Page 1

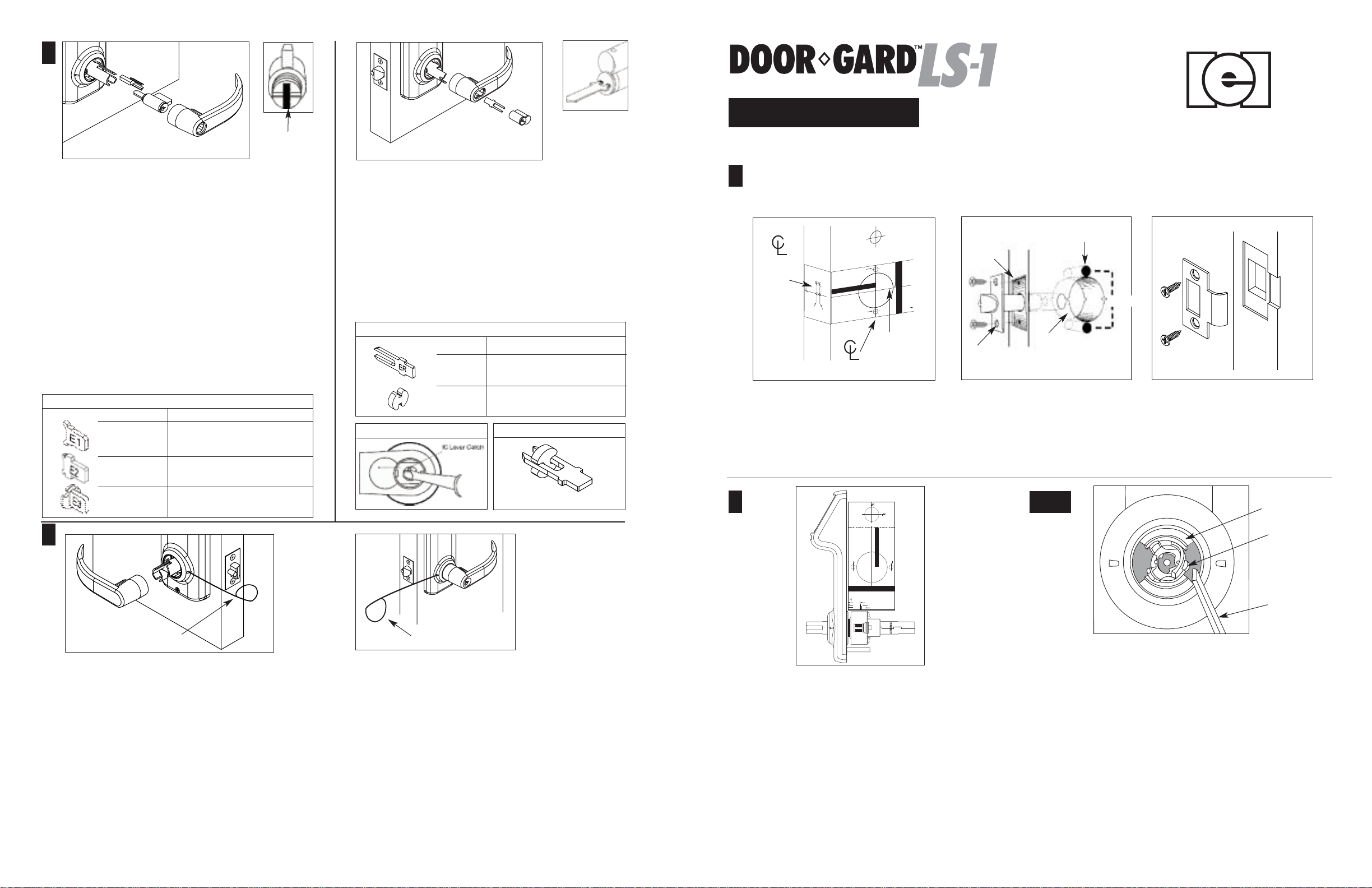

Mark for

1" dia.(25 m

m) Latch

Hole at Cente

r Line

of Door Thickness

1-3/4"

Door

Thickness

1-3/8"

Door

Thickness

FOLD ON EDGE OF DOOR

MA

R

K

CENTER

FOR

2-1/8"

(54 m

m

)

