Page 1

IM3051

11/2014

REV01

WELD PAK™ 2000

OPERATOR’S MANUAL

ENGLISH

Lincoln Electric Bester Sp. z o.o.

ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

www.lincolnelectric.eu

Page 2

English English

I

Declaration of conformity

14

Lincoln Electric Bester Sp. z o.o.

Declares that the welding machine:

WELD PAK™2000

conforms to the following directives:

2006/95/CEE, 2004/108/CEE

and has been designed in compliance with the

following standards:

EN 60974-1, EN 60974-5, EN 60974-10:2007

01.05.2014

Paweł Lipiński

Operations Director

Lincoln Electric Bester Sp. z o.o., ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

07/11

Page 3

English English

II

12/05

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specifications .................................................................................................................................................. 1

Electromagnetic Compatibility (EMC) .............................................................................................................................. 2

Safety .............................................................................................................................................................................. 3

Introduction ...................................................................................................................................................................... 4

Installation and Operator Instructions .............................................................................................................................. 4

WEEE ............................................................................................................................................................................ 13

Spare Parts .................................................................................................................................................................... 13

Electrical Schematic ...................................................................................................................................................... 13

Suggested Accessories ................................................................................................................................................. 13

Page 4

English English

1

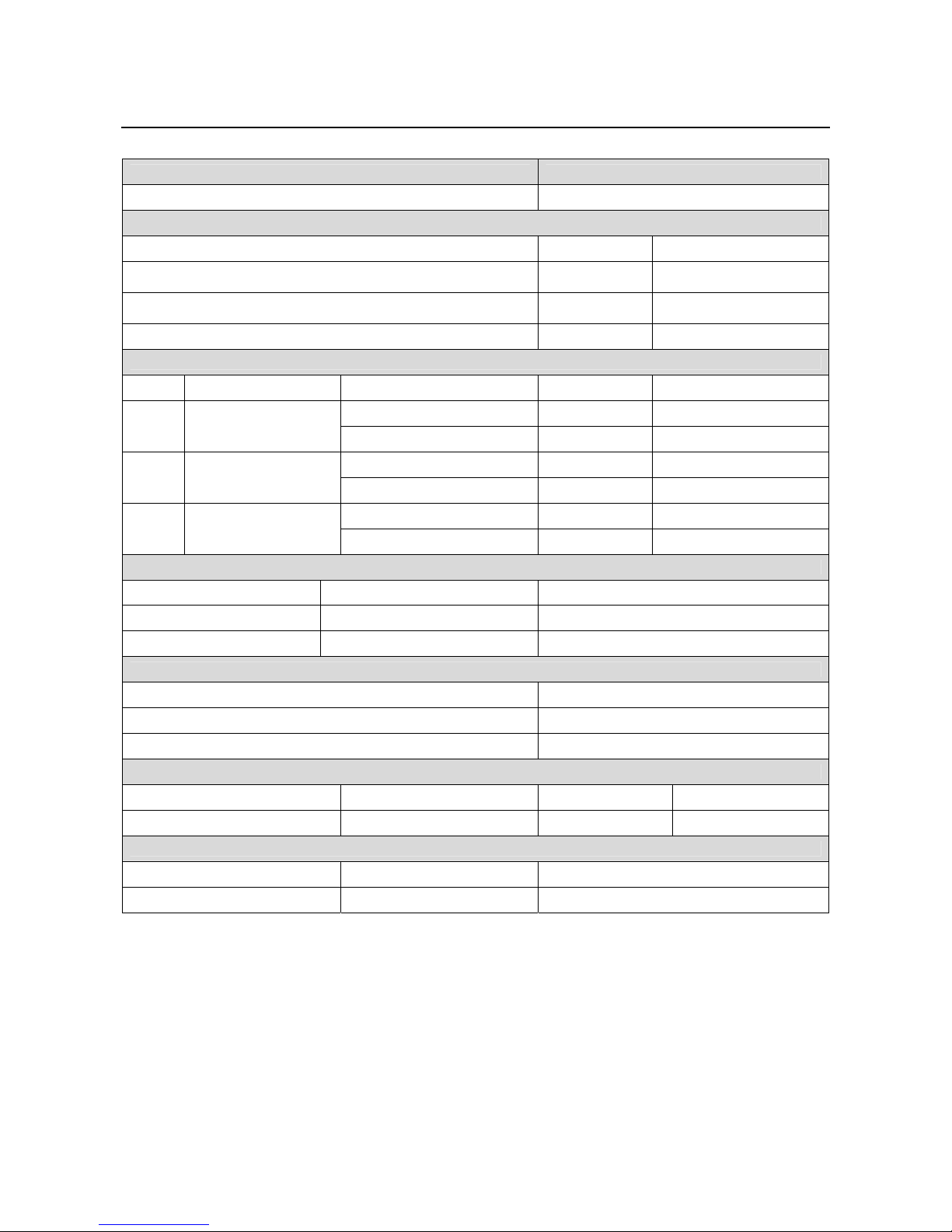

Technical Specifications

WELD PAK™ 2000

NAME INDEX

WELD PAK™2000 K14134-1

INPUT

Input Voltage U1 EMC Class Frequency

230 V ± 10%

1 – phase

A 50 / 60 Hz

Input Power at Rated Cycle

Input Amperes

I

1max

PF

7,6 kVA @ 20 % Duty Cycle (40°C) 33 A 0,66

RATED OUTPUT

Open Circuit Voltage

Duty Cycle 40°C

(based on a 10 min. period)

Output Current Output Voltage

GMAW

49 Vdc

100 80 A 18 Vdc

20 180 A 23 Vdc

FCAW-

SS

49 Vdc

100 80 A 18 Vdc

20 180 A 23 Vdc

SMAW

49 Vdc

100 70 A 23,2 Vdc

20 160 A 26,4 Vdc

WELDING CURRENT RANGE

GMAW FCAW-SS SMAW

20 A – 200 A 20 A – 200 A 20 A – 160 A

20 A – 200 A 20 A – 200 A 20 A – 160 A

RECOMMENDED INPUT CABLE AND FUSE SIZES

Fuse (time delayed) or Circuit Breaker Size Power Lead

