ATTACHING THE HEADER BRACKET TO THE CEILING

NO MORE

THAN 6 INCHES

DOOR

HEADER

WALL

FOR LOW HEADROOM SECTIONAL

DOOR INSTALLATIONS ONLY

CENTERLINE OF DOOR

HIGH-RISE POINT

OF DOOR

CENTERLINE OF DOOR

1 INCH (SECTIONAL)

2 INCHES (JAMB)

5 Connect the Rail to the Header Bracket

1 Place assembled operator on the empty carton on the

floor with rail towards the door.

2 Insert the end of the rail into header bracket.

3 Insert the 5/16” x 2-3/8” clevis pin through header

bracket and rail.

4 Secure the clevis pin with the hitch pin.

CONNECTING THE RAIL

INSERT HITCH PIN

INTO CLEVIS PIN

2-3/8" LONG

CLEVIS PIN

6 Hang the Operator

Installation requirements vary with garage construction.

Hanging brackets should be angled to provide rigid

support. Hanging material is not provided. Angle iron

and lag screws are recommended. DO NOT USE NAILS.

Following are typical operator hanging methods. Cer tain

installations will require improvised methods.

1 Raise the operator head and set it on top of a stepladder

(use extra spacers on top of ladder if it isn’t tall enough).

2 SECTIONAL DOORS: Carefully open the door to the

full up position. Lay a 2x4 across the top section of the

door as a spacer. Adjust the operator height until the rail

touches the spacer. The rail should be close to level.

JAMB DOORS: Carefully open the door to the high-

rise point. Adjust the operator height until the rail is 2”

above the door high-rise point. The rail should angle

up towards the header wall.

3 Center the operator head and rail with the centerline

mark on the top of the door.

4 For finished ceilings only: An angle iron cross piece

between the two closest joists above the operator will be

required. Mark mounting hole locations, drill pilot holes

and attach the piece with two lag screws (not supplied).

5 Measure the distance from each of the operator’s

hanging tabs to the ceiling joists or angle iron cross piece.

6 Cut two angle iron pieces to the required lengths for

hanging brackets. Bend brackets if required.

• For unfinished ceilings: Hold each bracket in place

and use a pencil to mark the locations where they will

be attached to the joists, drill pilot holes and attach the

pieces with two lag screws (not supplied).

• For finished ceilings with an angle iron cross piece:

Attach the two hanging brackets to the cross piece

with two bolts and two keps nuts (not supplied).

7 Attach operator to hanging brackets using two 5/16-18 x

1” hex bolts and two 5/16-18 keps nuts (supplied). Insert

bolts from the inside of hanger brackets with the nuts on

the outside of the operator. Tighten nuts with a ½” socket.

3

8 Tighten all hanging hardware.

9 Open and close the door manually. The door should

clear the rail by at least 1”.

10 Attach the trolley’s release lever to the red release

handle with the cord supplied so the handle is at least

6 feet from the floor. Cut off any excess cord.

11 Press the light cover release tabs in to open the covers.

4

Install two 100 watt maximum rough service lamps.

Swing the light covers closed, snapping them shut.

PREPARING TO HANG THE OPERATOR

ADJUSTING OPERATOR HEIGHT

JAMB DOOR

HANGING BRACKET OPTIONS

TYPICAL HANGING BRACKETS

SCREWED DIRECTLY TO JOISTS

HANGING THE OPERATOR

HANG THE OPERATOR

WITH TWO 5/16-18 x 1"

BOLTS AND NUTS

LIGHT COVER

RELEASE TAB

PLACE A 2x4 SPACER

BETWEEN THE DOOR AND RAIL

SECTIONAL DOOR

2" MAXIMUM BETWEEN

HIGH-RISE POINT AND

BOTTOM OF RAIL

ADJUST HEIGHT

AS REQUIRED

TYPICAL HANGING BRACKET

ASSEMBLY USING A CROSSPIECE

7 Install the Wall Station

WARNING

Children operating or playing with a garage door operator can injure themselves or others. The garage

door could cause serious injury or death. Do not allow children to operate the remote control(s) or

the wall station. Install the wall station out of reach of children and away from all moving parts of

the door. The door must be clearly visible from the wall station. A moving garage door could injure

someone under it. Only activate the door when it is properly adjusted, when it can be seen clearly

and when there are no obstructions to the door travel.

� NOTE: 22 AWG 2-conductor wall station and safety

beam wire is supplied with the operator, Use this wire

or the installation’s pre-wiring. For additional wire,

contact Linear for information regarding the 24-pack

Model HAE00009 wire and wire clip kit.

� UL NOTE: All low voltage Class 2 cable used with this

operator must be UL Listed Type CL2, CL2P, CL2R, or

CL2X or other cable with equivalent or better electrical,

mechanical, and flammability ratings.

1 Strip back ½” of insulation and connect a wire to each

of the two terminals on the back of the wall station.

2 Use the screws provided to mount the wall station near

an access door at a minimum height of five feet. SEE

IMPORTANT WARNING ABOVE!

3 For non-prewired installations, route the wire to the

back of the operator. Use insulated staples (not

supplied) to secure the wire. Staples must straddle

both wires to avoid electrical shorts.

4 Cut the wall station wire about 6” longer than needed to

reach the operator terminals. Strip back ½” of insulation.

5 Connect either wire to the operator’s PUSHBUTTON

terminal and the other wire to the operator’s COMMON

terminal.

6 Apply the User Safety Instruction Label to the wall next

to the wall station. Use staples or tacks to help the

label remain in place over time.

� IMPORTANT! DO NOT PLUG THE OPERATOR IN AT

THIS TIME! More installation is required.

8 Install the Safety Beam

WARNING

Persons, particularly children, could be killed

by a closing garage door without a properly

installed and adjusted safety beam optical

obstacle sensing system.

� NOTE: The safety beam’s infrared light beam must

not be obstructed by the door, or by any part of the

door hardware. Use wooden spacers between the

beam brackets and wall if necessary to create proper

clearance.

1 Assemble the two safety beam brackets from the four

L-shaped brackets using two ¼-20 x ¾” bolts and

¼-20 keps nuts (one nut & bolt for each bracket).

