Page 1

Invertec®V450-PRO

C

V

C

C

DC

3

PHASE

6

0

5

0

Hz

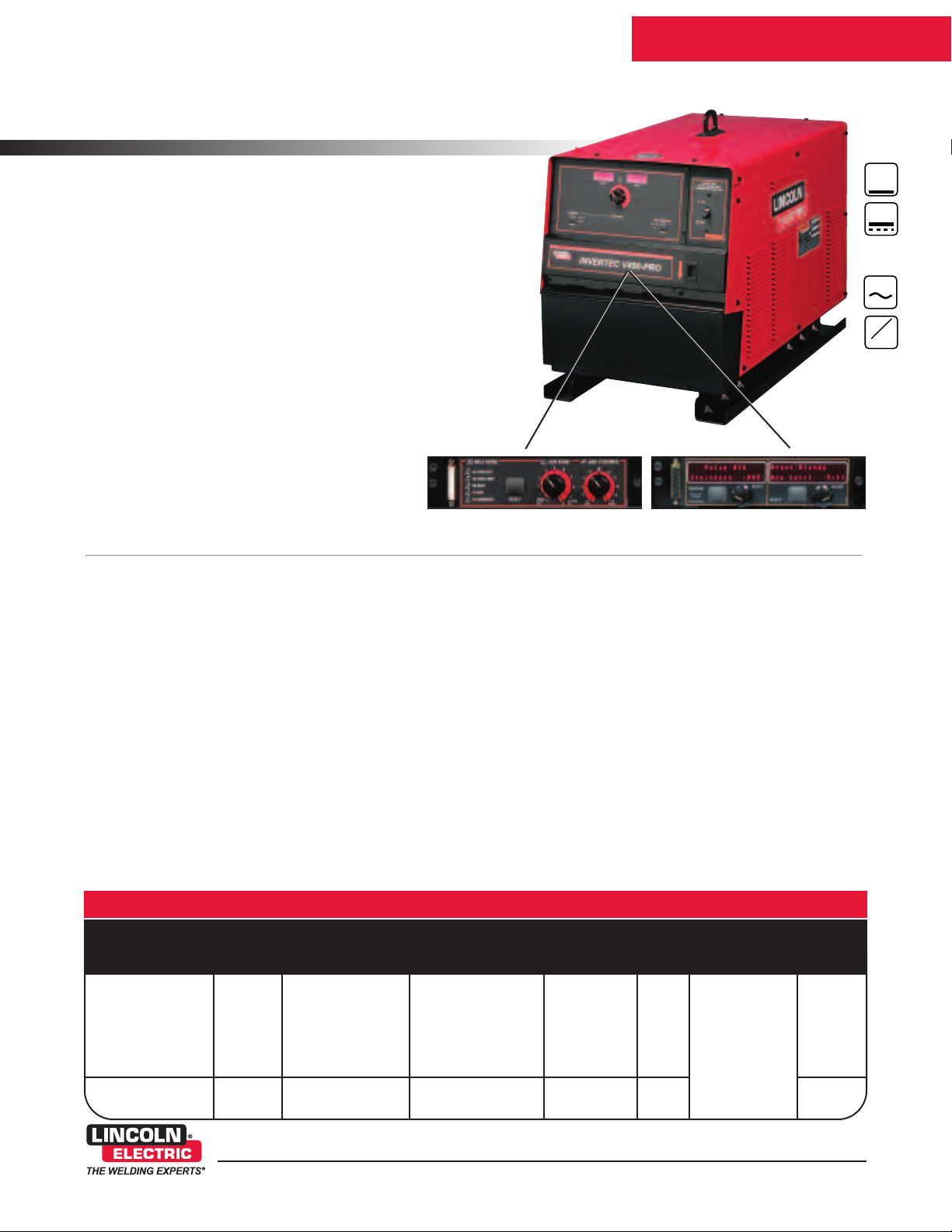

Substantial Output. Smart Performance.

Rugged Reliability.

Heavy fabrication welding operations will appreciate the broad multi-process

performance of the V450-PRO – featuring robust stick, MIG and cored wire

welding as well as precision Touch-Start TIG

is targeted for shops commonly welding with .052" or larger diameter wires

that also require plenty of power for arc gouging repair work with a 3/8" carbon.

