Page 1

H480-2 INSTALLATION INSTRUCTIONS

®

ABOUT THE H480-2 MOUNTING CLAMP DESIGN

The H480-2 speaker features rigid, heavy-duty

mounting clamps that ensure a quick, secure,

vibration-free installation in walls from 1/2” to 1-1/2” in

thickness.

The H480-2 model has four mounting clamps.

DAMPING THE WALL CAVITY

Damping the wall/ceiling cavity behind the speakers

by loosely filling it with fire-rated fiberglass insulation

can enhance the performance of your speakers and

reduce unwanted transmission of sound into adjacent

rooms.

PAINTING THE SPEAKERS

All speakers can be finished to match any room décor.

Their white, textured frames and no-rust aluminum

grilles readily accept most water-based interior latex

and spray enamels.

We recommend the grille and frame be painted

separately. To aid in frame painting, we’ve included a

plastic paint shield that will protect the speaker baffle.

Painting Tips:

speakers. The H481-6 brackets can be

mounted before the drywall is installed. Visit

the openhousesystem.com web site for further

information.

• Always maintain proper polarity when wiring

speakers. Failure to do so will result in poor stereo

imaging and a decrease in base response.

CUTTING SPEAKER OPENINGS IN FINISHED WALLS

1. Use a stud finder to locate the studs around the

intended speaker placement. NOTE: A studfinding device MAY NOT detect pipes, wiring, or

other obstructions located behind the drywall.

2. Use the inside portion of the speaker cutout

template to confirm the speaker placements.

3. Remove templates and drill or carefully poke a

pilot hole in both locations. A bent piece of wire

or a coat hanger may be used to probe the stud bay

for obstructions. If you experience resistance of

any kind––STOP! If any obstructions are detected,

patch the pilot holes and try again in another

location.

1. If not using spray paint, we recommend that the

paint be thinned to prevent clogging the speaker

grille perforations.

2. When painting, several light coats will yield the

best results.

As the installation of flush-mount speakers requires

cutting into walls where high-voltage wiring, pipes

and duct work may be present, installation should be

performed by experienced and trained professionals

only.

NOTES:

• Check for Obstructions––Before cutting holes

in any existing wall or ceiling surface, the cavity

behind each speaker’s installation location MUST

be probed for obstructions. Make sure to probe

both speaker locations in the room to ensure that

symmetrical placement is feasible.

• New Construction Installation—In new

construction installations, the H481-6 mounting

brackets can be used to mount the H480-2

4. Once you have determined the cavity is free from

obstructions, re-position the cutout template and

use a pencil to lightly trace the perimeter of the

tem-plate.

5. Use a keyhole saw, drywall router, or razor knife to

cut the openings.

IMPORTANT NOTE:

of the H480-2 speaker frame flanges

require that careful attention be paid

to not oversize the cut-out hole.

The slim design

IN-CEILING SPEAKER INSTALLATION:

Complete Assemblies

(with or without New

Construction Brackets)

1. Remove speaker grille

2. Locate the speaker wire and pull through the

ceiling opening.

Page 2

3. Connect the speaker wire. BE SURE TO

OBSERVE CORRECT POLARITY!