WARNING

To protect small children, do not install the

safety beam higher or lower than instructed.

2 Position the assembled brackets on each side of the

door so the center line of the safety beam lenses

will be 6” above the floor. Use the index marks on

the brackets to make the bracket assemblies equal

lengths. Mark the locations for the bracket mounting

screws (the brackets can be wall or floor mounted).

� NOTE: The safety beam receiver (the unit with two

indicators) should be located on the “shady” side of

the door to prevent sunlight from shining directly into

the receiver’s lens.

3 Drill two 3/16” pilot holes for lag screws at marks.

Mount the brackets with two ¼” x 1-1/4” lag screws

and tighten with a 7/16” socket (or use proper concrete

fasteners if floor mounting).

4 Insert the sender and receiver into the bracket holes

so the lenses of the units will face each other. Twist the

units until the spring clips lock into a detent mark on

the brackets. To protect the units from being bumped

after installation, it is recommended to mount the

sender and receiver inside the brackets as shown.

� IMPORTANT: Be careful to route the safety beam wiring

away from any moving parts of the door or operator.

5 For non-prewired installations, route the wires from

the sender and receiver, up the wall above the door

hardware, then over to the center of the door, then along

the top of the rail (or ceiling), and back to the operator

head. Cut the wires about 6” longer than needed to

reach the operator terminals. Strip back ½” of insulation

from the ends of the wires.

6 For non-prewired installations, secure all the wires

to the wall and ceiling with insulated staples (not

supplied). Staples must straddle both wires to prevent

shorts. Secure the wire to the top of the rail with wire

clips (supplied).

7 At the operator, twist one wire from each pair together,

then twist the other wire from each pair together.

8 Attach either twisted connection to the operator’s

BEAM terminal. Connect the other twisted connection

to the operator’s COMMON terminal.

CONNECTING AND LOCATING THE WALL STATION

MOUNTING THE WALL STATION

ROUTE WIRE

THROUGH

SLOT IN

CASE

CONNECTING THE WALL STATION WIRES

CONNECT THE WALL STATION

PUSHBUTTON

WIRES TO

COMMON

TERMINALS (EITHER

WIRE TO EITHER TERMINAL)

ASSEMBLING THE BRACKETS

SAFETY BEAM BRACKET OPTIONS

WALL MOUNTING FLOOR MOUNTING

MARKING THE CORRECT BEAM BRACKET HEIGHT

LOCATE THE SAFETY BEAM

BRACKETS SO THE BEAM

CENTERLINE IS 6" ABOVE THE FLOOR

INSTALLING THE BEAMS

INSERT UNIT

INTO BRACKET

PRE-ADJUSTING THE BEAMS

CONNECTING THE BEAM WIRES

CONNECT THE SAFETY BEAM

COMMON

WIRES TO

BEAM TERMINALS (EITHER

WIRE TO EITHER TERMINAL)

CONNECT PUSHBUTTON WIRES

TO WALL STATION'S TERMINALS

MOUNT WALL STATION

AT LEAST 5 FEET ABOVE

THE FLOOR LEVEL

USE WOOD SCREWS

WHEN MOUNTING

DIRECTLY TO WALL

PUT HOLE

PLUGS IN

TO HIDE

SCREWS

AND

ADJUST UNITS SO

LENSES POINT TOWARD

EACH OTHER

SPRING CLIP LACTHES

INTO DETENT MARKS

TO HOLD UNIT'S POSITION

AND

USE MACHINE SCREWS

WHEN MOUNTING TO

A SINGLE-GANG BOX

WIRES TO THE

WALL STATION

ASSEMBLE BRACKETS

WITH 1/4-20 x 3/4" BOLTS

AND KEPS NUTS

BRACKET

INDEX

MARKS

TWIST UNIT TO

LOCK INTO BRACKET

WALL

STATION

WIRES

BEAM

WIRES

9 Install the Door Bracket and Door Arm

SECTIONAL DOORS

1 Fully close the door. Hold the door bracket against the

inside of the door’s top panel. Align the top edge of the

bracket 2” to 4” below the top edge of the door; or, if

there is a structural support across the top of the door,

place the top edge of the bracket directly below the

support. Align the vertical centerline drawn on the door

with the center of the bracket. See the figure for details.

Mark the left and right holes of the bracket.

2 Drill ¼” holes at marks and insert two ¼-20 x 2”

carriage bolts (not supplied) from outside of door

through the door bracket.

3 Secure door bracket with two ¼-20 keps nuts (not

supplied). Tighten with a 7/16” socket.

4 Slide the 5/16” x 1-3/8” clevis pin through one hole on

door bracket; then the single hole on the curved door

arm; then through the other hole on the door bracket.

Secure the clevis pin with the hitch pin.

5 Insert the single hole end of the straight door arm into

the slot in the trolley. Slide the 1-1/8” clevis pin through

the hole and secure it with a hitch pin.

6 Flip the trolley release lever to disconnect the trolley.

7 Rotate the curved door arm upward to meet the

straight door arm connected to the trolley. Align the

two door arms so that the holes in both arms overlap.

� NOTE: The straight door arm should be slightly angled

toward the operator head.

JAMB DOORS

1 With the door fully open, hold the door bracket on

the vertical centerline drawn on top edge of the door.

Use a pencil to mark the four mounting holes of the

bracket.

2 Drill ¼” holes at marks and fasten the bracket with two

5/16” x 2” lag screws to the top of the door.

3 Slide the 5/16” x 1-3/8” clevis pin through one hole on

door bracket; then the single hole on the straight door

arm; then through the other hole on the door bracket.

Secure the clevis pin with the hitch pin.

4 Insert the single hole end of the curved door arm into

the slot in the trolley. Slide the 1-1/8” clevis pin through

the hole and secure it with a hitch pin.

5 Flip the trolley release lever to disconnect the trolley.

6 Rotate the straight door arm upward to meet the

curved door arm connected to the trolley. Align the two

door arms so that the holes in both arms overlap.