Take advantage of the benefits of inverter-based power sources, including a fast

response to changes at the arc and high input power efficiency and power factor

ratings for real savings on your electric bills. Combine those platform advantages

with the optional Advanced Process Panel to add pulsing capability and access

to Waveform Control Technology

®

and other arc performance Lincoln Nextweld

innovations. Add a rugged MaxTrac®wire drive system feeder to build an

economical, high value, high performance welding package you can count

on for use in your factories around the world.

®

performance. The V450-PRO

MULTI-PROCESS WELDERS

Output

Input

®

Protective Door Reveals Added Controls:

Processes

Stick, TIG, MIG, Pulsed

(1)

, Flux-Cored, Gouging

Advantage Lincoln

• Features full remote and multi-process capability – stick,

Touch-Start TIG

• 5-570 amp output range for all recommended processes is low

enough for TIG welding on thin sheetmetal and robust enough for

arc gouging with a 3/8" carbon.

• 88% efficiency with a high 95% power factor – the V450-PRO

inverter platform helps you dramatically lower energy consumption

to pocket real savings.

• Add the Advanced Process Panel Kit for access to Pulsed MIG

and a host of Lincoln Nextweld

allow you to tailor the arc, including: Pulse-on-Pulse®, Power Mode

and Waveform Control Technology®.

• Standard Controls include:

– Selectable Hot Start for stick welding: Turn it down for thin

material or turn it up to overcome cold starting at the beginning

of a weld.

– Variable Arc Control: Dial in the “soft” or “crisp” arc

characteristics you want for each application.

Invertec

Invertec

®

, MIG, flux-cored and arc gouging.

®

arc performance innovations that

TECHNICAL SPECIFICATIONS

Product Product Input Rated Output Input Current Output H x W x D Weight

Name Number Power Current/Voltage/Duty Cycle @ Rated Output Range in. (mm) lbs. (kg)

®

V450-PRO K2420-1 208/230/460/575/3/50/60 60Hz: 60Hz: 5-570A 26.1 x 19.9 x 32.9 293

®

V450-PRO K2421-1 380/415/3/50/60 400A/36V/100% 36/33A 5-500A 278

(CE) (500A/40V/60%) (48/44A) (126)

Standard Welding Controls Optional Advanced Process Panel

• Touch-Start TIG

®

makes it easy to achieve great arc starts with

minimal or no tungsten contamination.

• Clever stackable case design allows you to stack up to three units to

save valuable shop floor space.

• Supports 24, 42 or 115 VAC wire feeders.

• Heavy-duty construction, robust engineering and rigorous testing

result in tough IP23S rating for use in industrial environments.

• Front panel 15 amp 115 volt AC auxiliary power receptacles with

circuit breaker protection will power your lights, grinders or

®

gun/torch water coolers (on K2420-1 only).

• Easy-access front panel controls and connections are protected by

sturdy metal doors.

• Three year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001 environmental standards.

(1)

With Advanced Process Panel Kit only.

Dimensions Net

450A/38V/100% 58/53/25/22A (663 x 505 x 835) (133)

(570A/43V/60%) (82/78/37/31A)

50Hz: 50Hz:

400A/36V/100% 49/45/23/18A

(500A/40V/60%) (67/61/31/25A)

Publication E5.94 7/05

Web Update 6/07

www.lincolnelectric.com

Page 2

A CLOSER LOOK

PERFORMANCE

Exceptional Multi-Process Fabrication Welding

The Lincoln Invertec®inverter platform enables strong multi-process

welding performance with optimized arc characteristics for

each process.

• Fast arc response yields tight output control:

– More consistent bead appearance

– Smooth arc action

– Easy to follow puddle control

Five Welding Process Modes

1. CC-Stick Soft

Intended for low hydrogen stick applications.

Use to obtain outstanding E7018 performance for a variety of

construction and fabrication applications.

2. CC-Stick Crisp

Delivers a crisp shorting response optimized for cellulosic

(E6010) electrodes.

Stick

3. TIG GTAW

Standard Lincoln Touch-Start TIG®makes it easy to establish an arc

while minimizing tungsten contamination.

Add the optional TIG Module for touch-less high frequency starting.

4. CV-Wire

Intended for use for most MIG, and gas-shielded flux-cored or metalcored applications.

The V450-PRO features an exceptionally wide sweet spot

delivering the arc performance and finished weld quality every

operator appreciates:

• .030"-1/16" solid wire

• .035"-3/32" cored wire

Delivers outstanding performance with a wide variety of shielding gas

mixes, including 100% CO2, Ar/CO2or Ar/O shielding gas for carbon

steel as well as helium blends for stainless welding.

