Lincoln Electric VANTAGE 410 CE, K4178-1 Operator's Manual

VANTAGE® 410 CE

OPERATOR’S MANUAL

IM2076

09/2017

REV01

ENGLISH

Lincoln Electric Bester Sp. z o.o.

ul. Jana III Sobieskiego 19A, 58-263 Bielawa, Poland

www.lincolnelectric.eu

THE LINCOLN ELECTRIC COMPANY

EC DECLARATION OF CONFORMITY

Manufacturer and technical

documentation holder:

EC Company:

Hereby declare that welding equipment:

Product number:

Is in conformity with Council

Directives and amendments:

Standards: EN 60974-1:2012, Safety requirements for arc welding equipment,

Notified body (for 2000/14/EC

Conformity):

Guaranteed sound power level:

Measured sound power level: LWA 94 dB (net power Pel = 9.6 kW)

CE marking affixed in ‘16

Samir Farah, Manufacturer Jacek Stefaniak, European Community Representative

Compliance Engineering Manager European Product Manager Equipment

15August 2017

MCD522b

The Lincoln Electric Company

22801 St. Clair Ave.

Cleveland Ohio 44117-1199 USA

Lincoln Electric Europe S.L.

c/o Balmes, 89 - 8

0 2a

08008 Barcelona SPAIN

Vantage 410 CE

K4178-x (Product number may contain suffixes and prefixes.)

Machinery Directive 2006/42/EC;

Low Voltage Directive (LVD) 2014/35/EU

Electromagnetic Compatibility (EMC) Directive 2014/30/EU;

Noise emission in the environment by equipment for use outdoors

2000/14/EC; & 2005/88/EC

power sources;

EN 60974-10:2014, Arc Welding Equipment-Part 10: Electromagnetic

compatibility (EMC) requirements;

EN ISO 3744:2010, Acoustic – Determination of sound power levels of

noise sources using sound pressure …2010

EN60204-1 (2006): Safety of machinery – Electrical equipment of

machines, Part 1: General requirements.

EN12100 (2010): Safety of machinery – General principles for design

Risk assessment and risk reduction.

AV Technology LTD

Unit 2 Easter Court

Europa Boulevard, Warrington

Cheshire WA5 7ZB

LWA 97 dB (net power Pel = 9.6 kW)

29 August 2017

English English

I

THANKS! For having chosen the QUALITY of the Lincoln Electric products.

Please Examine Package and Equipment for Damage. Claims for material damaged in shipment must be notified

immediately to the dealer.

For future reference record in the table below your equipment identification information. Model Name, Code &

Serial Number can be found on the machine rating plate.

Model Name:

………………...…………………………….…………………………………………………………………………………………..

Code & Serial number:

………………….……………………………………………….. …………………………………………………….……………..

Date & Where Purchased:

…………………………………………………………………... ……………………….…………………………………………..

ENGLISH INDEX

Technical Specifications ...................................................................................................................................................... 1

Electromagnetic Compatibility (EMC) ................................................................................................................................. 3

Safety .................................................................................................................................................................................. 4

Installation and Operator Instructions ................................................................................................................................. 5

Diagrams ........................................................................................................................................................................... 21

WEEE ................................................................................................................................................................................ 30

Suggested Accessories ..................................................................................................................................................... 32

12/05

English English

II

A

(1)