CONNECTING DOOR ARMS

1 Line up door arms until trolley is positioned as shown.

Connect the arms together using two 5/16-18 x 1” bolts

inserted in the highest and lowest matching holes,

secure the bolts with two 5/16” keps nuts, tighten with

a ½” socket.

INSTALLING THE DOOR BRACKET (SECTIONAL DOOR)

DRILL TWO 1/4" PILOT HOLES

USE TWO

NUTS (NOT SUPPLIED) TO ATTACH THE DOOR BRACKET

INSTALLING THE DOOR BRACKET (JAMB DOOR)

ALIGN CENTER OF

DOOR BRACKET

WITH CENTERLINE

DRAWN ON DOOR

CONNECTING THE DOOR ARM TO THE DOOR BRACKET

SECTIONAL DOOR JAMB DOOR

CONNECTING THE DOOR ARM TO THE TROLLEY

CONNECTING THE DOOR ARMS

JAMB DOOR

10 Connect the Operator to Power Source

WARNING

To prevent electrocution or fire, installation

and wiring must be in compliance with local

electrical and building codes.

Cord and Outlet Connection

The operator should be connected to a grounded

receptacle on the ceiling or near the operator head. If

none is available which will accept the grounded operator

plug, one should be installed by a qualified electrician. Do

not use an extension cord.

1 Plug the operator into a grounded receptacle.

2 When the operator is plugged in, a click should sound

in the operator and the lights should turn on. If the

lights do not turn on, check the power source and light

bulbs.

Permanent Wiring

SOME LOCAL ELECTRICAL CODES REQUIRE

PERMANENT WIRING BETWEEN THE OPERATOR

AND THE POWER SOURCE THROUGH A CONDUIT.

IT IS RECOMMENDED THAT YOU HAVE A LICENSED

ELECTRICAL CONTRACTOR FOLLOW THESE STEPS

ONLY IF PERMANENT WIRING IS REQUIRED.

1 BE SURE POWER CORD IS UNPLUGGED.

2 Cut the power cord about 2” above the strain relief

bushing on the operator.

3 Remove the four side screws and bottom cover of

operator.

4 Use pliers to remove the strain relief bushing and

discard the bushing.

5 Remove the outer insulation from the power cord and

strip the white, black, and green wire insulation back

about ½”.

6 Pull white (neutral), black (hot) and green (ground)

wires through conduit.

7 Connect the conduit to the operator with the

appropriate termination.

8 Use wire nuts (not supplied) to connect the wires to the

matching color wires inside operator head.

9 Secure the wires away from all moving parts with a

zip-tie as shown in the figure.

10 Replace the operator cover and the four side screws.

11 Connect the conduit wires to the power source at

junction box.

12 When power is applied to the operator, a click should

sound and the lights should turn on. If the lights do

not turn on, check the power source, wiring, and light

bulbs.

To reduce the risk of electric shock, this

operator has a grounding pin. This plug will

only fit into a grounding type outlet. If the plug

doesn’t fit into the outlet, contact a qualified

electrician to install the proper outlet. Do not

change the plug in any way.

POWERING THE OPERATOR

REMOVING THE POWER CORD

CUT THE CORD ABOUT

2" ABOVE THE STRAIN

RELIEF BUSHING

REMOVING THE BUSHING

HARDWIRING THE OPERATOR

CONNECT CONDUIT

WIRING TO OPERATOR

WIRING WITH

WIRE NUTS

GREEN - GROUND

WHITE - NEUTRAL

BLACK - HOT

CAUTION! LIGHTWEIGHT SECTIONAL DOORS

NOT DESIGNED FOR USE WITH A GARAGE

DOOR OPENER MUST BE EQUIPPED WITH A

DOOR REINFORCEMENT KIT (CHECK WITH

THE GARAGE DOOR MANUFACTURER)

DOOR

STRUCTURAL

SUPPORT

BOLTS AND

CURVED

DOOR

ARM

CONNECT

SINGLE-HOLE

END OF

DOOR ARM

LINE UP DOOR ARMS UNTIL TROLLEY

IS POSITIONED AS SHOWN

18"

CONNECT ARMS WITH

TWO 5/16-18 x 1" BOLTS

IN THE HIGHEST AND

LOWEST MATCHING HOLES

INSTALL

HITCH PIN

1-3/8"

CLEVIS

PIN

TROLLEY

DOOR

BRACKET

1/4-20 x 2" CARRIAGE

APPROXIMATELY

WARNING

PLUG OPERATOR

INTO GROUNDED

OUTLET

FOR PERMANENT WIRING ONLY!

BE SURE THE POWER

CORD IS UNPLUGGED!!

FOR PERMANENT WIRING ONLY!

REMOVE STRAIN

RELIEF BUSHING

WITH PLIERS

FOR PERMANENT WIRING ONLY!

ALIGN THE DOOR BRACKET

ON THE CENTERLINE 2" TO 4"

BELOW THE TOP EDGE

OF THE DOOR, OR DIRECTLY

BELOW ANY DOOR

STRUCTURAL SUPPORT

USE TWO

5/16" X 2"

LAG SCREWS

TO FASTEN

BRACKET TO

DOOR

STRAIGHT

SLIDE IN THE

1-1/8" CLEVIS PIN

INSTALL THE

HITCH PIN

2" TO 4"

CONDUIT

DOOR

ARM

4" TO 6"

SECTIONAL DOOR

CEILING

OUTLET

WIRE

NUTS

INSTALL

HITCH PIN

1-3/8"

CLEVIS

PIN

STRAIGHT DOOR ARM (SECTIONAL)

CURVED DOOR ARM (JAMB)