5. CV-Innershield

®

Features a wide voltage range and tight voltage control optimized for

Lincoln Innershield self-shielded flux-cored applications.

Arc Gouging

CV-Wire

Arc Gouging accessible from all Stick and CV Welding Modes –

With a maximum 570 amps, the V450-PRO has plenty of power to

handle a 3/8" (9.5 mm) carbon.

[2]

Stainless

Invertec®V450-PRO

www.lincolnelectric.com

Page 3

A CLOSER LOOK

Get the Results You Prefer

Hot Start

Regulates the starting current at arc initiation for stick or

TIG applications.

Set it to your preference to help overcome cold starts at the

beginning of a weld, restarting AWS E7018 or stainless stick

electrodes or to improve starting for tie-in welding on tack welds.

Turn it down for thin material or root welding on pipe. Turn it up

for thick material or general construction welding.

FEATURES – KEY CONTROLS

Upper Control Panel

A) Large, bright, easy to read Amps Meter

B) Thermal Overload Indicator Light

C) Local/Remote Output Control Button

D) Weld Mode Selector Button

E) Serial Port for Software Updates

F) Hot Start Control Knob

G) Arc Control Knob

H) Weld Terminals Button – On or Remotely Controlled

I)Power On/Off Switch

J) Output Amps or Output Voltage Control Knob

K) Large, bright, easy to read Volt Meter

Variable Arc Control

Adds or reduces inductance (arc energy), particularly for short-circuit transfer mode. Arc Control increases or decreases the size and

frequency of arc droplet transfer.

Set it to your preference to help control spatter levels or electrode

stubbing as well as to improve weld toe wetting or to obtain a

uniform bead shape.

Turn it down to obtain a softer arc or turn it up for a stiffer, more

digging arc. For MIG, you can turn it up to aid with welding on

open gaps, out-of-position work or for use with 100% CO2or

75% Ar / 25% CO2.

K

A

J

B

C

D

I

H

G

E

F

Lower Case Connection Panel

L)6-pin MS-Style Connector for Remote Control

M) Negative Output Stud Terminal

N) 24/42 Volt Circuit Breaker Reset Button

O) 115 Volt AC Auxiliary Power Receptacles

P)115 Volt Circuit Breaker Reset Button

Q) Positive Output Stud Terminal

R) 14-pin MS-Style Connector for Wire Feeder Input Power

and Remote Control (24V/42V/115V AC)

S)Wire Feeder Voltmeter Polarity Switch

[3]

M

N

O

L

S

R

Q

P

Invertec®V450-PRO

www.lincolnelectric.com

Page 4

A CLOSER LOOK

TIME

WELDING CURRENT

Background

Peak

Ramp Up

Tail Out

Step Off

PULSE CYCLE

Low Heat

(Background)

High Heat

(Peak)

PTIONAL ADVANCED PROCESS PANEL KIT

O

Add the Advanced Process Panel to gain access to Lincoln’s Nextweld

Pulse-On-Pulse

®

, Power Mode®, Pulsed MIG.

• Displays gas, mode and wire size for easy setting and monitoring.

• Eight memories to quickly switch between weld modes.

®

Innovations, including

AC

T

Pulse-On-Pulse®on 3mm Aluminum

®

Power Mode

spatter and improves

bead appearance, even

reduces

for low voltage

procedures on

stainless.

B

A

U

Power Mode

bead wetting

and penetration

on aluminum.

AA

Z

Key Controls

T ) Serial Port for Software Updates

U ) Weld Mode Memory Set Button

V ) Weld Mode Select Knob

W ) Hot Start /Arc Control Select Button

X ) Hot Start /Arc Control Parameters Adjust Knob

Y ) Arc Control Setting

Z ) Shielding Gas Type

AA ) Consumable Diameter

AB ) Process

AC ) Material Type

V

Pulse-On-Pulse

W

®

X

Y

• Uses a sequence of varying pulse wave shapes to produce a TIG-like bead appearance

and excellent weld properties when MIG welding aluminum.

• Pulse-On-Pulse®controls arc length and heat input together, making it easier to achieve

good penetration.

For more information see Nextweld®Document NX-2.10

Power Mode

®

• Uses high-speed regulation of output power to deliver extremely fast response to changes in the

arc, for example, when using a whip technique.

®

aids

• Improved MIG welding performance, including low spatter, very uniform, consistent bead wetting

and controlled penetration.

• Great for low voltage applications on thin steel and stainless steel material less than

20 gauge (0.7 mm).