HOLE

IMPOR

T

ANT

PLACE TEMPLA

TE

ON HIGH EDGE O

F

DO

O

R BEVEL

2-3/4 " (70 mm) BACKSET

5/16" H

ole

5/16" Hole

Door Thickness Gauge

OUTSIDE

MOUNTING

PLAT

E

CENTER OF

RETRACTO R

8

MARK

CENTER

FOR

2-1/8"

(54 mm)

HOLE

DOOR THICKNESS GAUGE

IMPORTANT

PLACE TEMPLATE

ON HIGH EDGE OF

DOOR BEVEL

Mark for

1" dia.(25 mm)

Latch Hole

at Center Line

of Door Thickness

2-3/4 " (70 mm) BACKSET

5/16" Hole

OUTSIDE

MOUNTING

PLATE

1-5/8" DOOR

CENTER OF

RETRACTOR

1-3/4" DOOR

1-7/8" DOOR

5/16" Hole

DETACH ON DOTTED LINE

A1

B1

ACCESS CONTROL LOCKSET

Tailpiece in

Conventional Cylinder

A

vertical position

Installing The Levers

Inside Lever

1. See previous page

Conventional Cylinder (Figure A)

Outside Lever

1. Tailpiece must be in a vertical position in cylinder. (Fig. A1)

2. Insert cylinder in lever.

3. Press cylinder retainer into lever until flush with base of lever.

4. Align lever catch to face latch front (see Fig. 6).

5. Turn key in cylinder 45° in either direction.

6. Slide lever on tube until it stops at the lever catch.

7. Slightly wiggle and push until lever engages lever catch

and connector.

Conventional Tailpieces For the Door Gard LS-1

Part No. For

LS1P-TLS IEI Cylinders

LS1P-TIL Ilco Cylinders

B

IC Core Cylinder

horizontal position

IC Core Cylinder (Figure B)

Installing IC Core

1. Push lever on door in horizontal position until secure.

2. Insert control key (marked with a “C”) into IC core and

turn clockwise.

3. Insert tailpiece (See char t below.) into core. (Fig. B1)

4. With control key in core, insert core fully into lock.

5. Turn control key 15° to lock cylinder in place.

Remove control key.

I.C. Tailpieces For the Door Gard LS-1

Part No. For

LS1P-TIC7 7 pin IC Core Cylinder

Tailpiece in

LS1P-TICS Spacer to convert 7 pin tailpiece

To Remove IC Core Lever Handle

for use with 6 pin ic core.

Correct Orientation of Spacer

Installation Instructions

1

A

Of

Door

Edge

1-3/4"

(44 mm)

or 1-3/8"

(35 mm)

Door

Thickness

A. Affix paper template to door

and follow template instructions in preparing door.

Note: See template for measurements.

Vertical

Of

Lever

Mark

Height

Line

B

Mortise

Area

Latch

B. Install latch.

5/16" Hole

2-1/8" Hole

©2001 INTERNATIONALELECTRONICS, INC.

427 TURNPIKE STREET,CANTON, MA 02021

(781) 821-0734 • www.ieib.com

FAX INFO CENTER: (781) 821-0734

REFER TO DOC. #6058003 FOR CUT-SHEET

REFER TO DOC. #6058004 FOR PROGRAMMING MANUAL

REFER TO DOC. #6058005 FOR INSTALLATION INSTRUCTIONS

REFER TO DOC. #6108004 FOR INSTALLATION TEMPLATE

C

2-3/4"

C. Install strike.

LS1P-TSG Schlage Cylinders

9

Removal Tool

9A

Removal Tool

Removal of Levers

Inside Lever

1. Insert lever removal tool in slot. (Fig. 9)

2. Depress lever catch and pull lever to remove.

Warranty — International Electronics Incorporated (IEI) warrants its products to be free from defects in material and workmanship, when they have been installed

in accordance with the manufacturers instructions, and have not been modified or tampered with. IEI does not assume any responsibility for damage or injury to

person or property due to improper care, storage handling, abuse, misuse, normal wear and tear, or an act of God. IEI's sole responsibility is limited to the repair

(at IEIs option) or the replacement of the defective product or part when sent to IEIs facility (freight and insurance charges prepaid), after obtaining IEI's Return

Merchandise Authorization. IEI will not be liable to the purchaser or any one else for incidental or consequential damages arising from any defect in, or malfunction

of, its products.This warranty shall expire two years after shipping date for Prox. Pad Keypads. Except as stated above, IEI makes no warranties, either expressed or

implied, as to any matter whatsoever, including, without limitation to, the condition of its products, their merchantability, or fitness for any particular application.