Page 2

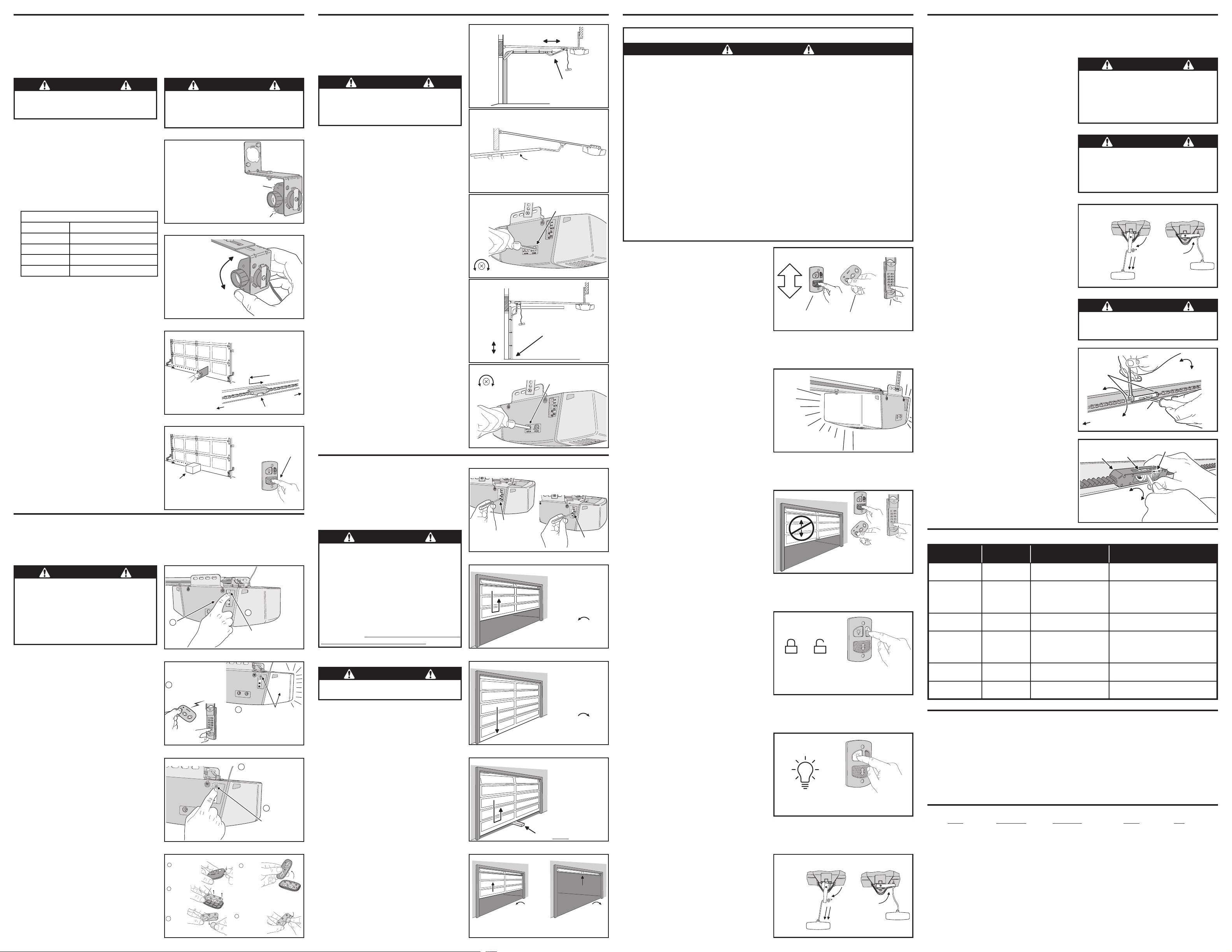

11 Aligning the Infrared Safety Beam

ADDING A REMOTE

The safety beam has two components, a sender and a receiver. The sender produces a narrow infrared beam that

travels across the bottom of the door opening to the infrared receiver. If an object blocks the infrared beam while the

door is closing, the door will stop, then reverse and fully open (the operator’s light will flash three times).

As a safety feature, the operator will ignore signals from all remote controls if the door is open and the

infrared safety beam is blocked or out of alignment. In this case, the door can be forced closed by pressing

and holding the wall station’s up/down arrow pushbutton (be sure the door area is in clear view).

WARNING

With the door closed, disengage the trolley

from the chain during these alignment tests by

pulling the red release handle.

Safety Beam Test

Serious injury or death from a closing garage

door may result because of failure to test and

adjust safety reverse system. Repeat this test

monthly and adjust as needed.

WARNING

1 Check that the operator has power. The green lights on

the sender and receiver should be lit.

2 If the receiver’s green light is on, but the red light is off,

SAFETY BEAM INDICATORS

the receiver has power but is not detecting the infrared

beam from the sender. The red light might flash when

the beam is partially detected. This can be caused by

mis-alignment or something blocking the beam. Adjust

the safety beam sender and receiver while watching the

receiver’s red light (stay out of the beam while aligning

it). When the red light stays on, the beam is aligned.

SAFETY BEAM INDICATOR TABLE

GREEN ON POWER ON

GREEN OFF POWER OFF

RED ON BEAM OK - NO BLOCKAGE

RED OFF BEAM BLOCKED OR MIS-ALIGNED

RED FLASHING BEAM ALIGNED POORLY

� NOTE: If the receiver’s red light remains off, check

GREEN LIGHT

ON = POWER ON

OFF = POWER OFF

RED LIGHT

ON = BEAM ALIGNED, NO OBSTRUCTION

OFF = BEAM NOT ALIGNED, OR OBSTRUCTION

BLINKING = BEAM NEEDS BETTER ALIGNMENT

ADJUSTING THE BEAM

ADJUST THE SENDER

AND RECEIVER UNTIL

THE RED INDICATOR

LIGHTS SOLID

RED LIGHT

GREEN LIGHT

for: 1) Dirt on the receiver’s lens, 2) Sunlight shining

into the receiver’s lens, 3) A short in the safety beam

wiring (from staples or at the operator terminals).

3 With the door closed and the operator disengaged

from the door, press the wall station’s UP/DOWN

ARROW button to move the traveler (the part on the

CHECKING FOR REVERSAL

belt or chain that the trolley engages with) to the up

position (away from the door).

4 Push the wall station’s UP/DOWN ARROW button

again. While the traveler is moving to the down

position (toward the door), block the safety beam. THE

TRAVELER MUST STOP, THEN REVERSE TO THE

UP POSITION. The operator’s lights should flash three

times.

5 Place an object in the path of the safety beam. Check

that constant pressure is required on the wall station’s

UP/DOWN ARROW button to cause the traveler

to move toward the down position. Release the

pushbutton before the operator stops; check that the

traveler returns to the up position.