• Delivers excellent arc characteristics on aluminum and other alloys such as silicon bronze and

nickel alloys.

For more information see Nextweld®Document NX-2.60

Pulsed MIG

• Varies weld current between peak (high heat) and background (low heat) current to provide

better control of heat input.

• Reduces warping and burnthrough on thin materials.

• Enables in-the-flat, horizontal, vertical up, or overhead welding without a slag system. It can be

used in hard automation, robotic, and semiautomatic applications.

• Optimized GMAW-P waveforms are available to use on aluminum, carbon steel, high strength

low alloy steel, stainless steel, and nickel alloys.

For more information see Nextweld®Document NX-2.70

Invertec®V450-PRO

[4]

www.lincolnelectric.com

Page 5

A CLOSER LOOK

UALITY AND RELIABILITY

Q

Robust Design

Safety, reliability and serviceability are built into Lincoln’s inverter design.

• Invertec inverter models operate at a high efficiency (88-90%) with a 95% minimum

power factor at rated output and are capable of operating from a universal 3 phase

input voltage (208 to 575 volts).

• Thermostatically protected.

• Electronic output over-current protection and electronic input over-voltage protection.

• Operating Temperature Range: -20ºC to +40ºC.

• Storage Temperature Range: -40ºC to +40ºC.

• Double insulation and varnish on main transformer.

• Shielded heavy duty input contactor in tightly sealed environmental enclosure.

• Tough PC Boards — potted and trayed, filled with epoxy, double locked harness

connectors, environmentally protected connectors, electrical silicone grease, high

current rating. Extra attention to detail provides excellent protection from dirt, dust

and the environment.

• Efficient Cooling System with industrial motor with sealed bearings and metal fan blade.

• Fan-As-Needed™— reduces power consumption, damaging thermal cycling and the

amount of debris that gets drawn into the machine by shutting the fan down when it

is not needed.

pen Construction for preventative

O

aintenance and diagnostics.

m

Automotive Grade Sleeves

rotect leads from abrasion.

p

Trayed and Potted PC Board

Efficient Cooling System

with Fan-As-Needed

™

.

provides excellent protection.

Rugged Testing and Reliability

All Lincoln inverters are fully tested for reliability before and after assembly.

• Each machine undergoes a functional weld test to ensure performance.

• Lincoln inverters are operated in an environmental chamber under extreme conditions

of temperature and humidity.

• Mechanical testing, including vibration and drop testing is performed.

• Extensive temperature testing is performed to ensure that all components are running

within allowable range.

• Three-year warranty on parts and labor.

• Manufactured under a quality system certified to ISO 9001 requirements and ISO 14001

environmental standards.

• Designed to the IEC/EN 60974-1 standard. Meets tough NEMA EW 1,

CSA NRTL/C standards.

• Meets rigorous IP23S environmental rating.

Electrical Connections coated

with protective compound for

long-term reliability in harsh

environments.

Environmental Chamber

[5]

Manufacturing and Testing

Invertec®V450-PRO

www.lincolnelectric.com

Page 6

SYSTEM SELECTION

READY-PAK®PACKAGES

Fully assembled and ready to weld. Select a Ready-Pak®Package and use one

order number on your order form.

(Package does not include input power cord, shielding gas, welding electrode

and personal protective equipment.)

V450-PRO/LF-72 Wire Feeder

Order K2494-1

• Invertec®V450-PRO power source

• LF-72 Heavy Duty Bench Model Wire Feeder

• Magnum®400 Gun and 15 ft. Cable Assembly,

• .035-.045" (0.8-1.1 mm) Drive Rolls and Wire Guides

• Work and Wire Feeder 2/0 Welding Cable and Work Clamp

Package - 10 ft. (3.0m)

• Harris®Flowmeter/Regulator with adapter and 10 ft. (3.0m) Hose

V450-PRO/LF-74 Wire Feeder

Order K2495-1

• Invertec®V450-PRO power source

• LF-74 Heavy Duty Bench Model Wire Feeder

• Magnum®400 Gun and 15 ft. Cable Assembly,

• .035-.045" (0.8-1.1 mm) Drive Rolls and Wire Guides

• Work and Wire Feeder 2/0 Welding Cable and Work Clamp

Package - 10 ft. (3.0m)

• Harris®Flowmeter/Regulator with adapter and 10 ft. (3.0m) Hose

®

450-PRO/LF-72 Heavy Duty

nvertec

V

I

ire Feeder Ready-Pak

W

Shown:

®

kg.