©2002 International Electronics, Inc. • 427 Turnpike Street, Canton, MA 02021

(800) 343-9502 • Fax Info center: (781) 821-0734 • www.ieib.com

Outside Lever

1. Insert key into cylinder and turn 45° in either direction.

2. Insert lever removal tool in slot. (Fig. 9A)

3. Depress lever catch and pull lever to remove.

2

1. Locks are factory assembled with a split spacer ring for

1-3/4" door thickness, (when lock chassis is firmly against ring.)

2. Locks can be adjusted for 1-5/8" to 1-7/8" door thickness.

Before installation, use door thickness gauge on template

(as shown), to check lock chassis position. Center of latch retractor

should align with mark on gauge for appropriate door thickness.

3. If chassis is not on center, screw chassis in or out to align with

mark. If adjusting for doors thinner than 1-3/4" thickness, split

spacer must be removed. Check that lever engages lever catch

before installation.

4. Make sure to adjust for correct door thickness.

2A

Spindle

Lever Catch

Screw Driver

1. To adjust lockset for desired door thickness, turn lock chassis in

the direction to adjust for narrow or thick doors. (For narrow

doors, remove split spacer ring.) It may be necessary to depress

the lever catch on spindle in order to rotate the chassis and spindle.

2. Using a standard screwdriver depress lever catch to clear spindle

support collar while turning lock chassis. Turn spindle to adjust

for correct door thickness.

3. Once lock is adjusted for door thickness, install exterior lever and

check that lever engages lever catch before completing lock

installation. Lever should snap securely into place with no play.

If lever wobbles or does not engage with catch, turn spindle until

lever snaps into place.