� NOTE: The garage door operator will not respond

BLOCK THE BEAM

WHILE THE TRAVELER

IS MOVING DOWN

CHECKING FORCED CLOSURE FEATURE

THE TRAVELER MUST REVERSE

WHEN THE BEAM IS INTERRUPTED

DOWN

UP

TOWARD

DOOR

TRAVELER

VERIFY THAT CONSTANT

PRESSURE IS REQUIRED

ON THE WALL STATION'S

PUSHBUTTON TO MAKE

THE TRAVELER GO DOWN

to a CLOSE command from a radio transmitter if the

safety beam is blocked.

6 To reconnect the operator, flip the release lever

up. Raise the door manually until the operator

reconnects.

PLACE AN OBJECT

IN THE BEAM'S PATH

RELEASE PUSHBUTTON

BEFORE THE OPERATOR STOPS,

THE TRAVELER SHOULD

RETURN TO THE UP POSITION

12 Remote Controls

The operator is supplied with a three-button remote control (the second and third buttons can be used to control an

additional operator or gate if it contains a Linear MegaCode™ receiver). Additional single and multi-button remote

controls can be purchased. An unlimited number of remote controls can be used with this operator. The short white

wire on the back of the operator serves as an antenna for the remote controls. Do not cut off the white wire or the

remote controls will not operate well.

WARNING

Children operating or playing with a garage door

operator can injure themselves or others. The

garage door could cause serious injury or death.

Do not allow children to operate the remote

control(s) or the wall station. A moving garage

door could injure or kill someone under it. Activate

the operator only when the door is clearly visible,

free of obstructions and adjusted properly.

To Add or Remove a Remote Control

1 Press the operator’s LEARN button. The red LEARN

light will glow. The red light will stay on for about 15

seconds. A remote must be added or removed while

the red LEARN light is still on.

2 Send a signal from a remote. The opener’s light and

the red light will flash once if a remote was added, or

the opener’s light and the red light will flash four times

if a remote was removed.

3 Repeat Steps 1 & 2 for any additional remote controls.

To Remove all Remote Controls

1 Press and hold the operator’s LEARN button for ten

seconds or more.

2 Release the LEARN button. The red LEARN light will

blink three times signaling that all of the remotes

in the operator’s memory were erased. The red

LEARN light will turn off, then turn on for 15 seconds.

A remote control can be entered during this time using

Step 2 above.

Testing

1 Before testing the remote control, straighten out the

operator’s white antenna wire so it points up.

2 Stand clear of the door, press the remote control’s

button and verify that the operator starts. PRESS THE

REMOTE CONTROL’S BUTTON AGAIN TO STOP

THE DOOR MID-TRAVEL.

3 Set the open and close limits as described in the

next section before any further testing.

Replacing a Remote Control’s Batteries

When the red light on the remote glows dimly, or fails

to light at all when the remote is activated, the batteries

need replacing.

1 Open the remote’s case and remove the circuit board

2 Replace old batteries with two Type 2032 batteries.

3 Re-assemble the remote.

PREPARING TO ADD A REMOTE

1

PRESS THE

LEARN

BUTTON

1

SEND A SIGNAL

FROM A REMOTE

PRESS A

- OR -

BUTTON

REMOVING ALL REMOTES

REPLACING A REMOTE'S BATTERY

1

TWIST DIME IN

SLOT TO OPEN

CASE

3

CAREFULLY

REMOVE THE

CIRCUIT BOARD

4

REMOVE OLD

BATTERIES AND

DISPOSE OF THEM PROPERLY

ENTER A CODE

AND PRESS

START/STOP

2

LEARN LIGHT WILL GLOW FOR

15 SECONDS, REMOTE MUST BE

ENTERED WHILE LEARN LIGHT IS ON

2

THE OPENER’S LIGHT AND RED

LIGHT WILL FLASH ONCE IF A

REMOTE IS ADDED, OR THE

OPENER’S LIGHT AND RED

LIGHT WILL FLASH FOUR TIMES

IF A REMOTE IS REMOVED

PRESS THE LEARN BUTTON

1

FOR 10 SECONDS OR MORE

2

THE LEARN LIGHT

WILL BLINK 3 TIMES

SIGNALING THAT

ALL REMOTES WERE

REMOVED

2

LIFT OFF

THE TOP OF

THE CASE

NOTE:

THE CIRCUIT BOARD WILL FIT ONLY ONE

WAY INTO THE CASE. ALIGN THE PLASTIC POST

IN THE CASE WITH THE HOLE IN THE CIRCUIT BOARD

5

INSERT TWO NEW

TYPE 2032 BATTERIES

PLUS SIDE UP THEN

REASSEMBLE UNIT

TOWARD

OPERATOR

13 Adjusting the Open and Close Limits

The limit adjustments that control how far the door will

open or close are located on the side of the operator. The

limits should be adjusted so the door opens just short of

any door stops, and closes right at the floor level. Each

full turn of a limit adjustment equals about 2-½” of door

travel.

CAUTION

Set the open and close limits carefully. Setting

the limits beyond the distance that the door can

travel could cause damage to the door, the door

hardware, or operator.

1 If this is a jamb door installation, with the operator

at mid-travel, turn the CLOSE LIMIT adjustment

five turns in the UP direction before proceeding.

2 Activate the remote control. Wait while the door moves

to the open position and stops.

3 Examine the position of the door.

• If the door needs to open more, turn the OPEN LIMIT

adjustment clockwise ¼-turn (towards UP on the label)

to raise the open limit.

• If the door needs to open less, turn the OPEN LIMIT

adjustment counterclockwise ¼-turn (towards DOWN

on the label) to lower the open limit.

� NOTE: On jamb doors, set the open limit so the door

stops just short of level (see figure).

4 Activate the remote control. Wait for the door to move

down a few feet, then activate the remote control again

to stop the door.

5 Repeat Steps 2-4 until the open limit is properly

adjusted.

6 Activate the remote control. Wait while the door moves

to the closed position and stops.

7 Examine the position of the door.

• If the door needs to close more, turn the CLOSE

LIMIT adjustment counterclockwise ¼-turn (towards

DOWN on the label) to lower the close limit.