P

TYPICAL V450-PRO WELDING SYSTEMS

For specific welding applications, assemble the products listed to best suit your needs.

V450-PRO/LF-74 Extra Torque: 5/64" (2.0mm) FCAW-SS

Welding System

• Invertec

• LF-74 Bench Model, Heavy-Duty, Extra Torque K2426-3

• 5/64" Drive Rolls and Wire Guides KP1505-5/64

• Lincoln Innershield®Gun and Cable Assembly K1500-1

• 10 ft. (3.0m) Magnum®Self-Shielded Gun and K115-5

• Weld Power Cable – 10 ft. (3.0m) K1842-10

• Work Cable and Clamp (GC-500) K910-2

• Dual Cylinder Platform Undercarriage K1570-1

• Harris®Flowmeter/Regulator and Gas Hose K586-1

V450-PRO/DH-10 : .035"

• Invertec®V450-PRO power source K2420-1

• DH-10 wire feeder K1499-3

• .045 Drive Roll – solid wire KP1505-045S

• .035 Drive Roll – solid wire KP1505-035S

• Magnum®400 Gun Package K471-21

• Weld Power Cable – 10 ft. K1842-10

• GC-500 Work Clamp K910-2

• Dual Cylinder Platform Undercarriage K1570-1

• Gas Regulator and Hose Kit K586-1

(1)

(2)

(3)

®

V450-PRO power source K2420-1

Wire Feeder

Cable Assembly, 5/64"

& .045" MIG Welding System

Fully assembled, no gun connector required.

Two required.

Both electrodes must have the same polarity.

(2)

(3)

(1)(2)

(2)

[6]

®

Invertec

V450-PRO

www.lincolnelectric.com

Page 7

RECOMMENDED OPTIONS

GENERAL OPTIONS

Advanced Process Panel

Includes Pulsed MIG, Pulse-OnPulse®and Power Mode®capabilities. Alpha-numeric display for

accurate setting.

Order K1763-1

Deluxe Adjustable Gas Regulator

& Hose Kit

Accommodates CO2, argon, or

argon-blend gas cylinders. Includes

a cylinder pressure gauge, dual

scale flow gauge and 4.3 ft. (1.3m)

gas hose.

Order K586-1

Cool-Arc™40 Water Cooler

Reliable and affordable water

cooler for water-cooled MIG, TIG,

or plasma cutting applications.

Order K1813-1 for 115V

Order K2187-1 for 230V

Lincoln Fume Extraction

Systems

A full line of fume extraction

systems are available.

Request Publications

E13.11 Miniflex

E13.40 Mobiflex

™

™

Dual Cylinder Platform

Undercarriage

Platform undercarriage for

mounting two gas cylinders at

rear of welder.

Order K1570-1

STICK OPTIONS

Accessory Kit – 400 Amp

For stick welding. Includes 35 ft.

(10.7 m) 2/0 electrode cable with

lug, 30 ft. (9.1 m) 2/0 work cable

with lugs, headshield, filter plate,

work clamp and electrode holder.

Order K704

Remote Output Control

For remote output of welding

voltage. Consists of control box

with 25 or 100 ft. (7.6 m or 30 m)

of four conductor cable and 6-pin

MS-type connector.

Order K857 for 25 ft. (7.6m)

Order K857-1 for 100 ft. (30m)

TIG OPTIONS

Pro-Torch®TIG Torch

V model two cable torches provide

a convenient gas control valve to

control shielding gas flow.

PTA-26V Two Cable Torch

Air-Cooled 200 amp

Order K1783-7 for 12.5 ft. 2 pc

Order K1783-9 for 25 ft. 2 pc

PTA-17V Two Cable Torch

Air-Cooled 150 amp

Order K1782-7 for 12.5 ft. 2 pc

Order K1782-9 for 25 ft. 2 pc

For High Frequency TIG Welding

TIG Module

Portable, high frequency unit with

gas valve for TIG welding. Rated

at 300 amps/60% duty cycle. Requires TIG Module Control Cable.

Order K930-2

Docking Kit

Provides a means to “dock” the

TIG module on top of a flat-roofed

power source, or any other flat

surface measuring at least

10" x 15" (254 mm x 381 mm).

Includes a latch and provisions for

a user-supplied padlock to lock the

TIG Module in place.

Order K939-1

TIG Module Control Cable

9-pin connector at the TIG Module

to 14-pin MS type connector at the

power source. (Contains input

power source. control, contactor

control, and ground circuits). For

machines having a 14-pin remote

control and power receptacle.