d

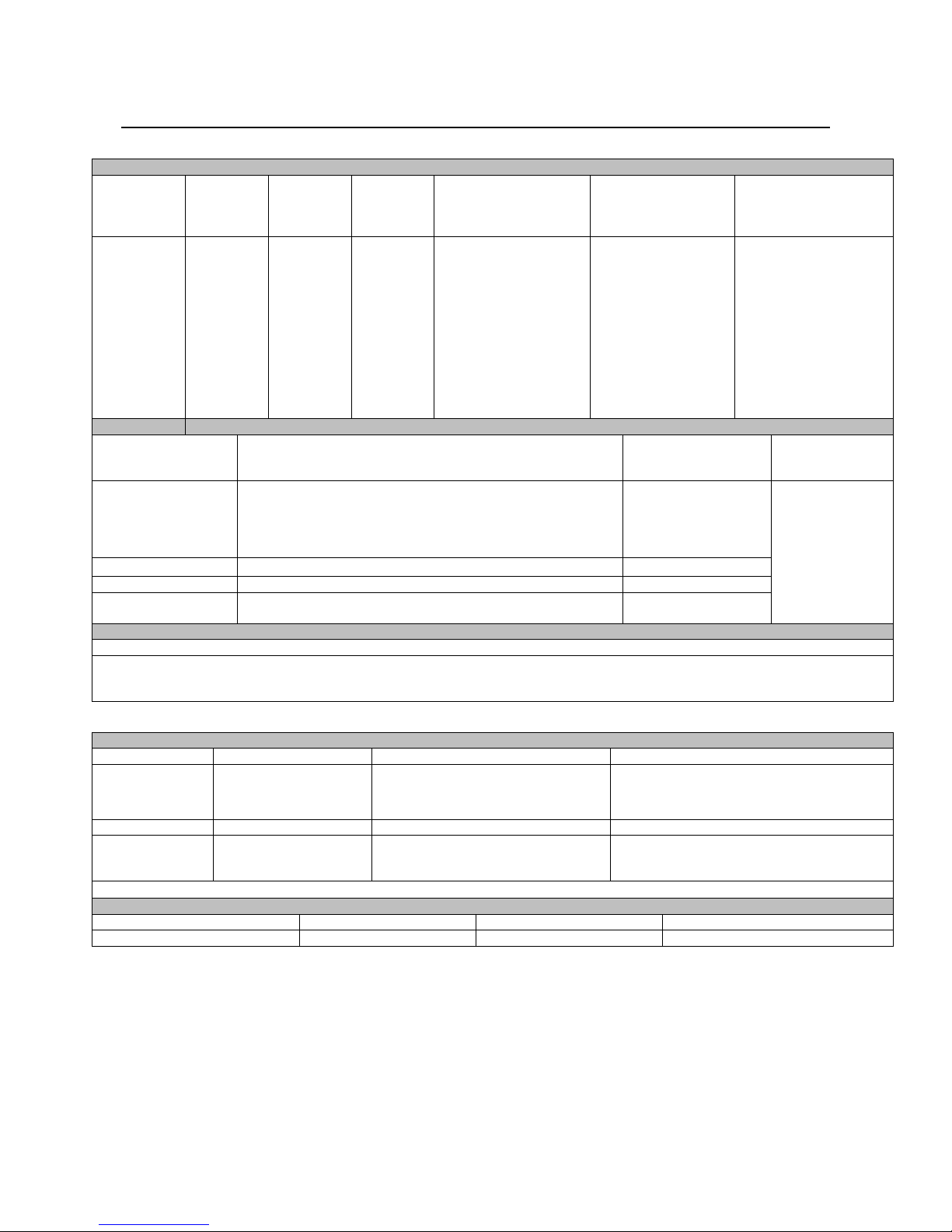

Technical Specifications

VANTAGE

Make/Model Description

®

410 (CE) (K4178-1) (Codes 12516, 12635)

Horse

power

@1800

RPM

INPUT – DIESEL ENGINE

Operating

Speed

(RPM)

Displacement Cu. In.

(ltrs.) Bore x Stroke

Inch (mm)

Starting system Capacities

High 1890

Full Load

1800

Low Idle

1350

91.41 (1.5)

Bore and Stroke

3.07 x 3.09 (78x78)

12Vdc Battery and

Starter

(Group 34;Battery 535

cold crank amps)

Battery charger

Fuel: 20 gal (75.7l)

Oil: 6.4 qts. (6.0l)

Radiator Coolant:

7.2 qts. (6.8l)

K4178-1

Kubota*

V1505

4 cylinder

Naturally

aspirated

Water

Cooled

Diesel

Engine

22HP

RATED OUTPUT @ 40°C - WELDER

Max. Weld

Welding Process Welding Output Current/Volatge/Duty Cycle Output Range

OCV@Rated

Load RPM

300A/32V/100%

DC Constant Current

350A/28V/100%

30 TO 410 AMPS

410A/23V/100%

60V

DC Pipe Current 300A/32V/100% 40 TO 300 AMPS

Touch-StartTM TIG 250V/30V/100% 20 TO 250 AMPS

DC Constant Voltage

Arc Gouging

300A/32V/100%

14 TO 32 VOLTS

90 TO 300 AMPS

RATED OUTPUT @ 40°C - GENERATOR

uxiliary Power

60 Hz 230 Volt, 15A 1-Phase

12.500 Watts Peak, /11.000 Watts Continuous,

60 Hz, 400 Volt, 16A, 3-Phase

LIFT BAIL WEIGHT RATOING 2300LBS. (1043 kg) MAXIMUM

ENGINE

LUBRIFICATION EMISSIONS FUEL SYSTEM GOVERNOR

Full Pressure

with Full Flow

Filter

EPA Tier 4

Interim Compliant

Mechanical Fuel Pump, Auto air bleed

system, Electric shutoff solenoid,

Indirect fuel injector.

Mechanical

Electronic

AIR CLEANER ENGINE IDLER MUFFLER ENGINE PROTECTION

Single Element Automatic Idler

Low noise Muffler with spark arrestor:

Made from long life, aluminized steel.

ENGINE WARRANTY: 2 years complete (parts and labor) 3

r

. year major components (parts and labor)

Shutdown on low oil

pressure & high engine

coolant temperature

PHYSICAL DIMENSIONS

Height Width Length Weight

(1)

913mm** 643 mm 1524 mm 488 kg

Output rating in watts is equivalent to volt-amperes at unity power factor. Output voltage is within ± 10% at all loads up

to rated capacity. When welding, available auxiliary power will be reduced.

*Engine warranty may vary outside of the USA. (See Engine warranty for details).

**

To Top of enclosure. Add 7.88'' (200.02mm) to top of exhaust pipe. Add 4.012”(101.9mm) to top of Lift Bail.

(2)

Reduced to less than 30V in the stick mode when VRD (Voltage Reduction Devise) is on.