• If the door needs to close less, turn the CLOSE LIMIT

adjustment clockwise ¼-turn (towards UP on the label)

to raise the close limit.

8 Activate the remote control. Wait for the door to move

up a few feet, then activate the remote control again to

stop the door.

9 Repeat Steps 6-8 until the close limit is properly adjusted.

� NOTE: If the door stops during opening or reverses

during closing before reaching the limits, the door force

adjustment needs to be set. Change the adjustment as

described in the next section then return to this section

to finish setting the limits.

CHECKING WHERE THE DOOR STOPS

SETTING THE OPEN LIMIT ON A JAMB DOOR

JAMB DOOR

NOTE: SETTING THE OPEN LIMIT TOO HIGH WILL CAUSE

THE OPERATOR TO "BUCK" WHEN STARTING DOWN

SETTING THE OPEN LIMIT

OPEN LIMIT

UP

DOWN

ADJUSTMENT

CHECKING WHERE THE DOOR STOPS

UP

DOWN

SETTING THE CLOSE LIMIT

UP

DOWN

CLOSE LIMIT

ADJUSTMENT

14 Testing & Adjusting the Door Force Safety System

The door force adjustments are located on the side of the

operator. The door force adjustments must be properly

set at all times. The CLOSE FORCE adjustment controls

how much force is required to cause the door to reverse

direction if an obstruction is encountered during closing.

The OPEN FORCE adjustment controls how much

force is required to stop the door if an obstruction is

encountered during opening.

SETTING THE DOOR FORCE

ADJUSTING THE

CLOSE FORCE

WARNING

Too much door force will interfere with the

proper operation of the safety system. SOMEONE

COULD BE SERIOUSLY INJURED OR KILLED IF THE

DOOR FORCE IS SET TOO HIGH. A closing door

UNDER-SETTING THE CLOSE FORCE

might not reverse properly when required and

someone could be pinned under it. An opening

door might not stop when going up and someone

hanging on the door could get pinned between

the door and the header. Do not increase the

door force beyond what is required to move the

door. DO NOT USE THE DOOR FORCE ADJUSTMENT

TO COMPENSATE FOR A BINDING OR STICKING

GARAGE DOOR. PERFORM THE SAFETY REVERSAL

SYSTEM TEST (STEPS 4-6) MONTHLY!

� NOTE: Read the following directions carefully before

setting the door force adjustments.

SETTING THE CLOSE FORCE

WARNING

Always perform the Door Force Safety System Test

after making any adjustments to the operator.

Door Force Safety System Test

1 Start with the door open. Use the remote control to

cycle the door during these tests.

Adjusting the Close Force

2 Turn the CLOSE FORCE adjustment 1/8-turn at a time

in the DECREASE direction (counterclockwise) until the

door stops and reverses mid travel while going down.

3 Turn the CLOSE FORCE adjustment 1/8-turn at a time

in the INCREASE direction (clockwise) until the door

fully closes without reversing.

Safety Reversal System Test

4 Lay a 2 x 4 board flat on the floor where it will be struck

by the center of the door as it closes.

5 Verify that the door reverses when it strikes the board.

The door must reverse within two seconds after

striking the board.

� NOTE: If the door stops after encountering the board

and does not reverse, the CLOSE FORCE needs to be

DECREASED.

6 Repeat the Safety Reversal System Test until the door

reverses within two seconds of striking the board.

Adjusting the Open Force

7 Turn the OPEN FORCE adjustment 1/8-turn at a time

in the DECREASE direction (counterclockwise) until

the door stops mid travel while going up.

8 Turn the OPEN FORCE adjustment 1/8-turn at a time

in the INCREASE direction (clockwise) until the door

fully opens without stopping.

TESTING THE SAFETY REVERSAL SYSTEM

UNDER-SETTING THE OPEN FORCE SETTING THE OPEN FORCE

DECREASE

DECREASE OPEN FORCE

ADJUSTMENT UNTIL THE

DOOR STOPS MIDWAY

WHILE GOING UP

OPEN FORCE

DOWN

SET THE OPEN LIMIT SO THE DOOR

STOPS JUST SHORT OF LEVEL

2 x 4 BOARD LAID FLAT

UNDER

UP

EXAMINE THE SPOT WHERE

THE DOOR STOPS OPENING

USE A SCREWDRIVER TO

ADJUST THE OPEN LIMIT

EXAMINE THE SPOT WHERE

DOOR STOPS CLOSING

USE A SCREWDRIVER TO

ADJUST THE CLOSE LIMIT

ADJUSTING THE

OPEN FORCE

DECREASE CLOSE FORCE

ADJUSTMENT UNTIL THE

DOOR REVERSES MIDWAY

WHILE GOING DOWN

DECREASE

CLOSE FORCE

INCREASE CLOSE FORCE

ADJUSTMENT UNTIL THE

DOOR CLOSES FULLY

WITHOUT REVERSING

INCREASE

CLOSE FORCE

TEST WITH SMALL OBSTACLE

THE DOOR MUST REVERSE

WITHIN 2-SECONDS AFTER

IMPACT WITH A 2 x 4 BOARD

CENTER OF DOOR

INCREASE

INCREASE OPEN FORCE

ADJUSTMENT UNTIL THE

DOOR OPENS FULLY

WITHOUT STOPPING

OPEN FORCE

15 Using the Garage Door Operator

IMPORTANT USER SAFETY INSTRUCTIONS

WARNING

A MOVING GARAGE DOOR CAN CAUSE INJURY OR DEATH!

TO REDUCE THE RISK OF DEATH OR SEVERE INJURY:

1 READ AND FOLLOW ALL INSTALLATION INSTRUCTIONS.

2 NEVER LET CHILDREN OPERATE, OR PLAY WITH DOOR CONTROLS! KEEP REMOTE CONTROL

AWAY FROM CHILDREN!

3 Always keep moving door in sight and away from people and objects until it is completely closed.

NO ONE SHOULD CROSS THE PATH OF THE MOVING DOOR.