230 V

D 25 A 3 Conductor, 1,5 mm2

DIMENSIONS AND WEIGHT

Weight Height Width Length

27,5 kg 600 mm 280 mm 800 mm

Protection Rating Operating Temperature Storage Temperature

IP23 from -10 ºC to +40 ºC from -25 ºC o +55 ºC

Page 5

English English

2

Electromagnetic Compatibility (EMC)

01/11

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

This machine has been designed to operate in an industrial area. The operator must install and operate

this equipment as described in this manual. If any electromagnetic disturbances are detected the operator

must put in place corrective actions to eliminate these disturbances with, if necessary, assistance from

Lincoln Electric

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

machine.

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

that all equipment in the area is compatible. This may require additional protection measures.

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

taking place.

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

additional precautions such as filtering the input supply.

The output cables should be kept as short as possible and should be positioned together. If possible connect the

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

applications.

WARNING

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

WARNING

This equipment does not comply with IEC 61000-3-12. If it is connected to a public low voltage system, it is the

responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network operator,

that the equipment may be connected.

Page 6

English English

3

Safety

01/11

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and

EN 12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal

Protective Equipments (PPE) having filter with a protection degree up to a maximum of 15, as

required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

Page 7

English English

4

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

MOVING PARTS ARE DANGEROUS: There are moving mechanical parts in this machine, which can

cause serious injury. Keep your hands, body and clothing away from those parts during machine

starting, operating and servicing.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Introduction

The welding machines WELD PAK™ 2000 enables

welding:

GMAW (MIG/MAG)

FCAW-SS

SMAW (MMA)

The following equipment has been added to WELD

PAK™ 2000:

Bracket with rear wheels, M5 screws (4 units) and

M5 lock nuts (4 units)

Gun for GMAW process – 3m

Work lead – 3m

Gas hose – 2m

For GMAW and FCAW-SS process, the technical

specification describes:

Type of welding wire

Wire diameter

Recommended equipment, which can be bought by

user, was mentioned in the chapter "Accessories".

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

Location and Environment

This machine will operate in harsh environments.

However, it is important that simple preventative

measures are followed to assure long life and reliable

operation:

Do not place or operate this machine on a surface

with an incline greater than 15° from horizontal.