(2)

English English

1

A

A

MACHINE SPECIFICATIONS

RECEPTACLES

(1) 115V Euro Style

(1) 230V Euro Style

(1) 400V Euro Style

UXILIARY POWER CIRCUIT

BREAKER

(2) 30Amp for Single Phase

(1) 15Amp for Single Phase

(1) 16Amp for Three Phase (3-pole)

OTHER CIRCUIT BREAKERS

10AMP for Engine Battery Charging

Circuit

10AMP for 42V Wire Feeder Power

4-pole, 25AMP x 1

Residual Current Device (RCD)

1 Phase, 15AMP x 1 for 230V

30AMP x 2 for 115V

MISCELLANEOUS

HARMONIC CONTENT EMC CLASSIFICATION

6.2% THF.

VANTAGE 410 CE IS CLASSIFIED AS A CLASS I MACHINE

THF < 8% :

MACHINE AMBIENT OPERATING CONDITIONS

TEMPERATURE

LTITUDE MAX ANGLE OF OPERATION

5°F (-15°C) TO 104°F (+ 40°C) 5997ft (1828m)* 15° ALL DIRECTIONS

* For use above 5997ft (1828m), contact Authorized Field Service Shop.

TRANSPORTATION & STORAGE TEMPERATURES

-13°F (-25°C) TO 131°F (+55°C) NOT EXCEEDING 158° (70°C) FOR 24 HOURS

English English

2

Electromagnetic Compatibility (EMC)

This machine has been designed in accordance with all relevant directives and standards. However, it may still generate

electromagnetic disturbances that can affect other systems like telecommunications (telephone, radio, and television) or

other safety systems. These disturbances can cause safety problems in the affected systems. Read and understand

this section to eliminate or reduce the amount of electromagnetic disturbance generated by this machine.

system, it is responsibility of the installer or user of the equipment to ensure, by consultation with the distribution network

operator if necessary, that the equipment may be connected.

Before installing the machine, the operator must check the work area for any devices that may malfunction because of

electromagnetic disturbances. Consider the following.

Input and output cables, control cables, and telephone cables that are in or adjacent to the work area and the

Radio and/or television transmitters and receivers. Computers or computer controlled equipment.

Safety and control equipment for industrial processes. Equipment for calibration and measurement.

Personal medical devices like pacemakers and hearing aids.

Check the electromagnetic immunity for equipment operating in or near the work area. The operator must be sure

The dimensions of the work area to consider will depend on the construction of the area and other activities that are

Consider the following guidelines to reduce electromagnetic emissions from the machine.

Connect the machine to the input supply according to this manual. If disturbances occur if may be necessary to take

The output cables should be kept as short as possible and should be positioned together. If possible connect the

Shielding of cables in the work area can reduce electromagnetic emissions. This may be necessary for special

The Class A equipment is not intended for use in residential locations where the electrical power is provided by the public

low-voltage supply system. There can be potential difficulties in ensuring electromagnetic compatibility in those locations,

due to conducted as well as radio-frequency disturbances.

This machine has been designed to operate in an industrial area. The operator must install and operate this

equipment as described in this manual. If any electromagnetic disturbances are detected the operator must

put in place corrective actions to eliminate these disturbances with, if necessary, assistance from Lincoln

Electric. This equipment does not comply with IEC 61000-3-12. If it is connected to a public low-voltage

machine.

that all equipment in the area is compatible. This may require additional protection measures.

taking place.

additional precautions such as filtering the input supply.

work piece to ground in order to reduce the electromagnetic emissions. The operator must check that connecting

the work piece to ground does not cause problems or unsafe operating conditions for personnel and equipment.

applications.

WARNING

English English

3

Safety

01/11

WARNING

This equipment must be used by qualified personnel. Be sure that all installation, operation, maintenance and repair

procedures are performed only by qualified person. Read and understand this manual before operating this equipment.

Failure to follow the instructions in this manual could cause serious personal injury, loss of life, or damage to this

equipment. Read and understand the following explanations of the warning symbols. Lincoln Electric is not responsible

for damages caused by improper installation, improper care or abnormal operation.

WARNING: This symbol indicates that instructions must be followed to avoid serious personal injury,

loss of life, or damage to this equipment. Protect yourself and others from possible serious injury or

death.

READ AND UNDERSTAND INSTRUCTIONS: Read and understand this manual before operating

this equipment. Arc welding can be hazardous. Failure to follow the instructions in this manual could

cause serious personal injury, loss of life, or damage to this equipment.

ELECTRIC SHOCK CAN KILL: Welding equipment generates high voltages. Do not touch the

electrode, work clamp, or connected work pieces when this equipment is on. Insulate yourself from

the electrode, work clamp, and connected work pieces.

ELECTRICALLY POWERED EQUIPMENT: Turn off input power using the disconnect switch at the

fuse box before working on this equipment. Ground this equipment in accordance with local electrical

regulations.

ELECTRICALLY POWERED EQUIPMENT: Regularly inspect the input, electrode, and work clamp

cables. If any insulation damage exists replace the cable immediately. Do not place the electrode

holder directly on the welding table or any other surface in contact with the work clamp to avoid the

risk of accidental arc ignition.

ELECTRIC AND MAGNETIC FIELDS MAY BE DANGEROUS: Electric current flowing through any

conductor creates electric and magnetic fields (EMF). EMF fields may interfere with some

pacemakers, and welders having a pacemaker shall consult their physician before operating this

equipment.

CE COMPLIANCE: This equipment complies with the European Community Directives.