4 NEVER GO UNDER A STOPPED, PARTIALLY OPEN DOOR.

5 Test door operator monthly. The garage door MUST reverse on contact with a 1-1/2 inch object (or a 2x4

board laid flat at the center of the door) on the floor. If adjusting either the force or the limit of travel,

re-test the door operator. Failure to adjust the operator properly may cause severe injury or death.

6 If possible, use the red emergency release handle only when the door is closed. Use caution when

using this release with the door open. Weak or broken springs may cause the door to fall rapidly,

causing injury or death.

7 KEEP GARAGE DOORS PROPERLY BALANCED. (See Garage Door Operator Maintenance) An

improperly balanced door could cause severe injury or death. Have a qualified service person make

repairs to cables, spring assembly and other hardware.

8

SAVE THESE INSTRUCTIONS.

Opening the Door

1 With the door in view, press the wall station’s UP/

DOWN ARROW button or the button assigned to the

operator on the remote control, or enter a valid access

code and press START/STOP on a remote keypad.

2 When the operator is activated, the operator’s lights

will turn on and the door will begin to open.

3 The door will open until the open limit is reached. If

an obstacle is encountered (operator’s lights flash four

times) while the door is opening, the door will stop.

4 The operator’s lights will stay on for about five minutes

after the door stops.

Closing the Door

1 With the door in view, press the wall station’s UP/

DOWN ARROW button or the button assigned to the

operator on the remote control, or enter a valid access

code and press START/STOP on a remote keypad.

2 When the operator is activated, the operator’s lights

will turn on and the door will begin to close.

3 The door will close until the close limit is reached. If

an obstacle is encountered (operator’s lights flash four

times), or the safety beam is interrupted (operator’s

lights flash three times) during closing, the door will

stop, then re-open.

4 The operator’s lights will stay on for about five minutes

after the door stops.

Stopping the Door Mid-travel

1 The door can be stopped immediately at any time

by pressing the wall station’s UP/DOWN ARROW

button, the remote control’s pushbutton, or press

the START/STOP button on a remote keypad.

2 The next time the operator is activated, the door will

move in the opposite direction.

Vacation Lock for Additional Security

1 Slide the wall station’s LOCK switch to the locked

position to prevent remote controls from opening the

door after the door is completely closed. The remotes

can close the door, but not open it. The door can

still be opened or closed by using the wall station’s

UP/DOWN ARROW pushbutton.

� NOTE: To signal that the vacation switch is locked,

the operator’s lights will flash five times if a remote is

activated in an attempt to open the door.

2 Slide the wall station’s LOCK switch to the unlocked

position to return the operator to normal operation.

Controlling the Operator’s Lights

1 The operator’s lights can be lit by pushing the wall

station’s LIGHT button. The lights will remain on until

the LIGHT button is pressed again or the operator is

cycled.

2 If the operator’s lights are on, pushing the wall station’s

LIGHT button will turn the operator’s lights off.

Disconnecting the Door from the Operator

1 With the door in any position (preferably closed),

carefully pull the red release handle. USE CAUTION

IF THE DOOR IS OPEN, THE DOOR MAY DROP.

2 The disconnected door can be opened or closed

manually.

3 To re-connect the operator, flip the release lever up.

Raise or lower the door manually until the operator

reconnects.

OPENING OR CLOSING THE DOOR

WALL STATION REMOTE CONTROL

PRESS THE

WALL STATION'S

UP/DOWN ARROW

SAFETY LIGHTING

WHENEVER OPERATING,

THE LIGHTS WILL TURN ON

FOR ABOUT 5 MINUTES

STOPPING THE DOOR

PREVENTING REMOTES

FROM OPENING THE DOOR

LOCK UNLOCK

CONTROLLING THE

OPERATOR'S LIGHTS

PRESS THE LIGHT

BUTTON TO TURN THE

LIGHTS ON OR OFF

IN CASE OF POWER FAILURE

OR IF DOOR BECOMES OBSTRUCTED

PULL THE RED

RELEASE HANDLE

TO DISCONNECT

THE OPERATOR

FROM THE

DOOR

PRESS A REMOTE

- OR -

CONTROL BUTTON

THE DOOR CAN BE STOPPED

AT ANY POSITION USING THE

WALL STATION, REMOTE CONTROL,

SLIDE THE VACATION SWITCH

DOWN TO LOCK (REMOTES DISABLED)

OR UP TO UNLOCK (REMOTES NORMAL)

THE LIGHTS WILL STAY ON UNTIL

THE LIGHT BUTTON IS PRESSED

OR THE OPERATOR IS CYCLED

FLIP THE LEVER UP

AND RAISE OR

NOTICE

IF DOOR BECOMES OBSTRUCTED,

PULL DOWN ON HANDLE

LOWER THE DOOR

TO RECONNECT

THE OPERATOR

ENTER AN

ACCESS CODE

AND PRESS

- OR -

START/STOP

NOTE: FLASHING

LIGHTS INDICATE

TROUBLE

WALL

STATION

REMOTE

CONTROL

OR A REMOTE KEYPAD

NOTICE

IF DOOR BECOMES OBSTRUCTED,

PULL DOWN ON HANDLE

REMOTE

KEYPAD

REMOTE

KEYPAD

16 Garage Door Operator Maintenance

Weather conditions may affect the door operation which could require some re-setting of the operator’s adjustments.

Doors may swell and become heavier during wet periods, door hinges and rollers might bind during cold periods. To

insure safe operation of the door, perform the following tests, including any additional test steps described.

Every Month

1 With the door closed, pull the red release handle to

disconnect the operator from the door.

2 From outside the garage, slowly open the door

manually all the way, and then close it all the way.

Notice if there is any binding, sticking or rubbing. The

door should move smoothly in both directions.

3 Raise the garage door about halfway up. Carefully

release the door and see if the door balances. It should

Garage door hardware (springs, cables,

brackets, pulleys, etc.) are under extreme

pressure and tension. DO NOT ATTEMPT TO

LOOSEN, TIGHTEN OR ADJUST ANY DOOR

HARDWARE. CALL A QUALIFIED GARAGE DOOR

INSTALLATION PROFESSIONAL!

WARNING

stay in place. Close the door.