4. Insert the speaker into the opening in the

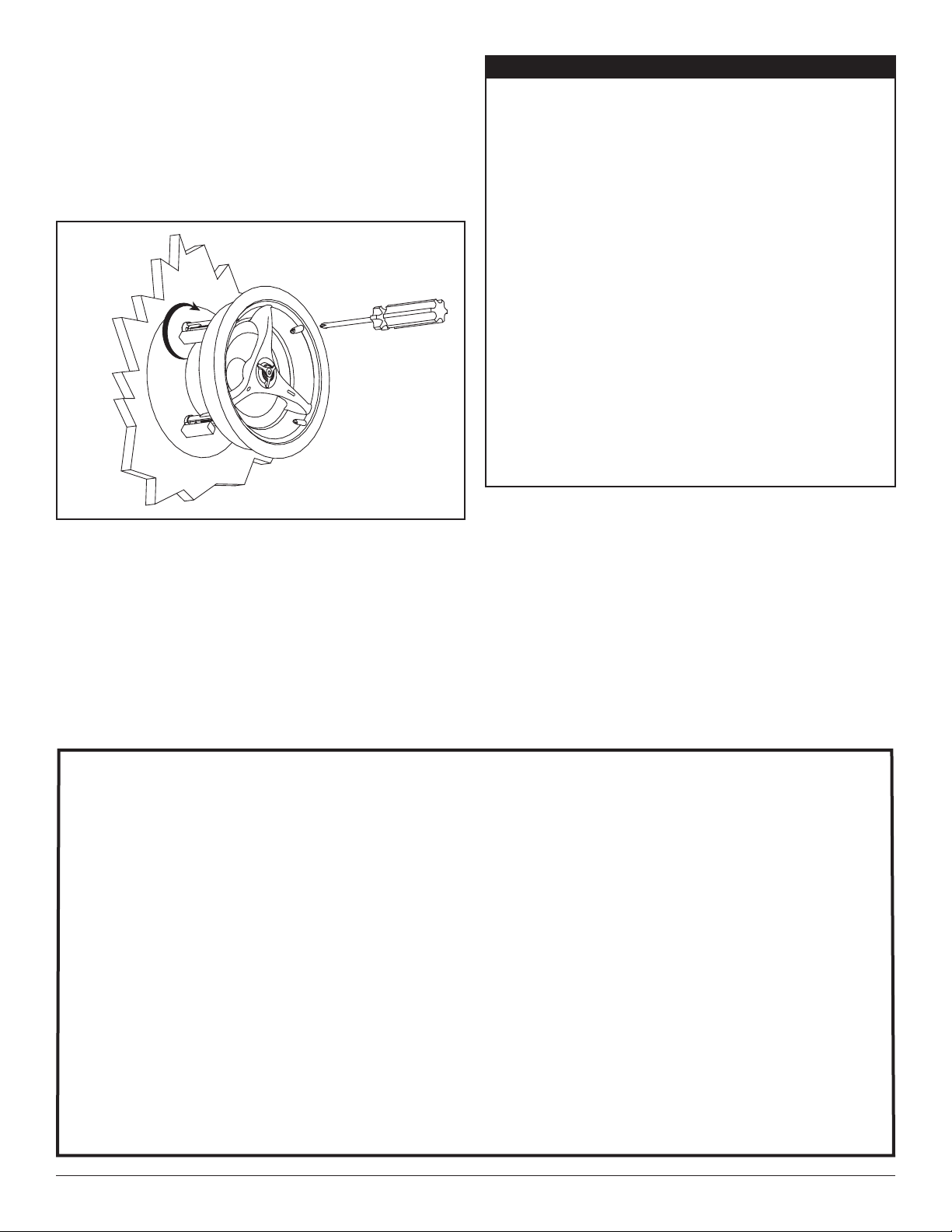

ceiling and CAREFULLY tighten each of the four

clamping screws, alternating diagonally between

each screw position to ensure proper fit and finish.

See FIGURE 1.

H480-2 SPECIFICATIONS AND DRIVER COMPONENTS

The H480-2 In-Wall/In-Ceiling Loudspeaker line is

constructed using the finest materials available to

provide a lifetime of listening enjoyment.

Tweeter Material PEI

Woofer Cone 6.5" Polypropylene

Woofer Surround Inverted Butyl

Woofer Basket Stamped

Crossover Response 6dB/octave

Crossover Switches None

Interconnect Wire 20AWG

Input Connectors Spring Terminals

Hardware Stainless Steel

Nominal Impedance 8 Ohms

Sensitivity Range 87dB (1W/1 Meter)

Power Handling 5-50W

Cutout Diameter 8-1/16"

Overall Dimensions 9-1/4" dia. x 3-5/8" deep

Figure 1

CAUTION: DO NOT OVER-TIGHTEN THE SCREWS!

If using a drill to tighten the clamping screws, be

sure to set the torque setting very low. Setting

the drill’s torque too high may break the mounting

clamps, the wall surface, and/or the speaker frame

assembly.

5. Replace the speaker grille.

Warranty

Linear LLC warrants this product to be free from defects in material and workmanship for two years (2 years). The time period will be measured using the date

code labeled on the product. Linear LLC is not responsible for damage to the product resulting from the buyer's improper handling, stocking or warehousing of

the product. Any implied warranty arising from the sale of the product including implied warranties of merchantability and fitness for purpose are limited. Linear

LLC shall not be responsible for any losses, damages or expenses, whether direct, consequential, or incidental arising from the use or the inability to use the

product. Some states and countries do not allow limitations on how long an implied warranty lasts or the exclusion or limitation or incidental or consequential

damages, so the above exclusions may not apply. The Linear LLC warranty gives specific legal rights in addition to other rights, which may exist and vary from

state to state and country to country.

The warranty is limited to repair or replacement of products returned, freight prepaid, to Linear LLC, there is NO PROVISION FOR LABOR COST OR OTHER

REIMBURSEMENTS OF ANY KIND.

1. Failures due to product abuse, such as negligence, improper use, and electrical surge including damage from lightening, water damage or other damage

due to natural disasters are not covered by the warranty. The most common form of product abuse is surge damage caused by lightening.

2. The warranty shall also be voided by any tampering with the date code, labels or other markings on the product.

3. Products that are damaged in transit to Linear LLC due to improper packaging or by the carrier (shipping company) will not be covered under the warranty.

If the product was damaged or lost by the carrier, it is the sender's responsibility to create a claim against the carrier.

4. The user is responsible for all labor costs associated with removing, reinstalling and returning the product to Linear LLC.

Linear LLC, at its option, will repair or replace the defective product. Replacements will be made from B-Stock, if an exact replacement is not available, Linear

LLC, at it's option, will select the nearest equivalent product. The user is responsible for freight charges to Linear LLC. Linear LLC will return warranted repaired

or replacements by UPS Ground or an equivalent service. A customer may pay the additional costs for second-day or next-day service.

All products returned for warranty service require a Return Product Authorization Number (RPA#). Contact Linear Technical Services at 1-800-999-5225 for an

RPA# and other important details.

Copyright © 2004 Linear LLC 224104 X2

Loading...

Loading...