Page 1

2003 INTERNATIONAL ELECTRONICS, INC.

427 TURNPIKE STREET, CANTON, MA 02021

(781) 821-5566 www.ieib.com

FAX INFO CENTER: (781) 821-0734

MORTISE LOCKSET

Installation Instructions

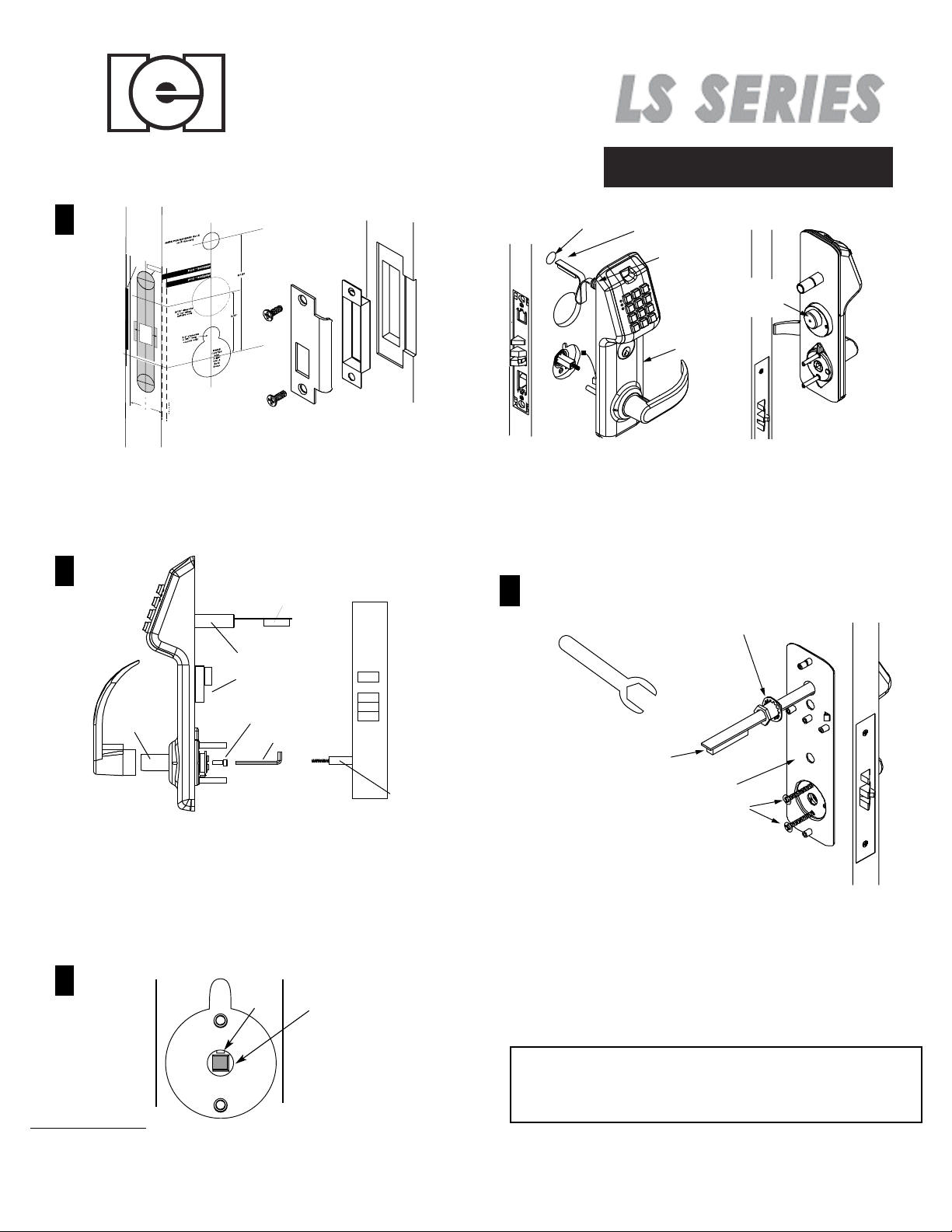

1

STRIKE

LIP

POSITION

1î

DIAMETER

Clearance

Anti-friction

for

latch

3/4î

Deep

of Hubs

Vertical

Center

line

of lock

C

L

1-3/4î

For

other

door

place

thicknesses,

on center

tear

line

of

of

f

door

and

edge.

