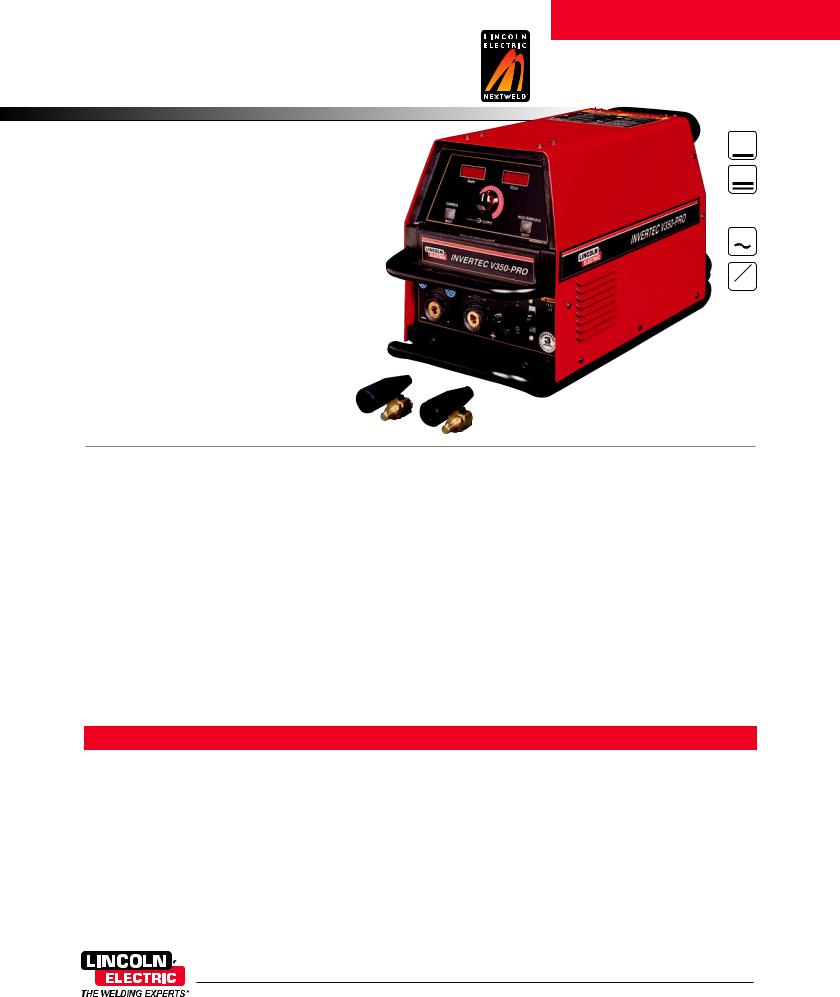

Lincoln Electric V350-PRO User Manual

Invertec® V350-PRO

Designed Smart. Built Tough.

The Invertec® V350-PRO is a versatile, multi-purpose, multi-process power source that’s lightweight and portable. Available in Construction, Factory, Factory (Tweco®), and Advanced Process models, the V350-PRO is capable of doing virtually any job, whether in the shop on the construction site. The V350-PRO is capable of stick, DC TIG, MIG, Pulsed MIG(1), flux-cored and arc gouging, making it the

most versatile inverter power source in its class. And it’s built tough to handle the rigors of harsh environments.

Processes

Stick, DC TIG, MIG, Pulsed(1), Flux-Cored, Gouging

Advantage Lincoln

MULTI-PROCESS WELDERS

Output

CC

CV

DC

Input

1 3

3

PHASE

50

60

Hz

Note: Plugs not included with Tweco® model.

•Choose the Construction Model for economy and lightweight portability, the Factory Model for full remote capabilities, and the Advanced Process Model for pulsed MIG applications.

•All input voltages and frequencies are both single and three phase rated—no output derating necessary on single phase.

•5-425 amp output range for all recommended processes from DC TIG to arc gouging.