ARTIFICIAL OPTICAL RADIATION: According with the requirements in 2006/25/EC Directive and

EN 12198 Standard, the equipment is a category 2. It makes mandatory the adoption of Personal

Protective Equipments (PPE) having filter with a protection degree up to a maximum of 15, as

required by EN169 Standard.

FUMES AND GASES CAN BE DANGEROUS: Welding may produce fumes and gases hazardous to

health. Avoid breathing these fumes and gases. To avoid these dangers the operator must use

enough ventilation or exhaust to keep fumes and gases away from the breathing zone.

ARC RAYS CAN BURN: Use a shield with the proper filter and cover plates to protect your eyes from

sparks and the rays of the arc when welding or observing. Use suitable clothing made from durable

flame-resistant material to protect you skin and that of your helpers. Protect other nearby personnel

with suitable, non-flammable screening and warn them not to watch the arc nor expose themselves to

the arc.

WELDING SPARKS CAN CAUSE FIRE OR EXPLOSION: Remove fire hazards from the welding

area and have a fire extinguisher readily available. Welding sparks and hot materials from the welding

process can easily go through small cracks and openings to adjacent areas. Do not weld on any

tanks, drums, containers, or material until the proper steps have been taken to insure that no

flammable or toxic vapors will be present. Never operate this equipment when flammable gases,

vapors or liquid combustibles are present.

WELDED MATERIALS CAN BURN: Welding generates a large amount of heat. Hot surfaces and

materials in work area can cause serious burns. Use gloves and pliers when touching or moving

materials in the work area.

English English

4

SAFETY MARK: This equipment is suitable for supplying power for welding operations carried out in

an environment with increased hazard of electric shock.

CYLINDER MAY EXPLODE IF DAMAGED: Use only compressed gas cylinders containing the

correct shielding gas for the process used and properly operating regulators designed for the gas and

pressure used. Always keep cylinders in an upright position securely chained to a fixed support. Do

not move or transport gas cylinders with the protection cap removed. Do not allow the electrode,

electrode holder, work clamp or any other electrically live part to touch a gas cylinder. Gas cylinders

must be located away from areas where they may be subjected to physical damage or the welding

process including sparks and heat sources.

EQUIPMENT WEIGHT OVER 30kg: Move this equipment with care and with the help of another

person. Lifting may be dangerous for your physical health.

The manufacturer reserves the right to make changes and/or improvements in design without upgrade at the same time

the operator’s manual.

Installation and Operator Instructions

Read this entire section before installation or operation

of the machine.

General Description

The Vantage® 410 CE is a diesel engine powered DC

multi-process welding power source and 115/230V 1ph

and 400V/3ph AC power generator. The engine drives a

generator that supplies three phase power for the DC

welding circuit, single phase and three phase power for

the AC auxiliary outlets. The DC welding control system

uses state of the art Chopper Technology (CT™) for

superior welding performance.

VRD (Voltage Reduction Device)

The VRD feature provides additional safety in the

CC-Stick mode especially in an environment with a

higher risk of electric shock such as wet areas and hot

humid sweaty conditions.

The VRD reduces the OCV (Open Circuit Voltage) at the

welding output terminals while not welding to less than

13VDC when the resistance of the output circuit is

above 200Ω (ohms).

The VRD requires that the welding cable connections be

kept in good electrical condition because poor

connections will contribute to poor starting. Having good

electrical connections also limits the possibility of other

safety issues such as heat-generated damage, burns

and fires.