� NOTE: If the garage door is unbalanced or the

door travel isn’t smooth, have a qualified garage door

professional adjust or repair the door.

4 To reconnect the operator, flip the release lever

up. Raise the door manually until the operator

reconnects.

5 Perform the Safety Beam Test (Section 11).

The garage door operator must not be

installed and used on an unbalanced door. The

operator’s internal door force sensor will not

function properly on an unbalanced door. Risk

of serious injury or death may result.

WARNING

6 Perform the Safety Reversal System Test as described

in Steps 4-6 in Section 14.

TO DISCONNECT OPERATOR

TO RECONNECT OPERATOR

After Servicing the Operator

1 Perform the Safety Beam Test (Section 11).

2 Perform the Open and Close Limit Adjustments

(Section 13).

3 Perform the entire Door Force Safety System Test

(Section 14).

Every 6 Months

Check the belt or chain tension.

• For belt-drive rails, examine the length of the tension

PULL THE RED

RELEASE HANDLE

TO DISCONNECT

THE OPERATOR

FROM THE

DOOR

IF DOOR BECOMES OBSTRUCTED,

NOTICE

PULL DOWN ON HANDLE

FLIP THE LEVER UP

AND RAISE OR

LOWER THE DOOR

TO RECONNECT

THE OPERATOR

NOTICE

IF DOOR BECOMES OBSTRUCTED,

PULL DOWN ON HANDLE

spring in the traveler. It should be about 1” long.

• For chain-drive rails, examine the spacing between

the turnbuckle and the rail. The turnbuckle should be

slightly above the rail.

� NOTE: Too much or too little chain tension will cause

excessive sprocket noise.

Chain Adjustment

If necessary, use the following steps to adjust the chain.

1 Hold the turnbuckle with a flat blade screwdriver and

loosen the two locknuts with a 7/16” end wrench.

2 Twist the turnbuckle to adjust the chain tension. Adjust

the chain until the turnbuckle is sightly above the rail.

Always perform the entire Door Force Safety

System Test (see Section 14) after making any

adjustments to the operator.

ADJUSTING A CHAIN-DRIVE

TURNBUCKLE

LOCKNUTS

LOCKNUTS

LOOSEN

WARNING

CHAIN

TIGHTEN

TWIST

TURNBUCKLE

CHAIN

LOOSEN

3 Hold the turnbuckle with a flat blade screwdriver and

tighten the two locknuts with a 7/16” end wrench.

Belt Adjustment

The tension spring in the traveler keeps the belt taut. The

TO HEAD

LOCKNUTS

TIGHTEN

HOLD TURNBUCKLE

WITH FLAT BLADE

SCREWDRIVER TO

BACKUP LOCKNUTS

factory setting for the tension spring length is .9” long. If

the tension spring is longer than 1”, adjust the belt.

1 Hold the traveler so the adjustment wheel is visible

through the large slot.

ADJUSTING A BELT-DRIVE

TRAVELER

ADJUSTMENT WHEEL

MEASURE THE TENSION

SPRING LENGTH

2 Use a flat blade screwdriver to turn the adjustment

wheel to compress the tension spring until its length is

between .9” and 1” long.

Every Year

Check the door hardware for lubrication needs. Lubricate

door hinges, rollers and bearings according to door

manufacturer’s recommended procedures.

TURN THE ADJUSTMENT

WHEEL UNTIL THE TENSION

SPRING IS ABOUT 1" LONG

LOOSEN

TIGHTEN

17 Troubleshooting

LAMPS FLASH

TROUBLE CODE

1 FLASH No problem

2 FLASHES Door won’t close Shorted wall station wires

3 FLASHES Door won’t close Safety beam obstacle

4 FLASHES

5 FLASHES

6 FLASHES

FCC NOTICE

Changes or modifications not expressly described in this manual or approved by the manufacturer could void the user’s authority to operate

the equipment.

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

LIMITED WARRANTY

This Linear product is warranted to the original consumer against defects in material and workmanship for:

MODEL ELECTRONICS MECHANICAL MOTOR BELT

LSO50 1 year 5 years Lifetime Lifetime

This product is warranted to the original consumer against defects in material and workmanship for the periods mentioned above. Linear will

repair, or at its option, replace, any device that it finds requires service under this warranty, and will return the repaired or replaced device

to the consumer at Linear’s cost. Devices must be sent to Linear for service at owner’s expense. This warranty does not apply to damage to

the product from negligence, abuse, abnormal usage, misuse, accidents, normal wear or tear or due to failure to follow Seller’s instructions,

or arising from improper installation, storage or maintenance. In no event will Linear be responsible for incidental, compensatory, punitive,

consequential, indirect, special or other damages. The remedies provided by this warranty are exclusive. Some states do not allow the

exclusion or limitation of incidental and consequential damages, so the above limitation or exclusion may not apply to you. Any warranties

implied by law are limited to the time periods set forth above. Some states do not allow limitations on how long an implied warranty lasts,

so the above limitation may not apply to you. This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

For warranty service and shipping instructions contact Linear at the phone number shown below. In order to be protected by this warranty, save

your proof of purchase and send a copy with equipment should repair be required. All products returned for warranty service require a Return

Product Authorization Number (RPA#). Contact Linear Technical Services at 1-800-421-1587 for an RPA# and other important details.

Copyright © 2010 Linear LLC 223711 B

PROBLEM CAUSE REMEDY

Remote control entered into

memory

Add any additional remote controls

(MegaCode™ type only)

Check wall station wires. Be sure both are

connected to the terminal screws. Check for

a staple in the wall station wires. Remove

any staples compressing the wire.

Check for obstacles. Align the safety beam

(Section 11)

Door reverses

or won’t open or

close

Door won’t open

from transmitter

Motor ran longer

than 30 seconds

Open or Close force exceeded,

or motor thermal shutdown

Remote was activated while

vacation switch was locked

Mechanical or electronic failure Call Technical Services Group for assistance

Check for binding or un-balanced door.

Adjust the door force (Section 14). If motor

had thermal shutdown, wait 30 minutes and

retry.

Unlock vacation switch on wall station

Loading...

Loading...