•Input voltage from 208-575 and 50 and 60 Hz operation—this one machine is capable of running on virtually any input power supply.

•Touch-Start TIG® for contamination-free starts.

•Low power consumption for energy savings—88% efficiency.

•Advanced Process model includes Pulsed MIG, Pulse-On-Pulse® and Power Mode® for best-in-class welding performance.

•Parallel two units for 700A carbon arc gouging.

•The K1728-5, -6, -7, -8, Invertec® V350-PRO includes Twist-Mate™ Cable Plugs (K852-70, quantity 2) for easy, tool-less cable connection. The K1728-13 Invertec® V350-PRO Factory (Tweco®) model includes Tweco® cable receptacles. Tweco® plugs are not included.

•Bright, large digital amp and volt meters are easy to monitor—even in sunlight—and presettable for precise procedure control.

•Rugged skid and tube handles for convenience and added protection.

•Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

•Three-year warranty on parts and labor. Two-year extended warranty available in the U.S.

(1) Advanced Process Panel only.

TECHNICAL SPECIFICATIONS

|

|

|

|

Rated Output |

|

|

Dimensions |

Net |

Product |

Product |

|

|

Current/ |

Input Current @ |

Output |

H x W x D |

Weight |

Name |

Number |

Model |

Input Power |

Voltage/Duty Cycle |

Rated Output |

Range |

inches (mm) |

lbs.(kg) |

|

K1728-5 |

Construction |

200-208/230/380-415/ |

350A/34V/60% |

3ph: 50/42/28-26/23/18 |

5-425A |

14.8 x 13.3 x 27.8 |

81 |

|

K1728-6 |

Factory |

460/575/1/3/50/60 |

|

1ph: 94/85/54/42/37 |

Max OCV: |

(376 x 338 x 709) |

(36.7) |

Invertec® |

K1728-7 |

Advanced Process |

208/230/415/ |

300A/32V/100% |

3ph: 41-39/36/23-22/19/16 |

80V DC |

|

|

V350-PRO |

K1728-13 |

Factory (Tweco®) |

460/575/1/3/50/60 |

|

1ph: 76/69/41/36/31 |

|

|

|

|

K1728-8 |

CE |

200-220/380-400/ |

350A/34V/60% (3ph) |

3ph: 48/28-27/26-24 |

|

|

86.5 |

|

|

|

415-440/1/3/50/60 |

320A/33V/60% (1ph) |

1ph: not rec’d - 82/55-50/48-45 |

|

|

(37.4) |

|

|

|

|

300A/32V/100% (3ph) |

3ph: 41-37/28-22/22-21 |

|

|

|

|

|

|

|

275A/31V/100% (1ph) |

1ph: not rec’d - 64/44-43/38-35 |

|

|

|

|

|

|

|

|

|

|

|

|

Tweco® is a registered trademark of Thermadyne.

Publication E5.91 11/07

www.lincolnelectric.com

A CLOSER LOOK

PERFORMANCE

Exceptional Multi-Process Fabrication Welding

The Lincoln Invertec® V350-PRO inverter welder enables strong multi-process welding performance with optimized arc characteristics for each process.

•Fast arc response yields tight output control:

–More consistent bead appearance

–Smooth arc action

–Easy to follow puddle control

Five Welding Process Modes

1. CC-Stick Soft

Intended for low hydrogen stick applications.

Use to obtain outstanding E7018 performance for a variety of construction and fabrication applications.

2. CC-Stick Crisp

Delivers a crisp shorting response optimized for cellulosic (E6010) electrodes.

3. DC TIG GTAW

Standard Lincoln Touch-Start TIG® makes it easy to establish an arc.

Add the optional TIG Module for touch-less high frequency starting.

4. CV-Wire

Intended for use for most MIG, and gas-shielded flux-cored or metalcored applications.

The Invertec® V350-PRO features an exceptionally wide sweet spot delivering the arc performance and finished weld quality every operator appreciates:

•.030-1/16" (0.8-1.6 mm) solid wire

•.035-3/32" (0.9-2.4 mm) cored wire

Delivers outstanding performance with a wide variety of shielding gas mixes, including 100% CO2, Ar/CO2 or Ar/O shielding gas for carbon steel as well as helium blends for stainless welding.