Do not use this machine for pipe thawing.

This machine must be located where there is free

circulation of clean air without restrictions for air

movement to and from the air vents. Do not cover

the machine with paper, cloth or rags when

switched on.

Dirt and dust that can be drawn into the machine

should be kept to a minimum.

This machine has a protection rating of IP23. Keep

it dry when possible and do not place it on wet

ground or in puddles.

Locate the machine away from radio controlled

machinery. Normal operation may adversely affect

the operation of nearby radio controlled machinery,

which may result in injury or equipment damage.

Read the section on electromagnetic compatibility in

this manual.

Do not operate in areas with an ambient

temperature greater than 40°C.

Duty cycle and Overheating

The duty cycle of a welding machine is the percentage of

time in a 10 minute cycle at which the welder can

operate the machine at rated welding current.

Example: 60% duty cycle

Welding for 6 minutes. Break for 4 minutes.

Excessive extension of the duty cycle will cause the

thermal protection circuit to activate.

The machine is protected from overheating by a

temperature sensor.

Page 8

English English

5

Input Supply Connection

WARNING

Only a qualified electrician can connect the welding

machine to the supply network. Installation had to be

made in accordance with the appropriate National

Electrical Code and local regulations.

Check the input voltage, phase and frequency supplied

to this machine before turning it on. Verify the

connection of ground wires from the machine to the input

source. The welding machine WELD PAK™ 2000 must

be connected to a correctly installed plug-in socket with

an earth pin.

Input voltage is 1x230V, 50/60Hz. For more information

about input supply refer to the technical specification

section of this manual and to the rating plate of the

machine.

Make sure that the amount of mains power available

from the input supply is adequate for normal operation of

the machine. The necessary delayed fuse (or circuit

breaker with "D" characteristic) and cable sizes are

indicated in the technical specification section of this

manual.

WARNING

The welding machine can be supplied from an engine

driven generator of output power at least 30% larger

than input power of the welding machine. Engine driven

generator must have voltage stabilization. Otherwise,

may cause a damage.

See "Technical Specifications" chapter.

WARNING

When powering welder from a generator be sure to turn

off welder first, before generator is shut down, in order to

prevent damage to welder!

Output Connections

Refer to points [8], [9] and [10] of the Figures below.

Controls and Operational Features

1. Power Switch ON/OFF (I/O): Controls the input

power to the machine. Be sure the power source is

connected to the mains supply before turning power

on ("I"). After input power is connected and the

power switch is turned on, the indicator will light up to

indicate the machine is ready to weld.

2. Process Welding’s Switch:

GMAW (MIG/MAG) process

Warning: Can be used to FCAWSS process.

SMAW (MMA) process

WARNING

When the machine is switched again on, last welding

process will be recalled.

WARNING

If the push-button is pushed in GMAW process in, the

output terminals will lived.

WARNING

During SMAW process, the output terminals are still

lived.

1

2

6

754

3

8

9

10

Figure 1

3. Welding Load Voltage / Current Control: Depending

on welding process, this knob controls:

GMAW

process

The welding load voltage and

set by this knob [6] (also during

welding).

SMAW

process

The welding current is set by

this knob [6] (also during

welding).

4. WFS/Hot Start Control: Depending on welding

process, this knob controls:

GMAW

process

Wire feed speed WFS: Value in

percentage of nominal value

wire feed speed.

SMAW

process

HOT START: Value in

percentage of nominal value

welding current during arc start

current. The control is used to

set the level of the increased

current and arc start current is

made easy.

5. Control: Depending on welding process, this knob

controls:

GMAW

process

Inductance: Arc control is

controlled by this knob. If the

value is higher, the arc will be

softer and during welding is less

spatters.

SMAW

process

ARC FORCE: The output

current is temporarily increased

to clear short circuit connections

between the electrode and the

workpiece.

Page 9

English English

6

6. LED Indicator Power switch: This LED lights

up when the welding machine is ON and is

ready to work

7. Thermal Overload Indicator: It indicates that

the machine is overloaded or that the cooling

is not sufficient.

WARNING

If the welding current exceed 200 A, output power will be

turned off after 5 seconds. It will be indicated by Thermal

Overload Indicator. Output power will be turned on again

after 3 minutes.