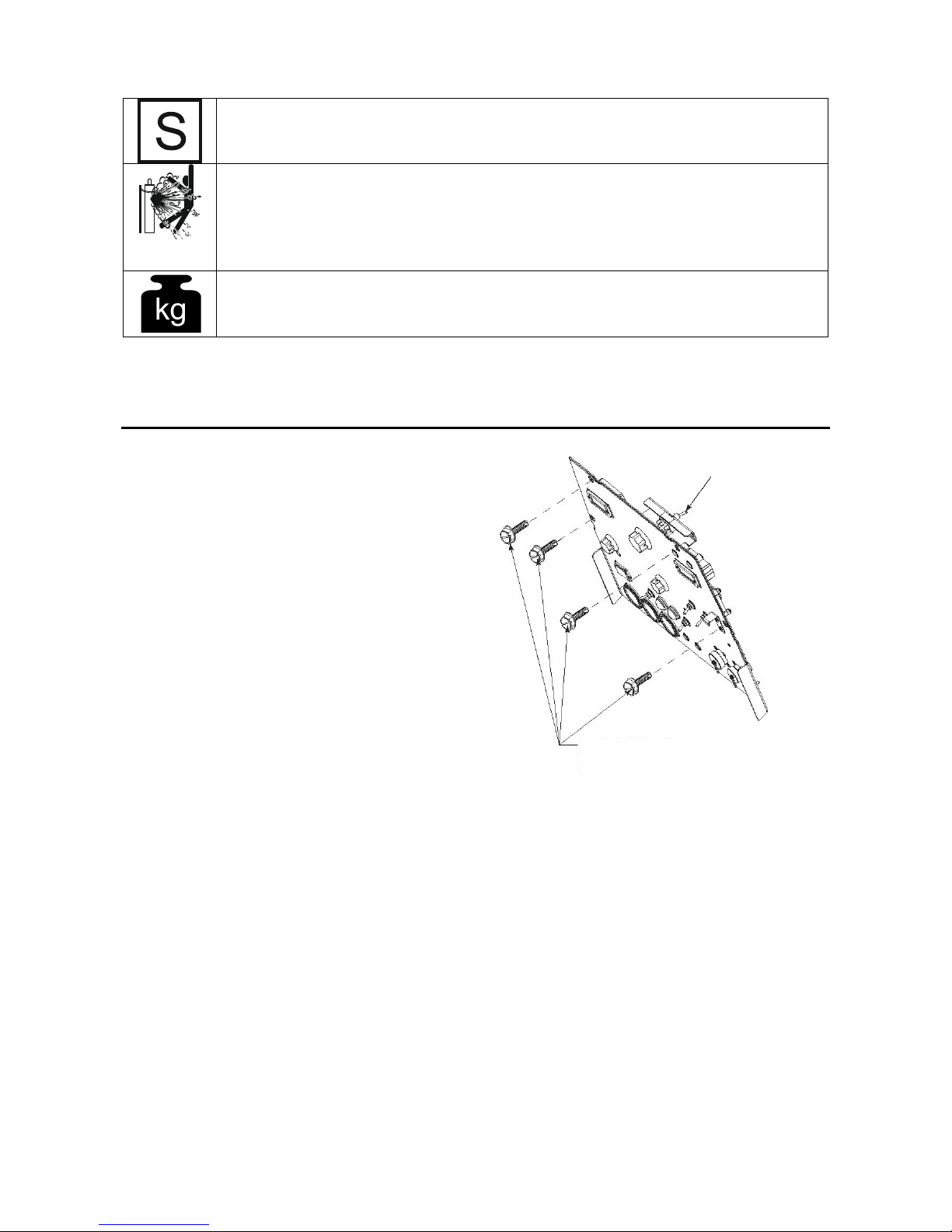

The machine is shipped with the VRD switch in the “Off”

position. To turn it “On” or “Off”:

Turn the engine “Off”.

Disconnect the negative battery cable.

Lower the control panel by removing 4 front panel

screws. (Figure 1)

Place the VRD switch in the “On or “Off” position.

(Figure 1)

With the VRD switch in the “On” position, the VRD lights

are enabled.

REMOVE 4 FRONT PANEL

SCREWS TO ACCESS (VRD)

SWITCH

Figure 1

Location and Ventilation

The welder should be located to provide an unrestricted

flow of clean, cool air to the cooling air inlets and to

avoid restricting the cooling air outlets. Also, locate the

welder so that the engine exhaust fumes are properly

vented to an outside area.

Stacking

VANTAGE® 410 CE machines cannot be stacked.

Angle of Operation

Engines are designed to run in the level condition which

is where the optimum performance is achieved. The

maximum angle of continuous operation is 20 degrees in

all directions, 30 degrees Intermittent (less than 10

minutes continuous) in all directions. If the engine is to

be operated at an angle, provisions must be made for

checking and maintaining the oil level at the normal

(FULL) oil capacity in the crankcase.

When operating the welder at an angle, the effective fuel

capacity will be slightly less than the amount specified.

(VRD)-VOLTAGE

REDUCTION DEVICE

SWITCH IS LOCATED

IN THIS AREA

English English

5

The machines maximum angle of operation is 15° in all

directions.

Lifting

The VANTAGE® 410 CE weighs approximately 1205lbs

(547kg) with a full tank of fuel (1706lbs (488kg) less

fuel). A lift bail is mounted to the machine and should

always be used when lifting the machine.

Falling equipment can cause injury.

Lift only with equipment of adequate

lifting capacity.

Be sure machine is stable when lifting.

Do not lift this machine using lift bail if it is equipped

with a heavy accessory such as trailer or gas

cylinder.

Do not lift machine if lift bail is damaged.

Do not operate machine while suspended from lift

bail.

WARNING

High Altitude Operation

At higher altitudes, output derating may be necessary.

For maximum rating, derate the machine 2.5% to 3.5%

for every 305 m. Due to new EPA and other local

emissions regulations, modifications to the engine for

high altitude are restricted within the United States. For

use above 1828 m an authorized Perkins engine field

service shop should be contacted to determine if any

adjustments can be made for operation in higher

elevations.

High Temperature Operation

At temperatures above 40°C, Welder output derating is

necessary. For maximum output ratings, derate the

welder output 2 volts for every 10°C above 40°C.

Cold Weather Starting

With a fully charged battery and the proper oil, the

engine should start satisfactorily down to -15C°. If the

engine must be frequently started at or below -5°C, it

may be desirable to install cold starting aides. The use

of No. 1D diesel fuel is recommended in place of No. 2D

at temperatures below -5°C. Allow the engine to warm

up before applying a load or switching to high idle.

Note: Extreme cold weather starting may require longer

glow plug operation.

Under no conditions should ether or other starting fluids

be used with this engine!

WARNING

Towing

Use a recommended trailer for use with this equipment

for road, in-plant and yard towing by a vehicle

user adapts a non-Lincoln trailer, he must assume

responsibility that the method of attachment and usage

does not result in a safety hazard or damage the welding

equipment. Some of the factors to be considered are as

follows:

1. Design capacity of trailer vs. weight of Lincoln

equipment and likely additional attachments.