Figure1

See template for measurements. See page 3 for instructions on

installing the lock body.

Affix template to door and follow template instructions

in preparing door as illustrated in Figure 1. Install strike correct for

handing and dust box.

Figure 2

2

Raceway

wires

Threaded

raceway

Cylinder plug

Wire Hole

Raceway

wires

Raceway

Tube

Cylinder

Plug

Exterior

Housing

2. Pass the

Raceway wires

through the wirehole, then

mount exterior housing through door preparation.Make sure

the spindle engages with the rotating hub in thecorrect

orientation, and the cylinder plug enters cylinder hole

in mortise lock.

Remove screw from Battery Cover to access interior backplate.

4

Lockwasher

Tube

Set Screw

Allen Wrench

Spindle /spring

Assemble Lever

assembly

1. Assemble inside and outside levers on shafts for

correct handing, using screw inside shaft to secure levers.

2. Locks auto adjust for 1 3/4" to 2 1/2" thick doors.

3. Locks are supplied either with 1 1/8" cylinder, or

prepped for a 1 1/8" cylinder (customer supplied). For

other options several purchased collar required.

3

Slot

1. VERY IMPORTANT

Align outside rotating hub in exterior housing so the slot is facing

up. Insert spindle spring assembly into outside lock hub.

Rotating Hub

Raceway

wires

Interior Backplate Assy

10-32x3/4" Thru-bolts

1. While holding the interior backplate in position, loosely

install the raceway nut first, then the two screws through

backplate and into posts.

2. Tighten the raceway nut on the raceway tube using

wrench supplied. When this connection is firm, secure

the thru-bolts.

Raceway wires- see separate instructions. LS-1 series

require motor cable connection to battery. LS-2 & LS-2P

series require motor cable connection; flex circuit connection;

and optional REX and door position switch connections.

Page 1

P/N 6043100 REV 1.0

Page 2

Installation Instructions

5

Figure 5

Raceway wires

7

Note: remove red ribbon

to activate batteries.

Figure 7

Battery

Cover

Center

Groved Stud

Brass #8-32 x 1/2" Lg

FHMS

Spindle/Spring

Assy.

#8-32 x 3/4" Lg

Oval HMS

Inside Lower

Housing Assy

1. Assemble the inside lower housing on backplate, while

engaging the spindle in lock hub. (Be sure wires are not

pinched.)

2. Fasten with two brass #8 screws and the finished #8 screw

at the bottom.

Center

6

Figure 6

Groved Stud

#8-32 x 3/4" Lg

Oval HMS

Inside Lower

Housing Assy

PUSH ALL EXCESS WIRE LENGTHS DOWN THROUGH

THE OPENING AT THE TOP OF THE INSIDE LOWER

HOUSING.

1. Attach the battery cover with two finished #8 screws. Battery cover

has a lip which engages the lower inside housing. It is important

that this lip be seated properly to insure correct alignment.

Deadbolt Function

1-3/4îCylinder

Turnpiece

Inside Lower

Housing Assy

NOTE: DUE TO PREDETERMINED POWER SETTINGS

IN THE LOCK, USE ONLY ALKALINE BATTERIES

1. View Raceway wiring instructions included in package.

2. Place the battery holder over the center grooved stud.

3. When properly aligned, push down on the battery holder

assembly, engaging the upper part of the hole into the

groove of the stud. Battery holder will be held between tabs.

Tailpiece

Cylinder set

screw

Insert tailpiece into slot in turnpiece.

Snap ring on turnpiece will hold

tailpiece in place.

Deadbolt functions may use 1-1/8 inch cylinder integrated with trim OR

can use optional 1-3/4 inch cylinder directly engaged with mortise lock.

With 1-3/4 inch cylinder screwed into mortise lock, tighten set screw

then replace lock front.