5.CV-Innershield®, Outershield®, Metalshield® and UltraCore®

Features a wide voltage range and tight voltage control optimized for Lincoln Innershield® self-shielded flux-cored applications and for gas shielded flux-cored Lincoln® Outershield® procedures.

6.Arc Gouging accessible from all Stick and CV Welding Modes

With a maximum 425 amps, the Invertec® V350-PRO has plenty of power to handle a 5/16" (7.9 mm) carbon.

Stick

Arc Gouging

CV-Wire

Stainless

Invertec ® V350-PRO

[2] |

www.lincolnelectric.com |

A CLOSER LOOK

FEATURES

Key Controls

A ) Large, bright, easy to read meters B ) Local/remote output control

C) Mode selection switch

D ) Remote Output Control Receptacles—6- & 14-pin E ) Negative and Positive Twist-Mate® or Tweco®

Output Teminals

F ) Wire Feeder Voltmeter Polarity Switch

G)Circuit Breaker Reset Buttons

H)On/Off Switch

I ) Hot Start Control

J ) Arc Control Knob

K ) Weld Terminals on or remotely controlled L ) Preset Output Amps and Voltage Control M) Thermal Overload Indicator Light

A

B

C

D

E

Shown:

Invertec® V350-PRO

Factory Model

M

L

K

J

I

H

F G

Pulse-On-Pulse®

•Uses a sequence of varying pulse wave shapes to produce a TIG-like bead appearance and excellent weld properties when MIG welding aluminum.

•Pulse-On-Pulse® controls arc length and heat input together, making it easier to achieve good penetration.

For more information see Nextweld |

® Document NX-2.10 |

Pulse-On-Pulse ® on 3mm Aluminum

|

|

|

|

|

|

|

|

Power Mode ® reduces |

Power Mode ® aids |

||||||

|

spatter and improves |

bead wetting |

|||||

|

|

bead appearance, |

and penetration |

||||

|

even for low voltage |

on aluminum. |

|||||

|

|

procedures on |

|

|

|

||

|

|

stainless. |

|

|

|

||

|

|

|

PULSE FREQUENCY |

||||

CURRENT |

|

|

Peak |

|

|

|

|

|

|

|

|

|

|||

|

Ramp Up |

Tail Out |

|||||

|

|

||||||

WELDING |

|

|

|

|

|||

|

Background |

|

Step Off |

||||

|

|

|

|||||

|

|

|

|

|

|

||

|

|

|

|

|

|

|

|

|

|

TIME |

|

|

|

|

|

|

|

|

|

|

|

|

|

Low Heat |

High Heat |

|

(Background) |

(Peak) |

|

|

|

|

|

|

|

Power Mode®

•Uses high-speed regulation of output power to deliver extremely fast response to changes in the arc, for example, when using a whip technique.

•Improved MIG welding performance, including low spatter, very uniform, consistent bead wetting and controlled penetration.

•Great for low voltage applications on thin steel and stainless steel material less than 20 gauge (0.7 mm).

•Delivers excellent arc characteristics on aluminum and other alloys such as silicon bronze and nickel alloys.

For more information see Nextweld |

® Document NX-2.60 |

Pulsed MIG

•Varies weld current between peak (high heat) and background (low heat) current to provide better control of heat input.

•Reduces warping and burnthrough on thin materials.

•Enables in-the-flat, horizontal, vertical up, or overhead welding without a slag system. Great for hard automation, robotic, and high production semiautomatic applications.

•Optimized GMAW-P waveforms are available to use on aluminum, carbon steel, high strength low alloy steel, stainless steel, and nickel alloys.

For more information see Nextweld |

® Document NX-2.70 |

Invertec ® V350-PRO

[3] |

www.lincolnelectric.com |

Loading...

Loading...