Order K936-1

Hand Amptrol

®

Provides 25 ft. (7.6 m) of remote

current control for TIG welding.

(6-pin plug connection). Velcro

straps secure torch.

Order K963-3 (one size fits all

Pro-Torch TIG torches).

Foot Amptrol

®

Provides 25 ft. (7.6 m) of remote

current control for TIG welding.

(6-pin plug connection).

Order K870

Arc Start Switch

May be used in place of the Foot or

Hand Amptrol®. Comes with a 25 ft.

(7.6 m) cable. Attaches to the TIG

torch for convenient finger control

to start and stop the weld cycle at

the current set on the machine.

Order K814

[7]

Invertec®V450-PRO

www.lincolnelectric.com

Page 8

NVERTEC

I

®

450-PRO ORDER FORM

V

PRODUCT DESCRIPTION ORDER NUMBER QUANTITY PRICE

INVERTEC®V450-PRO (208/230/460/575/3/50/60) K2420-1

INVERTEC®V450-PRO CE (380/415/3/50/60) K2421-1

NVERTEC

I

NVERTEC

I

R

dvanced Process Panel K1763-1

A

Deluxe Adjustable Gas Regulator and Hose Kit K586-1

Cool-Arc™40 Water Cooler:

Fume Extraction Systems:

Dual Cylinder Platform Undercarriage K1570-1

R

ccessory Kit – 400 amp K704

A

Remote Output Control

®

450-PRO/LF-72 READY-PAK

V

®

450-PRO/LF-74 READY-PAK

V

®

ACKAGE K2494-1

P

®

ACKAGE K2495-1

P

ECOMMENDED GENERAL OPTIONS

or 115V K1813-1

F

or 230V K2187-1

F

™

Miniflex

obiflex

M

™

See Publication E13.11

ee Publication E13.40

S

ECOMMENDED STICK OPTIONS

25 ft. (7.6 m) K857

00 ft. (30 m) K857-1

1

RECOMMENDED TIG OPTIONS

P

P

ro-Torch

ro-Torch

®

TA-26V Two Cable Torch, 12.5 ft. (3.8 m) K1783-7

P

®

TA-26V Two Cable Torch, 25 ft. (7.6 m) K1783-9

P

Pro-Torch®PTA-17V Two Cable Torch, 12.5 ft. (3.8 m) K1782-7

Pro-Torch®PTA-17V Two Cable Torch, 25 ft. (7.6 m) K1782-9

TIG Module K930-2

Docking Kit K939-1

TIG Module Control Cable K936-1

Hand Amptrol

Foot Amptrol

®

®

K963-3

K870

Arc Start™Switch K814

RECOMMENDED WIRE FEEDERS

LN-8 See Publication E8.30

LN-15 See Publication E8.60

LN-25 See Publication E8.100

LN-742 See Publication E8.20

LF-72 See Publication E8.11

LF-74 See Publication E8.11

LN-10 See Publication E8.200

DH-10 See Publication E8.200

Cobramatic®Wire Feeder See Publication E8.300

TOTAL:

®

The business of The Lincoln Electric Company

needs of our customers and to exceed their expectations. On occasion, purchasers may ask Lincoln Electric for advice or information about their use of our products. We respond

to our customers based on the best information in our possession at that time. Lincoln Electric is not in a position to warrant or guarantee such advice, and assumes no liability,

with respect to such information or advice. We expressly disclaim any warranty of any kind, including any warranty of fitness for any customer’s particular purpose, with respect to

such information or advice. As a matter of practical consideration, we also cannot assume any responsibility for updating or correcting any such information or advice once it has

been given, nor does the provision of information or advice create, expand or alter any warranty with respect to the sale of our products.

Lincoln Electric is a responsible manufacturer, but the selection and use of specific products sold by Lincoln Electric is solely within the control of, and remains the sole responsibility

of the customer. Many variables beyond the control of Lincoln Electric affect the results obtained in applying these types of fabrication methods and service requirements.

Subject to Change – This information is accurate to the best of our knowledge at the time of printing. Please refer to www.lincolnelectric.com for any updated information.

is manufacturing and selling high quality welding equipment, consumables, and cutting equipment. Our challenge is to meet the

C U S T O M E R A S S I S T A N C E P O L I C Y

THE LINCOLN E L E C T R I C COMPANY

®

22801 St. Clair Ave., Cleveland, OH 44117-1199 • 216.481.8100 • www.lincolnelectric.com

Loading...

Loading...