8. EURO Socket: For connecting a welding gun (for

GMAW / FCAW-SS process).

9. Positive Output Socket for the Welding

Circuit: For connecting an electrode holder

with lead / work lead.

10. Negative Output Socket for the Welding

Circuit: For connecting an electrode holder

with lead / work lead.

11. Gas Connector: Connection for gas line.

12. Power Lead with Plug (3m): Power lead with plug is

a standard equipment. Connect the power lead with

plug to the main supply before turning power on.

12

11

Figure 2.

13

1415

17

18

16

Figure 3

13. Wire Drive (for GMAW, FCAW-SS process): 2-Roll

wire drive.

14. Welding Wire (for GMAW / FCAW-SS).

15. Spooled Wire (for GMAW / FCAW-SS): The machine

does not include a spooled wire.

16. Wire Spool Support: Maximum 15kg spools. Accepts

plastic, steel and fiber spools onto 51mm spindle.

Also accepts Readi-Reel

®

type spools onto included

spindle adapter.

17. Shield of Changing Polarity.

18. Terminal Block of Changing Polarity (for GMAW /

FCAW-SS process): This terminal block enables to

set the welding polarity (+ ; -), which will be given at

the welding holder.

WARNING

Positive (+) polarity is set at the factory.

WARNING

Before welding check the polarity for using electrodes

and wires.

If the welding polarity has to be changed, user should:

Switch off the machine.

Determine the wire polarity for the wire to be used.

Consult the electrode data for this information.

Take off the terminal block’s shield [17].

The tip of the wire on the terminal block [18] and

work lead fix as is shown in the Table 1 or

the Table 2.

Put on the terminal block’s shield.

WARNING

The machine must be used with the door completely

closed during welding.

WARNING

Not use handle to move the machine during work.

Page 10

English English

7

Table 1.

Positive polarity

(factory setting)

Table 2.

Negative polarity

Page 11

English 8 English

Wire Spool Loading

Wire spool type S300 and BS300 can be installed on the

wire spool support without adapter.

Wire spool type S200, B300 or Readi-Reel® can be

installed, but the applicable adapter must be purchased.

The applicable adapter can be purchased

separately(see "Accessories" chapter).

Wire Spool Type S300 & BS300 Loading

WARNING

Turn the input power OFF at the welding power source

before installation or changing a wire spool.

19

22

20

21

Figure 4

Turn the input power OFF.

Open the side panel.

Unscrew the Locking Nut [19] and remove it from

the Spindle [21].

Place the spool type S300 or BS300 [20] on the

Spindle [21] making certain the Spindle Brake Pin

[22] is put in the hole in back side of spool type

S300 or SB300.

WARNING

Position the spool type S300 or SB300 so that it will

rotate in a direction when feeding so as to be de-reeled

from bottom of the spool.

Re-install the locking nut [19]. Make sure that the

locking nut is tightened.

Wire Spool Type S200 Loading

WARNING

Turn the input power OFF at the welding power source

before installation or changing a wire spool.

19

25

22

21

2423

Figure 5

Turn the input power OFF.

Open the side panel.

Unscrew the Locking Nut [19] and remove it from

the Spindle [21].

Place the adapter of spool type S200 [23] on the

spindle [21] making certain the spindle brake pin

[22] is put in the hole in back side of the adapter

[23]. The adapter of spool type S200 can be

purchased separately (see "Accessories" chapter).

Place the spool type S200 [25] on the spindle [21]

making certain that the adapter brake pin [24] is put

in the hole in the back side of the spool.

WARNING

Position the spool type S200 so that it will rotate in a

direction when feeding so as to be de-reeled from

bottom of the spool.

Re-install the locking nut [19]. Make sure that the

locking nut is tightened.

Page 12

English 9 English

Wire Spool Type B300 Loading

WARNING

Turn the input power OFF at the welding power source

before installation or changing a wire spool.

19

22

21

26 27

Figure 6

Turn the input power OFF.

Open the side panel.

Unscrew the Locking Nut [19] and remove it from

the spindle [21].