4. Complete lockset installation.

Doc #6058004 Rev. 2.0

1 of 4

Page 2

Installation Instructions

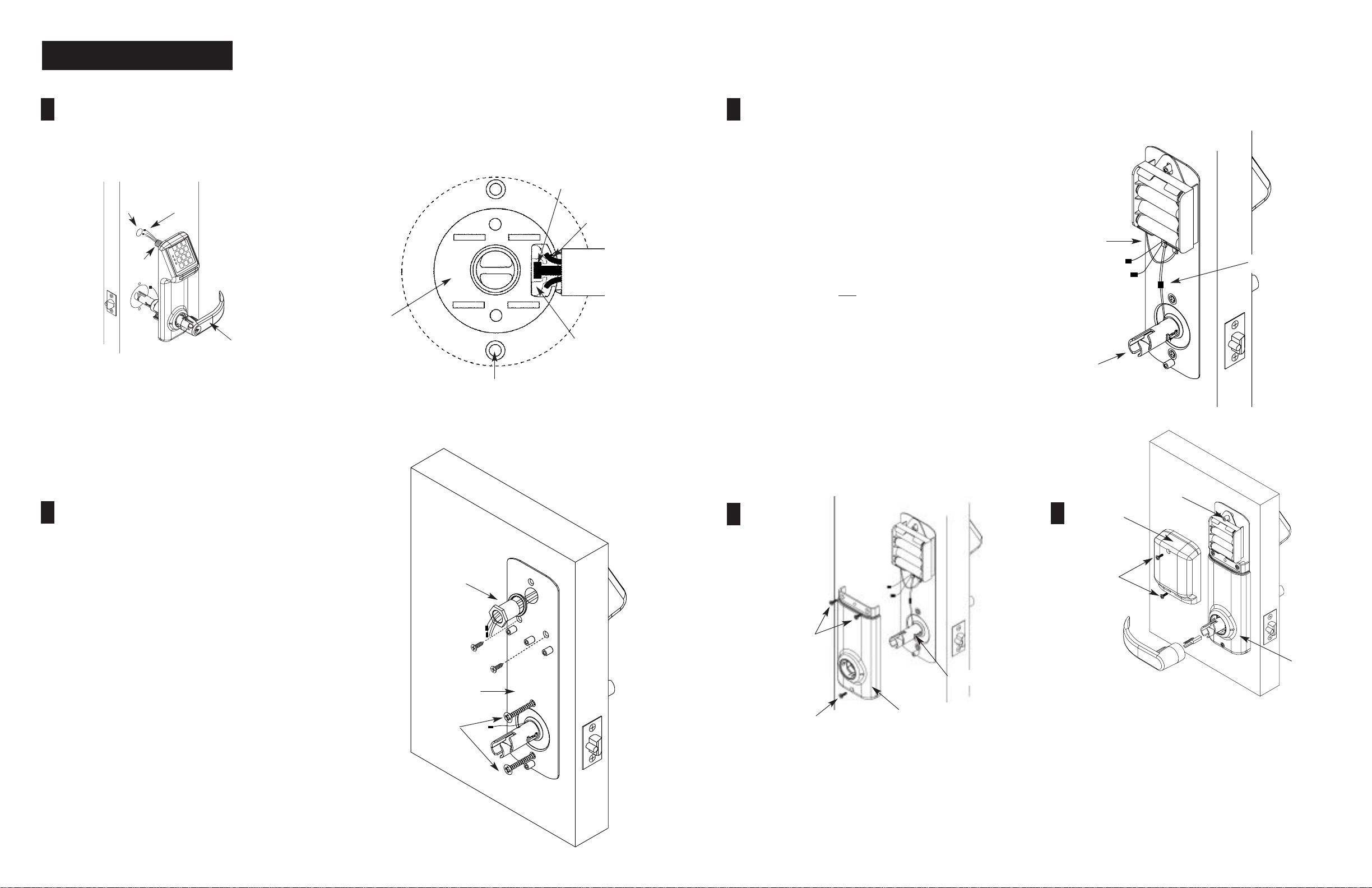

3

Tube

Wires with

connectors

Lever should

snap securely

into place

with no play.

3/4”

Hole

Raceway

Pass the wires and connectors through the 3/4" hole, then mount

the exterior housing through door preparation. Make sure that the

lock chassis and latch are properly engaged as shown.

(See Fig. 2A)

Figure 2A

Lock Housing

Posts

Latch Tail

Latch

Retractor

Prongs

5

Note: It is recommended to use only alkaline batteries, due to predetermined

power settings in the lock.

Insert 4 AA batteries into battery holder. (Note polarity.)

Note:All wire pairs are color coded to connect with like colored pairs.

1. Connect the grey/red wires from the raceway to the

grey/red wires from the lever tube.

2. Connect the red/black wires from the raceway to

the red/black wires from the battery pack. The four

remaining wires are only

switch, as well as the request to exit (REX) function.

(See the programming manual for details.)

3. Place the battery holder over the center grooved stud.

Note:The fork,located on the bottom of the battery holder will clear

the lower inside housing.

4. When properly aligned, push down on the battery

holder assembly, engaging the upper part of the hole

into the groove of the center stud. This will connect the

lower fork with the center post, giving a very secure fit.

for the optional door position

Red/Black

Grey/Red

Lever Tube

4

1. Remove screw from Battery Cover to access backplate.

2. Feed the wires and connectors through the backplate and

raceway nut. Install lock washer on the raceway nut.

3. While holding the interior backplate in position, loosely

install the two thru-bolts.

4. Tighten the raceway nut on the raceway tube that passes

through the door using a crescent or 7/8" socket wrench.

When this connection is tight, secure the thru-bolts.

5. Install two screws to the backplate to the door (wooden door

application). The two predrilled holes on the backplate are

located below the raceway nut.

Raceway Nut

Interior Backplate

Thru-bolts

6

Brass #8 Screws

Lever Catch

Finished #8 Screw

1. Slide the inside lower housing over the lever tube until it has

passed over the lever catch. Make sure the four remaining

wires (if not used) are properly placed so they are not

pinched by the lower housing.

2. Fasten with two brass #8 screws. Once secure, fasten the

finished #8 screw at the bottom.

Inside Lower Housing

Center

Grooved Stud

7

Battery Cover

#8 Screws

Inside Lower

Housing

PUSH ALL EXCESS WIRE LENGTHS DOWN THROUGH THE

OPENING AT THE TOP OF THE INSIDE LOWER HOUSING.

1. Attach the battery cover with two finished #8 screws.

Battery cover has a lip which engages the lower inside

housing, it is important that this lip be seated properly to

insure correct alignment.

2. Insert cylinder retainer into lever until flush with base of lever.

3. Push level on door in horizontal position until secure.

2 of 4

3 of 4

Loading...

Loading...