2. Proper support of, and attachment to, the base of

the welding equipment so there will be no undue

stress to the framework.

3. Proper placement of the equipment on the trailer to

insure stability side to side and front to back when

being moved and when standing by itself while

(1)

. If the

being operated or serviced.

4. Typical conditions of use, i.e., travel speed;

roughness of surface on which the trailer will be

operated; environmental conditions; like

maintenance.

5. Conformance with federal, state and local laws

(1)

Consult applicable federal, state and local laws regarding

specific requirements for use on public highways.

(1)

Vehicle Mounting

Improperly mounted concentrated loads may cause

unstable vehicle handling and tires or other components

to fail.

Only transport this Equipment on serviceable

vehicles which are rated and designed for such

loads.

Distribute, balance and secure loads so vehicle is

stable under conditions of use.

Do not exceed maximum rated loads for compo-

nents such as suspension, axles and tires.

Mount equipment base to metal bed or frame of

vehicle.

Follow vehicle manufacturer’s instructions.

WARNING

Pre-Operation Engine Service

Read the engine operating and maintenance instructions

supplied with this machine.

WARNING

Stop engine and allow to cool before fueling

Do not smoke when fueling.

Fill fuel tank at a moderate rate and do not over-fill.

Wipe up spilled fuel and allow fumes to clear before

starting engine.

Keep sparks and flame away from tank.

Oil

The Vantage®410 CE is shipped with the engine

crankcase filled with high quality SAE 10W-30. Oil that

meets classification CG-4 or CH-4 for diesel engines.

Check the oil level before starting the engine. If it is not

up to the full mark on the dip stick, add oil as required.

Check the oil level every four hours of running time

during the first 50 running hours. Refer to the engine

Operator’s Manual for specific oil recommendations and

break-in information. The oil change interval is

dependent on the quality of the oil and the operating

environment. Refer to the Engine Operator’s Manual for

more details on the proper service and maintenance

intervals.

Fuel

DIESEL FUEL ONLY-Low sulphur fuel or ultra low

sulphur fuel in U.S.A. and Canada.

WARNING

Fill the fuel tank with clean, fresh fuel. The capacity of

the tank is 20 gals 75.7l. When the fuel gauge reads

empty the tank contains approximately 7.6 l of reserve

fuel.

Note: A fuel shut off valve is located on the pre-filter/

sediment filter. Which should be in the closed position

when the welder is not used for extended periods of

time.

English English

6

Engine Cooling System

Air to cool the engine is drawn in the side and exhausted

through radiator & case back. It is important that the

intake and exhaust air is not restricted. Allow a

minimum clearance of 0.6m from the case back and

406mm from either side of the base to a vertical surface.

WARNING

Battery Connection

Use caution as the electrolyte is a strong acid that can

burn skin and damage eyes.

The Vantage

battery cable disconnected. Make certain that the RUNSTOP switch is in the STOP position. Remove the two

screws from the battery tray using a screwdriver or a

10mm socket. Attach the negative battery cable to the

negative battery terminal and tighten using a 13mm

socket or wrench.

Note: This machine is furnished with a wet charged

battery; if unused for several months, the battery may

require a booster charge. Be careful to charge the

battery with the correct polarity. (See Battery in

“Maintenance Section”)

®

410 CE is shipped with the negative

WARNING

Spark Arrester

Some laws may require that gasoline or diesel engines

be equipped with exhaust spark arresters when they are

operated in certain locations where unarrested sparks

may present a fire hazard. The standard muffler included

with this welder has a spark arrestor mounted to the

muffler outlet. This device also enables the machine to

conform to the sound power requirements of the

European Union and should not be removed unless of

cleaning. Please note: compliance to CE sound power is

achieved with spark arrestor installed.

An incorrect spark arrestor may lead to damage to the

engine or adversely affect performance.

WARNING

Remote Control

The Vantage® 410 CE is equipped with a 6-pin and a 14pin connector. When in the Arc Gouging or CV-WIRE

modes and when a remote control is connected to the 6pin Connector, the auto-sensing circuit automatically

switches the OUTPUT control from control at the welder

to remote control.

When in TOUCH START TIG mode and when a Amptrol

is connected to the 6-Pin Connector, the OUTPUT dial is

used to set the maximum current range of the

CURRENT CONTROL of the Amptrol.

When in the CC-STICK or DOWNHILL PIPE mode and

when REMOTE CONTROL is connected to the 6-Pin or

14-pin Connector, the OUTPUT CONTROL dial is used

to set the maximum current range of the OUTPUT

CONTROL of the REMOTE.

EXAMPLE: When the OUTPUT CONTROL on the

welder is set to 200 amps the current range on the

remote control will be Min.- 200 amps, rather than the

full Min.-Max. amps. Any current range that is less than

the full range provides finer current resolution for more

fine tuning of the output.

The 14-pin connector is used to directly connect a wire

feeder control cable. In the CV-WIRE mode, if the feeder

being used has a voltage control when the wire feeder

control cable is connected to the 14-Pin Connector, the

auto-sensing circuit automatically makes OUTPUT

CONTROL inactive and the wire feeder voltage control

active. Otherwise, the OUTPUT CONTROL is used to

preset the voltage.