Place the adapter of spool type B300 [26] on the

spindle [21].Make certain that the spindle brake pin

[22] is put in the hole in the back side of the

adapter [26]. The adapter of spool type B300 can be

purchased separately (see "Accessories" chapter).

Re-install the locking nut [19]. Make sure that the

locking nut is tightened.

26

27

28

29 30

Figure 7

Rotate the spindle and adapter so the retaining

spring [27] is at the 12 o'clock position.

Place the spool type B300 [29] on the adapter [26].

Set one of the B300 inside cage wires [30] on the

slot [28] in the retaining spring tab [27] and slide the

spool onto the adapter.

WARNING

Position the spool type B300 so that it will rotate in a

direction when feeding so as to be de-reeled from

bottom of the spool.

29

27

Figure 8

Wire Spool Type Readi-Reel® Loading

WARNING

Turn the input power OFF at the welding power source

before installation or changing a wire spool.

1931

22

21

34

33

32 30

Figure 9

Turn the input power OFF.

Open the spool wire case.

Unscrew the locking nut [19] and remove it from the

spindle [21].

Place the adapter of spool type Readi-Reel® [31] on

the spindle [21].Make certain that the spindle brake

pin [22] is put in the hole in the back side of the

adapter [31]. The adapter of spool type Readi-Reel

®

can be purchased separately (see "Accessories"

chapter).

Page 13

English 10 English

Re-install the locking nut [19]. Make sure that the

locking nut is tightened.

Rotate the spindle and adapter so the retaining

spring [32] is at the 12 o'clock position.

Place the spool type Readi-Reel

®

[34] on the

adapter [31]. Set one of the Readi-Reel

®

inside

cage wires [30] on the slot [33] in the retaining

spring tab [32].

WARNING

Position the spool type Readi-Reel® so that it will rotate

in a direction when feeding so as to be de-reeled from

bottom of the spool.

Loading the Electrode Wire

Turn the input power OFF.

Open the side panel of the machine.

Unscrew the locking nut of the sleeve.

Load the spool with the wire [15] on the sleeve such

that the spool turns anticlockwise when the wire [14]

is fed into the wire feeder.

Make sure that the spool locating pin goes into the

fitting hole on the spool.

Screw in the looking nut of the sleeve.

Put on the wire roll using the correct groove

corresponding to the wire diameter.

Free the end of the wire and cut off the bent end

making sure it has no burr.

WARNING

Sharp end of the wire can hurt.

Rotate the wire spool anticlockwise and thread the

end of the wire into the wire feeder as far as the

Euro socket.

Adjust force of pressure roll of the wire feeder

properly.

Adjustments of Brake Torque of Sleeve

To avoid spontaneous unrolling of the welding wire the

sleeve is fitted with a brake.

Adjustment is carried by rotation of its screw M10, which

is placed inside of the sleeve frame after unscrewing the

fastening cap of the sleeve.

36

35

19

Figure 10

19. Fastening cap.

35. Adjusting screw M10.

36. Pressing spring.

Turning the screw M10 clockwise increases the spring

tension and you can increase the brake torque

Turning the screw M10 anticlockwise decreases the

spring tension and you can decrease the brake torque.

After finishing of adjustment, you should screw in the

fastening cap again.

Adjusting of Force of Pressure Roll

Force

The pressure arm controls the amount of force the drive

rolls exert on the wire.

Pressure force is adjusted by turning the adjustment nut

clockwise to increase force, counterclockwise to

decrease force. Proper adjustment of pressure arm

gives the best welding performance.

WARNING

If the roll pressure is too low the roll will slide on the wire.

If the roll pressure is set too high the wire may be

deformed, which will cause feeding problems in the

welding gun. The pressure force should be set properly.

Decrease the pressure force slowly until the wire just

begins to slide on the drive roll and then increase the

force slightly by turning of the adjustment nut by one

turn.

Inserting Electrode Wire into Welding

Gun

Turn the input power OFF.

Depending on welding process, connect the proper

gun to the euro socket, the rated parameters of the

gun and of the welding machine should be matched.

Remote the nozzle from the gun and contact tip or

protection cap and contact tip. Next, straighten the

gun out flat.

Insert the wire through the guide tube, over the

roller and through the guide tube of Euro Socket into

liner of gun. The wire can be pushed into the liner

manually for a few centimetres, and should feed

easily and without any force.