Page 2

Page 3

Lock Body Installation Knob or Lever Mortise

PREPARING THE DOOR

Note: If the strike already exists in the door frame, position lock using strike as reference. (See

strike position on template)

1. Draw horizontal line on both sides and edge of door at the desired height of knob above floor

2. Draw vertical center line on door edge.

TO BEVEL LOCK

Locksets

1. Loosen adjustment screws at top

and bottom of case.

2. Turn front to desired bevel.

.

3. Re-tighten adjustment screws.

3. Draw vertical line on each side at the proper backset to align the templates.

4. Position template on edge and side of door. Mark holes ONLY for each side, and top and

bottom holes of mortise cavity on door edge.

5. Remove template; place lock face against door edge. Trace outline of faceplate as guide for

faceplate routing.

MORTISE THE DOOR

1. Mortise door for lock body and faceplate per instructions on template.

INSTALLING THE LOCK BODY

LUBRICATION

Figure 3.5

1. Insert the lock into the cavity.

2. Mark & drill faceplate holes. Fasten with faceplate screws to hold lock in place.

INSTALLING THE STRIKE

Select correct strike for handing.

1. Refer to template to determine strike location on jamb.

2. Using strike as template, mark and chisel recess. Drill screw holes and fasten.

All locks come lubricated from the factory with a lithium

based grease. We recommend, however, periodic

lubrication of internal moving parts with commercial

quality grease. This can add years to the life of the

lockset reducing excessive wear. For more severe

environments, lubrication be applied more frequently.

Trouble Shooting

Adjustment

screw

Top of Lock

Pivot lock front

SYMPTOM

1. Beeping after assemby is completed

(4 long beeps)

2. Solid green LED, no motor action

3. Yellow LED flashes and sounder chirps

after install

4. Motor locks but will not unlock

5. Unable to change system default

6. Does not read proximity cards

SYMPTOM

1. Key bypass does not work

2. Handle rests in down position

3. Cannot tighten the raceway by hand

4. LED goes green, units does not

unlock

ELECTRICAL

PROBABLE CAUSE

Low Voltage

Control Module not sending lock/unlock pulse

Unit not intialized

REX loop is shorted

(Brown and Orange on P 4 wire harness)

Various

Unit may not be an LS-2P

MECHANICAL

PROBABLE CAUSE

a. Cylinder is not straight

b. Wrong cam on mortise

Lockset is binding

Race threads are damaged

Hub outside trim is out of alignment

CORRECTION

Replace Batteries

Verify continuity of wire harness and

replace if necessary

Contact IEI

Inspect connection and remove short

Various

Check the FCC Label.

If the label does not refer to model LS-2P

then it is an LS-2 and not an LS-2P.

CORRECTION

a. Loosen cylinder retaining nut and straighted cam.

b. Use straight cam on 1 1/4" cylinder and clover cam

on 1 3/4" cylinder.

Check holes in he door for clearance

Use thread chaser to clean threads or contact IEI

Refer to page 1 #3 of this manual

Page 3

Page 4

To Reverse Handing

Note on reverse handing:

Unit is shipped from factory set for right or left handing and with correct

strike (see external label which indicates handing). If handing is reversed

Hand

1. Remove the 5 screws securing the lock body cover.

2. Remove the latch, turn it over, and re-insert it. Make sure the latch

washer is in the position indicated, or the latch will not function properly.

3. Remove auxiliary latch. Detach nose from auxiliary latch tail and reattach

in opposite direction. Make sure the orientation of the auxiliary latch is the

same as the orientation of the latch.

4. Replace all parts and re-fasten the cover.

5. Install dust box and appropriate strike - see note above.

LH

Left

OUTSIDE OUTSIDE

RH

Right

Hand

LHR

Left

Hand

Reverse

RHR

Right

Hand

Reverse

With Auxiliary Latch without Deadbolt

Assembly shown is for a right hand door.

With Auxiliary Latch with Deadbolt

Assembly shown is for a right hand door.

Page 4

Loading...

Loading...