NOTE: When a wire feeder with a built in welding

voltage control is connected to the 14-pin connector, do

not connect anything to the 6-pin connector.

WARNING

Electrical Connections

Machine Grounding

Because this portable engine driven welder creates its

own power, it is not necessary to connect its frame to an

earth ground, unless the machine is connected to

premises wiring (home, shop, etc.).

To prevent dangerous electric shock, other equipment to

which this engine driven welder supplies power must:

Be grounded to the frame of the welder using a

grounded type plug or be double insulated.

Be double insulated.

Do not ground the machine to a pipe that carries

explosive or combustible material.

When this welder is mounted on a truck or trailer, its

frame must be electrically bonded to the metal frame of

the vehicle. Use a 8mm

connected between the machine grounding stud and the

frame of the vehicle. When this engine driven welder is

connected to premises wiring such as that in a home or

shop, its frame must be connected to the system earth

ground. See further connection instructions in the

section entitled "Standby Power Connections" as well as

the article on grounding in the latest National Electrical

Code and the local code.

In general, if the machine is to be grounded, it should be

connected with a 8mm

earth ground such as a metal water pipe going into the

ground for at least ten feet and having no insulated

joints, or to the metal framework of a building which has

been effectively grounded.

The National Electrical Code lists a number of alternate

means of grounding electrical equipment. A machine

grounding stud marked with the symbol

on the front of the welder.

WARNING

2

or larger copper wire

2

or larger copper wire to a solid

is provided

Welding Terminals

The Vantage®410 CE is equipped with a toggle switch

for selecting "hot" welding terminal when in the "WELD

TERMINALS ON" position or "cold" welding terminal

when in the "REMOTLY CONTROLLED" position.

Welding Output Cables

With the engine off connect the electrode and work

cables to the output studs. The welding process dictates

the polarity of the electrode cable. These connections

should be checked periodically and tightened with a

19mm wrench.

English English

7

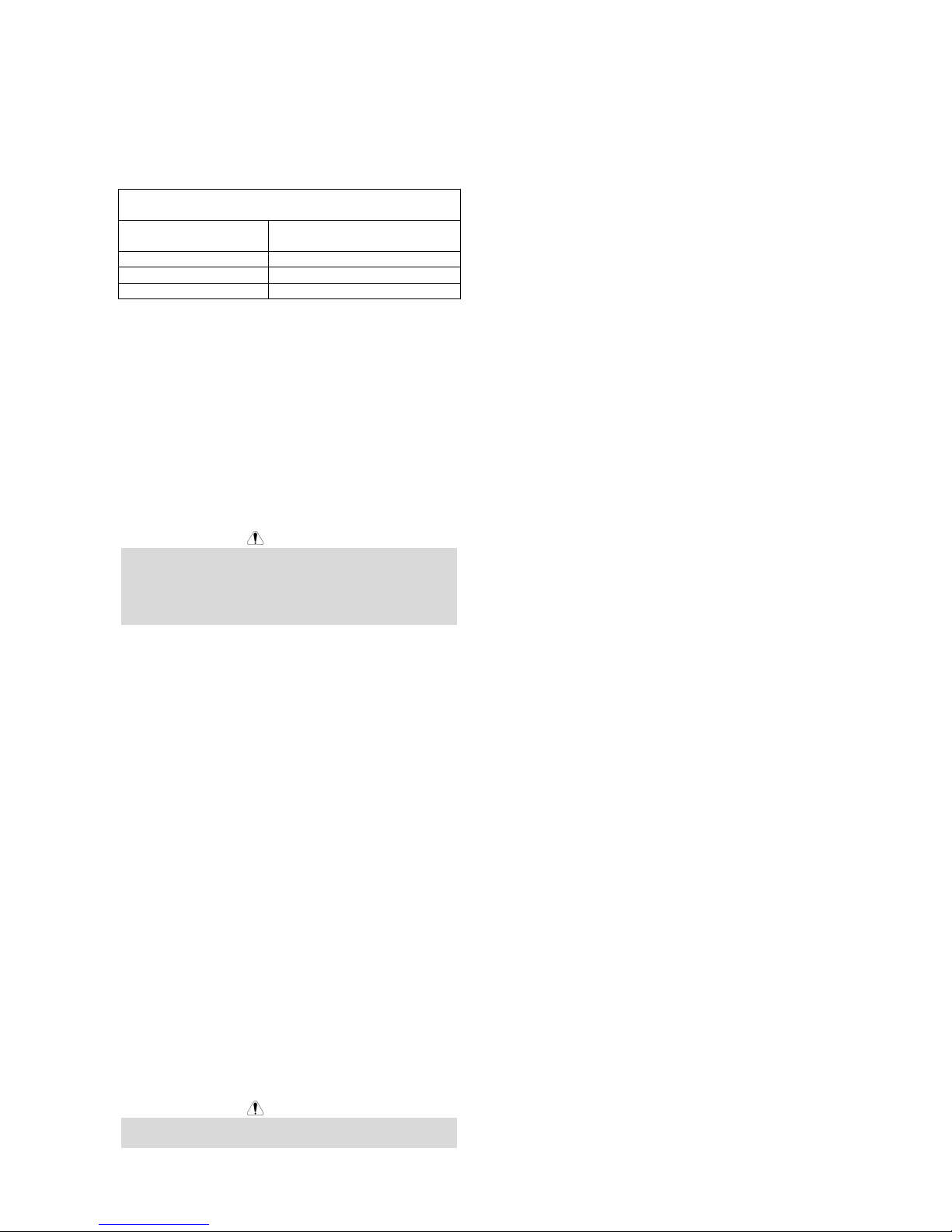

Table below lists recommended cable sizes and lengths

for rated current and duty cycle. Length refers to the

distance from the welder to the work and back to the

welder. Cable diameters are increased for long cable

lengths to reduce voltage drops.