WARNING

If force is required it is likely that the wire has missed the

liner of gun.

Turn the input power ON.

Depress the gun trigger to feed the wire through the

gun liner until the wire comes out of the threaded

end.

When trigger is released spool of wire should not

unwind.

Adjust wire spool brake accordingly.

Turn the welding machine off.

Install a proper contact tip.

Depending on the welding process and the type of

the gun, install the nozzle (GMAW process) or

protection cap (FCAW-SS process).

WARNING

Take precaution to keep eyes and hands away from the

end of the gun while the wire is being come out of the

threated end.

Page 14

English 11 English

Changing Driving Rolls

WARNING

Turn the input power OFF at the welding power source

before installation or changing drive rolls and/or guides.

WELD PAK™

®

2000 is equipped with drive roll

V0.8/V1.0 for steel wire. For others wire sizes, is

available the proper drive rolls kit (see "Accessories"

chapter) and follow instructions:

Turn the input power OFF.

Release the pressure roll lever [37].

Unscrew the fastening cap [38].

Change the drive roll [39] with the compatible ones

corresponding to the used wire.

WARNING

Be sure that the gun liner and contact tip are also sized

to match the selected wire size.

Screw fastening cap [38].

Manually feed the wire from the wire reel, the wire

through the guide tubes, over the roller and guide

tube of Euro Socket into liner of gun.

Lock the pressure roll lever [37].

39 38

37

Figure 11

Gas Connection

A gas cylinder must be installed with a proper flow

regulator. Once a gas cylinder with a flow regulator has

been securely installed, connect the gas hose [11] to the

flow regulator.

WARNING

The welding machine supports all suitable shielding

gases at a maximum pressure of 5,0 bar.

WARNING

Always fasten gas cylinder properly in vertical position in

a special holder on the wall or on a carriage. Remember

to close gas cylinder valve after having finished welding.

WARNING

Gas cylinder can be fasten on the machine’s shelf, but

the height of gas cylinder doesn’t have to be higher than

43in/1,1m. See the Figure 12. The gas cylinder which is

fastened on the machine’s shelf has to be secured by

attaching it to the machine using the chain.

Figure 12

Welding GMAW, FCAW-SS Process

WELD PAK™2000 can be used to welding GMAW and

FCAW-SS process.

WELD PAK™2000 includes the gun necessary for

GMAW.

Procedure of begin welding of GMAW or FCAW-SS

process:

Place the machine conveniently near the work area

in a location to minimize exposure to weld spatter

and to avoid sharp bends in the gun cable.

Determine the wire polarity for the wire to be used.

Consult the wire data for this information.

Connect output the gas-cooled gun to GMAW /

FCAW-SS process to Euro Socket [8].

Depending on the using wire, connect the work lead

to output socket [9] or [10]. See [18] point – terminal

block of changing polarity.

Connect the work lead to the welding piece with the

work clamp.

Install the proper wire.

Install the proper drive roll.

Manually push the wire into the gun’s liner.

Make a sure, if it is needed (GMAW process), that

the gas shield has been connected.

Turn the machine on.

Insert the wire into the welding gun.

WARNING

Keep the gun cable as straight as possible when loading

electrode through cable.

WARNING

Never use defected gun.

Close the wire drive door.

Set the welding parameters.

The welding machine is now ready to weld.

WARNING

The wire drive door has to be completely closed during

welding.

WARNING

Keep the gun cable as straight as possible when welding

or loading electrode through cable.

WARNING

Do not kink or pull cable around sharp corners.

By applying the principle of occupational health and

safety at welding, welding can be begun.

Page 15

English 12 English

In manual mode can be set:

The welding load voltage

WFS (wire feed speed)

Inductance

Welding SMAW (MMA) Process

WELD PAK™2000 does not include the electrode

holder with lead necessary for SMAW welding, but the

one can be purchased separately. See "Accessories"

chapter.

Procedure of begin welding of SMAW process:

Determine the electrode polarity for the electrode to

be used. Consult the electrode data for this

information.

Depending on the polarity of using electrode,

connect the work lead [19] and the electrode holder

with lead to output socket [8] or [9] and lock them.

See the Table 3.

Table 3.