Total Combined Length of Electrode and Work

Cable Length Cable Size for 400 A @

0-30 meters 2/0 AWG (67,4mm2)

30-46 meters 2/0 AWG (67,4mm2)

46-61 meters 3/0 AWG (85mm2)

Cables

60%Duty Cycle

Cable Installation

Install the welding cables to your Vantage® 410 CE as

follows:

1. The engine must be OFF to install welding cables.

2. Remove the flanged nuts from the output terminals.

3. Connect the electrode holder and work cables to the

weld output terminals. The terminals are identified

on the case front.

4. Tighten the flanged nuts securely.

5. Be certain that the metal piece you are welding (the

“work”) is properly connected to the work clamp and

cable.

6. Check and tighten the connections periodically.

WARNING

Loose connections will cause the output terminals to

overheat. The terminals may eventually melt.

Do not cross the welding cables at the output

terminal connection. Keep the cables isolated and

separate from one another.

Auxiliary Power

The auxiliary power capacity is 12500W Peak, 11000W

continuous of 60Hz, single phase power. The auxiliary

power capacity rating in watts is equivalent to voltamperes at unity power factor. The max permissible

current of the 400 VAC output is 16A. Output voltage is

within ±10% at all loads up to the rated capacity.

Single phase power is:

3,500 Watts Peak / 3,500 Watts Continuous, 60 Hz

230 Volts 1-Phase (Euro).

Standby Power Connections

The machine is suitable for temporary, standby or

emergency power using the engine manufacturer's

recommended maintenance schedule.

The machine can be permanently installed as a standby

power unit for 400 VAC, three phase, 16A service

Connections must be made by a licensed electrician who

can determine how the power can be adapted to the

particular installation and comply with all applicable

electrical codes.

Take necessary steps to assure load is limited to

the capacity of the Vantage

®

410 CE.

Connection of Lincoln Electric Wire

Feeders

Shut off welder before making any electrical

connections.

WARNING

Connection of the LN-7 or LN-8 to the Vantage®

410 CE.

1. Shut the welder off.

2. Connect the LN-7 or LN-8 per instructions on the

appropriate Section "Diagram".

3. Set the "WIRE FEEDER VOLTMETER" switch to

either "+" or "-" as required by the electrode being

used.

4. Set the "MODE" switch to the "CV WIRE " position.

5. Set the "ARC CONTROL" knob to "0" initially and

adjust to suit.

6. Set the "WELD TERMINALS" switch to the

"REMOTELY CONTROLLED" position.

7. Set the "IDLE" seitch to the "HIGH" position.

Connection of LN-15 to the Vantage® 410 CE

1. Shut the welder off.

2. For electrode Positive, connect the electrode cable

to the "+" terminal of the welder and work cable to

the "-" terminal of the welder. For electrode

Negative, connect the electrode cable to the "-"

terminal of the welder and work cable to the "+"

terminal of the welder.

3. Choose Model:

Across The-Arc Model:

4. Attach the single lead from the front of the LN-15 to

work using the spring clip at the end of the lead.

This is a control lead to supply current to the wire

feeder motor; it does not carry welding current.

5. Set the "WELD TERMINALS" switch to "WELD

TERMINALS ON".

6. When the gun trigger is closed, the current sensing

circuit will cause the Vantage

to the high idle speed, the wire will begin to feed

and the welding process started. When welding is

stopped, the engine will revert to low idle speed

after approximately 12 seconds unless welding is

resumed.

®

410 CE engine to go

Control Cable Model:

4. Connect Control Cable between Engine Welder and

Feeder.

5. Set the "WELD TERMINALS" switch to

"REMOTELY CONTROLLED".

6. Set the MODE switch to thr "CV-WIRE" position.

7. Set the "WIRE FEEDER VOLTMETER" switch to

either "+" or "-" as required by the electrode polarity

being used.

8. Set the "ARC CONTROL" knob to "0" initially and

adjust to suit.

9. Set the "IDLE" switch to the "AUTO" position.

10. When the gun trigger is closed, the current sensing

circuit will cause the Vantage

to the high idle speed, the wire will begin to feed

and the welding process started. When welding is

stopped, the engine will revert to low idle speed

after approximately 12 seconds unless welding is

resumed.

®

410 CE engine to go

Connection of the LN-25 to the Vantage® 410

CE

The LN-25 with or without an internal contactor may be

used with the Vantage

"Diagram" Section.

NOTE: The LN-25 (K431) Remote Control Module and

(K432) Remote Cable are not recommended for use with

the Vantage

®

410 CE

®

410 CE. See the appropriate

English English

8

Loading...

Loading...