Output socket

POLARITY

DC (+)

The electrode holder

with lead to SMAW

[9]

Work lead [10]

DC (-)

The electrode holder

with lead to SMAW

[10]

Work lead [9]

Connect the work lead to the welding piece with the

work clamp.

Install the proper electrode in the electrode holder.

Turn the welding machine on.

Set the welding parameters.

The welding machine is now ready to weld.

By applying the principle of occupational health and

safety at welding, welding can be begun.

User can set functions:

The welding current

HOT START

ARC FORCE

Maintenance

WARNING

For any repair operations, modifications or

maintenances, it is recommended to contact the nearest

Technical Service Center or Lincoln Electric. Repairs

and modifications performed by unauthorized service or

personnel will cause, that the manufacturer’s warranty

will become null and void.

Any noticeable damage should be reported immediately

and repaired.

Routine maintenance

Check condition of insulation and connections of the

work leads and insulation of power lead. If any

insulation damage exists replace the lead

immediately.

Remove the spatters from the welding gun nozzle.

Spatters could interfere with the shielding gas flow

to the arc.

Check the welding gun condition: replace it, if

necessary.

Check condition and operation of the cooling fan.

Keep clean its airflow slots.

Periodic maintenance

Perform the routine maintenance and, in addition:

Keep the machine clean. Using a dry (and low

pressure) airflow, remove the dust from the external

case and from the cabinet inside.

If it is required, clean and tighten all weld terminals.

The frequency of the maintenance operations may vary

in accordance with the working environment where the

machine is placed.

WARNING

Do not touch electrically live parts.

WARNING

Before the case of welding machine will be removed, the

welding machine had to be turned off and the power lead

had to be disconnected from mains socket.

WARNING

Mains supply network must be disconnected from the

machine before each maintenance and service. After

each repair, perform proper tests to ensure safety.

Page 16

English 13 English

WEEE

07/06

English

Do not dispose of electrical equipment together with normal waste!

In observance of European Directive 2002/96/EC on Waste Electrical and Electronic Equipment (WEEE)

and its implementation in accordance with national law, electrical equipment that has reached the end of its

life must be collected separately and returned to an environmentally compatible recycling facility. As the

owner of the equipment, you should get information on approved collection systems from our local

representative.

By applying this European Directive you will protect the environment and human health!

Spare Parts

12/05

Part List reading instructions

Do not use this part list for a machine if its code number is not listed. Contact the Lincoln Electric Service

Department for any code number not listed.

Use the illustration of assembly page and the table below to determine where the part is located for your particular

code machine.

Use only the parts marked "X" in the column under the heading number called for in the assembly page (# indicate

a change in this printing).

First, read the Part List reading instructions above, then refer to the "Spare Part" manual supplied with the machine, that

contains a picture-descriptive part number cross-reference.

Electrical Schematic

Refer to the "Spare Part" manual supplied with the machine.

Suggested Accessories

K10413-15-3M The gas-cooled gun LG150 to GMAW process - 3m

K10413-15-4M The gas-cooled gun LG150 to GMAW process - 4m

K10413-15-5M The gas-cooled gun LG150 to GMAW process - 5m

KP10461-1 Gas nozzle conical Ø12mm

KP10440-06 Contact Tip M6x25mm ECu 0.6mm

KP10440-08 Contact Tip M6x25mm ECu 0.8mm

KP10440-09 Contact Tip M6x25mm ECu 0.9mm

KP10440-10 Contact Tip M6x25mm ECu 1.0mm

KP10468 Protection cap to FCAW-SS process

E/H-200A-25-3M Welding cable with electrode holder to SMAW process - 3m

K14010-1 Work Lead -3m.

KIT-200A-25-3M

Lead’s KIT to SMAW process:

The electrode holder with lead to SMAW process - 3m

Work lead - 3m

K14042-1 Adapter for spool type S200

K10158-1 Adapter for spool type B300

K363P

Adapter for spool type Readi-Reel

®

Drive rolls to 2 driven rolls

Solid wires:

KP14016-0.8 V0.6 / V0.8

KP14016-1.0 V0.8 / V1.0

Cored wires:

KP14016-1.1R VK0.9 / VK1.1

Loading...

Loading...